Novel air inlet nozzle runner and air column bag

A technology of air inlet nozzle and air column bag, which is applied in the field of new air inlet nozzle flow channel and air column bag, which can solve the problems of high production cost, heat sealing failure, insufficient air pressure, etc., and achieve air tightness and heat sealing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

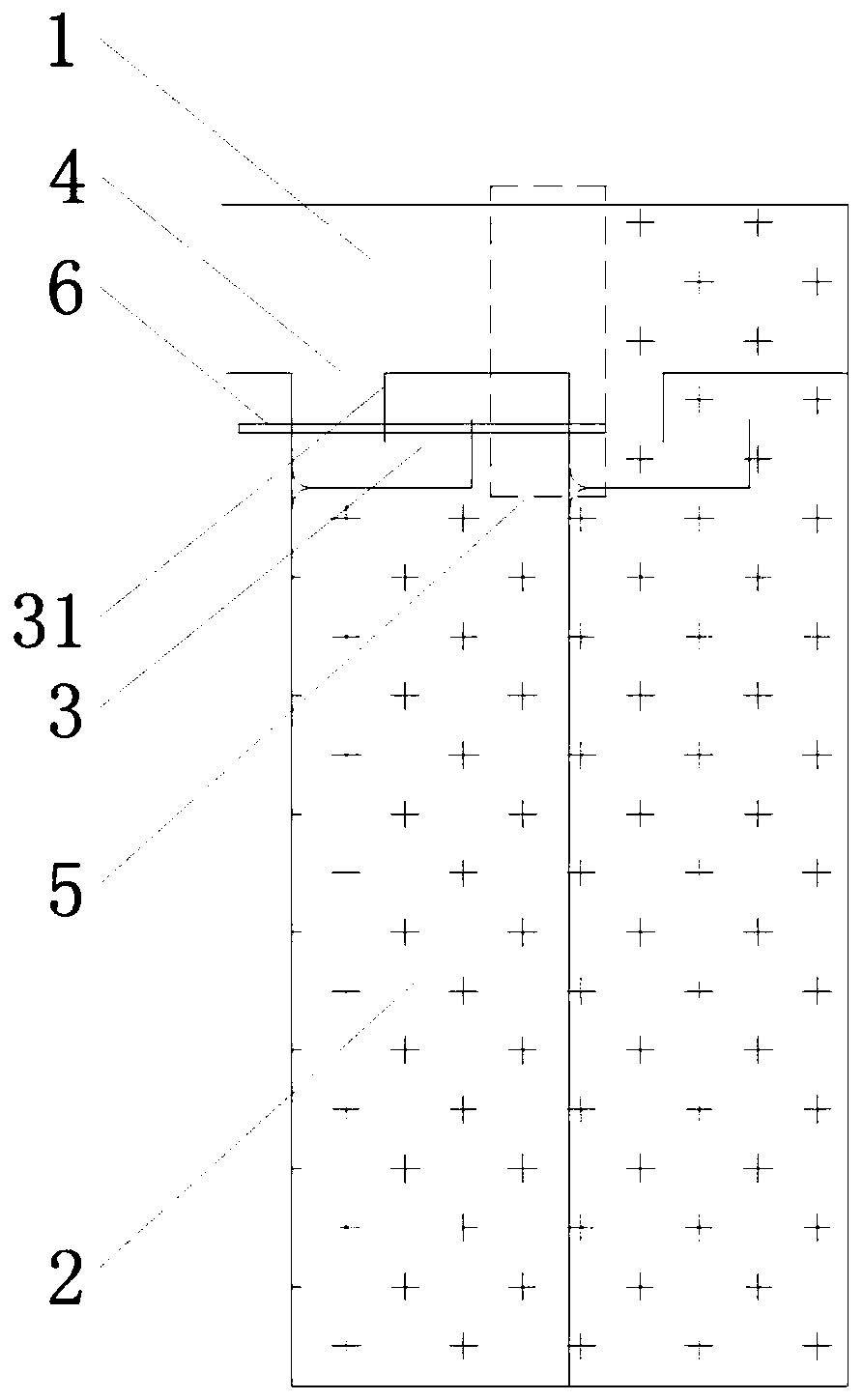

[0030] An air column bag with an air inlet flow path, comprising an air inlet channel 1 formed by heat sealing of upper and lower films and a plurality of air column bag units 2. The air inlet flow path 3 includes an inlet 4 and an outlet 5. The air inlet The inlet 4 and outlet 5 of the runner 3 are respectively connected to the air inlet channel 1 and the air column bag unit 2, and the air inlet runner 3 is separated by a sealing line 31 to form two right-angle bends, such as figure 2 As shown, during the heat sealing process, after the inlet 4 area is heat-sealed, the heat-sealing pressing area (rectangular frame in the figure) moves to the right. At this time, the high-pressure gas is still locked in the right area, and the gas will not affect the inlet 4 The heat-sealing line 6 at the location is affected, and the heat-sealing line 6 begins to cool. When the hot-pressing zone moves to the right of the outlet 5 area, the high-pressure gas will flow through the inlet nozzle ru...

Embodiment 2

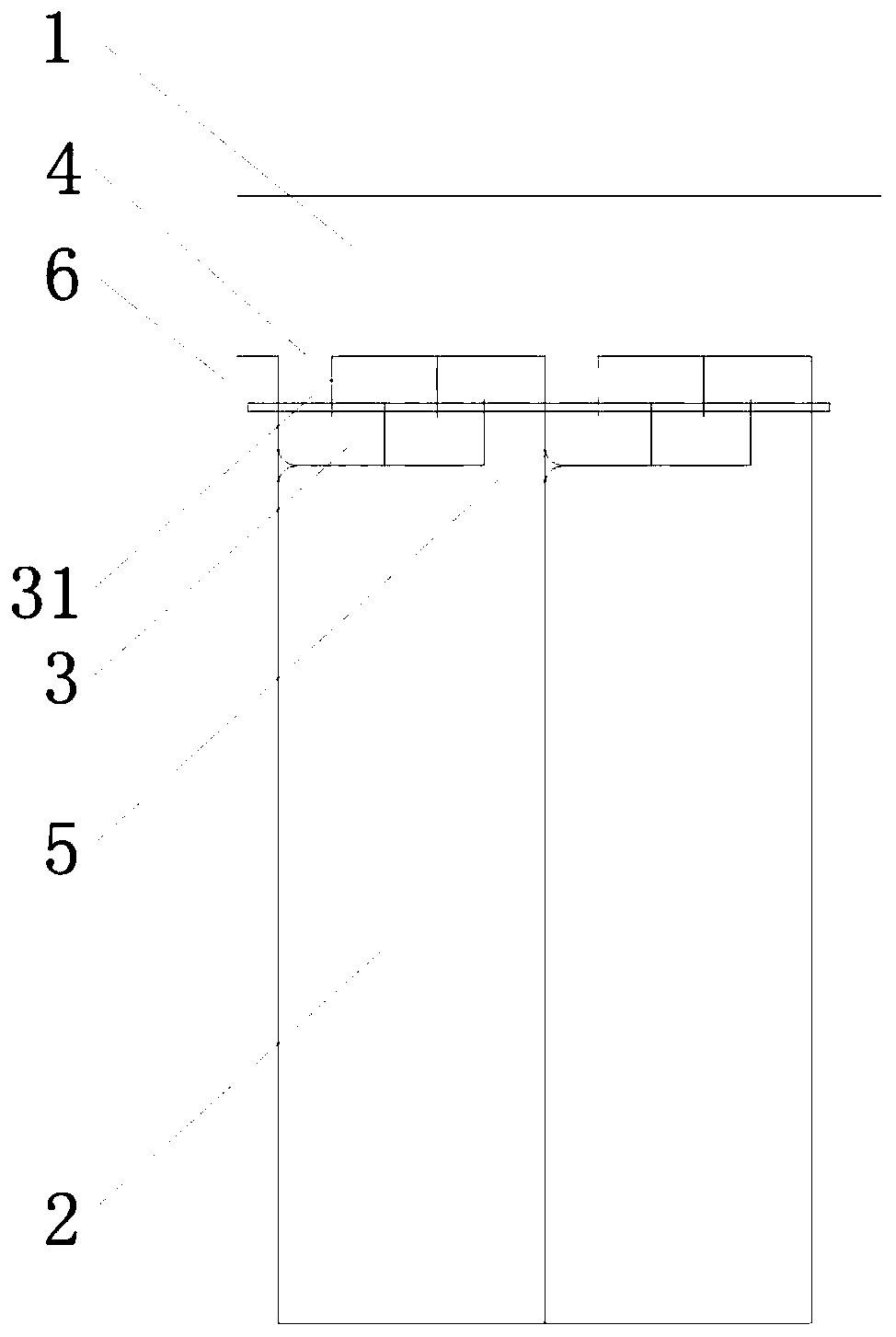

[0032] The difference between this embodiment and embodiment 1 is that the inlet nozzle runner 3 is separated by the sealing line 31 to form 4 right-angle bends, such as image 3 As shown, by increasing the number of bends, the effect of blocking high-pressure gas is more obvious.

Embodiment 3

[0034] The difference between this embodiment and embodiment 1 is that the angle of the curve is greater than 90 degrees, such as Figure 4 Shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com