Internal-hole high-frequency quenching induction coil

A technology of high-frequency quenching and induction coils, which is applied in the direction of quenching devices, heat treatment equipment, and energy efficiency improvement. It can solve the problems of non-concentrated heating areas of magnetic conductors, low heating efficiency, and wide heating range, so as to improve production efficiency. Improve heating efficiency and reduce contact surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

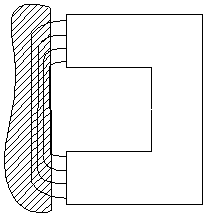

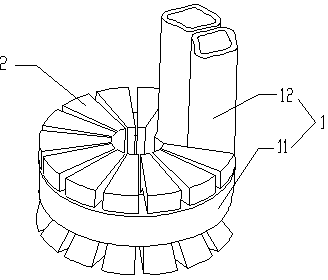

[0016] see Figure 3~Figure 5 , the present invention relates to an induction coil for inner hole high-frequency quenching treatment, which includes a cooling water pipe 1 and a plurality of magnetic blocks 2, the cooling water pipe 1 includes a C-shaped water pipe section 11 and two straight water pipe sections 12, the The two straight water pipe sections 12 are located on the same side of the C-shaped water pipe section 11, the two straight water pipe sections 12 are vertically connected to the two ends of the C-shaped water pipe section 11, and the longitudinal section of the magnetic block 2 is C-shaped. structure, the C-shaped structure includes an upper horizontal section 21, a vertical section 22 and a lower horizontal section 23, the outer end of the lower horizontal section 23 is provided with a downward slope, and the slope angle of the slope is 40~45°, The cross-section of the magnetic conductive block 2 is fan-shaped, and a plurality of magnetic conductive blocks 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com