A drug material flow equalization device for a propellant extruder

A technology for extruders and propellants, applied in explosives, explosives processing equipment, offensive equipment, etc., can solve the problems of slow flow rate of charge, waste of charge, affecting the uniformity of charge column density, etc., and achieve the flow rate of charge Balance and improve the effect of current sharing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

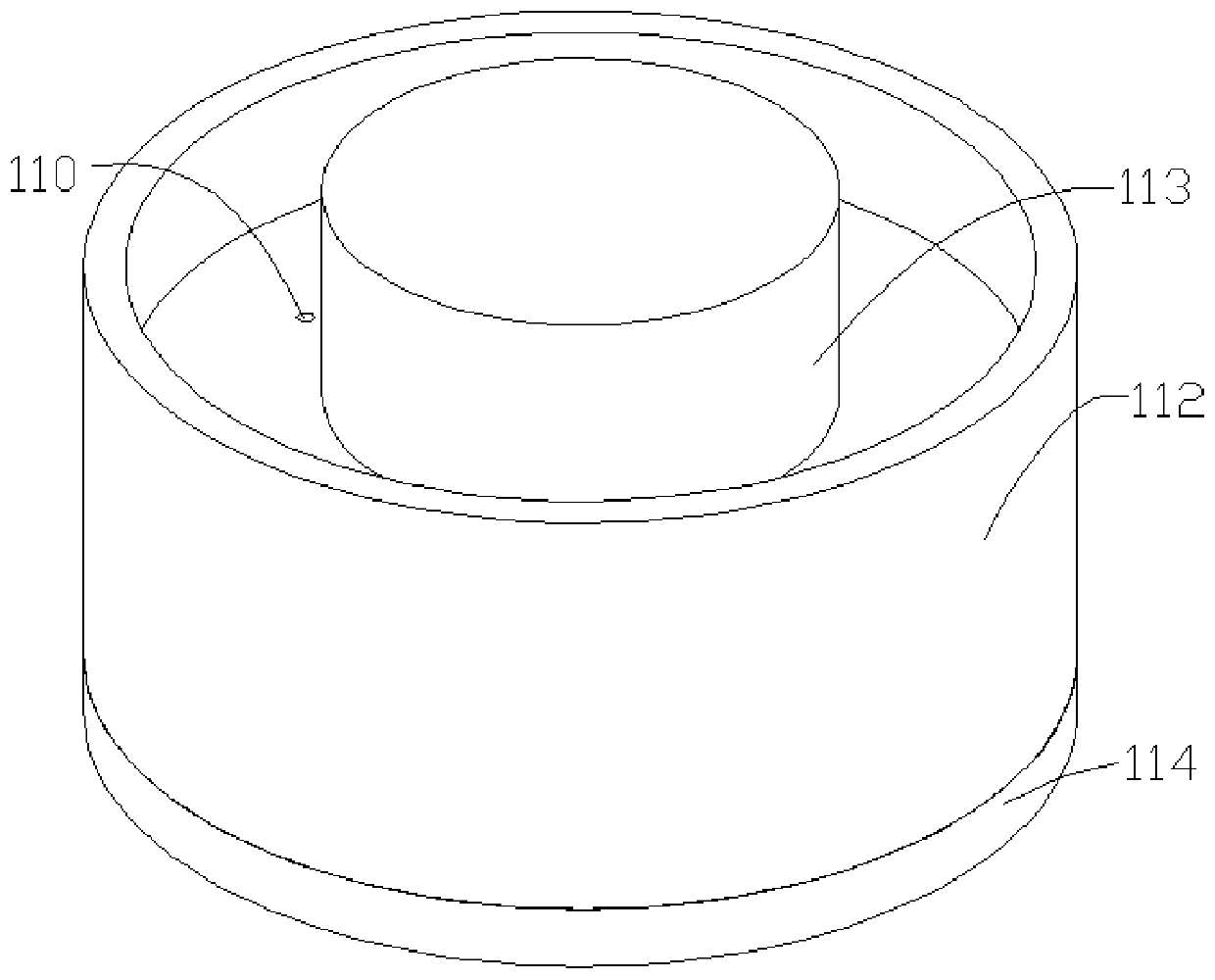

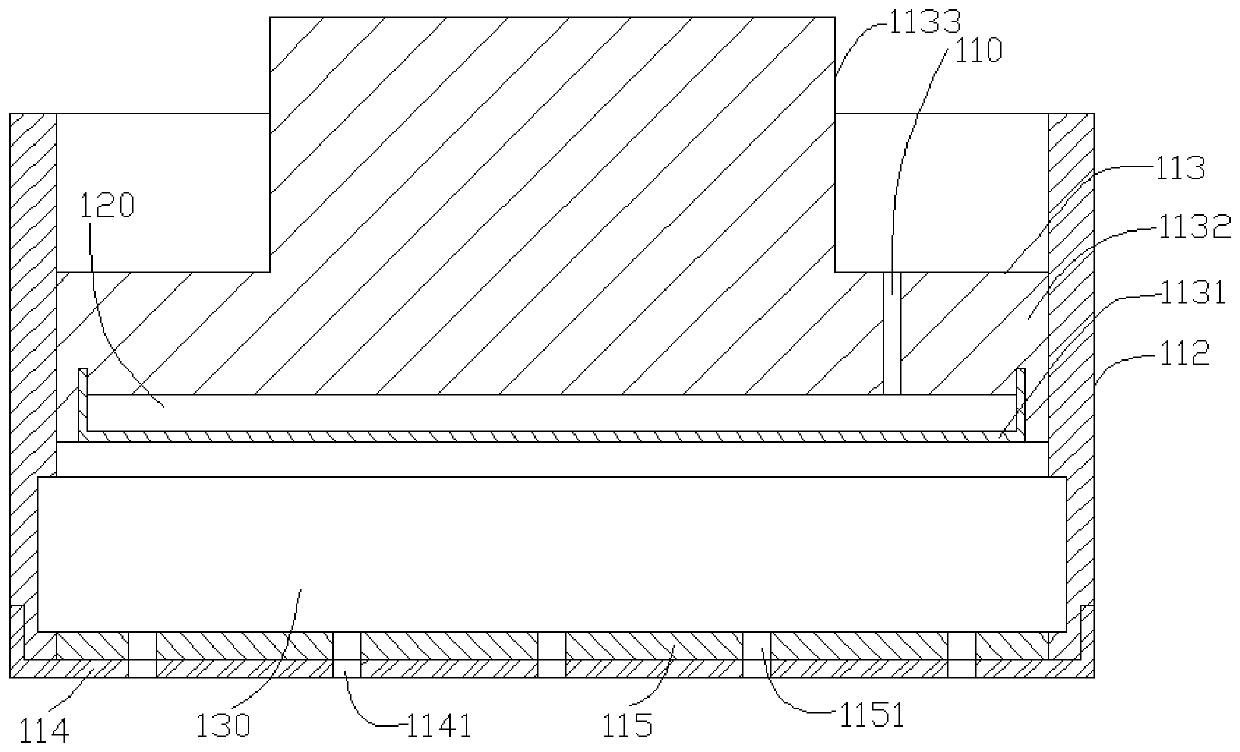

[0025] In this embodiment, the charge equalizing device used in the propellant extruder is as figure 1 , figure 2 As shown, the outer cylinder 112, the mold body 114, the piston 113 and the rubber gasket 115 are included.

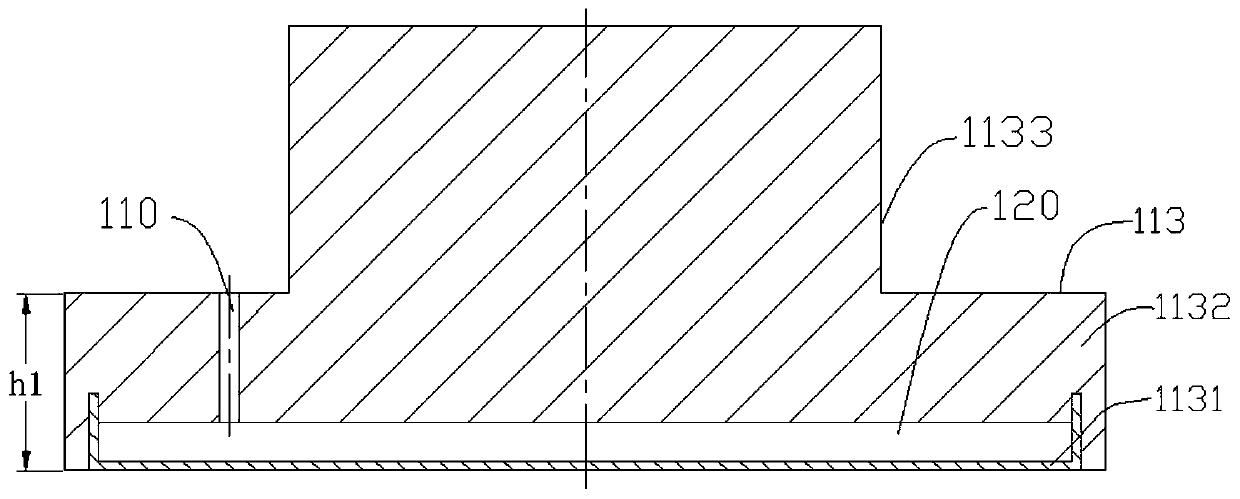

[0026] The piston 113 is as figure 2 , image 3 As shown, it consists of a piston body 1132, a piston rod 1133 and a rubber disc 1131. The piston rod 1133 is installed on the top surface of the piston body 1132. The center line of the piston rod and the center line of the piston body should be in a straight line during installation. The bottom of 1132 is provided with a groove, and the top surface is provided with a vent 110 communicating with the groove. The size of the rubber disk 1131 matches the groove. The rubber disk is fixed to the bottom of the piston body by vulcanization and covers the groove , And the bottom surface of the rubber plate 1131 is flush with the bottom surface of the piston body 1132, so that the cavity of the groove becomes the air st...

Embodiment 2

[0032] In this embodiment, the charge equalizing device used in the propellant extruder is as figure 1 , figure 2 As shown, the outer cylinder 112, the mold body 114, the piston 113 and the rubber gasket 115 are included. The difference from the structure of Embodiment 1 is: Aperture D2=Aperture D1+L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com