Self-sucking type bearing lubricating device

A bearing lubrication, self-priming technology, applied in bearing components, shafts and bearings, bearing cooling, etc., can solve problems such as failure to meet equipment use requirements, unfavorable product promotion and application, unfavorable bearing heat dissipation, etc., and achieve product investment and use costs. Low cost, improved service life, good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

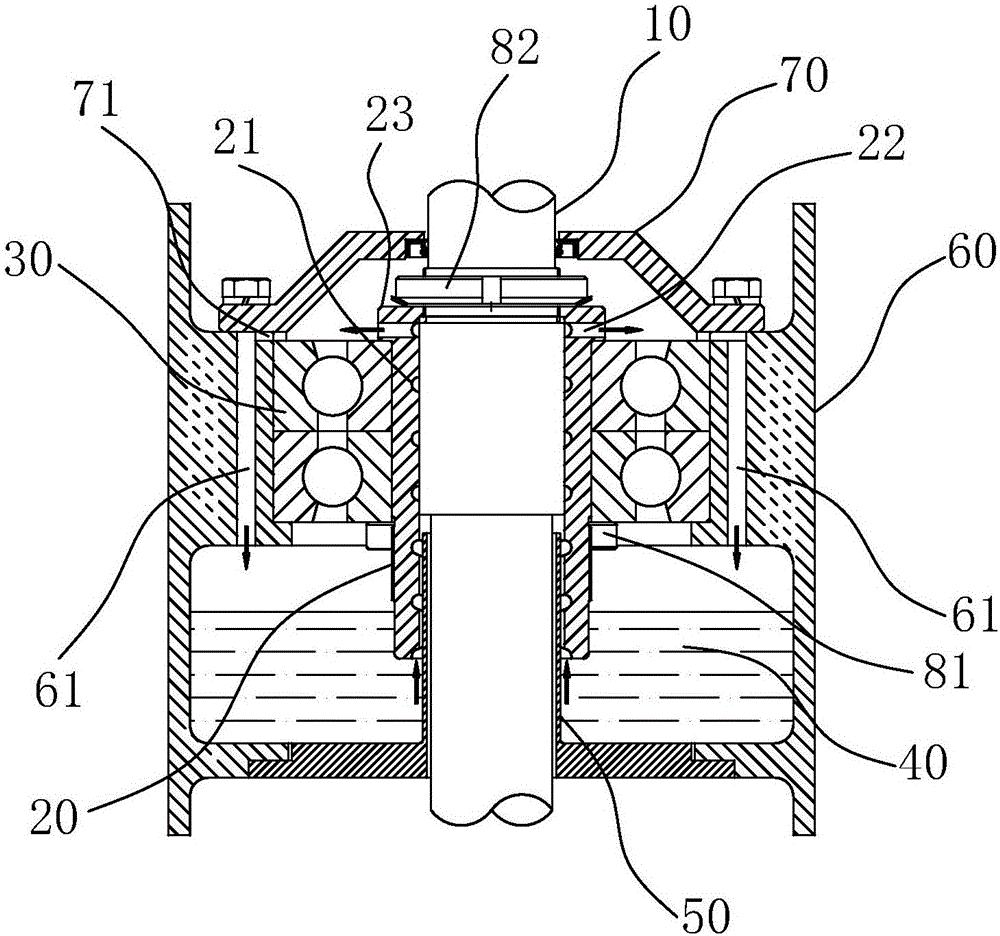

[0024] Now illustrate structural features of the present invention in conjunction with accompanying drawing:

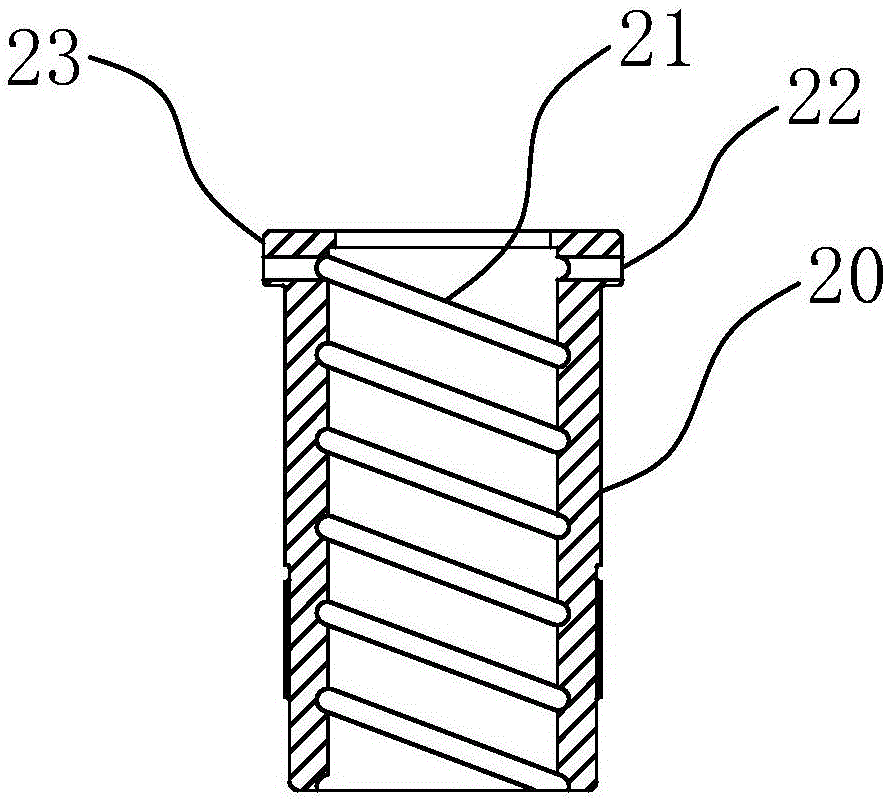

[0025] The present invention includes a self-priming sleeve 20 that is sleeved on the outer peripheral surface of the transmission shaft 10 and rotates axially with the transmission shaft 10, and a bearing 30 that is sleeved on the outer peripheral surface of the self-priming sleeve 20. The inner wall of the bushing 20 is provided with a spiral form and the lubricating oil in the oil storage chamber 40 at the lower end of the self-priming bushing 20 is spirally lifted to the oil-absorbing groove 21 at the upper end of the self-priming bushing 20, and the self-priming bushing 20 is also provided with a The lubricating oil lifted to the upper end of the self-suction shaft sleeve 20 is thrown to the oil throwing channel 22 on the upper end surface of the bearing 30 . The present invention is proposed for vertical equipment, and realizes the oil bath heat dissipation of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com