Air frying pan

A technology of air fryer and frying basket, which is applied in kitchen utensils, household utensils, roasters/barbecue grids, etc., to achieve the effects of even heating of food, easy cleaning, and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

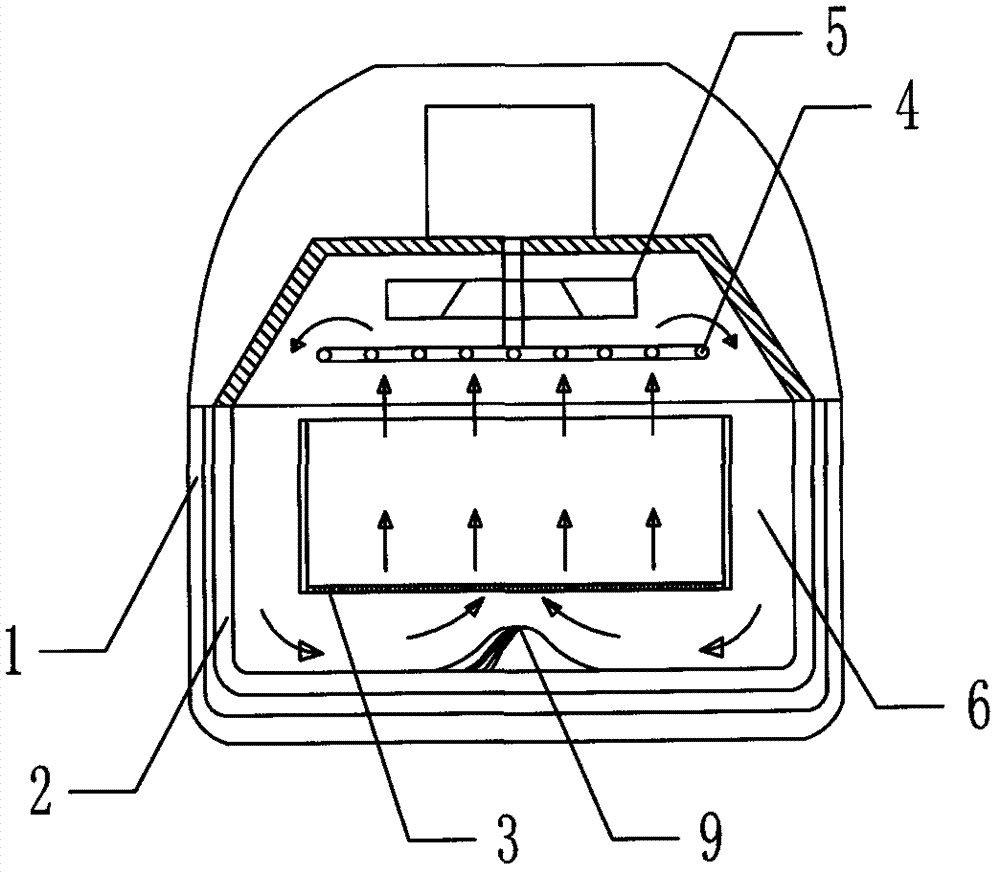

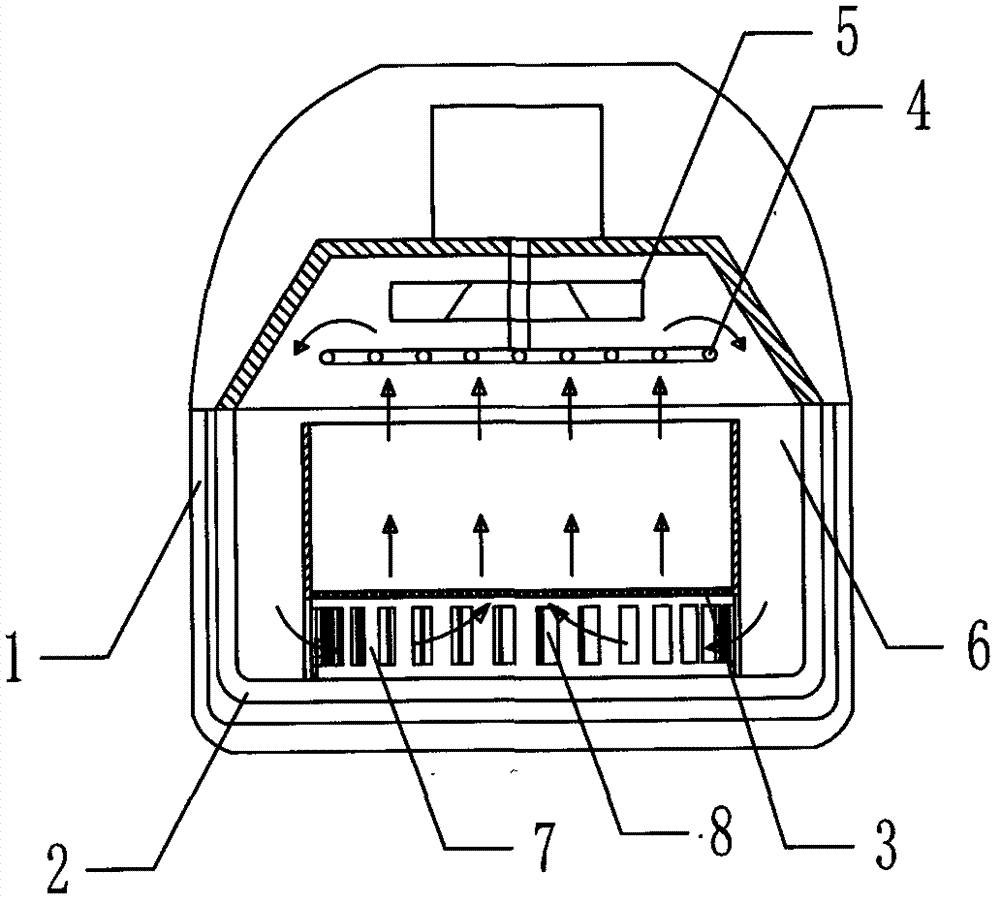

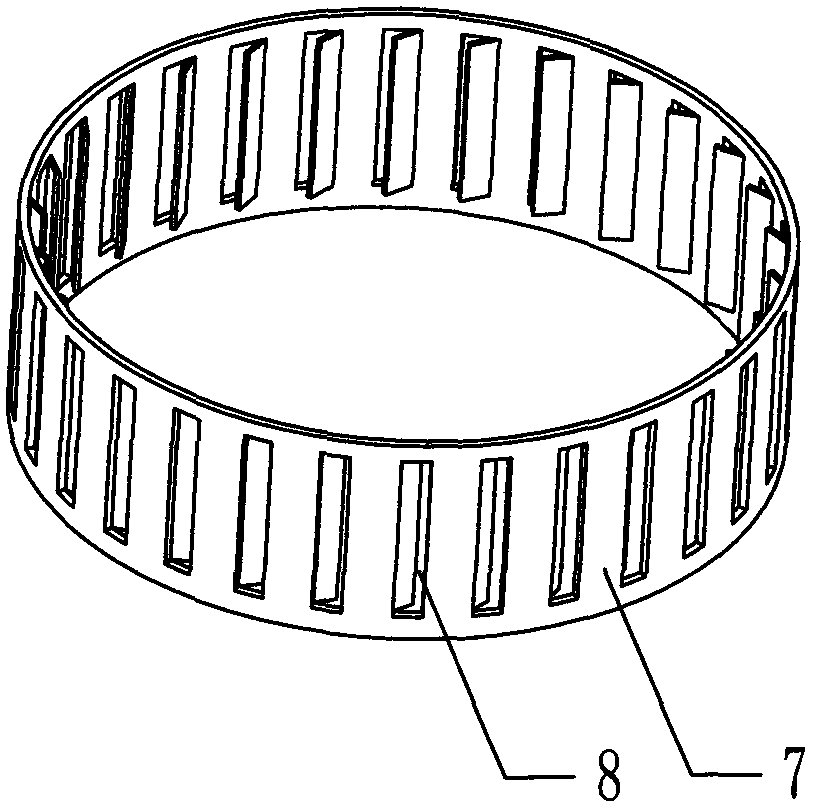

[0018] Embodiment one: if figure 2 , image 3 As shown, in the air fryer of this embodiment, the pot body 1 has an inner container 2 as a food baking chamber, a frying basket 3 for loading food is arranged in the inner container 2, and an electric heating tube is also provided above the frying basket 3 4 and the fan 5 located above the electric heating tube 4, the side wall of the frying basket 3 is a thin plate, and the bottom is a grid, and an airflow channel 6 is formed between the inner tank 2 and the frying basket 3. In order to facilitate the airflow circulation and support stability, the The outer periphery of the bottom of the frying basket 3 extends downwards with a guide tube 7 of a cylindrical structure. The lower end of the guide tube 7 is preferably directly supported on the bottom wall of the inner container 2, and the gap between the two is as small as possible, so that the guide tube The air intake slant hole 8 is provided on the side wall of the flow tube 7,...

Embodiment 2

[0019] Embodiment two: if Figure 4 As shown, the main structure of the air fryer of this embodiment is basically the same as that of Embodiment 1. The difference is that the support body 7 has a structure with a large opening at the upper end and a small opening at the lower end. The guide tube 7 of this structure, The airflow flows more smoothly, and the swirling airflow guided by the air intake inclined hole 8 spreads upward faster.

Embodiment 3

[0020] Embodiment three: as Figure 5 As shown, the main structure of the air fryer of this embodiment is basically the same as that of Embodiment 1, the difference is that the guide cylinder 7 is a structure with a large opening diameter at the upper and lower ends and a relatively small diameter at the middle, and the inclined air inlet hole 8 It is installed on the side wall of the lower part of the air guide tube 7. The guide tube 7 with this structure is conducive to accelerating the airflow velocity in the small diameter of the middle part, thereby improving the penetration of the airflow through the bottom of the frying basket 3 and the food gap. .

[0021] A further advantage is that the side wall of the deflector tube extends upwards to be movably socketed with the frying basket 3, and the side wall and the bottom wall of the frying basket 3 can be integrally formed by grids, which will significantly reduce the overall weight of the frying basket 3. It is more conven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com