Method for rolling large circular steel by primary rolling mill

A blooming mill and round steel technology, applied in metal rolling, metal rolling, rolls, etc., to expand the range of product series, increase the commonality of rolls, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

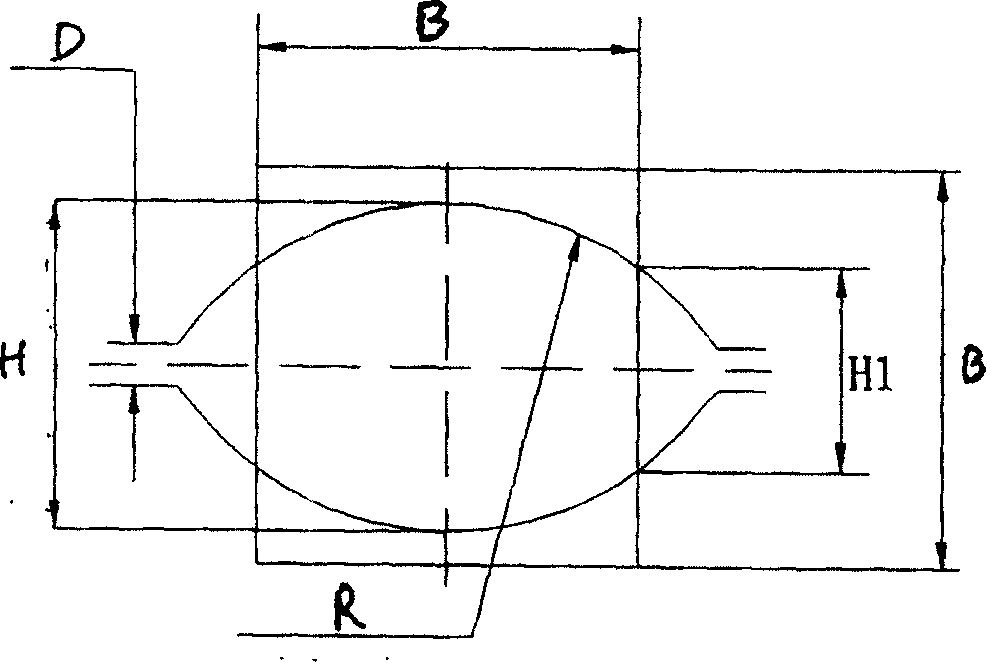

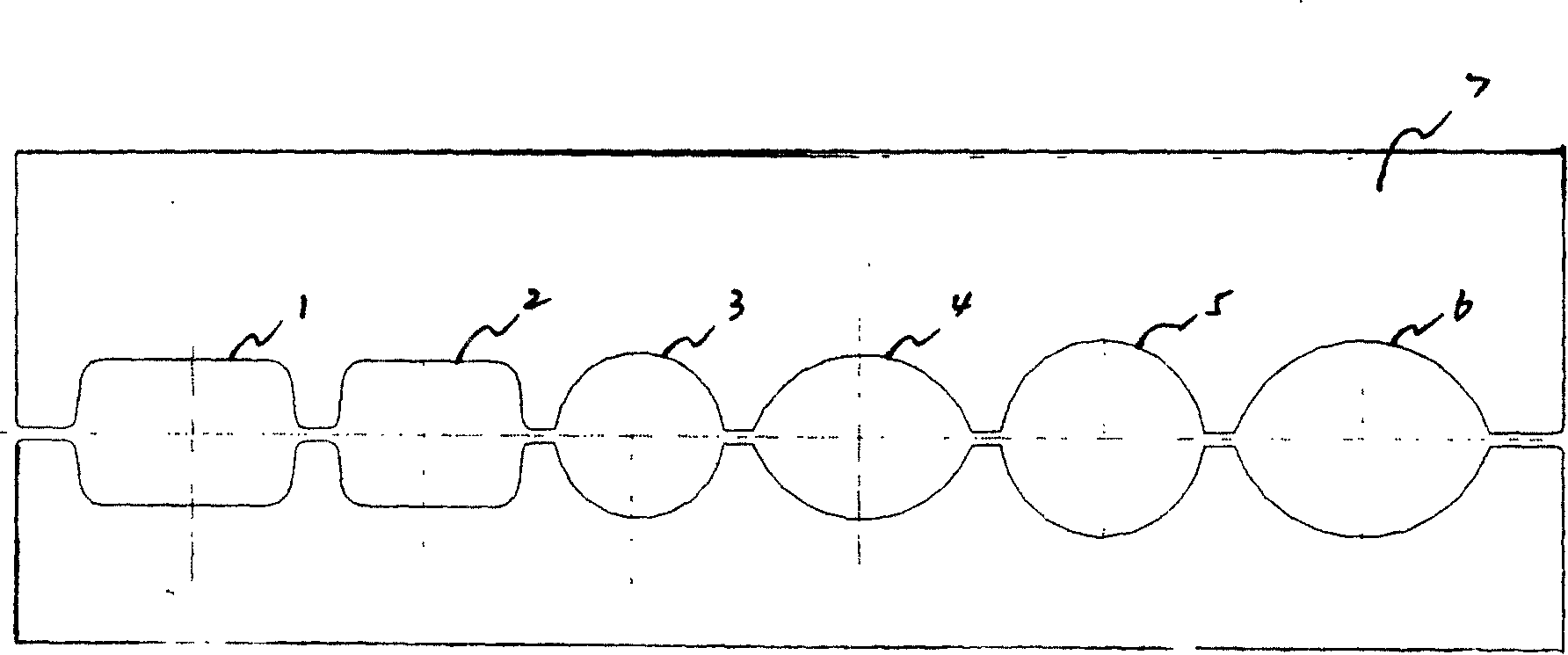

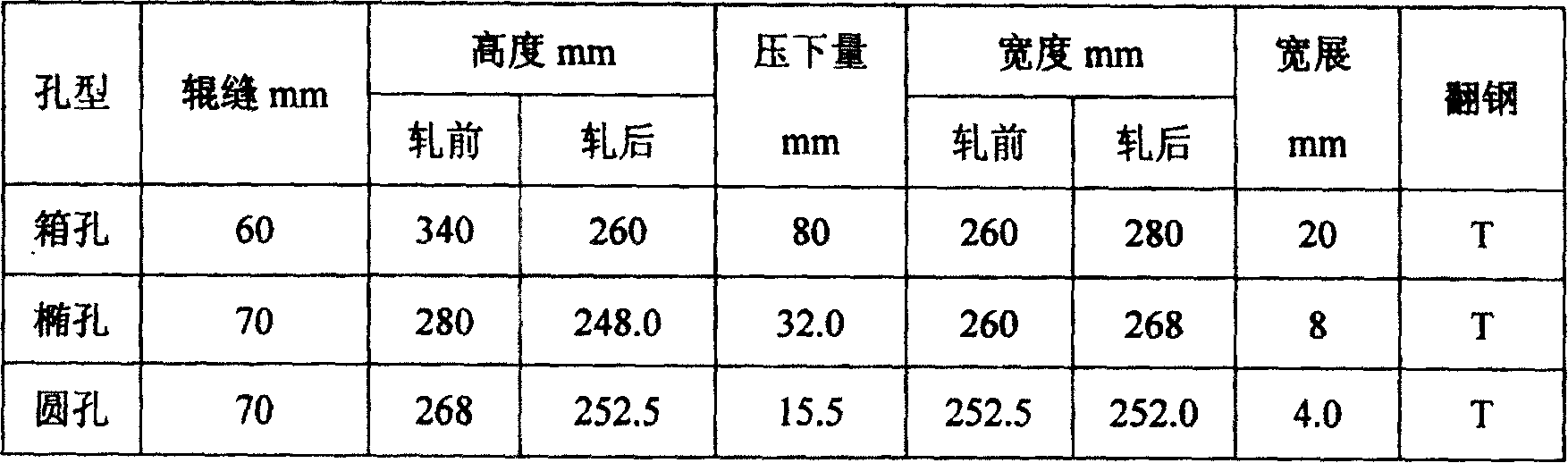

[0016] Embodiment 1, with reference to figure 1 , 2 , Rolling of Ф250 medium carbon steel 42CrMo, the roll pass design of the preliminary rolling mill is: the pass arrangement order on the roll 7 is 1# box hole 1, 2# box hole 2, 2# round hole 3, 2# oval hole 4 , 1# round hole 5, 1# oval hole 6, the roll can carry out the rolling of two kinds of large round steel. The rolling procedure is shown in Table 1:

[0017] Table 1: Ф250 round steel reduction rules (rectangular billet 340×260)

[0018]

[0019] The dimensional accuracy of the round steel can be controlled within ±4mm, which fully meets the requirements of the forging industry or machining industry.

Embodiment 2

[0020] Example 2, the rolling of Ф300 medium carbon steel 42CrMo, the rolling procedure is shown in Table 2: the dimensional accuracy of the round steel can be controlled within ±5mm, and the rest is the same as that of Example 1.

[0021] Table 2: Ф300 round steel reduction rules (rectangular billet 400×310)

[0022]

Embodiment 3

[0023] Example 3, the rolling of Ф350 medium carbon steel 42CrMo, the rolling procedure is shown in Table 3: the dimensional accuracy of the round steel can be controlled within ±5mm, and the rest is the same as that of Example 1.

[0024] Table 3: Ф350 round steel reduction rules (rectangular billet 440×360)

[0025]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com