Impact-resistant fast-response thermocouple

A thermocouple and fast-response technology, which is applied in the direction of directly heat-sensitive electric/magnetic element thermometers, measuring heat, and using electric devices, etc., can solve problems such as rapid measurement of temperature signals, and achieve fast and fast response to temperature The effect of speed and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

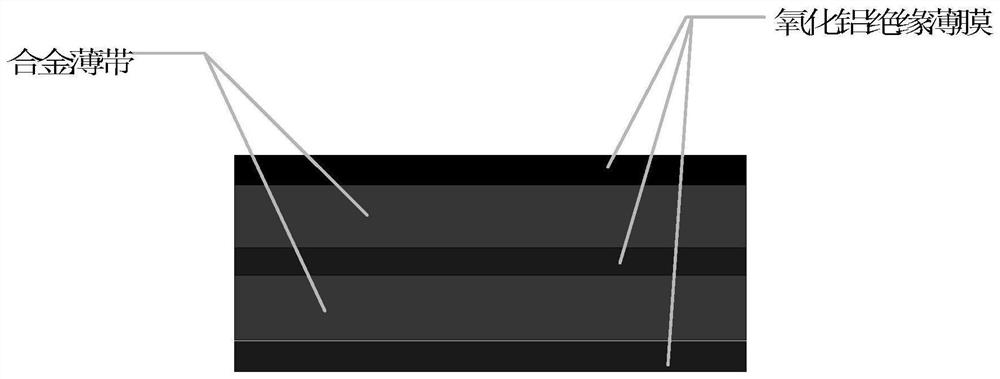

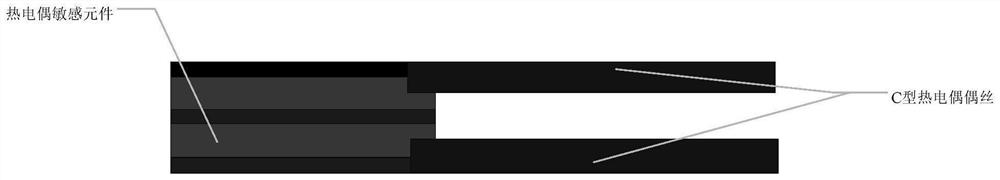

[0034] The W5%Re alloy and W26%Re alloy were rolled into alloy strips with a thickness of 80 μm, a width of 2 mm and a length of 31 mm, respectively, and 10 μm alumina films were coated on both sides of the two alloy strips by magnetron sputtering technology. The total thickness of the thin strip is about 200 μm after pressing and solid, and it is used as a thermocouple sensitive element. Grind and polish the 1mm rear end of the thermocouple sensitive element to expose the alloy. Use low-temperature silver paste to connect two C-type thermocouple wires 4 with a diameter of 0.3mm, a length of 50mm, and the composition of W5%Re alloy and W26%Re respectively, and the thermocouple sensitive element. The two sides of the element 1 are connected to transmit the temperature signal output by the temperature sensor.

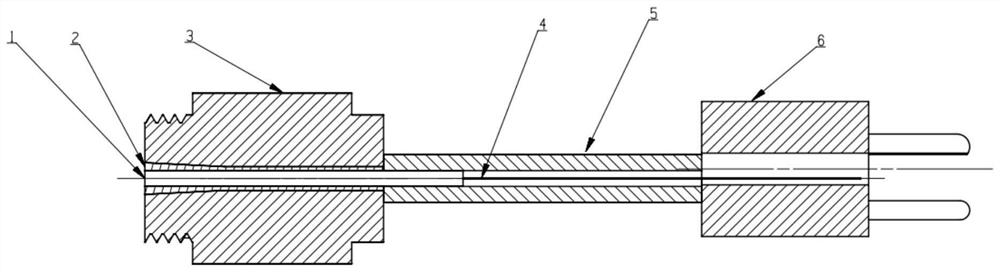

[0035] The 99.98% high-purity alumina powder was pressed at 200MP to form a semi-cylindrical protector with a diameter of 4mm and a length of 60mm, and then sintered at 180...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com