Method for preparing negative electrode materials of lithium batteries from waste and old zinc-manganese batteries

A zinc-manganese battery and negative electrode material technology, applied in battery electrodes, battery recycling, recycling technology, etc., to achieve the effect of simple method, simple method and good application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

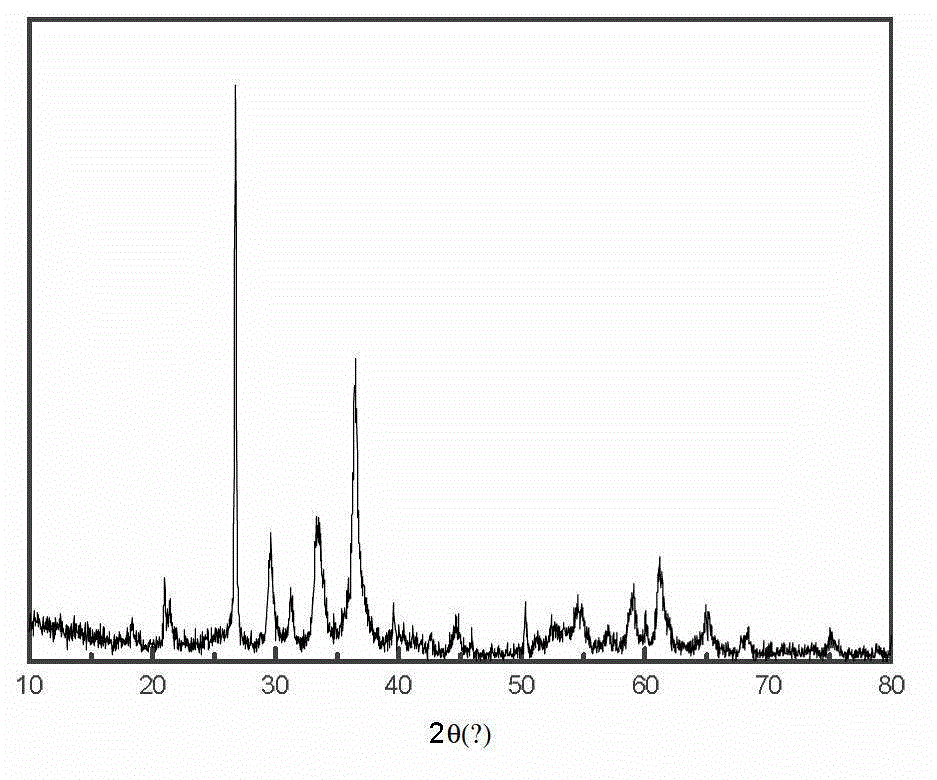

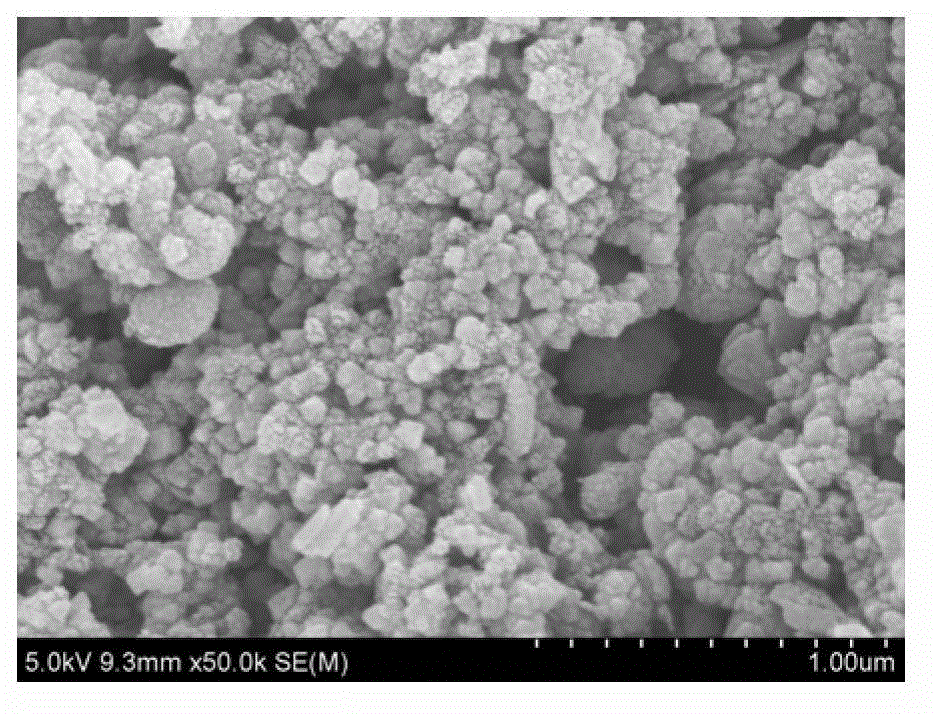

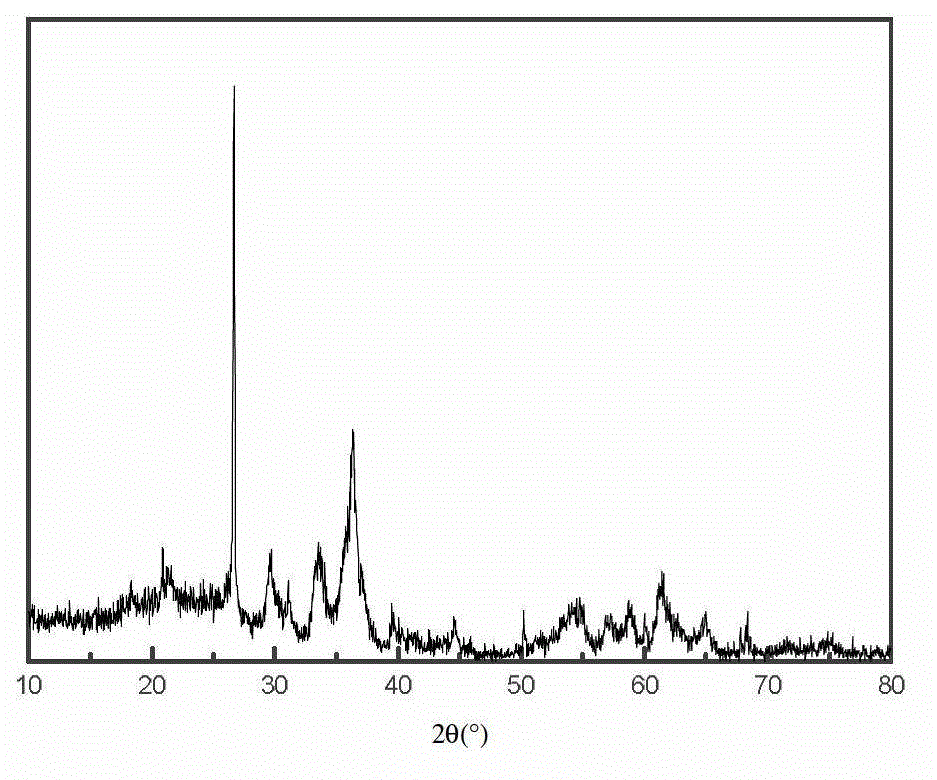

[0034] Weigh 5.1682 g of the black mixture after ball milling into a stainless steel reaction kettle lined with polytetrafluoroethylene, and add a certain amount of water, wherein Zn:Mn=0.95:2, pH=5. After sealing, put the reaction kettle into a homogeneous reactor, and the filling degree of the treated materials (black mixture, zinc skin, water) in the reaction kettle is 80vol%; react at 180°C for 1 day. After the reaction was completed, the reactor was taken out and cooled to room temperature. The resulting product is taken out, washed with deionized water, filtered and dried to obtain ZnMn 2 o 4 Powder, under 0.1C charge and discharge rate, the first discharge specific capacity is 551.5mAh / g.

Embodiment 2

[0036] Weigh 5.1682g and 0.0222g of the black mixture after ball milling into a stainless steel reaction kettle lined with polytetrafluoroethylene, add a certain amount of water, and adjust the pH to 7 with a certain amount of ammonia water, where Zn:Mn=1:2. After sealing, put the reaction kettle into a homogeneous reactor, and the filling degree of the treated materials (black mixture, zinc skin, water and ammonia water) in the reaction kettle is 80vol%; react at 190°C for 2 days. After the reaction was completed, the reactor was taken out and cooled to room temperature. The resulting product is taken out, washed with deionized water, filtered and dried to obtain ZnMn 2 o 4 Powder, under 0.1C charge and discharge rate, the first discharge specific capacity is 609.5mAh / g.

Embodiment 3

[0038] Weigh 5.1682g of the black mixture after ball milling and 0.0444g of the zinc skin into a stainless steel reaction kettle lined with polytetrafluoroethylene, add a certain amount of water, and adjust the pH to 9 with a certain amount of ammonia water, where Zn:Mn=1.034:2 . After sealing, put the reaction kettle into a homogeneous reactor, and the filling degree of the treated materials (black mixture, zinc skin, water and ammonia water) in the reaction kettle is 80vol%; react at 180°C for 3 days. After the reaction was completed, the reactor was taken out and cooled to room temperature. The resulting product is taken out, washed with deionized water, filtered and dried to obtain ZnMn 2 o 4 Powder, under 0.1C charge and discharge rate, the first discharge specific capacity is 689.5mAh / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com