Rotary drum and airflow mixed flow drying device for oil-tea fruit shell wastes

A technology of camellia husk and airflow dryer, which is applied in dryer combination, drying, dryer and other directions, can solve the problems of long drying time, low drying efficiency and high energy consumption, and achieve the effect of improving energy utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

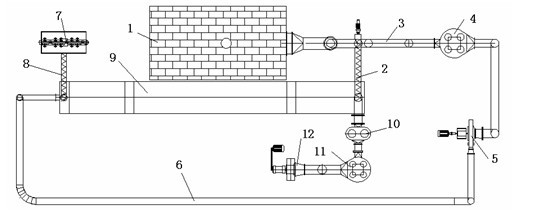

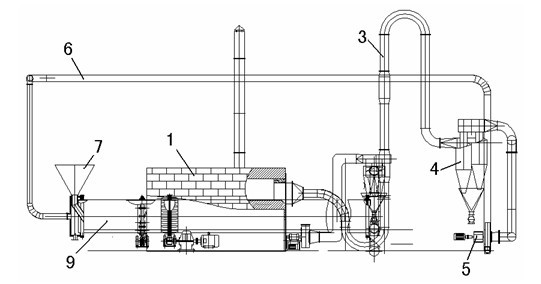

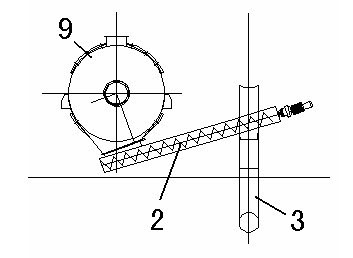

[0012] Such as figure 1 , figure 2 , image 3 Shown, the present invention is realized like this, and it comprises biomass hot blast stove 1, secondary drying feeder 2, secondary airflow dryer 3, cyclone separator 4, secondary drying blower fan 5, air return pipe 6, Disperser 7, primary drying feeder 8, primary rotary drum dryer 9, double cyclone dust collector 10, quadruple cyclone dust collector 11 and primary drying fan 12, characterized by biomass hot blast stove 1 It is connected with the secondary airflow dryer 3; the secondary airflow dryer 3, the cyclone separator 4 and the secondary drying fan 5 are connected in turn, and the secondary drying fan 5 is connected to the inlet of the primary rotary drum dryer 9 through the return air pipe 6. The tuyeres are connected, and the tail gas dried by the secondary airflow is used as the heat source of the primary rotary drum dryer; the air outlet of the primary rotary drum dryer 9 is connected with the double cyclone dust c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com