Method for manufacturing fin and flat tube assembly for heat exchanger

A technology for heat exchangers and manufacturing methods, applied in the direction of heat exchange equipment, etc., can solve problems such as insufficient fin strength, damaged fin shape, low fin strength, etc., and achieve a wide application range, high production efficiency, and high strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The advantages of the present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

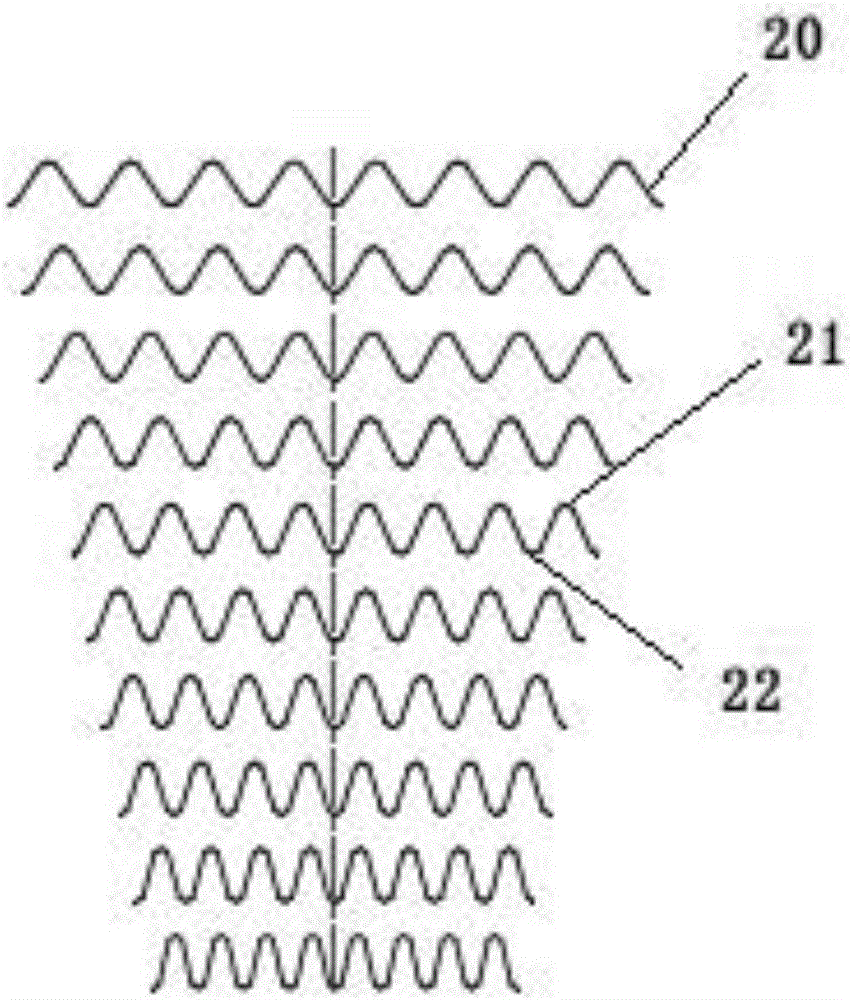

[0047] refer to Figure 1-5 , respectively showing the method of manufacturing fins for heat exchangers, specifically:

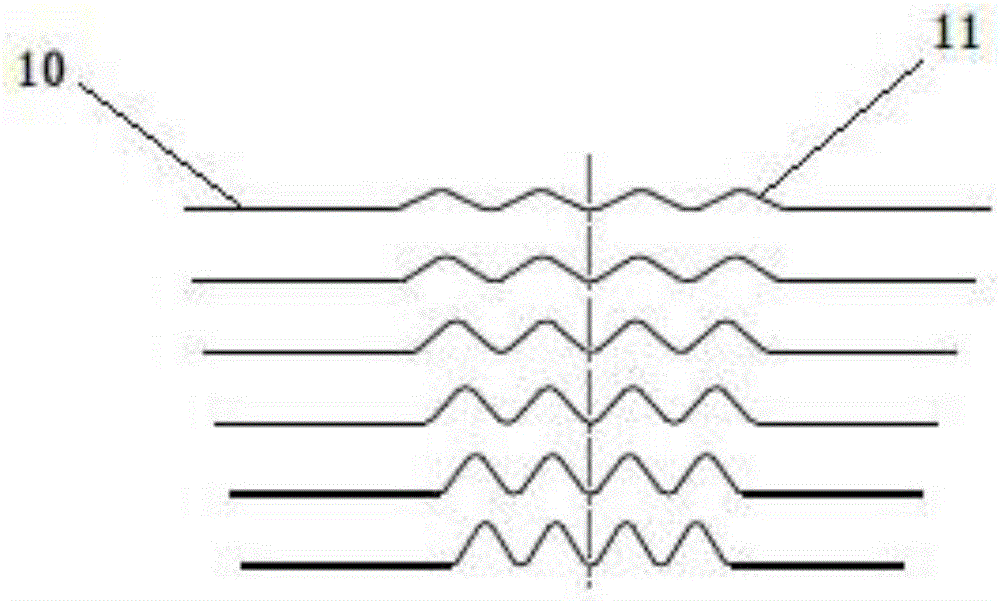

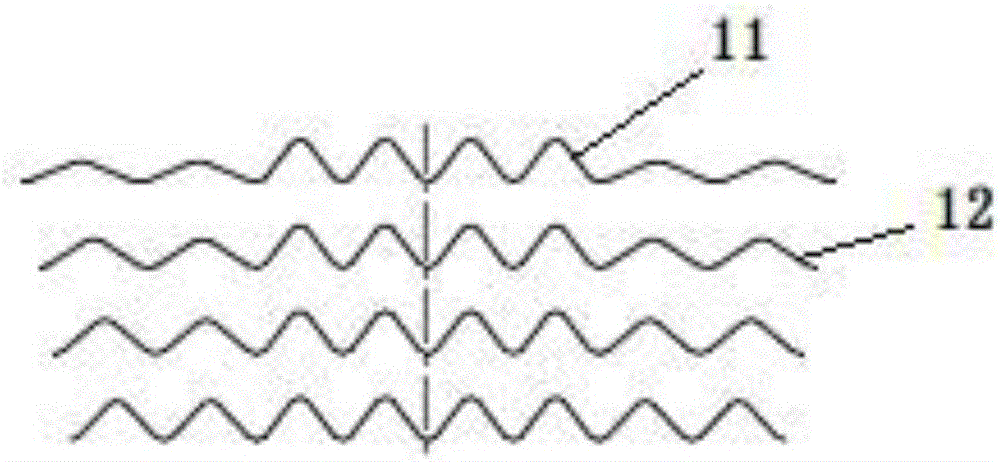

[0048] - Step 1: If figure 1 As shown, the user obtains a metal substrate 10 as the basis for manufacturing flat tubes. The metal substrate 10 can be aluminum foil, metal strip (composite layer), etc., and is first straightened to meet the continuous and seamless surface of the final formed fin. bumps or pits. Then the metal base material 10 is put into a mold, and the middle part of the metal base material 10 is rolled. The rolled metal base material 10 has a pair of first wavy protrusions 11 formed therein. Specifically, for example, four groups of protrusion units are formed by repeatedly rolling the middle of the metal base material 10 on both ends of the metal base material 10 , each protrusion unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com