Patents

Literature

48results about How to "Improve current sharing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

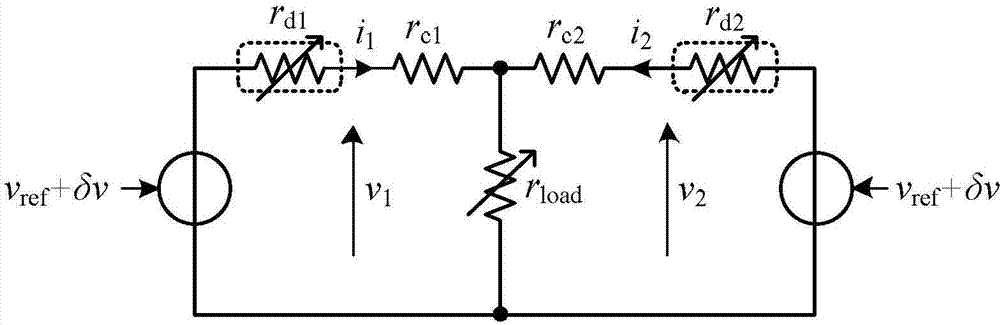

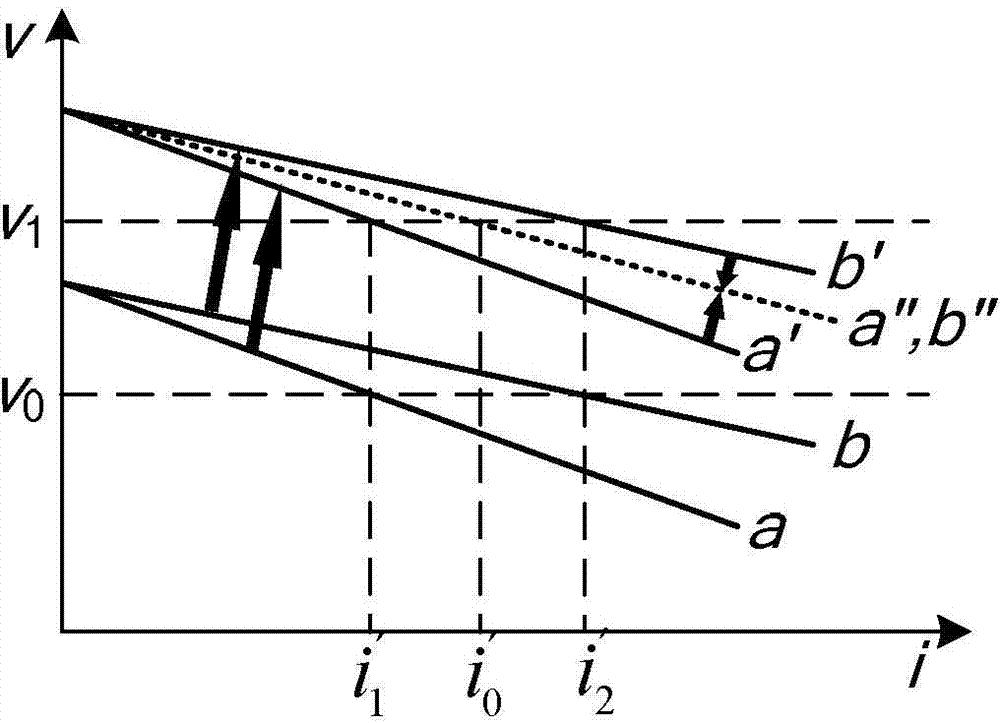

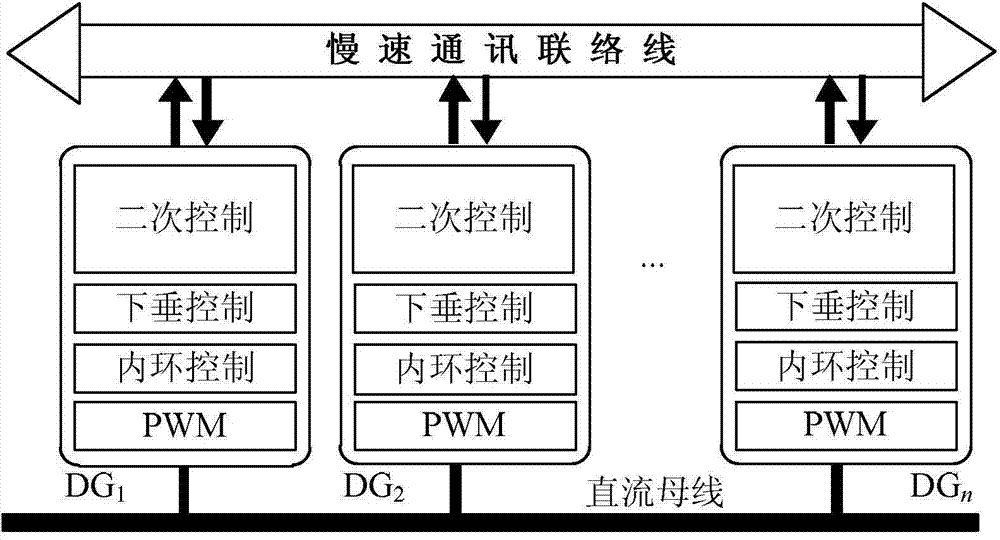

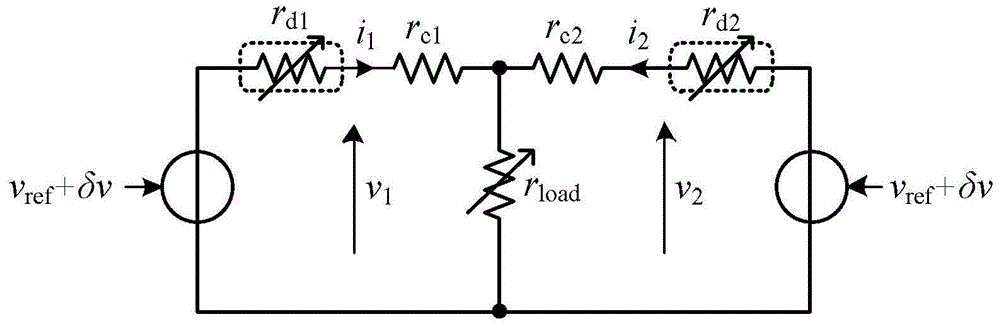

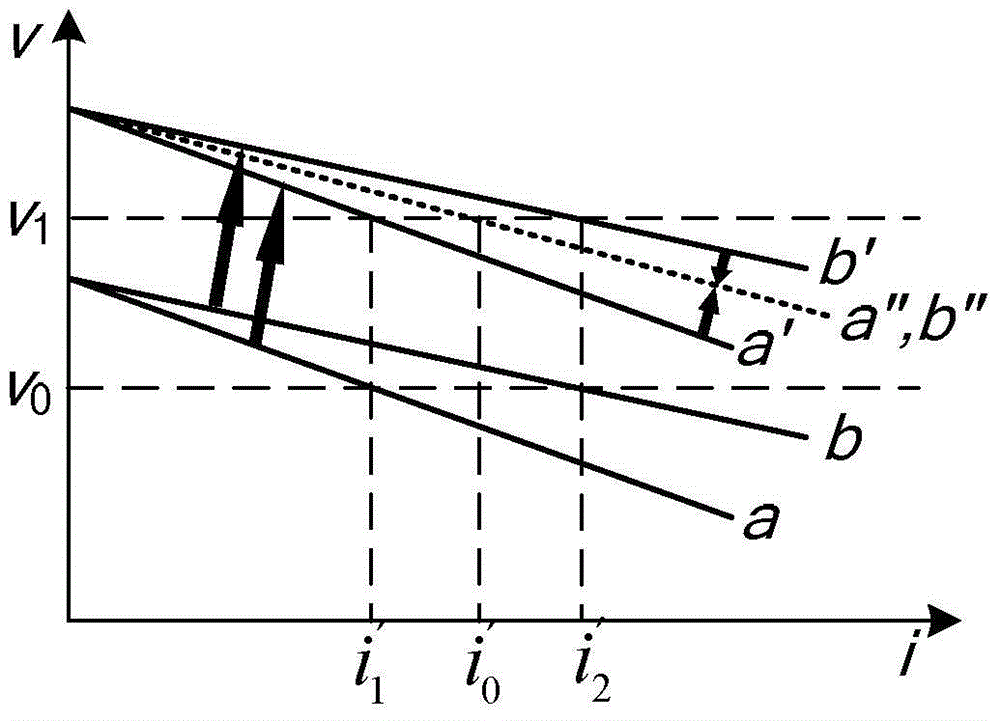

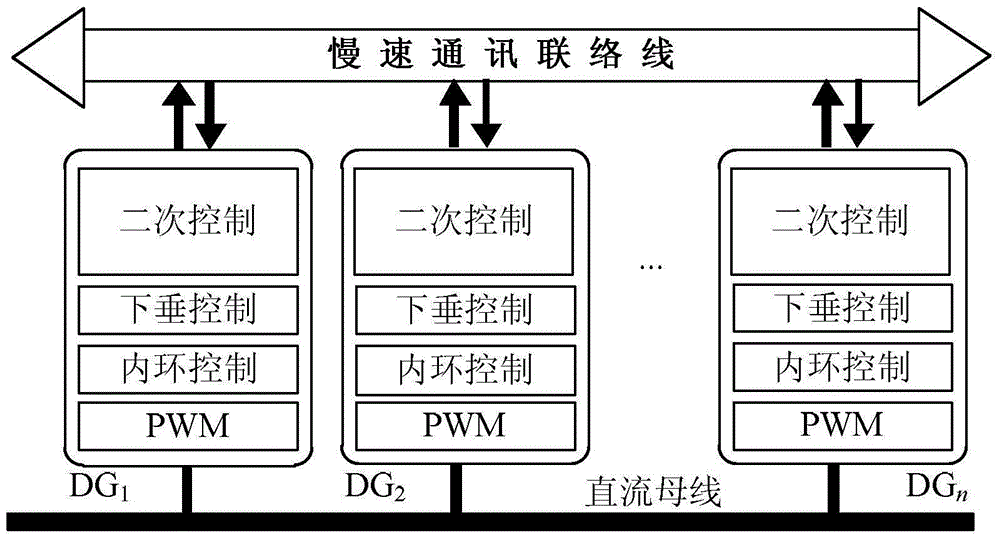

Droop control method of DC converter with function of secondary adjustment of adaptive impedance

ActiveCN104753059AEasy to dropImprove homeostasisDc source parallel operationDroop speed controlLow speed

The invention belongs to the technical field of droop control of DC converters, relates to a droop control method of a DC converter with a function of secondary adjustment of adaptive impedance, and aims to solve the problems that distributed generating unit cable impedance difference causes poor droop current homogenization effect to the DC distributed power supply system and the DC micro grid based on droop control and the parallel DC converters is low in steady state and dynamic current homogenization precision. The method has the advantages that the steady state and dynamic current homogenization precision of the parallel DC converters in the distributed DC power supply system and the DC micro grid based on droop control is improved; parameters, such as voltage, current and droop coefficient, of the parallel converters are transmitted in real time through low-speed communication, the droop coefficient is adjusted in self-controllers of the parallel converters, and finally external characteristic impedances of the parallel converters are equalized; droop curves are subjected to shifting adjustment, and bus voltage drop caused by droop control is improved.

Owner:HARBIN INST OF TECH

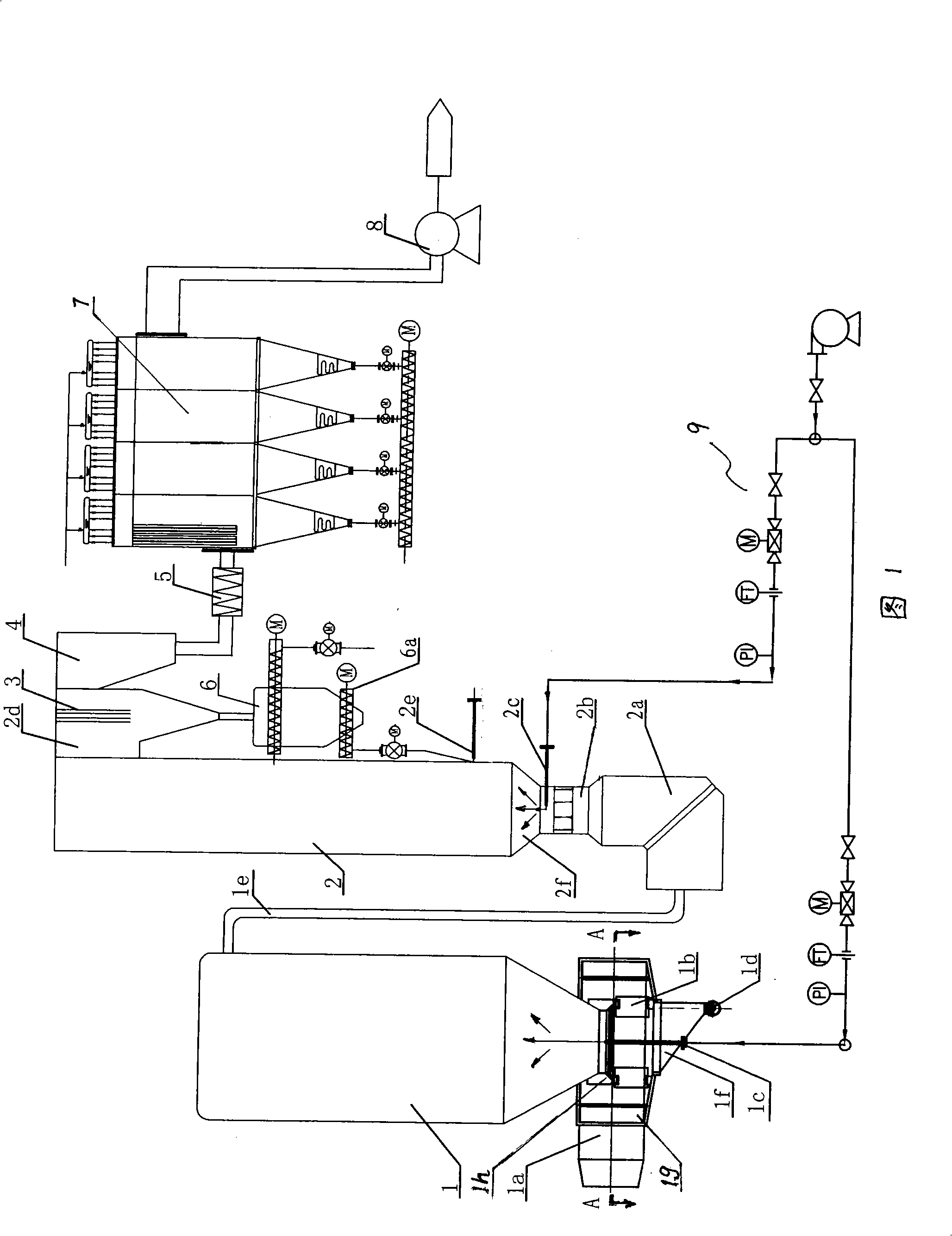

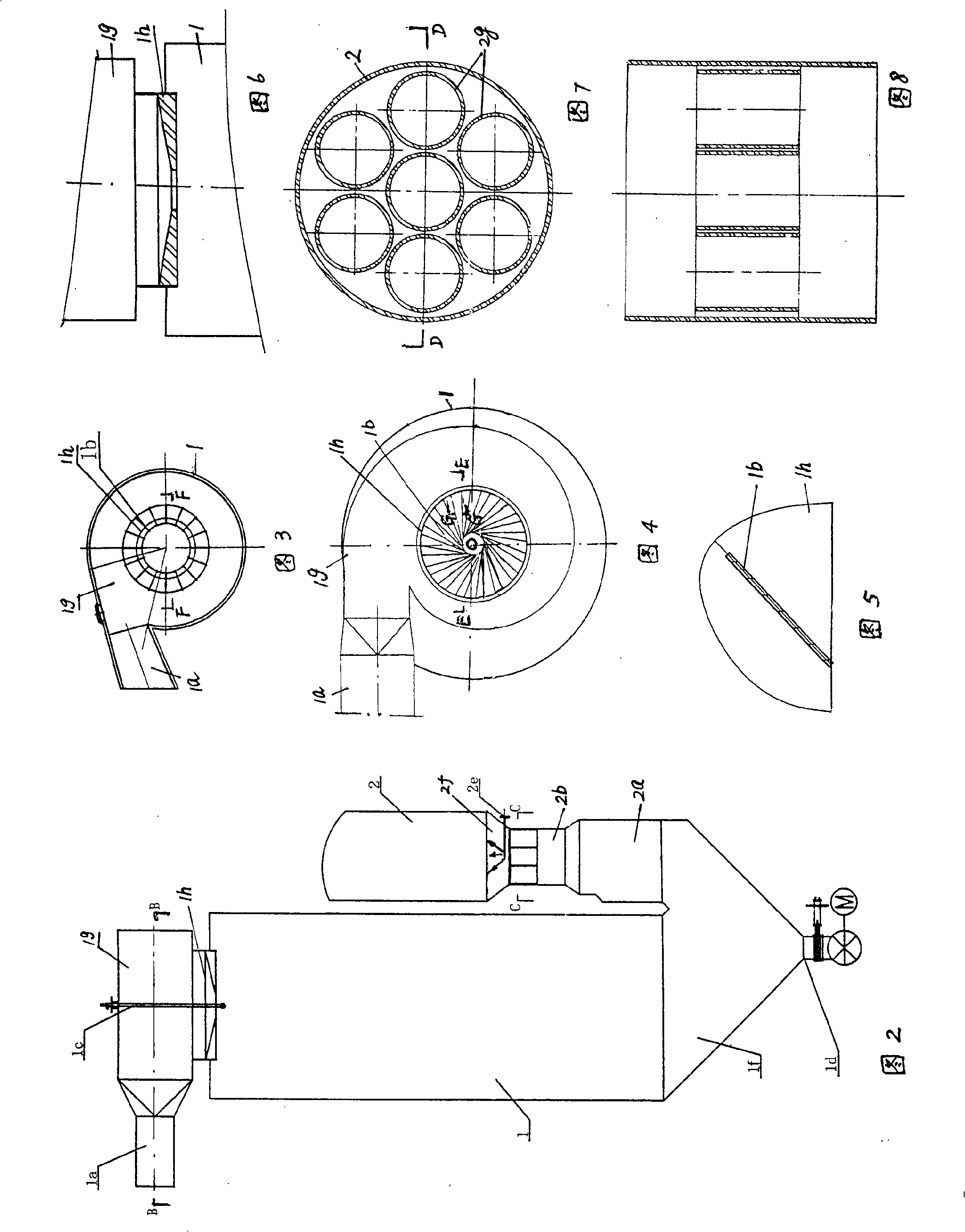

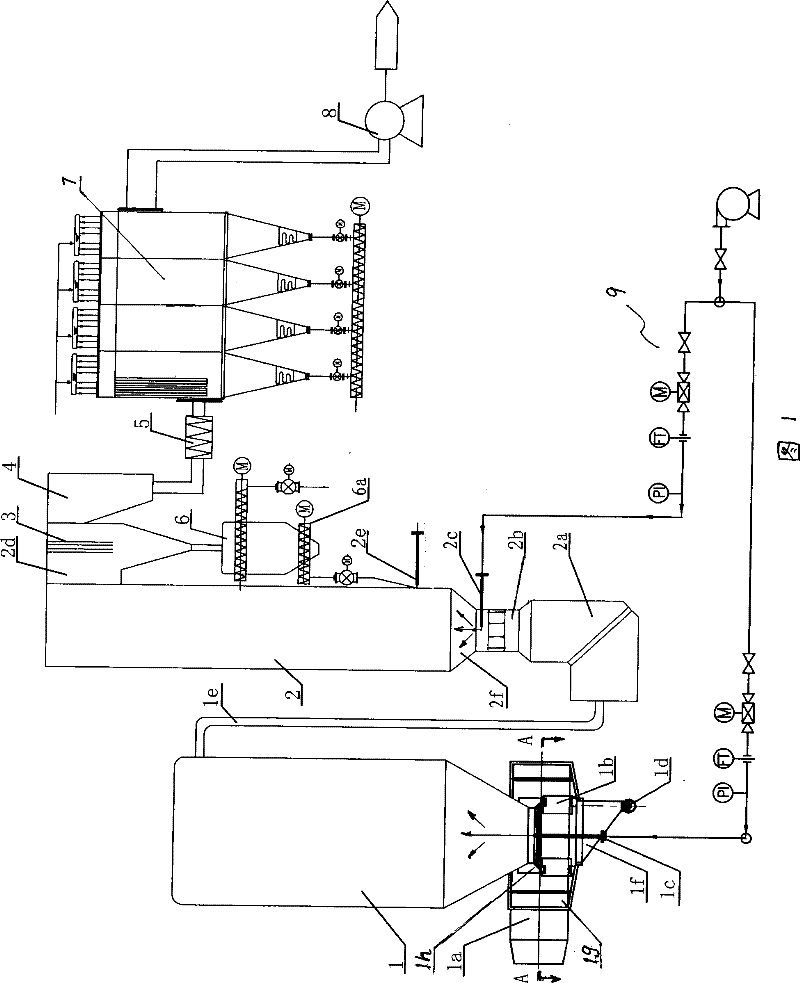

Semi-dry process smoke eliminator with independent temperature-reducing column

ActiveCN101342458AEnhanced rectificationImprove current sharing effectDispersed particle separationEvaporationInlet manifold

The invention relates to a smoke gas purification device by a semidry process, which is provided with an independent desuperheating tower, comprising a reaction tower provided with an smoke inlet box, a smoke gas outlet, a venturi tube type tower wall arranged on a tower bottom, a water injector arranged on the tower wall and a nozzle for lime dry powder and revert dust; and the smoke gas outlet is connected with an inertia separator, an activated carbon mixer, a bag-type dust remover and a draught fan. The invention is characterized in that the invention is also provided with the desuperheating tower which is provided with a boiler smoke gas inlet manifold, a single-stage water injector, an ash bucket with an ash hole and a gas flue; the gas flue of the desuperheating tower is connected with the smoke inlet box into one unit. The boiler smoke gas disperses within the two towers for cooling, thereby improving the adaptability of a system to a load; the boiler smoke gas particularly can be cooled down urgently to a set temperature in the desuperheating tower; and the reaction tower can be humidified only by evaporation with a little water to complete a deacidifying reaction and remove dioxin, thereby avoiding the disadvantages of scale formation on the tower wall of the prior reaction tower and bag burning of the bag-type dust remover, guaranteeing a sustaining and stable smoke purification process and having the advantages of good purification effect and low energy consumption.

Owner:HANGZHOU NEW CENTURY ENERGY ENVIRONMENTAL PROTECTION ENG CO LTD

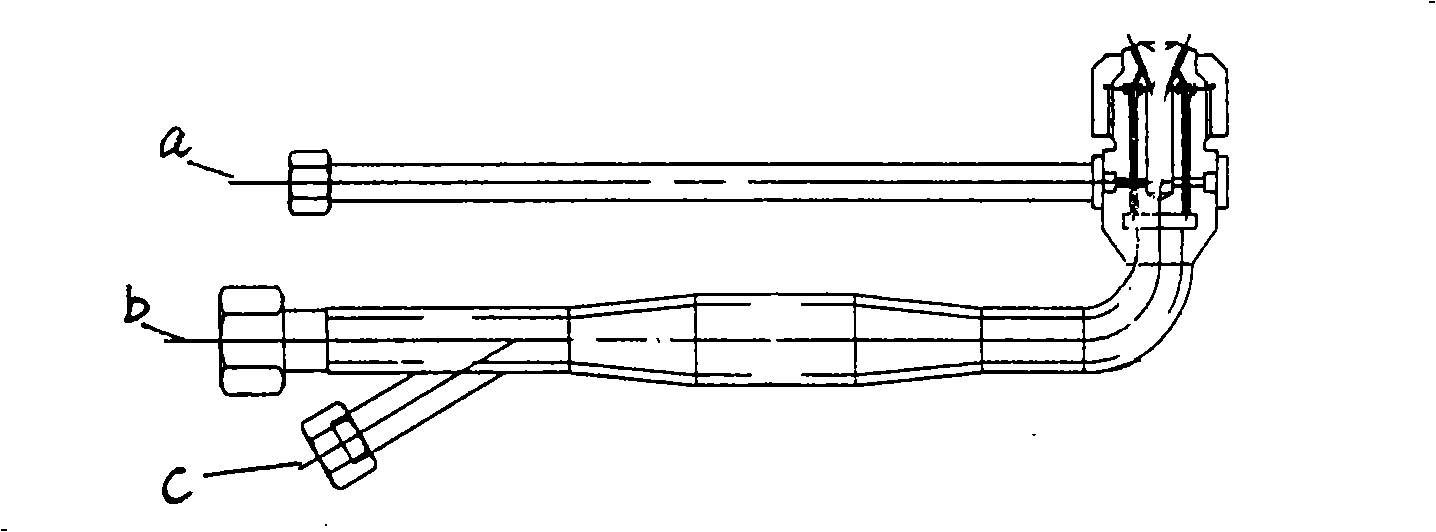

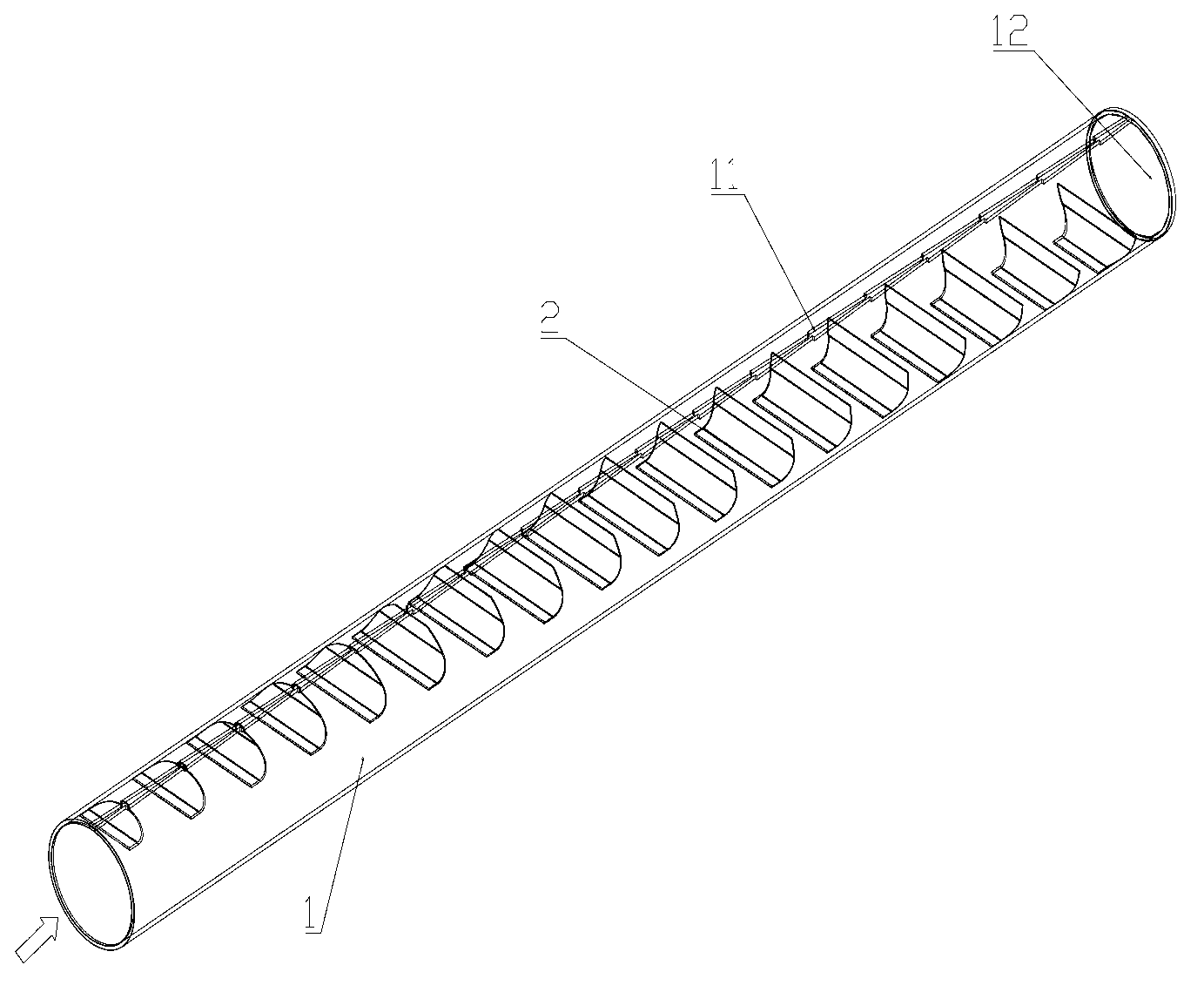

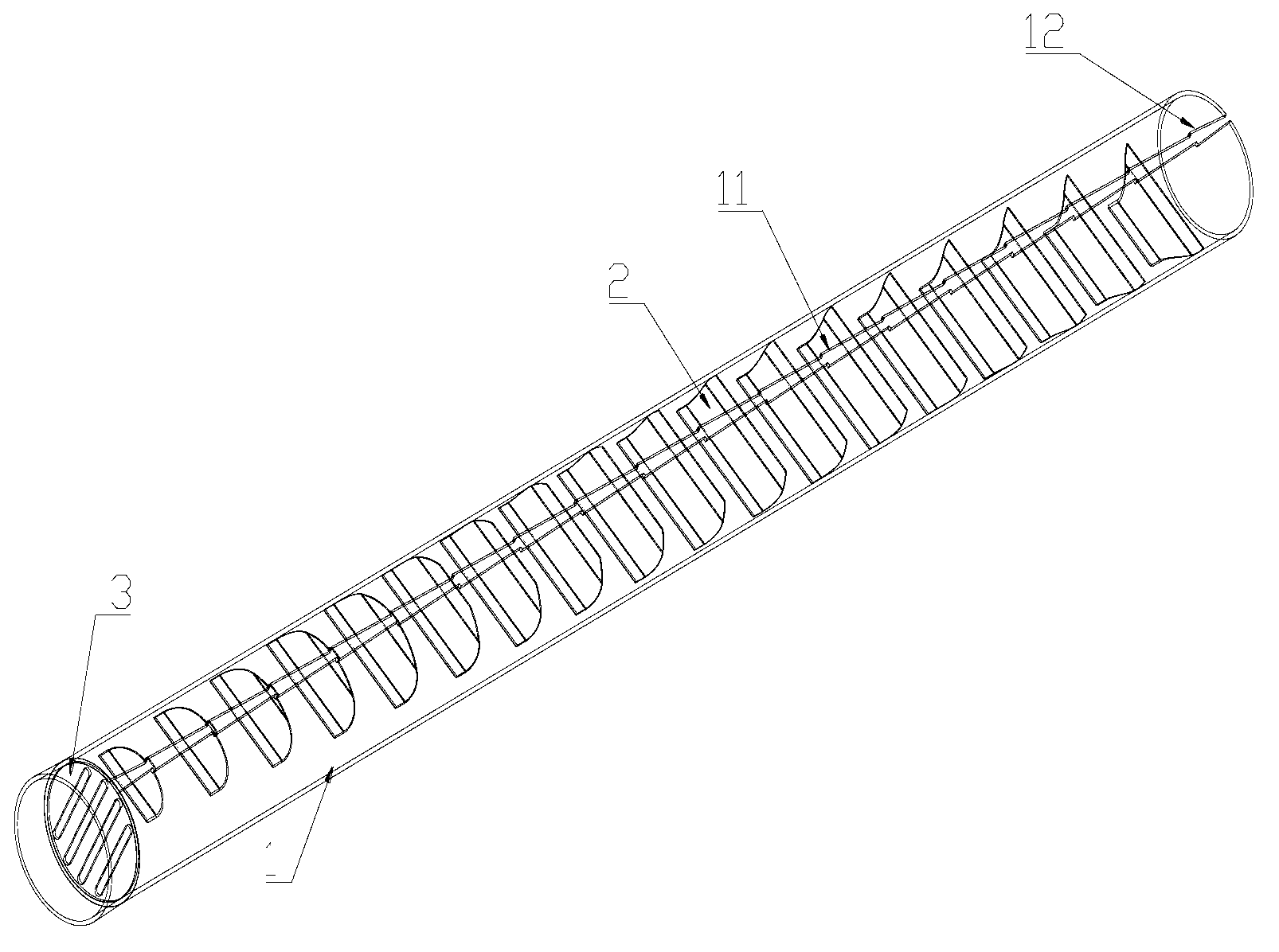

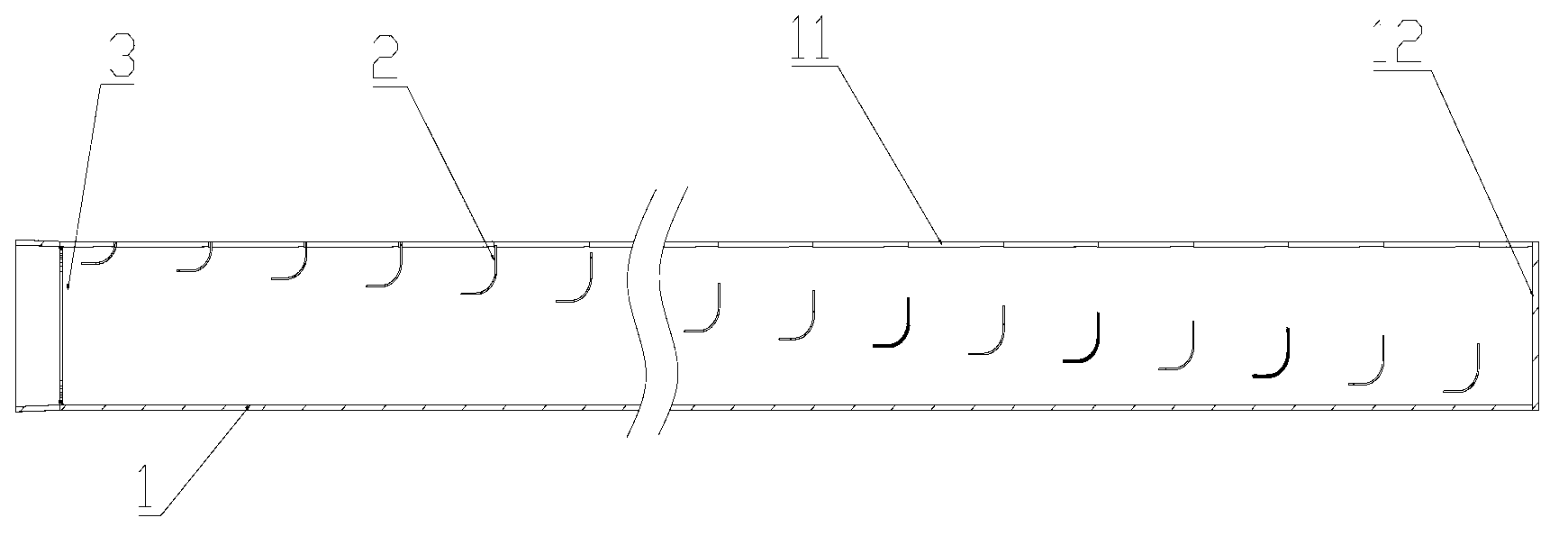

Fluid distributor

InactiveCN103217052AImprove uniformityReduce eddy currentHeat exchanger casingsProject areaEngineering

The invention discloses a fluid distributor and belongs to the fluid distributing technical field. The fluid distributor comprises a distributing pipe body and guide plates. A flow distributing groove is formed in the pipe wall of the distributing pipe body. A blanking plate is arranged at the tail end of the distributing pipe body. The guide plates are arranged in the distributing pipe body. The guide plates are connected by inlet plates and outlet plates. The plate surfaces of the inlet plates extend along the entrance direction of the distributing pipe body. The plate surfaces of the outlet plates extend along the direction of the flow distributing groove. The guide plates are sequentially ranked along the length direction of the distributing pipe body. The inlet plates are ranked of a step shape, and projected areas on a cross section of space areas of the adjacent inlet plates are basically identical. Distance from the inlet plates to the flow distributing groove increases by degrees along the entrance of the distributing pipe body to the tail end of the distributing pipe body. The fluid distributor solves the technical problems of an existing distributor that heat exchange efficiency of a heat exchanger is low due to uneven flow distributing of an existing distributor, and is particularly suitable for refrigerant distributing of a plate type heat exchanger.

Owner:陆群英

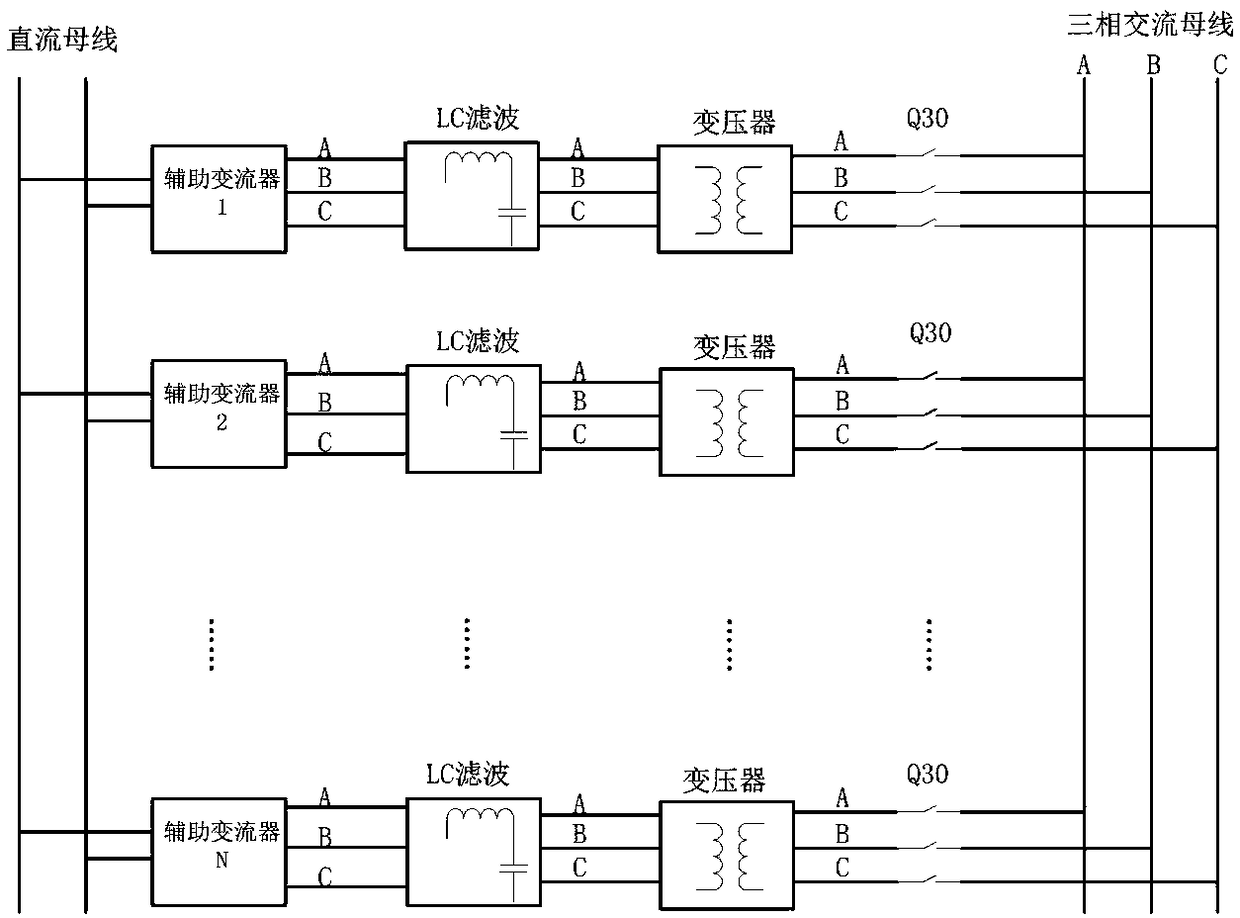

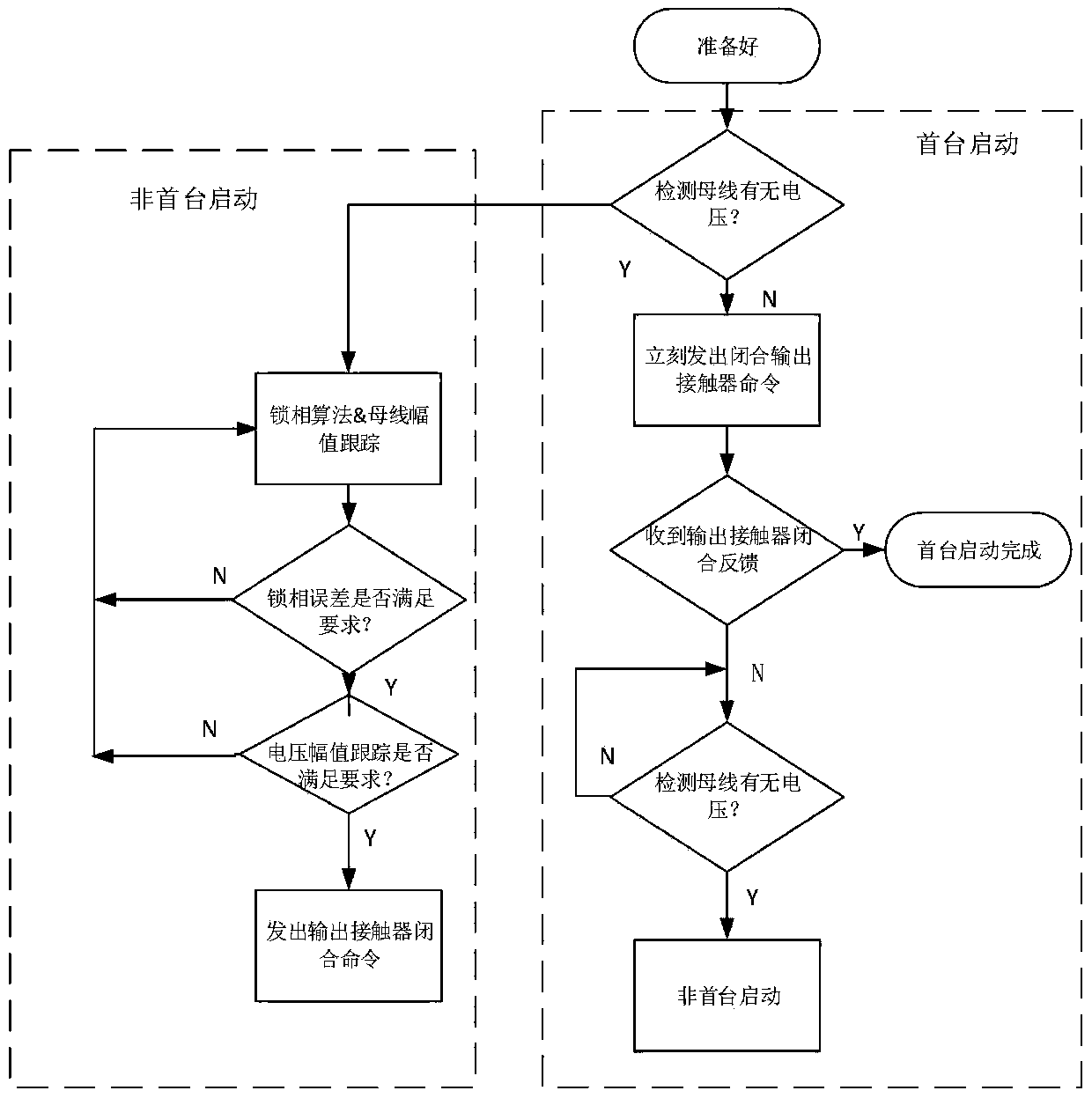

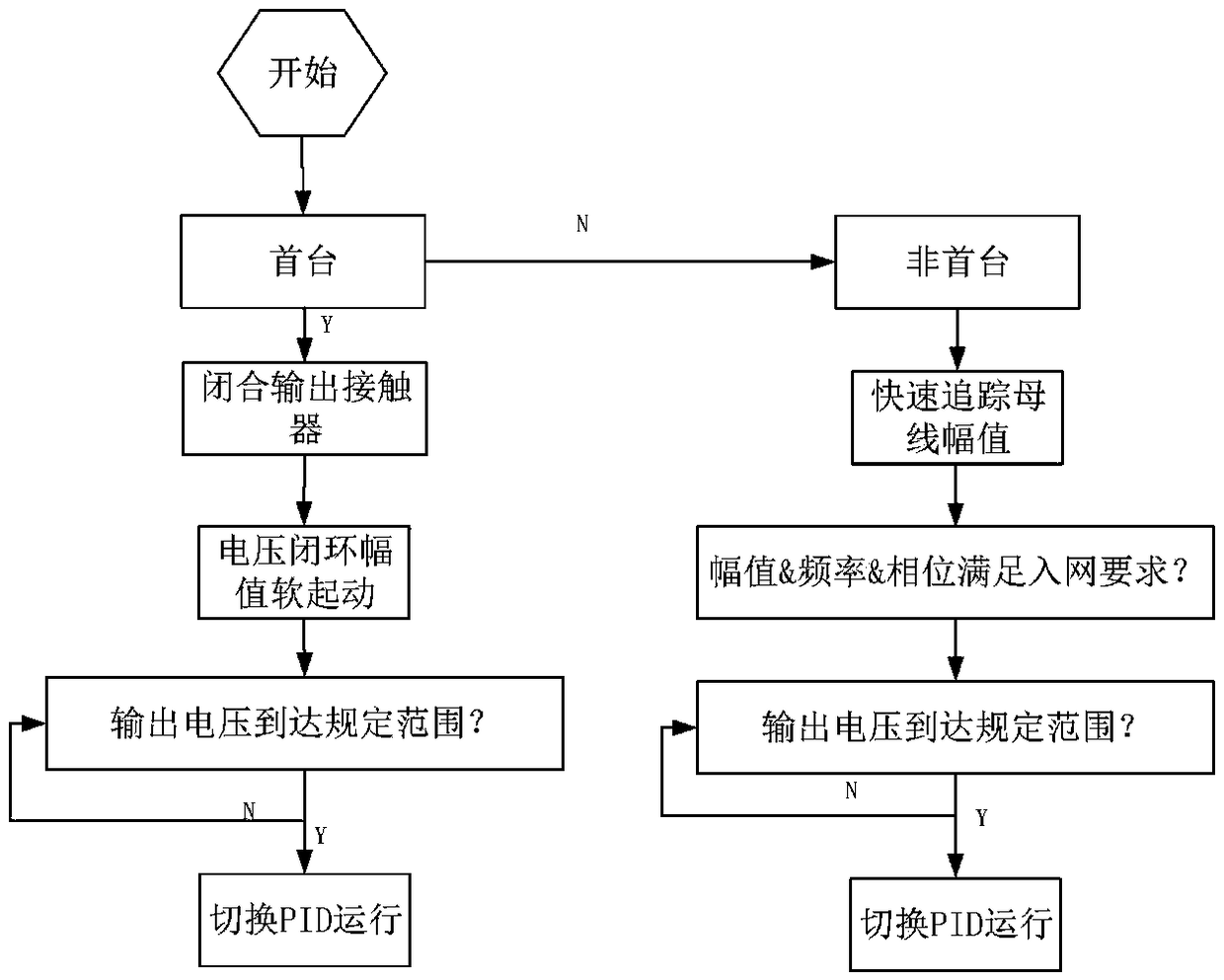

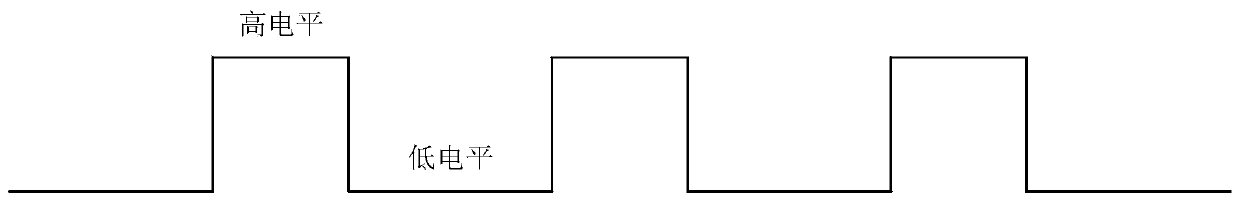

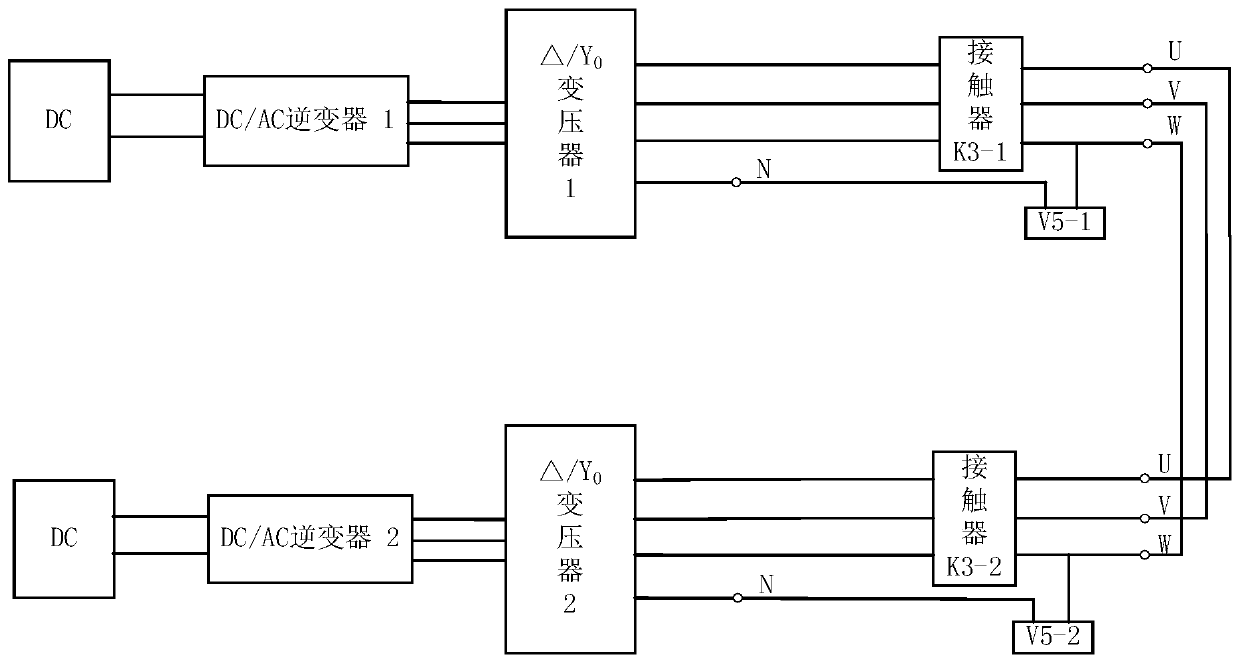

Synchronous soft-start networking control strategy of EMU parallel auxiliary converter

ActiveCN109193795AFast networkingReduce shockProgramme controlSpeed controllerSynchronous motorNetwork connection

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST

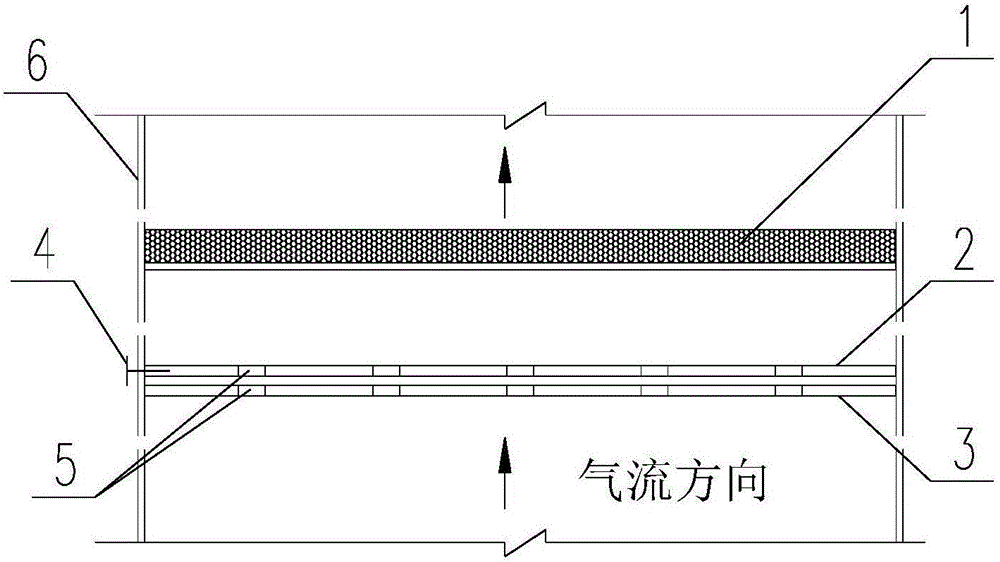

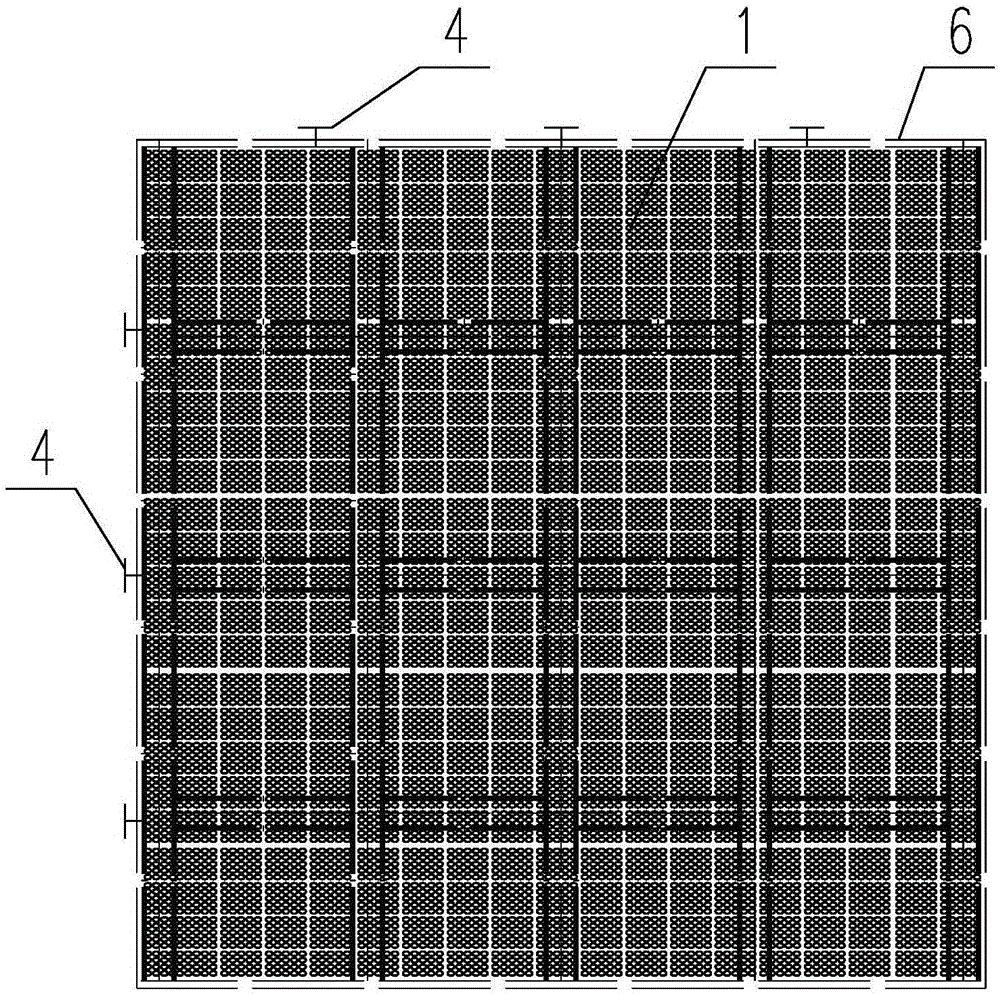

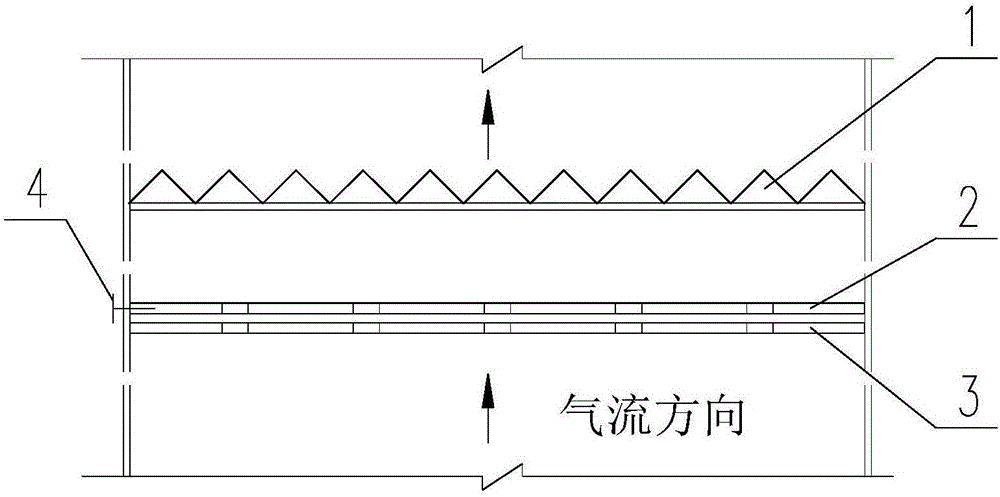

Mixing and flow-homogenizing structural body

ActiveCN106563340AImprove mixing uniformityOverlap rate can be adjustedGas treatmentDispersed particle separationShortest distanceFlue gas

The invention relates to a mixing and flow-homogenizing structural body, which includes a pore plate flow-homogenizing layer and a foam metal flow-homogenizing layer which are arranged vertically to the gas flow direction. The pore plate flow-homogenizing layer is composed of a pore plate flow-homogenizing layer fixed sheet and a pore plate flow-homogenizing layer movable sheet, which are arranged adjacently to each other. A plurality of flow-homogenizing pores are formed in corresponding positions on both the pore plate flow-homogenizing layer fixed sheet and the pore plate flow-homogenizing layer movable sheet. The pore plate flow-homogenizing layer movable sheet can slide transversally and vertically at short distance, and when the movable sheet slides, the overlapping ratio of the flow-homogenizing pores in the movable sheet and the corresponding flow-homogenizing pores in the fixed sheet is changed. By means of the combined structure of the foam metal flow-homogenizing layer and the pore plate flow-homogenizing layer. The overlapping ratio of the flow-homogenizing pores in the movable sheet and the fixed sheet can be adjusted, thereby greatly improving flow-homogenizing effect. When being used for removal of NOx through ammonia process under large flue gas load status, gas flows and pressures in multiple chambers can be equalized, and gas flow distribution in single chamber is uniform. Meanwhile, mixing uniformity of ammonia gas or a thermal-desorption gas with flue gas is improved.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

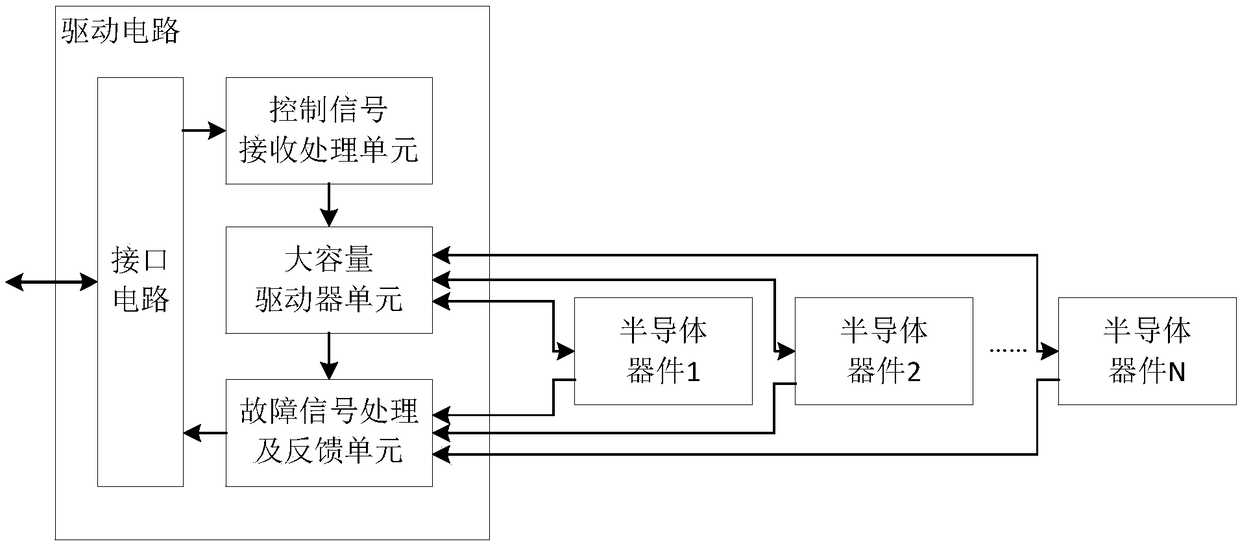

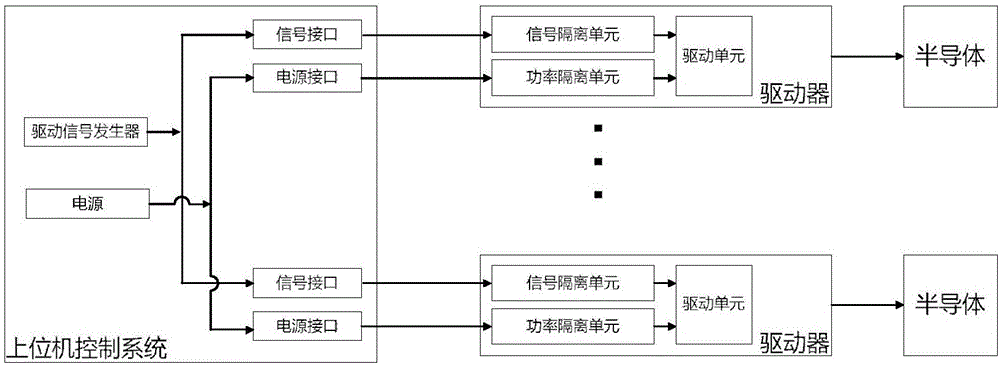

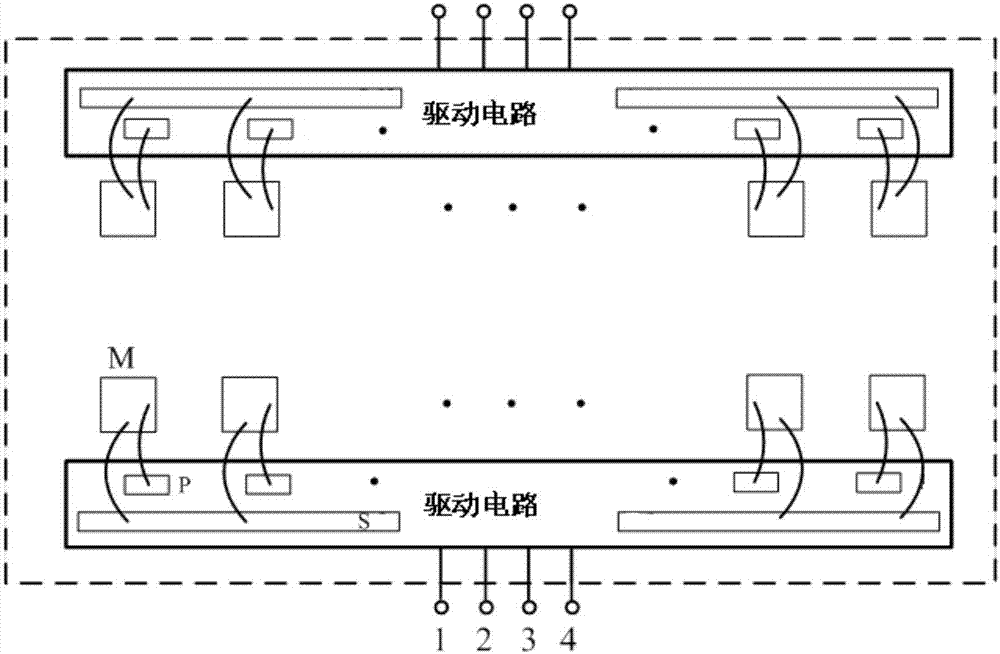

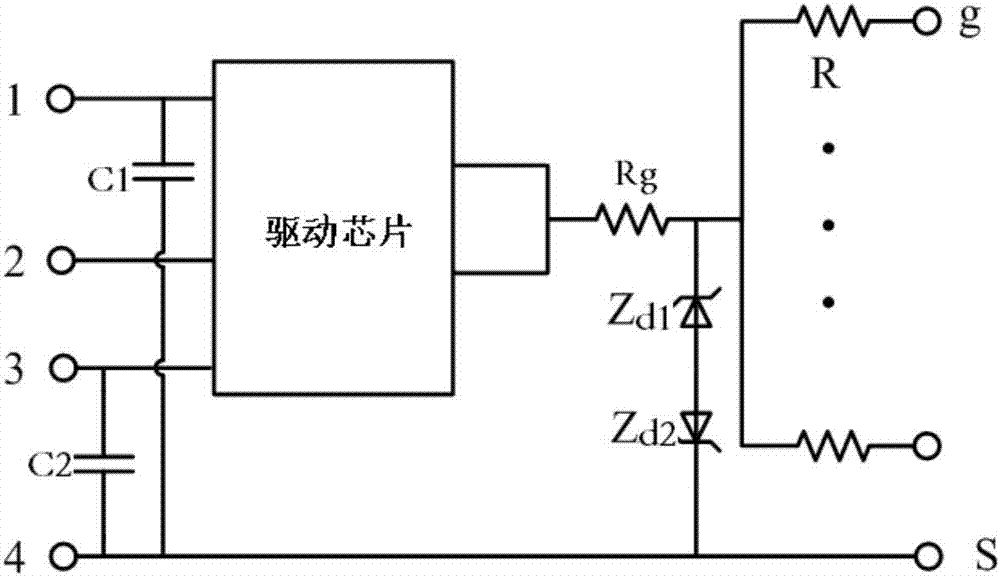

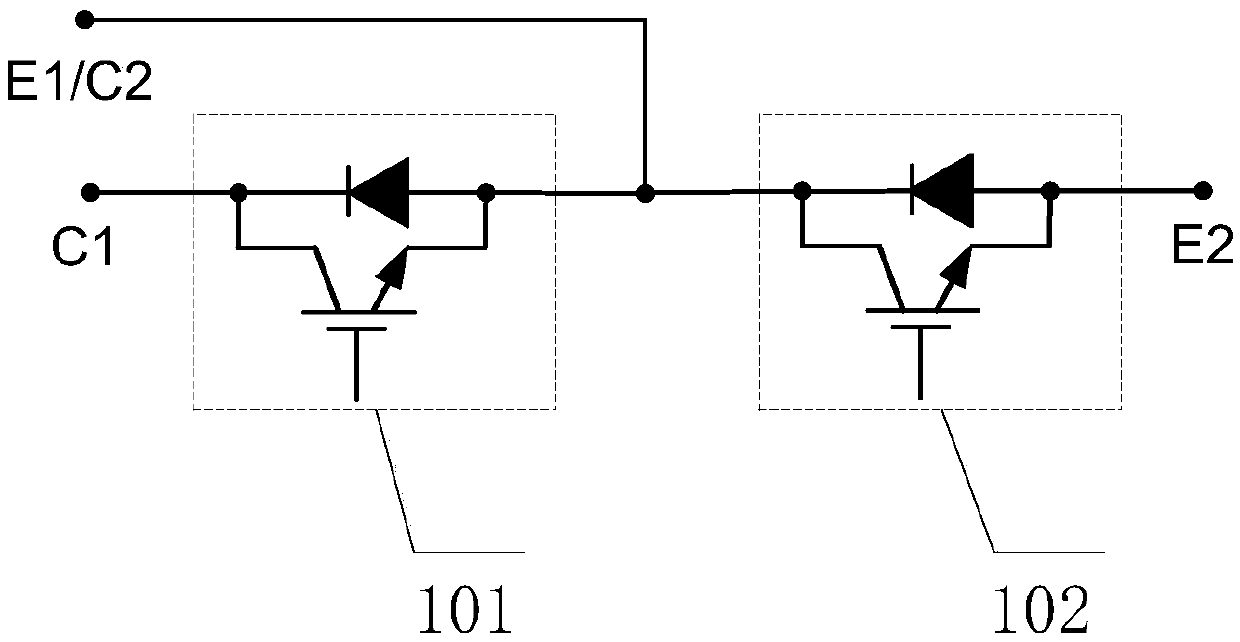

Driving circuit of semiconductor devices in high-power converter and working method thereof

InactiveCN108964427AGuaranteed synchronicityImprove current sharing effectEmergency protective circuit arrangementsPower conversion systemsPower semiconductor deviceControl signal

The invention discloses a driving circuit of semiconductor devices in a high-power converter and a working method thereof. The driving circuit includes a control signal receiving and processing unit,a large-capacity driver unit and a fault signal processing and feedback unit. The control signal receiving and processing unit is used for generating two complementary driving signals with dead zone from an external driving signal and transmitting the driving signals to the large-capacity driver unit. The large-capacity driver unit is connected with the semiconductor devices, and is used for receiving and amplifying the driving signals sent by the control signal receiving and processing unit and sending the driving signals to the semiconductor devices, and obtaining the voltage value across the two ends of each semiconductor device and feeding the voltage values back to the fault signal processing and feedback unit. The large-capacity driver unit simultaneously drives one or more semiconductor devices, which ensures the synchronization of the driving signals of the semiconductor devices and improves the current sharing of the semiconductor devices. The currents and temperatures of thesemiconductor devices are monitored and protected on the basis, which ensures the safe and stable operation of the semiconductor devices of the high-power converter.

Owner:西安翌飞核能装备股份有限公司

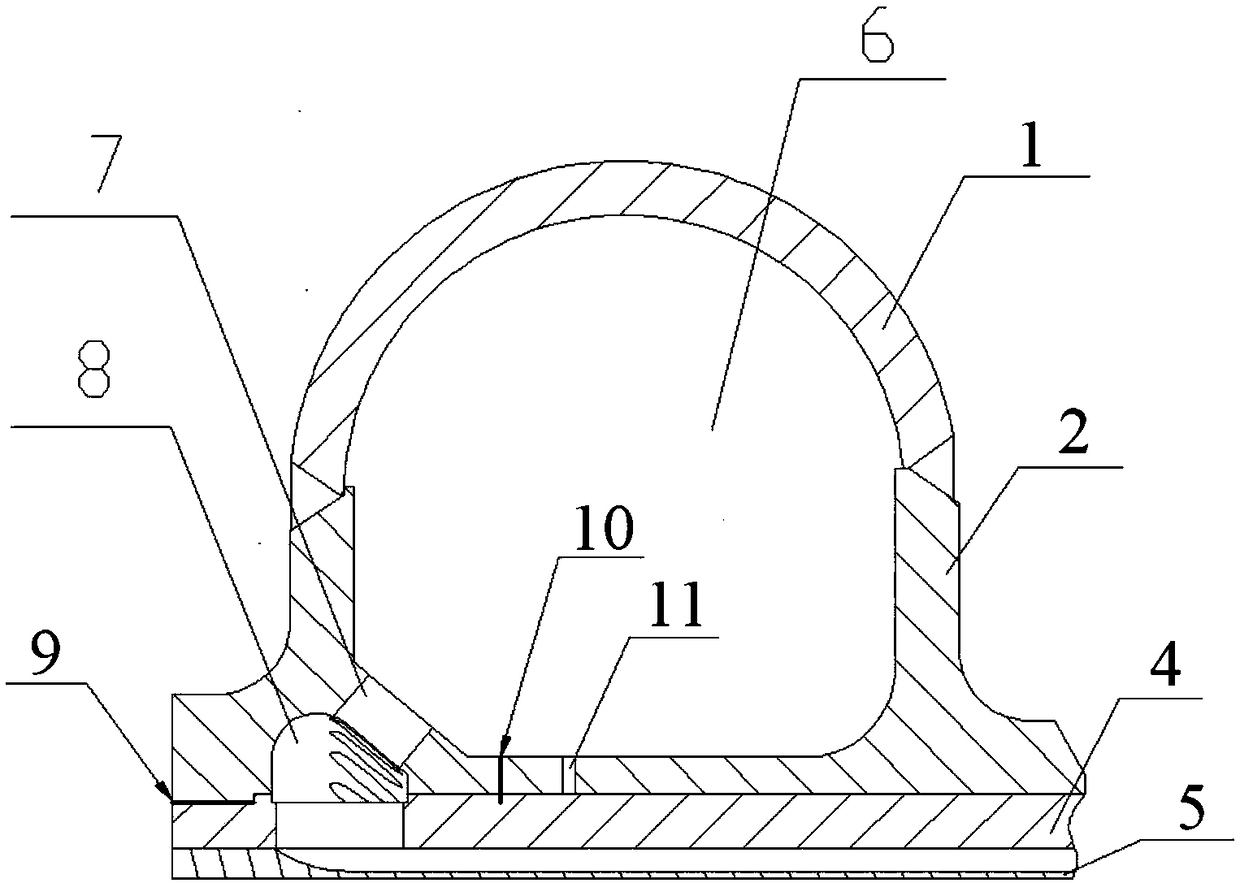

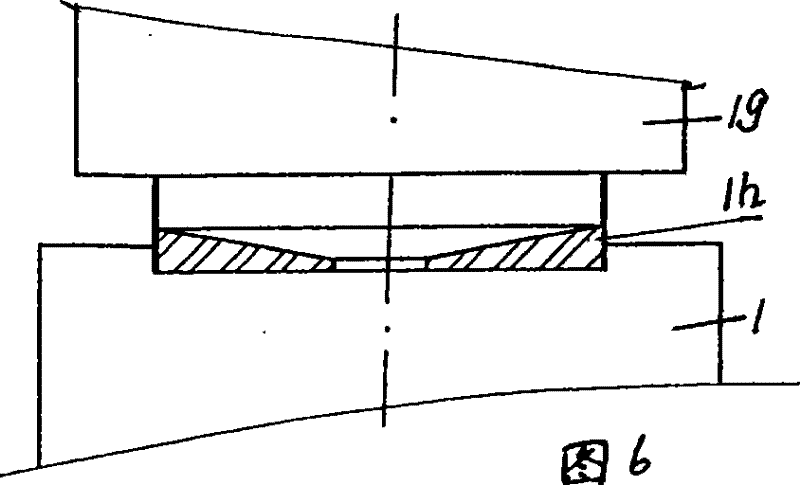

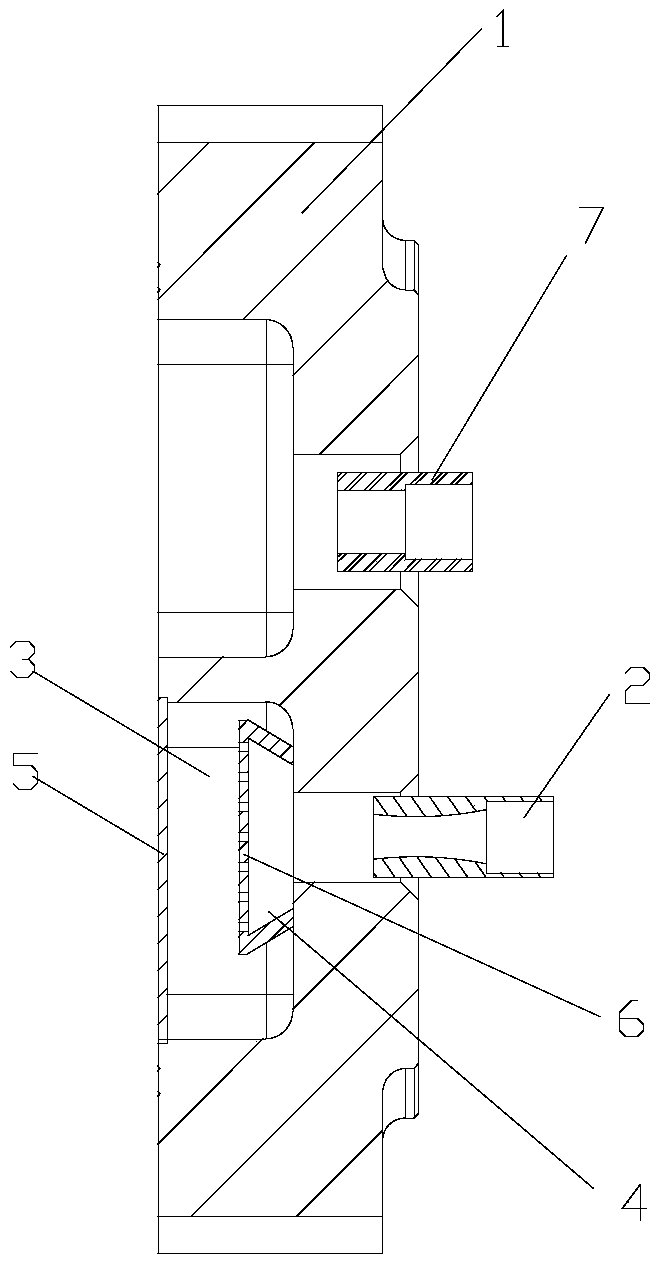

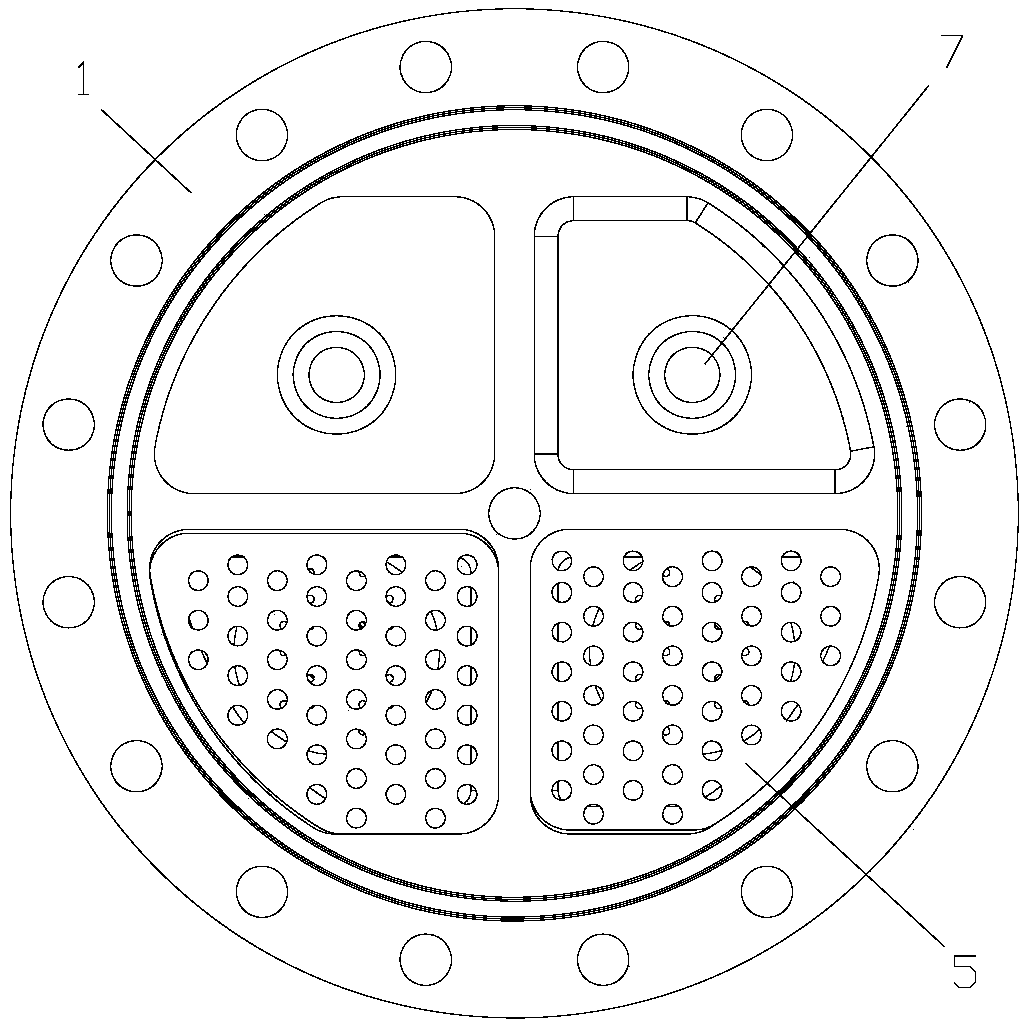

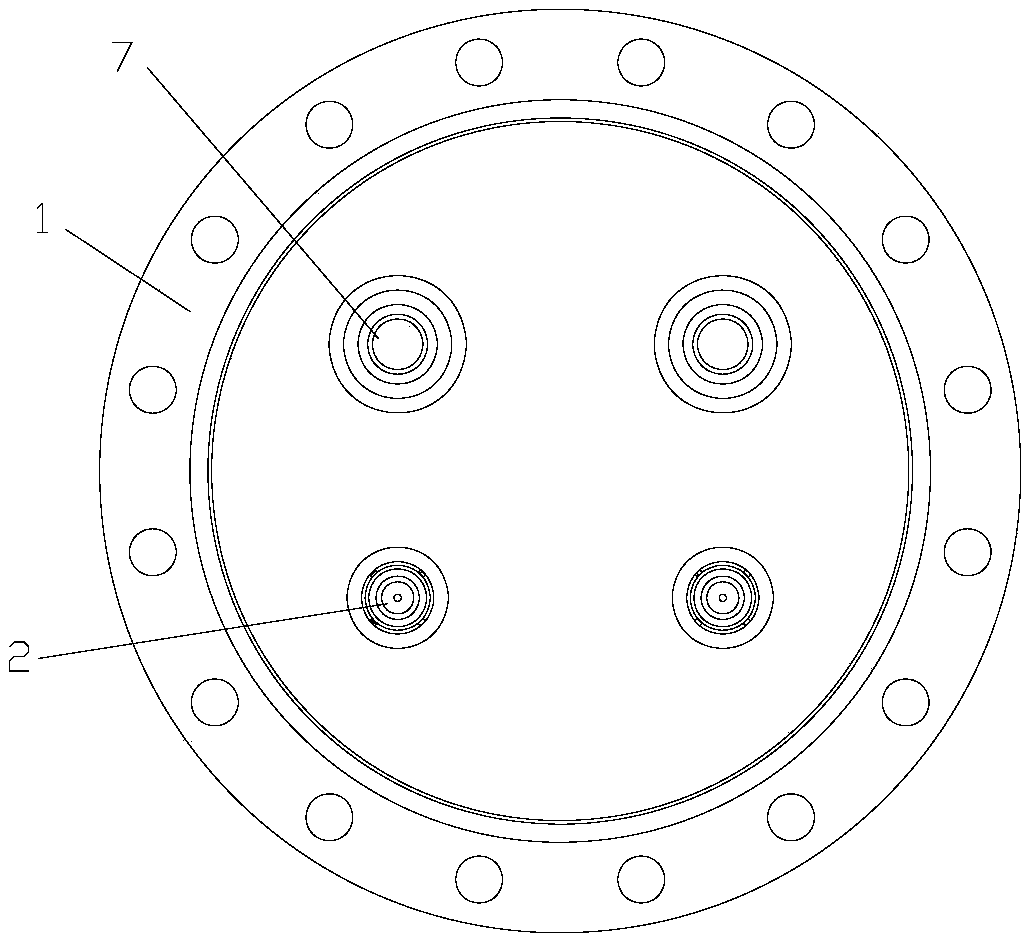

Liquid collecting ring on body part of thrust chamber of liquid rocket engine

PendingCN108979900AImprove current sharing effectGood strength and rigidityRocket engine plantsSteel jacketThrust chamber

The invention relates to a liquid collecting ring on the body part of a thrust chamber of a liquid rocket engine. The liquid collecting ring comprises an upper liquid collecting ring cover (1) and a lower liquid collecting ring cover (2), and a radial hole (7) and a collection slot (8) are formed in the lower liquid collecting ring cover (2). The cross section of the upper liquid collecting ring cover (1) takes the shape of an elliptical arc, and a concave slot is formed in the cross section of the lower liquid collecting ring cover (2). The upper liquid collecting ring cover (1) and the lowerliquid collecting ring cover (2) are connected to form a liquid collecting chamber (6), and the liquid collecting chamber (6) communicates with the collection slot (8) through the radial hole (7). The liquid collecting ring has the advantages of good flow equalization, small pressure loss and good strength and rigidity and can also solve the problem that the welding airtightness of a steel jacket(3) and the body part of the thrust chamber is poor in the prior art.

Owner:BEIJING AEROSPACE PROPULSION INST

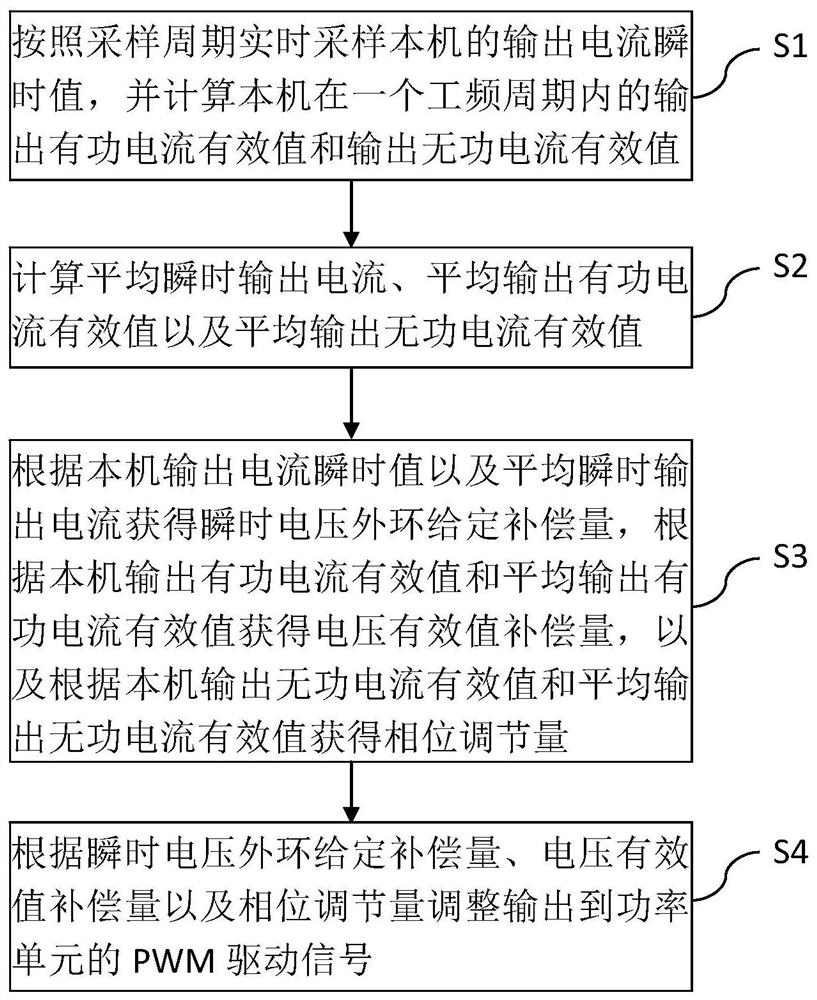

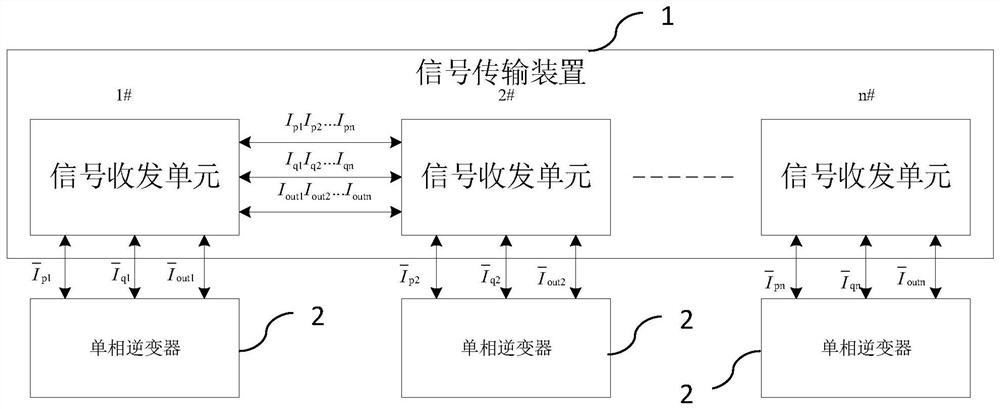

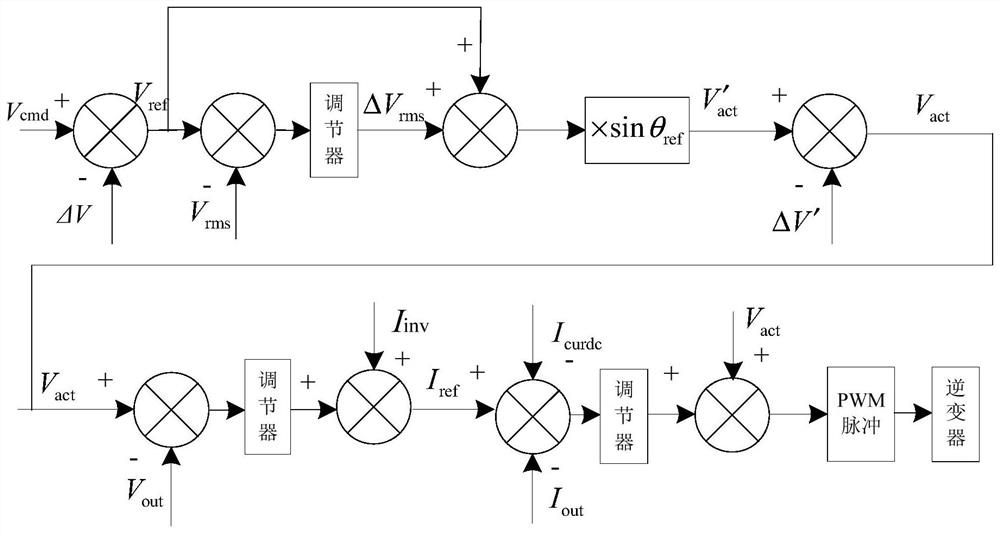

Current sharing control method and single-phase inverter parallel system

The invention provides a current sharing control method and a single-phase inverter parallel system, and the method comprises the following steps executed on each single-phase inverter: a, sampling anoutput current instantaneous value of a local machine in real time according to a sampling period, and calculating an output active current effective value and an output reactive current effective value, wherein the sampling period is smaller than the power frequency period; b, calculating an average instantaneous output current, an average output active current effective value and an average output reactive current effective value; c, obtaining an instantaneous voltage outer loop given compensation amount, a voltage effective value compensation amount and a phase adjustment amount; and d, adjusting a PWM driving signal output to a power unit according to the instantaneous voltage outer loop given compensation amount, the voltage effective value compensation amount and the phase adjustment amount. The method can quickly respond when the single-phase inverter is suddenly loaded and unloaded dynamically, and the current sharing performance of a parallel system is improved.

Owner:SHENZHEN ECOWATT POWER

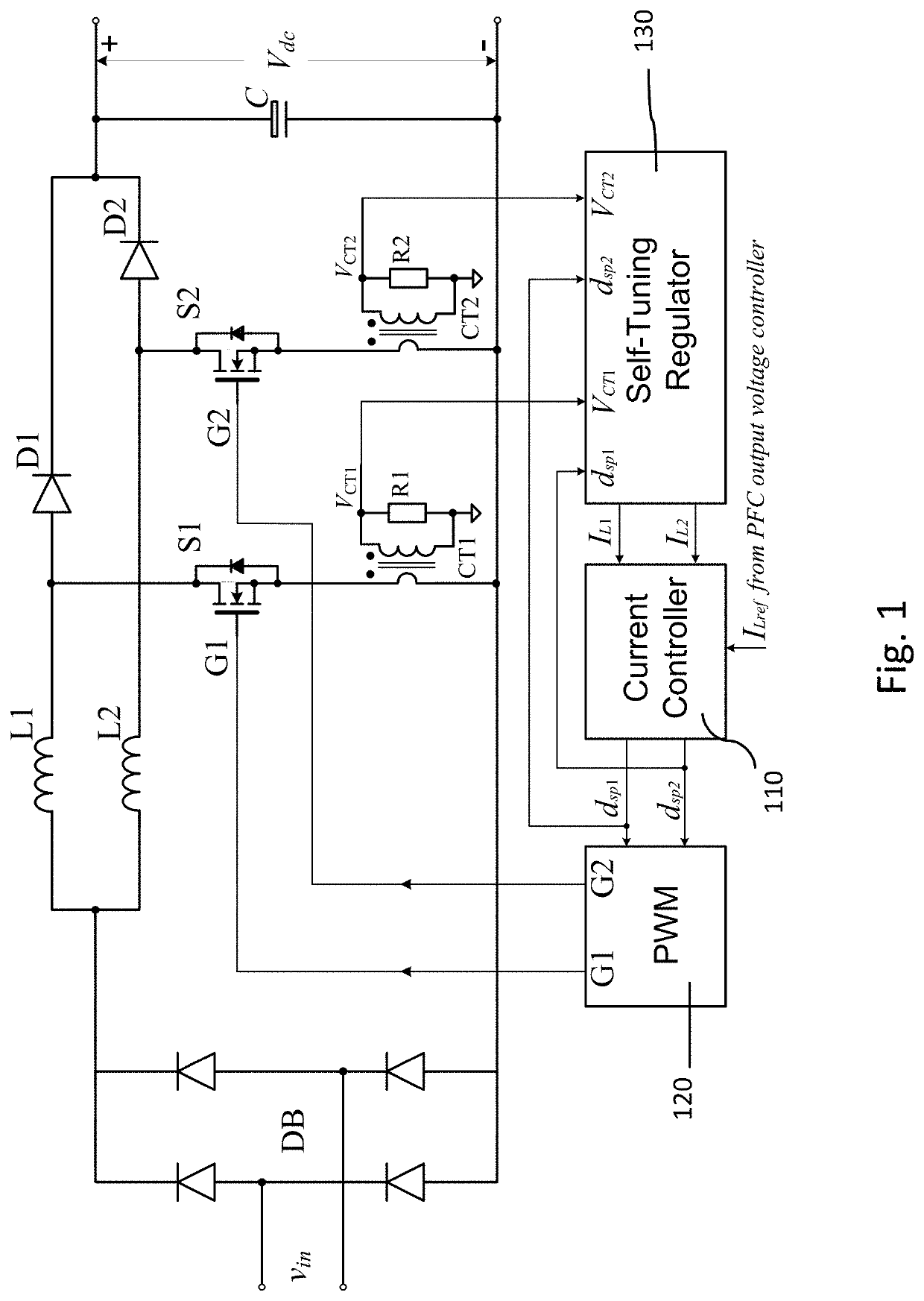

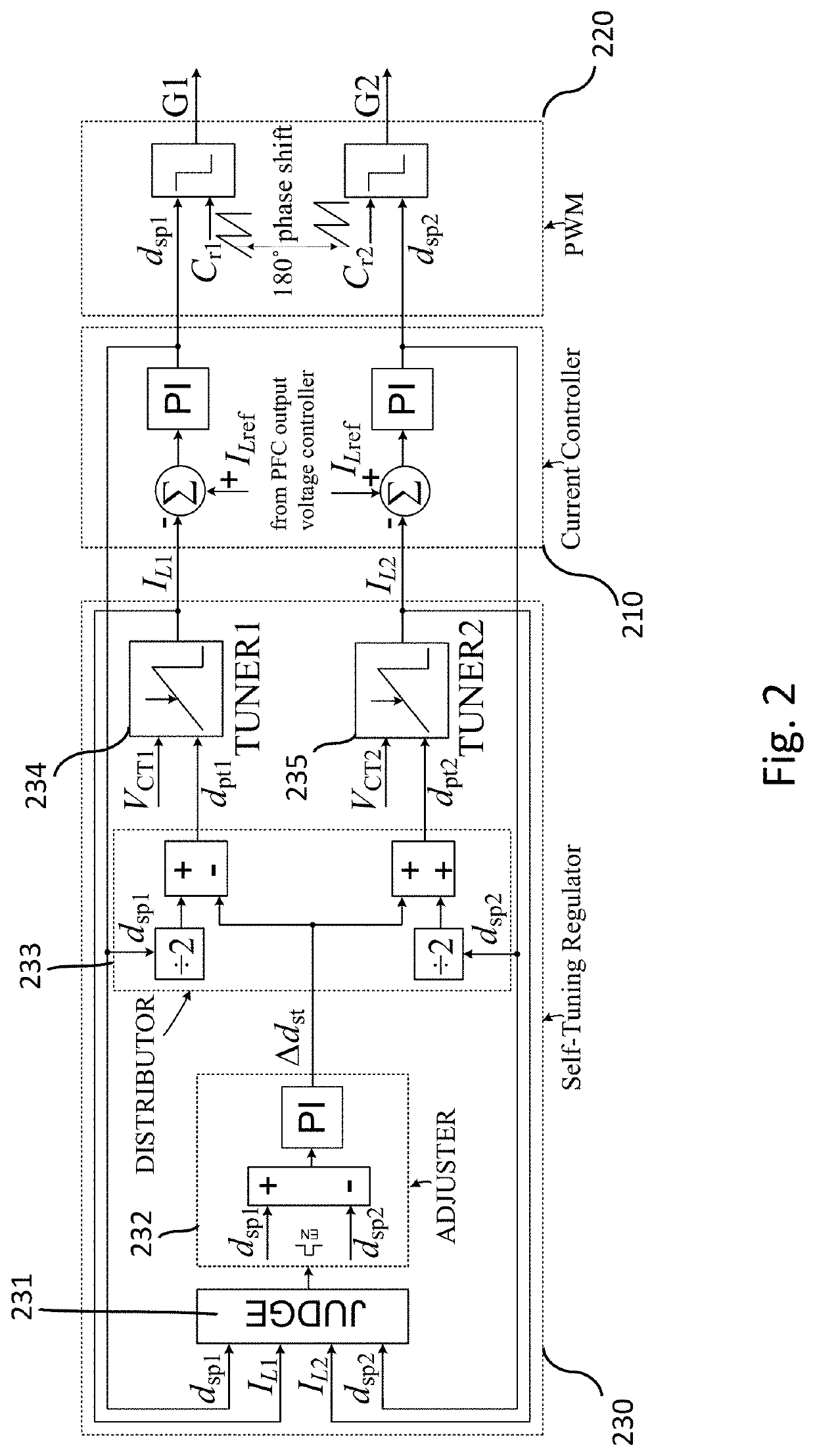

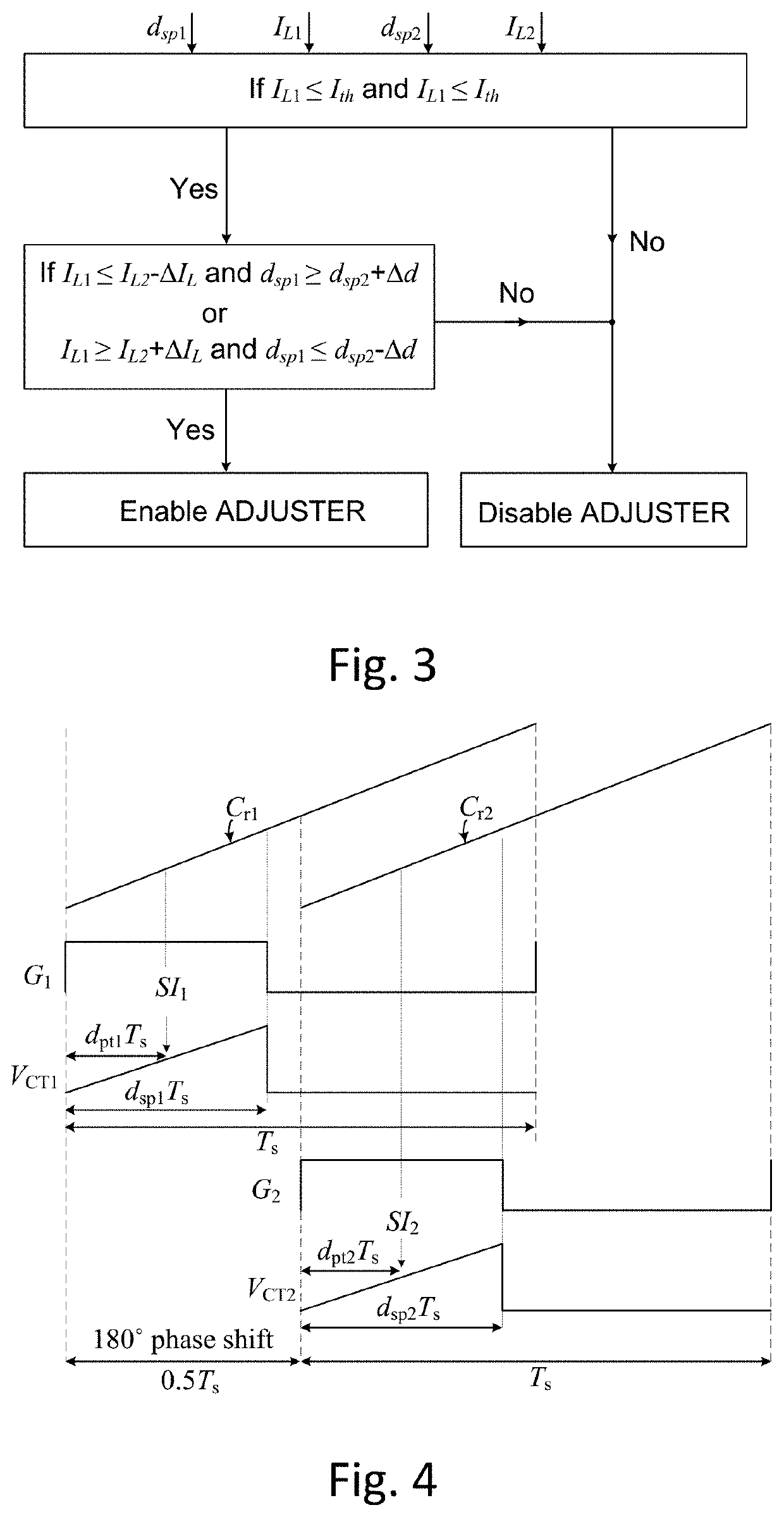

Self-tuning regulator for interleaved power factor correction circuits and method of self-tuning regulation

PendingUS20220158545A1Increase currentDeteriorated accuracyEfficient power electronics conversionDc-dc conversionControl engineeringControl theory

A regulator for an interleaved power factor correction circuit to enhance current sharing performance includes adjuster circuitry that determines a duty cycle adjustment; judge circuitry that determines whether to activate the adjuster circuitry; distributor circuitry that determines tuned duty cycles based on input duty cycles and the duty cycle adjustment; and tuner circuitry that determines tuned average inductor currents in first and second phases of the interleaved power factor correction circuit based on the tuned duty cycles.

Owner:MURATA MFG CO LTD

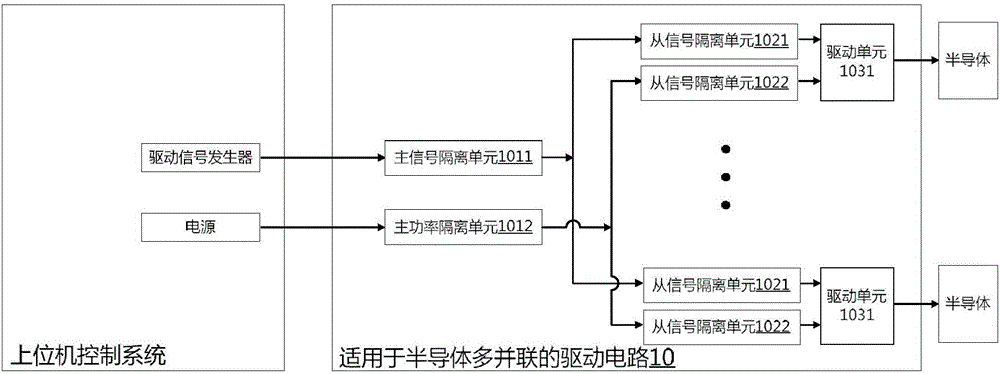

Novel drive circuit suitable to multiple semiconductors in parallel connection

InactiveCN106100298ALow costReduce volumePower conversion systemsEngineeringElectrical and Electronics engineering

The invention discloses a drive circuit suitable for multiple semiconductor parallel connections, which is used to drive any multiple semiconductor parallel loads, including one main signal isolation unit and one main power isolation unit connected to the upper computer control system and n One-way slave signal isolation unit and n-way slave power isolation unit, the drive unit is connected to the semiconductor, the main signal isolation unit isolates the signal obtained from the upper computer control system, and at the same time inputs the isolated signal into n slave signal isolation units; the main signal isolation unit The power signal obtained by the power supply of the power isolation unit is isolated, and at the same time, the isolated power is output to n slave power isolation units. The present invention is used to adopt the signal isolation unit and the power isolation unit with the master-slave arrangement, only the main signal isolation unit and the main power isolation unit need to meet the high insulation withstand voltage setting, which solves the problem of large volume and high cost of the traditional multi-semiconductor parallel drive question.

Owner:HANGZHOU FIRSTACK TECH

Semi-dry process smoke eliminator with independent temperature-reducing column

ActiveCN101342458BImprove current sharing effectGuarantee continuous and stable operationDispersed particle separationEvaporationInlet manifold

The invention relates to a smoke gas purification device by a semidry process, which is provided with an independent desuperheating tower, comprising a reaction tower provided with an smoke inlet box, a smoke gas outlet, a venturi tube type tower wall arranged on a tower bottom, a water injector arranged on the tower wall and a nozzle for lime dry powder and revert dust; and the smoke gas outlet is connected with an inertia separator, an activated carbon mixer, a bag-type dust remover and a draught fan. The invention is characterized in that the invention is also provided with the desuperheating tower which is provided with a boiler smoke gas inlet manifold, a single-stage water injector, an ash bucket with an ash hole and a gas flue; the gas flue of the desuperheating tower is connected with the smoke inlet box into one unit. The boiler smoke gas disperses within the two towers for cooling, thereby improving the adaptability of a system to a load; the boiler smoke gas particularly can be cooled down urgently to a set temperature in the desuperheating tower; and the reaction tower can be humidified only by evaporation with a little water to complete a deacidifying reaction and remove dioxin, thereby avoiding the disadvantages of scale formation on the tower wall of the prior reaction tower and bag burning of the bag-type dust remover, guaranteeing a sustaining and stable smokepurification process and having the advantages of good purification effect and low energy consumption.

Owner:HANGZHOU NEW CENTURY ENERGY ENVIRONMENTAL PROTECTION ENG CO LTD

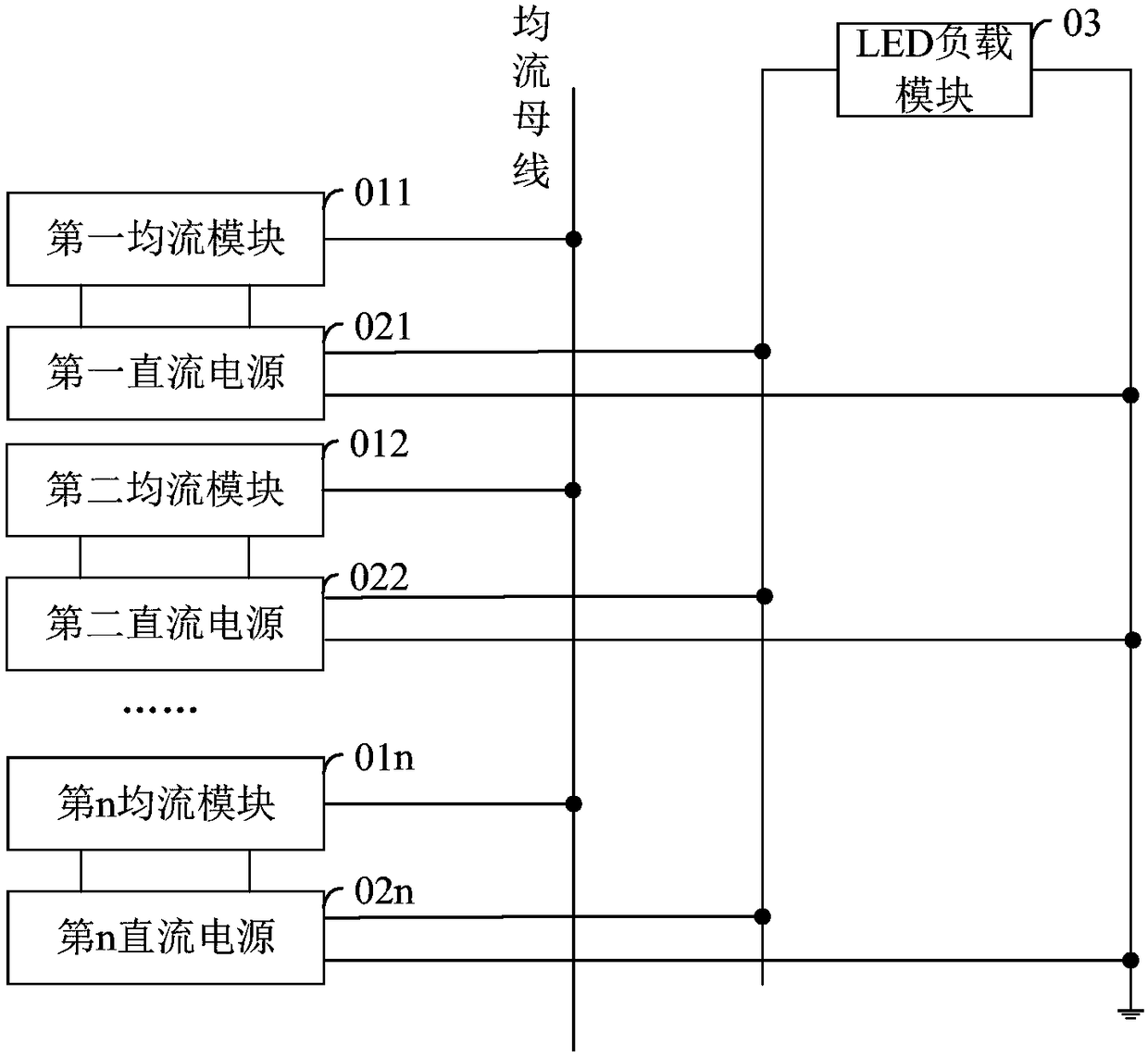

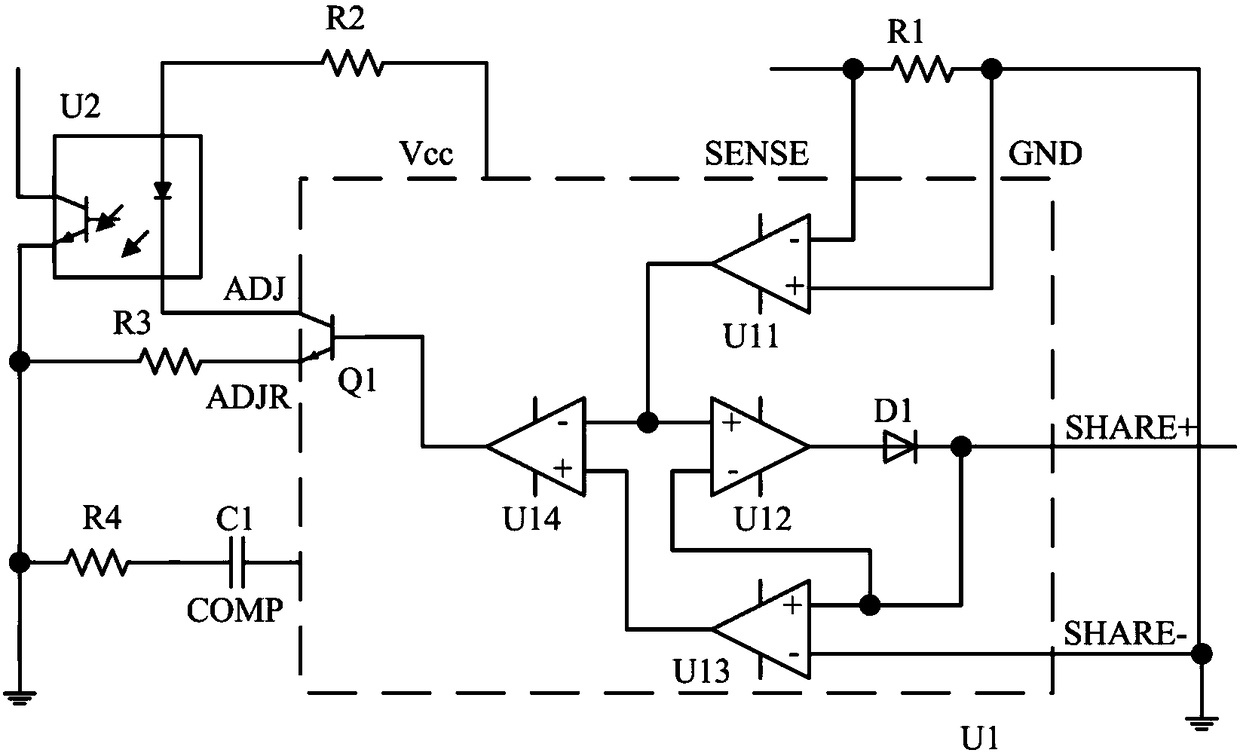

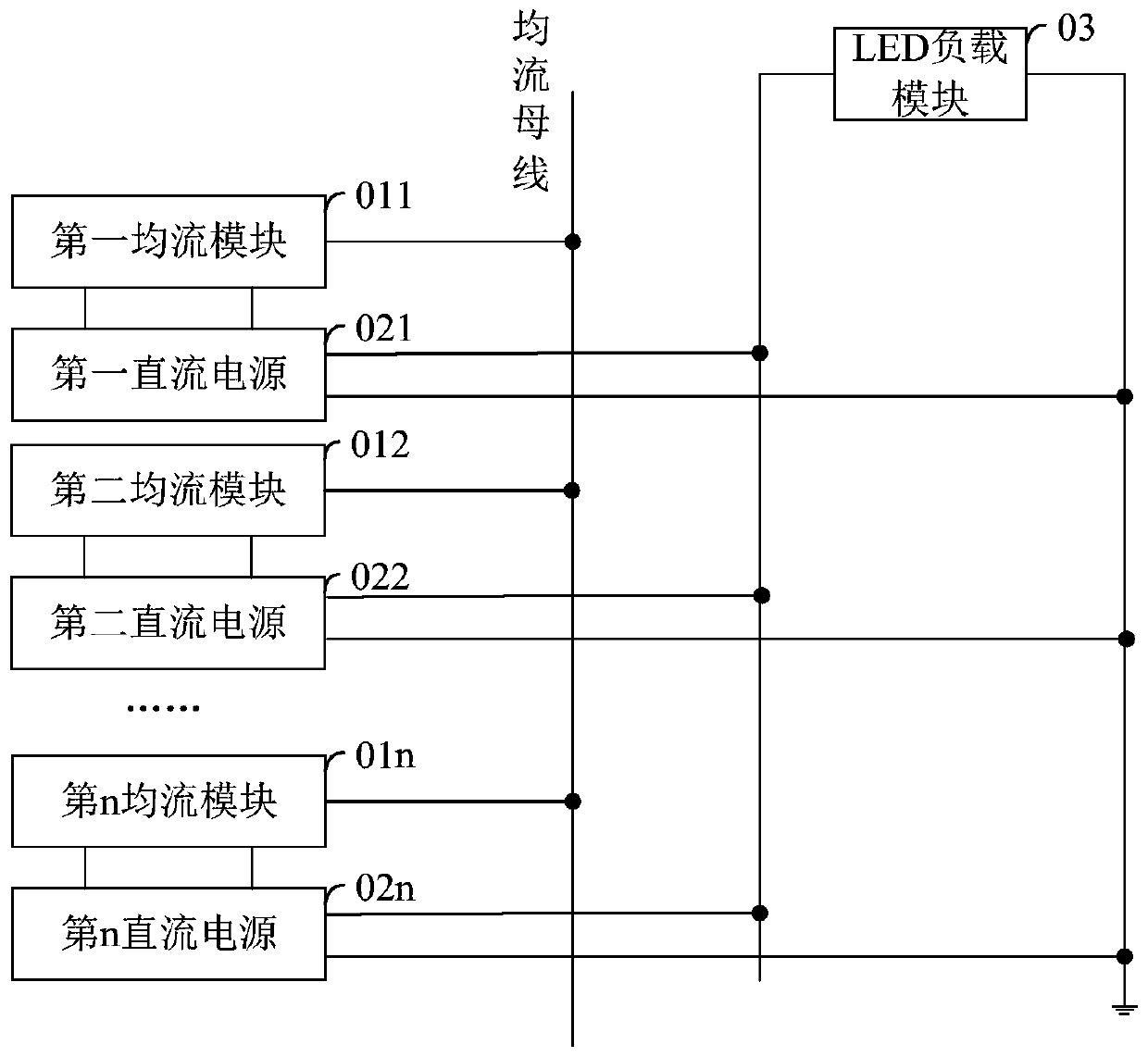

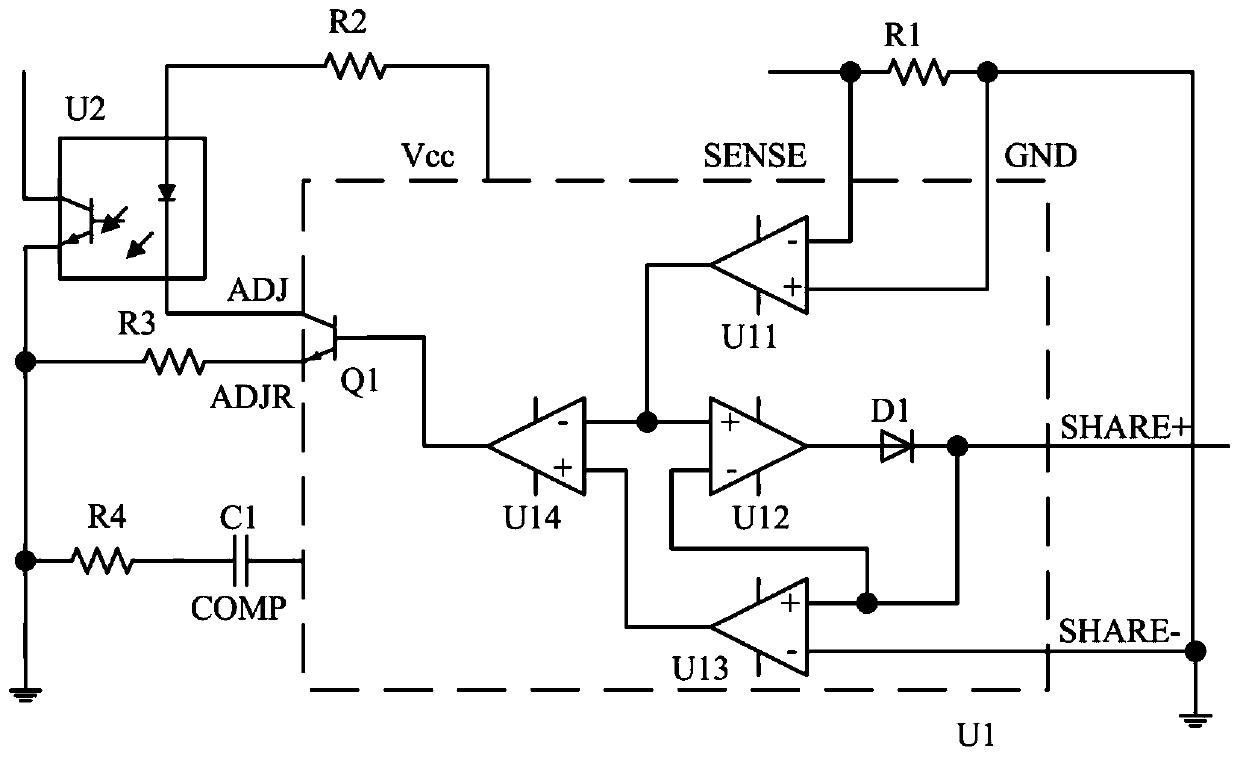

Constant-voltage and current sharing system for LED

ActiveCN108668403AImprove current sharing effectAc-dc conversion without reversalElectroluminescent light sourcesEngineeringBus voltage

The invention belongs to the field of LED, and provides an constant-voltage and current sharing system for LED. According to the constant-voltage and current sharing system for LED, comprises a plurality of current sharing modules, a plurality of DC power sources and a LED load module; the plurality of current sharing modules are in one-to-one correspondence connection with the plurality of DC power sources; each current sharing module detects an output voltage of a corresponding DC power source, and generates an equalization voltage according to the output voltage; a plurality of equalizationvoltages generated by the plurality of current sharing modules are output to the current sharing bus to generate a current bus voltage, and each current sharing module generates a feedback signal according to the current sharing bus voltage so as to adjust the output voltage of the corresponding DC power source, so that the current sharing effect of the parallel power source of the LED load module can be improved.

Owner:TRIDONIC

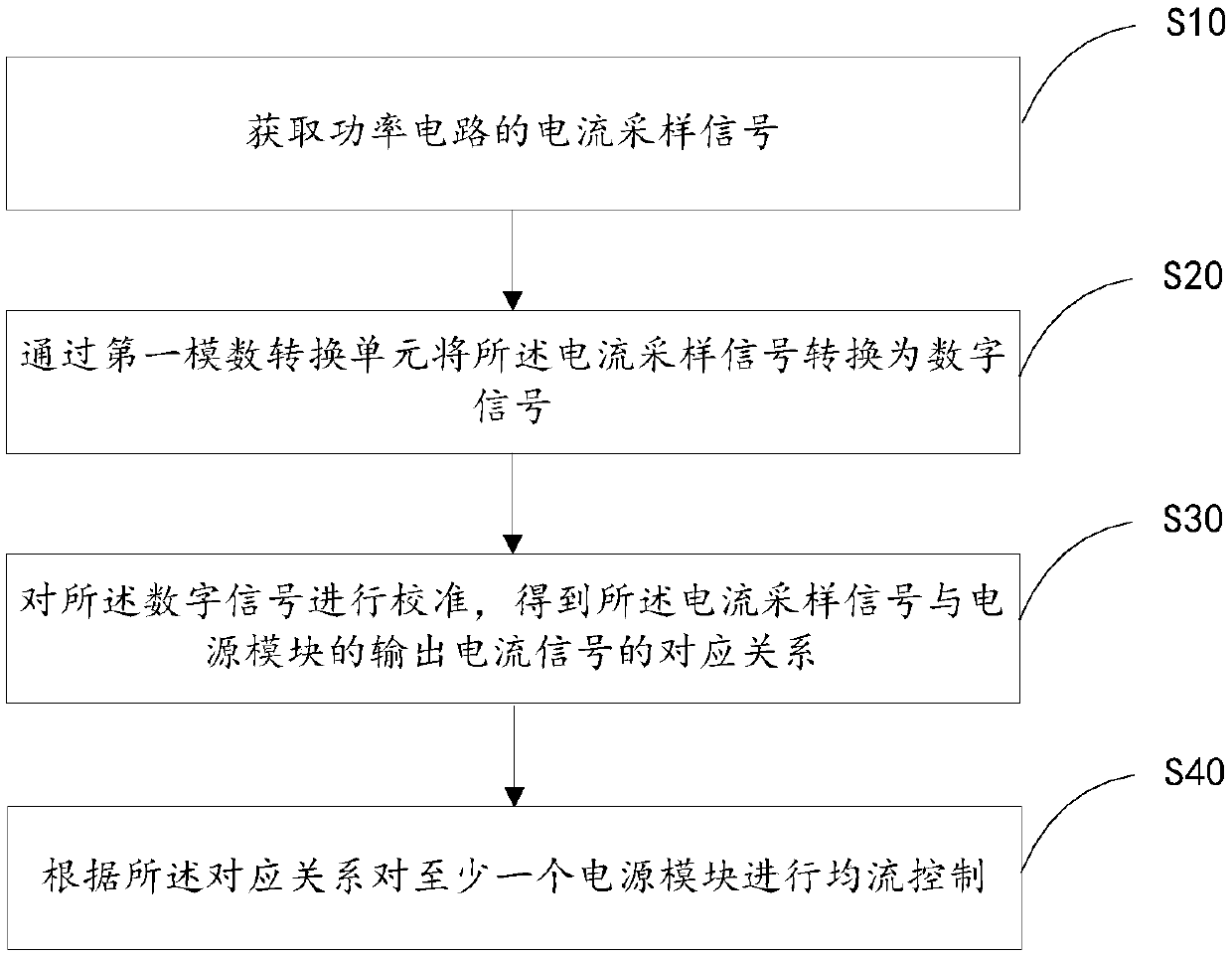

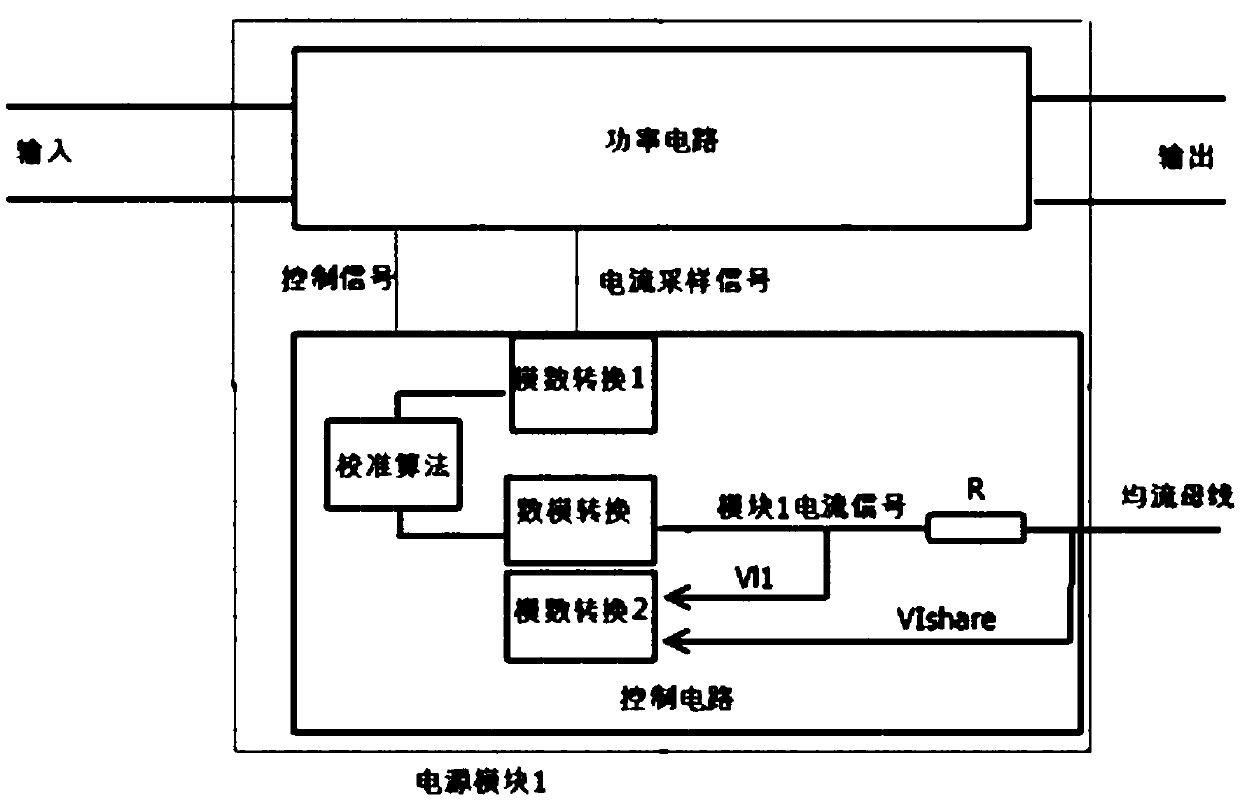

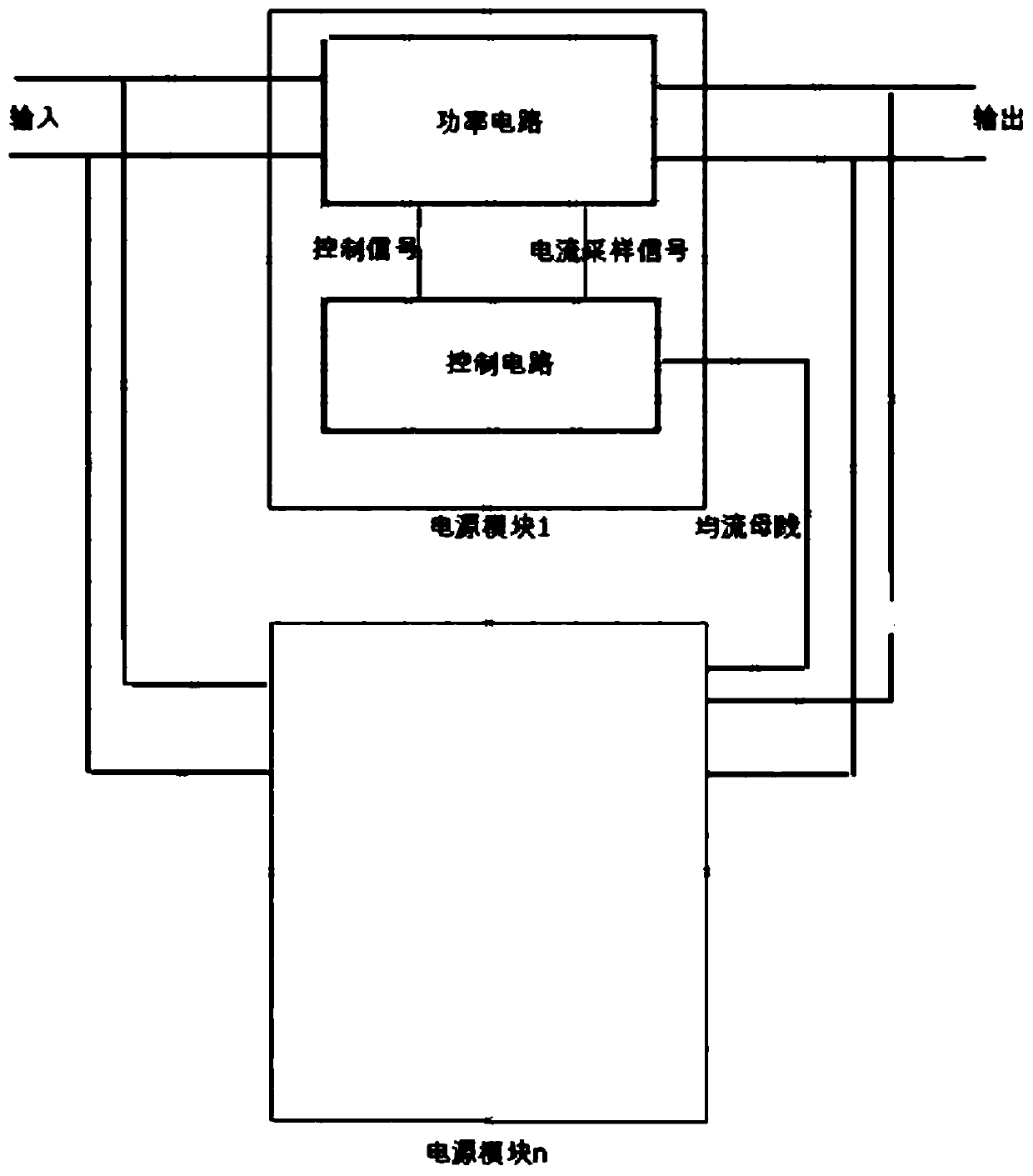

Current sharing control method and device, equipment and computer readable storage medium

ActiveCN110542786AImprove current sharing effectEliminate biasDc-dc conversionMeasurement using digital techniquesPower circuitsElectrical current

The invention discloses a current sharing control method and device, equipment and a computer readable storage medium and belongs to the technical field of communication. The method comprises steps ofacquiring a current sampling signal of a power circuit; converting the current sampling signal into a digital signal through a first analog-to-digital conversion unit; calibrating the digital signalto obtain the corresponding relationship between the current sampling signal and an output current signal of a power supply module; and performing current sharing control of at least one power supplymodule according to the corresponding relationship. The method is advantaged in that deviation caused by difference of sampling circuits to current sharing control of the parallel power supply modulesis eliminated, the current sharing effect of the power supply modules is improved, and system reliability is improved.

Owner:ZTE CORP

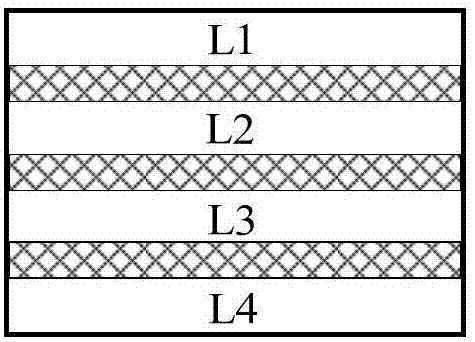

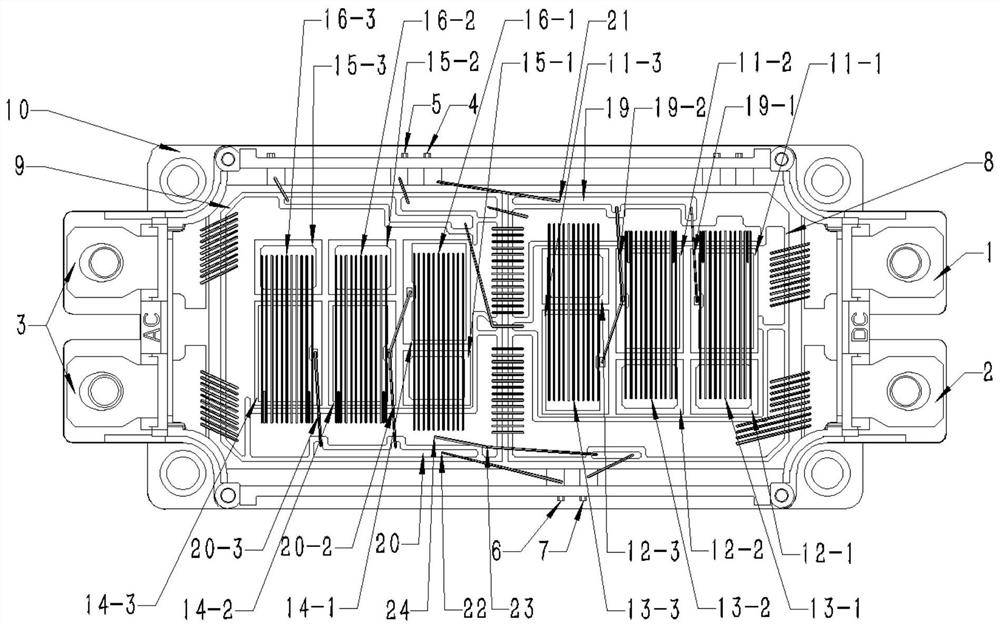

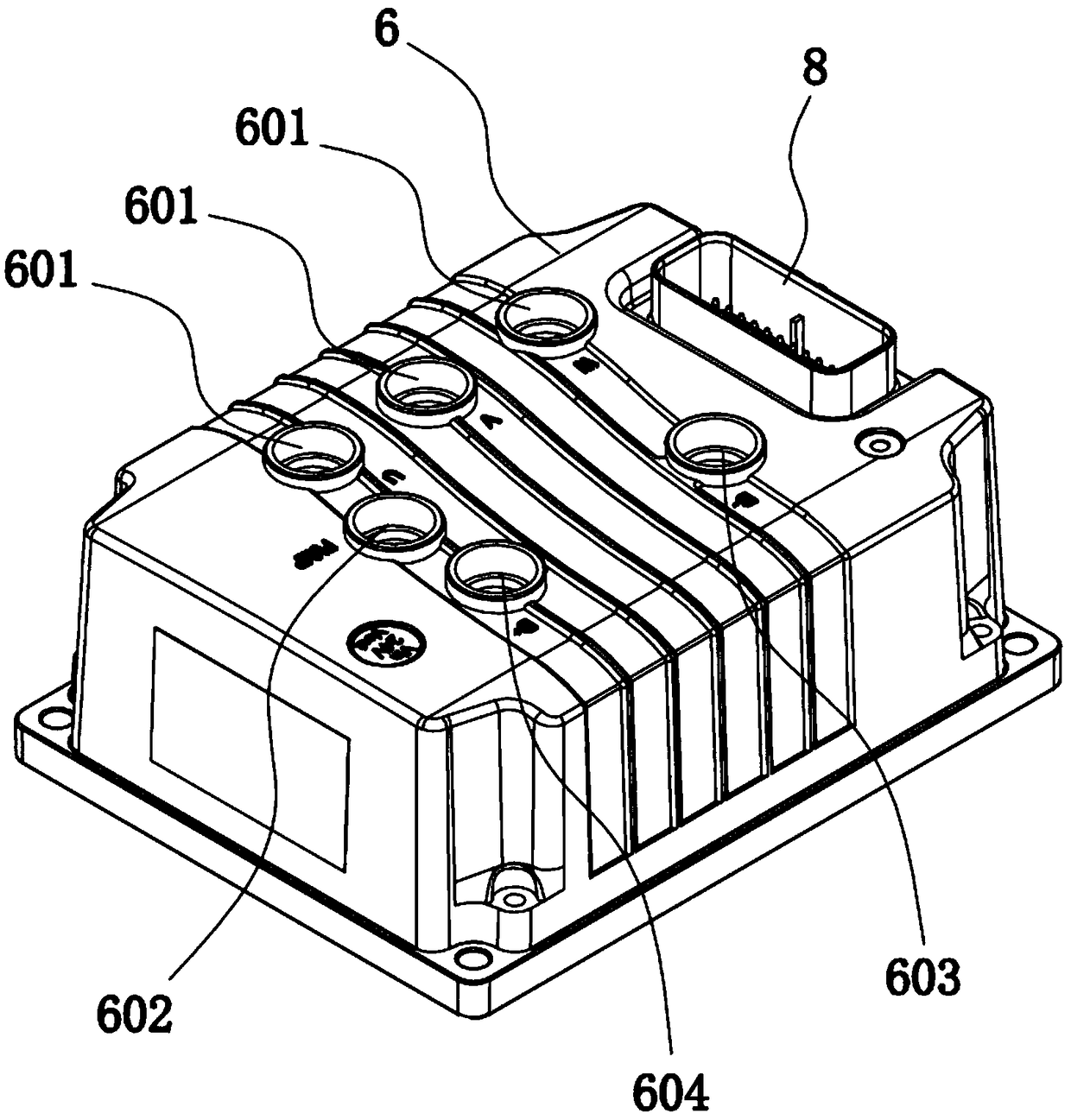

Driving control circuit for multiple SiC MOSFET chip parallel power module and printed circuit board thereof

ActiveCN107370347AReduce areaReduce inductanceEfficient power electronics conversionPower conversion systemsMOSFETCapacitance

The invention discloses a driving control circuit for a multiple SiC MOSFET chip parallel power module and a printed circuit board thereof. The driving control circuit comprises a positive voltage input terminal, a negative voltage input terminal, a driving signal input terminal, a ground wire, a driving chip, a first decoupling capacitor, a second decoupling capacitor, a total driving resistor, a first voltage stabilizing diode, a second voltage stabilizing diode, N driving current-sharing resistors and N control terminals. The circuit and the printed circuit board thereof can implement driving on the multiple SiC MOSFET chip parallel power module and meanwhile, ensure safe and stable operation of each SiC MOSFET chip.

Owner:XI AN JIAOTONG UNIV

A half-bridge power semiconductor module

ActiveCN106971992BReduce parasitic inductanceImprove current sharing effectSemiconductor/solid-state device detailsSolid-state devicesInter layerLayer interface

Owner:CSR ZHUZHOU ELECTRIC LOCOMOTIVE RES INST

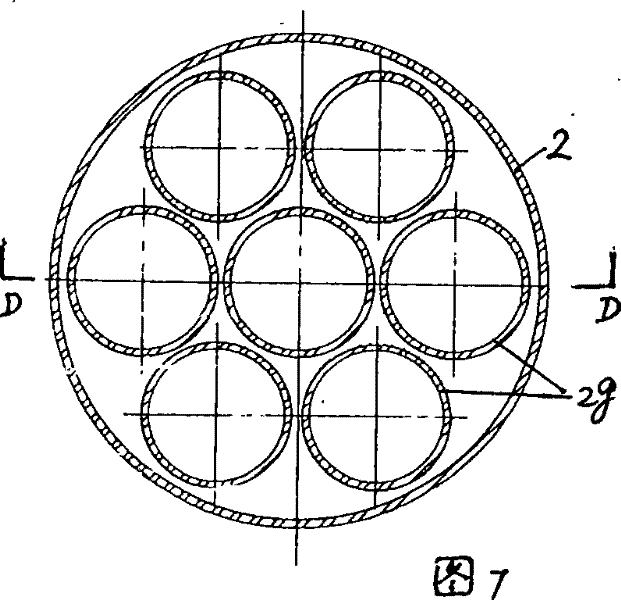

Medicine material flow equalizing device for propellant extruder

The invention discloses a medicine material flow equalizing device for a propellant extruder. The device comprises an outer cylinder, a mold body, a piston and a rubber pad, wherein the piston consists of a piston body, a piston rod and a rubber disc; a groove is formed in the bottom of the piston body; a ventilation hole communicated with the groove is formed in the top surface of the piston body; the rubber disc is fixed at the bottom of the piston body to enable a groove cavity of the groove to become an air storage chamber; inner holes of the outer cylinder are sequentially a pore diameterD1 section, a pore diameter D2 section and a pore diameter D3 section from top to bottom, and D2 > D1, D3 = D1; a plurality of medicine outlet holes with the same shape and size are formed in the mold body, through holes with the same position, number, size and shape as the medicine outlet holes on the mold body are formed in the rubber pad, and each through hole on the rubber pad is respectivelyaligned with the corresponding medicine outlet hole on the mold body when the rubber pad is fixedly connected with the mold body; and the piston body is mounted in the pore diameter D1 section, the rubber pad is mounted in the pore diameter D3 section, the mold body covers the bottom of the outer cylinder and is fixedly connected with the wall of the outer cylinder, and the pore diameter D2 section and the top surface of the rubber pad form a medicine material extrusion cavity.

Owner:SICHUAN UNIV

Multi-injection-tube type fire sheet

PendingCN109695875AEmission reductionImprove current sharing effectGaseous fuel burnerNitrogen oxidesMulti injection

The invention discloses a multi-injection-tube type fire sheet. The multi-injection-tube type fire sheet comprises a fire sheet body, a burning part is arranged at the top of the fire sheet body, theburning part is provided with a fire hole, the fire sheet body is provided with a plurality of vertical injection tubes which are evenly distributed from left to right, and all the injection tubes arein bilateral symmetry with respect to the vertical center faces of the injection tubes. According to the multi-injection-tube type fire sheet, the injection tubes are evenly distributed and are in bilateral symmetry, thus obstruction of the injection tubes to airflow can be effectively lowered, the injection ability can be improved, the air-fuel ratio is increased advantageously, the flow equalization effect of the fire sheet can be effectively improved, the uniformity degree of a flame is improved, full burning is ensured, and the emissions of nitrogen oxide and carbon monoxide are decreased.

Owner:刘维

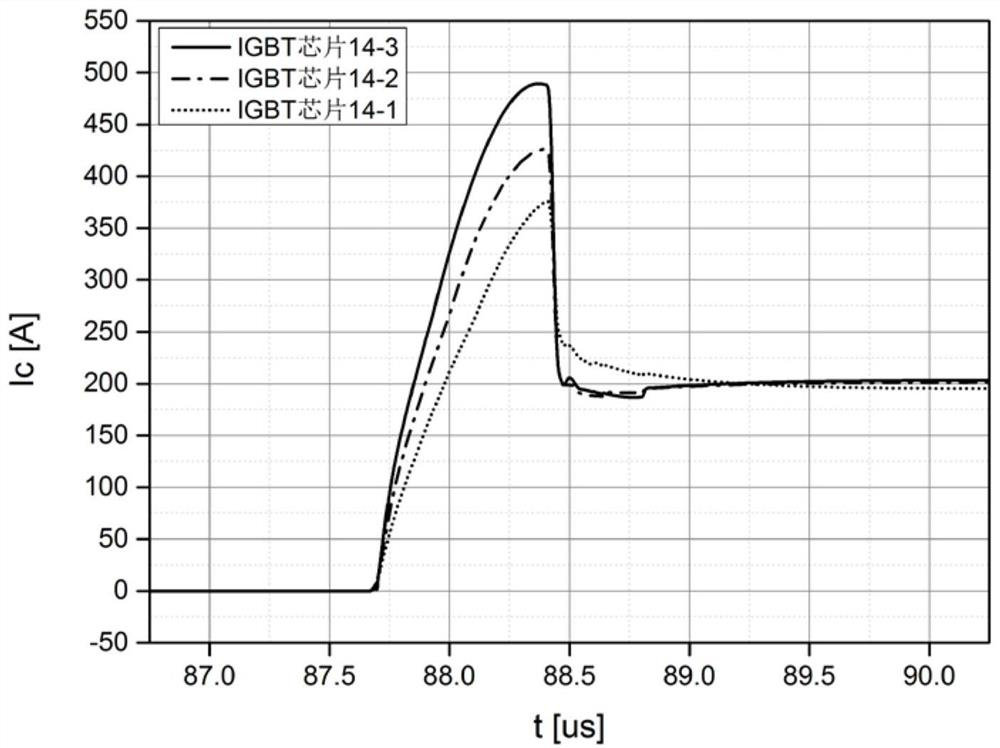

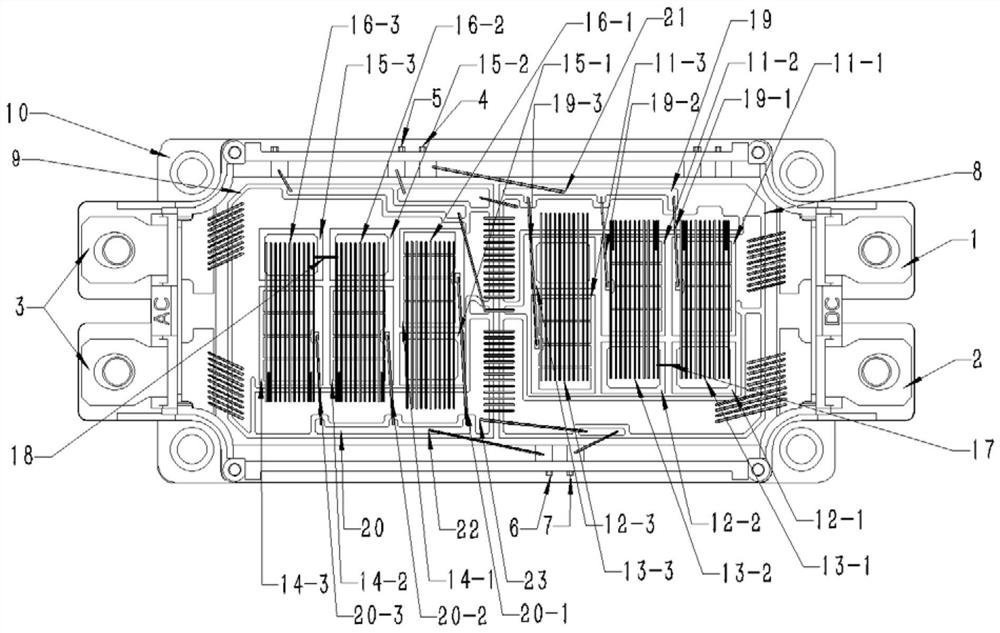

Chip layout structure of half-bridge IGBT module

ActiveCN112185950AImprove current sharing effectReduce shockSemiconductor/solid-state device detailsSolid-state devicesStructural engineeringPeak current

The invention discloses a chip layout structure of a half-bridge IGBT module. The structure comprises an upper bridge IGBT chip and a lower bridge IGBT chip, the upper bridge IGBT chip and the lower bridge IGBT chip are connected with an FRD chip through bonding wire groups to realize chip front connection, grids are positioned on the left side of the IGBT chip, and the reverse sides of the upperbridge IGBT chip and the lower bridge IGBT chip are welded on an upper bridge DCB substrate; dgrids of the lower bridge IGBT chip are all located on the right sides of the IGBT chip, and the upper andlower IGBT chips and the FRD chip are distributed in a central symmetry mode relative to the module. The drop points of the bonding wires of an upper half-bridge signal terminal and a lower half-bridge signal terminal are located on the grid signal copper layers of the upper half-bridge and the lower half-bridge respectively, and the drop points of the bonding wires of the upper half-bridge and the lower half-bridge are located between the drop points of the grid bonding wires of the two non-adjacent IGBT chips on the grid signal copper layers. Simulation shows that the peak current difference rate of the three IGBT chips is reduced from 30% to 9.3%, so that the current sharing performance of the chips is improved; the reduction of the maximum peak current of the chips reduces the impactof the turn-on current on the chips, and facilitates the long-term stable operation of the chips.

Owner:NARI TECH CO LTD

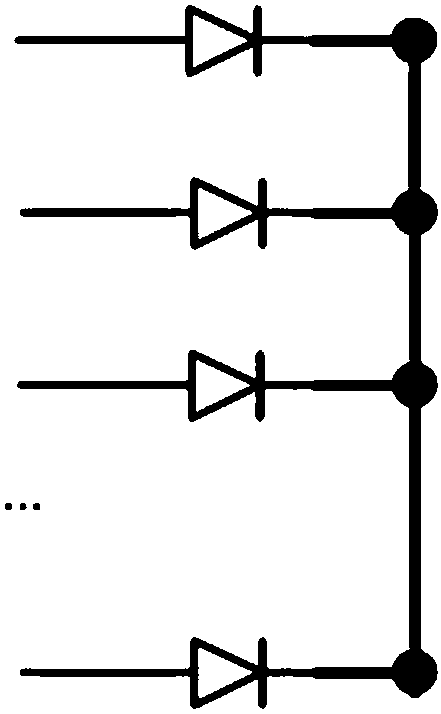

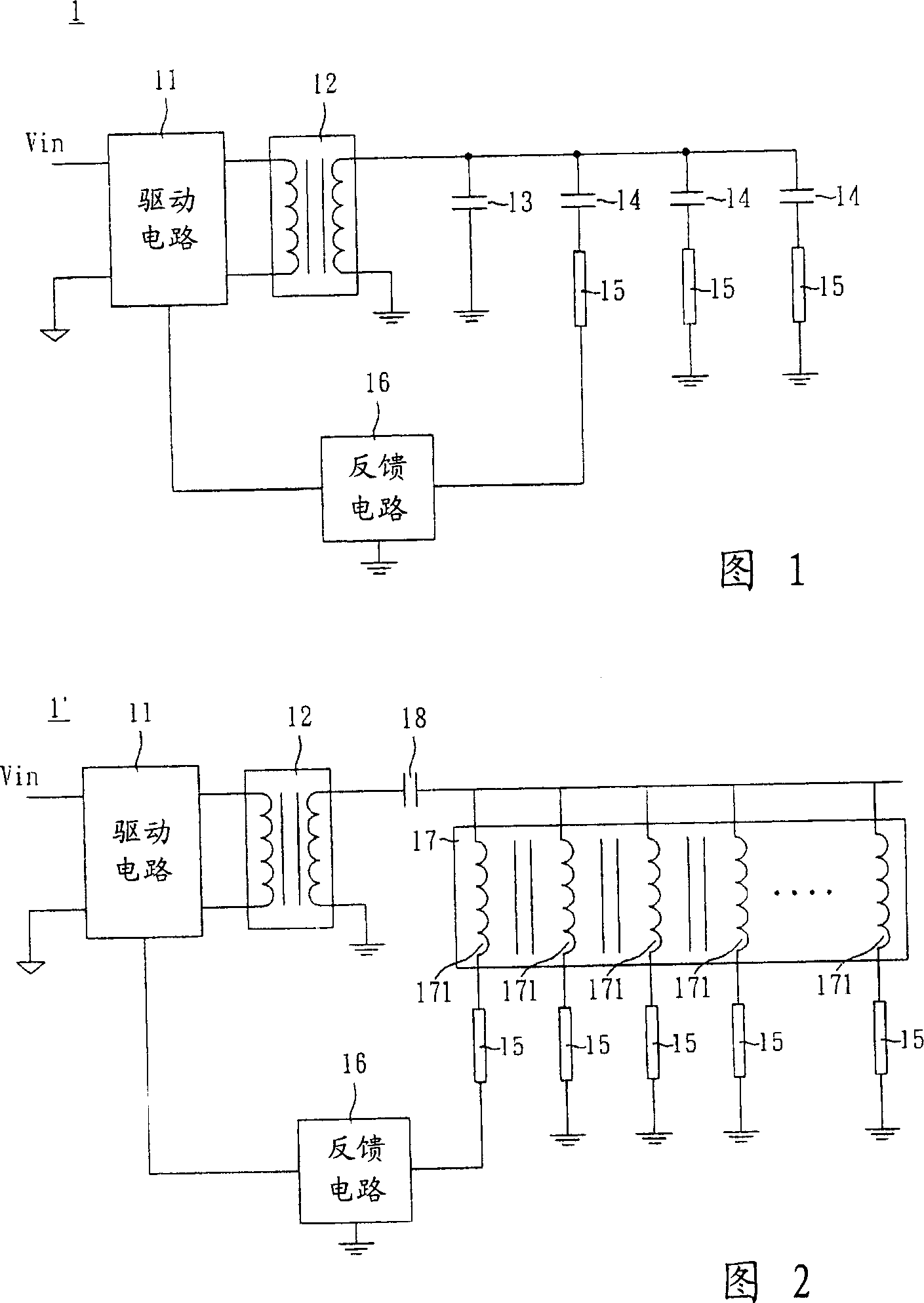

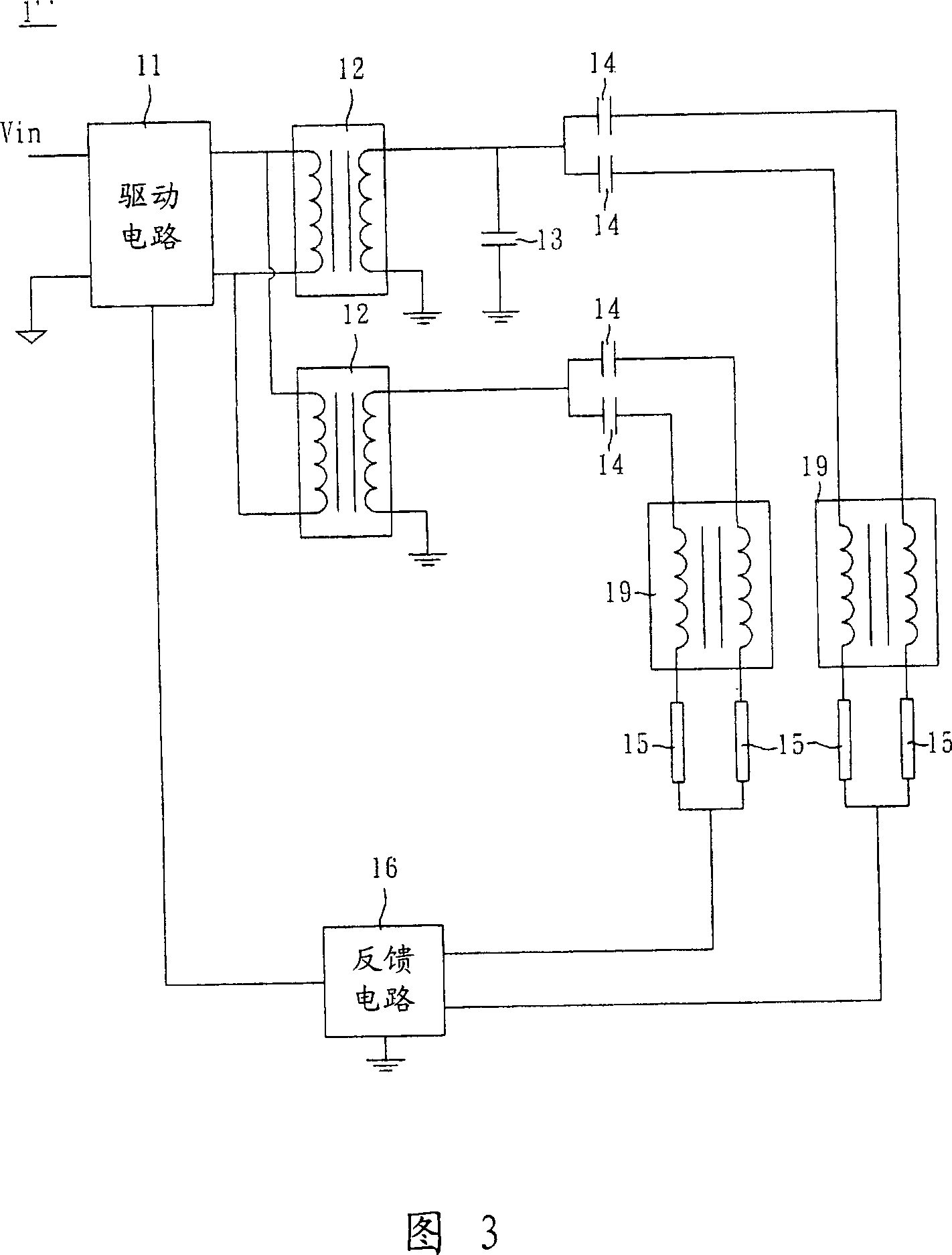

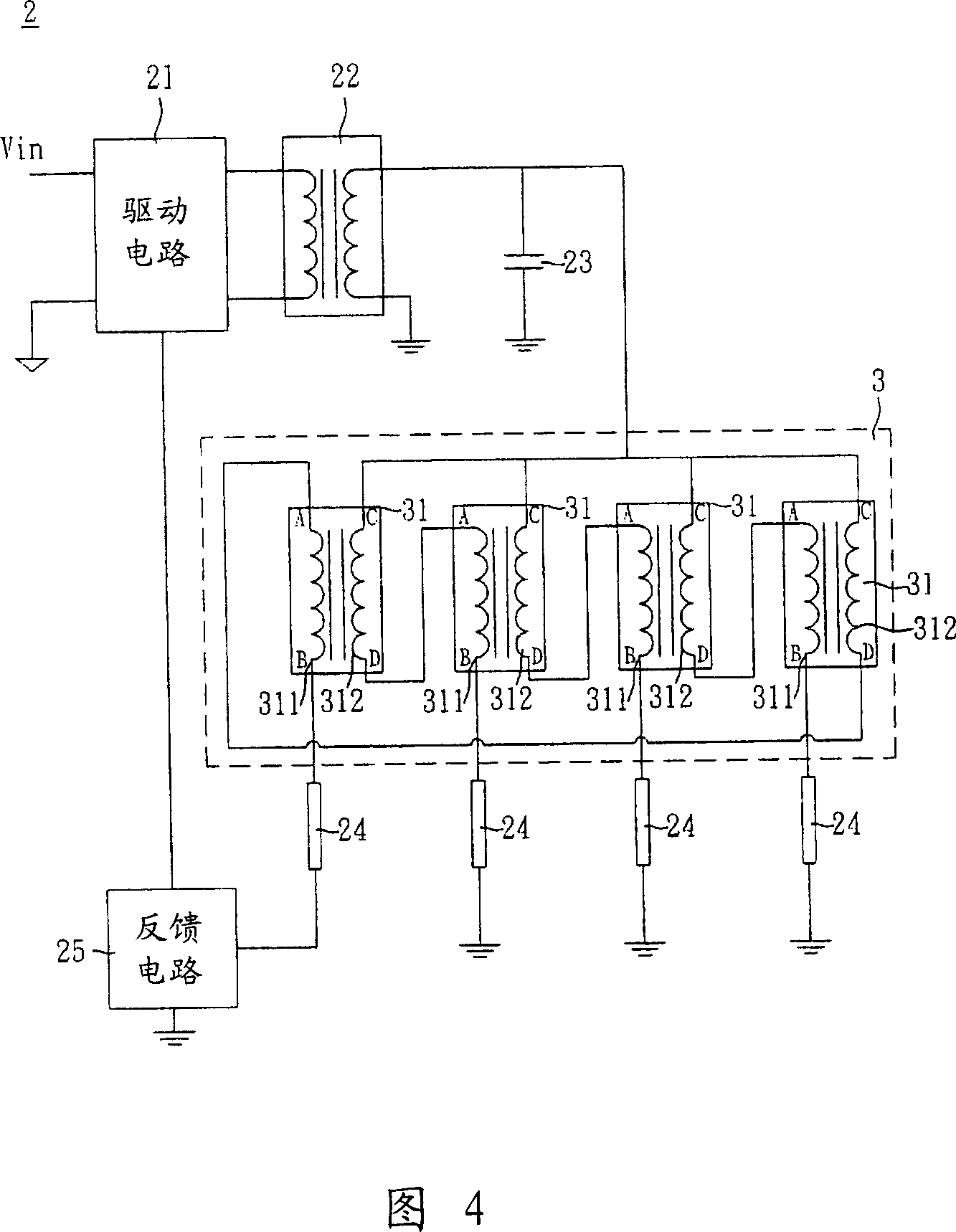

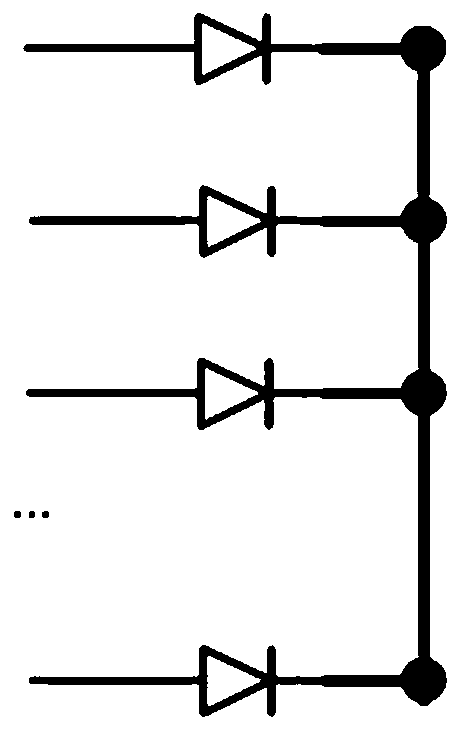

Homogeneous current circuit

InactiveCN101093643AIncrease the number of timesImprove current sharing effectStatic indicating devicesElectricityTransformer

A current equalized circuit is prepared for electric-connecting each first balance transformer separately to each lamp tube and series-connecting multiple first balance transformer in sequence.

Owner:DELTA ELECTRONICS INC

Droop Control Method of DC Converter with Adaptive Impedance Secondary Adjustment

ActiveCN104753059BEasy to dropImprove homeostasisDc source parallel operationDroop speed controlEngineering

The invention belongs to the technical field of droop control of DC converters, relates to a droop control method of a DC converter with a function of secondary adjustment of adaptive impedance, and aims to solve the problems that distributed generating unit cable impedance difference causes poor droop current homogenization effect to the DC distributed power supply system and the DC micro grid based on droop control and the parallel DC converters is low in steady state and dynamic current homogenization precision. The method has the advantages that the steady state and dynamic current homogenization precision of the parallel DC converters in the distributed DC power supply system and the DC micro grid based on droop control is improved; parameters, such as voltage, current and droop coefficient, of the parallel converters are transmitted in real time through low-speed communication, the droop coefficient is adjusted in self-controllers of the parallel converters, and finally external characteristic impedances of the parallel converters are equalized; droop curves are subjected to shifting adjustment, and bus voltage drop caused by droop control is improved.

Owner:HARBIN INST OF TECH

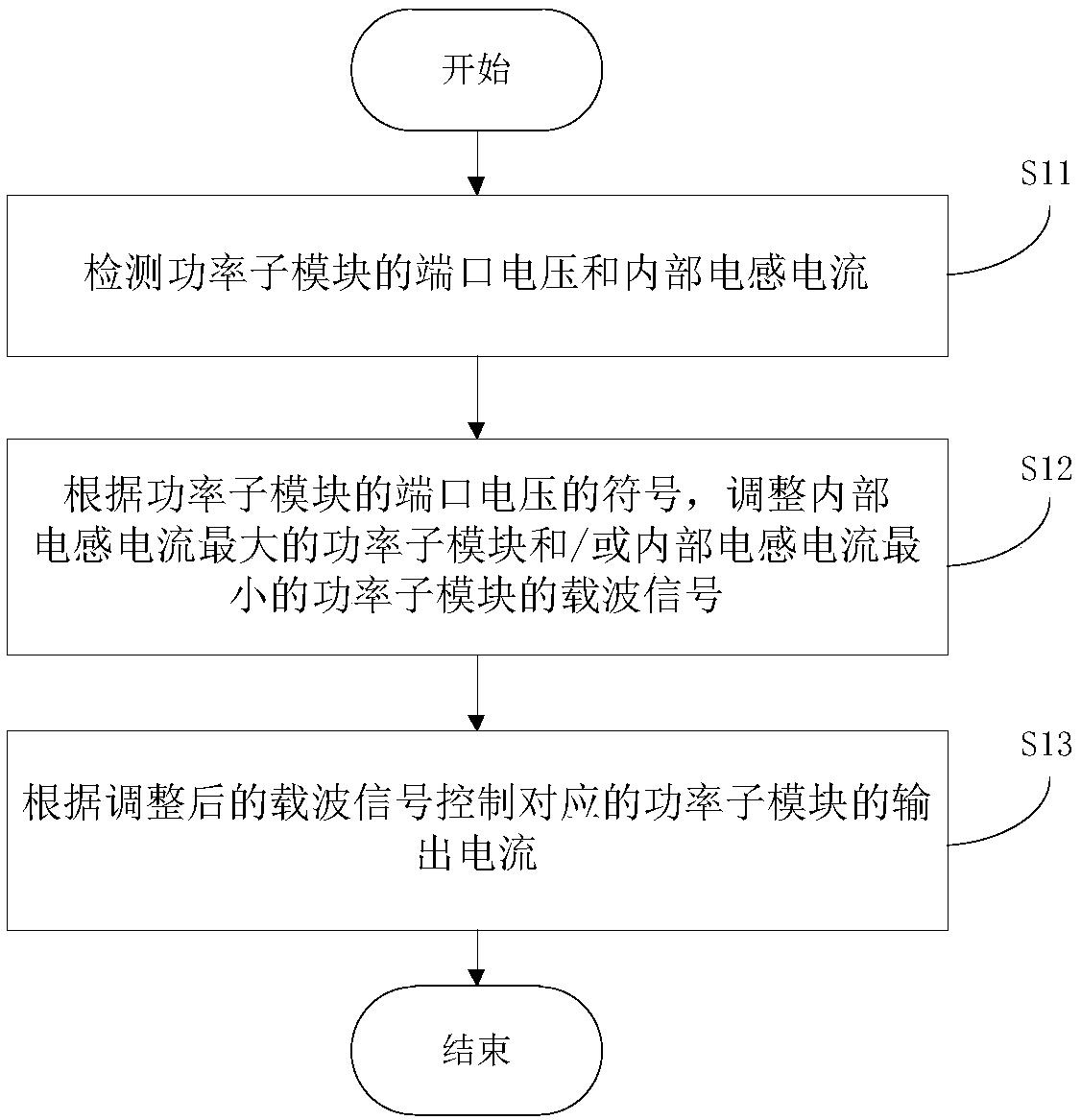

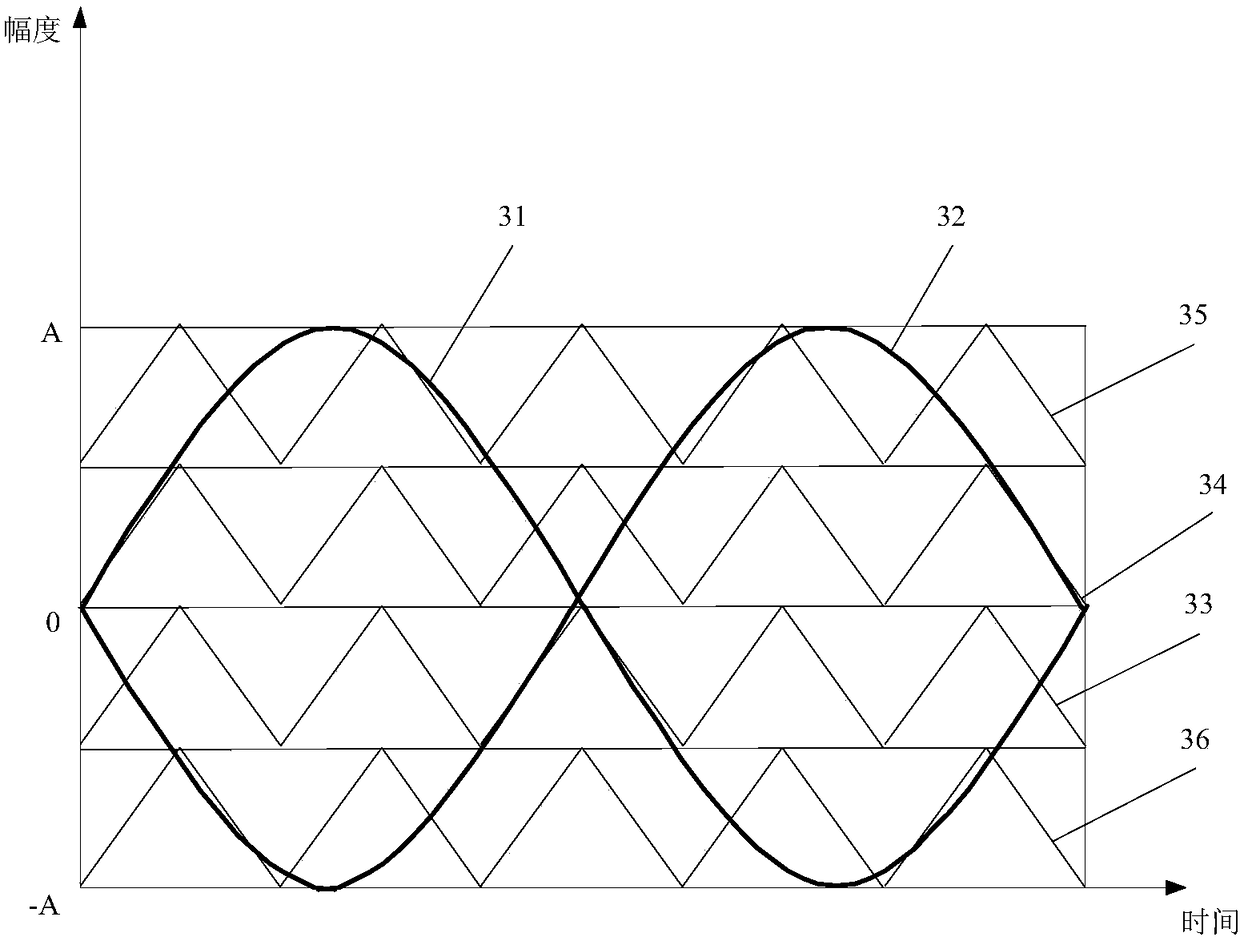

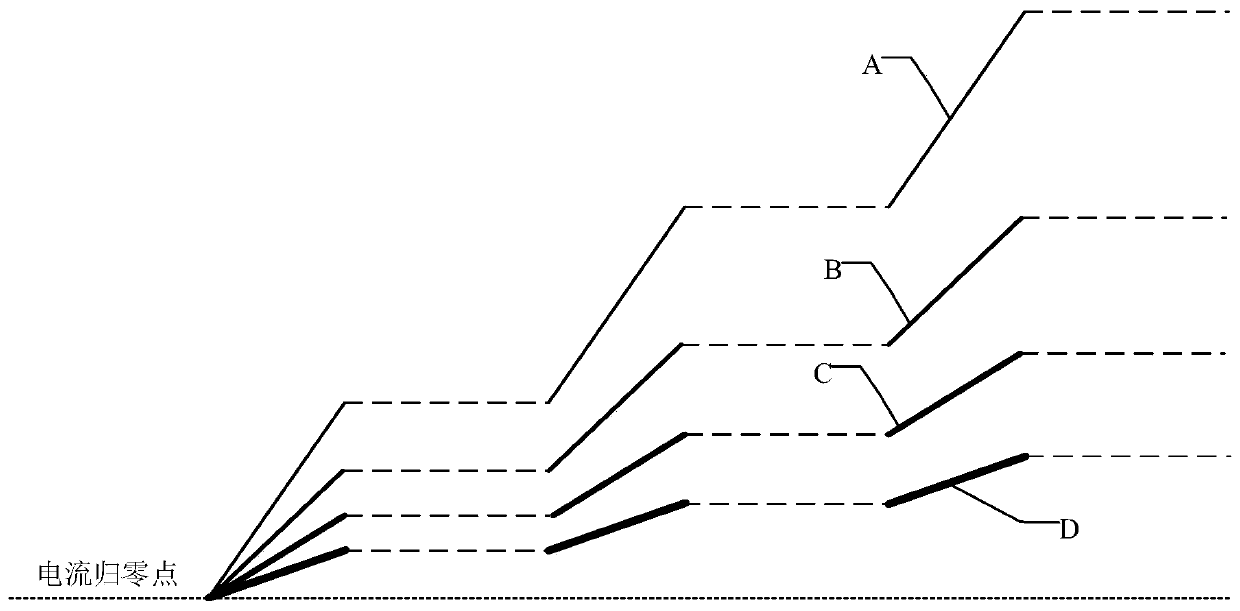

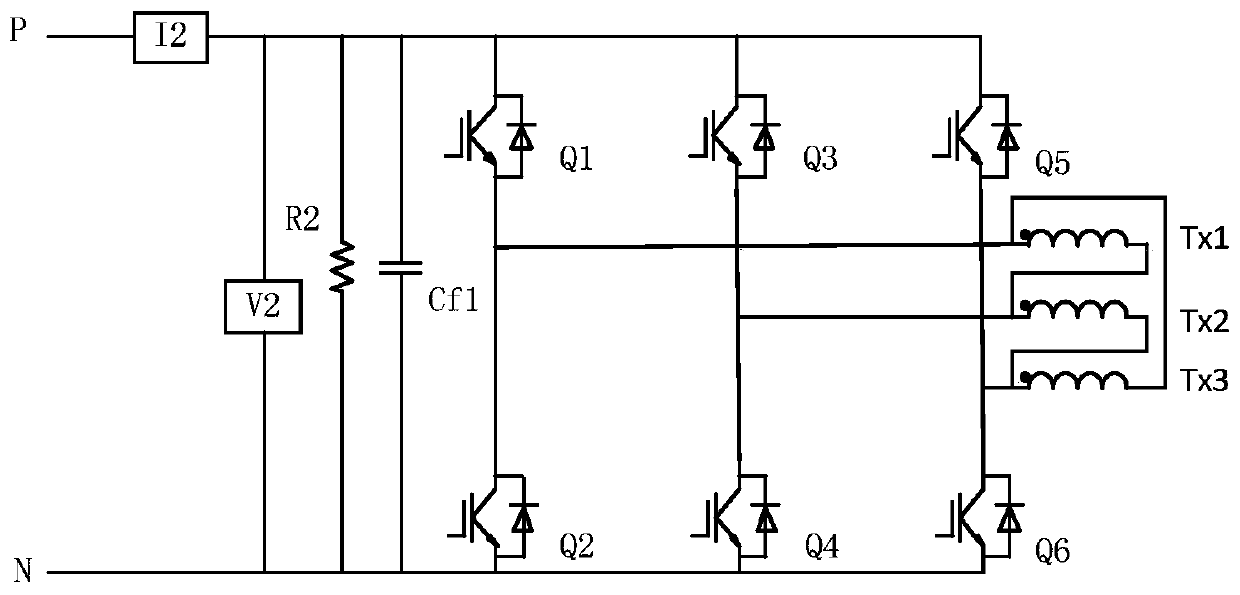

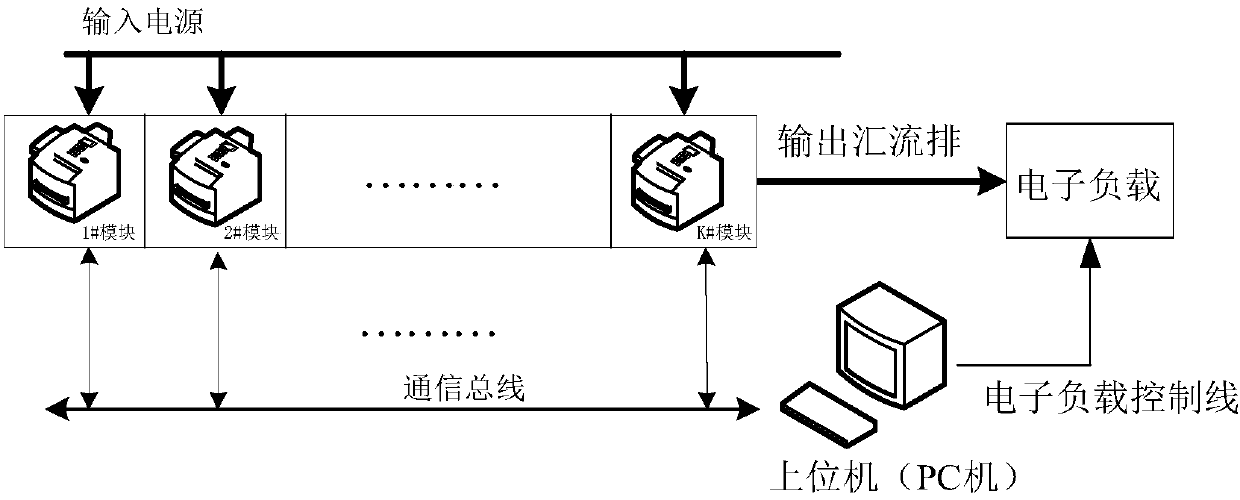

A current sharing method and device for a converter

ActiveCN106208725BRealize current sharingSimplify current sharing stepsConversion without intermediate conversion to dcCarrier signalEngineering

The invention provides a current equalizing method and device of a current transformer. The method comprises the following steps of detecting a port voltage and an internal induction current of a power sub-module; adjusting a carrier signal of the power sub-module with maximum internal induction current and / or the power sub-module with minimum internal induction current according to a symbol of the port voltage of the power sub-module; and controlling an output current of the corresponding power sub-module according to the adjusted carrier signal. Therefore, excessive large current and excessive small current are prevented from occurring in the output current of the current transformer, current equalizing of the current transformer is achieved, and the current equalizing effect is improved; and the carrier signal of the power sub-module with maximum / minimum internal induction current is only adjusted each time, and thus, the steps of current equalizing of the current transformer are simplified.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +2

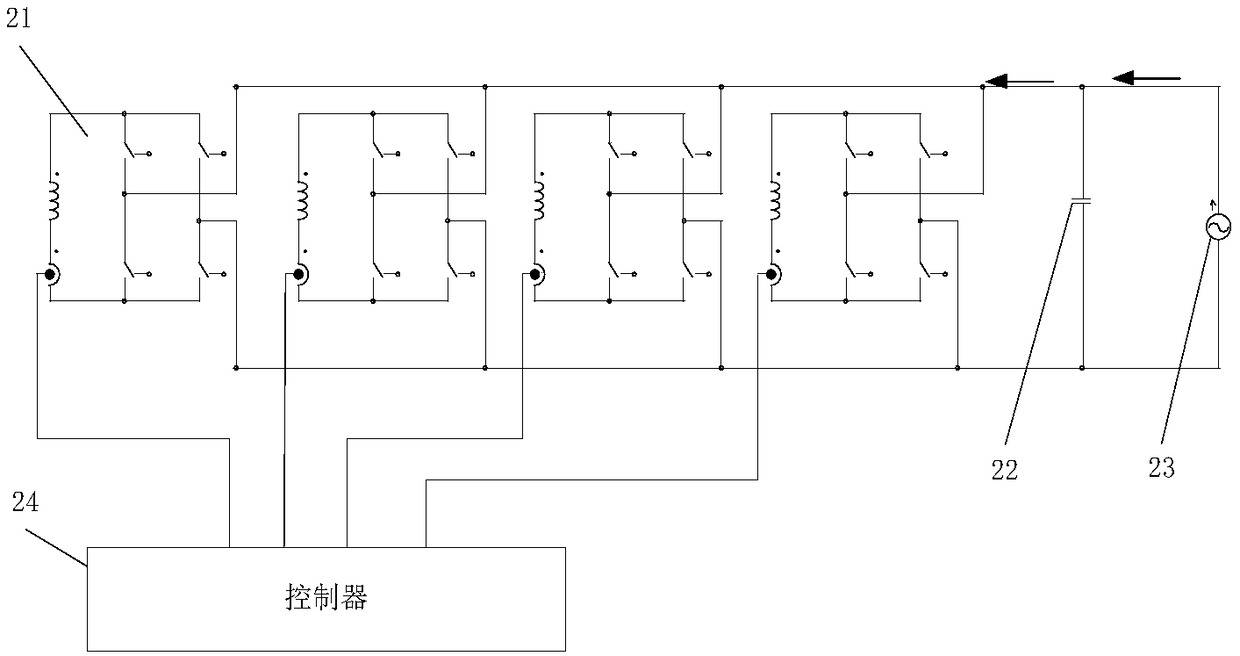

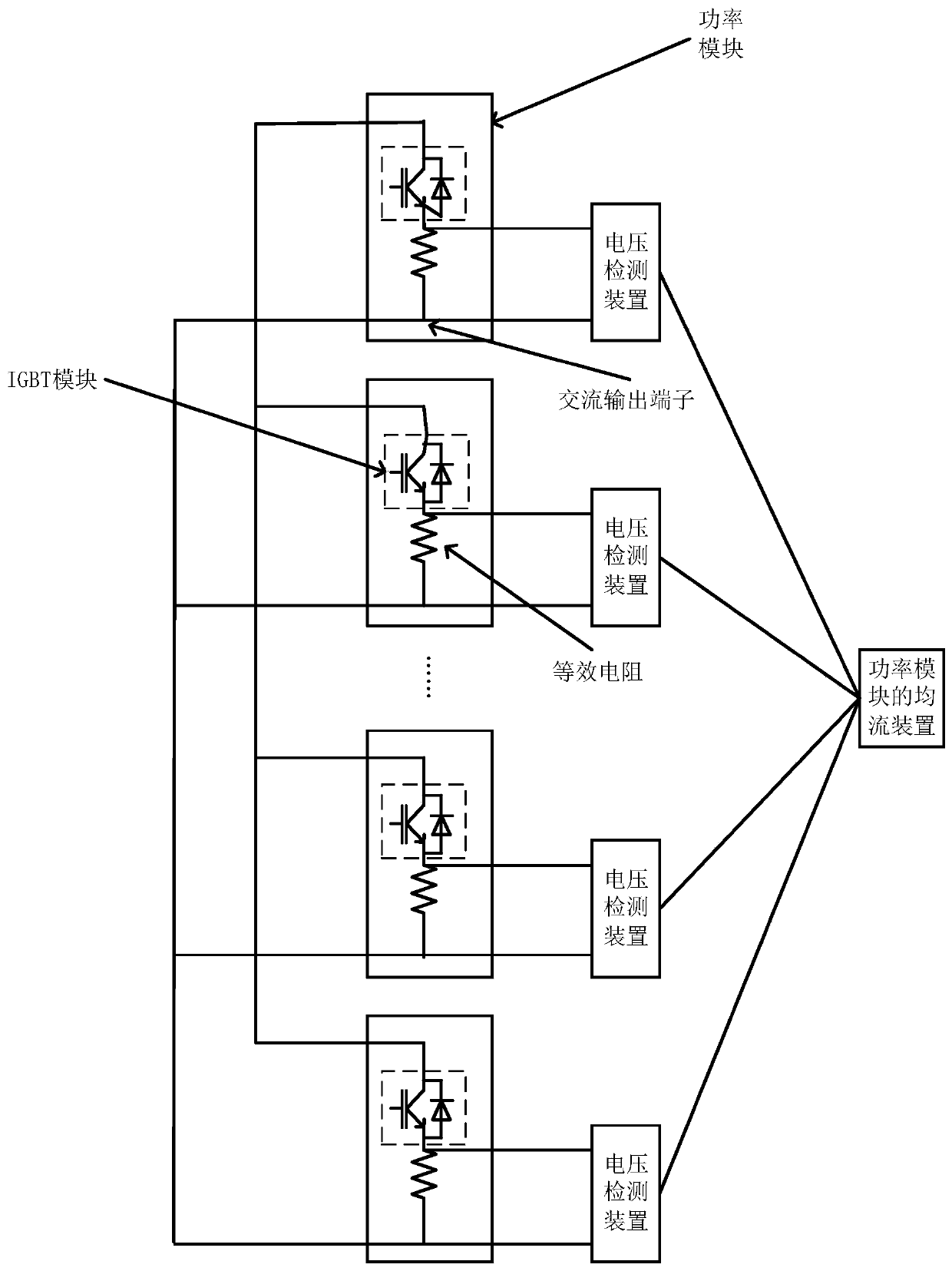

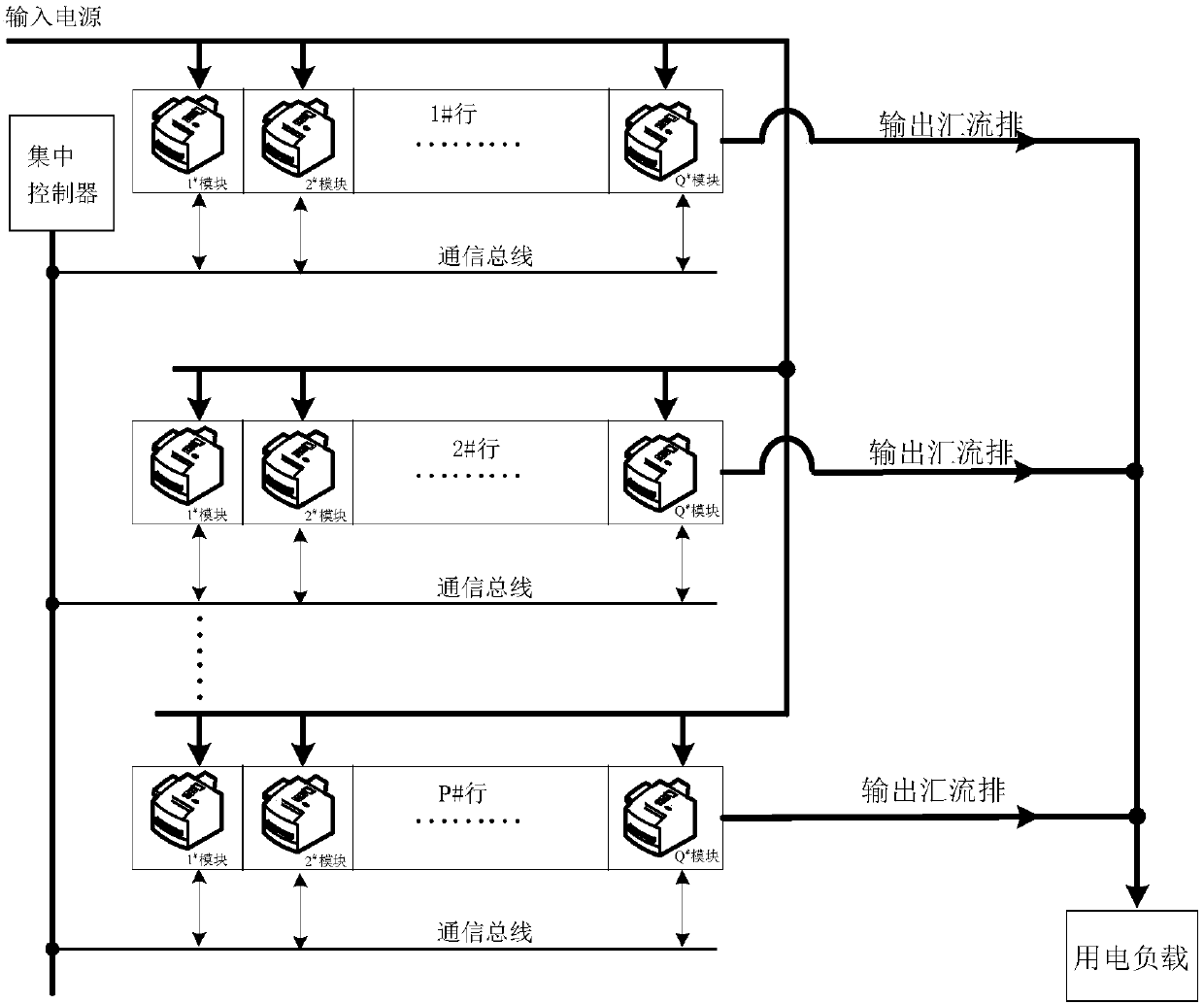

Power module current sharing method, device and system

ActiveCN109921606BLow costImprove current sharing effectPower conversion systemsEngineeringComputer science

The embodiment of the invention discloses a current-sharing method, device and system of a power module. The method comprises the following steps: acquiring a voltage between an emitter of an IGBT module of each power module in parallel connection and an AC output terminal of the IGBT module in the current pulse duration of the PWM pulse; adjusting the pulse duration of the next PWM pulse of eachpower module according to the acquired voltage, and performing current sharing on the power module in parallel connection. Through the current-sharing method, device and system disclosed by the embodiment of the invention, the pulse duration of the next PWM pulse of each power module is automatically adjusted according to the voltage between the emitter of the IGBT module of each power module in parallel connection and the AC output terminal of the IGBT module in the current pulse duration of the PWM pulse, an operation of using a current-sharing electric reactor or a circulation suppression electric reactor is avoided, and then the cost can be reduced and the current-sharing effect is improved.

Owner:BEIJING ETECHWIN ELECTRIC

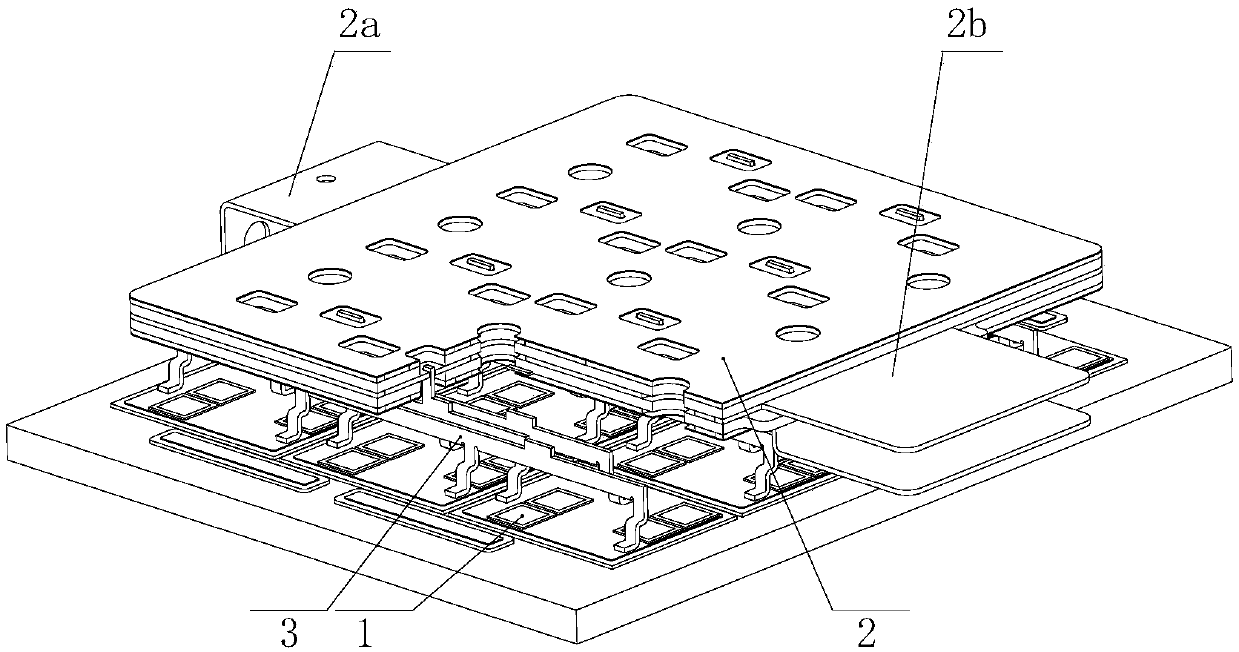

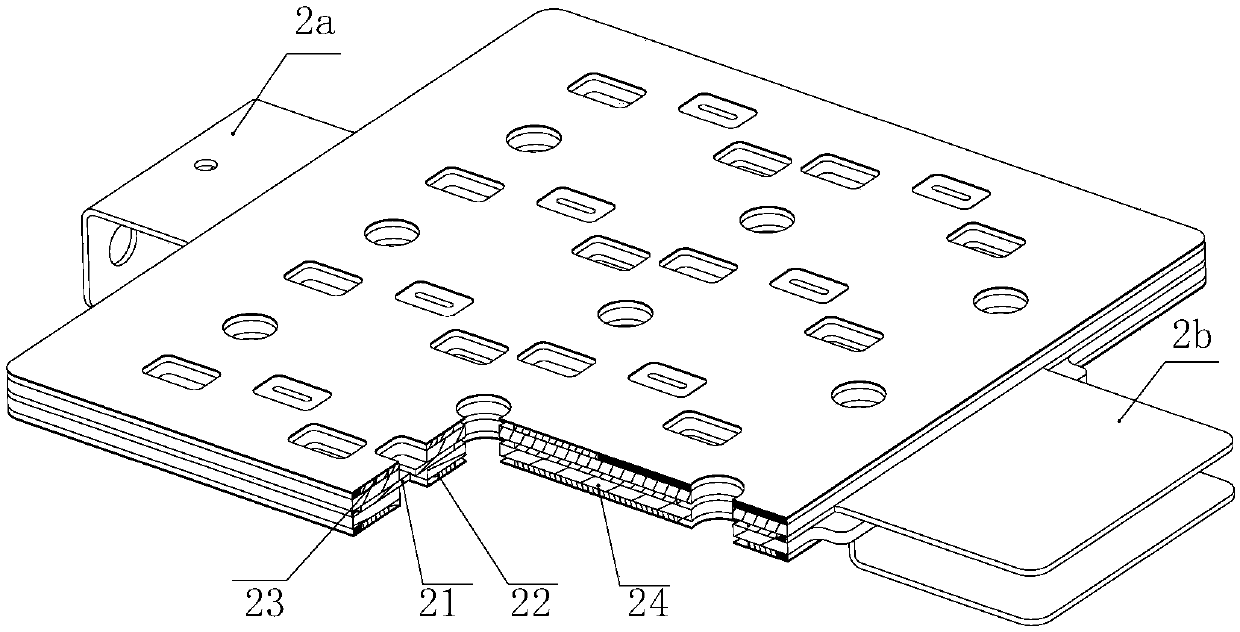

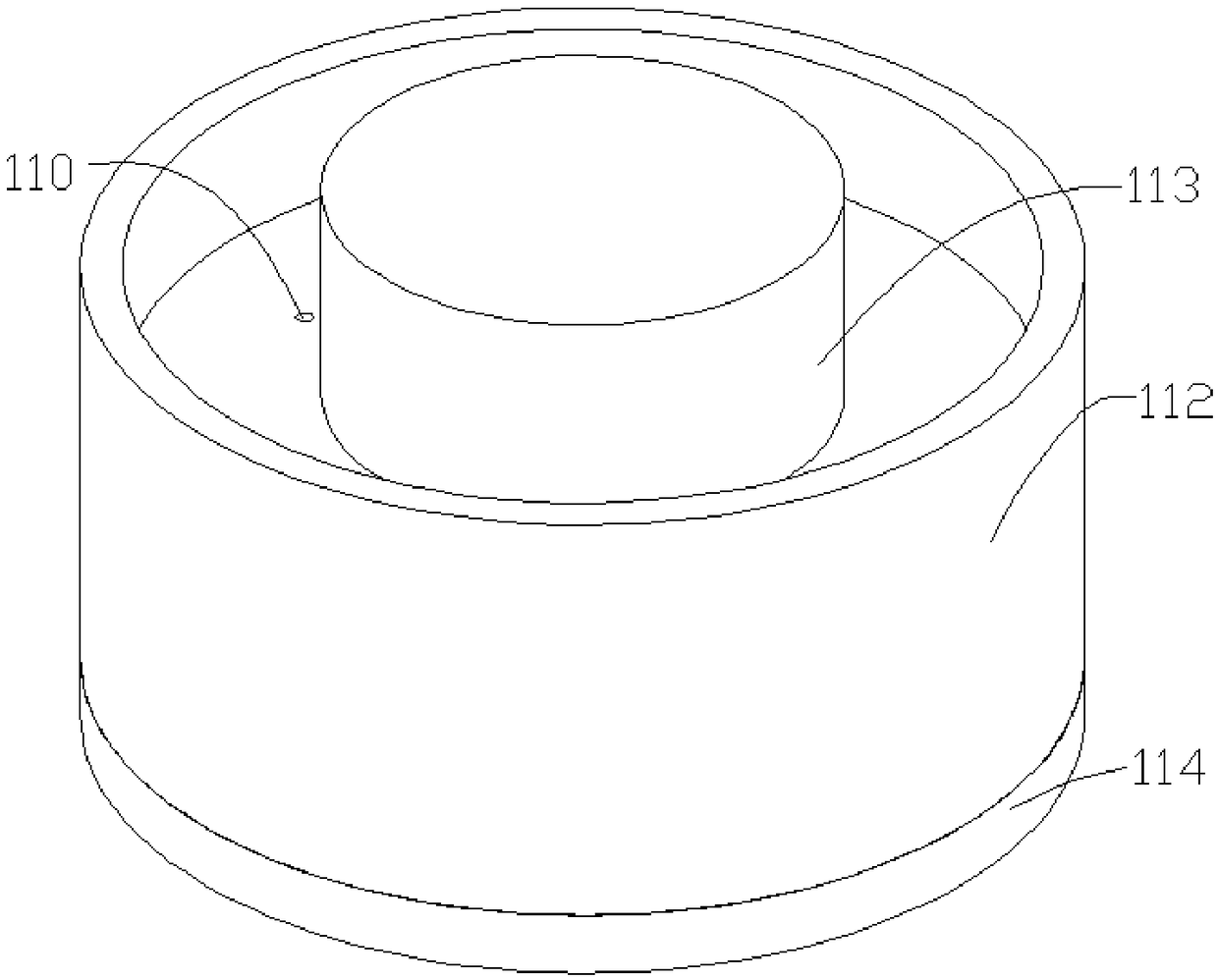

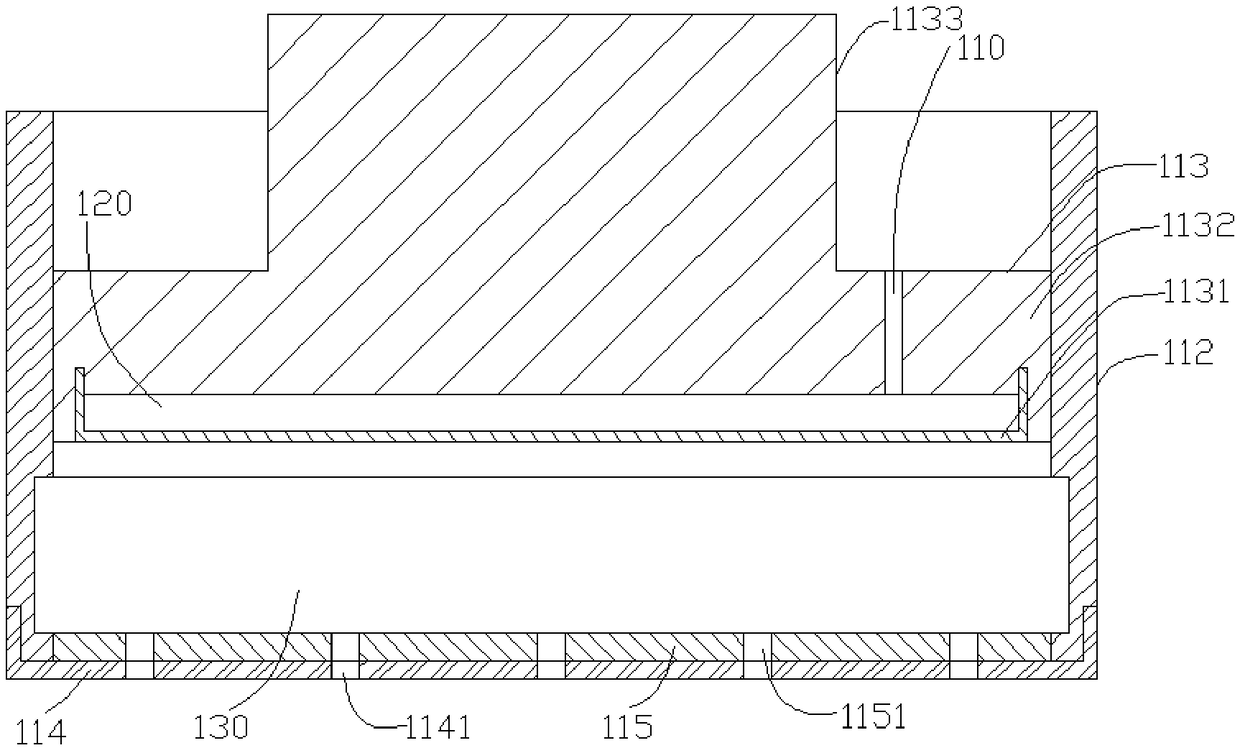

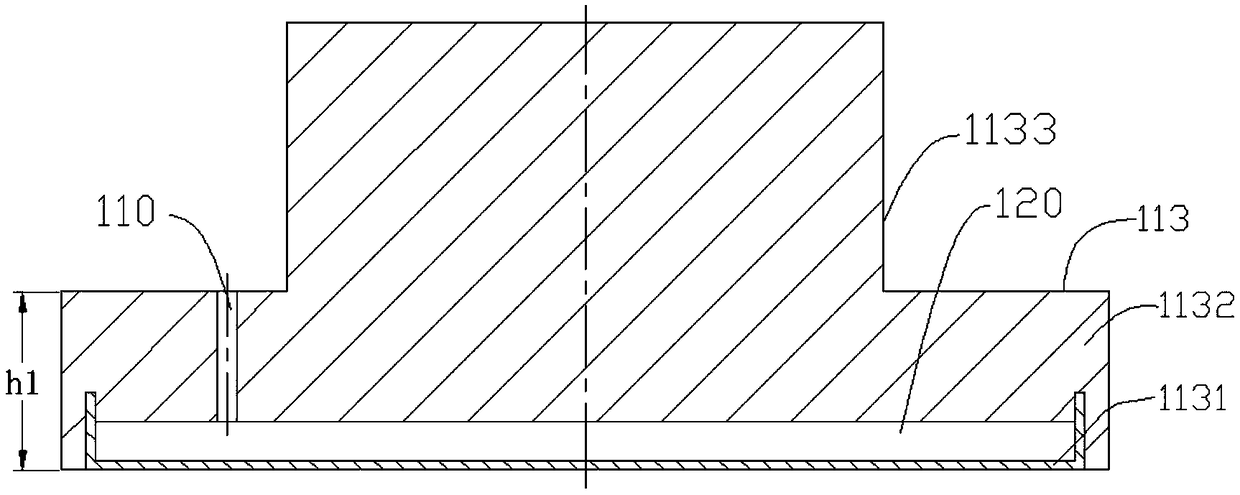

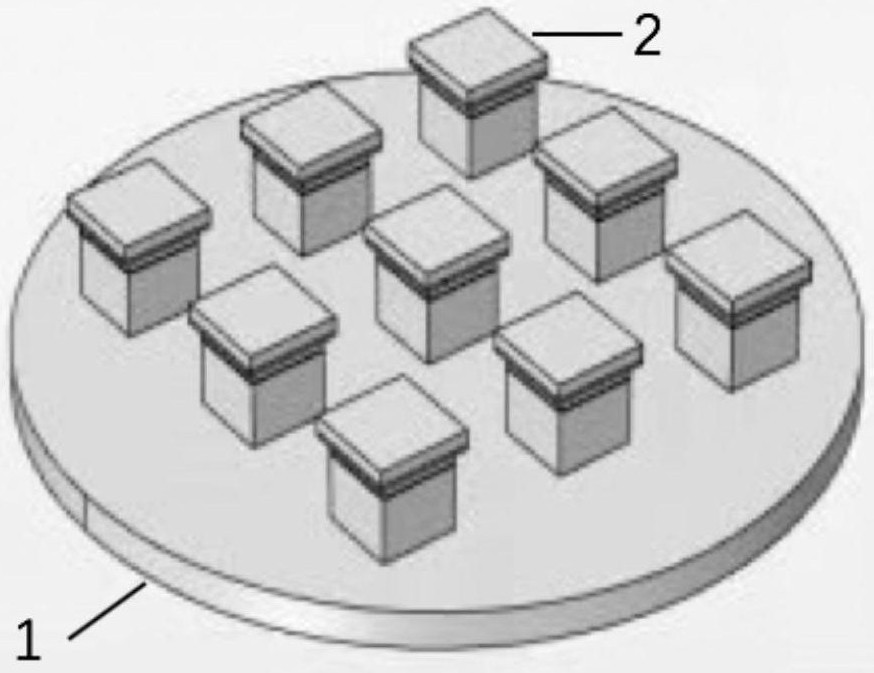

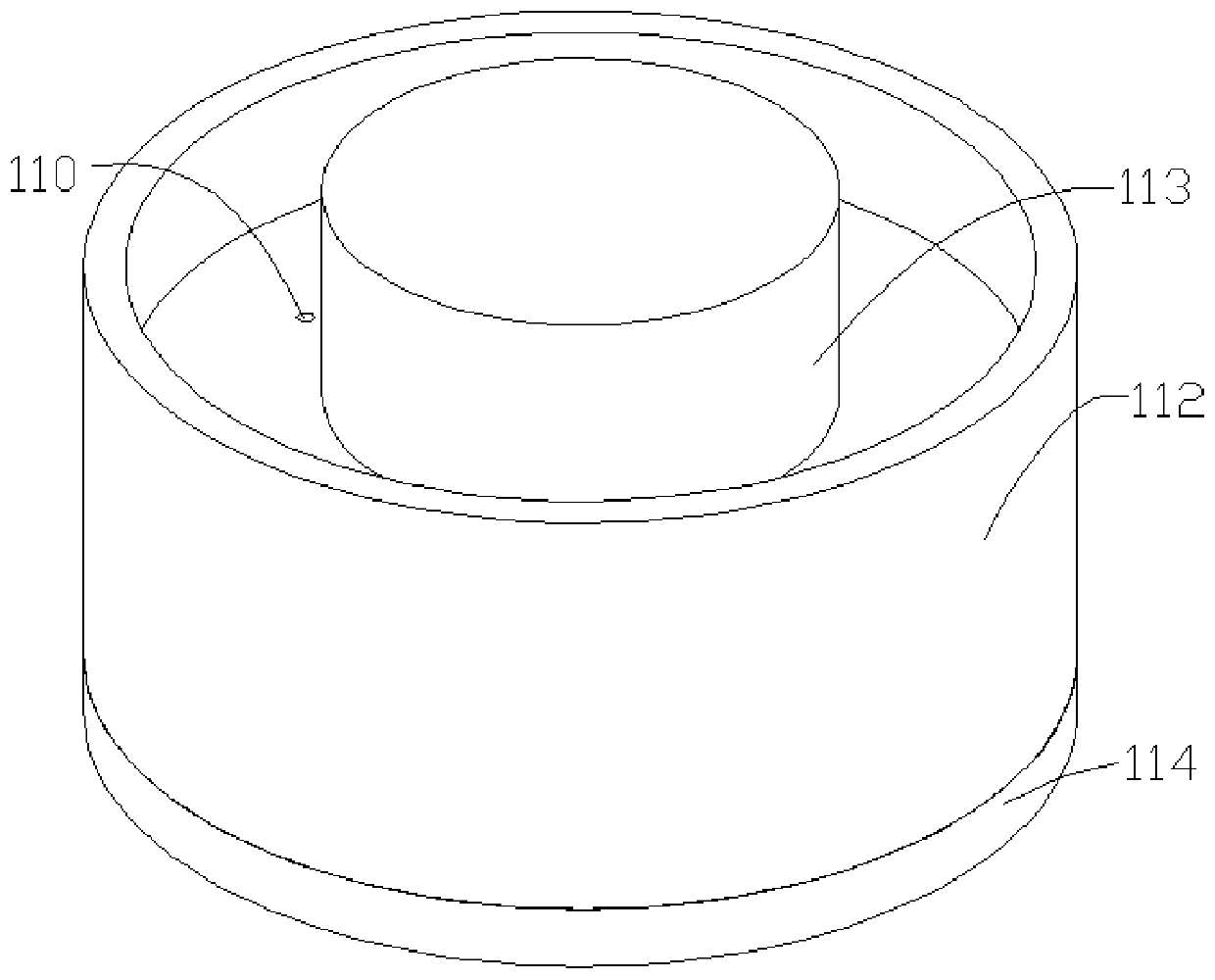

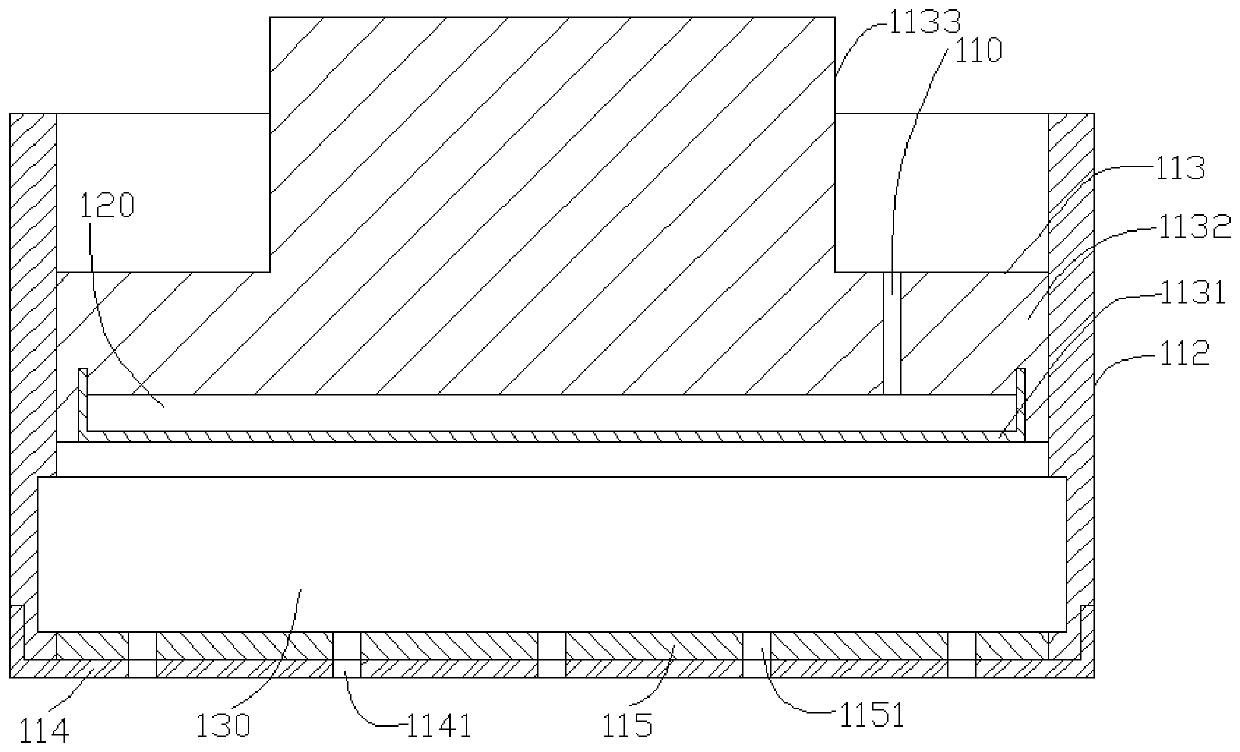

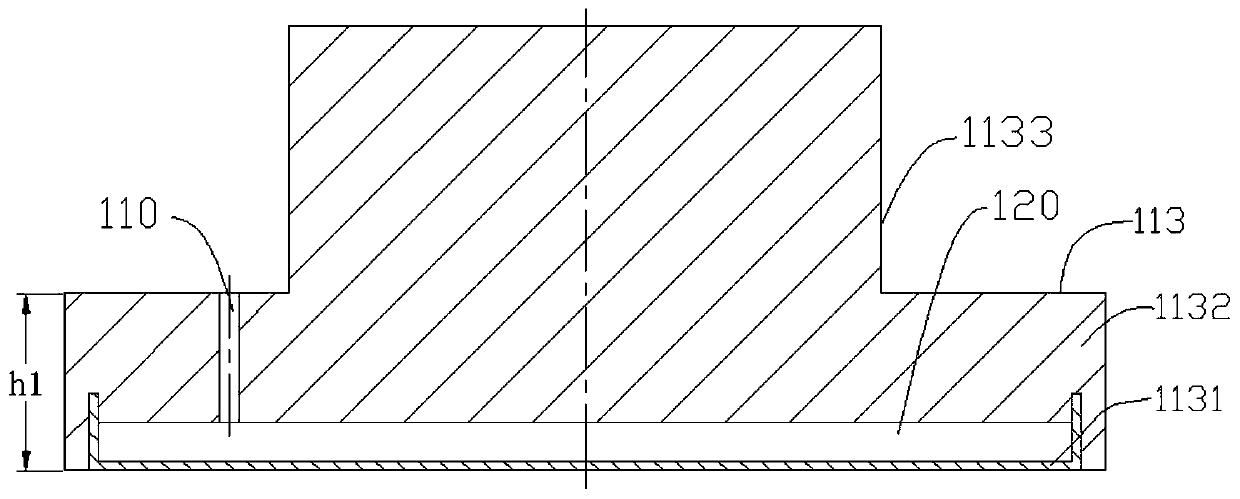

A crimping type power switch module and preparation method thereof

ActiveCN110676233BEnsure that electromagnetic fields do not interfere with each otherGuaranteed non-interferenceSemiconductor/solid-state device detailsSolid-state devicesMetal frameworkWorkspace

A crimping type power switch module, characterized in that it includes: an upper end plate, a lower end plate, a PCB board, and at least one subunit between the upper end plate and the lower end plate, the subunit includes: a supporting frame, and a The conductive metal sheet, the first molybdenum sheet, the power switch chip, and the second molybdenum sheet are arranged from bottom to top inside the support frame; the support frame includes a metal frame and an insulating layer wrapped outside the metal frame. The invention avoids the technical problem of severe current interference between multiple bullet element chips in the crimping device, increases the safe working area of the power device, and improves the current equalization performance among each bullet element.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

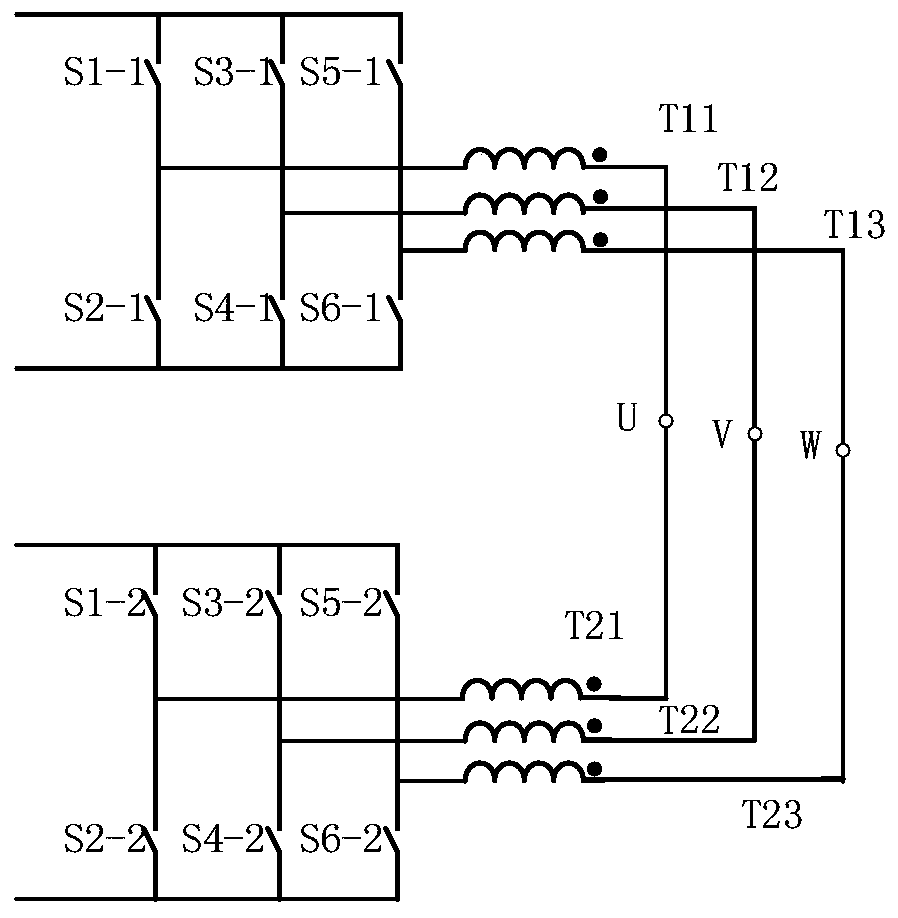

Switching harmonic suppression method for inverter parallel system and inverter parallel system

ActiveCN108377002BImprove reliabilityReduce circulationAc-dc conversionSingle network parallel feeding arrangementsHarmonicCarrier signal

The invention discloses a switch sub-harmonic suppression method of an inverter parallel connection system and an inverter parallel connection system. The method comprises the following steps: all inverters in an inverter parallel connection system share the voltage of an AC bus, one inverter accesses the parallel connection system, and other inverters do not access the parallel connection system;after the inverter accessing the parallel connection system is operated stably, each parallel connection circuit detects the voltage of the AC bus, and a carrier synchronous signal of each inverter can be obtained according to the voltage of the AC bus; each inverter accesses the parallel connection system, and a carrier phase value of each inverter and a counting direction of the carrier wave are obtained by adopting a rectangular pulse rising edge and falling edge triggering way by virtue of capture interruption; and the obtained carrier phase value of each inverter and the counting direction of the carrier wave are compared with zero or a carrier period value to obtain an adjusting amount for the carrier period of each inverter, so that the period value of the carrier wave is adjusted,and the synchronization of carrier signals of multiple inverters can be realized.

Owner:BEIJING JIAOTONG UNIV

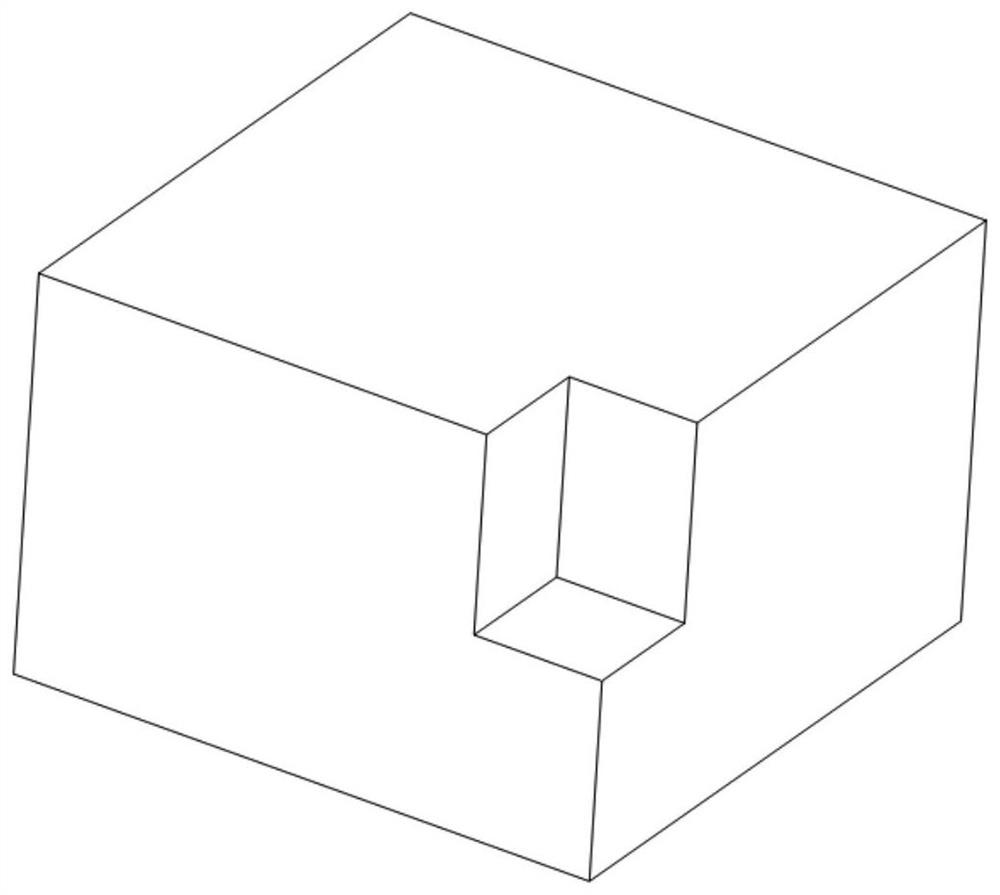

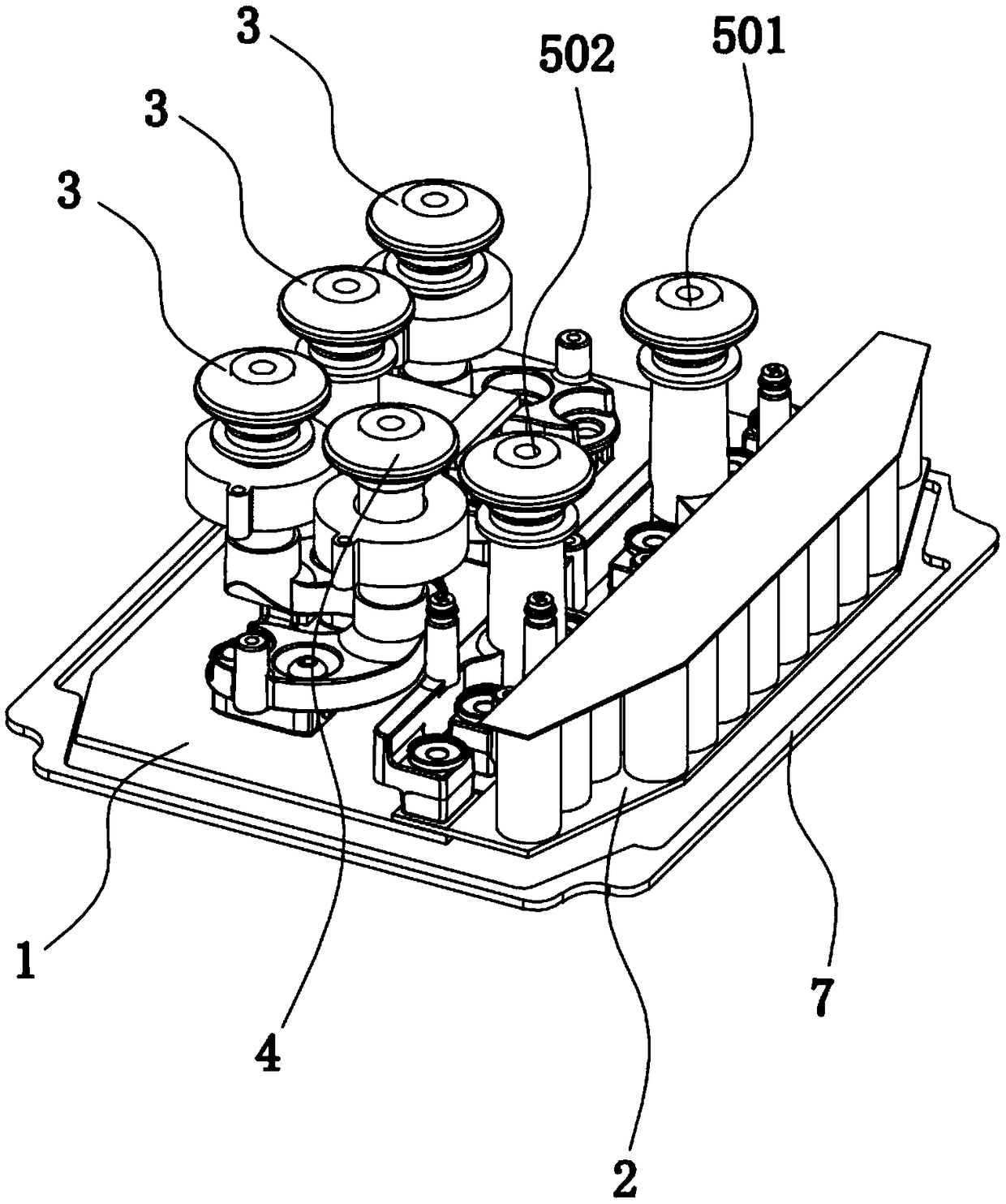

A drug material flow equalization device for a propellant extruder

ActiveCN109485529BSlow flowFast flowExplosive working-up apparatusPore diameterMechanical engineering

The invention discloses a medicine material flow equalizing device for a propellant extruder. The device comprises an outer cylinder, a mold body, a piston and a rubber pad, wherein the piston consists of a piston body, a piston rod and a rubber disc; a groove is formed in the bottom of the piston body; a ventilation hole communicated with the groove is formed in the top surface of the piston body; the rubber disc is fixed at the bottom of the piston body to enable a groove cavity of the groove to become an air storage chamber; inner holes of the outer cylinder are sequentially a pore diameterD1 section, a pore diameter D2 section and a pore diameter D3 section from top to bottom, and D2 > D1, D3 = D1; a plurality of medicine outlet holes with the same shape and size are formed in the mold body, through holes with the same position, number, size and shape as the medicine outlet holes on the mold body are formed in the rubber pad, and each through hole on the rubber pad is respectivelyaligned with the corresponding medicine outlet hole on the mold body when the rubber pad is fixedly connected with the mold body; and the piston body is mounted in the pore diameter D1 section, the rubber pad is mounted in the pore diameter D3 section, the mold body covers the bottom of the outer cylinder and is fixedly connected with the wall of the outer cylinder, and the pore diameter D2 section and the top surface of the rubber pad form a medicine material extrusion cavity.

Owner:SICHUAN UNIV

Optimal Control Method for Parallel Power Supply System Based on Current Sharing Standard Deviation Matrix Column and Minimum

InactiveCN106130080BWide applicabilityImprove current sharing effectAc-dc network circuit arrangementsAdaptive controlOptimal controlStandby power

Owner:WENZHOU UNIV

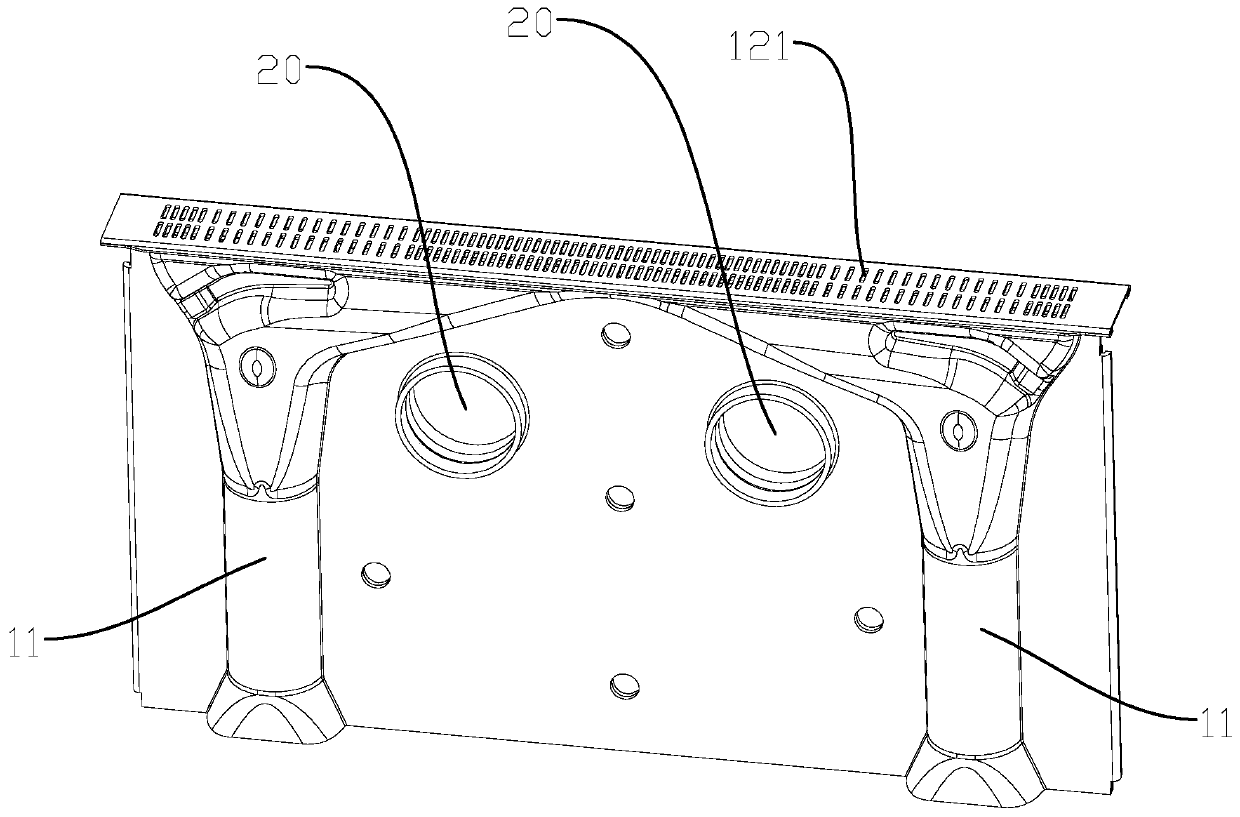

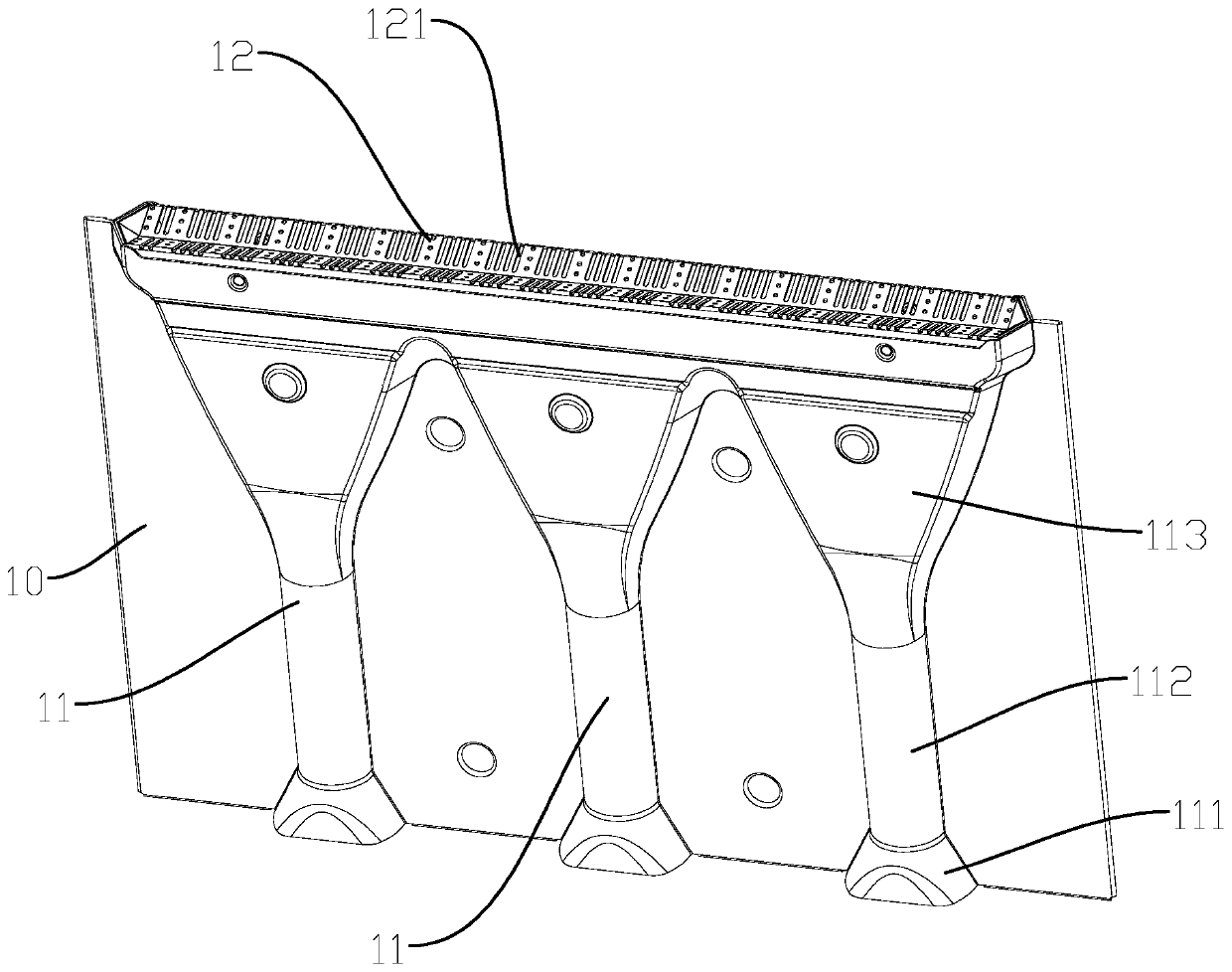

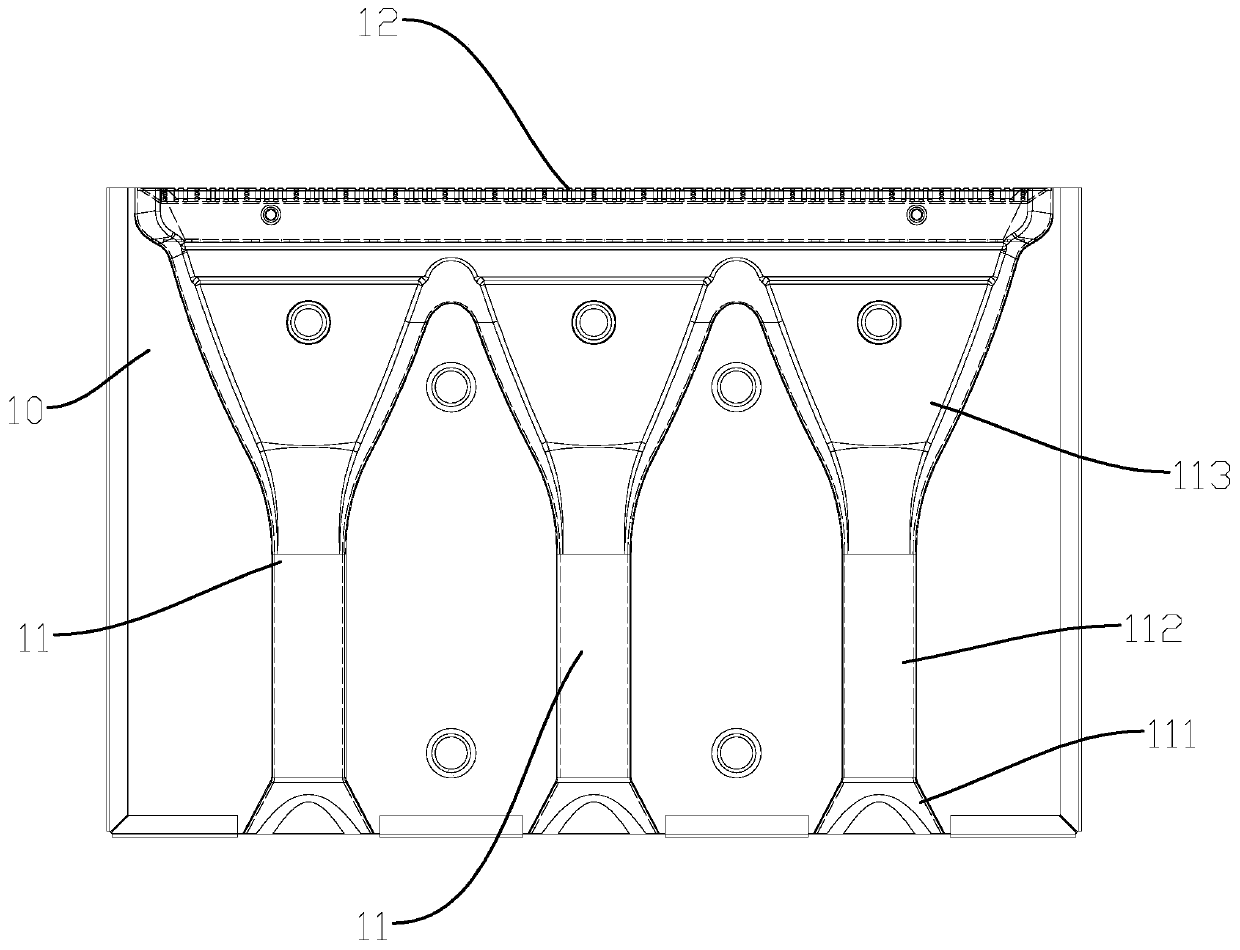

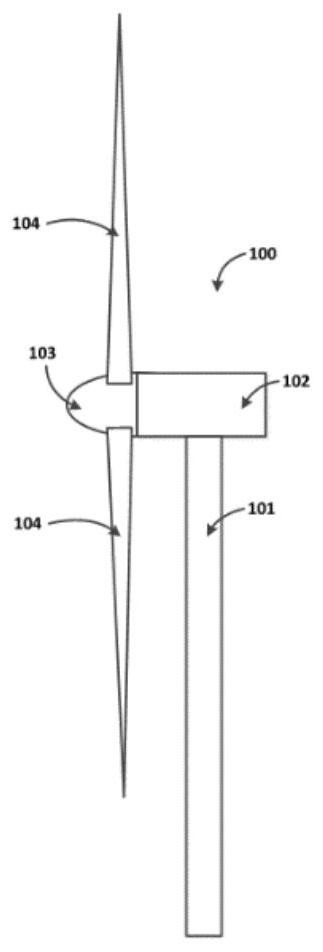

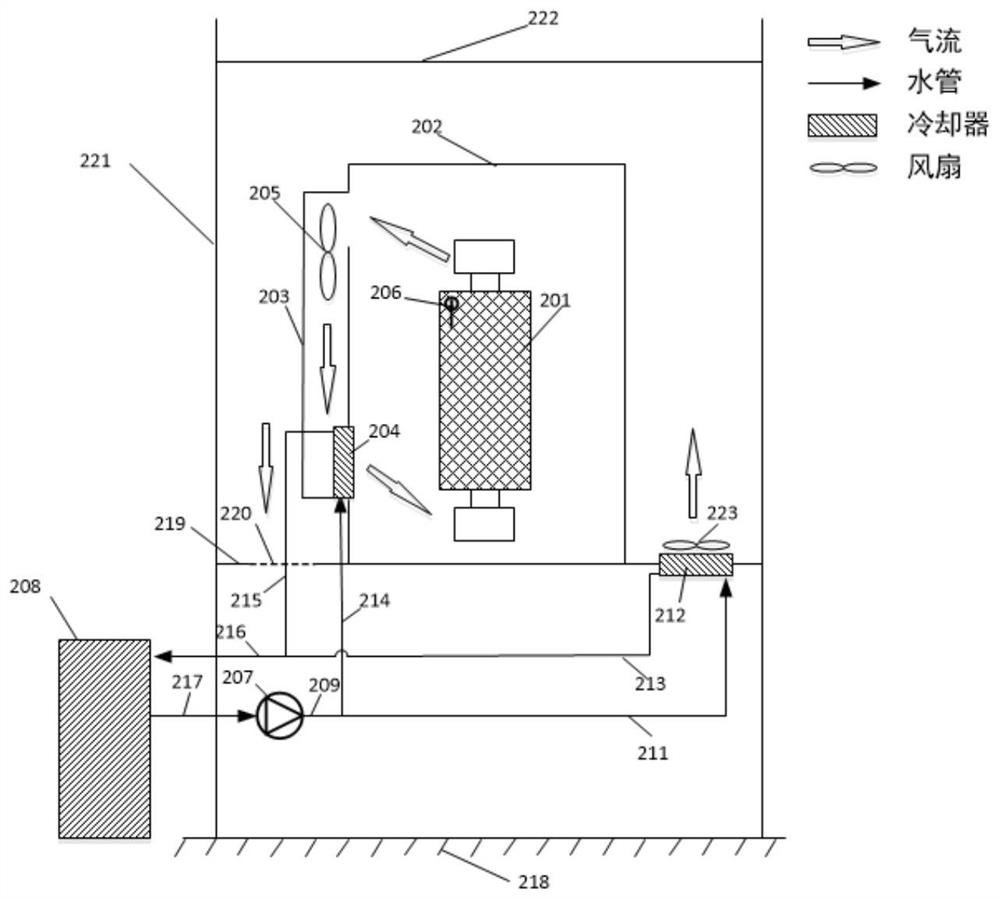

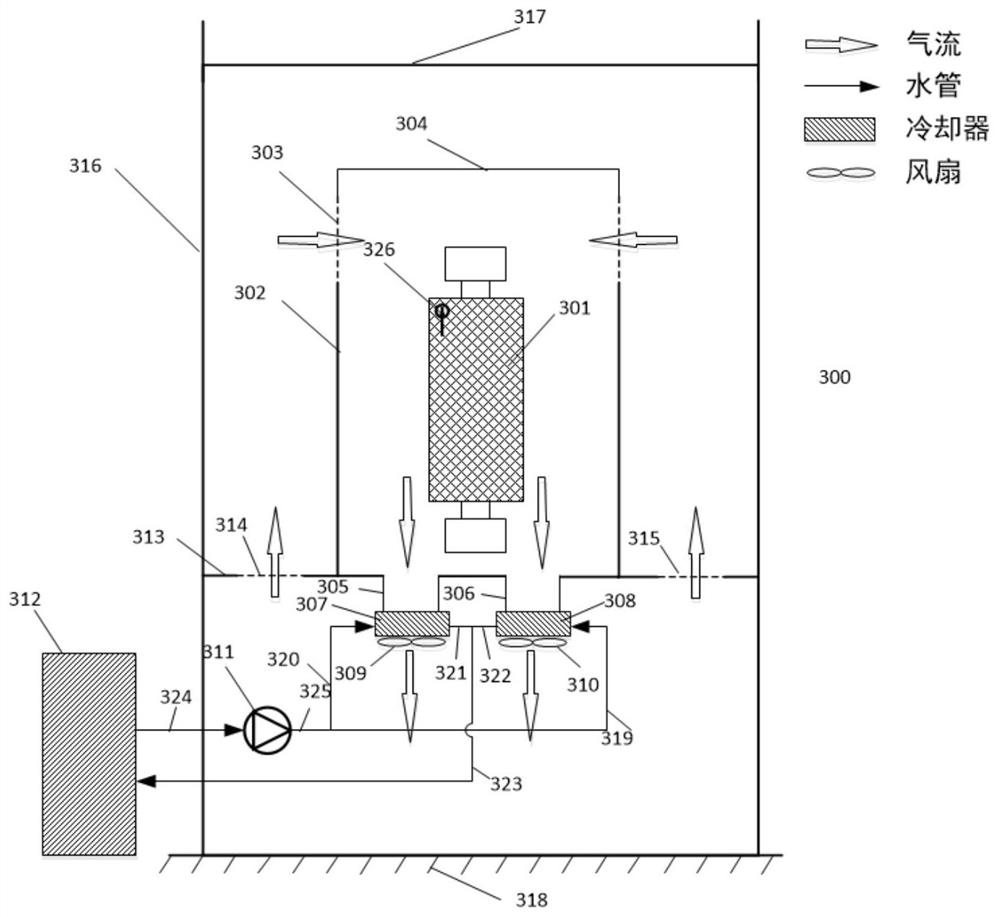

Semi-open high-power equipment cooling system and cooling method

ActiveCN113539629AReduce self-consumptionSelf-consumption mitigationTransformers/inductances coolingWind energy generationThermodynamicsProcess engineering

The invention relates to the technical field of cooling systems, and provides a semi-open high-power equipment cooling system and method. The system comprises a semi-open high-power equipment structure, semi-open high-power equipment, inner radiators, inner radiator fans and a pipeline connection cooling system. The cooling requirements of the semi-open high-power equipment and a closed environment can be met at the same time, so that the total cost of the cooling system is greatly reduced. The convection heat transfer of the outer wall of the semi-open high-power equipment structure can be enhanced by 5-10 kW, and therefore self power consumption of the cooling system is remarkably reduced. A cooling backpack is omitted, and the plurality of inner radiators are arranged below the semi-open high-power equipment, so that the size limitation pressure of the high-power equipment in the layout in a closed environment is effectively relieved. Compared with single-side ventilation, double-side ventilation is adopted, so that local hot spots of a heating element are effectively reduced.

Owner:YUANJIAN WIND POWER JIANGYINENVISION ENERGY CO LTD

A LED constant voltage and current sharing system

ActiveCN108668403BImprove current sharing effectAc-dc conversion without reversalElectroluminescent light sourcesEqualizationBus voltage

The invention belongs to the field of LEDs, and provides an LED constant voltage and current sharing system; in the invention, by including a plurality of current sharing modules, a plurality of DC power supplies and an LED load module; a plurality of current sharing modules and a plurality of DC power supplies one by one Corresponding to the connection, each current sharing module detects the output voltage of its corresponding DC power supply, and generates a balanced voltage according to the output voltage. Multiple balanced voltages generated by multiple current sharing modules are output to the current sharing bus to generate a current sharing bus voltage. Each current sharing module generates a feedback signal according to the current sharing bus voltage to adjust the output voltage of its corresponding DC power supply, so the current sharing effect of the parallel power supply of the LED load module can be improved.

Owner:TRIDONIC

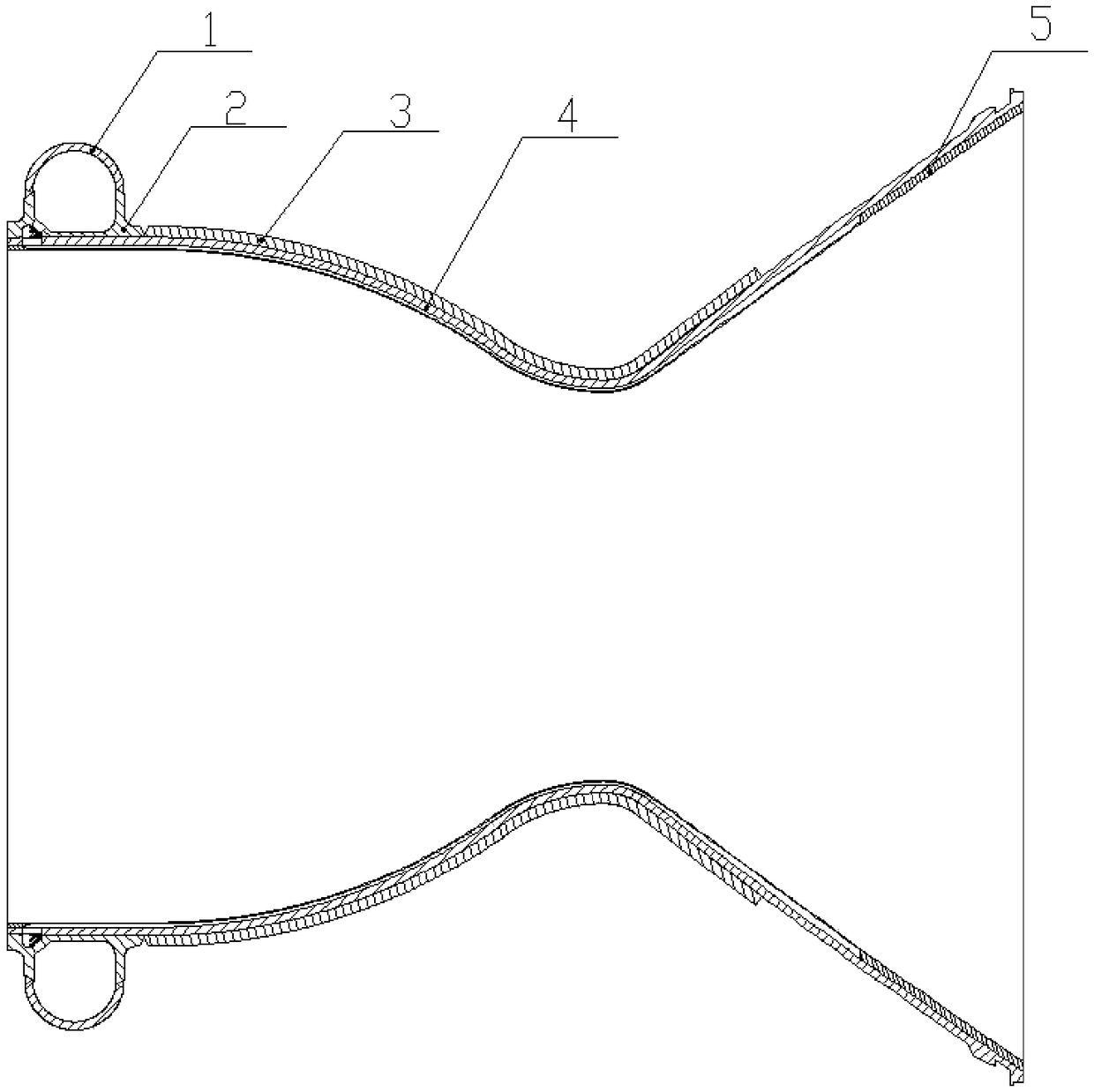

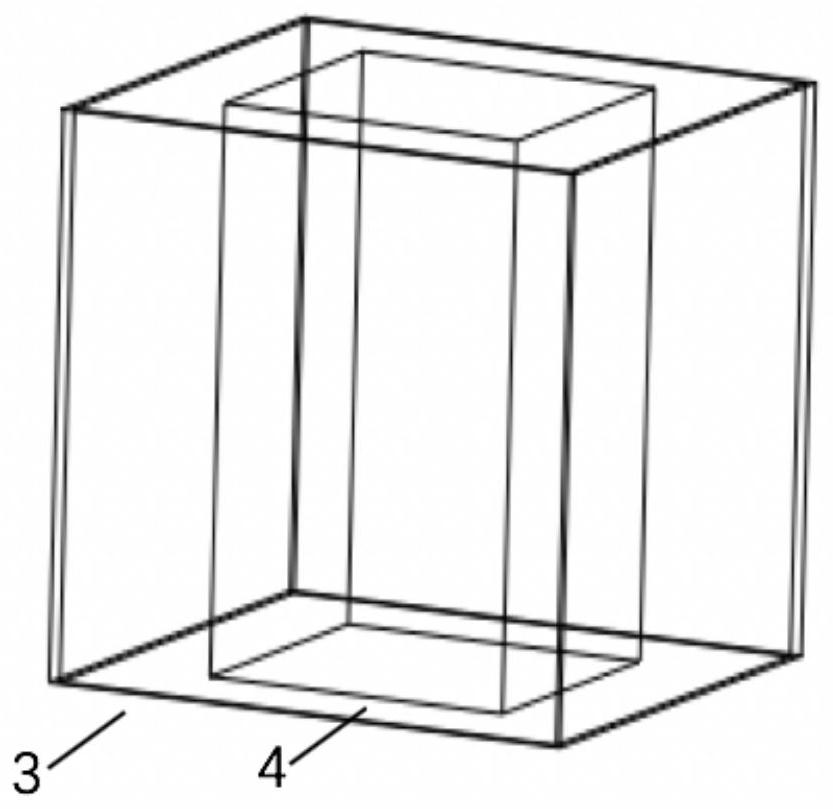

Tube and box structure, shell and tube heat exchanger and air conditioner

ActiveCN106482550BInto the uniformImprove current sharing effectEvaporators/condensersSpace heating and ventilation detailsPlate heat exchangerShell and tube heat exchanger

The invention provides a tube box structure, a shell and tube heat exchanger and an air-conditioner. The tube box structure comprises a shell (1) and a refrigerant liquid inlet connection pipe (2) connected to the shell (1). A liquid equalizing cavity (3) is formed in the shell (1). A flow equalizing pipe (4) and a first flow equalizing plate (5) located on the outlet side of the flow equalizing pipe (4) are arranged in the liquid equalizing cavity (3). The flow equalizing pipe (4) is connected to the outlet position of the refrigerant liquid inlet connection pipe (2). According to the tube box structure, the flow equalizing effect of the heat exchanger can be improved, and the heat exchange efficiency of the heat exchanger is also improved.

Owner:GREE ELECTRIC APPLIANCES INC

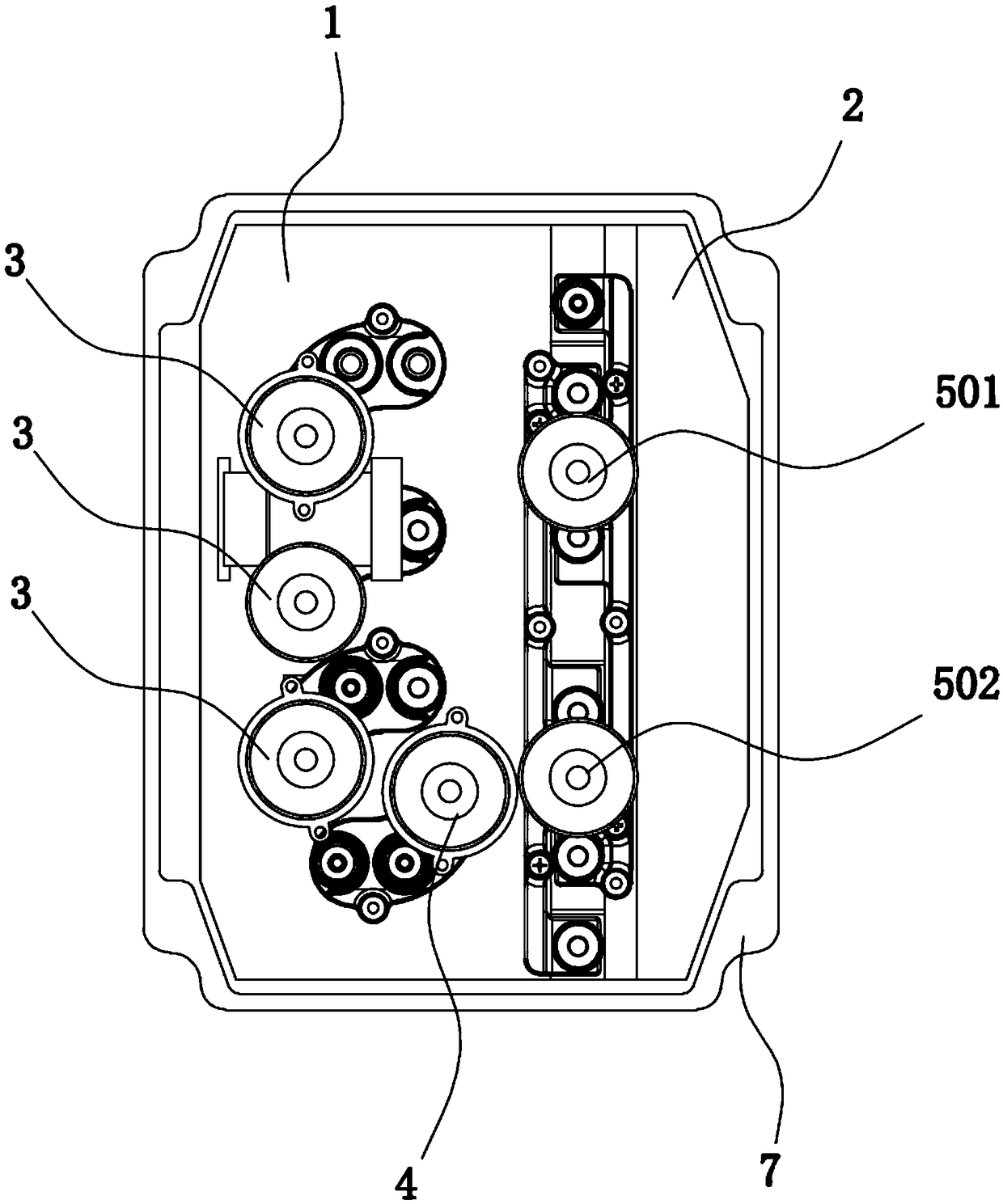

Current-sharing circuit structure and electric vehicle motor control adopting that structure

PendingCN109217770AShorten the pathOptimize layoutSpeed controllerAC motor controlElectric machineEngineering

The present application discloses a current sharing circuit structure and an electric motor controller of an electric industrial vehicle using the structure. The current sharing circuit structure comprises a power board and a power board, the top surface of the power board is provided with a U, V, W three-phase terminal and DC pump motor terminal, the U, V, W three-phase terminal is externally connected with a three-phase alternating current motor, The DC pump motor terminal is externally connected with the DC pump motor, and a positive input terminal and a negative input terminal for simultaneously supplying power to the power board and the power board are arranged between the power board and the power board, and the positive input terminal and the negative input terminal are externally connected with a DC power supply. The present application solves the technical problems of poor current sharing effect and poor layout rationality of the motor controller of an electric industrial vehicle.

Owner:北京友信宏科电子科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com