Coagulation salt block for sylvite solid mine backfilling and manufacturing method thereof

A manufacturing method and technology of coagulation salt, which are applied in solid waste management, sustainable waste treatment, climate sustainability, etc., can solve problems such as affecting the production and safety of mining areas, low backfill strength, and coal seam collapse, etc., and achieve good social benefits. and economic benefits, low cost and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

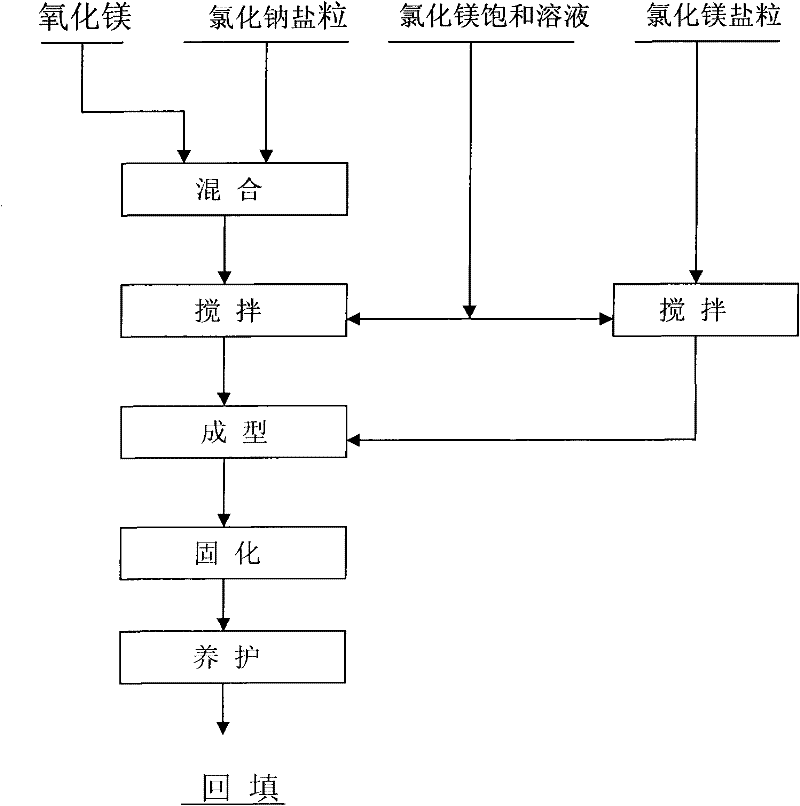

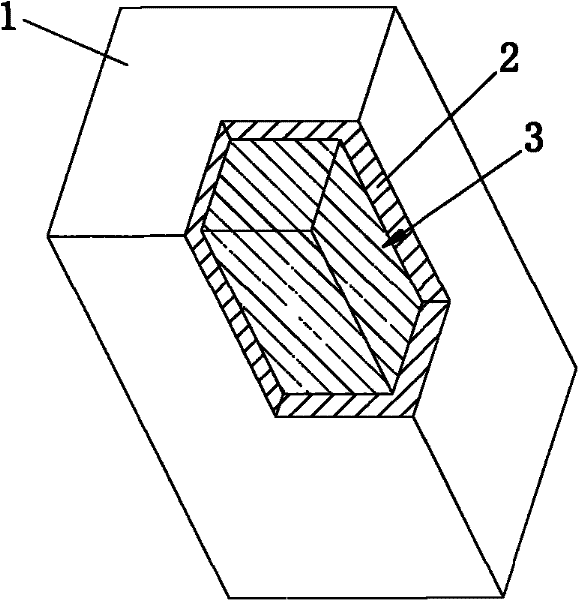

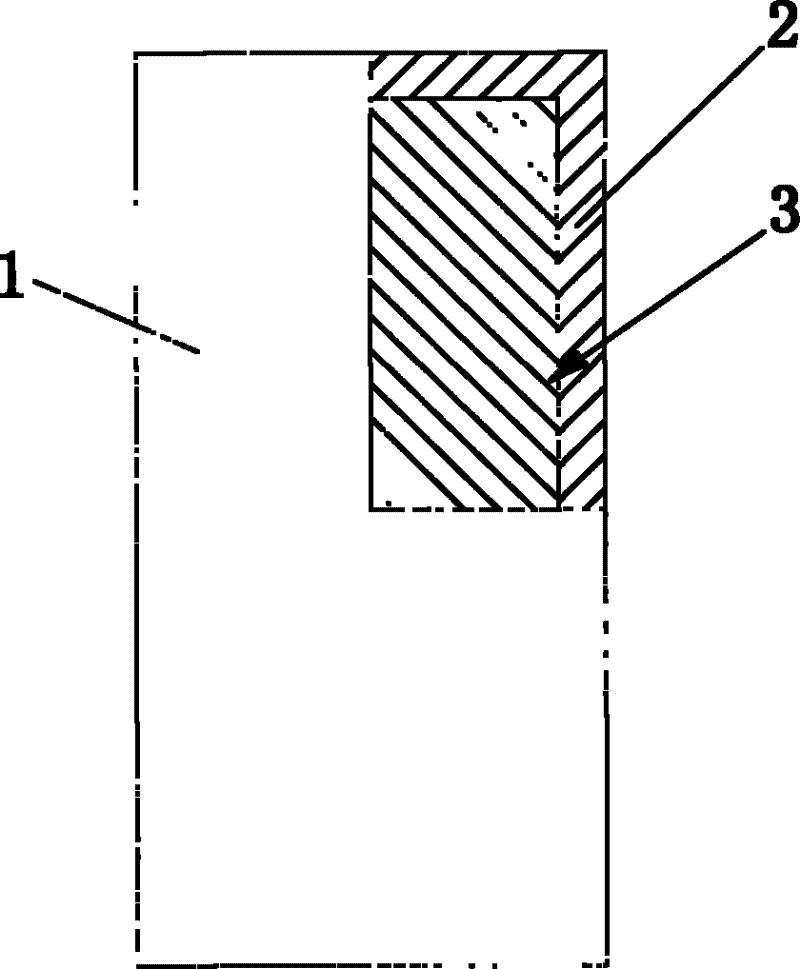

[0025] Such as figure 1 As shown, the manufacturing method of the coagulated salt block for backfilling of this potassium salt solid mine includes, taking 10.00 kg of lightly burned powder (mainly containing active magnesium oxide) roasted by magnesite, saturated magnesium chloride solution (prepared by magnesium chloride hydrate Become saturated solution, specific gravity is 1.33) 12.00kg, sodium chloride salt grain 50.00kg, and its salt grain diameter is 8mm, then solution and material are stirred in the mixer, make the first slurry, refer to simultaneously figure 2 , image 3 , injecting the slurry into a hollow mold with a specification of 600×300×300mm to make the outer layer 1 of the concrete salt block, pouring and pressing to obtain a hollow outer layer 1 with a wall 2 thickness of 30 mm; then take 10.00 kg of magnesium chloride salt grains, The salt particle size is 8mm, and 1.25kg of saturated magnesium chloride solution is mixed to form a second slurry, and the se...

Embodiment 2

[0035] The manufacturing method of coagulated salt block for this potassium salt solid mine backfill of the present embodiment is to get 10.00 kg of lightly burned powder (main content is active magnesium oxide) of magnesite roasting, saturated solution of magnesium chloride (using magnesium chloride hydrate to prepare saturated solution) , the specific gravity is 1.35) 8.00kg, sodium chloride salt grains 150.00kg, the salt grain diameter is 5mm, then the solution and materials are stirred evenly in the mixer, and the injection specifications after making the first slurry are 600×300× In the 300mm hollow mould, the thickness of the wall 2 is 30mm for compression molding, take 120.00kg of magnesium chloride salt grains, the salt grain size is 5mm, mix 8.00kg of magnesium chloride saturated liquid into the second slurry and inject it into the hollow, and use the second slurry after compaction. A slurry cover is compacted and formed. After demoulding, it is cured for 24 hours unde...

Embodiment 3

[0043] A kind of manufacturing method of coagulation salt block for backfilling of potassium salt solid mine, get caustic dolomite powder (main component is active magnesium oxide) 10.00kg, magnesium chloride saturated solution (adopting magnesium chloride hydrate to prepare saturated solution, specific gravity It is 1.33) 12.00kg, sodium chloride salt grain 50.00kg, and its salt grain diameter is 5mm, then solution and material are stirred in the mixer, make the first slurry, get magnesium chloride salt grain 10.00kg, its salt grain The particle size is 5mm, and 1.25kg of magnesium chloride saturated liquid is mixed into the second slurry and then injected into a mold of 520×220×220 for compression molding. After taking it out, put it into a mold with a specification of 600×300×300mm and wrap it with the first slurry. The wall thickness of the outer layer made of a slurry is 40mm, pressed and formed, and cured for 12 hours under the condition of ambient temperature and air hum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com