Treatment method of wastewater with high salinity and high organic matters

A treatment method and organic matter technology, applied in the direction of heating water/sewage treatment, oxidized water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of reducing waste water, unable to solve the problem of concentrated water treatment, etc., to achieve the reduction of membrane pollution, achieve continuous and stable operation, and reduce the effect of membrane fouling tendency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

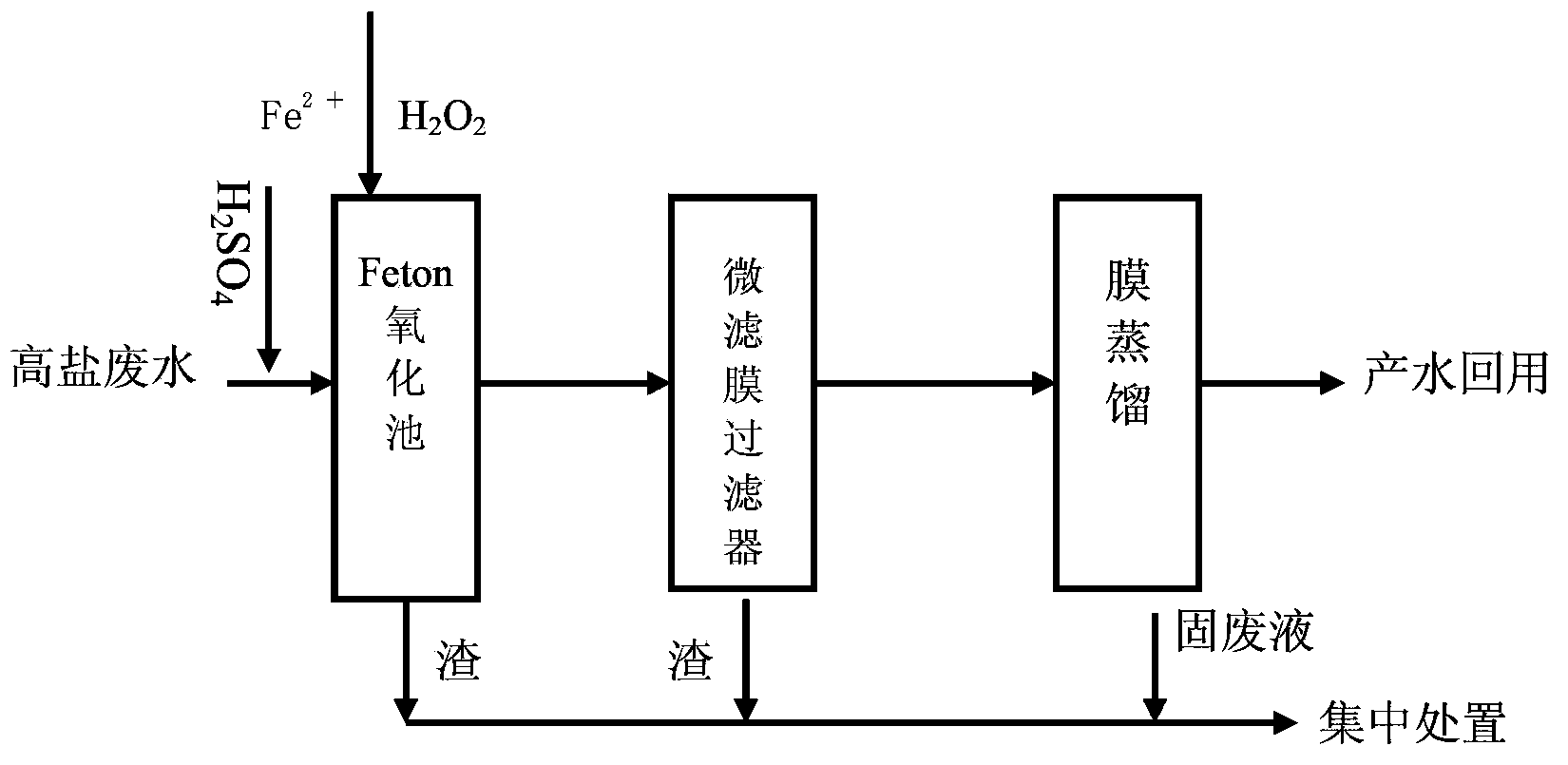

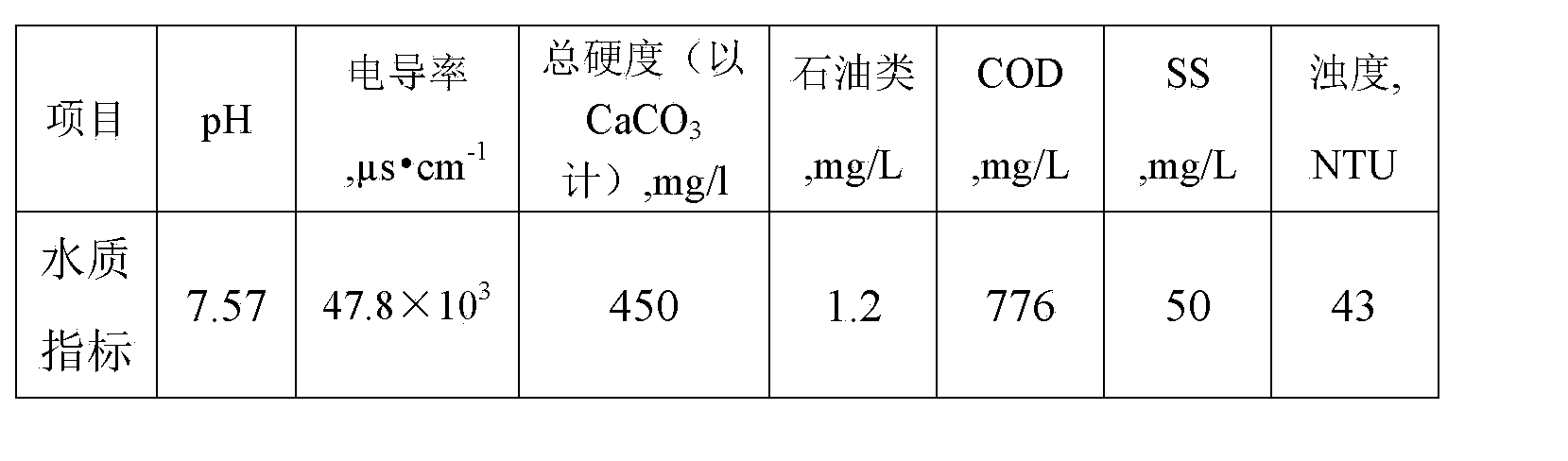

[0037] The waste lye wet oxidation wastewater in an ethylene production, the water quality indicators of each pollutant in the wastewater are shown in Table 1:

[0038]

[0039] The waste water is treated as follows:

[0040] (1) First use a sulfuric acid solution with a volume fraction of 98% to adjust the pH of the wastewater to 2, and add H according to the COD concentration in the wastewater 2 o 2 The concentration is 155mg / L, Fe 2+ The dosing concentration is 52 mg / L, and the two chemicals are added to the Feton oxidation tank at the same time. The residence time of the wastewater in the Feton oxidation tank is 60 minutes, and the reaction equilibrium can be reached. Add NaOH solution until the pH of the wastewater is 7.8.

[0041](2) After the wastewater passes through the Feton oxidation pool, it enters the microfiltration membrane filter. The membrane filtration form selected in this process is a ceramic membrane filter with a membrane pore size of 0.1μm. The SS c...

Embodiment 2

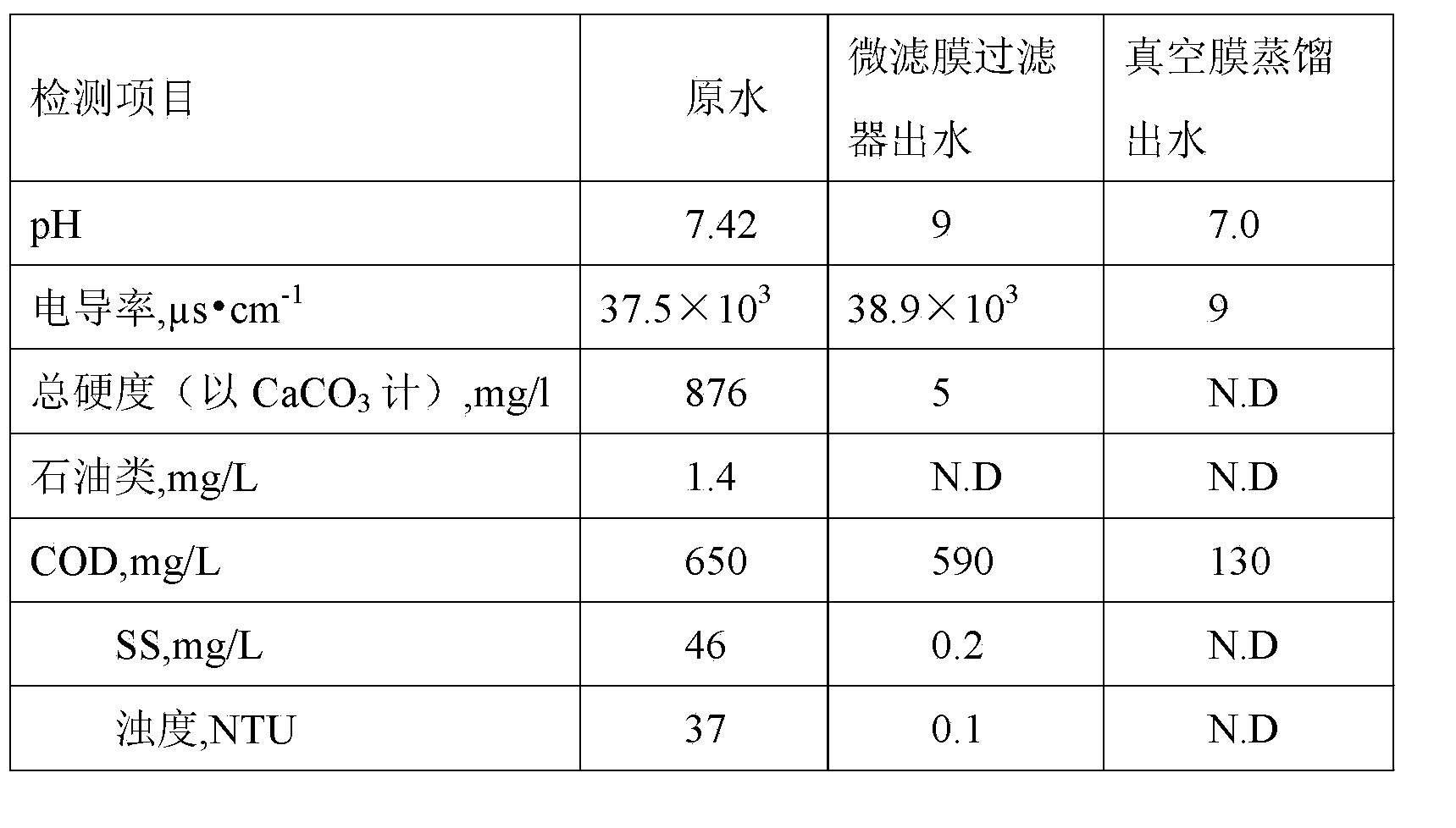

[0047] For the high-salt and high-organic waste water of a chemical plant, the water quality indicators of various pollutants in the waste water are shown in Table 3:

[0048]

[0049] The waste water is treated as follows:

[0050] (1) First use a sulfuric acid solution with a volume fraction of 98% to adjust the pH of the wastewater to 2.8, and add H according to the COD concentration in the wastewater 2 o 2 Concentration of 325 mg / L, Fe 2+ The dosing concentration is 95 mg / L, and the two chemicals are added to the system reactor at the same time. The residence time of the wastewater in the Feton oxidation tank is 70 minutes, and the reaction equilibrium can be reached. Add NaOH solution until the pH of the wastewater is 7.8.

[0051] (2) After the wastewater passes through the Feton oxidation pool, it enters the microfiltration membrane filter. The membrane filtration form selected in this process is a ceramic membrane filter with a membrane pore size of 0.1 μm. The S...

Embodiment 3

[0057] For the high-salt and high-organic waste water of a chemical plant, the water quality indicators of various pollutants in the waste water are shown in Table 4:

[0058]

[0059] The waste water is treated as follows:

[0060] (1) First use a sulfuric acid solution with a volume fraction of 98% to adjust the pH of the wastewater to 3, and add H according to the COD concentration in the wastewater 2 o 2 Concentration of 580 mg / L, Fe 2+ The dosing concentration is 190mg / L, and the two chemicals are added to the system reactor at the same time. The residence time of the wastewater in the Feton oxidation tank is 80 minutes, and the reaction balance can be reached. NaOH solution was added until the pH of the wastewater was 8.

[0061] (2) After the wastewater passes through the Feton oxidation pool, it enters the microfiltration membrane filter. The membrane filtration form selected in this process is a ceramic membrane filter with a membrane pore size of 0.1 μm. The SS...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com