Hot stamping die steel and production method thereof

A technology of hot stamping dies and production methods, applied in the field of die steel manufacturing, which can solve the problems of low hardness of the matrix, small deformation of workpieces, and unsuitability for large-scale production, and achieve the effects of improving thermal conductivity, impact toughness, and performance indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] A kind of production method of special die steel for hot stamping of the present invention comprises the following steps:

[0072] 1) Smelting and casting

[0073] Electric furnace smelting according to the above chemical composition, pouring steel ingots, and then electroslag remelting;

[0074] 2) Annealing and cooling

[0075] Annealing temperature 700±10°C, heat preservation 8h, cooling;

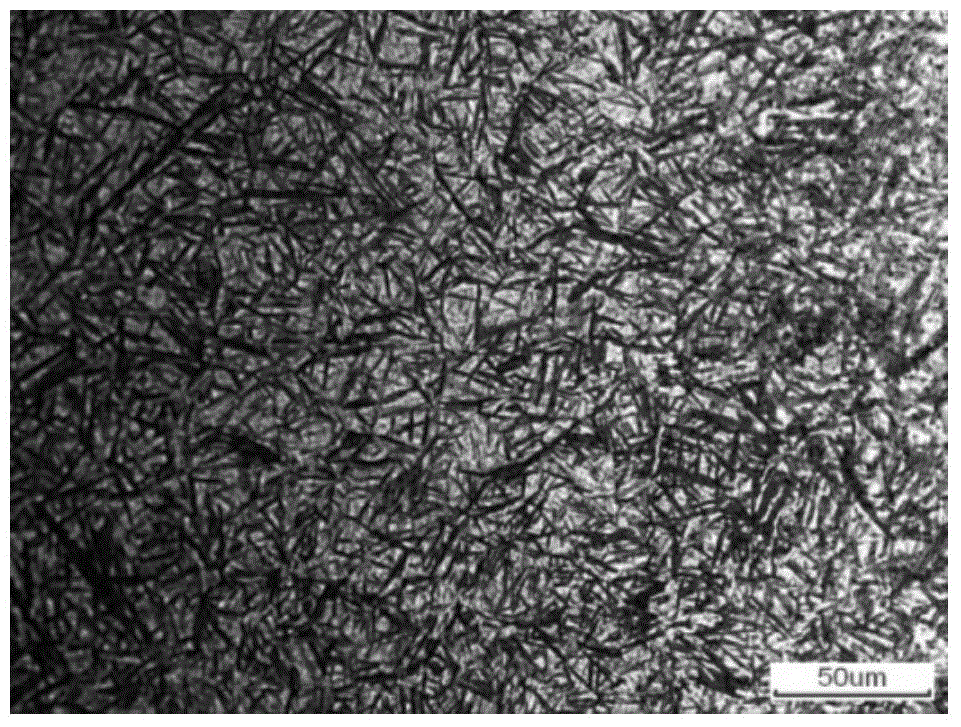

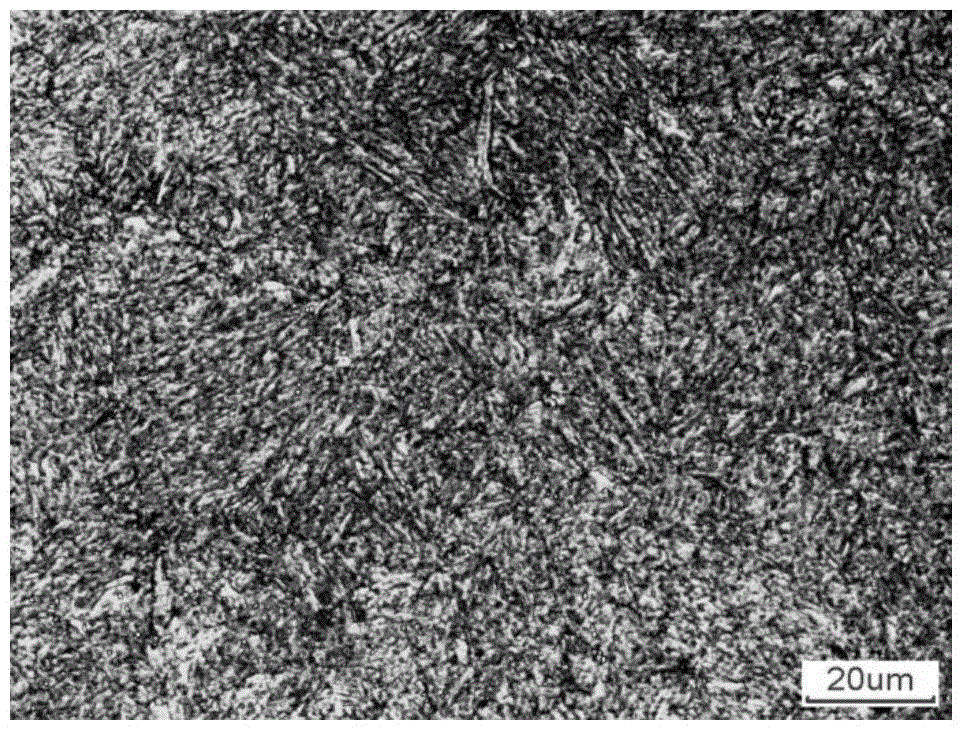

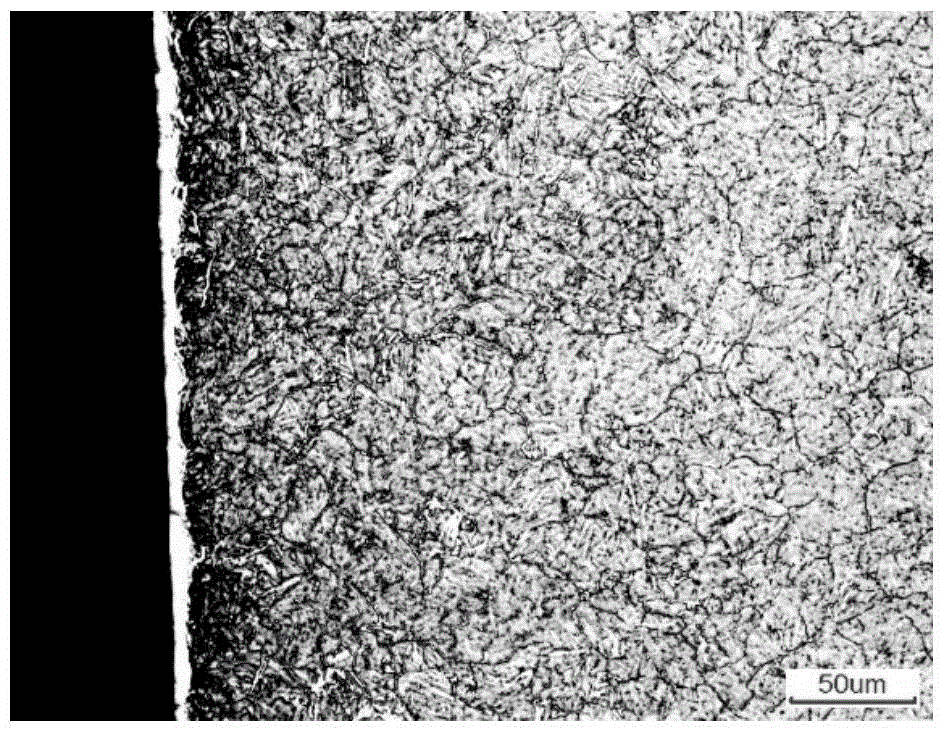

[0076] 3) Ultrafine heat treatment

[0077] High-temperature homogenization heat treatment: heat the cooled steel ingot to 1235-1250°C, and keep it warm for 8-10 hours to homogenize the steel composition, prevent composition segregation, improve the solidification structure of the material, and then place it in the air to cool;

[0078] Forging: Heating the steel ingot to 1200-1230°C for multi-directional forging, the final forging temperature is 950°C, and the forging ratio is greater than 6; after forging, it is annealed at 860°C for 8 hours and cooled;

[0079] 4) Spheroidi...

Embodiment 2

[0087] A kind of production method of die steel special for hot stamping of the present invention, comprises the following steps:

[0088] 1) Smelting and casting

[0089] Electric furnace smelting according to the above chemical composition, pouring steel ingots, and then electroslag remelting;

[0090] 2) Annealing and cooling

[0091] Annealing temperature 700±10°C, heat preservation 8h, cooling;

[0092] 3) Ultrafine heat treatment

[0093] High-temperature homogenization heat treatment: heat the cooled steel ingot to 1235-1250°C, and keep it warm for 8-10 hours to homogenize the steel composition, prevent composition segregation, improve the solidification structure of the material, and then place it in the air to cool;

[0094] Forging: Heating the steel ingot to 1200-1230°C for multi-directional forging, the final forging temperature is 950°C, and the forging ratio is greater than 6; after forging, it is annealed at 860°C for 8 hours and cooled;

[0095] 4) Spheroid...

Embodiment 3

[0104] A kind of production method of die steel special for hot stamping of the present invention, comprises the following steps:

[0105] 1) Smelting and casting

[0106] Electric furnace smelting according to the above chemical composition, pouring steel ingots, and then electroslag remelting;

[0107] 2) Annealing and cooling

[0108] Annealing temperature 700±10°C, heat preservation 8h, cooling;

[0109] 3) Ultrafine heat treatment

[0110] High-temperature homogenization heat treatment: heat the cooled steel ingot to 1235-1250°C, and keep it warm for 8-10 hours to homogenize the steel composition, prevent composition segregation, improve the solidification structure of the material, and then place it in the air to cool;

[0111] Forging: heat the steel ingot to 1200-1230°C for multi-directional forging, the final forging temperature is 950°C, the forging ratio is greater than 6, anneal at 860°C for 8 hours after forging, and cool;

[0112] 4) Spheroidizing annealing: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com