Wear-resistant and aging-resistant polyurethane resin and preparation method thereof

A polyurethane resin and anti-aging technology, applied in the field of polyurethane and its production equipment, can solve the problems of poor wear resistance, reduced service life, and poor aging resistance of polyurethane resin, so as to reduce labor intensity, improve production efficiency, and ensure quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0106] A wear-resistant and aging-resistant polyurethane resin, made of the following raw materials in parts by weight: 1,6-hexanediol polyadipate diol: 10-15 parts, polycarbonate diol: 12-18 parts , 1,6-hexanediol: 3-5 parts, trimethylolpropane: 2-4 parts, hexamethylene diisocyanate: 8-10 parts, antioxidant: 0.35-0.55 parts, organic bismuth catalyst: 0.15 to 0.25 parts, isophorone diamine: 0.5 to 0.8 parts, KH-560: 0.15 to 0.25 parts, solvent: 45 to 75 parts; the hexamethylene diisocyanate is DesmodurN 3300A from Bayer Germany and Germany The mixture of Bayer's Desmodur BL3175A has a mass ratio of 1:1.8-2.1; the solvent is a mixture of dimethylformamide and acetone, and the mass ratio of the two is 1:2-4.

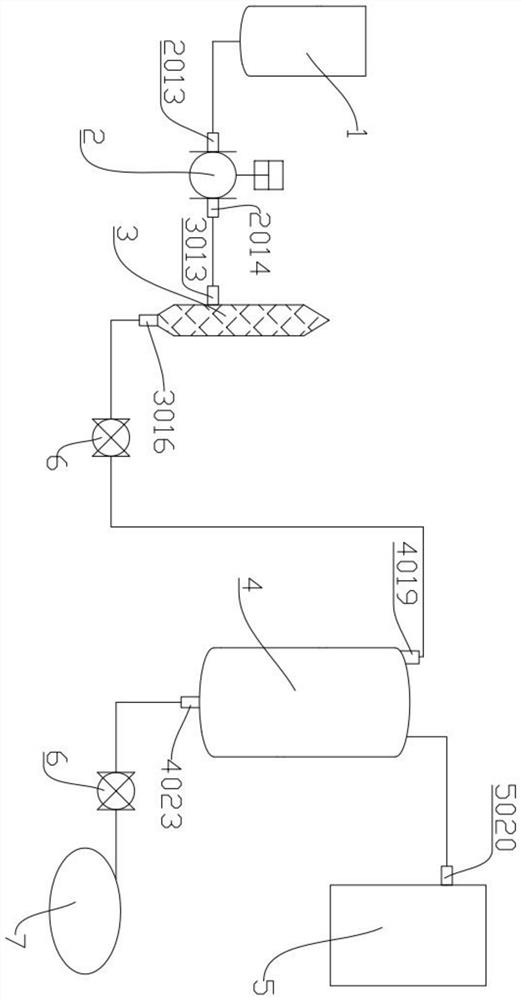

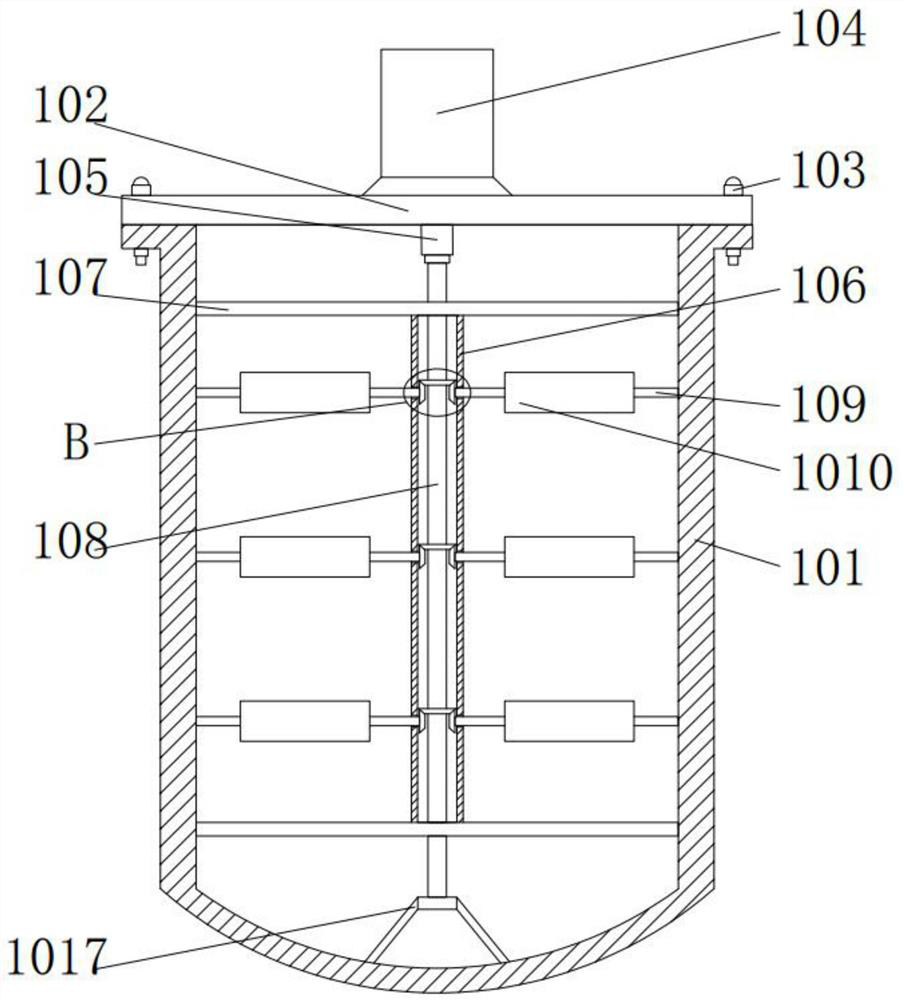

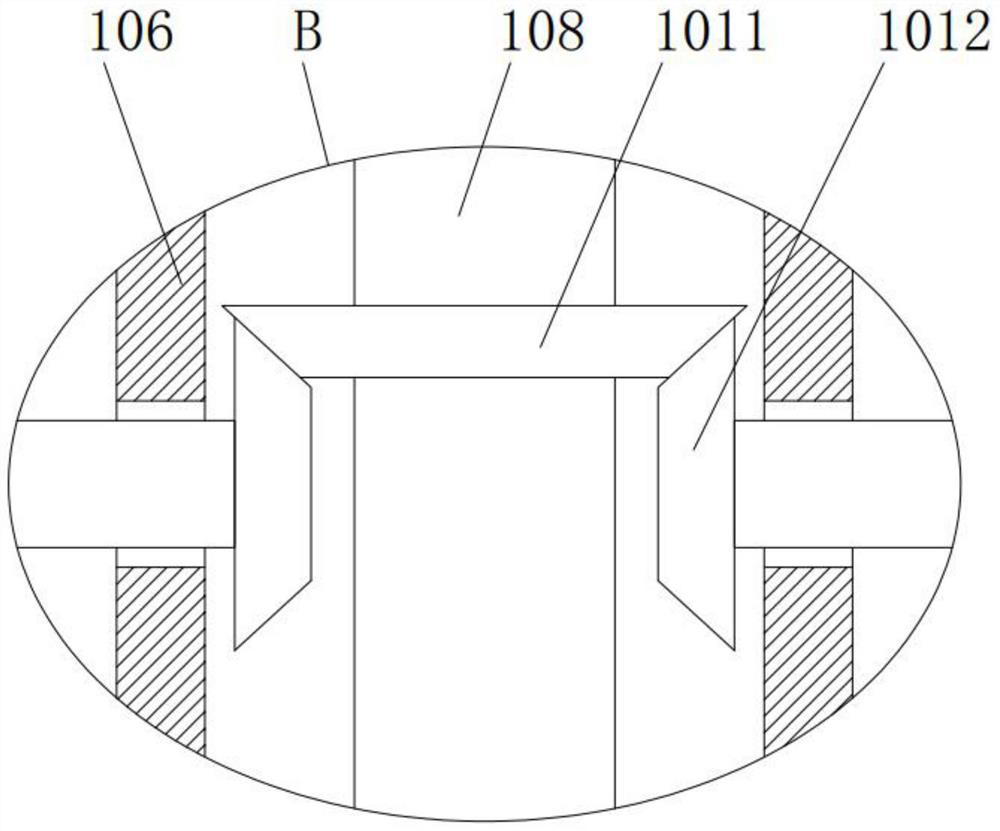

[0107] The present invention also provides a method for preparing the wear-resistant and aging-resistant polyurethane resin, which uses a reaction system for polyurethane production to carry out continuous production and preparation, including the following steps:

[0108...

Embodiment 2

[0116] A wear-resistant and aging-resistant polyurethane resin, made of the following raw materials in parts by weight: 1,6-hexanediol polyadipate diol: 10 parts, polycarbonate diol: 12 parts, 1,6 - Hexylene glycol: 3 parts, trimethylolpropane: 2 parts, hexamethylene diisocyanate: 8 parts, antioxidant: 0.35 parts, organic bismuth catalyst: 0.15 parts, isophorone diamine: 0.5 parts , KH-560: 0.15 parts, solvent: 45 parts; the hexamethylene diisocyanate is a mixture of DesmodurN 3300A of Bayer Germany and Desmodur BL3175A of Bayer Germany, and the mass ratio of the two is 1:1.8; The solvent is a mixture of dimethylformamide and acetone, and the mass ratio of the two is 1:2.

[0117] In this embodiment, the preparation method of the wear-resistant and aging-resistant polyurethane resin adopts a reaction system for polyurethane production for continuous production and preparation, including the following steps:

[0118] 1) each raw material of the wear-resistant and aging-resista...

Embodiment 3

[0166] The difference from Example 2 is that a wear-resistant and aging-resistant polyurethane resin is made of the following raw materials in parts by weight: poly-1,6-hexanediol adipate diol: 15 parts, polycarbonate binary Alcohol: 18 parts, 1,6-hexanediol: 5 parts, trimethylolpropane: 4 parts, hexamethylene diisocyanate: 10 parts, antioxidant: 0.55 parts, organic bismuth catalyst: 0.25 parts, iso Phornediamine: 0.8 parts, KH-560: 0.25 parts, solvent: 75 parts; the hexamethylene diisocyanate is a mixture of Desmodur N3300A of Bayer Germany and Desmodur BL3175A of Bayer Germany, the mass ratio of the two 1:2.1; the solvent is a mixture of dimethylformamide and acetone, and the mass ratio of the two is 1:4.

[0167] In this embodiment, the preparation method of the wear-resistant and aging-resistant polyurethane resin adopts a reaction system for polyurethane production for continuous production and preparation, including the following steps:

[0168] 1) each raw material of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com