Full-automatic continuous four-side sealing packaging machine

A fully automatic, four-side sealing technology, applied in packaging, transportation packaging, transportation and packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

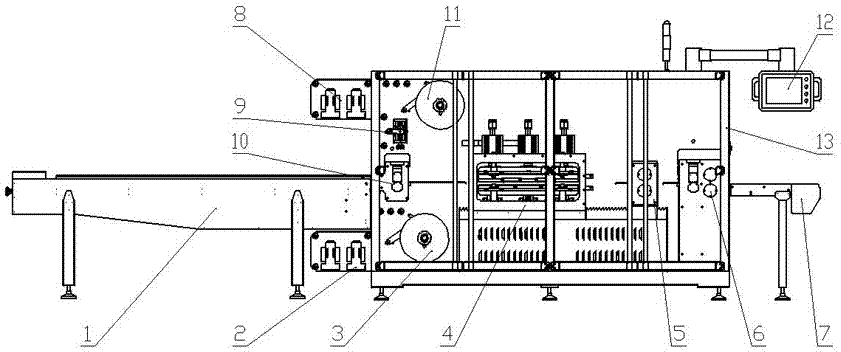

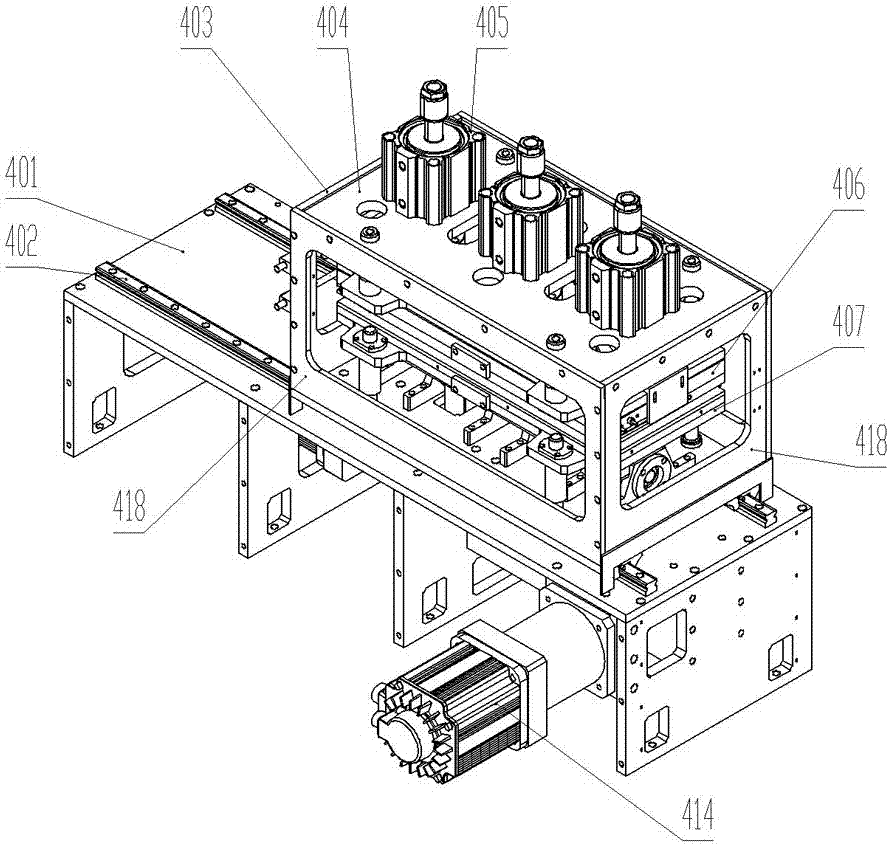

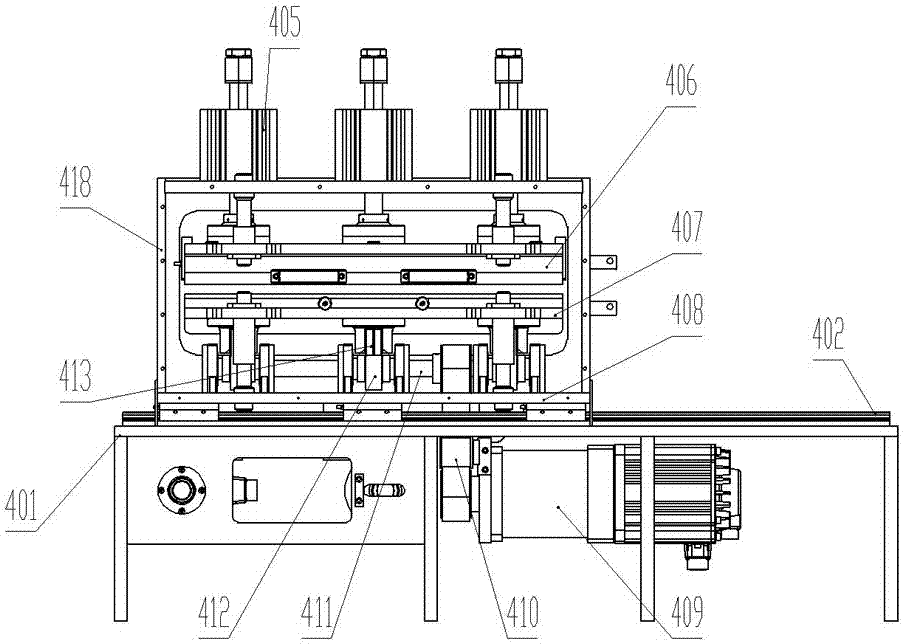

[0010] Such as Figure 1~Figure 4 Shown: a fully automatic continuous four-side sealing packaging machine, including a touch screen electronic control system 12 and a material conveying mechanism 1 set in sequence, a traction unit 10, a heat sealing mechanism 4, an easy-tear opening pressing unit 5, a continuous traction and cutting unit 6, Finished product output part 7, above the traction part 10 is provided with an upper roll film material receiving part 11, an upper roll film coding mechanism 8, a cursor alignment part 9, and a lower roll film material receiving mechanism 3 is provided below the traction part 10 , The coding mechanism 2 for the lower roll film is characterized in that: the heat-sealing mechanism 4 includes a heat-sealing frame 401 and a heat-sealing assembly 403, the heat-sealing frame 401 is provided with a second servo motor 414, a timing pulley 416, the second synchronous pulley 417, the first synchronous pulley 416 and the second synchronous pulley 417...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com