Normal pressure air suction type operation and cooling fuel cell

A fuel cell and inhalation technology, applied in fuel cells, fuel cell additives, fuel cell heat exchange, etc., can solve the problems of large volume, high cost, heavy weight, etc., to reduce volume and weight, save materials, and facilitate assembly easy simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

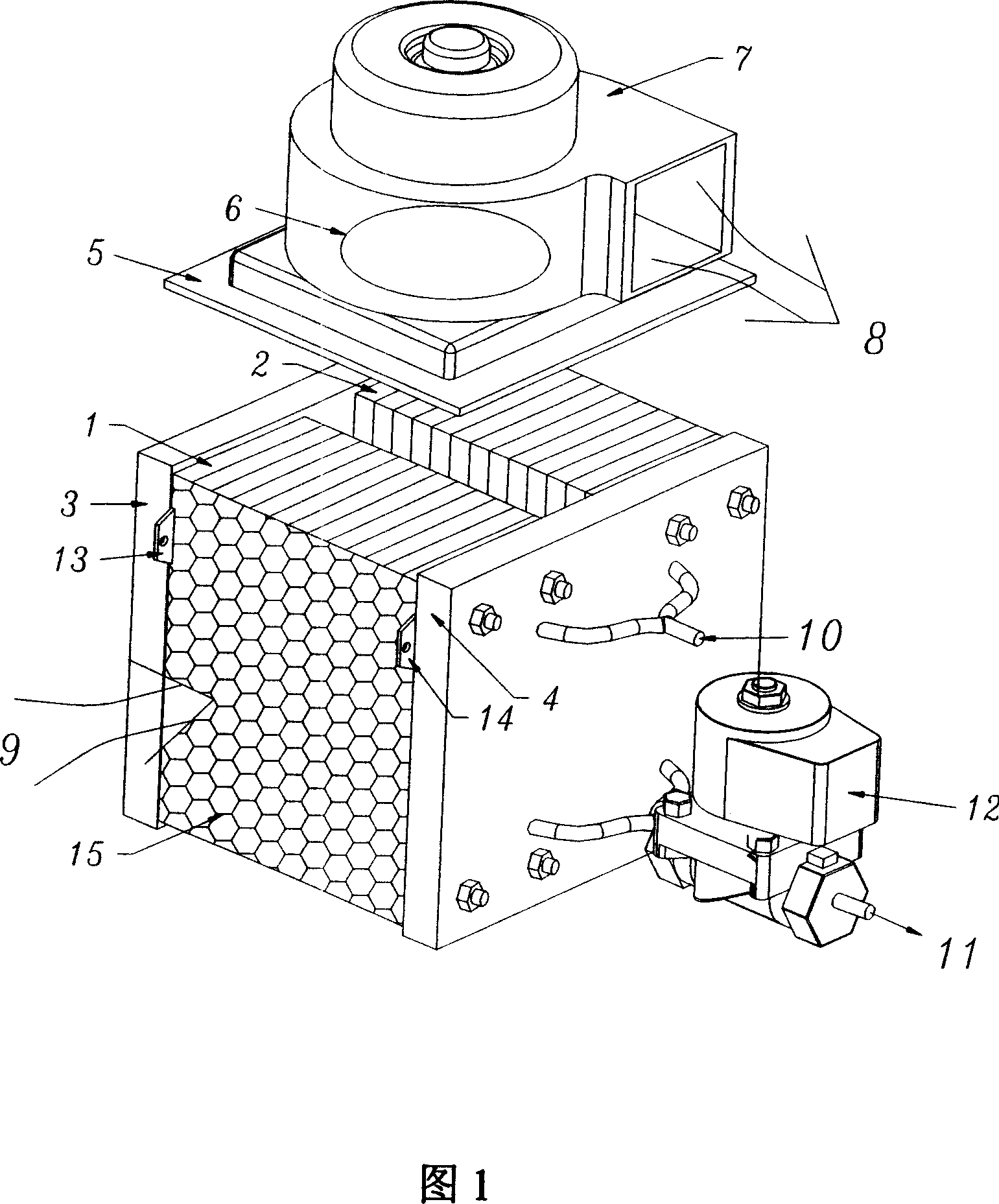

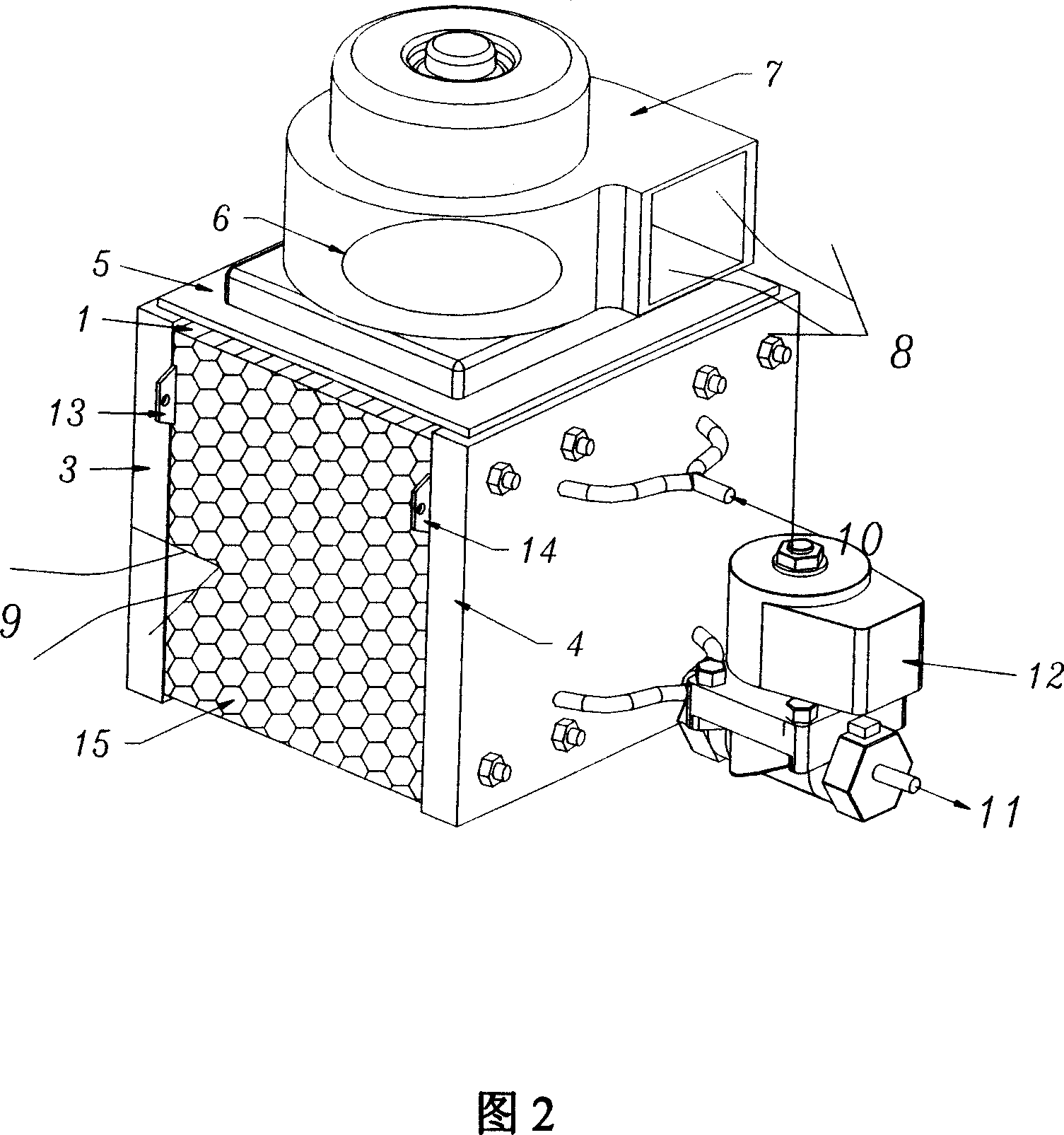

[0026] As shown in Figure 2, it is a normal-pressure air-inhaled operation and cooling fuel cell power generation system composed of two fuel cell modules. Including membrane electrode, diversion plate, current collector motherboard, front and rear end plates, fastening rods, and air and hydrogen supply device, the air supply device includes a shared fan 7, air collecting cover 5, the hydrogen supply device It includes a hydrogen storage tank (not shown in the figure), a hydrogen exhaust solenoid valve 12, hydrogen enters from 10, and is discharged from 11. Since the fan is suction type, the negative pressure is generated by the action of the air collecting cover 5, and the air enters from the end faces of the air passages of the two fuel cell modules covered with a layer of air filter 15, and then is discharged from the fan outlet 8. The power of such a fuel cell power generation system can reach 200-400W, which is twice the power of a single fuel cell power generation system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com