Ordinary-pressure vertical cyclone solid-liquid separation method and equipment

A solid-liquid separation and solid-liquid separator technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of high moisture content of materials, increased production and operation, poor separation effect, etc., to reduce land occupation. Area, simplified application conditions, accelerated drying and granulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

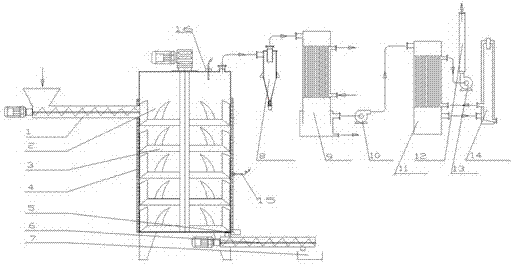

[0036] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings. Obviously, the described embodiments are only some of the embodiments of the invention.

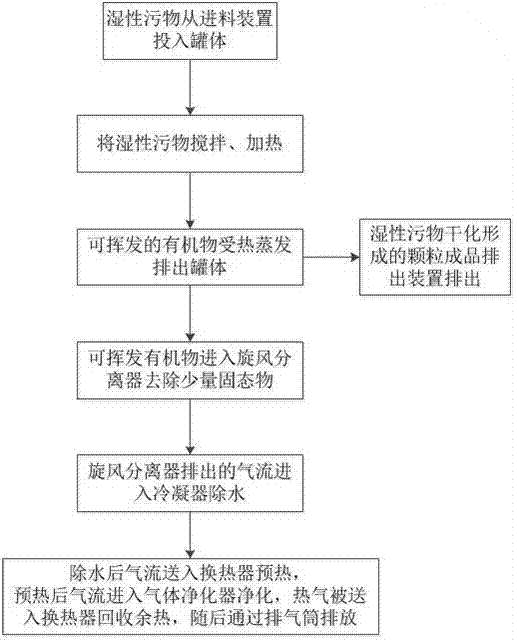

[0037] Such as figure 1 Shown embodiment, its a kind of atmospheric pressure vertical cyclone solid-liquid separation method is as follows:

[0038] 1. Start the device and enter the normal working state;

[0039] 2. Sludge is input from the material port to be treated;

[0040] 3. The feeding device 1 sends the sludge into the vertical tank body 2, and the feeding device is a screw conveyor;

[0041] 4. Under the action of the centrifugal force of the stirring device 3, the sludge entering the tank is thrown along the centrifugal force direction to the tank wall preheated by the heating device 4 for heating, and the sludge falls under the action of gravity and high temperature, and the stirring device 3 The mul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com