Patents

Literature

78results about How to "Expanded range of specifications" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

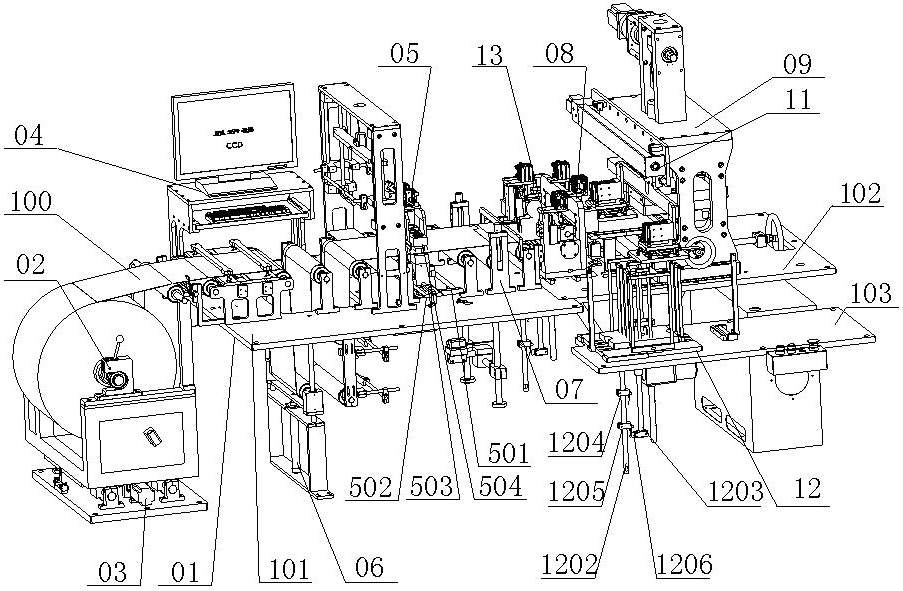

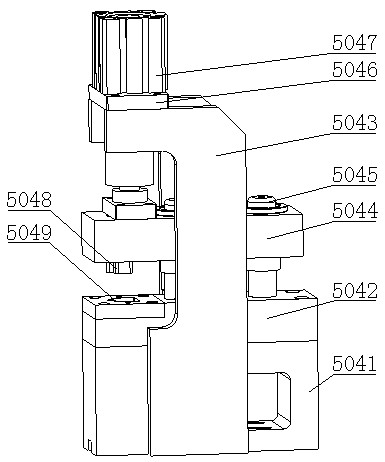

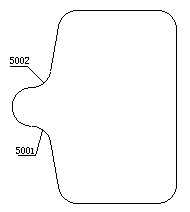

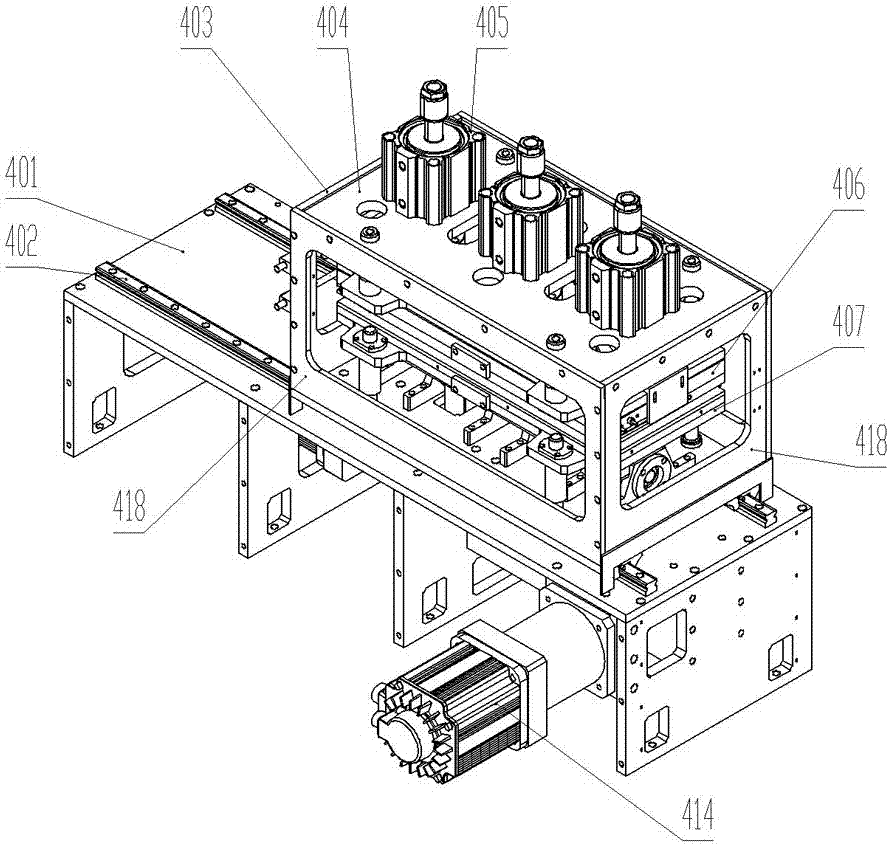

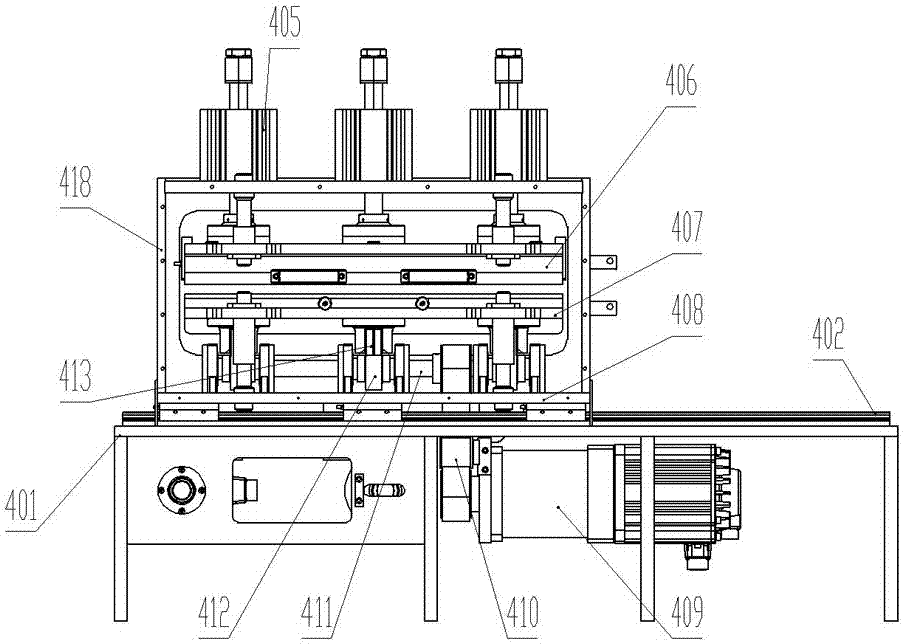

Electrode sheet forming machine

ActiveCN102306744AReduce manufacturing costExpanded range of specificationsElectrode manufacturing processesMetal-working feeding devicesPunchingAgricultural engineering

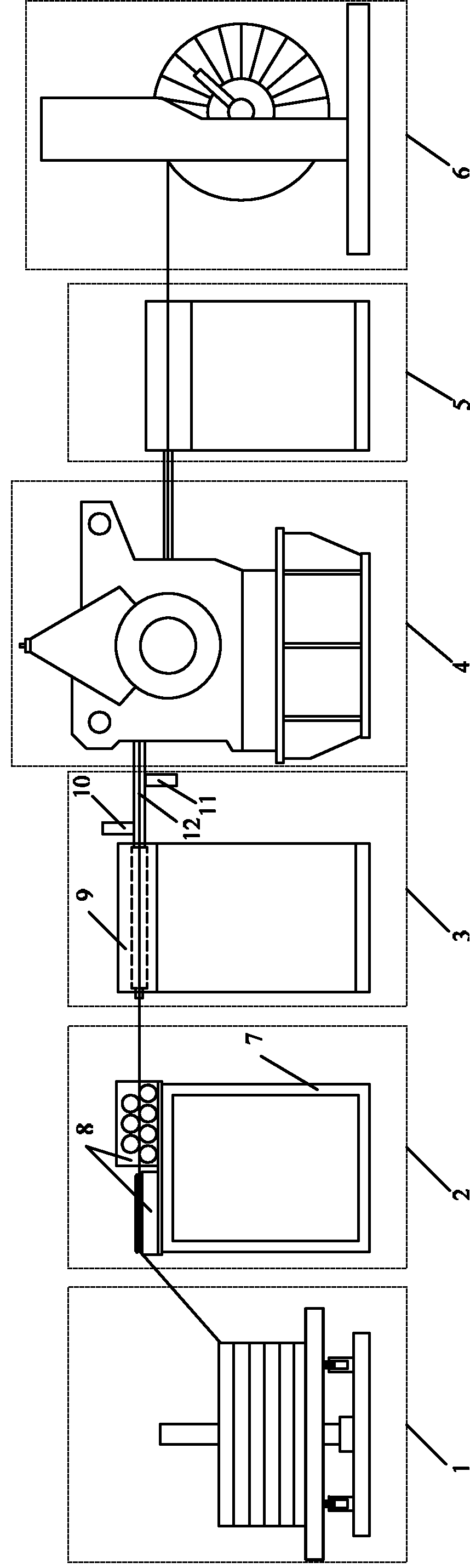

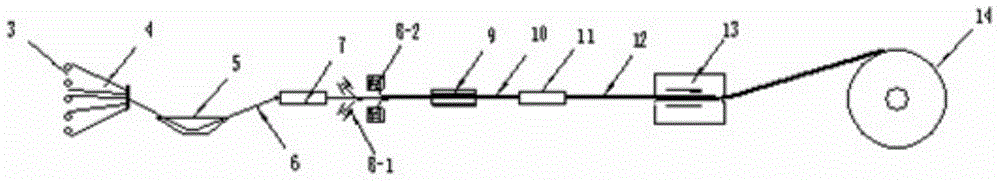

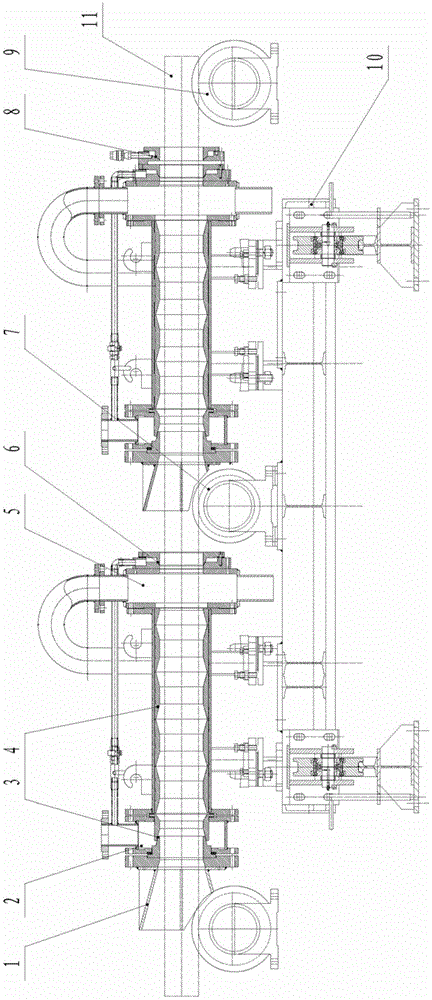

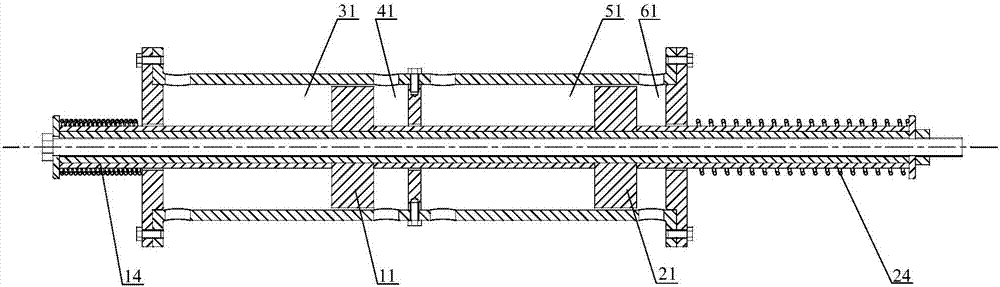

The present invention discloses an electrode sheet forming machine. The electrode sheet forming machine comprises a support mechanism, an unwinding mechanism, an unwinding rectification mechanism, an unwinding traction mechanism, a tension mechanism, a forming mechanism and a material collecting mechanism. The electrode sheet forming machine is characterized in that: the forming mechanism comprises a chamfer clipping mechanism, a constant length cutting mechanism and an electrode lug punching mechanism, wherein the chamfer clipping mechanism, the constant length cutting mechanism and the electrode lug punching mechanism are sequentially arranged on an electrode sheet belt in an unwinding direction; the chamfer clipping mechanism is provided for carrying out clipping for both sides of the electrode sheet belt to form the chamfer of each single electrode sheet, the constant length cutting mechanism is provided for carrying out constant length cutting for the electrode sheet belt to formthe single electrode sheet, the electrode lug punching mechanism is provided for punching the electrode lug of the single electrode sheet. Compare to the prior art, with the present invention, the die cost is saved.

Owner:深圳市和合自动化有限公司

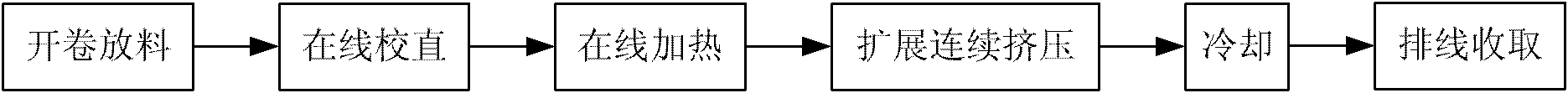

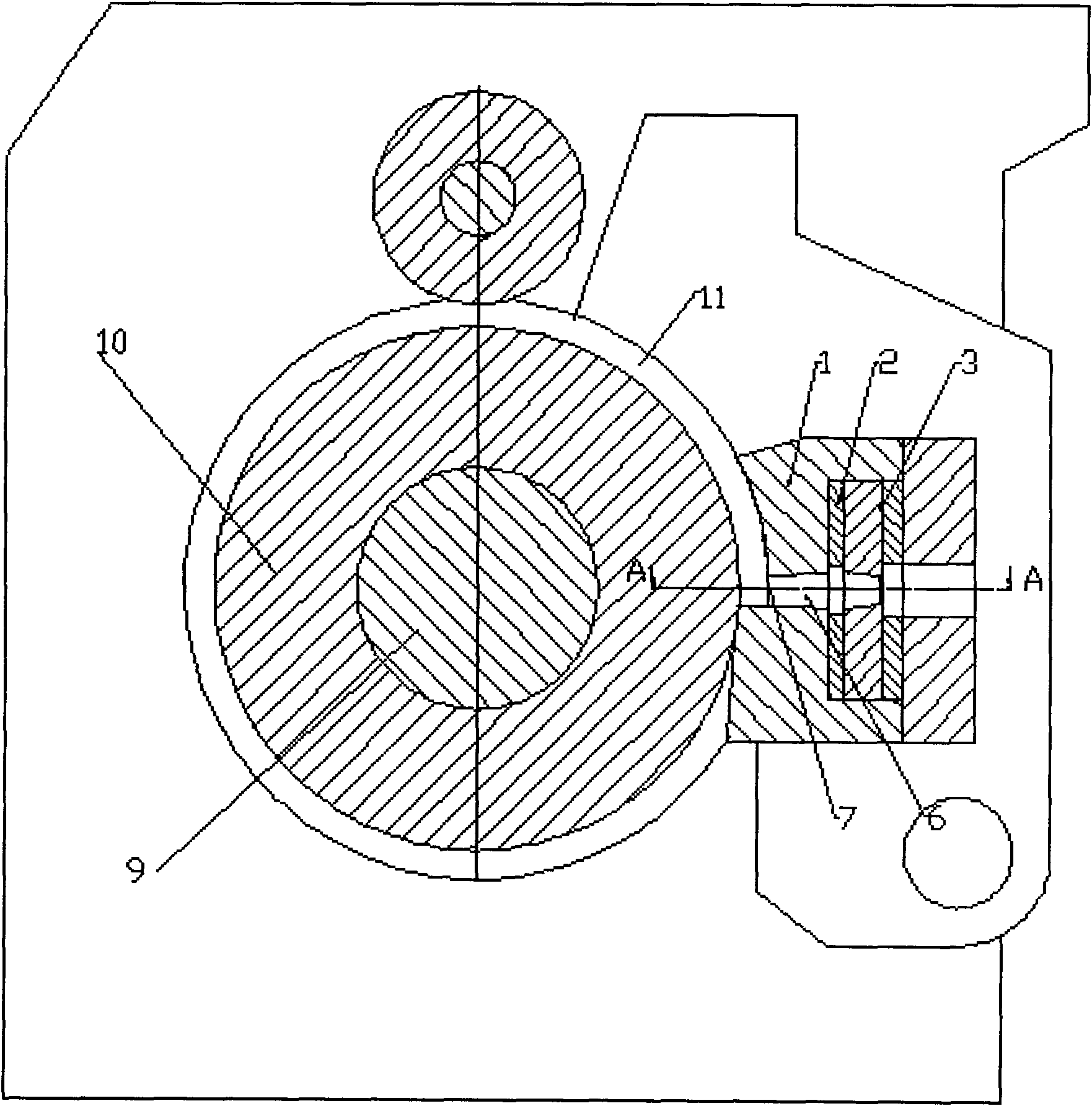

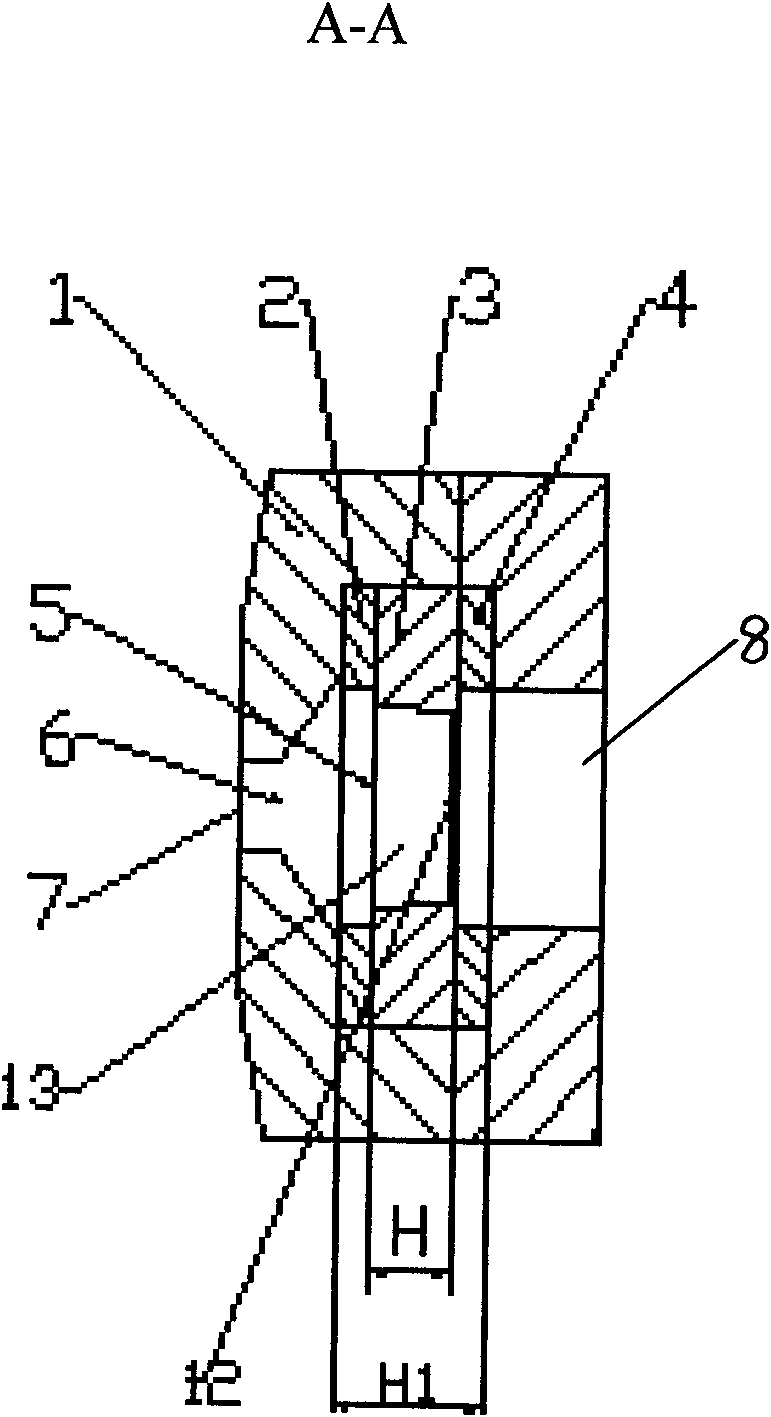

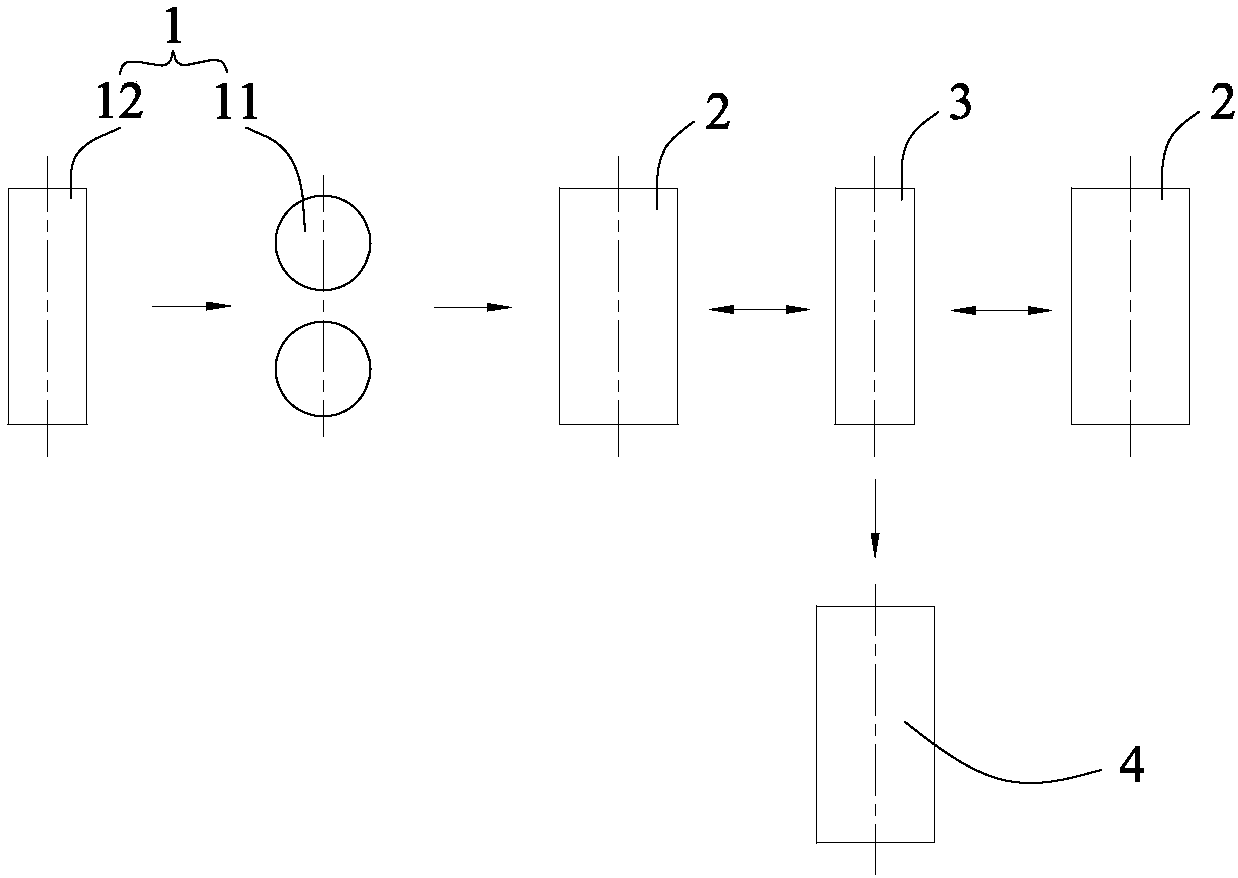

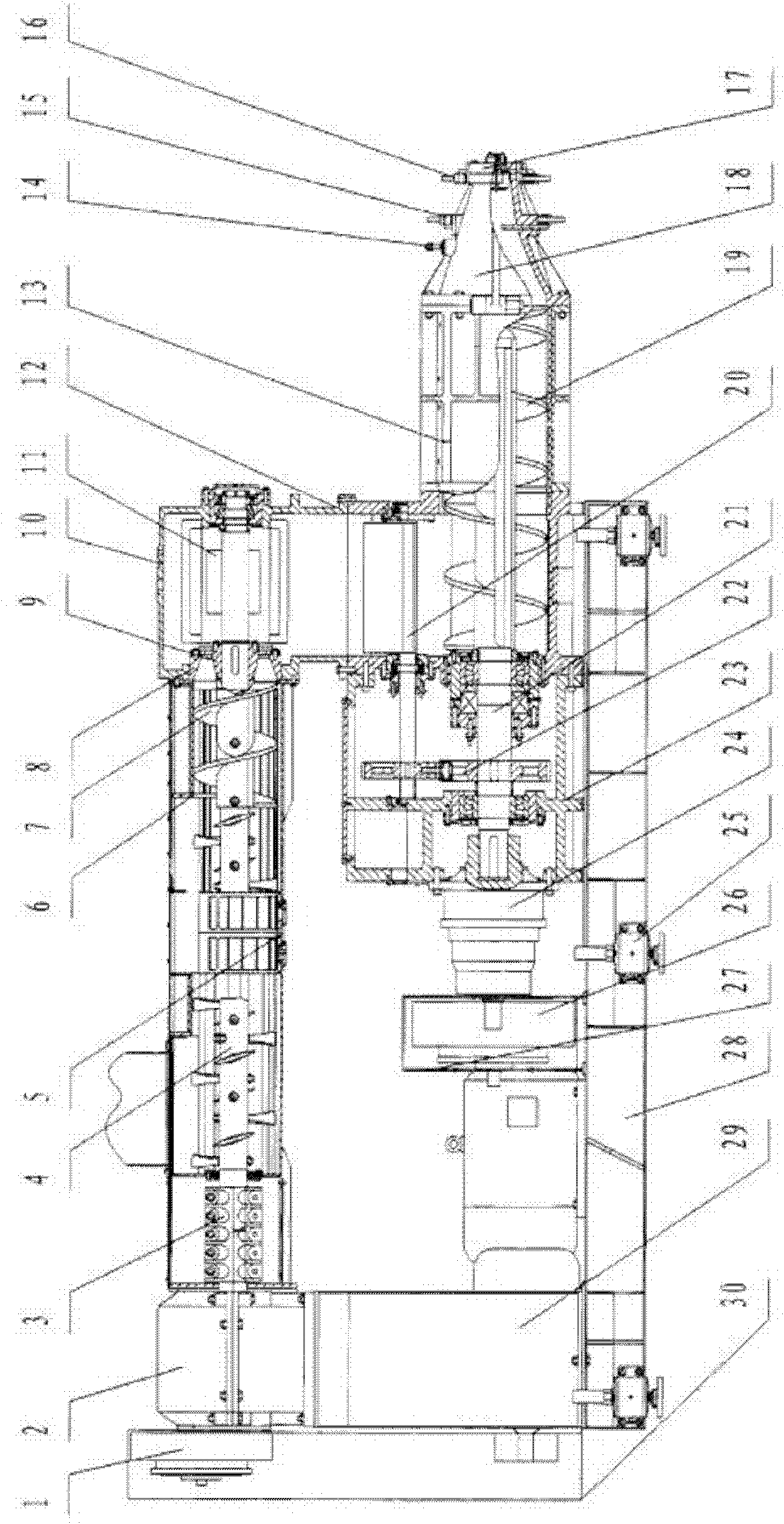

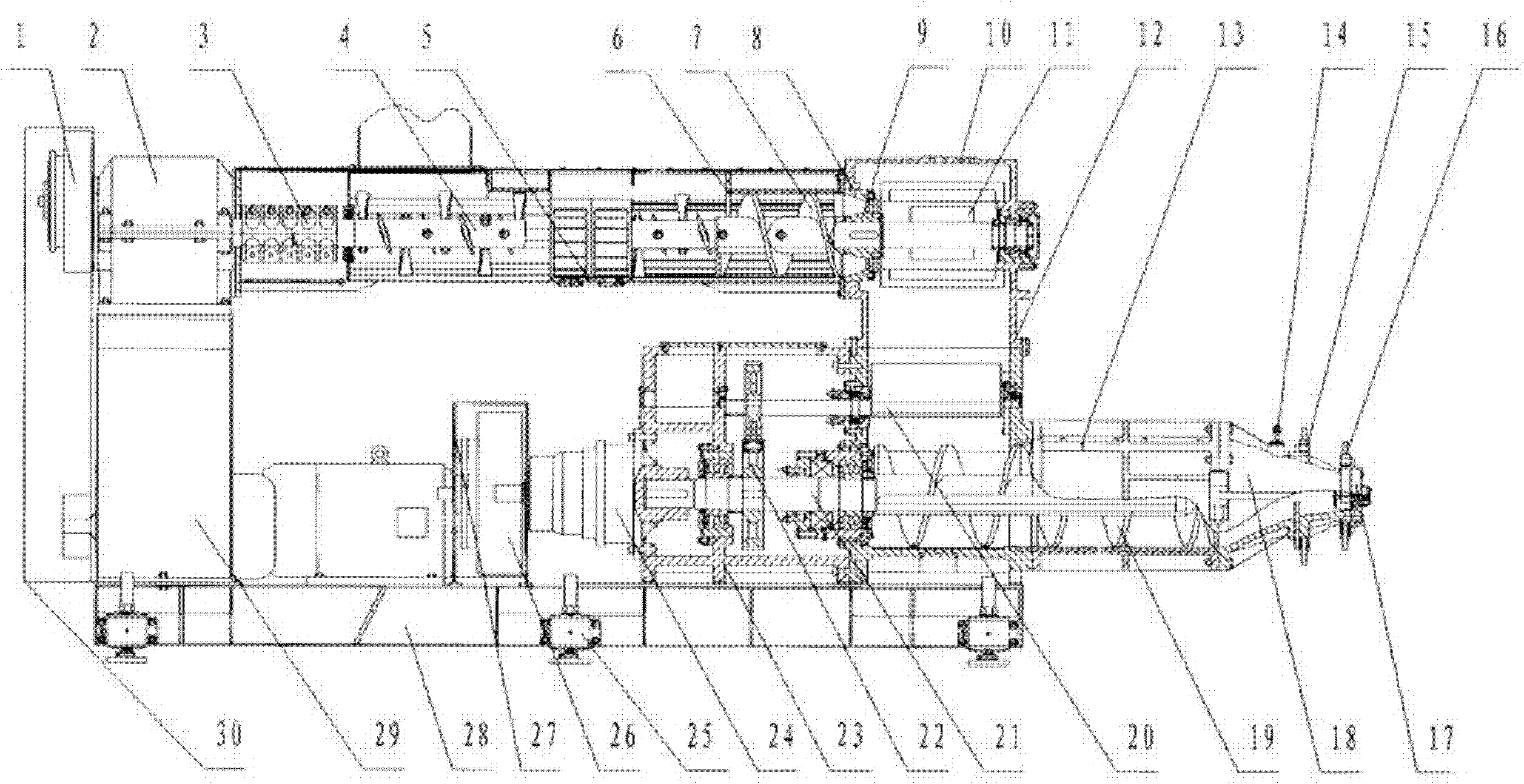

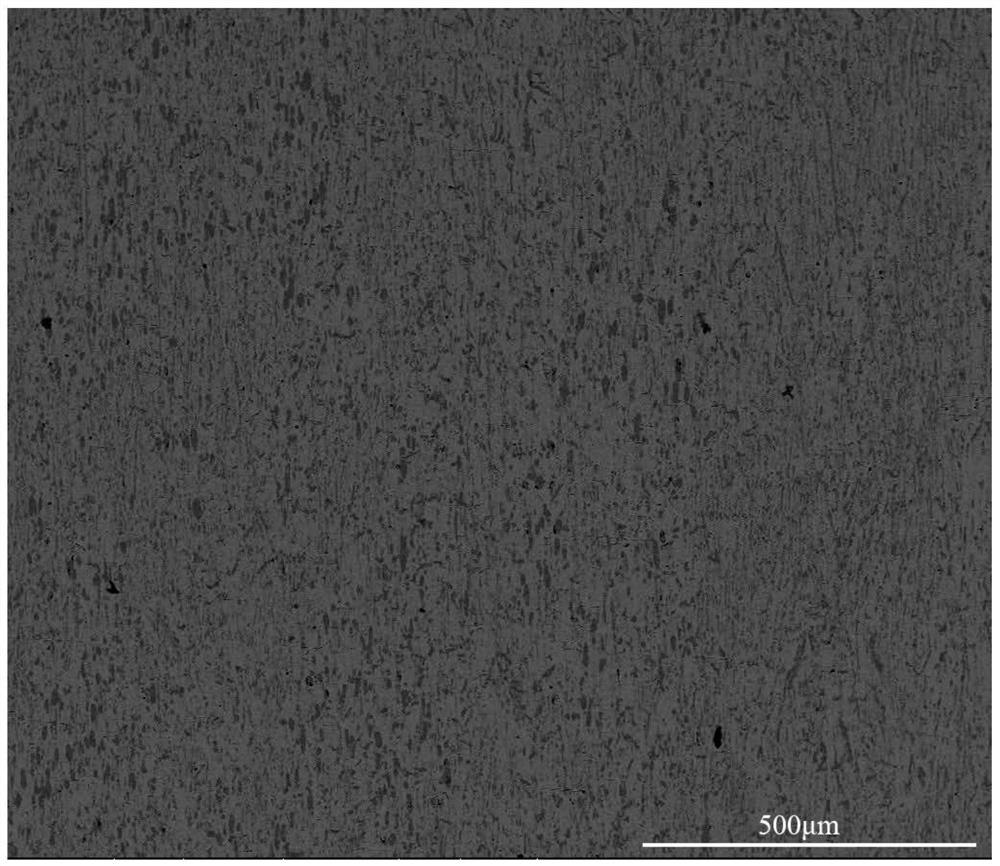

System and method for continuous extrusion production of fine-grain magnesium alloy strip

ActiveCN102688907AShort processIncrease productivityExtrusion control devicesProduction lineLine heating

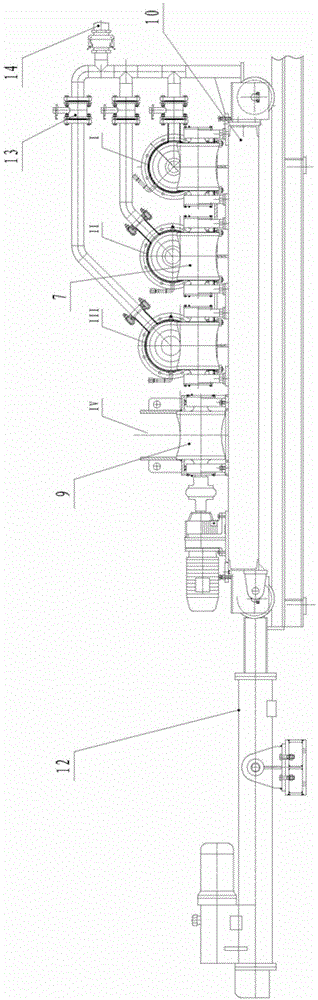

The invention discloses a system and a method for continuous extrusion production of a fine-grain magnesium alloy strip. The system comprises a decoiling emptying device, an on-line straightening device, an on-line heating device, a continuous extrusion device, a cooling device and a winding displacement collection device. Through control of a temperature of a rod, a good extrusion driving force is produced between the rod and an extrusion wheel groove. Through an expansion mold cavity and a flow-blocking mold, magnesium alloy expansion flowing in a width direction is realized. In order to extrude a plate having larger width, the system adopts a two / three rod feeding-type extrusion mode so that joining and intermetallic welding of multiple rods in a corresponding multi-rod mold cavity are realized. The system and the method have the advantages that a process route is short; production efficiency is high; a grain refinement degree of a product microstructure is high; plate formability is good; and a continuous production line provided by the invention is suitable for industrial application.

Owner:DALIAN JIAOTONG UNIVERSITY

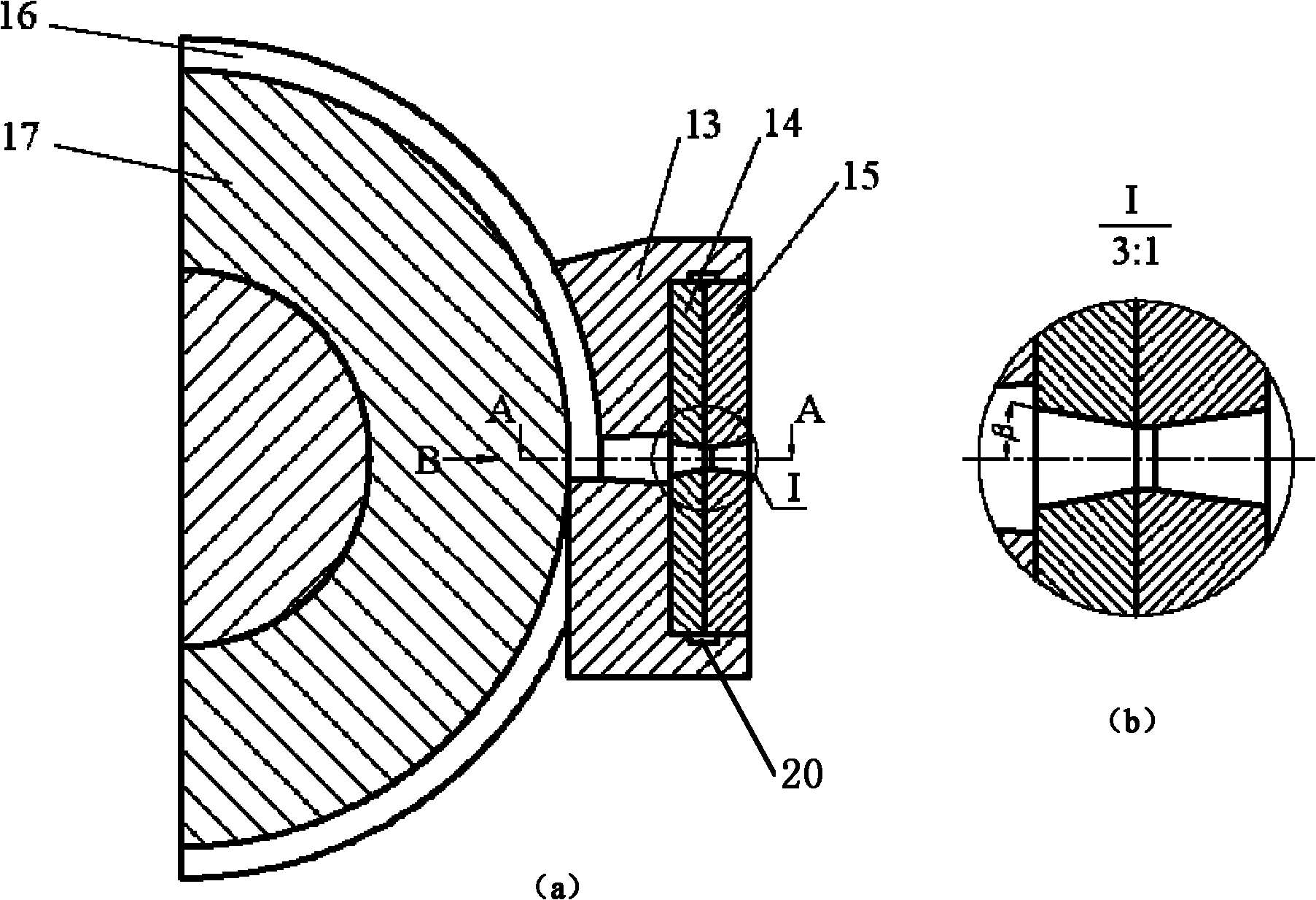

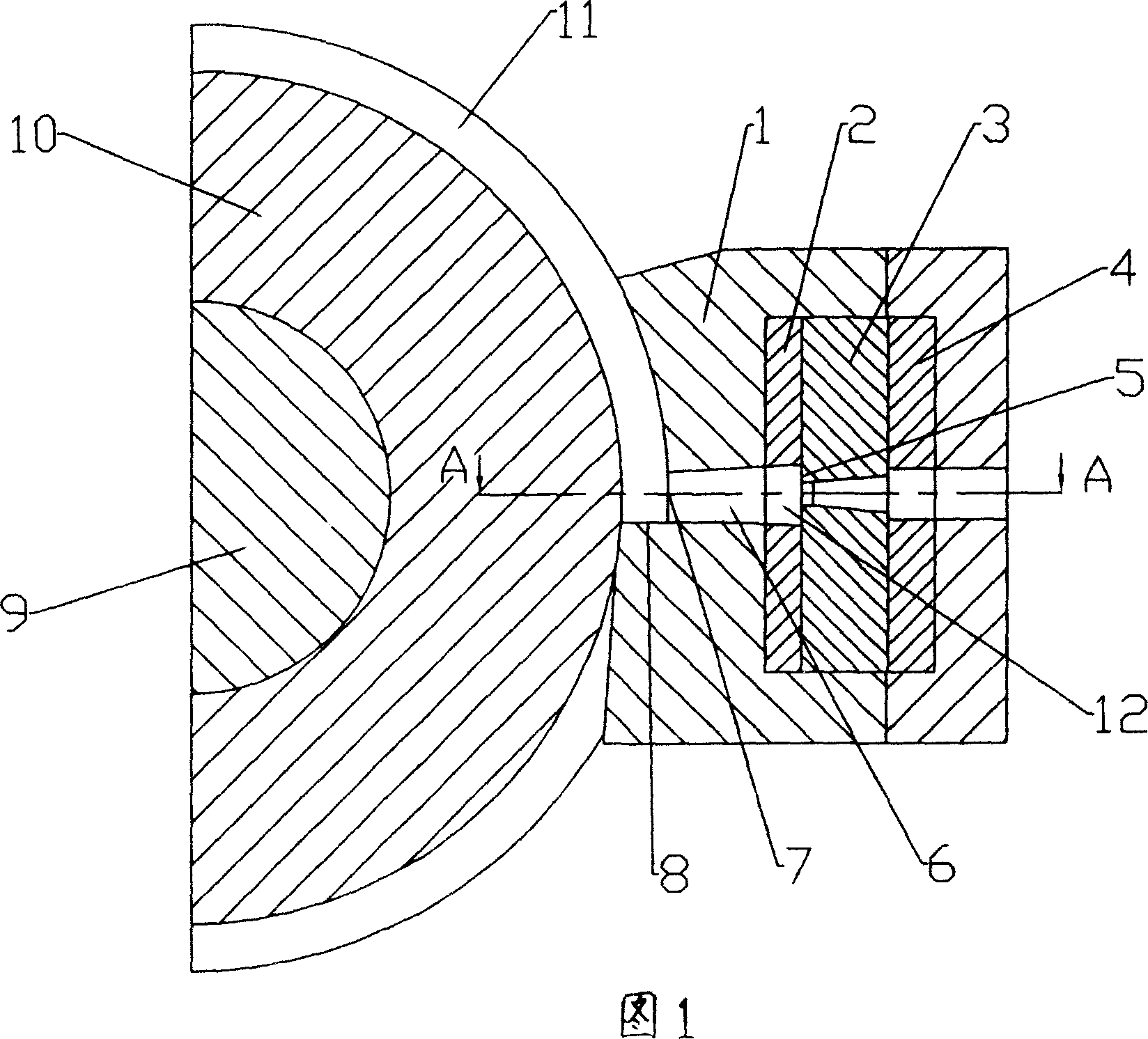

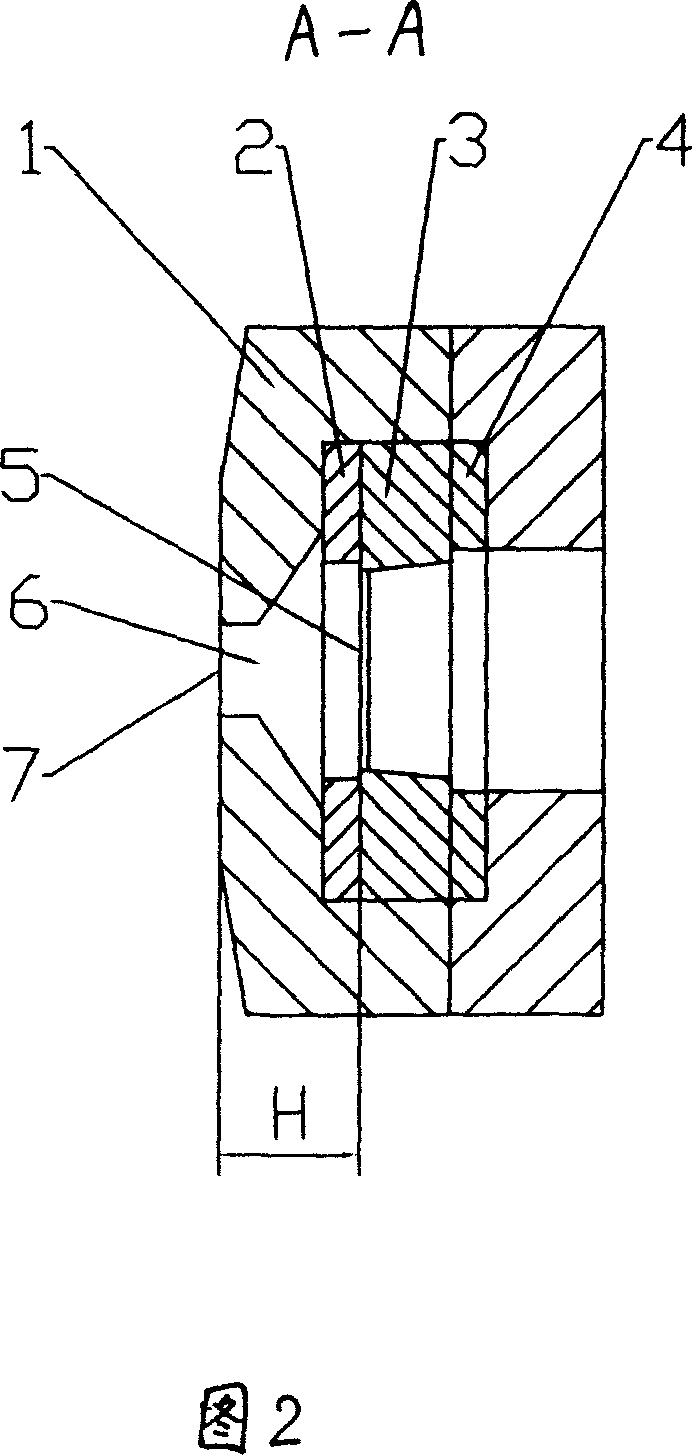

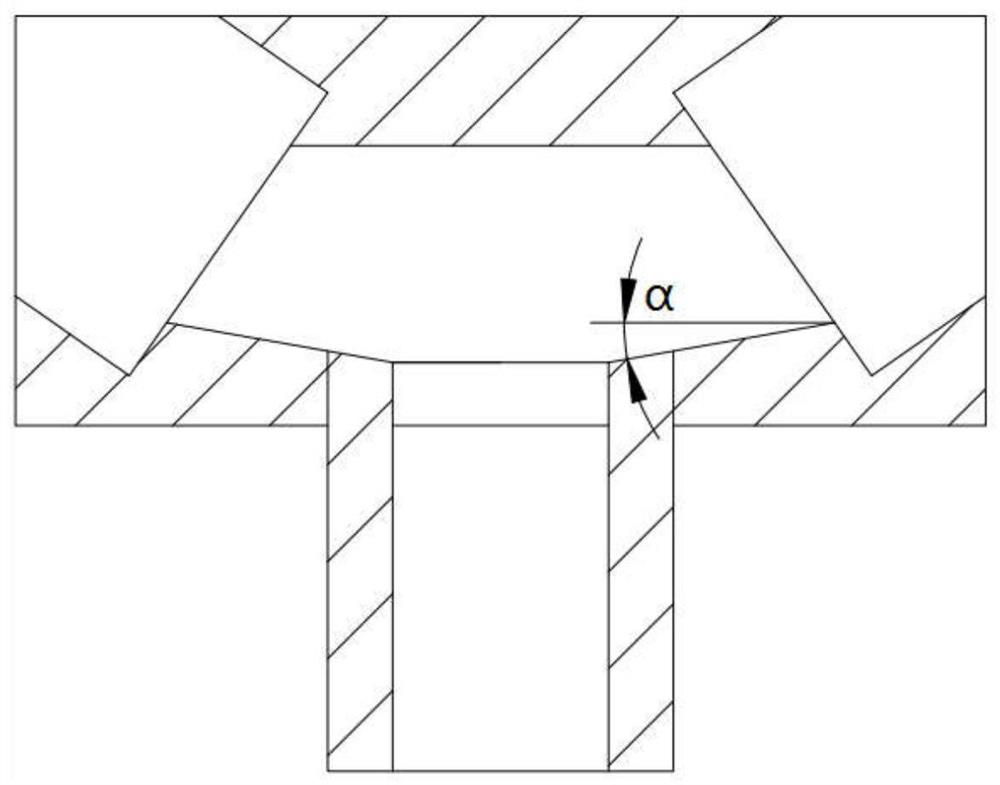

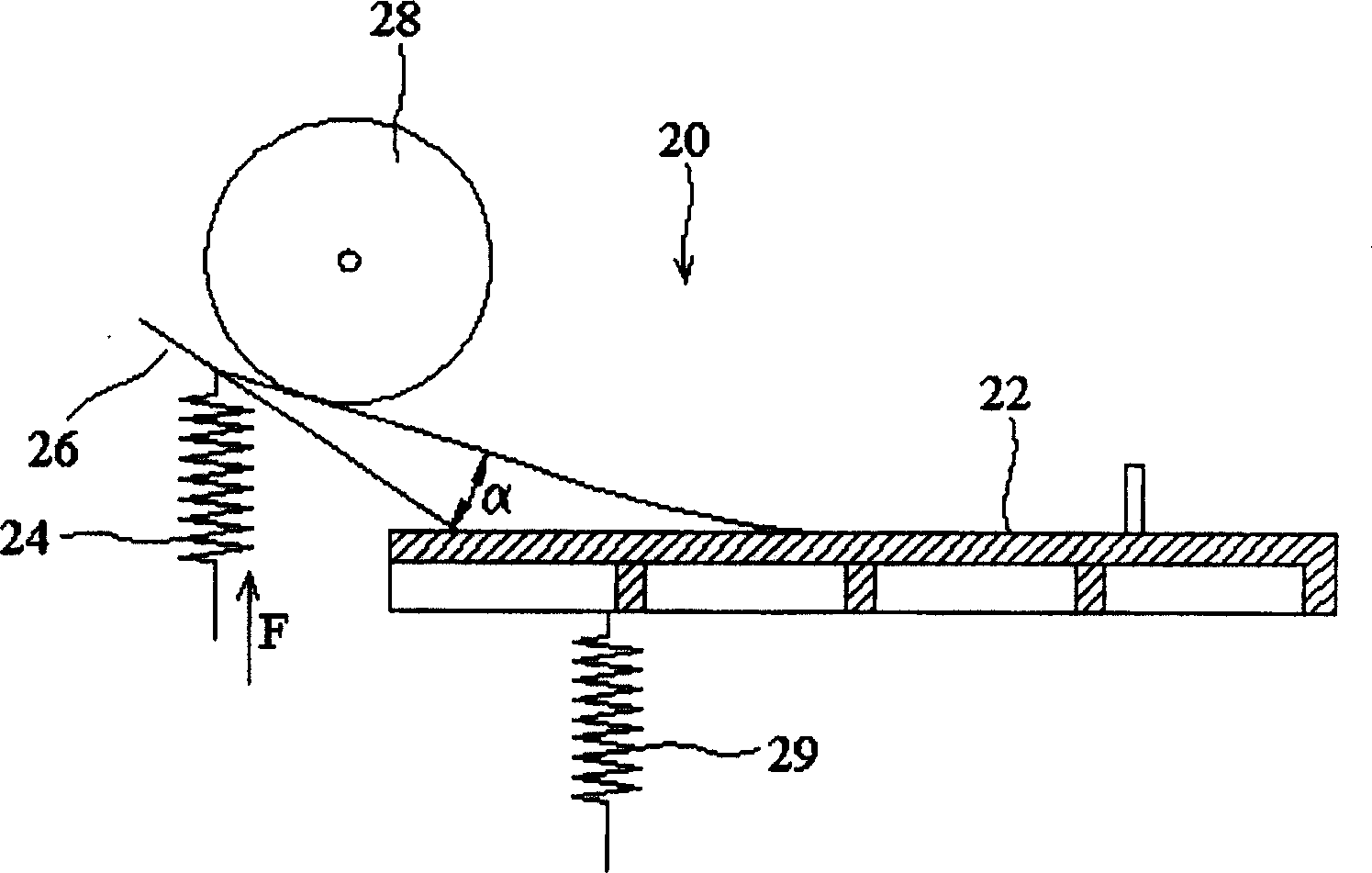

Continuous extrusion method of stacked assembling die with reversed cone angle and equipment

InactiveCN101607271AReduce manufacturing costReduce the temperatureExtrusion diesEngineeringEnergy expenditure

The invention relates to a metal continuous extrusion method, in particular to a continuous extrusion method of a stacked assembling die with a reversed cone angle. The height of the die assembly of the related die with a reversed cone angel is not changed, after blank material enters the die assembly, the sectional area of an extrusion product is maximally nine times larger than that of the blank material, and the height of the die with a reversed cone angle is shortened as much as possible. In the invention, the extrusion force and energy consumption in extrusion are reduced to the greatest extent in the condition of guaranteeing a required size of expanding extrusion, product quality and product forming. The die has a reversed cone angle, and the reversed cone angle can increase the lateral spreading flowing capacity of the blank material in the die. The range of the size of a product produced in a cavity with the same specification is enlarged greatly, and a product with a larger size can be produced by a small machine, so that the service life and the production efficiency of the cavity are improved greatly, and the product with the same size produced by the method consumes less electric energy.

Owner:大连康丰科技有限公司

Method for manufacturing multiunit tube

InactiveCN101234406AExpanded range of specificationsSuitable for piping requirementsShaping toolsRigid pipesCondensation processPapermaking

The invention pertains to a manufacturing method of disclosed composite pipe, which comprises: an inner pipe (compound layer) adopts stainless steel material and an outer pipe (base layer) adopts carbon steel material, the inner pipe is arranged in the outer pipe, pull / push method is adopted and the function of a formed die is matched to cause the inner pipe and the outer pipe to generate plastic deformation of equal-wall thickness and to compound together in the condensation process. The bimetal composite pipe produced by the manufacturing process can replace stainless steel pipe, non-ferrous metal pipe and various plastics-steel composite pipes and have the same corrosion prevention performance; furthermore, the bimetal composite pipe can also act parts in reducing construction cost of the product, improving working strength, extending application temperature range, improving solderability, facilitating construction, etc., which is widely used in the industries such as petroleum, chemical engineering, electric power, papermaking, medication, food, etc.

Owner:偃师市安力电力设备有限公司

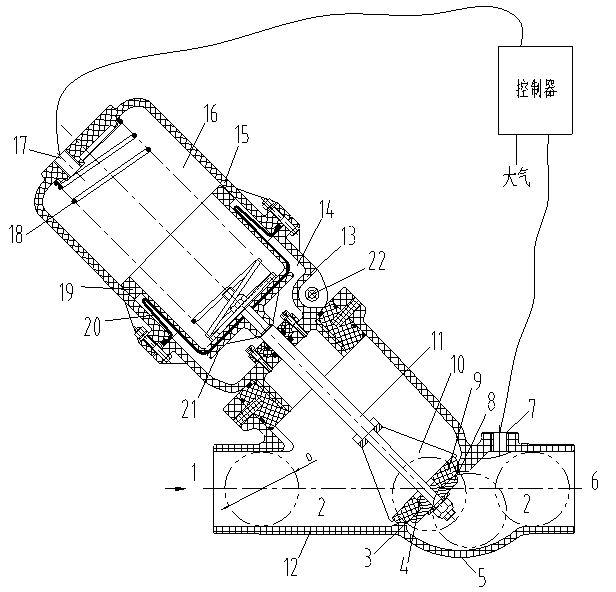

Vacuum angle seat valve

ActiveCN101806365ASave resourcesOpen and close quicklyOperating means/releasing devices for valvesLift valveResource savingEngineering

The invention relates to a vacuum angle seat valve which comprises a valve body; one end of the valve body is provided with an inlet, and the other end thereof is provided with an outlet; a valve seat is arranged between the inlet and the outlet; a valve core and the valve seat are arranged in a sealing way; the valve core is connected with a valve rod; after the valve rod passes through a free chamber, the rail end of the valve rod is arranged in a control chamber, and the valve rod is also connected with a reset device; the control chamber is connected with the valve body through the free chamber; a sealing device is arranged between the control chamber and the free chamber; simultaneously, the valve body and the free chamber are separated in the sealing way; and the control chamber is provided with a control chamber interface, the outlet is provided with a vacuum taking port, and the control chamber interface and the vacuum taking port are connected with a vacuum controller. The vacuum angle seat valve is characterized by resource saving, quick on and off, good sealing, no easy blockage, low price, light weight and relatively better reliability and maintenance.

Owner:JIANGSU CRRC ENVIRONMENT CO LTD

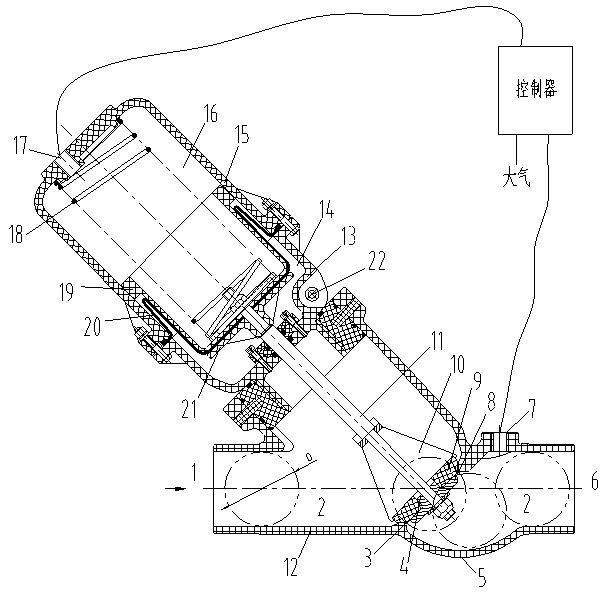

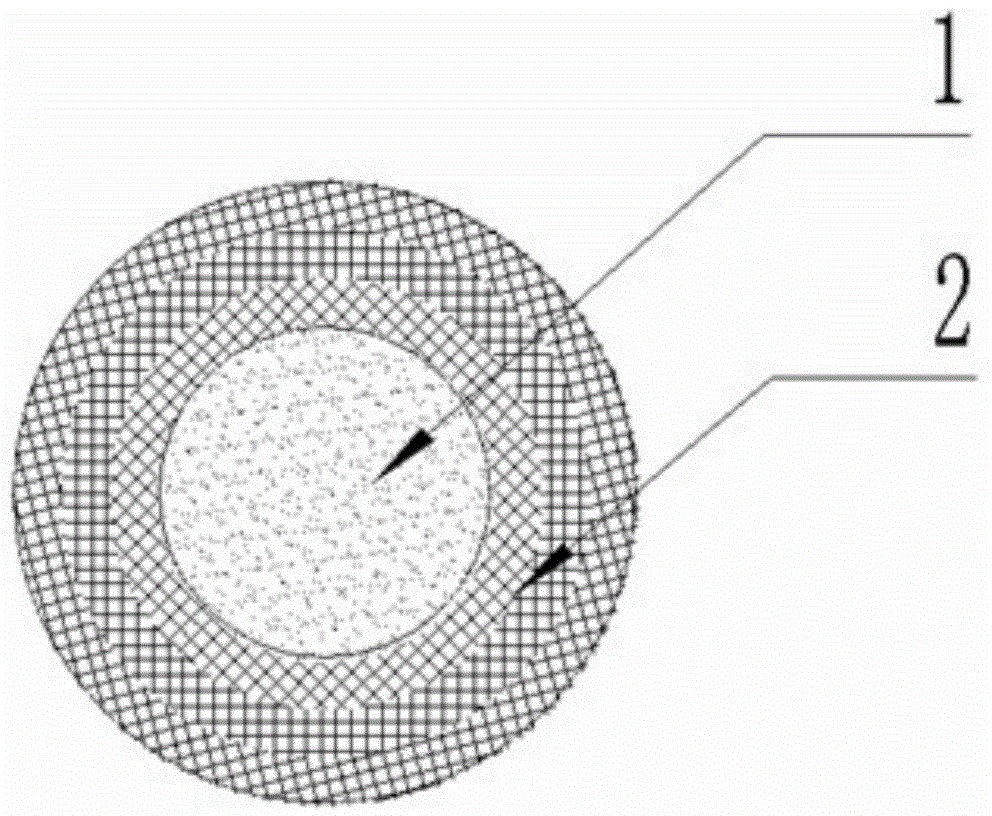

Modified composite core rod and manufacturing method thereof

ActiveCN104008798AImprove flexibilityEasy to passInsulated cablesCable/conductor manufactureResin-Based CompositeOptoelectronics

The invention discloses a modified composite core rod and a manufacturing method thereof. The composite core rod comprises an inner fiber core, an outer fiber layer wound or / and braided or / and longitudinally wrapped outside the inner core, and thermosetting or thermoplastic high temperature-resistant resin uniformly embedded into the inner fiber core and the outer fiber layer. The inner fiber core is composed of a plurality of longitudinal fibers, and the outer diameter is 5.0-11.0mm. The outer fiber layer includes at least two layers. The inner fiber core and the outer fiber layer are cured by the resin to form an integral body. The outer diameter of the composite core rod is 10.0-20.0mm. The Tg of the high temperature-resistant resin is higher than or equal to 90 DEG C, and the volume fraction of the resin is 25-40%. The invention mainly provides a solution for the problem that a conventional fiber-reinforced resin-based composite core rod has low tensile strength and poor bending performance and the cross section of the composite core rod cannot be too large. The bending performance of the composite core rod is improved, the specification range of the composite core rod is expanded, and the tensile strength of the composite core rod is improved. The composite core rod can meet the requirements of transmission lines in harsh environments such as large-span areas and strong-wind areas.

Owner:FAR EAST CABLE +2

Production system for H-shaped steel

ActiveCN107695094ASmall elongation coefficientImprove biteMetal rolling arrangementsStrip millMaterials science

The invention provides a production system for H-shaped steel. The production system comprises a rough rolling unit, X-hole-shaped universal rolling mills, edging mills and an H-hole-shaped universalrolling mill. The rough rolling unit is used for rolling continuous casting billets for producing the H-shaped steel into intermediate billet materials first. Each X-hole-shaped universal rolling millcomprises two second horizontal rolls and two second vertical rolls, and an X-shaped rolling hole is formed between each two second horizontal rolls and the corresponding two second vertical rolls. When the intermediate billet materials rolled by the rough rolling unit enter the X-shaped rolling hole of each X-hole-shaped universal rolling mill, the corresponding two second horizontal rolls rollwebs of the billet materials, then the corresponding two second horizontal rolls and the corresponding two second vertical rolls roll the webs and flanges of the billet materials, and X-shaped billetmaterials are rolled. The X-shaped billet materials obtained after rolling of the X-hole-shaped universal rolling mills enter the edging mills, and the edging mills roll the flanges of the X-shaped billet materials to adjust the width of the flanges. The H-hole-shaped universal rolling mill is used for rolling the X-shaped billet materials rolled by the edging mills into the H-shaped steel.

Owner:刘庚申 +1

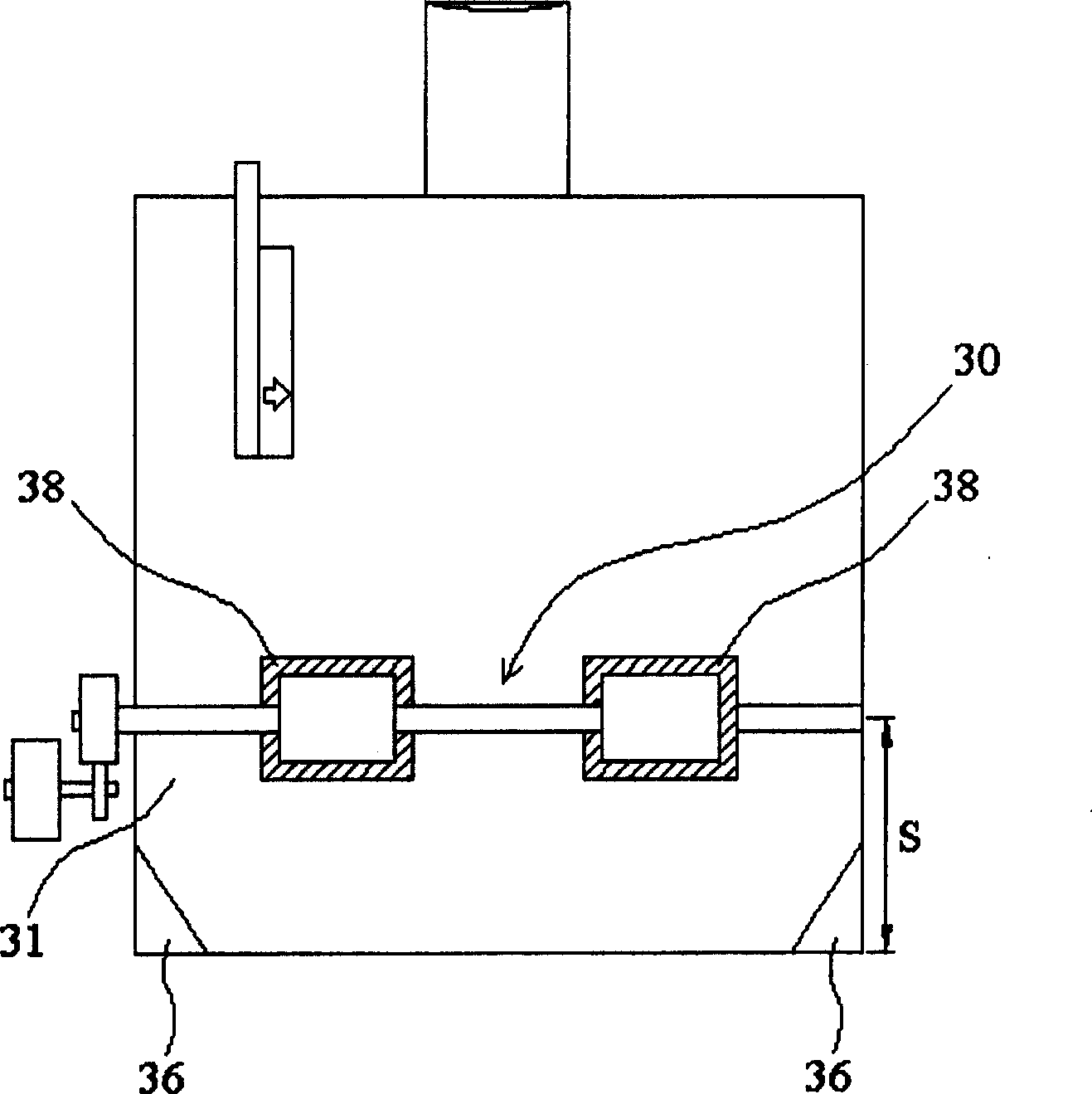

Continuous extruding method with pre-moulding and special device

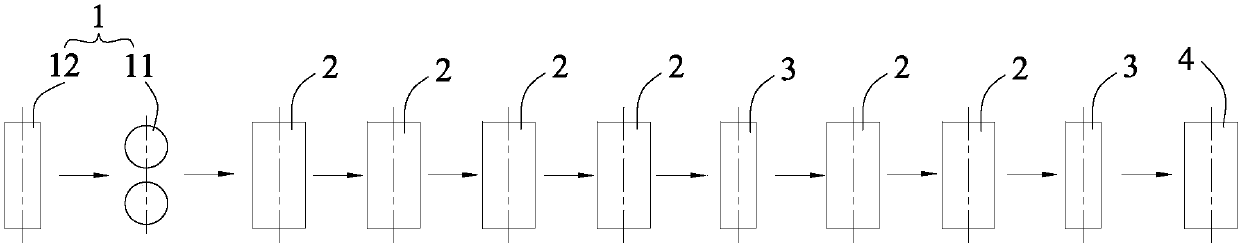

InactiveCN1943892AExtended service lifeIncrease productivityExtrusion diesRams/plungersSize changeEngineering

The present invention relates to metal extruding method, and is especially continuous extrusion method with pre-formation. The method is that the blank after entering into the feeding port of the cavity is first preformed and then extruded into the product. Before the extruding mold, there is one performing area in sizes changing with the sizes of the extruded products. The present invention makes it possible to obtain products of different sizes in the same cavity, to reduce the load on the cavity, lower the temperature of cavity stopper, raise the production efficiency of the cavity and increase the service life of the cavity greatly.

Owner:大连康丰科技有限公司

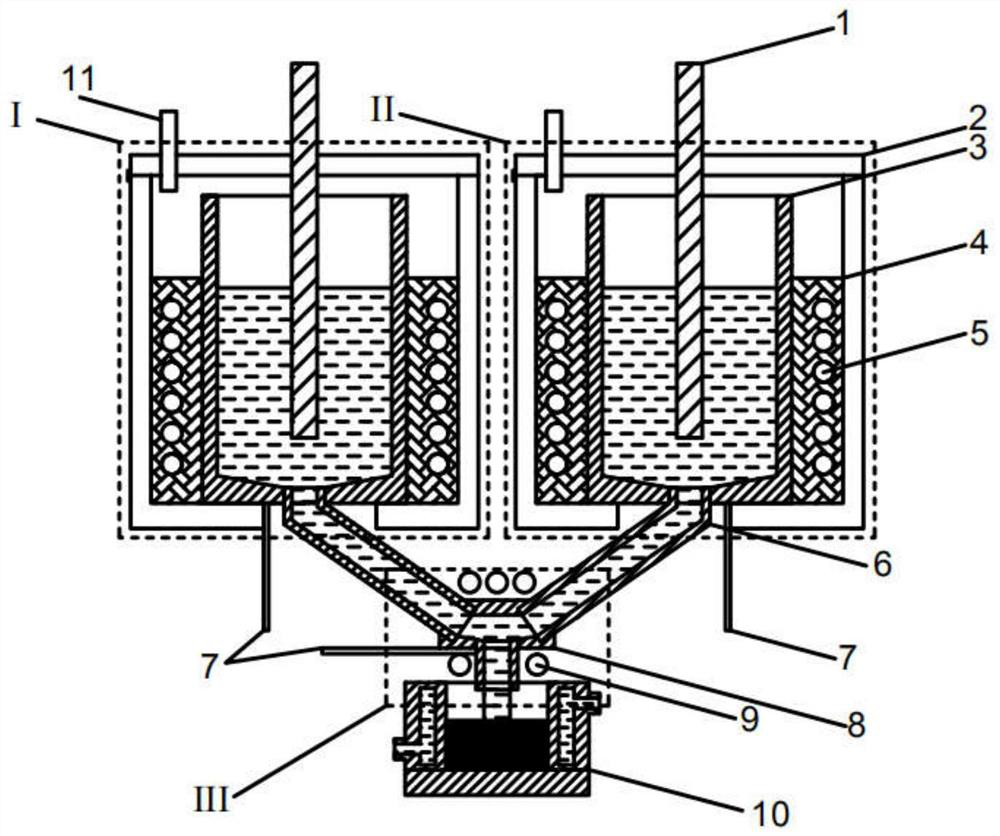

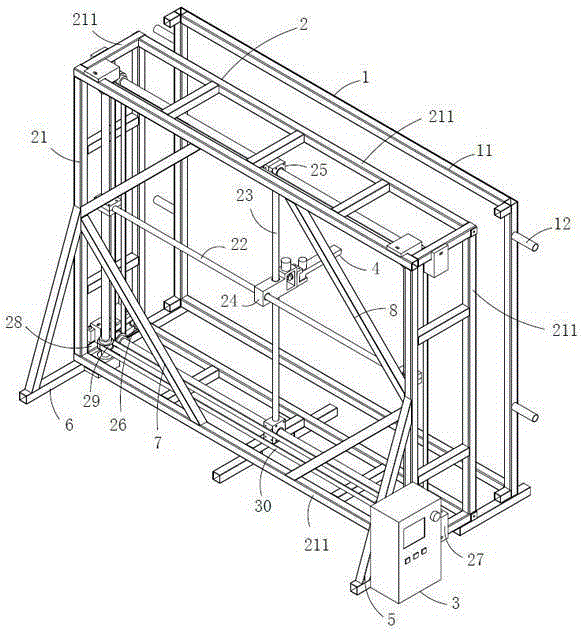

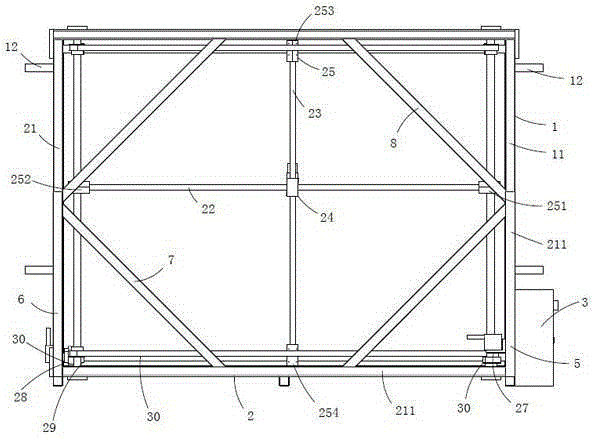

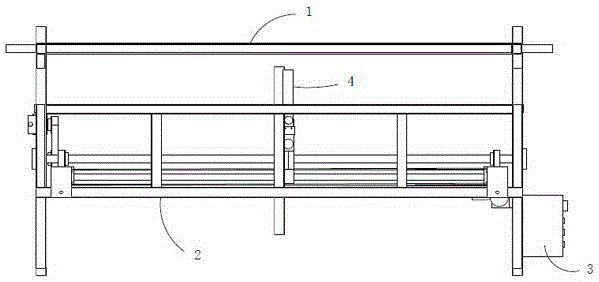

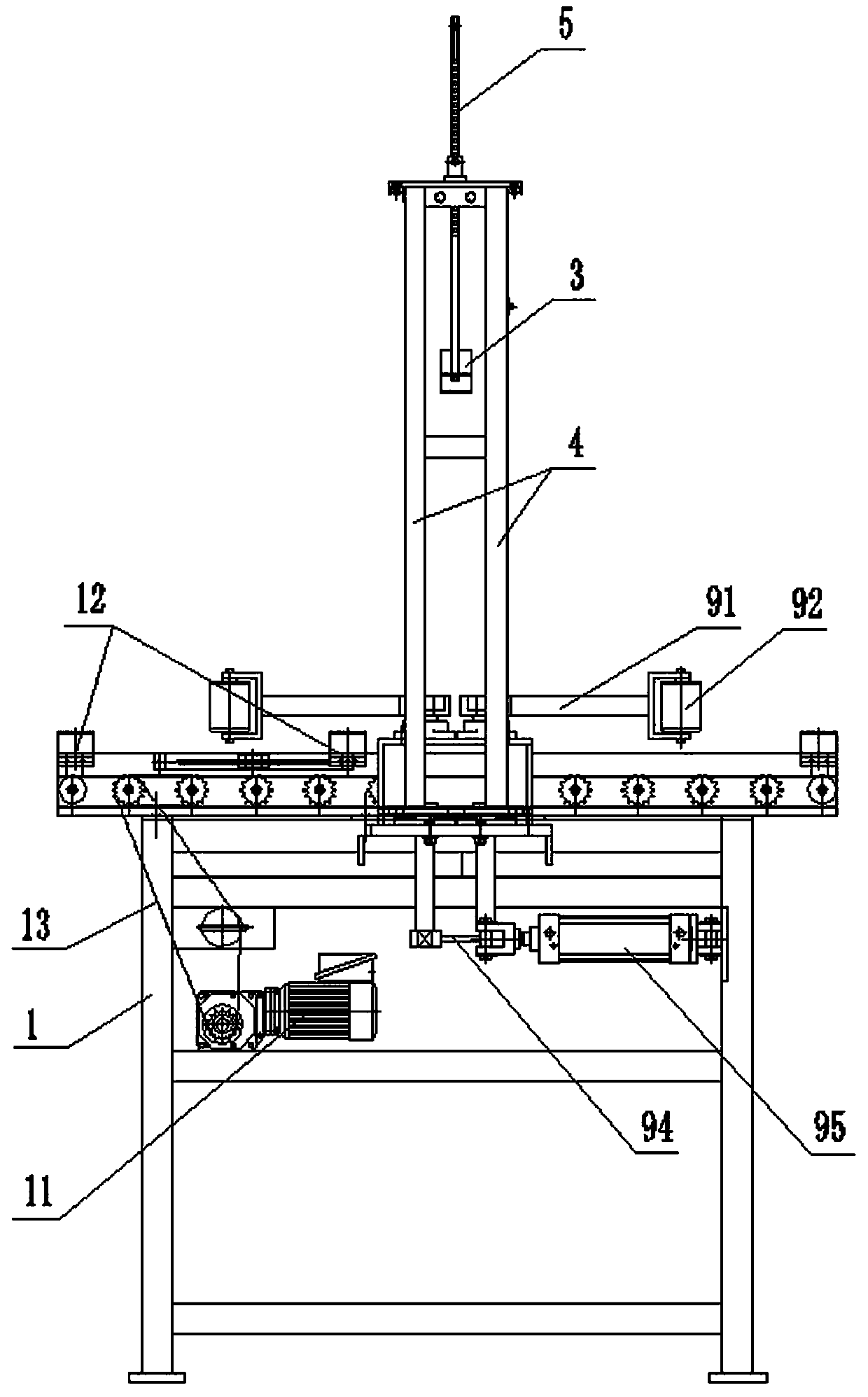

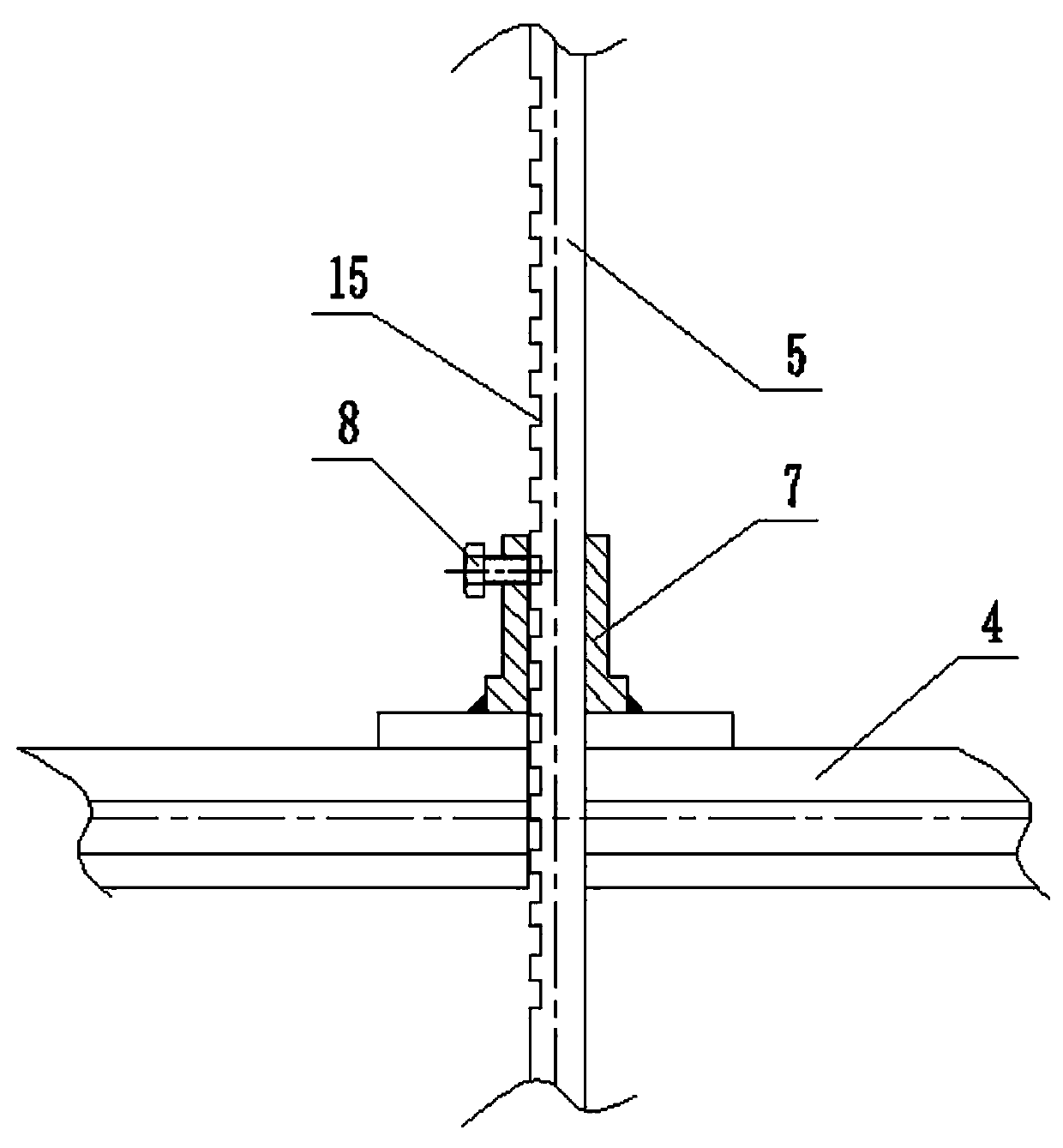

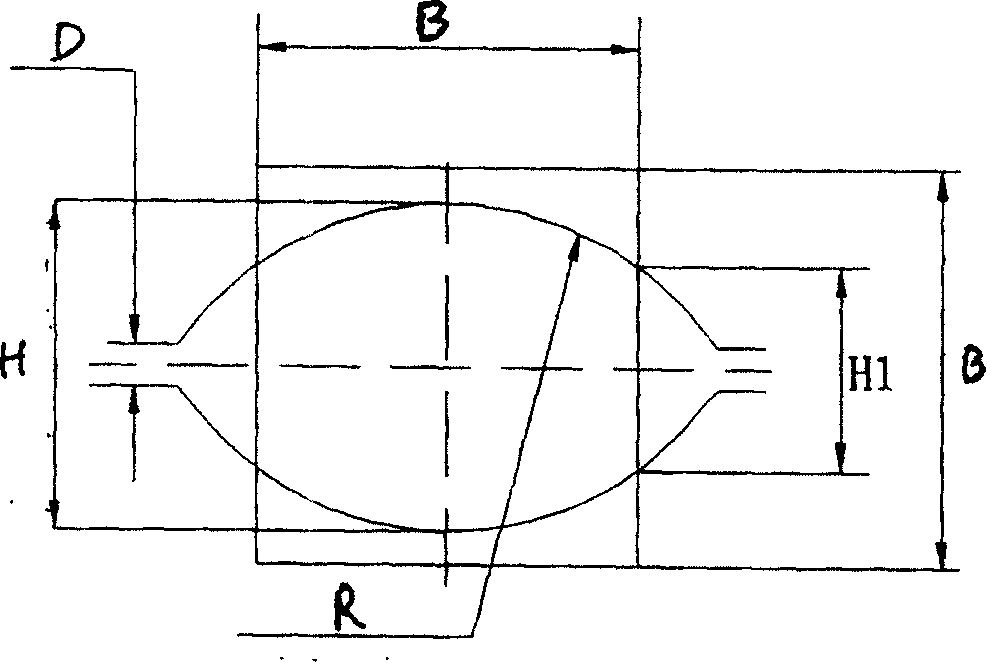

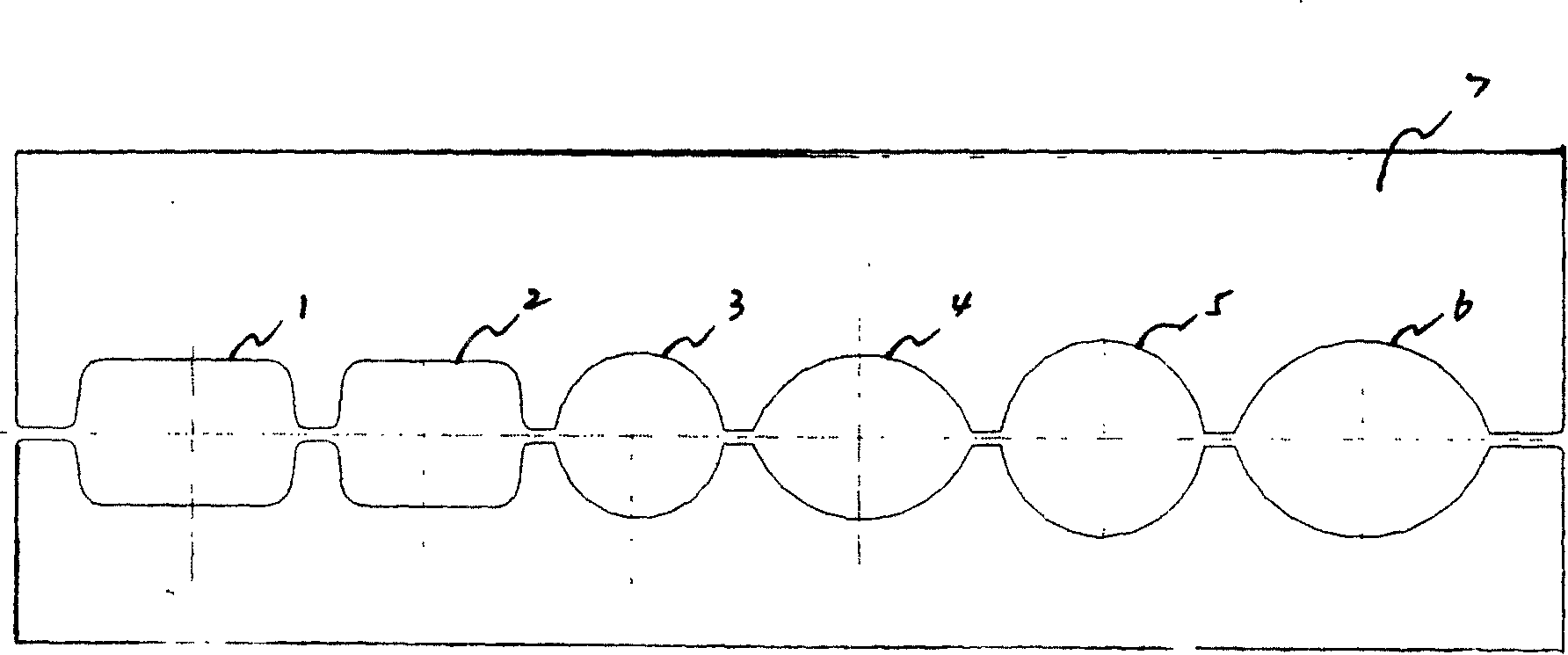

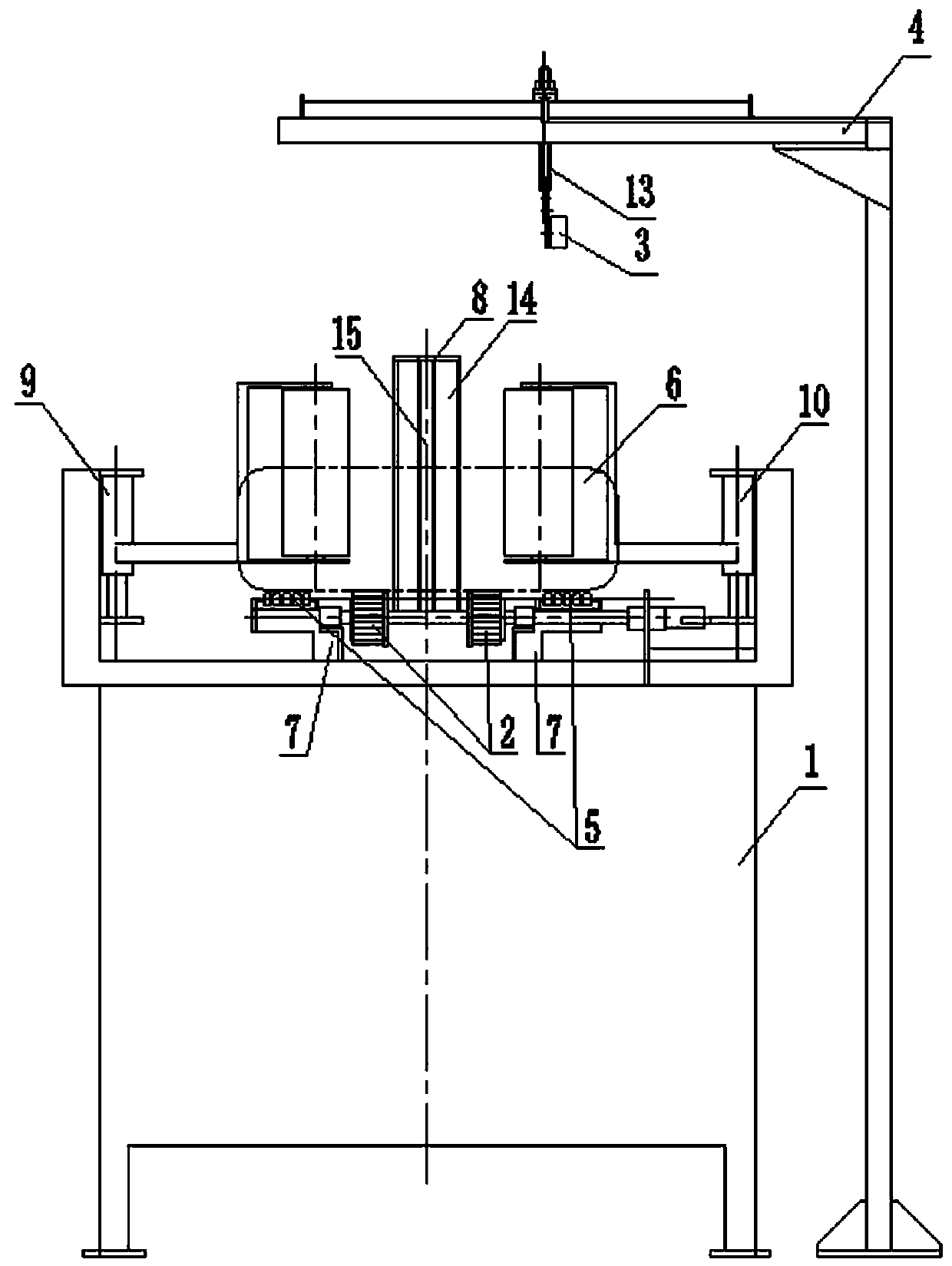

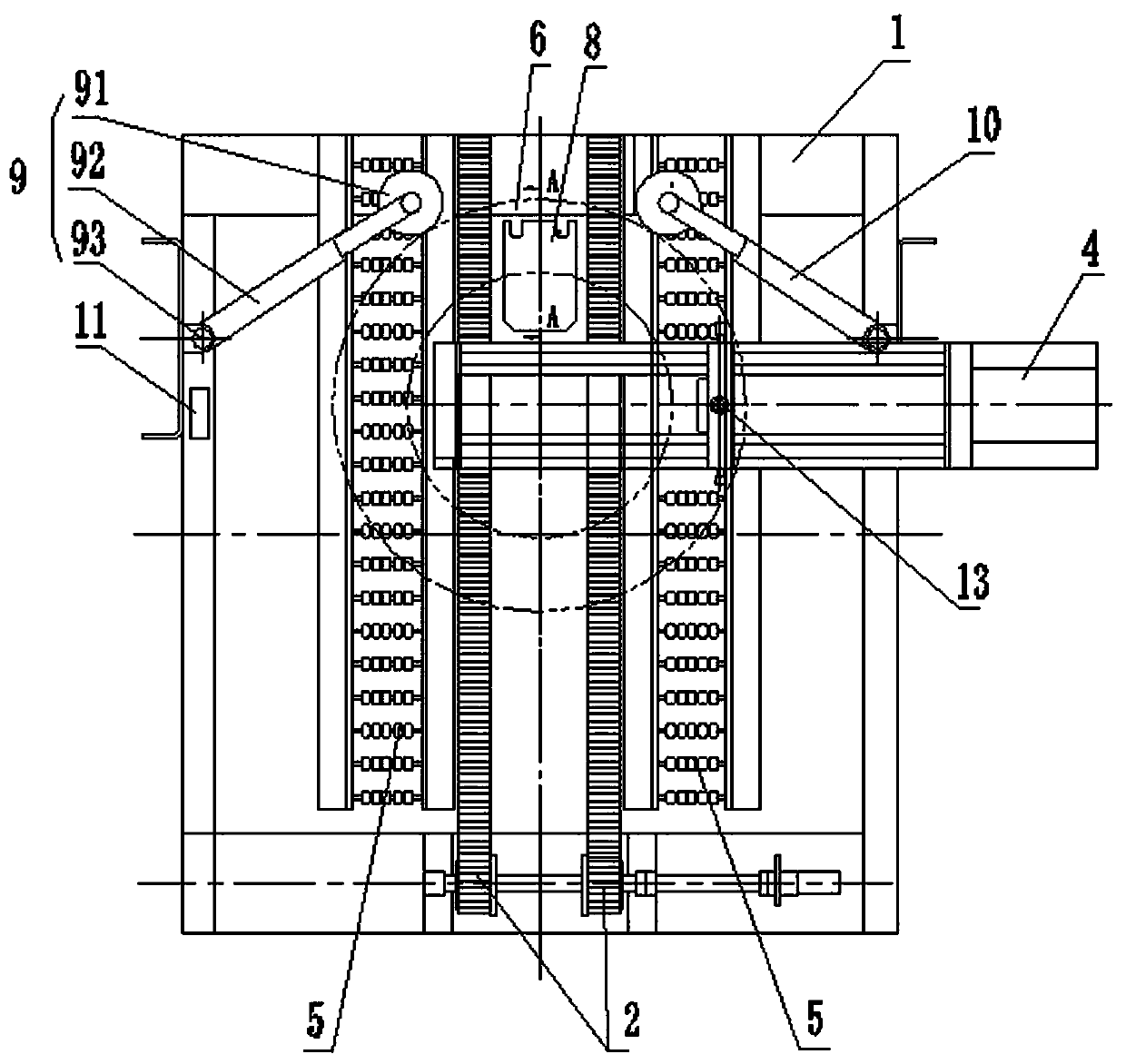

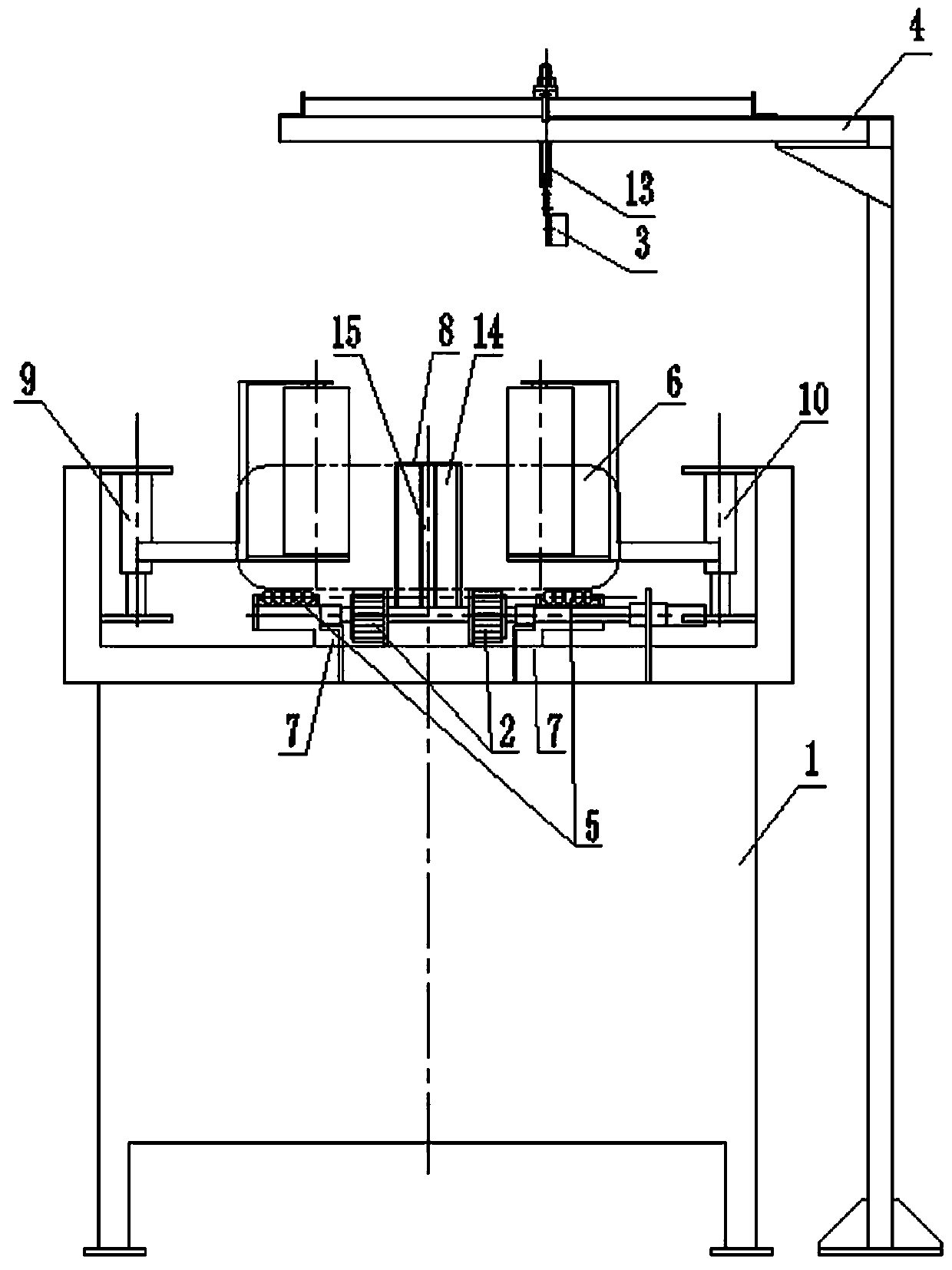

Hollow Hanging Board and Split Brick Multifunctional Vacuum Extruder

The invention aims to provide a vacuum extruder for hollow hanging plates and split bricks. The multifunctional vacuum extruder is provided with two parts, namely an upper mechanism which is positioned on the upper part and is used for transporting, extruding and mixing materials, and a lower mechanism which is positioned on the lower part and is used for extruding the materials, wherein the lower mechanism is positioned on a base; one end of the upper mechanism is fixedly supported on the base through an upper bracket and the other end of the upper mechanism is communicated with a mud feeding hopper in the lower mechanism through a vacuum chamber; a variable frequency motor in the upper mechanism is connected with a clutch to drive the clutch to rotate and is connected with a shell coupler through two output shafts of a double output shaft arc bearing speed reducer for coaction so as to rotate two stirring shafts relatively; an output shaft of a variable frequency motor of the lower mechanism is connected with a planet speed reducer; the planet speed reducer is directly connected with a spindle; the spindle is connected with a spiral extrusion reamer; the tail end of the spiral extrusion reamer is positioned in a cylinder II; and an outer end of the cylinder II is connected with a core, a middle section, an outlet end adjusting plate and a machine head in turn. The vacuum extruder can adapt to various raw materials to produce the hollow hanging plates and the split bricks, and also can produce sintered insulating bricks and sintered insulating block bricks in various specifications and sizes.

Owner:程永科

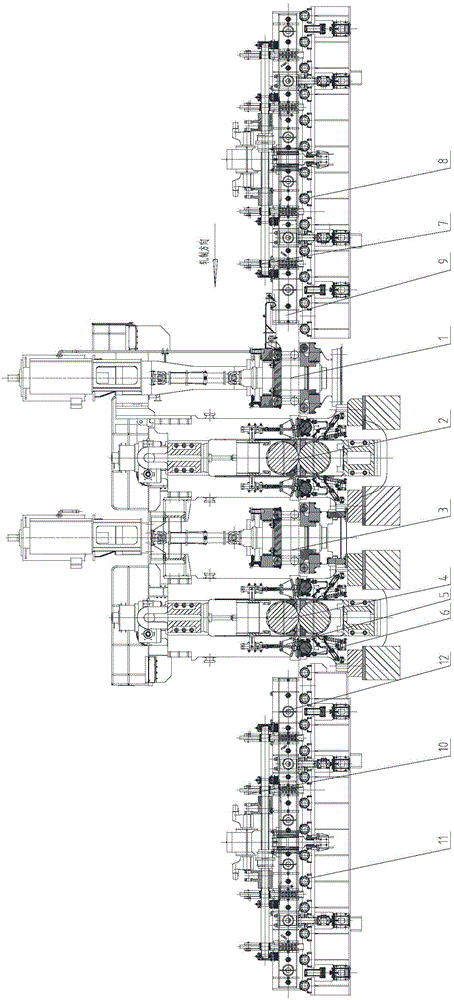

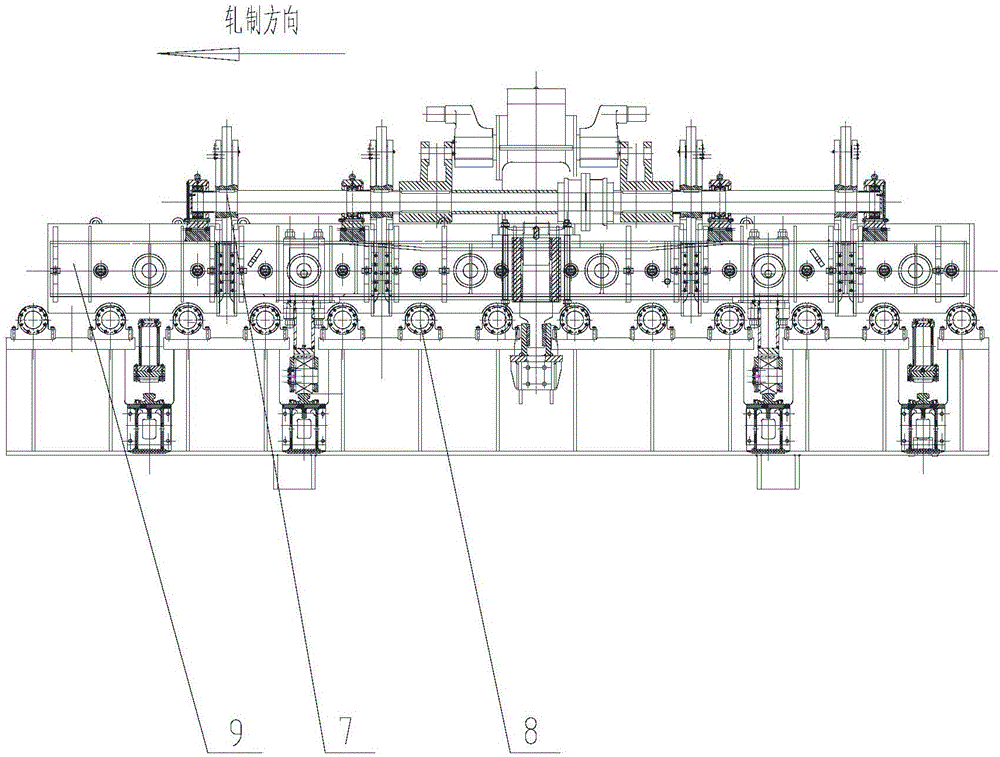

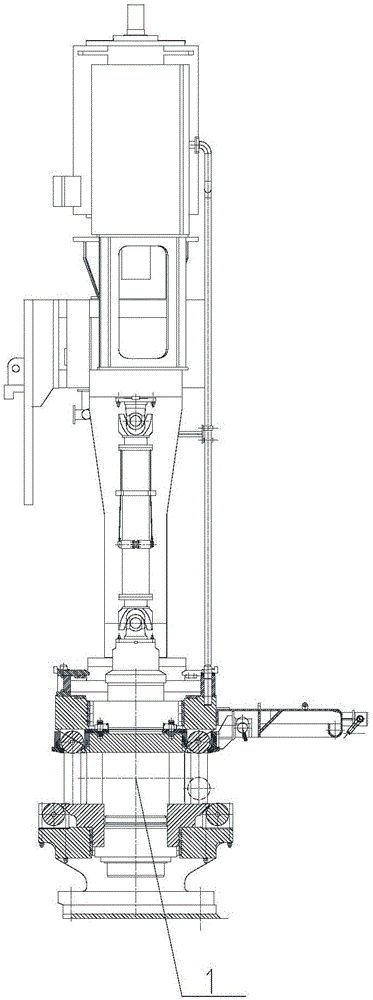

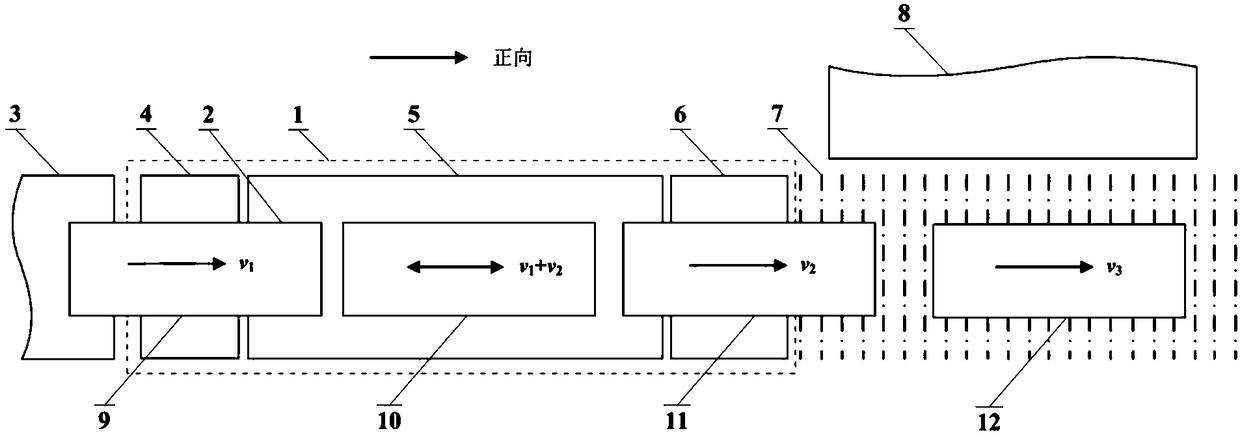

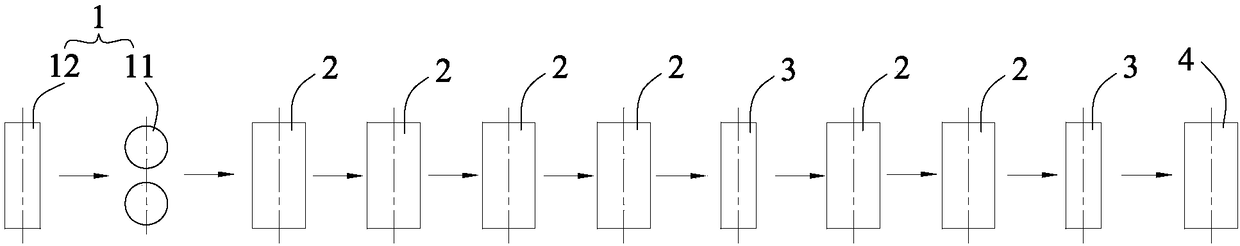

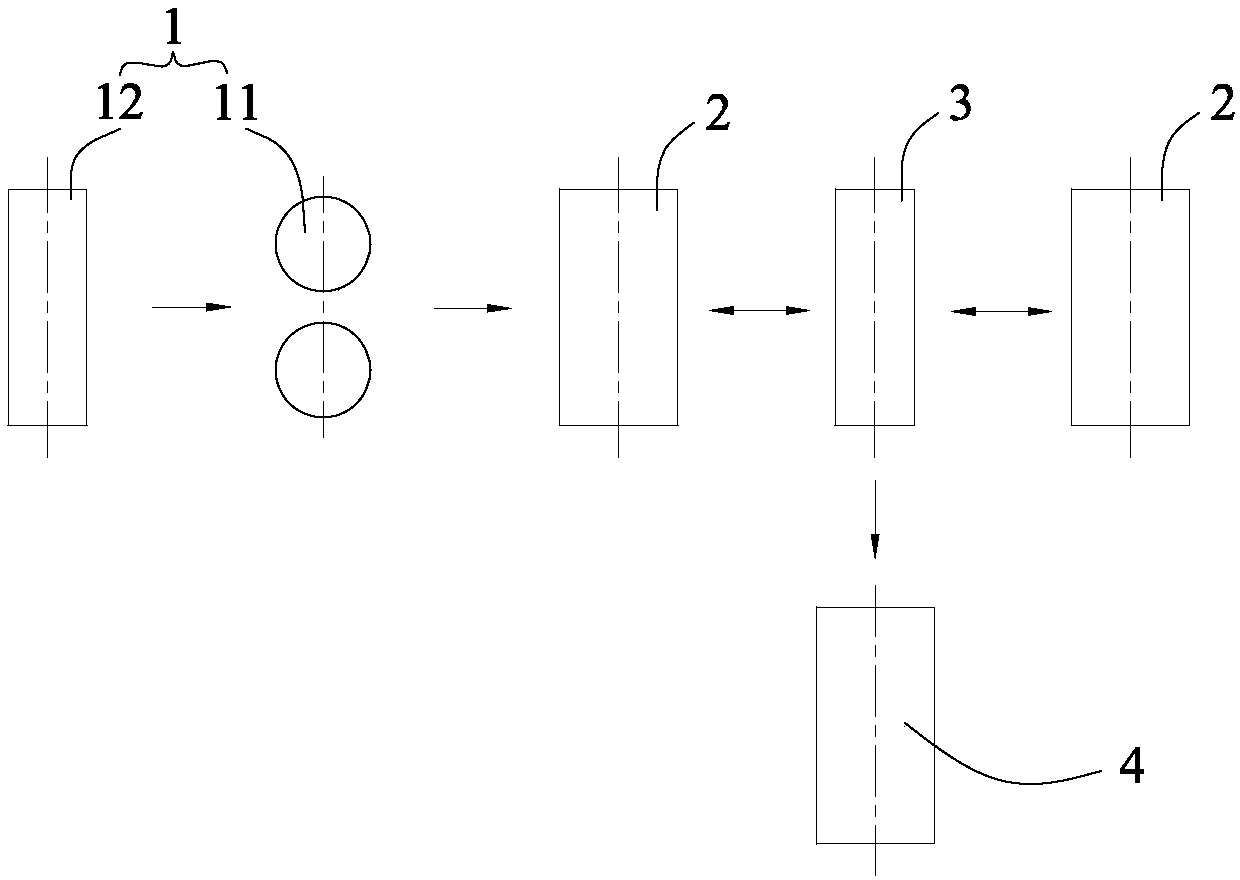

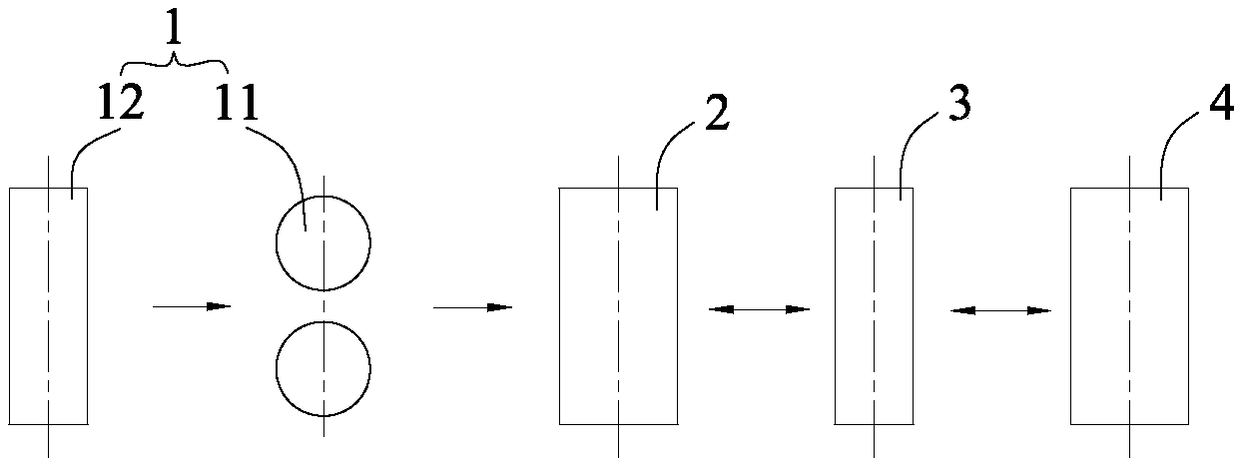

Mould flat steel continuous reversible rolling machine unit and mould flat steel rolling method

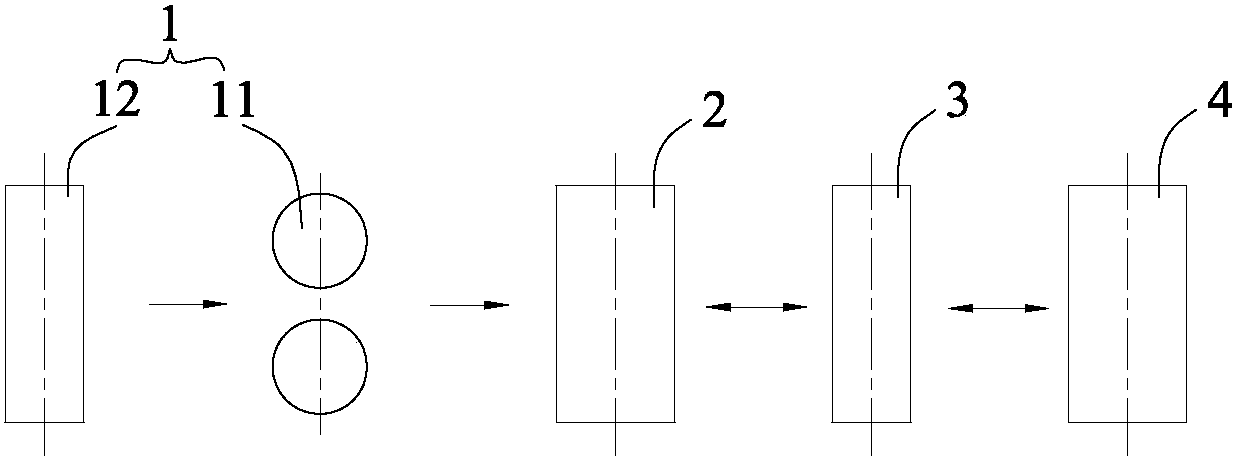

ActiveCN106513435AFlexible organizationSatisfy product quality precisionRoll force/gap control deviceTemperature control deviceProduction lineStrip mill

The invention discloses a mould flat steel continuous reversible rolling machine unit and a mould flat steel rolling method. The mould flat steel continuous reversible rolling machine unit comprises vertical rolling mills and horizontal rolling mills, wherein the vertical rolling mills comprise a vertical rolling mill I and a vertical rolling mill II; the horizontal rolling mills comprise a horizontal rolling mill I and a horizontal rolling mill II; and the vertical rolling mill I, the horizontal rolling mill I, the vertical rolling mill II and the horizontal rolling mill II are arranged on a horizontal working surface sequentially according to a rolling direction. According to the mould flat steel continuous reversible rolling machine unit and the mould flat steel rolling method, which are provided by the invention, production of multi-size large-size mould flat steel and square steel with the thickness being 6 to 300 mm and the width being 100 to 1000 mm is realized by one production line, the quality precision of products is met, energy consumption is reduced, and the size and the range of the products are enlarged. Therefore, high market adaptive capability is achieved, and enterprises can organize production flexibly according to the market requirements and create more economic benefits.

Owner:DALIAN DESIGN INST CO LTD CHINA FIRST HEAVY IND +1

Imitated nylon modified fibre of dyeable polypropylene

InactiveCN101333691AImprove liquidityImprove flexibilityMonocomponent polyolefin artificial filamentArtifical filament manufactureEthyleneDyeing

The invention relates to an imitated nylon differential fiber of dyeable polypropylene fiber for dyeing, which comprises: 80 to 90 percent of polypropylene, 9 to 11 percent of dyeable master batch, 0.3 to 0.7 percent of cooling auxiliary agent and 4.0 to 5.0 percent of polyethylene. The fiber has the advantages that: firstly, the polypropylene fiber has the flexibility, tensile property and elasticity as nylon through modifying the polypropylene fiber; and secondly, the dyeability of the modified polypropylene fiber is realized.

Owner:ZHEJIANG SITONG NEW MATERIAL TECH CO LTD

Method for preparing rice nursling seedlings and dryly planting mature seedlings

InactiveCN102511347AExpanded range of specificationsSimple preparation processFertilising methodsRice cultivationAlkali soilRecovery period

The invention discloses a method for preparing rice nursling seedlings and dryly planting mature seedlings. The method for preparing the rice nursling seedlings comprises a seed soaking process and a seed producing process, wherein the seed soaking process comprises a preparation stage and a seed stage; the seed producing process comprises a seed stage, a nursling bud stage, a nursling seedling stage and seed producing termination; and the method for dryly planting the mature seedlings comprises a soil preparation stage before seeding, a dry seeding stage, a seedling producing stage, a continuous irrigation stage, a wetting management stage and a personalized irrigation stage. The seedling producing stage totally or partially substitutes the bud producing stage in conventional nursling seedling preparation, and bud production before seeding is changed into bud production after seeding, so that the preparation technology of the nursling seedlings is simplified, the seedling recovery period is shortened, and the heading period is ahead of time; by continuous irrigation, the growth of rice buds is promoted, the seedlings emerge regularly, and the germination rate is high; the total salt content of a soil plough layer is effectively reduced, and dry planting in saline-alkali soil becomes true; and a shallow water layer of below 3 centimeters is established before the first complete leaf is expanded to allow the rice seedlings to grow from the position below water to the position above the water, so that seedling death due to salt accumulation in the soil under a wetting management or dry management condition is effectively prevented, and the live seedling rate is improved.

Owner:COASTAL AGRI RES INST HEBEI ACAD OF AGRI & FORESTRY SCI

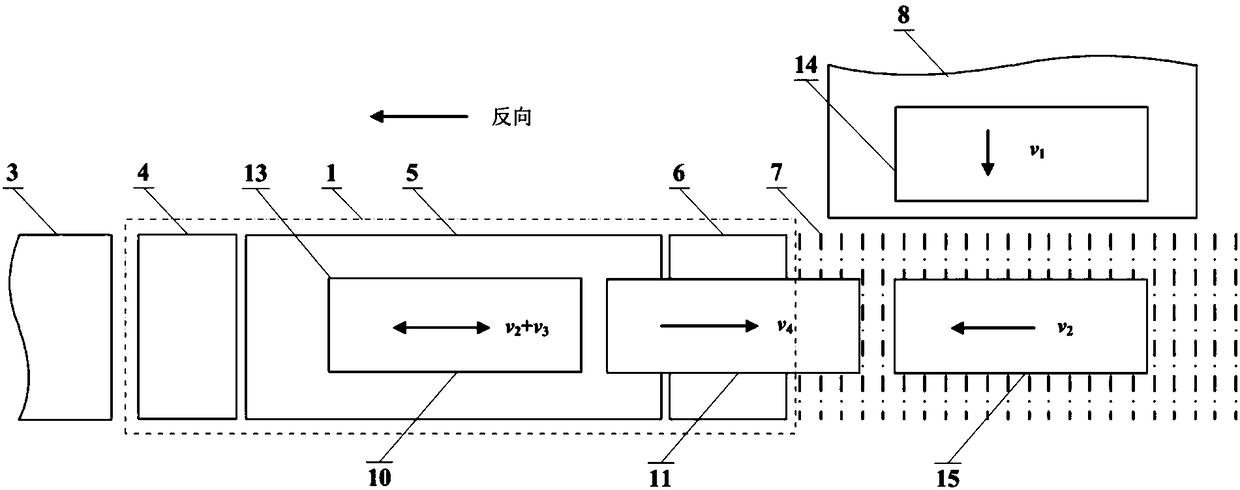

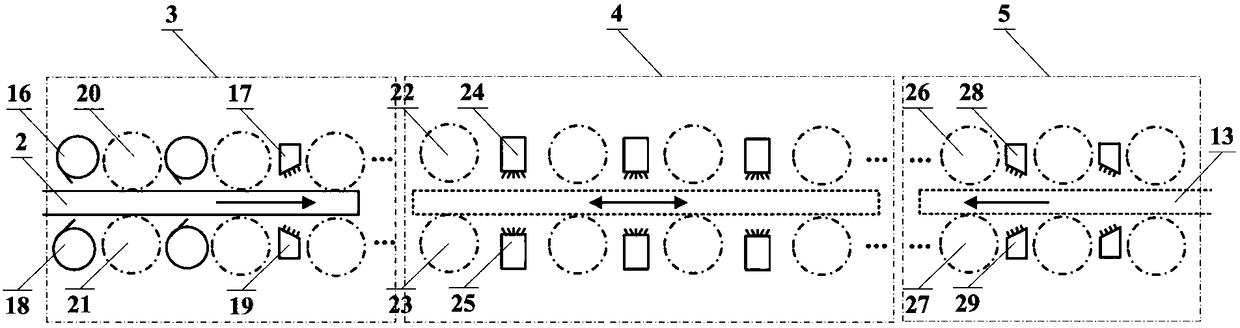

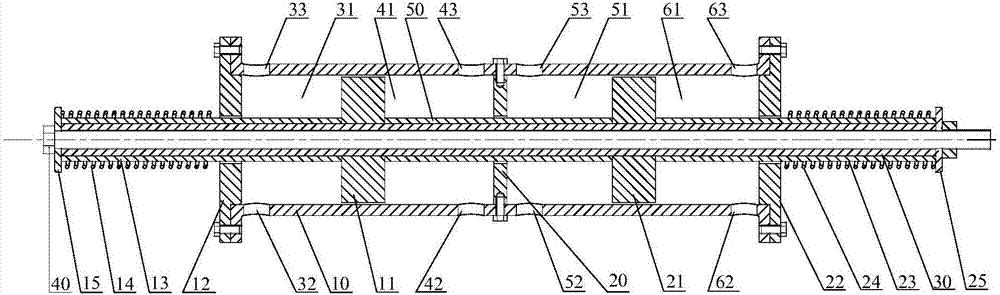

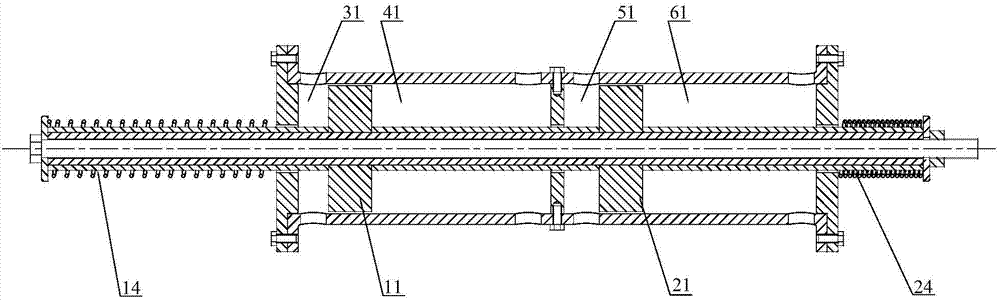

Plate-strip roller type quenching device and method capable of realizing reverse quenching

InactiveCN108486332AIncrease productivityIncrease profitFurnace typesHeat treatment furnacesHigh pressureQuenching

The invention belongs to the technical field of metal plate-strip heat treatment devices, and provides a plate-strip roller type quenching device and a plate-strip roller type quenching method capableof realizing reverse quenching. The device is formed by a front high-pressure cooling area, a rear high-pressure cooling area and a middle low-pressure cooling area; when a plate-strip enters from the front high-pressure cooling area, a forward quenching method is implemented; and when the plate-strip enters from the rear high-pressure cooling area, a reverse quenching method is implemented. According to the device and the method, the utilization rate of the quenching device can be greatly improved; and a special cooling device and a special cooling strategy are adopted for the thin and thickplates-strips, so that the heat treatment plate shapes and the uniformity of the plates-strips are improved at the same time, and multiple purposes are realized through one machine.

Owner:NORTHEASTERN UNIV

One-step folding forming method for honeycomb paper

InactiveCN102529175AContinuous operationIncrease profitPaper/cardboard articlesIsosceles trapezoidFolded form

The invention discloses a one-step folding forming method for honeycomb paper. In the existing honeycomb paper core making process, the multi-layer raw paper bonding / cutting or cutting / bonding forming method is adopted, which has the problems of low work efficiency, poor product quality and large material consumption. The method comprises the following steps of: firstly, pressing raw paper by gears to form isosceles trapezoids and inverted isosceles trapezoids, which are interconnected and provided with three equal three sides; then, coating adhesives on the surfaces of the isosceles trapezoids and the surfaces of V-shaped structures; subsequently, mechanically connecting the upper bottom outer surfaces of the trapezoids on the left side of one V-shaped structure with the upper bottom outer surfaces of the trapezoids on the left side of a corresponding inverted V-shaped structure, and mechanically connecting the inner surfaces of the V-shaped structures; and finally, mechanically cutting the honeycomb paper core in the transverse direction, to obtain finished products of honeycomb paper core. The paper sheets as raw materials are continuously fed one by one and not scissored or divided or cut in the whole process, and are always connected as an integral body. The honeycomb paper is in end-to-end connection all the time. The method achieves the effect of continuous operation.

Owner:ZHEJIANG SCI-TECH UNIV

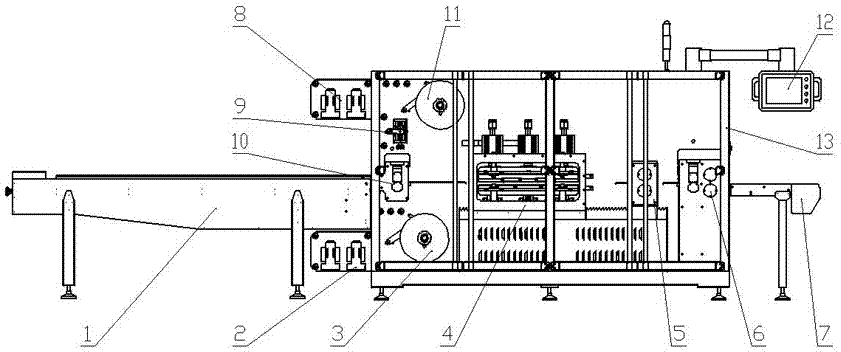

Full-automatic continuous four-side sealing packaging machine

InactiveCN106945886AGuaranteed heat sealing performanceExpanded range of specificationsWrapper twisting/gatheringMotor driveElectric machinery

The invention discloses a full-automatic continuous four-side sealing packaging machine. The full-automatic continuous four-side sealing packaging machine is characterized in that a heat sealing mechanism comprises a heat sealing frame and a heat sealing assembly; a second servo motor, a synchronous pulley I and a synchronous pulley II are arranged on the heat sealing frame; a synchronous belt II is wound on the synchronous pulley I and the synchronous pulley II; the second servo motor and the synchronous pulley I are linked; linear rails are further arranged on the heat sealing frame; the heat sealing assembly is provided with a top plate and a bottom plate; an upper module and a lower module are arranged between the top plate and the bottom plate; the bottom plate is mounted on sliding blocks of the linear rails; the synchronous belt II is linked with the bottom plate; a first servo motor is further fixedly mounted on the bottom surface of the bottom plate; a spindle is arranged on the top surface of the bottom plate; a plurality of eccentric wheels are arranged on the spindle at equal intervals; the first servo motor drives the spindle through a synchronous belt I; the upper module is connected with cylinders arranged on the top plate; and rollers which correspond to the eccentric wheels and are in contact with the eccentric wheels are arranged on the bottom surface of the lower module. According to the full-automatic continuous four-side sealing packaging machine, structure is simple, arrangement is convenient, the heat sealing effect is good, and continuous operation of the entire machine is achieved.

Owner:瑞安市华源包装机械厂

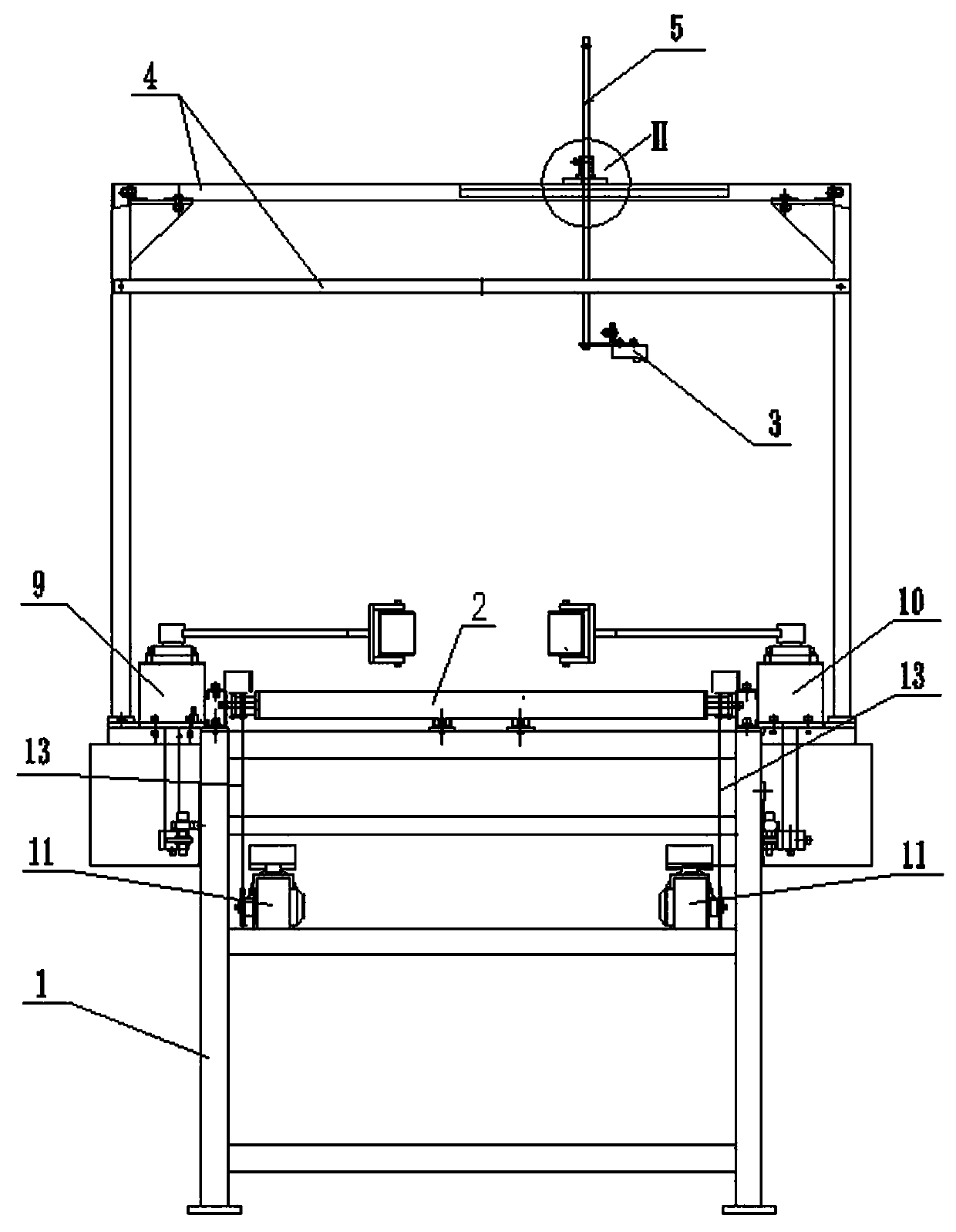

Cooling equipment for large bar material

ActiveCN103357677BImprove performanceImprove rapid cooling effectWork treatment devicesMetal rolling arrangementsManufacturing technologySpray nozzle

The invention discloses cooling equipment for a large bar material, which is used for cooling a bar material (11) after rolling. The cooling equipment is equipped with a short passing water cooler; the bar material (11) penetrates through the short passing water cooler; a water spraying box (2) is arranged on the short passing water cooler at the entering end part of the bar material (11); an annular nozzle (3) is arranged on the spraying box (2). Through adopting the technical scheme, the fast cooling capacity is improved, sufficient cooling is achieved, stability and uniformity of cooling are achieved, and the manufacture requirement of passing water cooling manufacture technology for rolling the large bar material (Phi 60-Phi 150 mm) is satisfied; the products can be manufactured are various and have a wide specification range; the position change is convenient and fast; the bar material product subjected to passing water cooling has increased performance with obvious economical benefits; the cooling equipment is safe and reliable in use, saves energy, protects the environment and is easy for popularization.

Owner:MAANSHAN SHUANGYI MACHINERY MFG

Drawing, expanding and follow-up heating device of cold-drawing unit

The invention discloses a drawing, expanding and follow-up heating device of a cold-drawing unit. One end of a water-cooled cable is connected with a high-voltage electric heating capacitor bank, and the other end is connected with an induction heating coil; one end of an insulation pull rod is fixed on a follow-up trolley, and the other end is connected with the induction heating coil; each lifting carrier roller consists of an air cylinder and a carrier roller rack; the extension length of each air cylinder is adjusted through an adjusting bolt; a traction rod is divided into three sections; pin shaft adjusting holes are drilled in the middle section at equal intervals; one end of the traction rod is connected with the follow-up trolley through a pin shaft I; the other end of the traction rod is connected with the drawing trolley through a pin shaft II; a traction rod carrier wheel is formed by assembling two bearing blocks and one carrier wheel; the lifting sequence of the lifting carrier rollers is controlled by travel switches; and the induction heating coil is formed by winding a copper tube on a stable frame which is fixed on an insulation bakelite plate through welded stainless steel bolts. According to the drawing, expanding and follow-up heating device, the heating speed and the drawing speed are synchronized; the heating speed for a workpiece is high; and the heating is uniform.

Owner:安徽宝泰特种材料有限公司

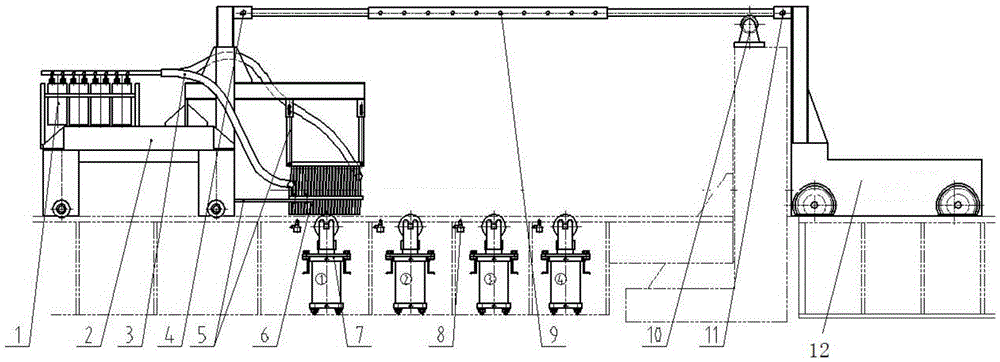

A kind of cu-fe composite material double-melt mixed casting equipment and technology

The invention discloses a Cu-Fe composite double-melt mixed casting equipment and process, comprising a first melting furnace for heating and melting pure Cu; a second melting furnace for heating and melting Cu-Fe alloy; a mixing chamber, The flow guide tube communicates with the liquid outlets of the first melting furnace and the second melting furnace to mix the heated and melted pure Cu and Cu-Fe alloy; The body is heated and electromagnetically stirred; the crystallizer is docked with the liquid outlet of the mixing chamber; the stopper mechanism is used to control the opening and closing of the liquid outlet and the melt flow of the first melting furnace and the second melting furnace; An air pressure regulating mechanism for adjusting the air pressure in the first melting furnace and the second melting furnace. The casting equipment and process not only solve the problem of inhomogeneous composition and structure of Cu-Fe composite materials in the casting process, but also can significantly improve production efficiency and reduce production costs, and are suitable for industrial scale production.

Owner:CENT SOUTH UNIV

Driving device of header

InactiveCN107027414AExpanded range of specificationsThe transmission mechanism is simpleMowersPistonLinear motion

The invention provides a driving device of a header. The driving device comprises a cylinder sleeve. A middle distance piece is fixedly arranged inside the cylinder sleeve so that an internal cavity of a cylinder body can be divided into a first cavity and a second cavity which are independent; a first piston is arranged inside the first cavity so that the first cavity can be partitioned into a first air chamber and a second air chamber which are independent and the first piston can reciprocate inside the first cavity; a second piston is arranged inside the second cavity so that the second cavity can be partitioned into a third air chamber and a fourth air chamber which are independent and the second piston can reciprocate inside the second cavity; a spindle pipe is arranged inside the cylinder sleeve and sequentially penetrates through a first end cover, the first piston, the middle distance piece, the second piston and a second end cover, and the spindle pipe can reciprocate inside the cylinder body. The driving device can directly convert linear motion of the pistons into power, and a transmission mechanism of the header is simplified, so that the efficiency of the driving device is improved.

Owner:HUBEI UNIV OF TECH

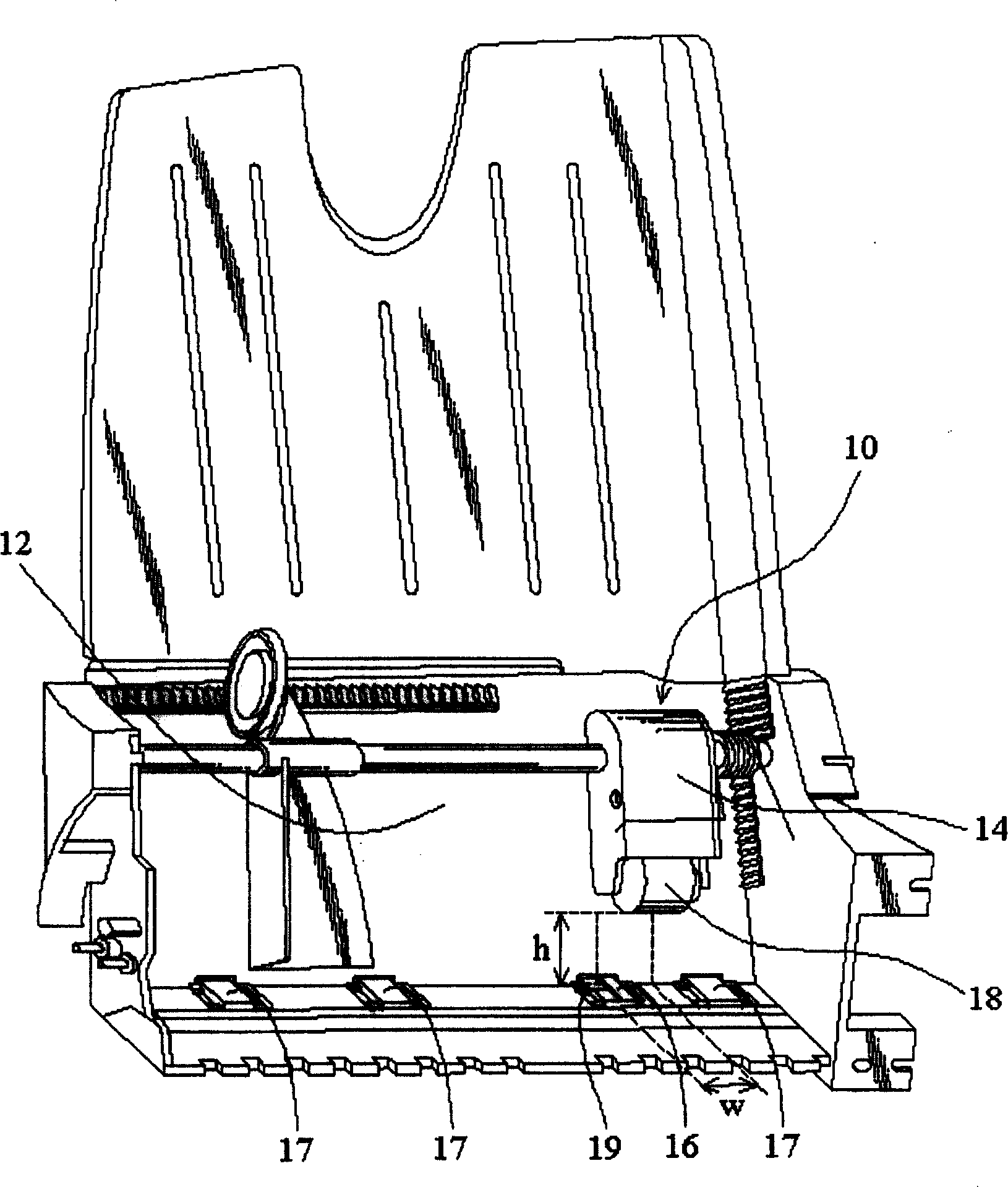

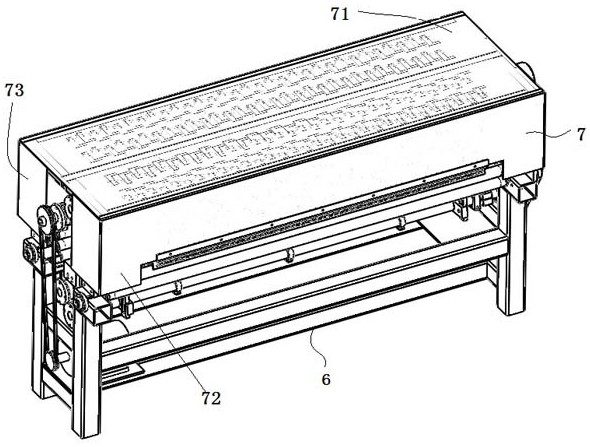

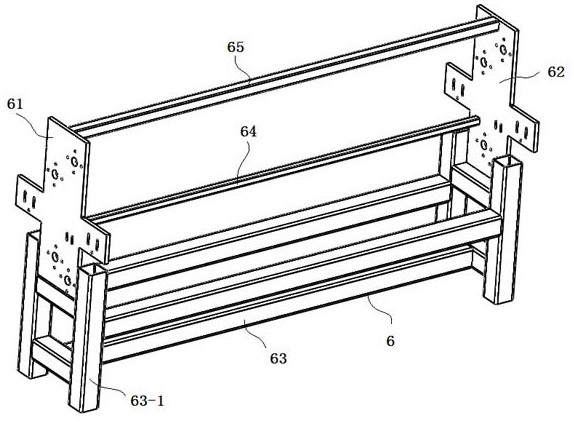

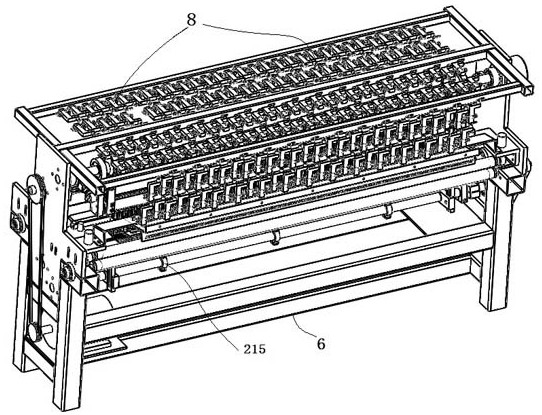

Recording medium feeding system and method

InactiveCN1569473AIncrease pressureIncrease elasticityOther printing apparatusOffice printingEngineeringElectrical and Electronics engineering

The invention is a recording medium feeding system, which can be applied to lead and output several recording media. The system includes a tray, a separating device, a limiting device and a rolling wheel. The tray has the first end and the second end, the first end is relative to the second one, all the recording media are placed on the tray. The separation device is arranged on the first end of the tray. The limiting device is arranged on the second end of the tray. The recording media is between the separating device and the limiting device. The rolling wheel is arranged on the tray, it can rotate along the first direction and the second direction, the recording media is against to the rolling wheel.

Owner:BENQ CORP

Digital control tufting machine

InactiveCN105200683AReduce processing costsIncrease productivityTufting apparatusFixed frameElectric machinery

The invention relates to a digital control tufting machine, and belongs to the field of textile machinery. The digital control tufting machine comprises a first assembly, a second assembly, a power distribution cabinet and a tufting gun controlled by two built-in motors, wherein the first assembly comprises a fixing frame and a plurality of handrails; the second assembly is connected with the first assembly; the power distribution cabinet is connected with the second assembly; the second assembly comprises a fixing framework, a guide rod I, a guide rod II, a permanent seat, a guide slide block, a motor I, a motor II, a motor board, a synchronizing wheel and a synchronizing belt; the permanent seat is provided with two guide holes in different directions; the guide rod I and the guide rod II pass through the two guide holes respectively; the two ends of the guide rod I and the guide rod II are connected with fixing framework through the guide slide block; both the motor I and the motor II are fixed on the motor board; the motor board is connected with the fixing framework; the tufting gun is arranged on the permanent seat of the second assembly. The digital control tufting machine has the advantages of reasonable structure, stability, reliability, low production cost, high production efficiency, convenience in installation and detachment, and occupation of a small space.

Owner:王永清 +1

Tire centring and rotating scanning system and tire centring and rotating scanning data pickup method

PendingCN110577052AEasy to manageRealize refined managementControl devices for conveyorsCo-operative working arrangementsTire rotationIdentification device

The invention belongs to the technical field of tire production and particularly relates to a tire centring and rotating scanning system and a tire centring and rotating scanning data pickup method. The tire centring and rotating scanning system is characterized in that the tire centring and rotating scanning system comprises a conveying channel and an automatic identifying device, when a to-be-detected tire carrying an identity information carrier reaches the middle of the conveying channel along the conveying channel, the tire rotates, the automatic identifying device located above the tireautomatically identifies identity information in the identity information carrier on the tire, the tire stops rotating within the set time of 0.5-5 seconds after the information is identified, and theto-be-detected tire is sent out through the conveying channel. Compared with the prior art, the tire centring and rotating scanning system and the tire centring and rotating scanning data pickup method have the advantages that (1) fully-automatic unmanned operation is achieved; and (2) the tire identity information is rapidly picked up and recorded, the uniqueness of tire identity in the whole tire production process is ensured, in the whole life period of the tire, the identity can still serve as the basis of various data applications such as quality analysis, process evaluation analysis andcustomer analysis, and quality improvement of a product and fine management of a sale scheme are facilitated.

Owner:鞍山彩盛机械制造有限公司

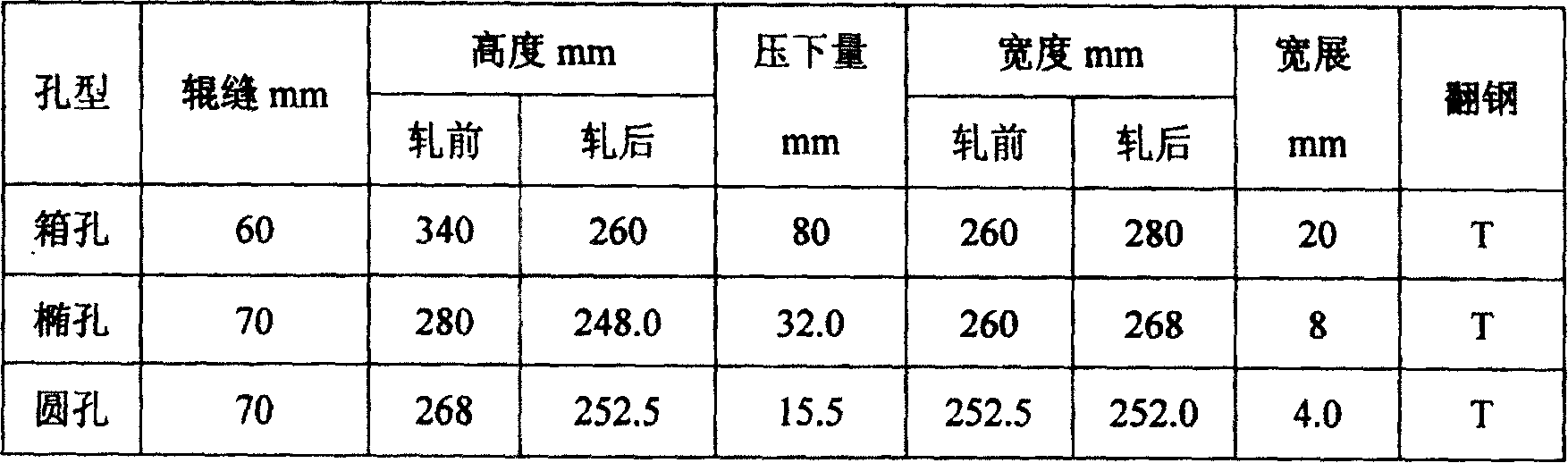

Method for rolling large circular steel by primary rolling mill

ActiveCN100382902CImprove interoperabilityExpanded range of specificationsRollsMetal rolling arrangementsMaterials scienceRolling mill

Owner:BAOSHAN IRON & STEEL CO LTD

Tire detection precise brake positioning system and method thereof

PendingCN110579362AIncrease the level of automationQuality is easy to controlVehicle tyre testingQuality controlPositioning system

The invention belongs to the technical field of tire production, and particularly relates to a tire detection precise brake positioning system and a method thereof. The method is characterized by precisely positioning a tire and allowing the tire ready to undergo uniformity and balance detection to be sent out in an orientation forming the same included angle relative to a feature datum point, andspecifically comprises the steps of: 1) calibrating equipment parameters; 2) acquiring rim data of the tire; 3) carrying in the tire; 4) lifting a brake pressing plate; 5) positioning the tire by means of holding arms; 6) rotating the tire to find a zero point; (7) descending the brake pressing plate for braking; 8) unfolding the holding arms; 9) withdrawing the brake pressing plate; 10) and sending out the tire. Compared with the prior art, the tire detection precise brake positioning system and the method thereof have the beneficial effects that: the whole process of position tracking, feature point identification and precise brake positioning of the tire are conducted in an unmanned operating manner, and the logic zero point is provided for the tire in a curve form, thus the qualitative detection on tire performance parameters is achieved, uniformity positioning and quantitative detection and recording are achieved, and the automation level and quality control of tire production are facilitated.

Owner:鞍山彩盛机械制造有限公司

H-beam production system

InactiveCN107695094BSmall elongation coefficientImprove biteMetal rolling arrangementsRolling millFlange

The invention provides a production system for H-shaped steel. The production system comprises a rough rolling unit, X-hole-shaped universal rolling mills, edging mills and an H-hole-shaped universalrolling mill. The rough rolling unit is used for rolling continuous casting billets for producing the H-shaped steel into intermediate billet materials first. Each X-hole-shaped universal rolling millcomprises two second horizontal rolls and two second vertical rolls, and an X-shaped rolling hole is formed between each two second horizontal rolls and the corresponding two second vertical rolls. When the intermediate billet materials rolled by the rough rolling unit enter the X-shaped rolling hole of each X-hole-shaped universal rolling mill, the corresponding two second horizontal rolls rollwebs of the billet materials, then the corresponding two second horizontal rolls and the corresponding two second vertical rolls roll the webs and flanges of the billet materials, and X-shaped billetmaterials are rolled. The X-shaped billet materials obtained after rolling of the X-hole-shaped universal rolling mills enter the edging mills, and the edging mills roll the flanges of the X-shaped billet materials to adjust the width of the flanges. The H-hole-shaped universal rolling mill is used for rolling the X-shaped billet materials rolled by the edging mills into the H-shaped steel.

Owner:刘庚申 +1

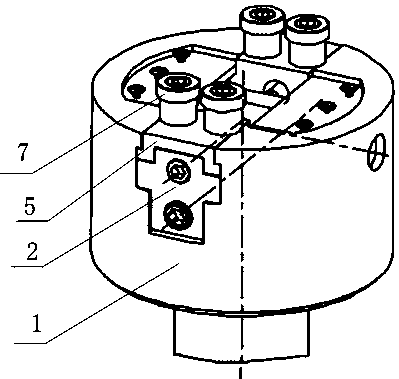

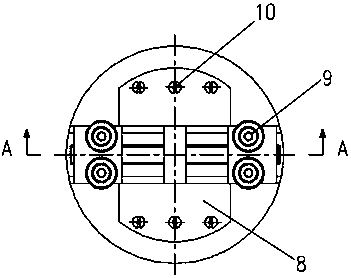

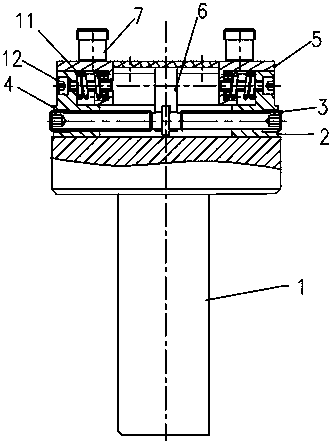

Four-pressure-roller mechanical intra-machine puller

ActiveCN111299630AExpanded range of specificationsStable clampingChucksMetal working apparatusScrew threadIndustrial engineering

The invention discloses a four-pressure-roller mechanical intra-machine puller. A main body is of a stepped structure composed of a large cylinder and a small cylinder, a sliding groove penetrating ina radial direction is formed in the middle of the upper end face of the large cylinder, a reverse-flighted screw is installed in the sliding groove, a fixed sleeve is installed at a middle flange ofthe reverse-flighted screw, both ends of the reverse-flighted screw are inserted at threaded holes of two sliding bodies, the sliding bodies are installed opposite to each other, the upper end faces of the two sliding bodies are respectively equipped with two pressure rollers for pressing a to-be-pulled workpiece, the pressure rollers protrude out of an opening of the upper surface of the slidinggroove, each sliding body comprises a fixing block and a sliding block, the sliding blocks are slidably connected with the fixing blocks through long screws, compression springs sleeve rod portions ofthe long screws, one ends of the compression springs abuts against the sliding blocks, and the other ends of the compression springs abut against the fixing blocks. According to the puller, rough andfine adjustment of clamping force can be carried out, the degree of abrasion of a clamping jaw of the puller is reduced, replacement of the pressure rollers is extremely convenient and economical, and the overall service life of the puller is prolonged.

Owner:HUBEI JIANGSHAN HEAVY IND

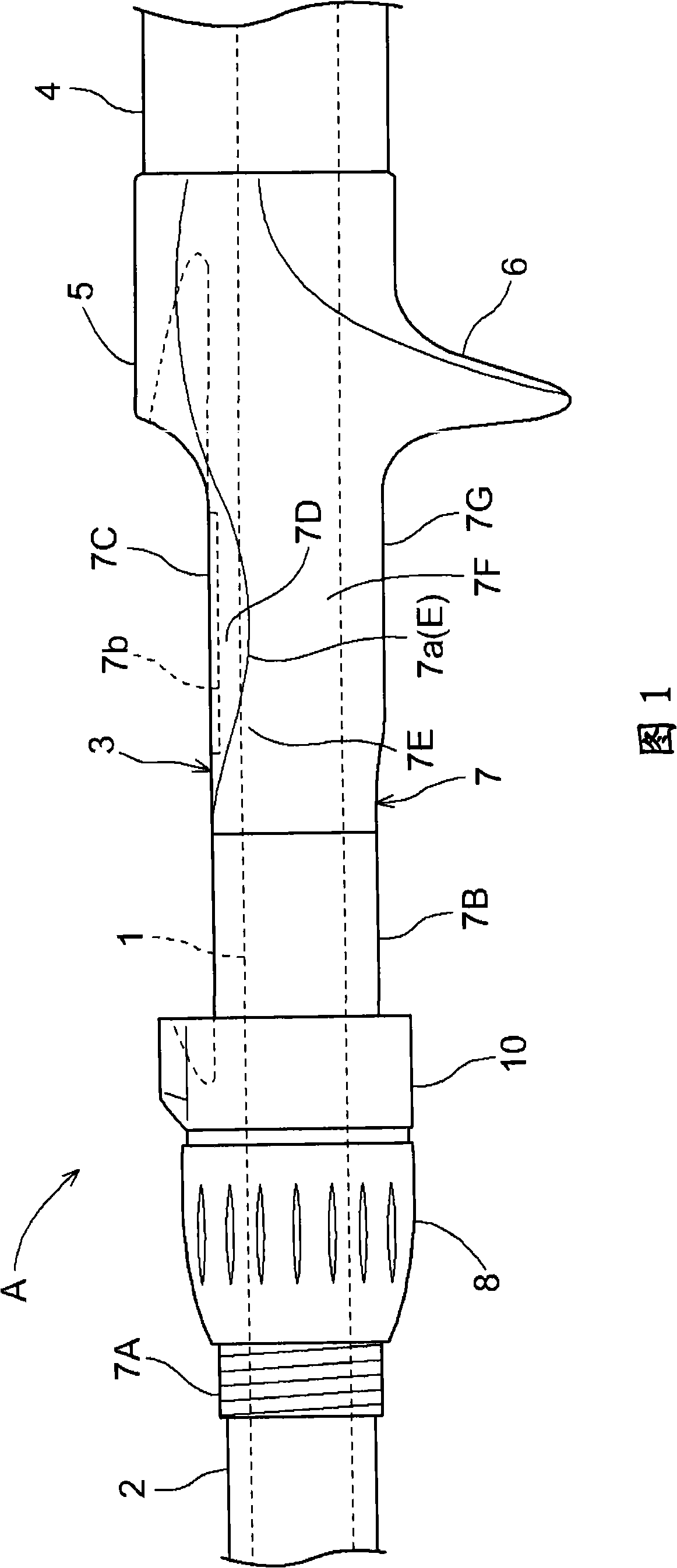

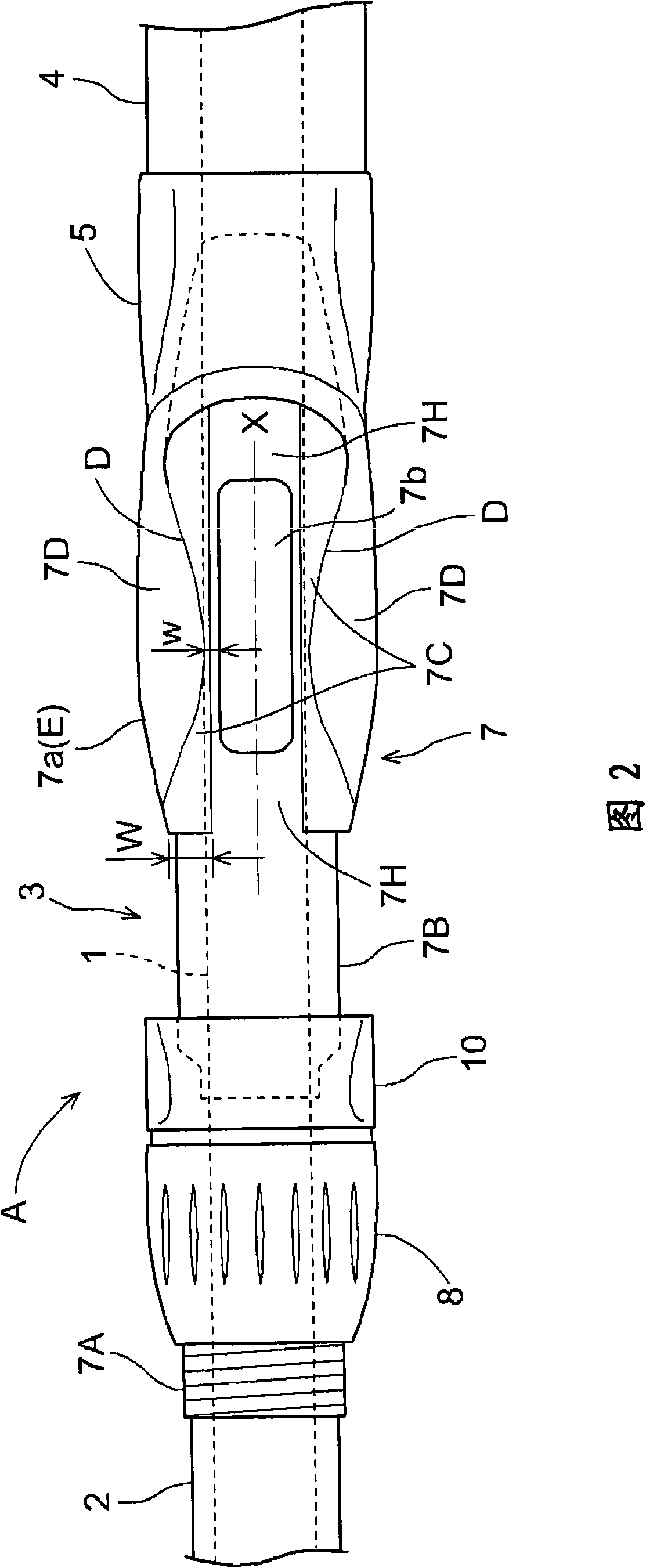

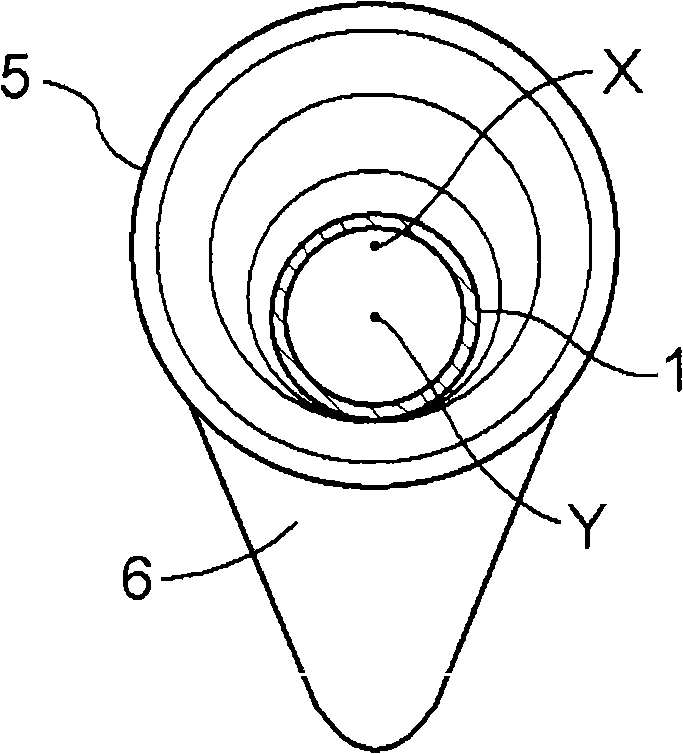

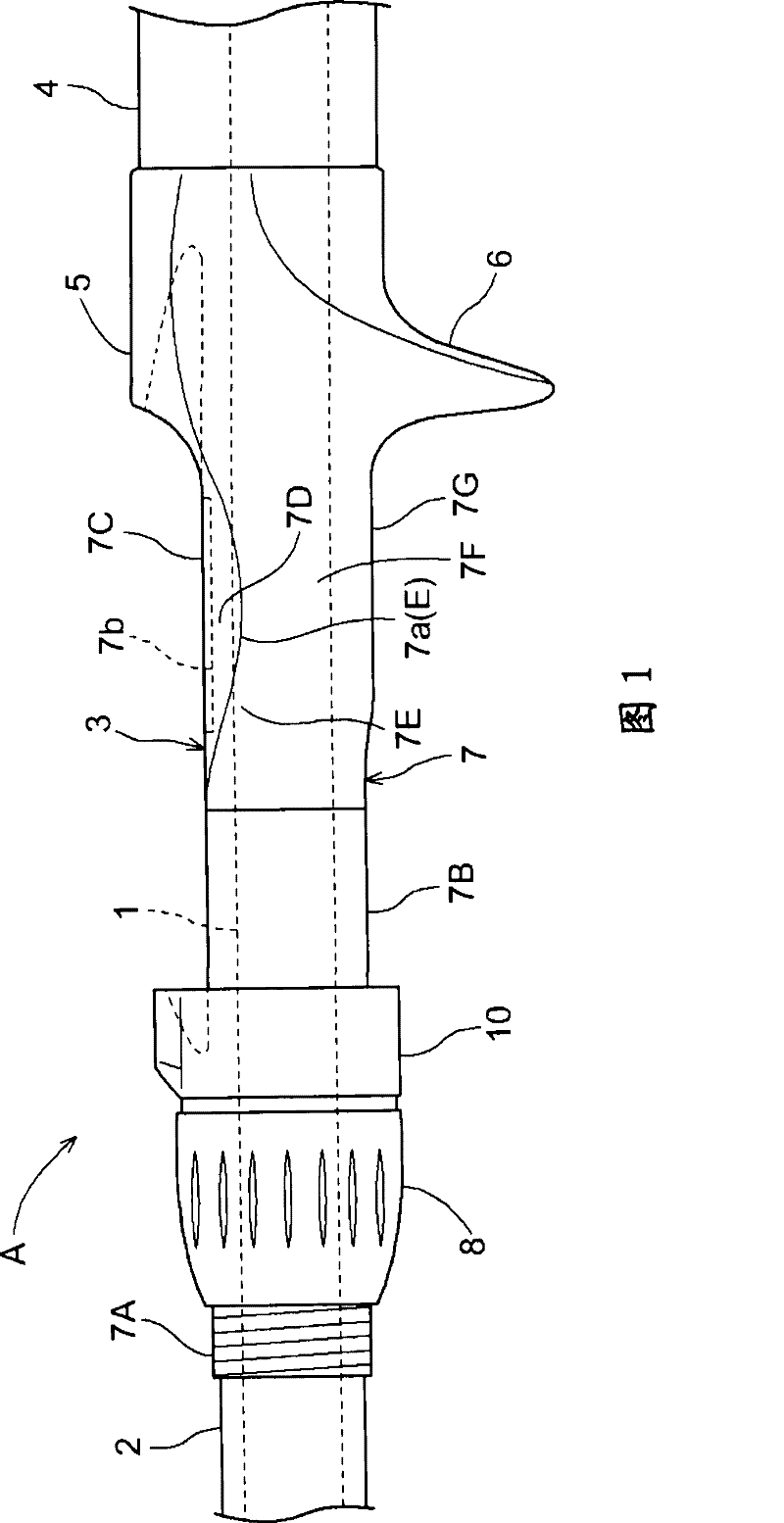

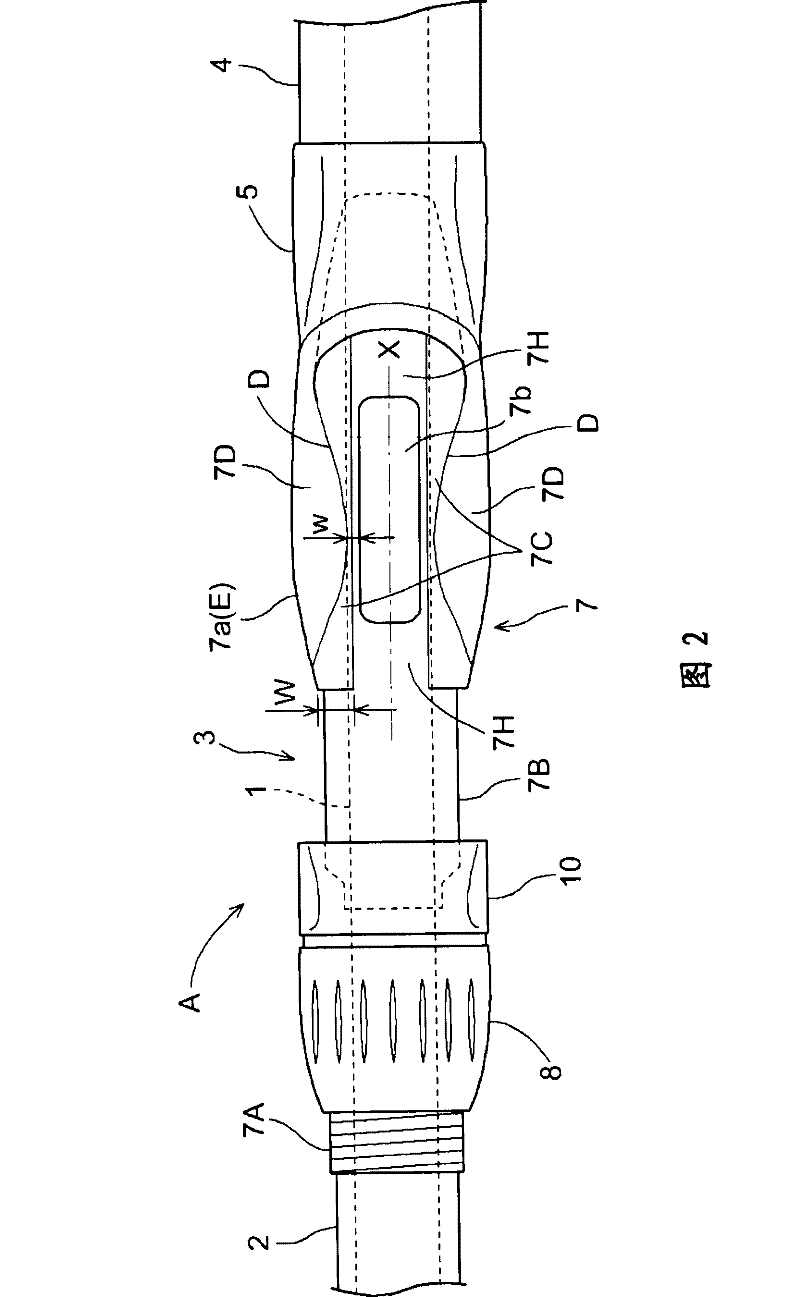

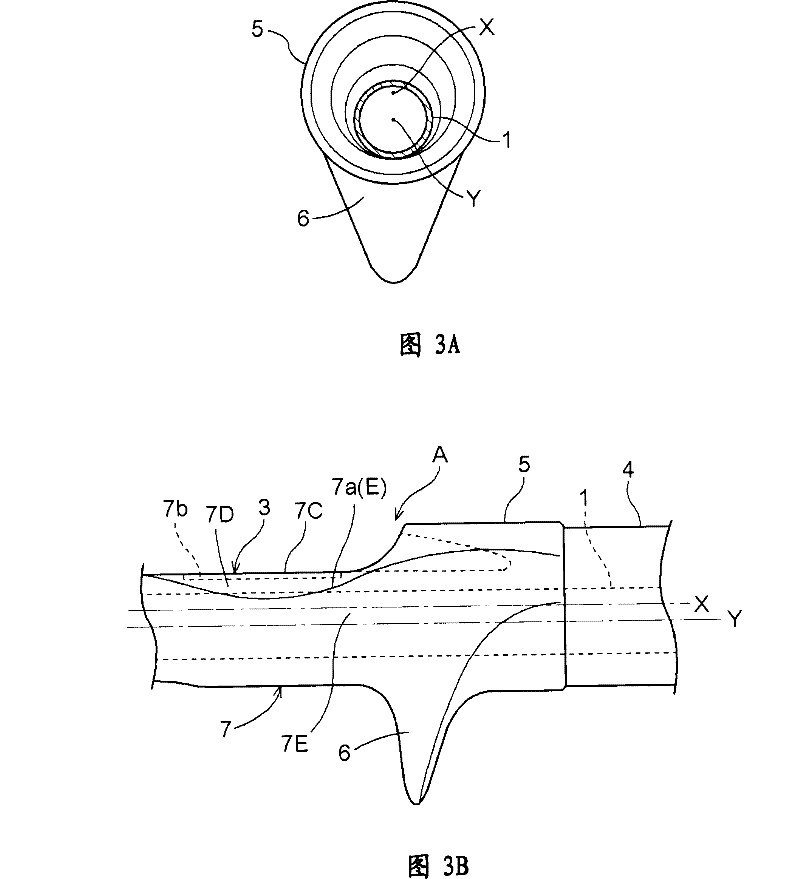

Wire-tire seat and fishing rob with wire-tire seat

The invention provides a wire wheel seat which is able to reduce weight-bearing sense and lessen situations of losing weight balance by carrying out simple variations to a holding mechanism for holding a wire wheel support of a movable cover. A guide portion (10d) from an inlet side to an inner side is formed at a sidewall surface in an internal space, and an inclination maintaining face portion (10a) is formed at deeper inner side of the guide portion (10d). The spacing between opposite sidewall surfaces are enabled to be smaller as deeper to the inner side, such that the guide portion (10d) and the inclination maintaining face portion (10a) are respectively inclined and inclined angle of the inclination maintaining face portion (10a) is larger than that of the guide portion (10d).

Owner:SHIMANO INC

Method for preparing rice nursling seedlings and dryly planting mature seedlings

InactiveCN102511347BExpanded range of specificationsSimple preparation processFertilising methodsRice cultivationAlkali soilContinuous irrigation

The invention discloses a method for preparing rice nursling seedlings and dryly planting mature seedlings. The method for preparing the rice nursling seedlings comprises a seed soaking process and a seed producing process, wherein the seed soaking process comprises a preparation stage and a seed stage; the seed producing process comprises a seed stage, a nursling bud stage, a nursling seedling stage and seed producing termination; and the method for dryly planting the mature seedlings comprises a soil preparation stage before seeding, a dry seeding stage, a seedling producing stage, a continuous irrigation stage, a wetting management stage and a personalized irrigation stage. The seedling producing stage totally or partially substitutes the bud producing stage in conventional nursling seedling preparation, and bud production before seeding is changed into bud production after seeding, so that the preparation technology of the nursling seedlings is simplified, the seedling recovery period is shortened, and the heading period is ahead of time; by continuous irrigation, the growth of rice buds is promoted, the seedlings emerge regularly, and the germination rate is high; the total salt content of a soil plough layer is effectively reduced, and dry planting in saline-alkali soil becomes true; and a shallow water layer of below 3 centimeters is established before the first complete leaf is expanded to allow the rice seedlings to grow from the position below water to the position above the water, so that seedling death due to salt accumulation in the soil under a wetting management or dry management condition is effectively prevented, and the live seedling rate is improved.

Owner:COASTAL AGRI RES INST HEBEI ACAD OF AGRI & FORESTRY SCI

Wire-tire seat and fishing rob with wire-tire seat

The invention provides a wire wheel seat which is able to reduce weight-bearing sense and lessen situations of losing weight balance by carrying out simple variations to a holding mechanism for holding a wire wheel support of a movable cover. A guide portion (10d) from an inlet side to an inner side is formed at a sidewall surface in an internal space, and an inclination maintaining face portion (10a) is formed at deeper inner side of the guide portion (10d). The spacing between opposite sidewall surfaces are enabled to be smaller as deeper to the inner side, such that the guide portion (10d)and the inclination maintaining face portion (10a) are respectively inclined and inclined angle of the inclination maintaining face portion (10a) is larger than that of the guide portion (10d).

Owner:SHIMANO INC

A fully automatic carpet machine

ActiveCN113046946BImprove machining accuracyQuality improvementTufting apparatusEngineeringSmall footprint

The invention relates to a fully automatic carpet machine with high degree of automation, which belongs to the field of carpet machines. The present invention comprises a power transmission mechanism, a crochet needle rest assembly, a knitting needle piston assembly, a cylinder assembly, an outer cover plate, a support frame assembly and a plurality of electromagnetic valves, the outer cover plate is connected with the support frame assembly, and the plurality of electromagnetic valves are all arranged on the outer cover plate , the support frame assembly includes a side plate fixing plate 1 and a side plate fixing plate 2, the side plate fixing plate 1 and the side plate fixing plate 2 are respectively installed on both sides of the support frame assembly, the power transmission mechanism is connected with the support frame assembly, and the crochet knife rest The assembly is connected with the power transmission mechanism, and the knitting needle piston assembly is connected with the cylinder assembly. The invention has reasonable structural design, stability and reliability, low cost, small occupied space, high work efficiency and high degree of automation, and meets the use requirements.

Owner:胡智土 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com