Plate-strip roller type quenching device and method capable of realizing reverse quenching

A quenching device, plate and strip technology, applied in the direction of quenching device, heat treatment equipment, furnace, etc., can solve problems such as inability to meet, and achieve the effect of improving production efficiency, improving equipment utilization, and expanding the scope of specifications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

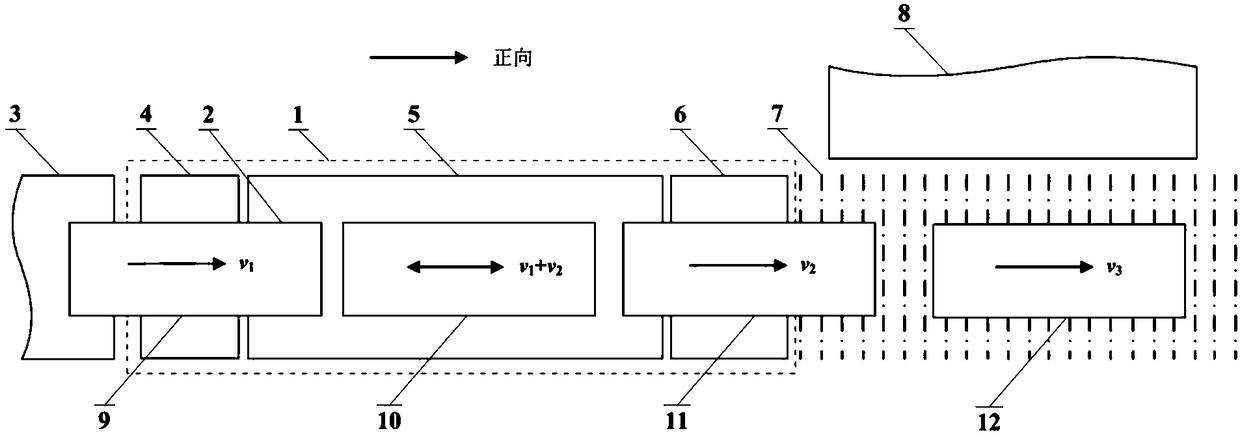

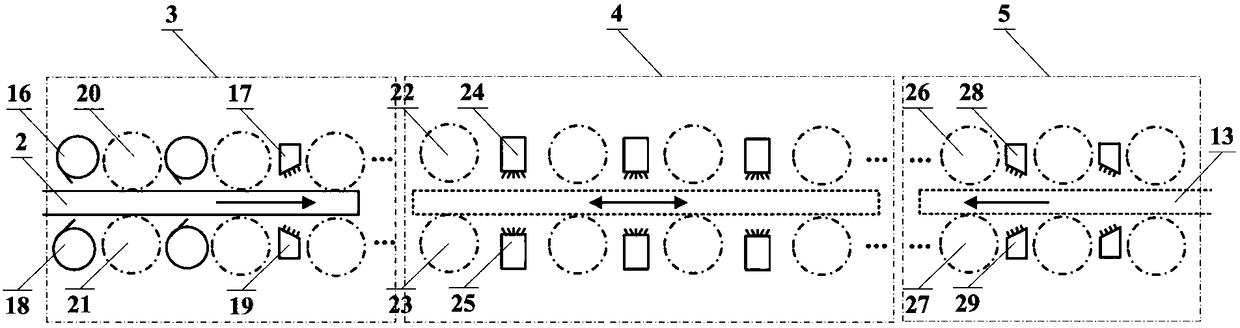

[0023] Embodiment 1, this embodiment provides a forward quenching method implementation process of the present invention, which can realize reverse quenching plate and strip roll quenching device and method, such as figure 1 , 3As shown, choose 6mm thick, 2500mm wide, 8m long plate and strip as an example to illustrate the implementation process. After the forward quenching plate strip 2 is heated to the process temperature in the roller hearth heat treatment furnace 3, the front high-pressure cooling zone 4 and the middle low-pressure cooling zone 5 of the roller quenching device 1 open the upper slit nozzle 16 and the lower slit nozzle in sequence according to the process regulations. Slit nozzles 18, multiple rows of round-hole inclined jet nozzles 17 on the front high-pressure cooling zone, multiple rows of round-hole inclined jet nozzles 19 on the lower front high-pressure cooling zone, upper rows of multi-angle arc-shaped round-hole jet nozzles 24, and lower rows Multi-...

Embodiment 2

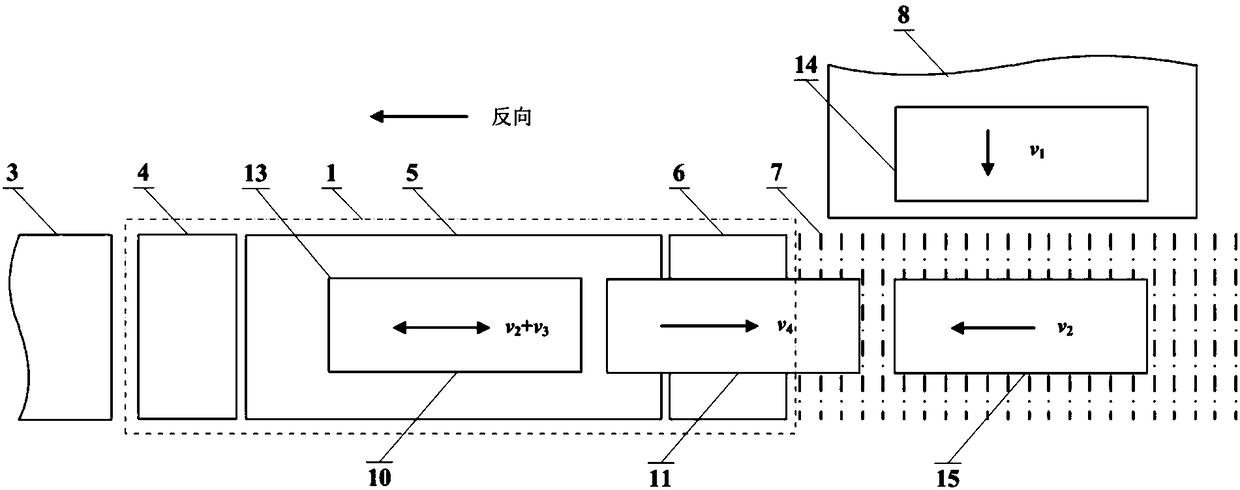

[0024] Embodiment 2. This embodiment provides a reverse quenching method implementation process of a plate and strip roll quenching device and method of the present invention that can realize reverse quenching, such as figure 2 , 3 As shown, choose 80mm thick, 2500mm wide, 8m long plate and strip as an example to illustrate the implementation process. After the reverse quenching plate strip 13 is heated to the process temperature in the external mechanized furnace 8, the rear high-pressure cooling zone 6 and the middle low-pressure cooling zone 5 of the roller quenching device 1 open multiple rows of round holes in the rear high-pressure cooling zone in sequence according to the process regulations Inclined jet nozzles 28, multiple rows of round-hole oblique jet nozzles 29 in the rear high-pressure cooling zone, upper rows of multi-angle arc-shaped round-hole jet nozzles 24, lower rows of multi-angle arc-surface round-hole jet nozzles 25, and upper slit nozzles 16. The lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com