A crimping type power switch module and preparation method thereof

A power switch module and power switch chip technology, which is applied in the direction of output power conversion devices, semiconductor/solid-state device parts, semiconductor devices, etc., can solve the problems of high chip current density and device failure, and achieve improved current sharing performance, The effect of increasing the safe working area and reducing the mutual inductance parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

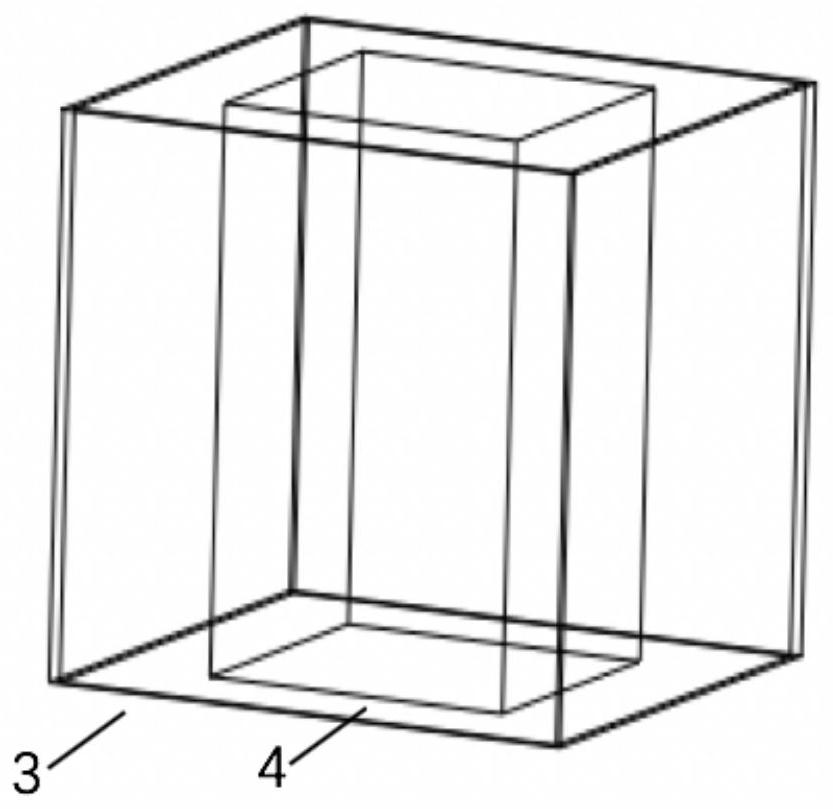

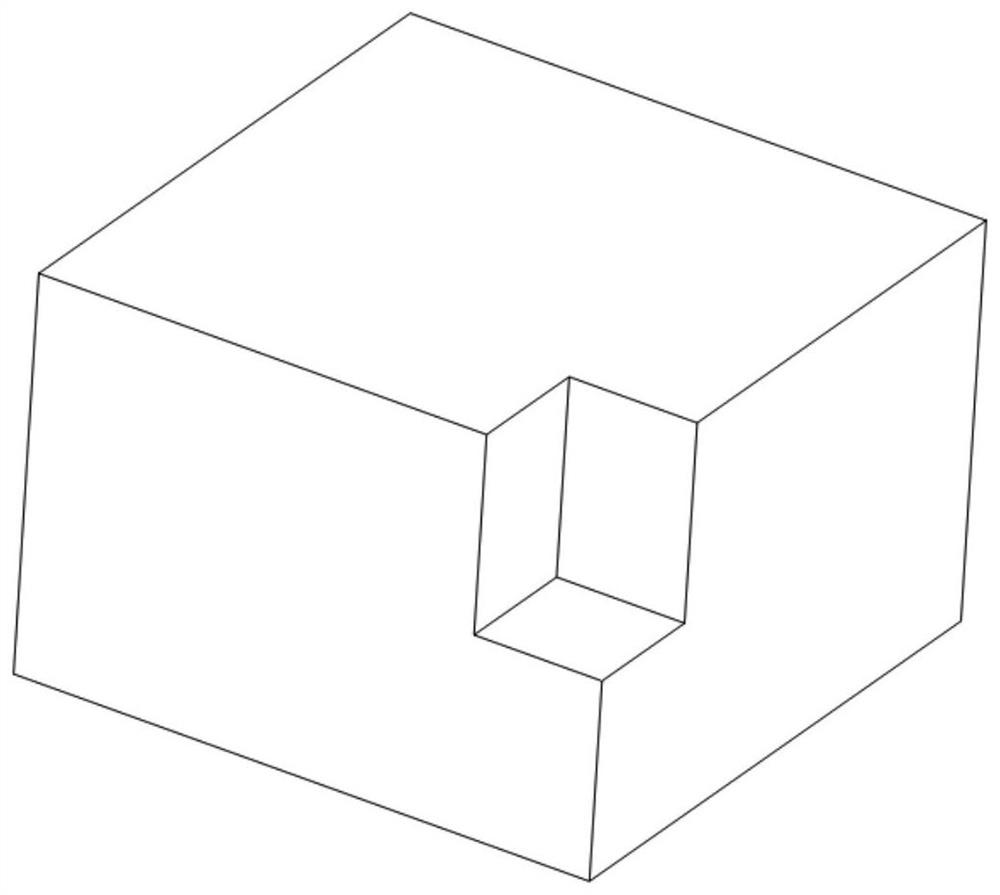

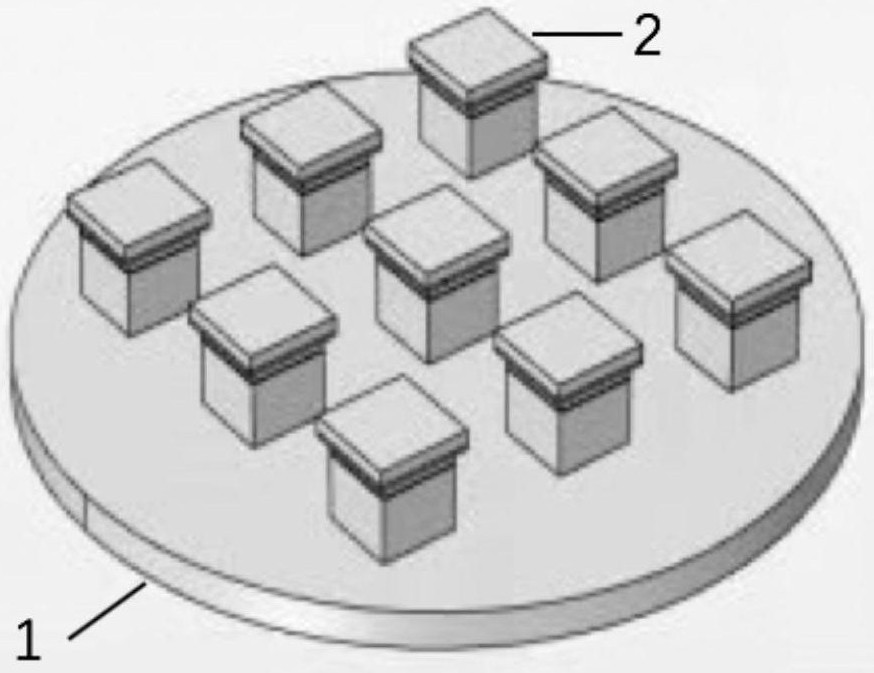

[0031] This embodiment provides a crimping type power switch module, such as Figure 1-6 As shown, it includes: an upper end plate, a lower end plate 1, a PCB board, and at least one subunit 2 between the upper end plate and the lower end plate. The subunit includes: a supporting frame 3, and a bottom-up The set conductive metal sheet, the first molybdenum sheet, the power switch chip, and the second molybdenum sheet; the support frame includes a metal frame and an insulating layer wrapped outside the metal frame.

[0032] The thickness of the metal frame is 2mm-4mm; the thickness of the insulating layer is at least 2mm, and the upper and lower gaps do not exceed 2mm; the distance between the support frame and the power switch chip is 4mm-8mm. Different surface thicknesses and structures need to be uniformly set, and the shielding effect of the grid is relatively poor compared to the plate type.

[0033] The material of the metal frame is a highly conductive metal material, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com