A spray coater of an electric control system

An electrical control system, spraying machine technology, applied in coating, spray booth, spraying device and other directions, can solve the problems of poor surface quality, low work efficiency, poor adhesion performance, etc., to improve work efficiency, good production operation requirements, The effect of reducing product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

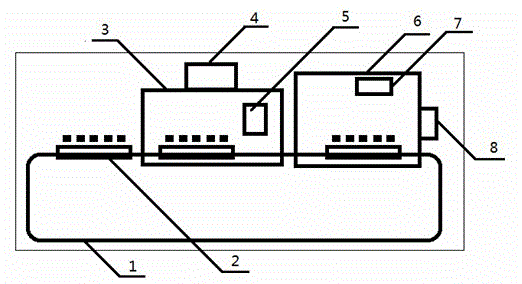

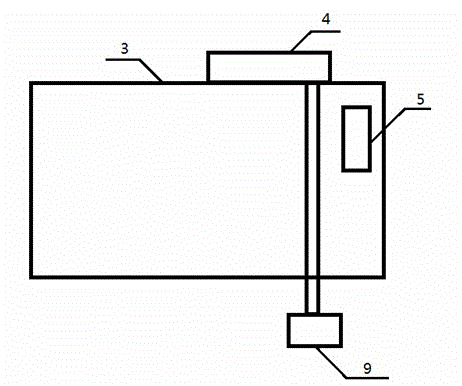

[0012] Such as figure 1 , figure 2 , as shown, a spraying machine with an electrical control system, including a conveyor belt 1, a number of loading plates 2, a paint spraying room 3, a brushing device 5, a sewage discharge system 4 in the painting room, an air supply system 7, an electrical control system 8, and a drying Room 6, the carrier board 2 is fixed on the conveyor belt 1 by screw device, the conveyor belt 1 is installed on the guide rail on the front ground of the spray booth 3, the sewage system 4 of the spray booth is installed outside the middle part of the spray booth 3, and the brushing device 5 is installed on the The end of the paint spraying room 3, the drying room 6 is connected with the painting room 3, the air supply system 7 is in the drying room 6, and the electrical control system 8 is installed on the outside of the drying room 6.

[0013] Described brushing device 5 is a roller brush.

[0014] The conveyor belt 1 is an endless belt, and the belt b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com