Hollow Hanging Board and Split Brick Multifunctional Vacuum Extruder

A vacuum extruder, multi-functional technology, applied in ceramic molding machines, manufacturing tools, etc., can solve the problems of difficult to meet the requirements of hollow hanging board or split brick manufacturing, hollow hanging board is not widely used, and raw materials are single, etc. The effect of expanding the range of product specifications, promoting close integration, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

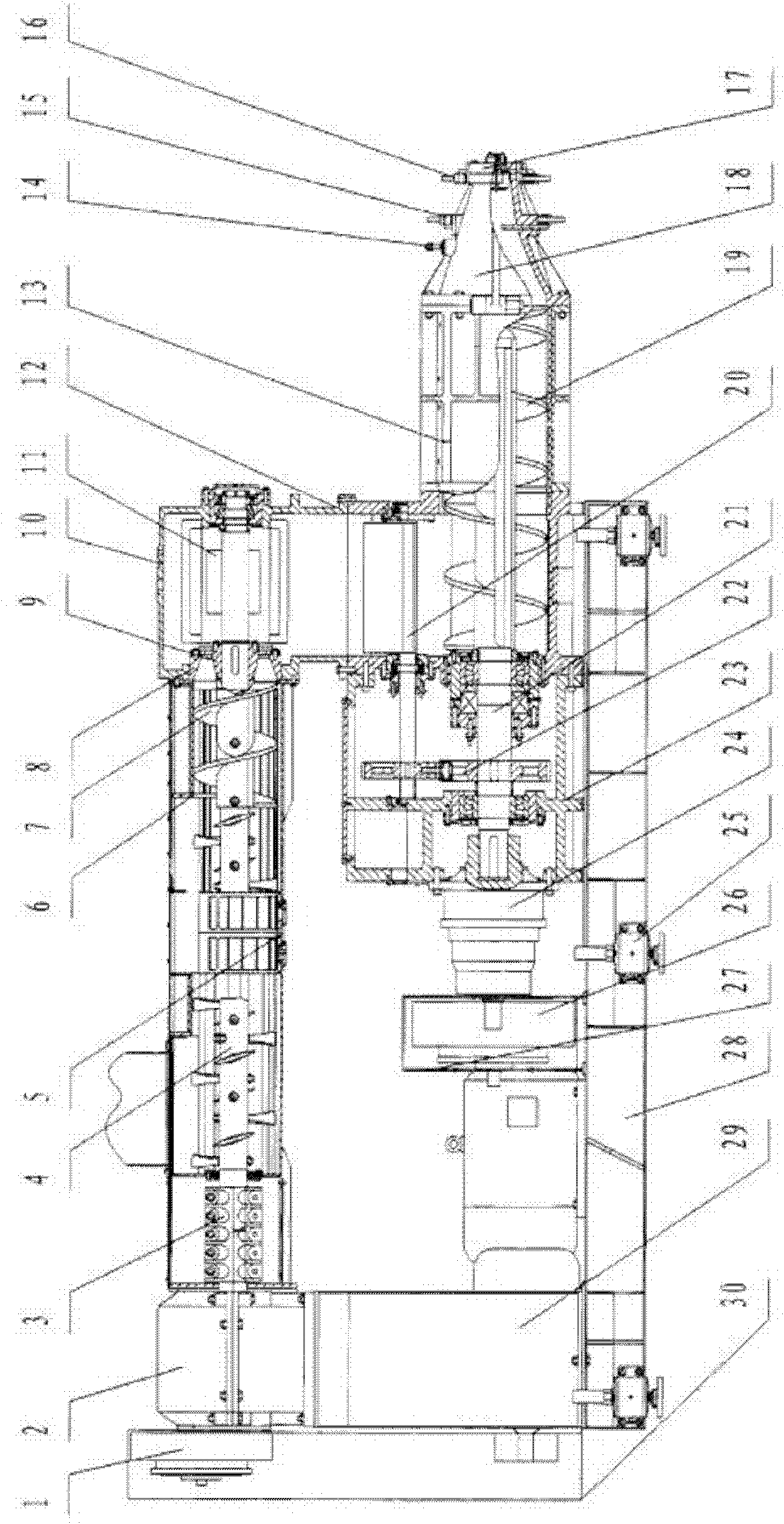

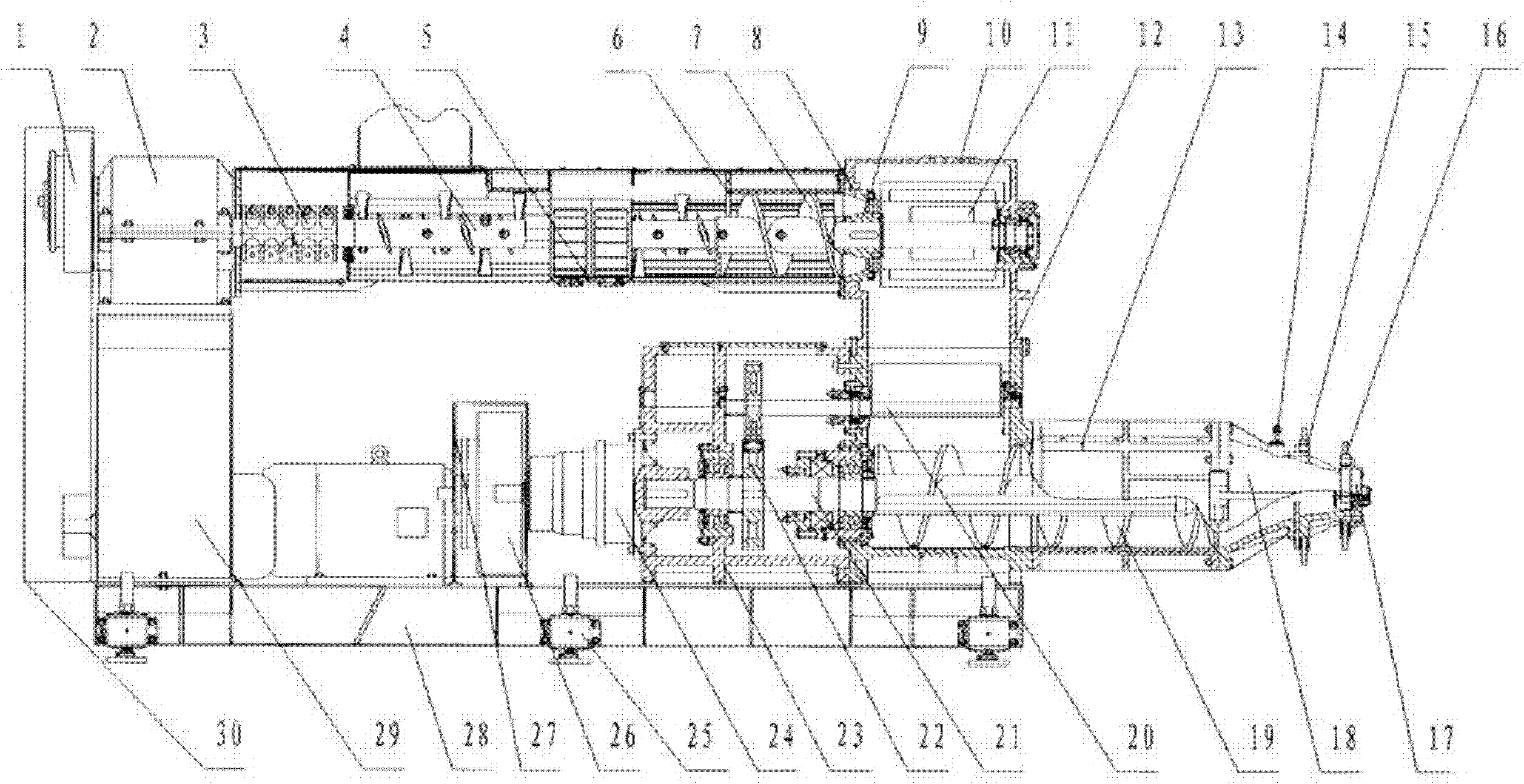

[0012] The figure is a specific embodiment of the present invention.

[0013] Hollow hanging plate and split brick multi-functional vacuum extruder has two parts: the upper mechanism on the upper part for conveying and extruding and mixing materials and the lower mechanism on the lower part to realize material extrusion. The lower mechanism is located on the base 28, and the upper mechanism is One end of the mechanism is supported and fixed on the base 28 by the upper bracket 29, and the other end of the upper mechanism communicates with the mud bucket 12 in the lower mechanism through the vacuum chamber 10; The clutch 1 is connected to drive its rotation, and the two output shafts of the double output shaft arc bearing reducer 2 are connected with the shell coupling 3 to make the two agitating shafts 4 rotate relative to each other, and the end of the agitating shaft 4 is connected with a conveying Huff reamer 7. The conveying Huff reamer 7 is connected to the vacuum chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com