Device for separating iron mold with casting piece during casting production of sand coated iron mold of wheel castings and method thereof

An iron mold sand-covered casting and iron mold technology, which is applied in the field of devices for separating iron molds and castings, can solve the problems of unrealistic mass production, castings being lifted from iron molds, and castings breaking, so as to improve the level of mechanization and automation, Easy to separate and realize the effect of automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

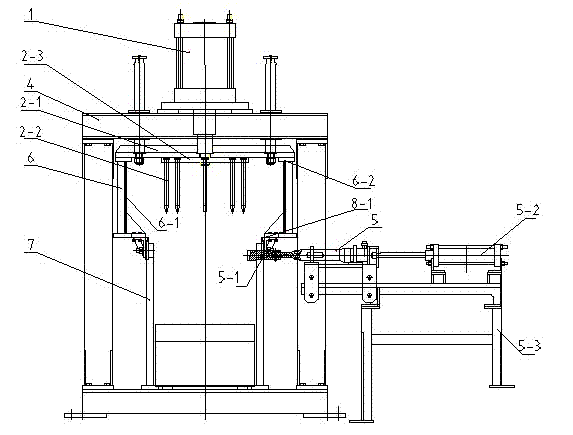

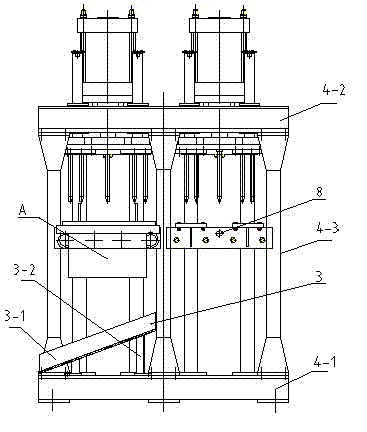

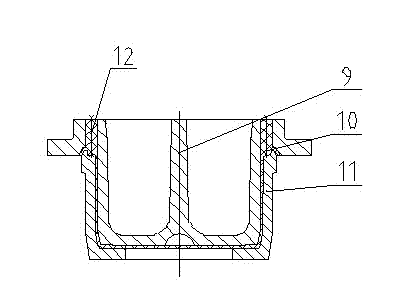

[0023] see Figure 1-Figure 3, the present invention comprises ejection cylinder 1, ejector rod plate 2-1, ejector rod 2-2, casting connection device 3, frame 4, vibration device 5, iron type conveying roller table 6, iron type receiving seat 7, iron type Type positioning device 8. see image 3 The iron mold wrapped with the casting after pouring and cooling is completed and unpacked includes an iron mold 9 , a sand-coated layer 10 and a casting 11 , and the iron mold 9 is provided with a sand shooting hole 12 .

[0024] The frame 4 includes a base 4-1, an upper cover 4-2 and a column 4-3. The ejector cylinder 1 is fixed on the upper cover plate 4-2 of the frame 4, the piston rod of the ejector cylinder 1 is connected with the ejector rod plate 2-1, and a plurality of ejector rods 2-2 are arranged on the ejector rod plate 2-1 , the number of ejector pins 2-2 and the distribution position on the ejector pin plate 2-1 correspond to the number and position of the sand shooting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com