Patents

Literature

209results about How to "Improve closing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

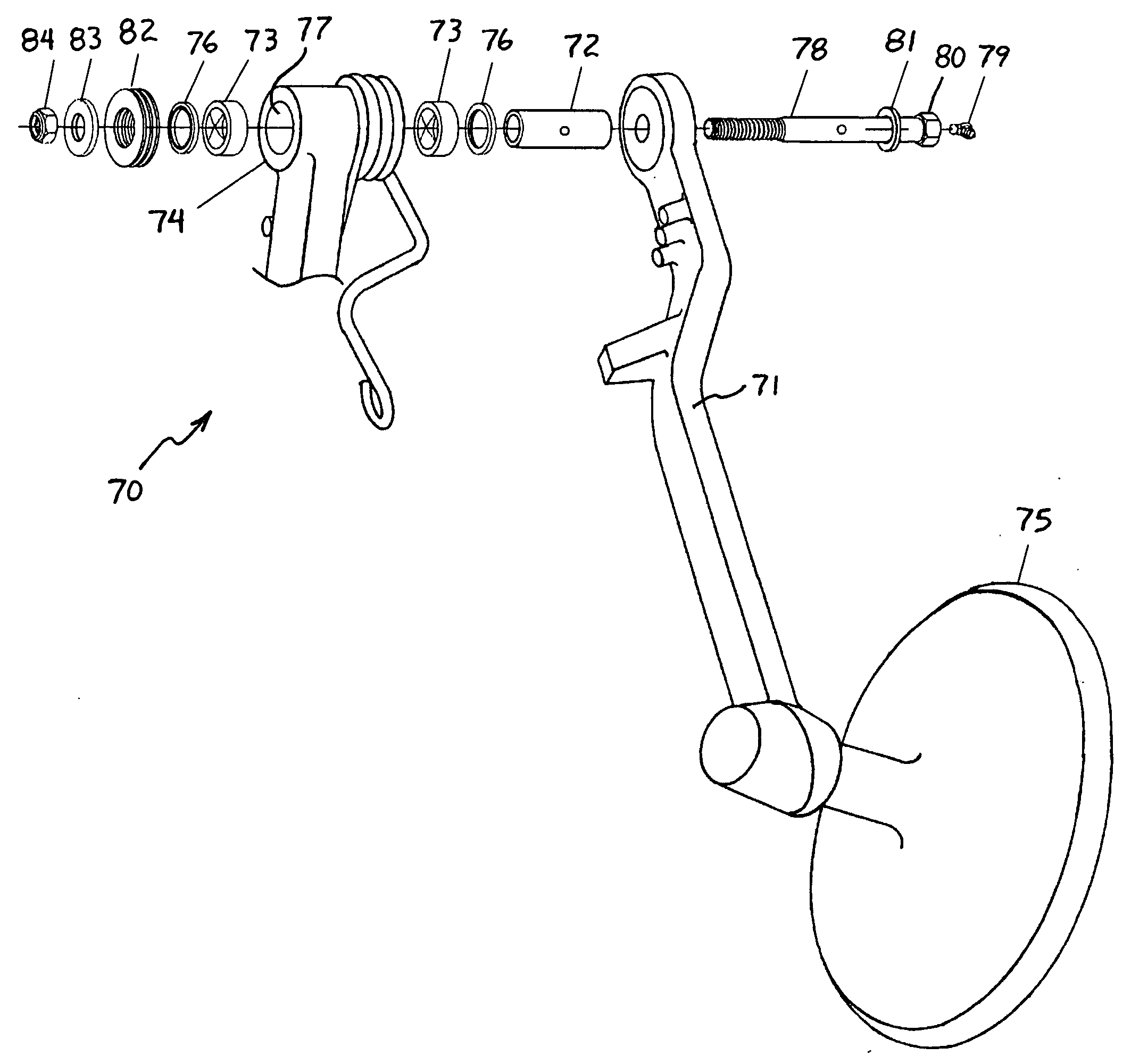

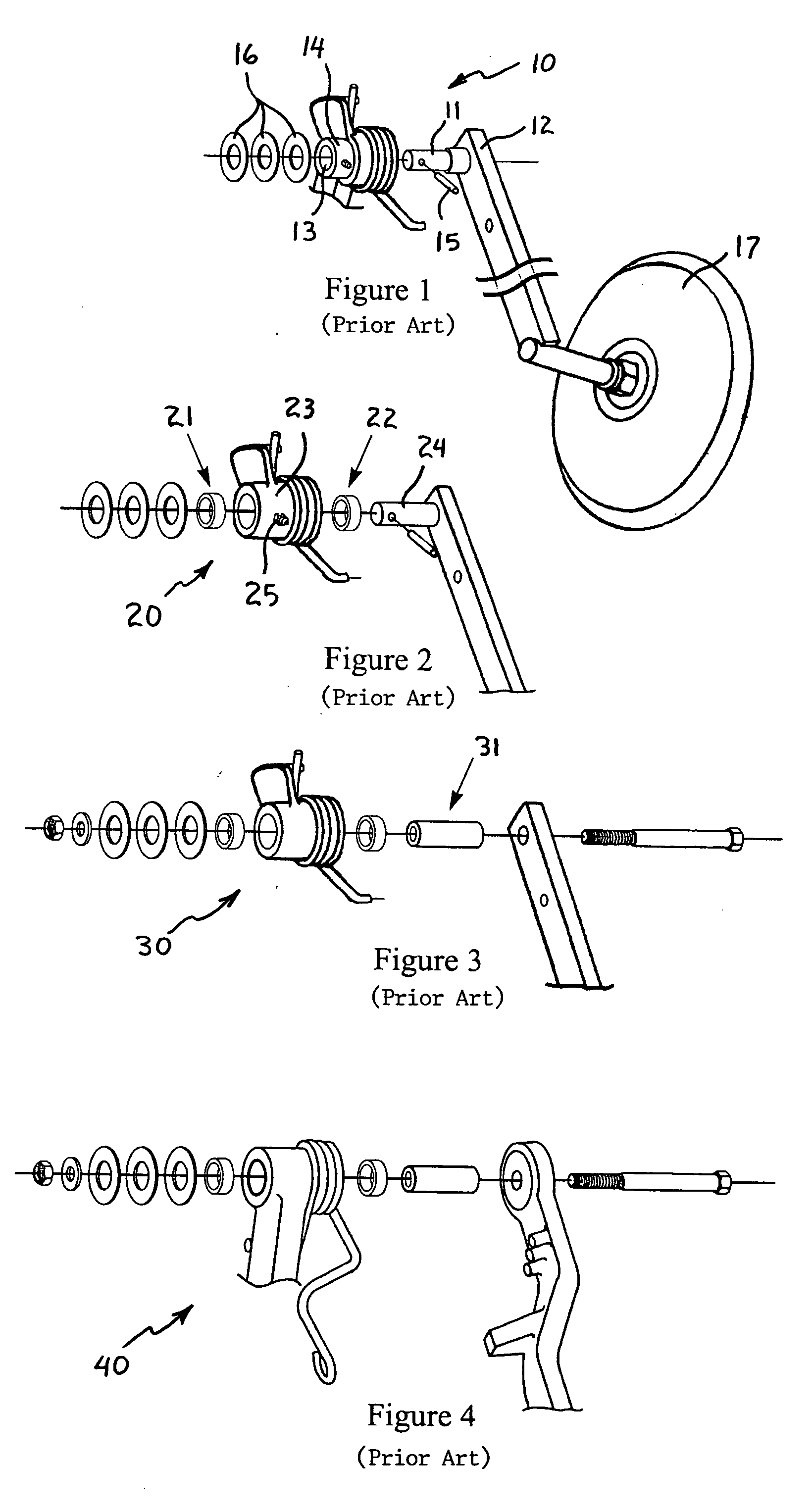

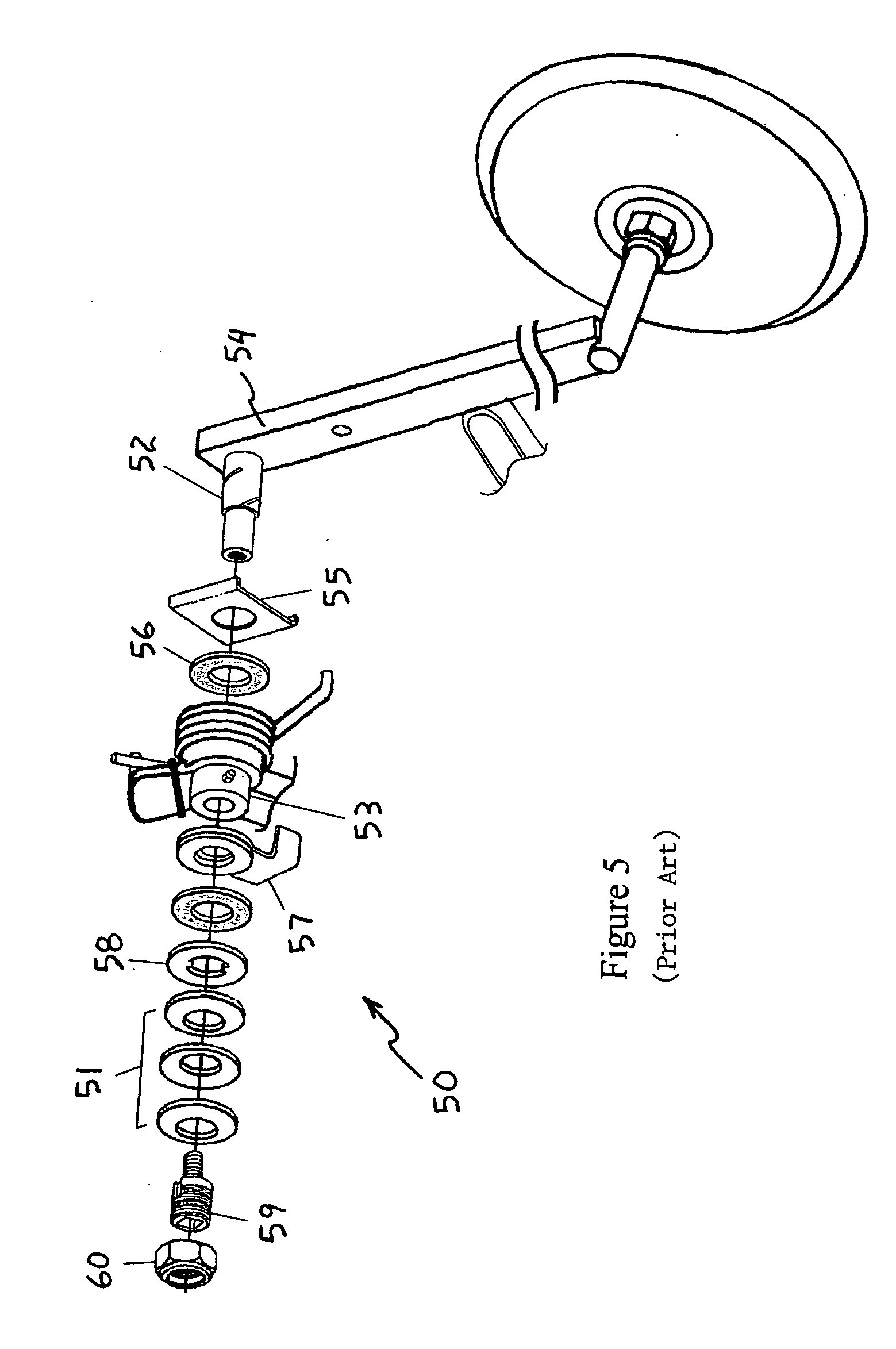

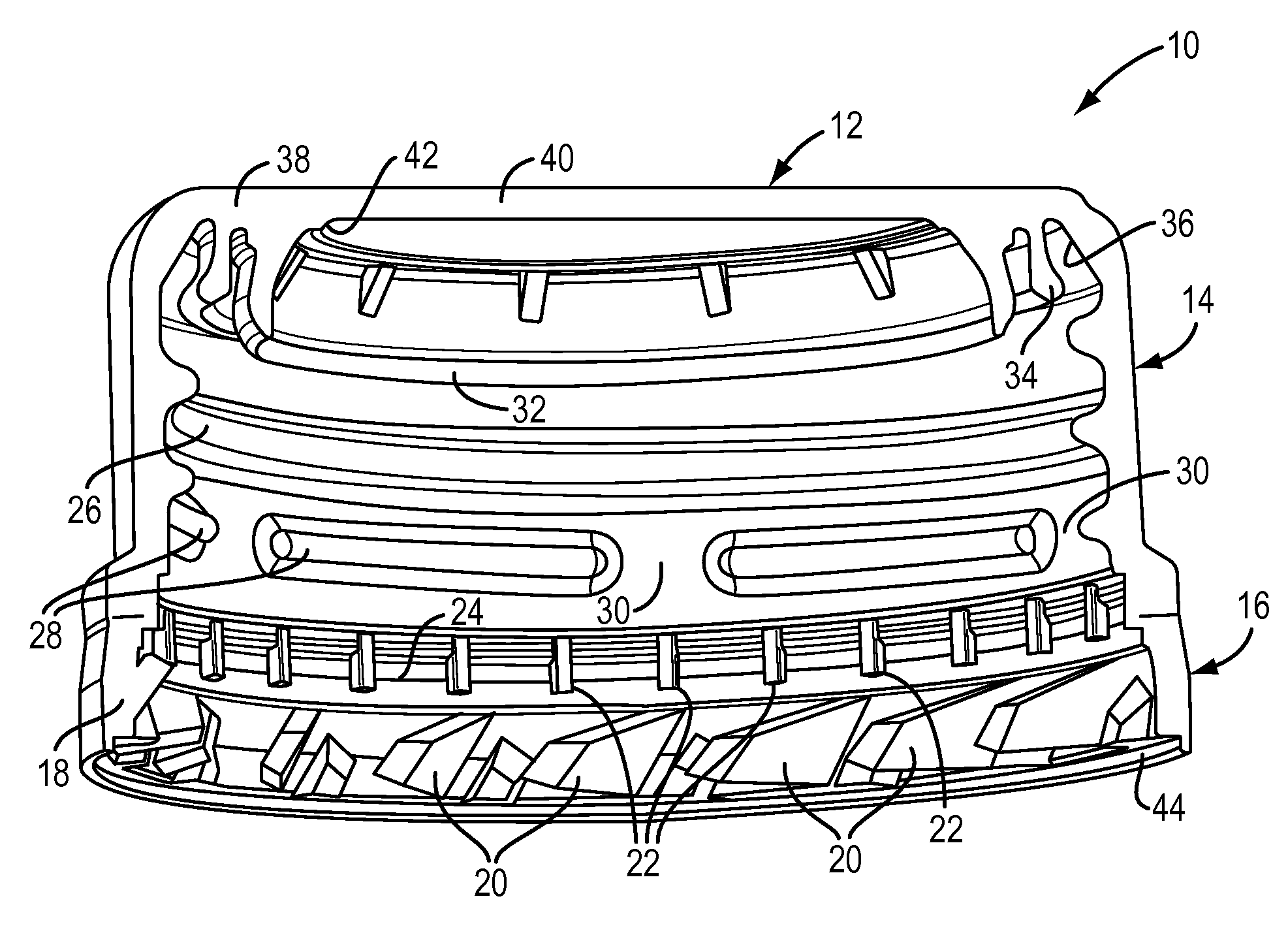

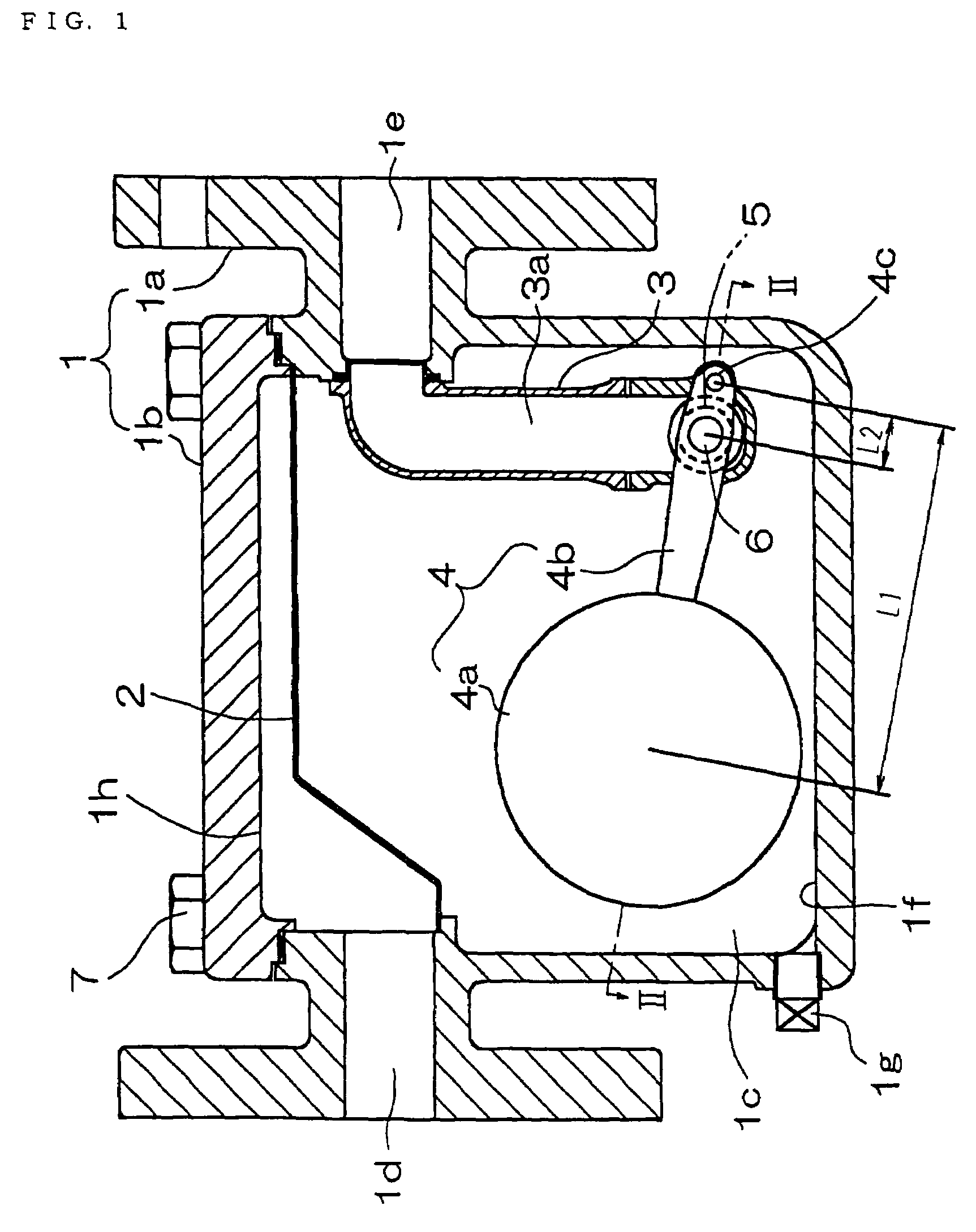

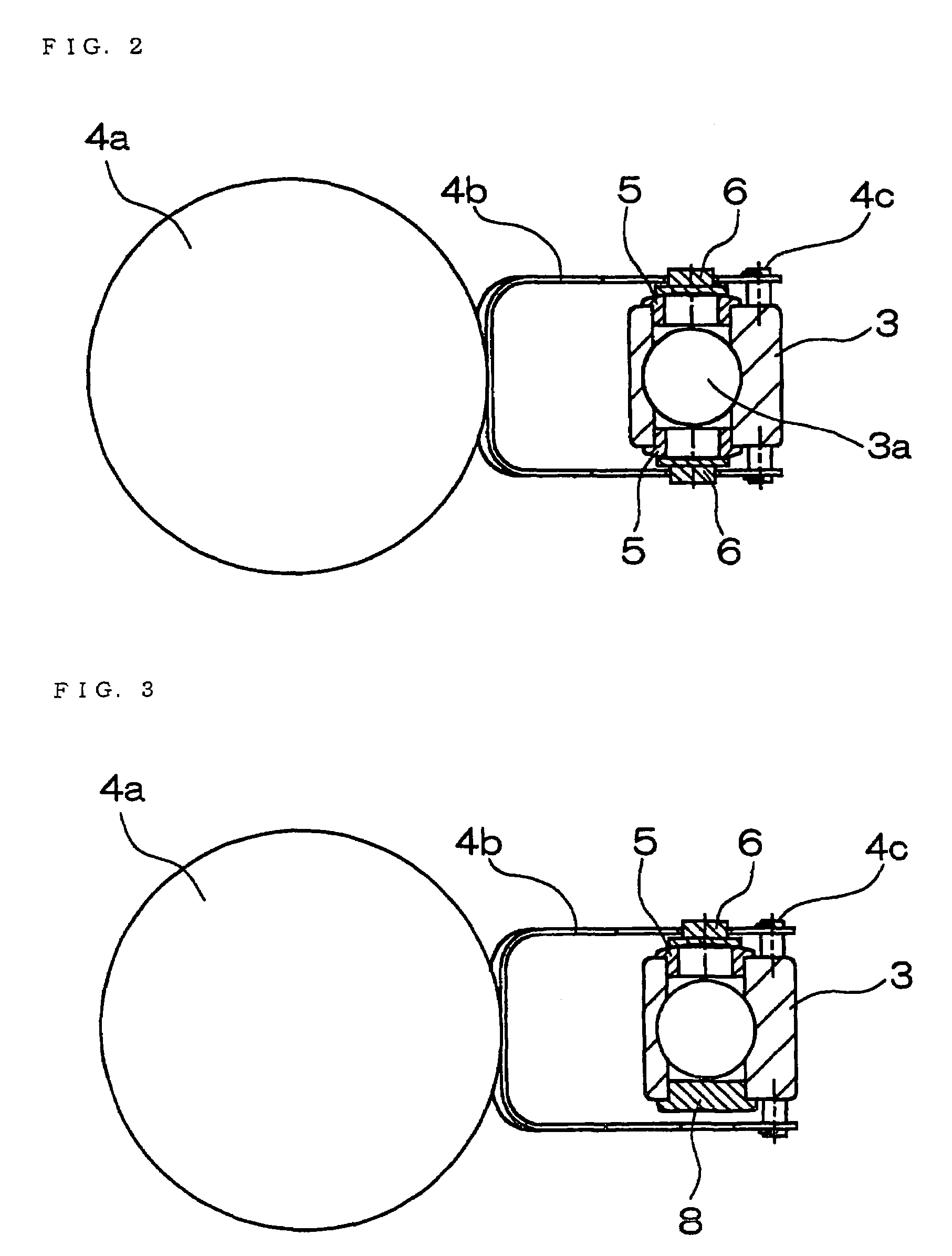

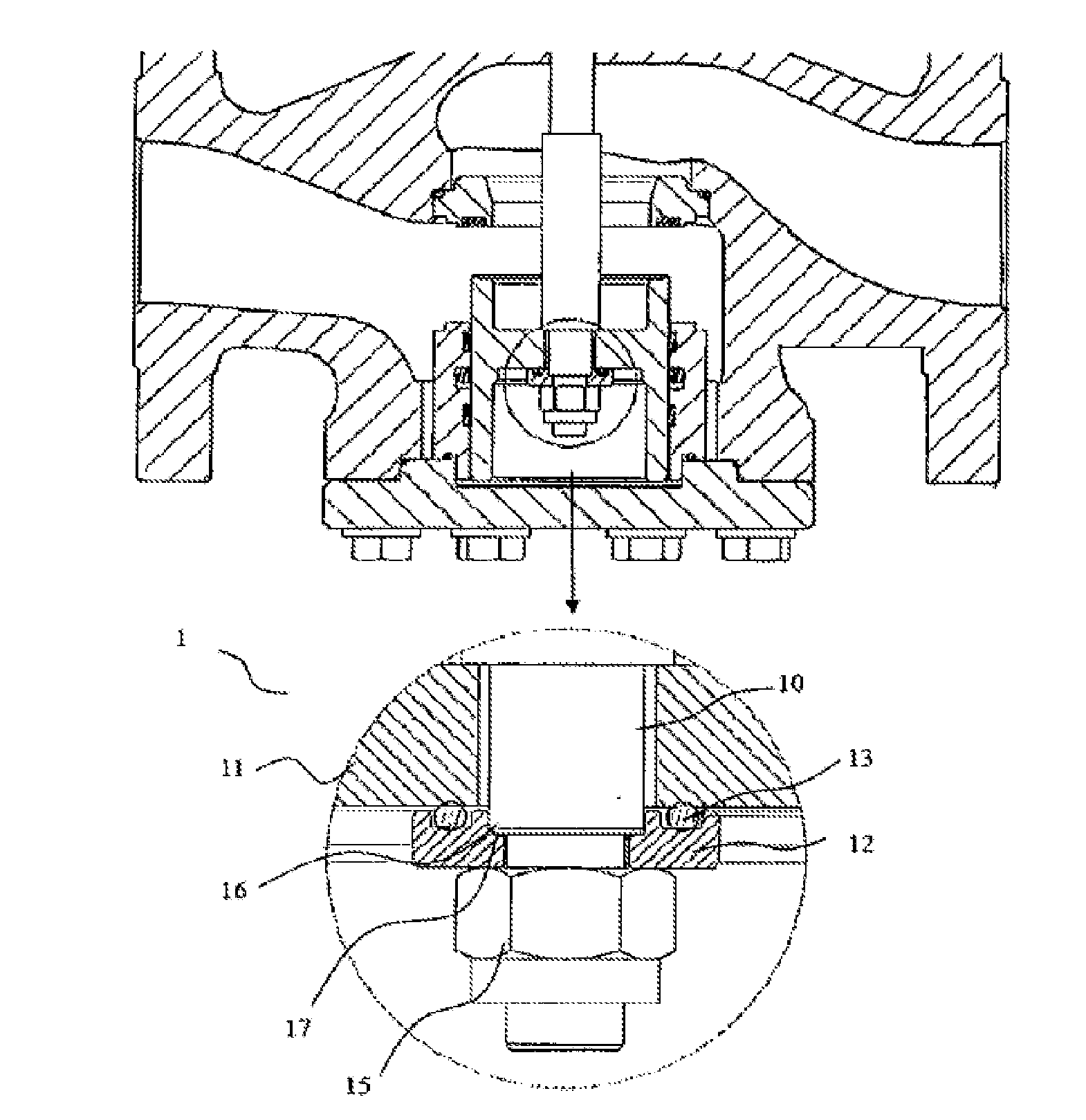

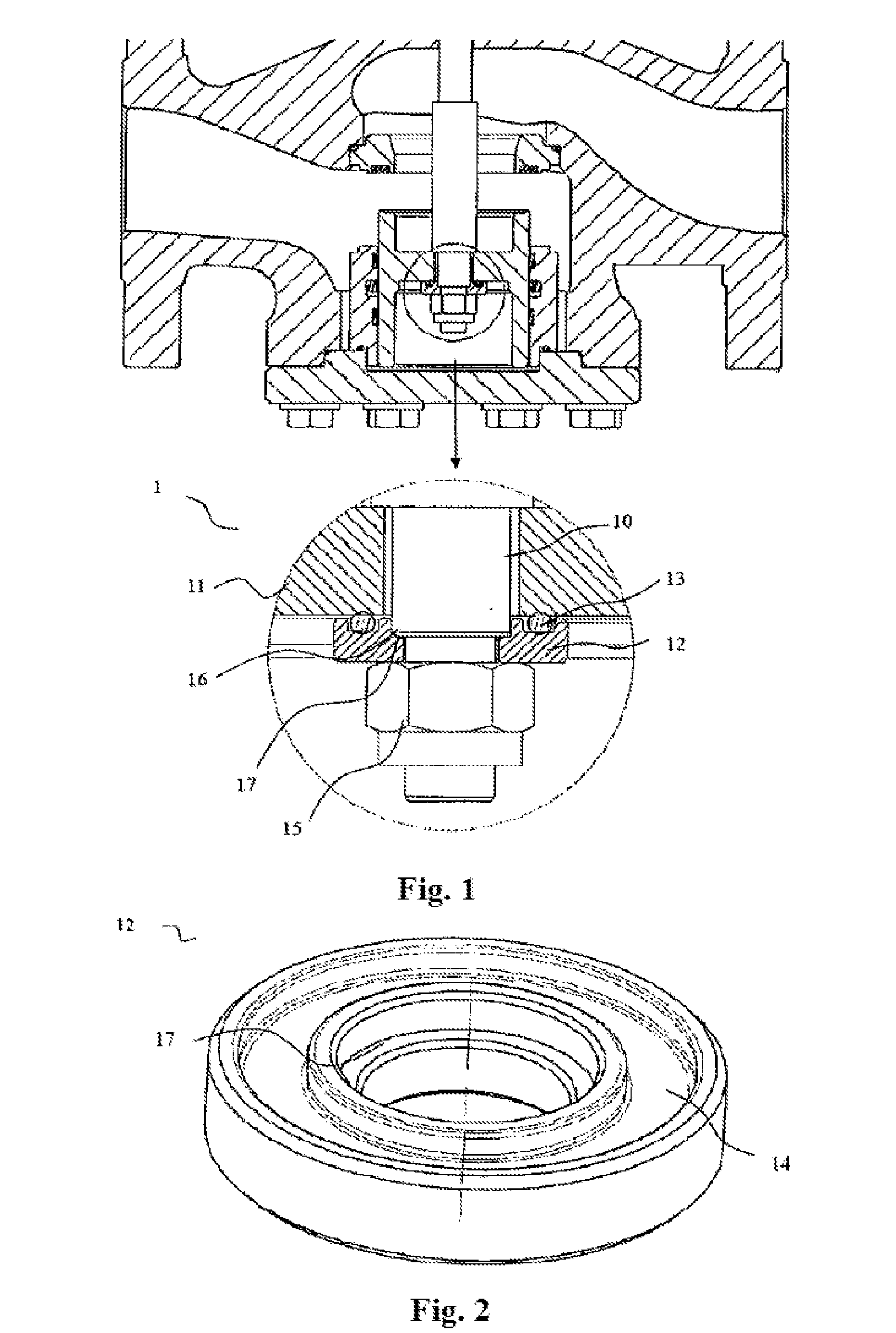

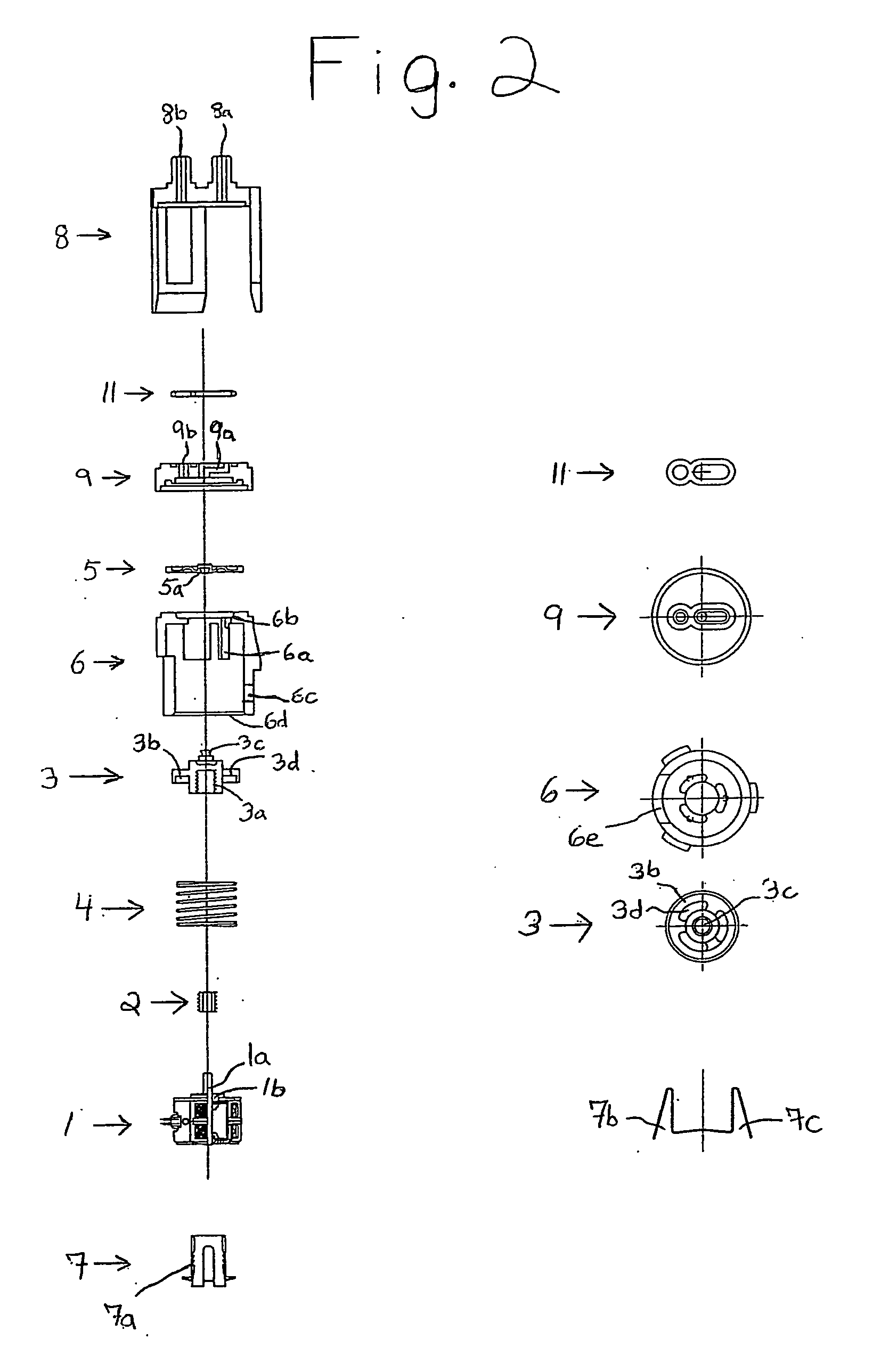

Closing wheel arm pivot assembly

InactiveUS20050072344A1Extend your lifeImprove closing effectSpadesAgricultural machinesEngineeringReamer

A pivot assembly for attaching a closing wheel arm to a bearing housing of a no-till drill has a pair of sleeve bearings, a pair of seals, and a pivot bushing or pivot pin that extends through the sleeve bearings and seals. The sleeve bearings are press fit into opposite ends of a bore of the bearing housing and have grooves formed across bearing surfaces thereof for grease to flow to outer ends of the bearings. The seals are also press fit into the opposite ends of the bearing housing bore. The pivot bushing or pivot pin is installed into the sleeve bearings with an outer surface thereof providing a close-running fit with the bearing surfaces of the sleeve bearings. The close-running fit has a clearance within the range of 0.001 to 0.002 inch and can be provided by passing a reamer through the inner bore of the sleeve bearings.

Owner:KESTER PHILIP C

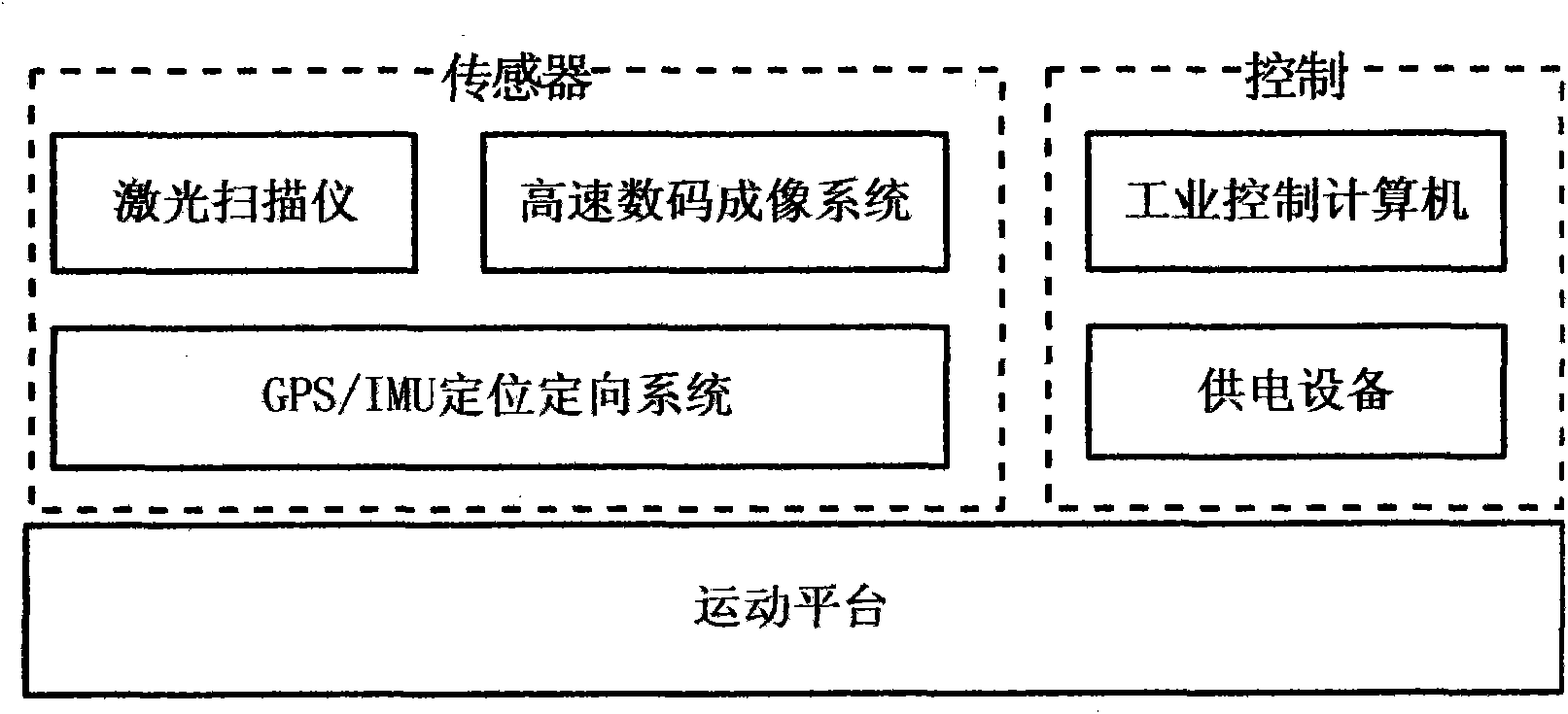

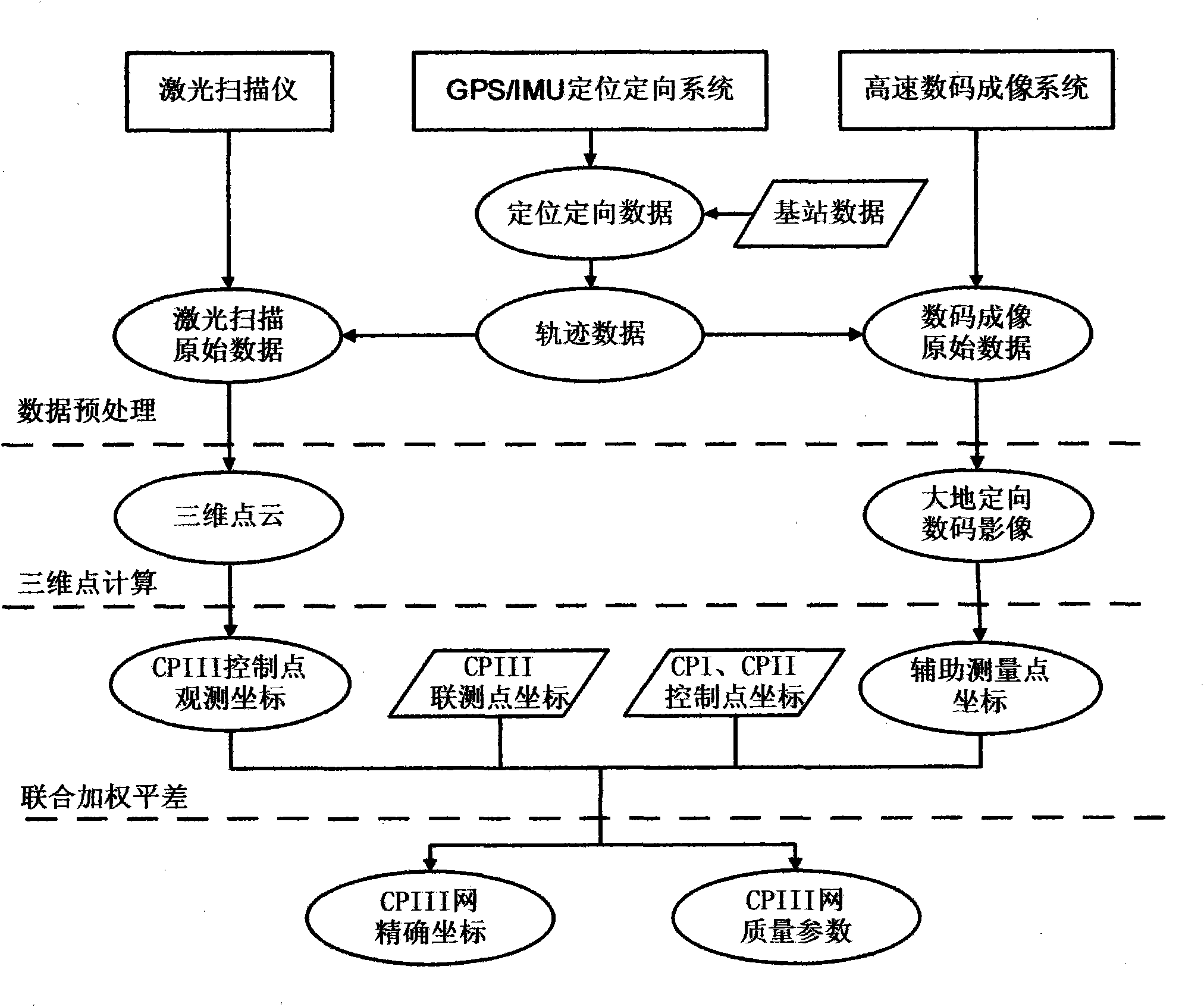

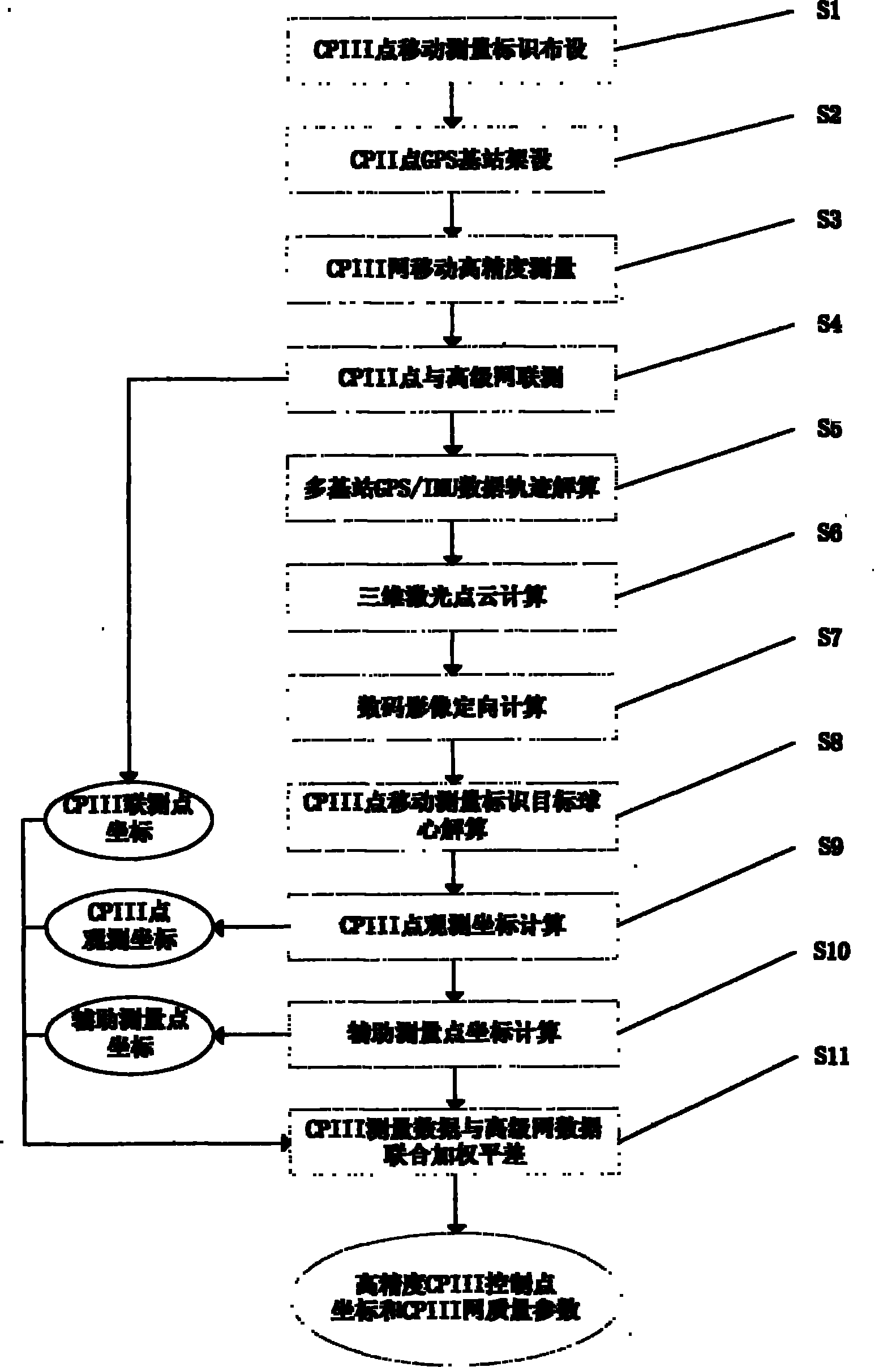

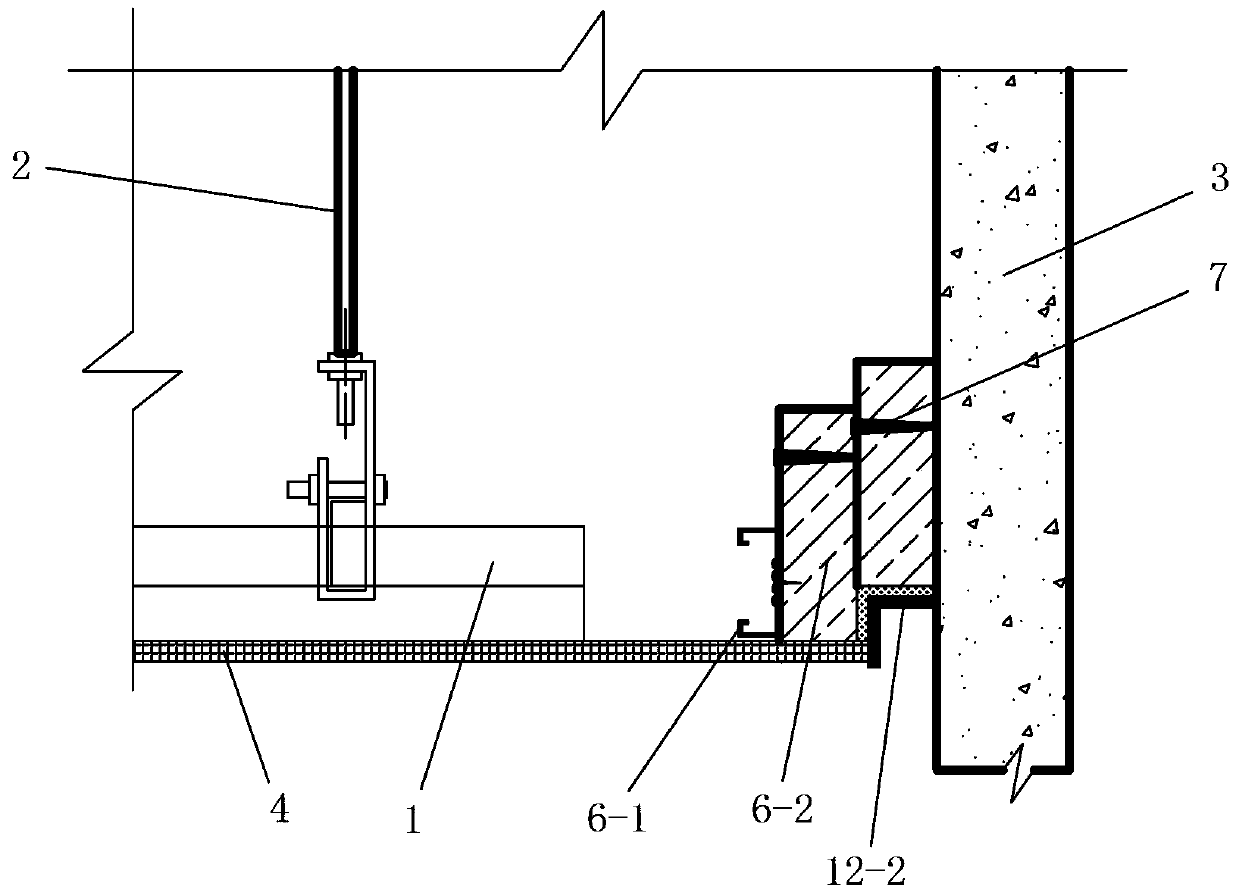

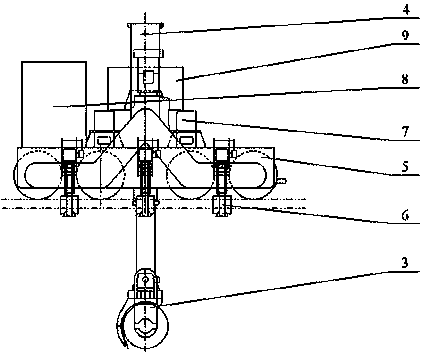

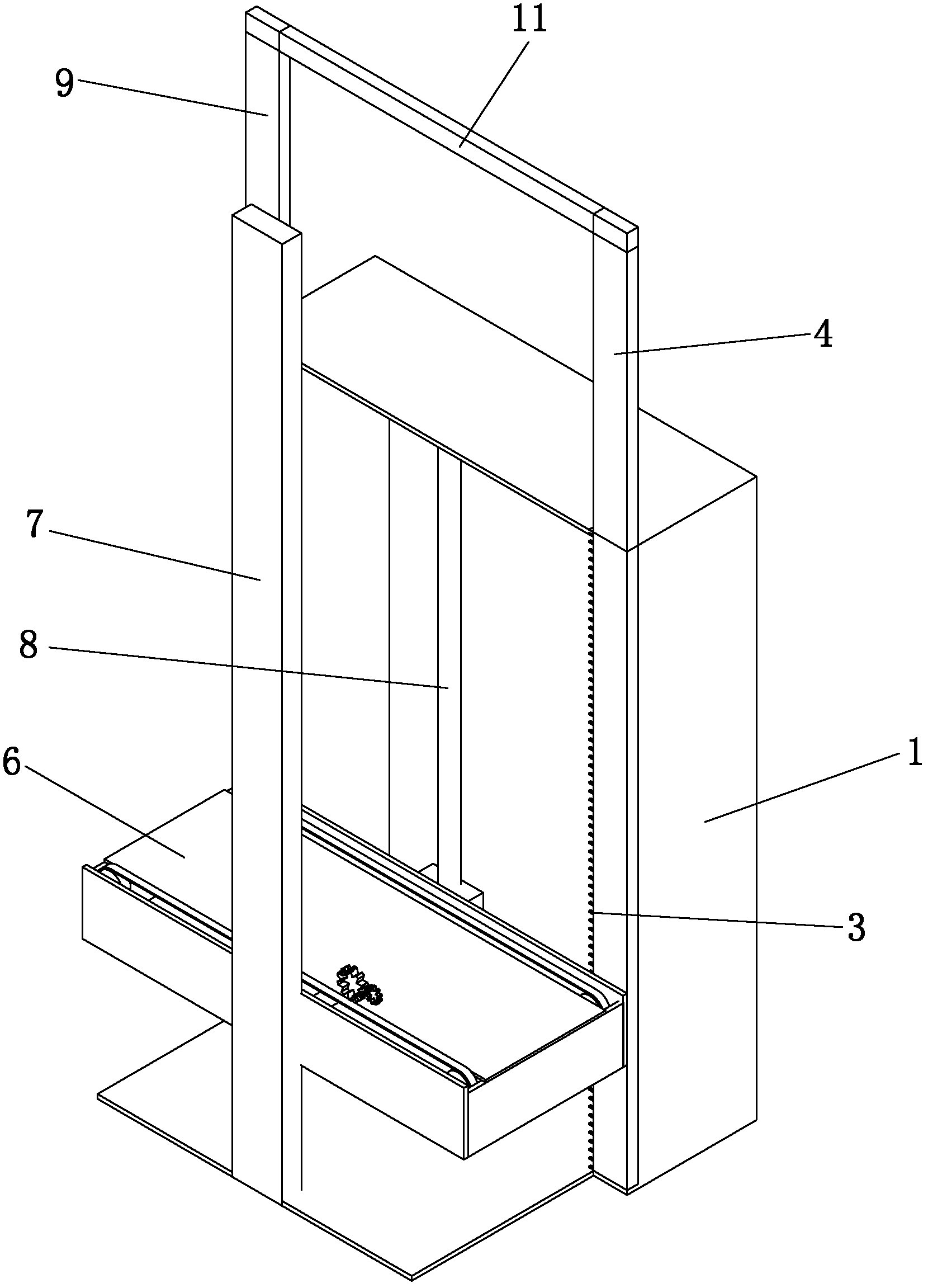

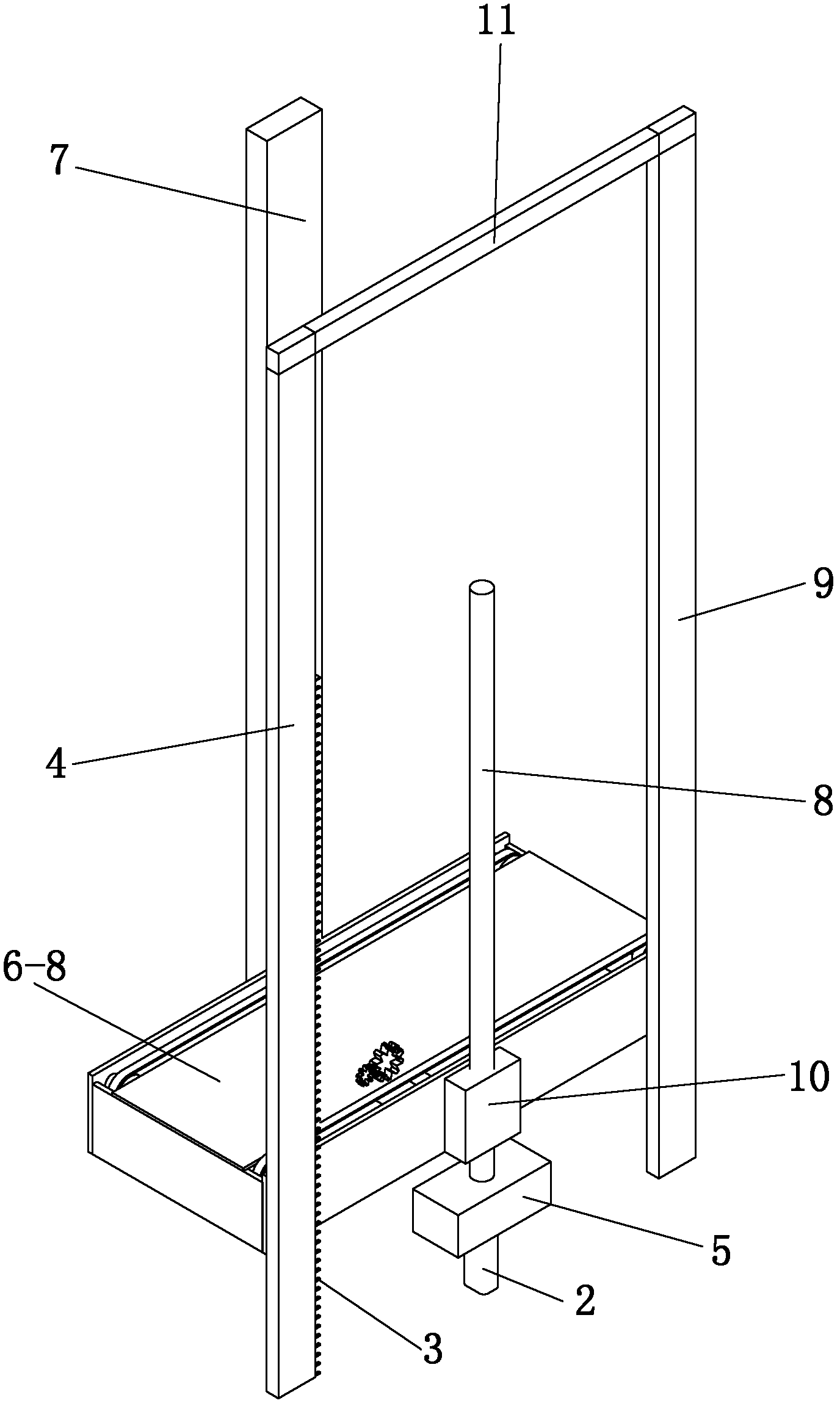

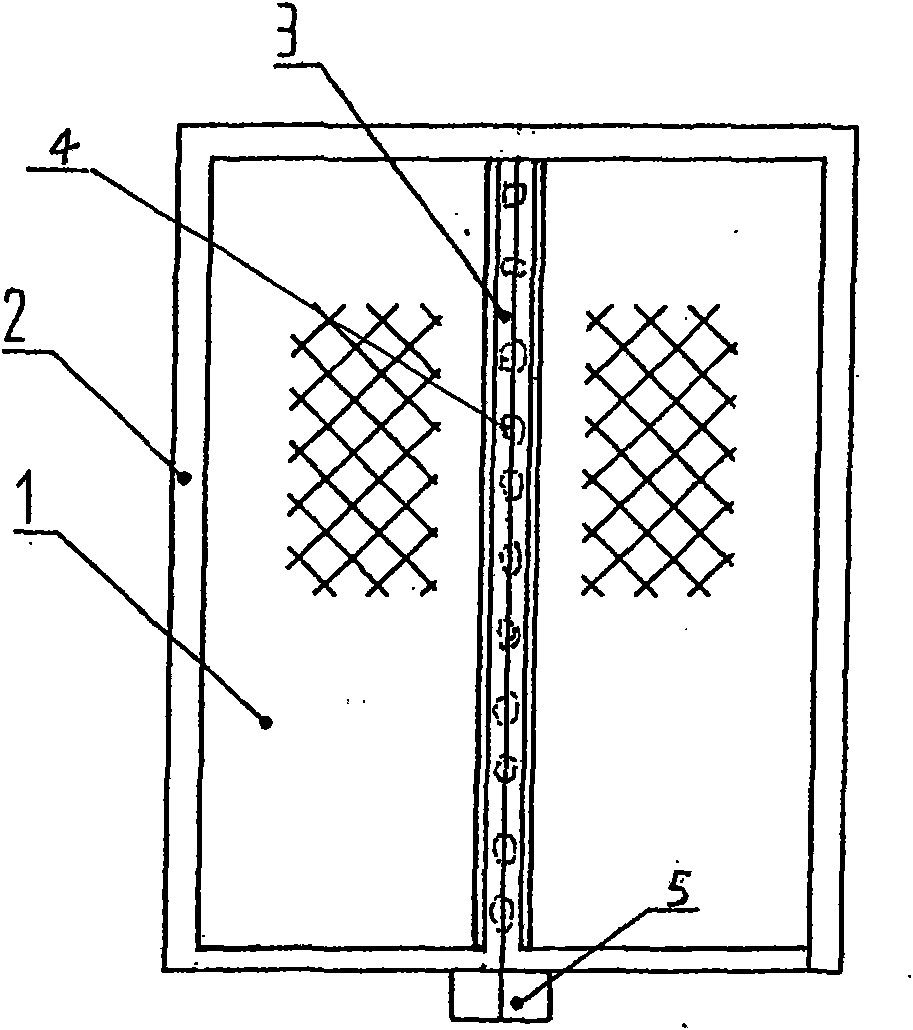

Method for rapidly measuring foundation pile control net (CPIII) of rapid transit railway

InactiveCN101914881AReduced measurement timeSimplify your measurement workSurveying instrumentsMeasuring apparatusFast measurementRelative precision

The invention relates to the field of precise engineering survey, in particular to a method for rapidly measuring a foundation pile control net (CPIII) of a rapid transit railway on the basis of movable laser radar measuring technology and high-speed digital imaging technology. control net (CPIII) measurement data is obtained by using a movable high-precision measurement system comprising a laser scanner (1), a GPS / IMU positioning and orientating system (2), a high-speed digital imaging system (3), an industrial computer (4) and a power supply device (5); and united weighted adjustment is carried out on advanced net data, united measured data and auxiliary measurement points extracted from images to obtain high-precision control net (CPIII) control point coordinates. The invention can greatly shorten the measurement time of the control net (CPIII), overcomes the defect of little total correlation of discrete single-point measurement, carries out integral adjustment on all control points, has good closing property and high relative precision, obtains plane and elevation coordinates of all control points, and greatly simplifies the measurement work of the control net (CPIII).

Owner:扬州德可达科技有限公司

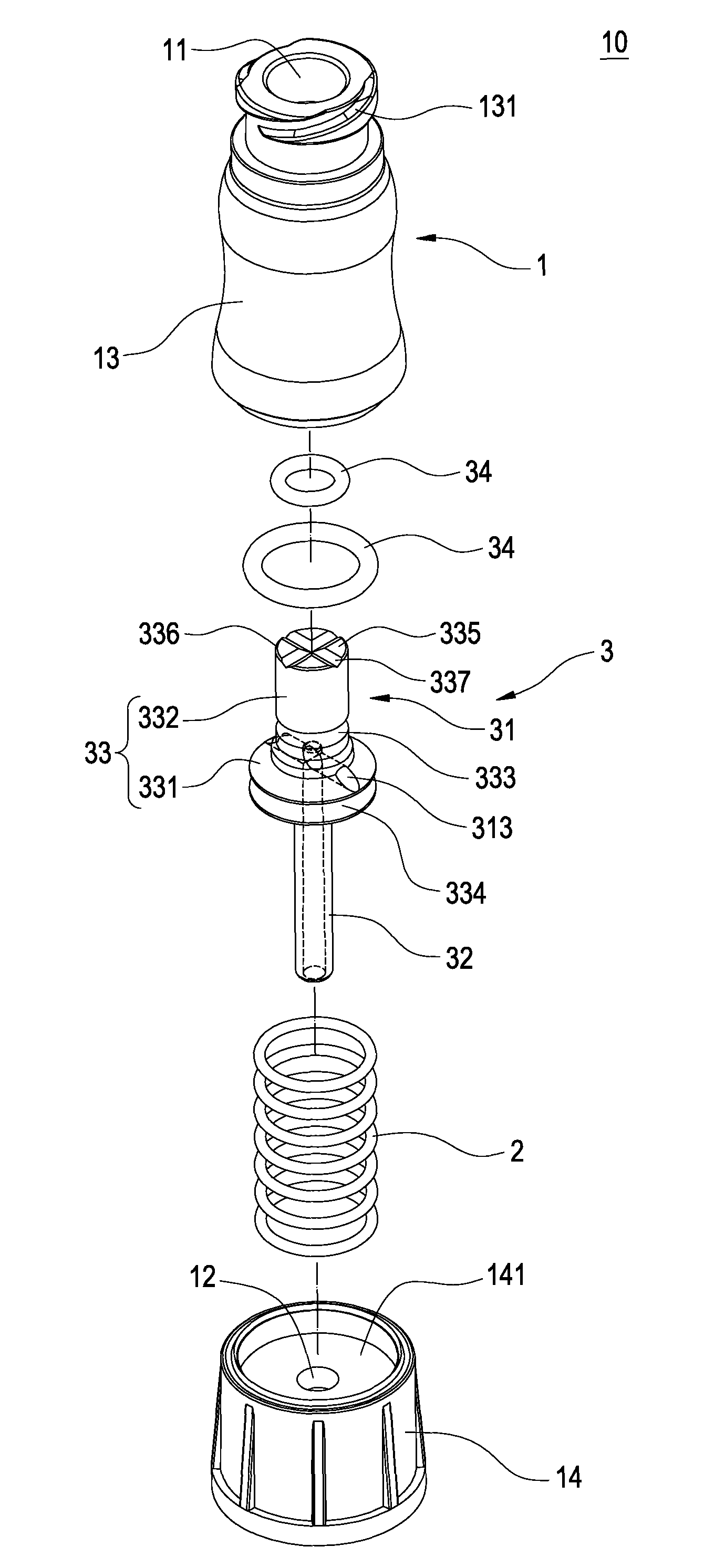

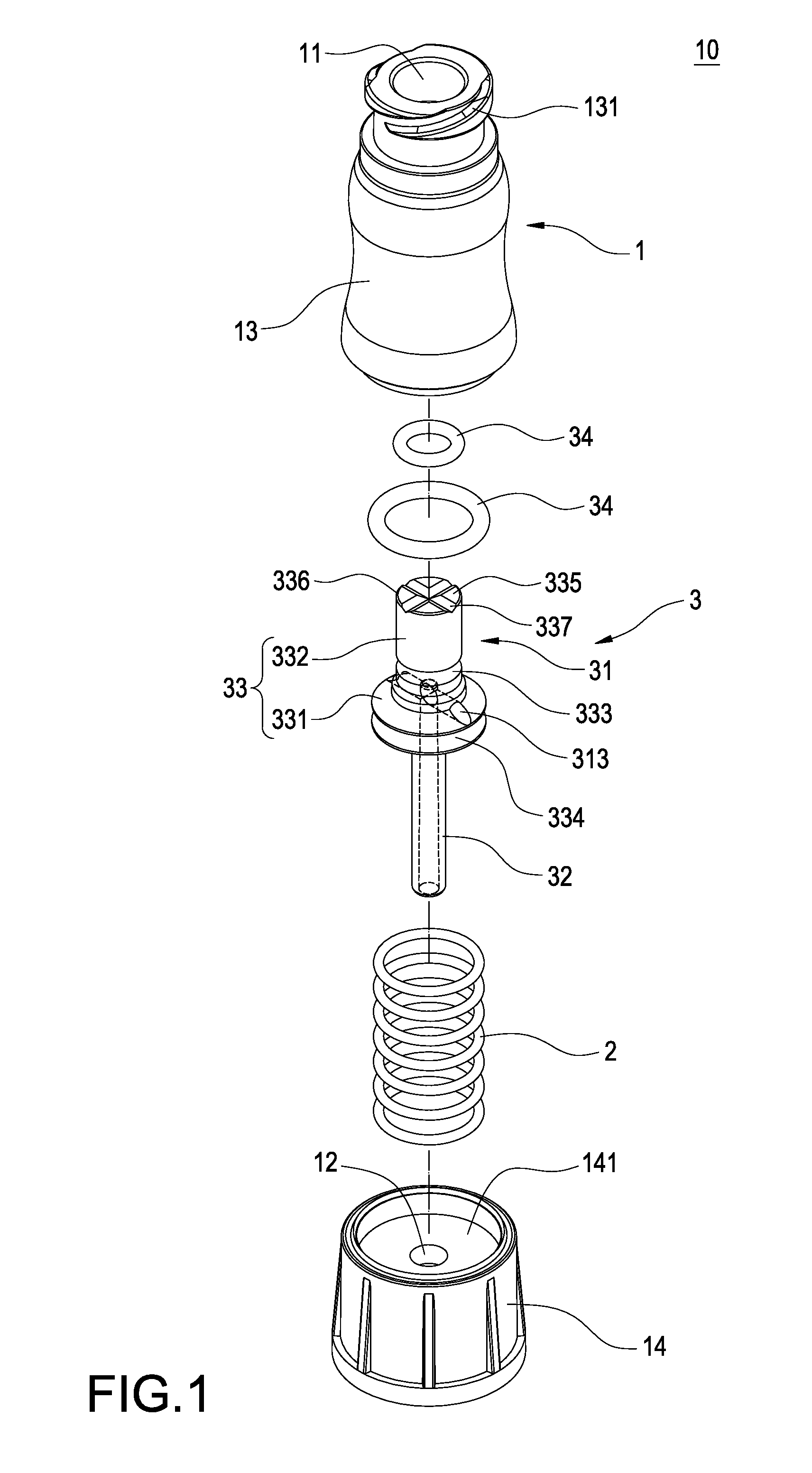

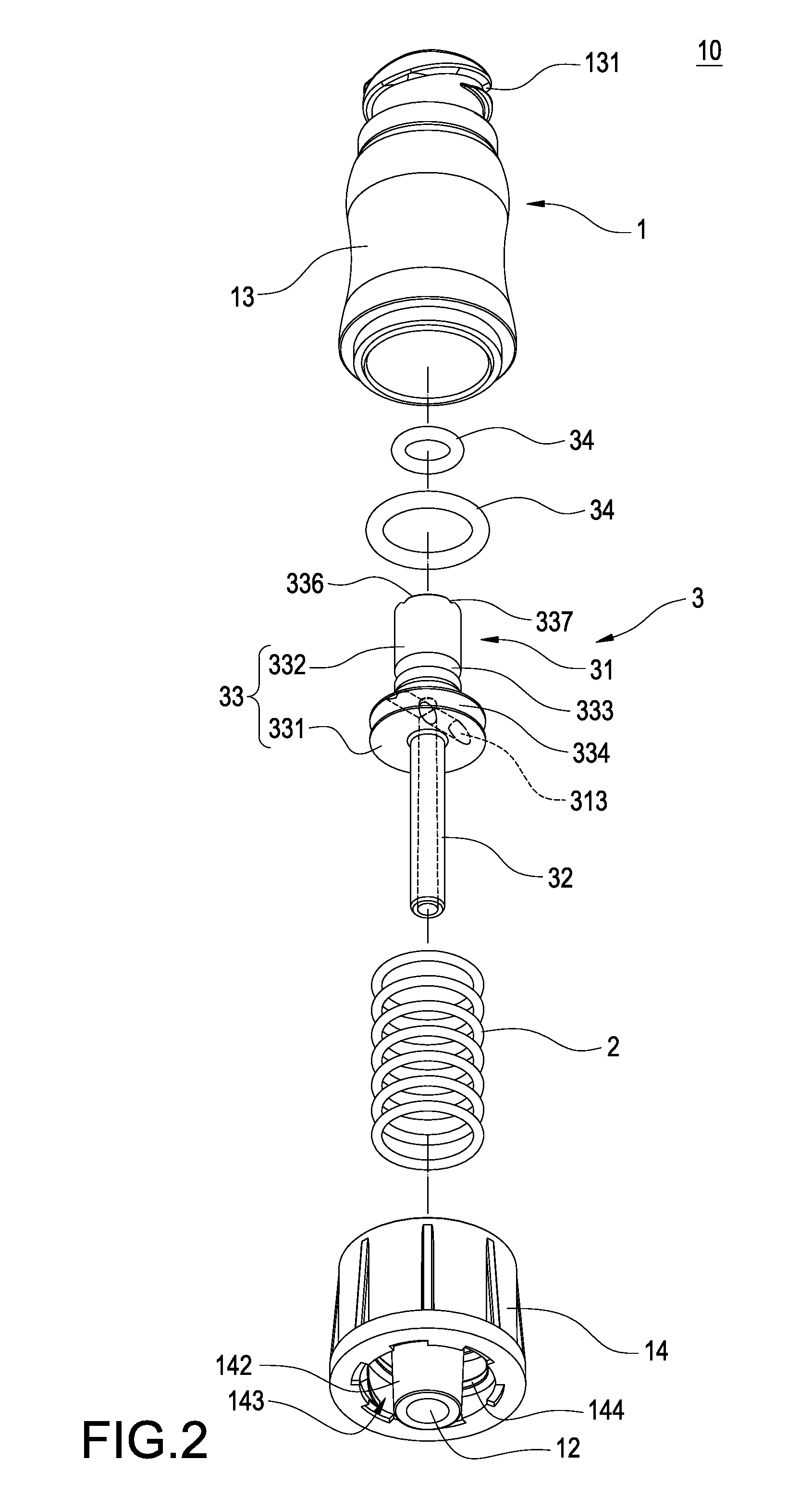

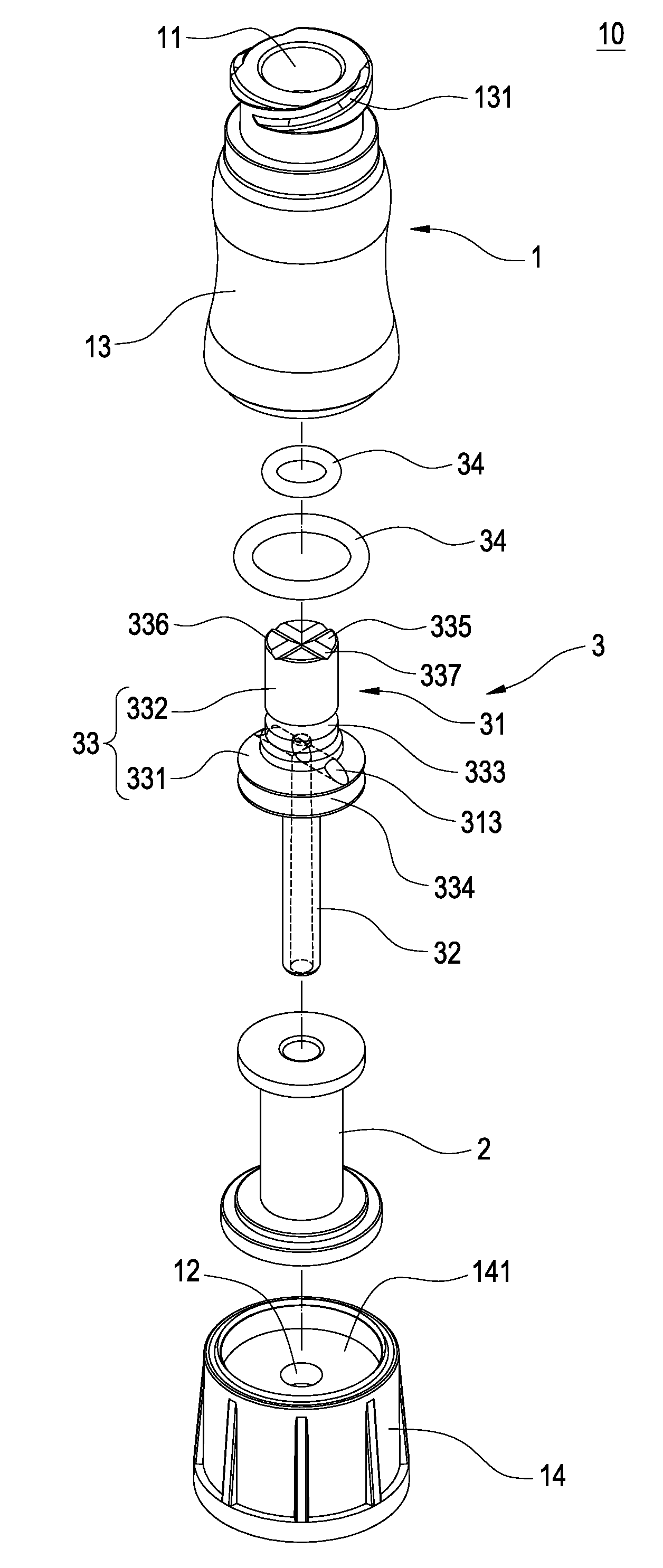

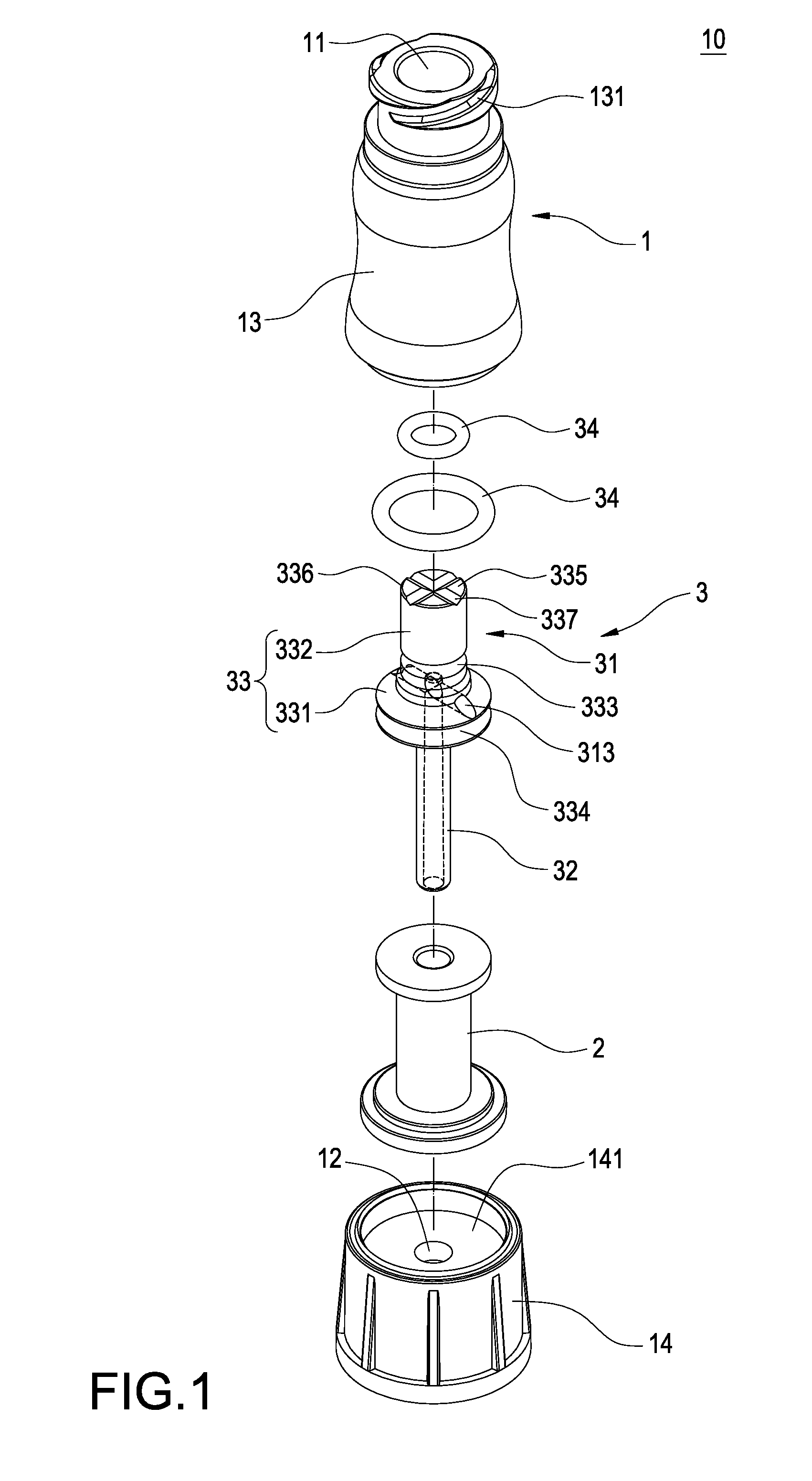

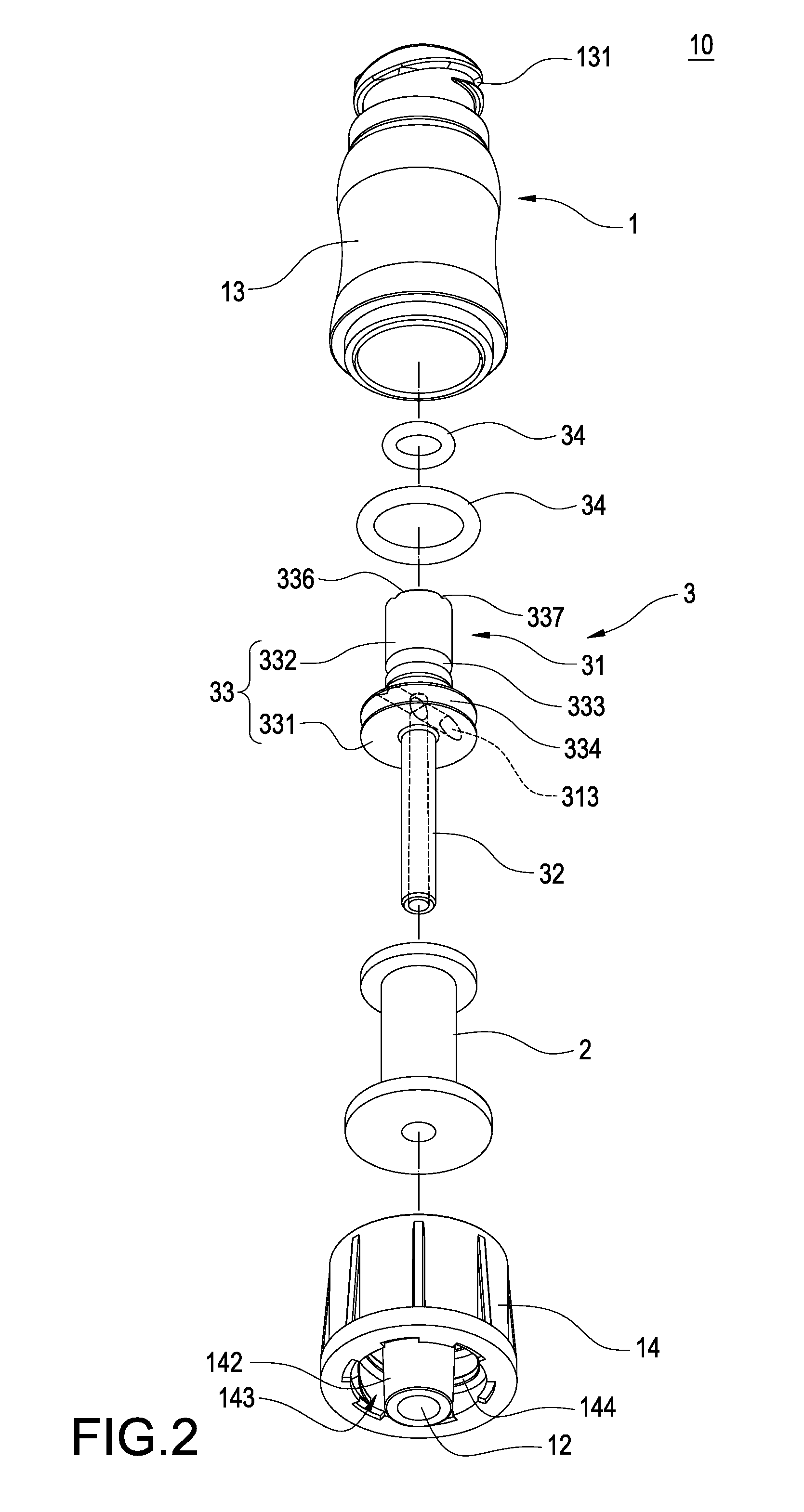

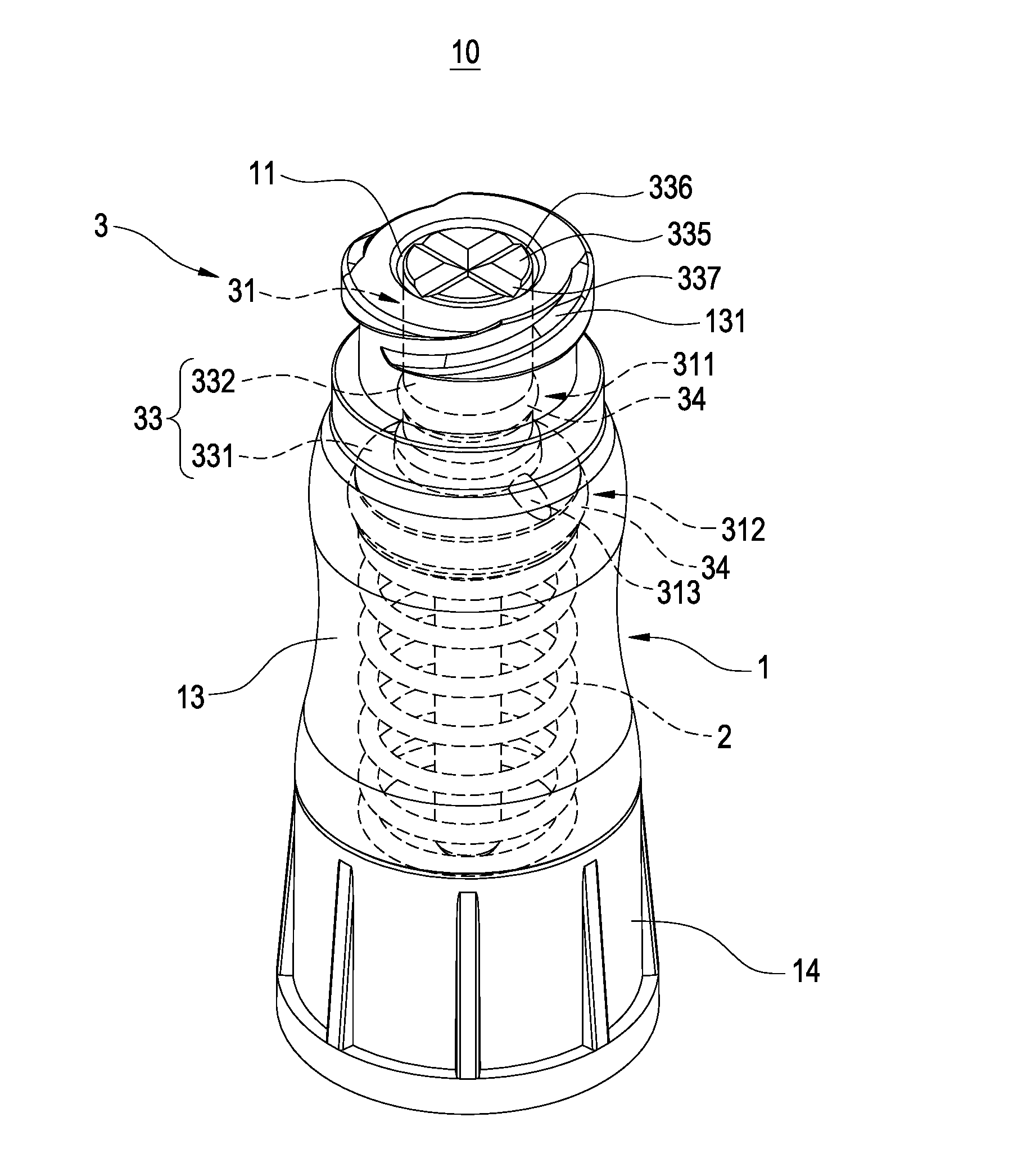

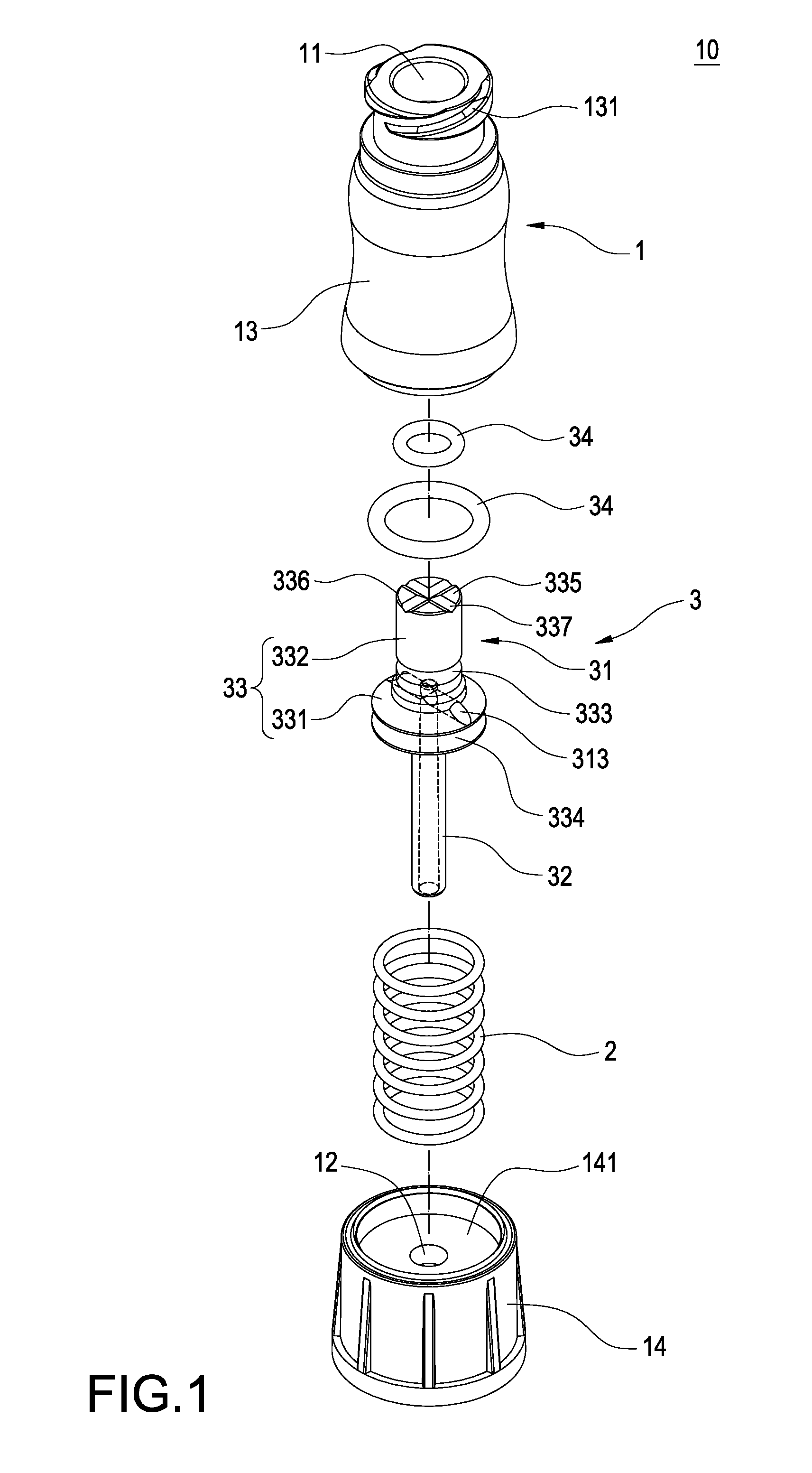

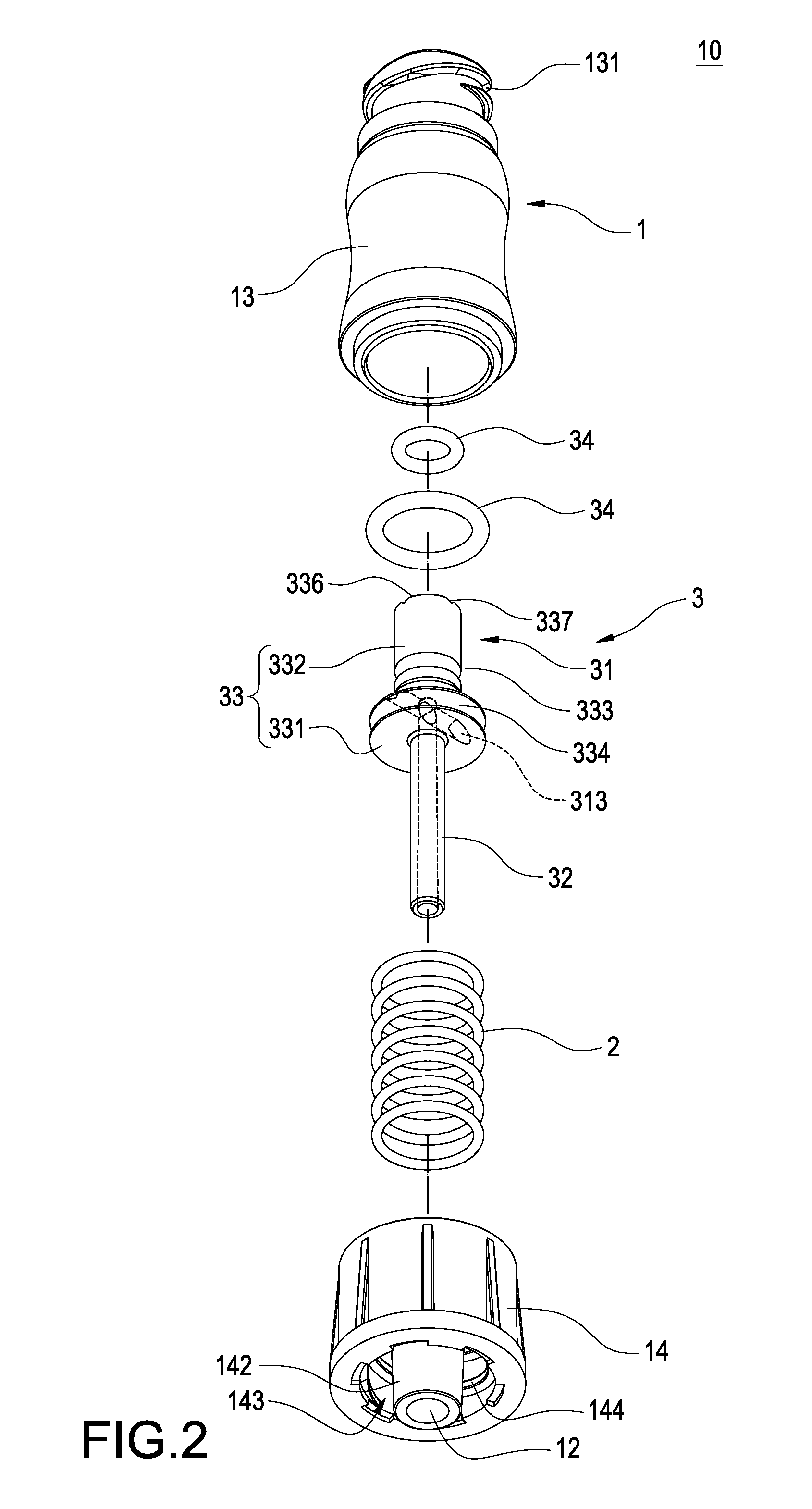

Needleless connector

InactiveUS8979804B2Improve closing effectImprove structural stabilityInfusion syringesCatheterEngineeringGuide tube

A needleless connector includes a hollow connector, a spring, and a switch assembly. The inner perimeter of the hollow connector forms a first annular wall and a second annular wall. The spring is disposed in the hollow connector. The switch assembly has a stop member and a guide tube connected to the stop member, the stop member being pressed between the annular block and the spring, the guide tube being disposed in the hollow connector, the external perimeter of the stop member forming a first annular portion against the first annular wall and a second annular portion against the second annular wall, a groove being disposed between the first annular portion and the second annular portion of the stop member, the groove being connected to the guide tube. Thus, the integral structure stability and good closing performance are achieved such that the outside air cannot leak into the connector structure.

Owner:PACIFIC HOSPITAL SUPPLY

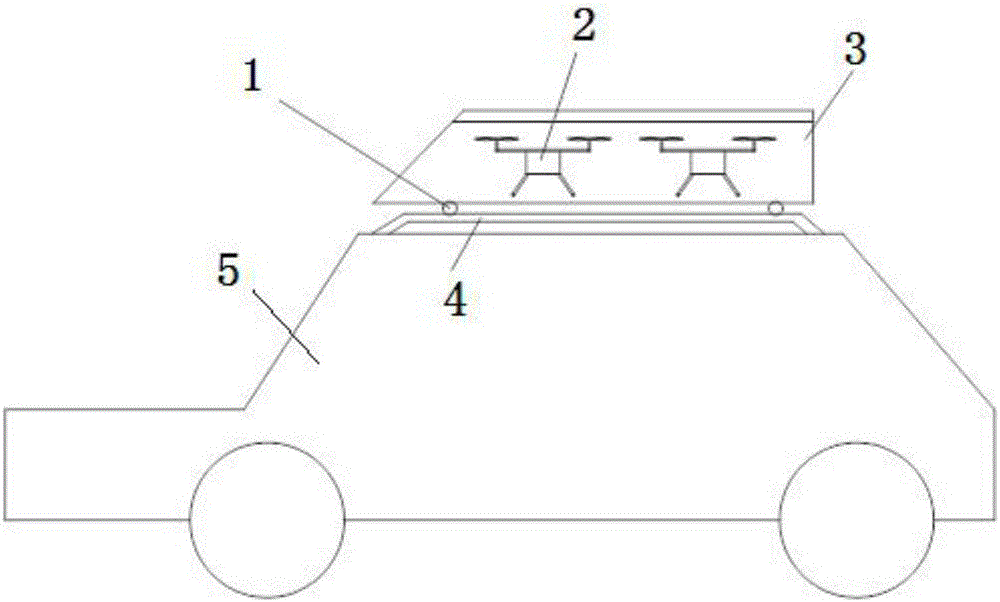

Vehicle-mounted multifunctional platform of unmanned aerial vehicle

InactiveCN106004626ATurn on the implementationAchieve closureAnchoring installationsVehicle carriersIn vehicleRemote control

The invention discloses a vehicle-mounted multifunctional platform of an unmanned aerial vehicle. The vehicle-mounted multifunctional platform of the unmanned aerial vehicle comprises a multifunctional platform bin detachably connected with a roof of the vehicle. A movable bin door is arranged on the top of the multifunctional platform bin and connected with the side wall of the multifunctional platform bin through a bin door control mechanism. A plurality of undercarriage lock control mechanisms are arranged at the bottom of the multifunctional platform bin. The bin door control mechanism and the undercarriage lock control mechanisms are connected with a control circuit board through data lines. The control circuit board is connected with a power source through an external power connection line and connected with a remote control operation terminal via electric signals. The vehicle-mounted multifunctional platform of the unmanned aerial vehicle has the characteristics that the unmanned aerial vehicle can fly at any time, assembling is not needed, the vehicle-mounted multifunctional platform is convenient to carry and transport and can be fixed to a luggage carrier on the roof, all-weather storage is achieved, and the platform can contain a plurality of unmanned aerial vehicles; a controller can follow the unmanned aerial vehicle after the unmanned aerial vehicle takes a flight, the unmanned aerial vehicle can fly by the maximum distance and then land automatically in a specific location, and the unmanned aerial vehicle can be charged in time when not taking a flight.

Owner:郭永

Needle-free connector

InactiveUS20140180258A1Improve structural stabilityExcellent closing capabilityCatheterTube connectorsNeedle freeEngineering

A needle-free connector includes a hollow connector, an elastic block, and a switch assembly. The inner perimeter of the hollow connector forms a first annular wall and a second annular wall. The elastic block is disposed in the hollow connector. The switch assembly has a stop member and a guide tube connected to the stop member, the stop member being pressed between the annular block and the elastic block, the guide tube being disposed in the hollow connector, the external perimeter of the stop member forming a first annular portion against the first annular wall and a second annular portion against the second annular wall, a groove being disposed between the first annular portion and the second annular portion of the stop member, the groove being connected to the guide tube. Thus, the structure stability and closing performance are achieved such that the outside air cannot leak into the connector.

Owner:PACIFIC HOSPITAL SUPPLY

Needleless connector

InactiveUS20140180219A1Improve structural stabilityExcellent closing capabilityInfusion devicesTube connectorsEngineeringGuide tube

A needleless connector includes a hollow connector, a spring, and a switch assembly. The inner perimeter of the hollow connector forms a first annular wall and a second annular wall. The spring is disposed in the hollow connector. The switch assembly has a stop member and a guide tube connected to the stop member, the stop member being pressed between the annular block and the spring, the guide tube being disposed in the hollow connector, the external perimeter of the stop member forming a first annular portion against the first annular wall and a second annular portion against the second annular wall, a groove being disposed between the first annular portion and the second annular portion of the stop member, the groove being connected to the guide tube. Thus, the integral structure stability and good closing performance are achieved such that the outside air cannot leak into the connector structure.

Owner:PACIFIC HOSPITAL SUPPLY

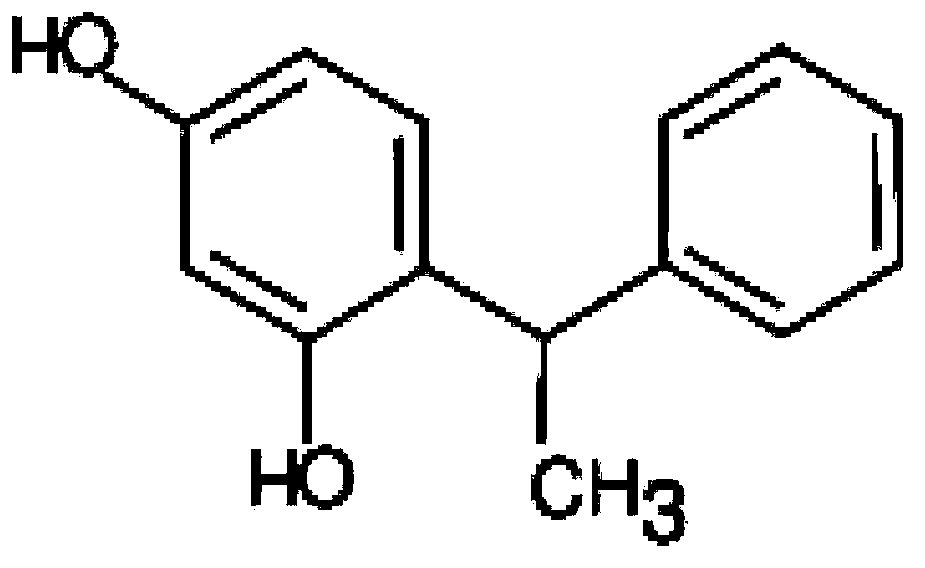

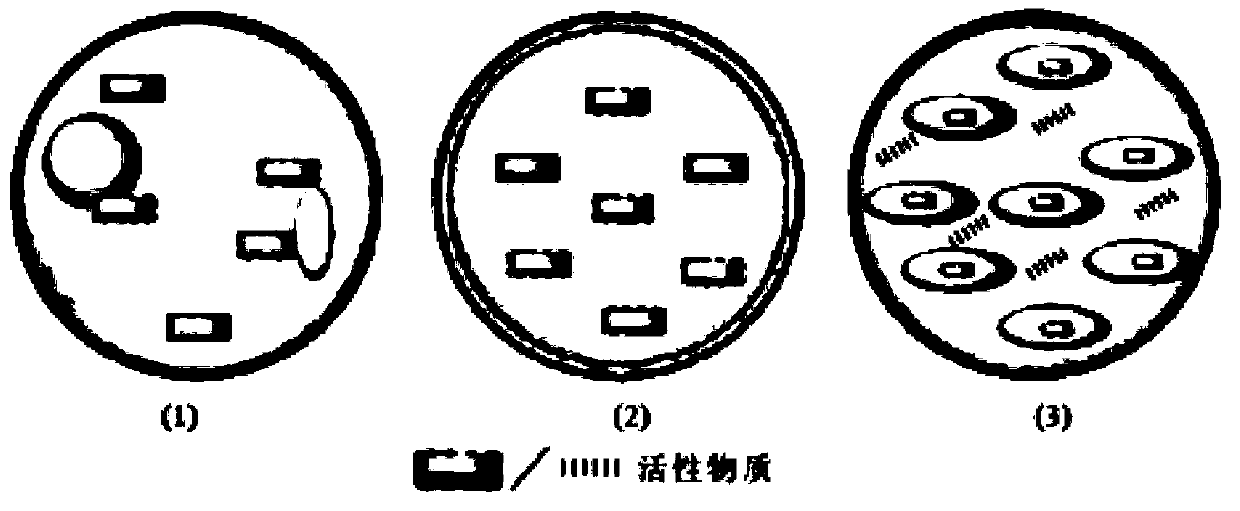

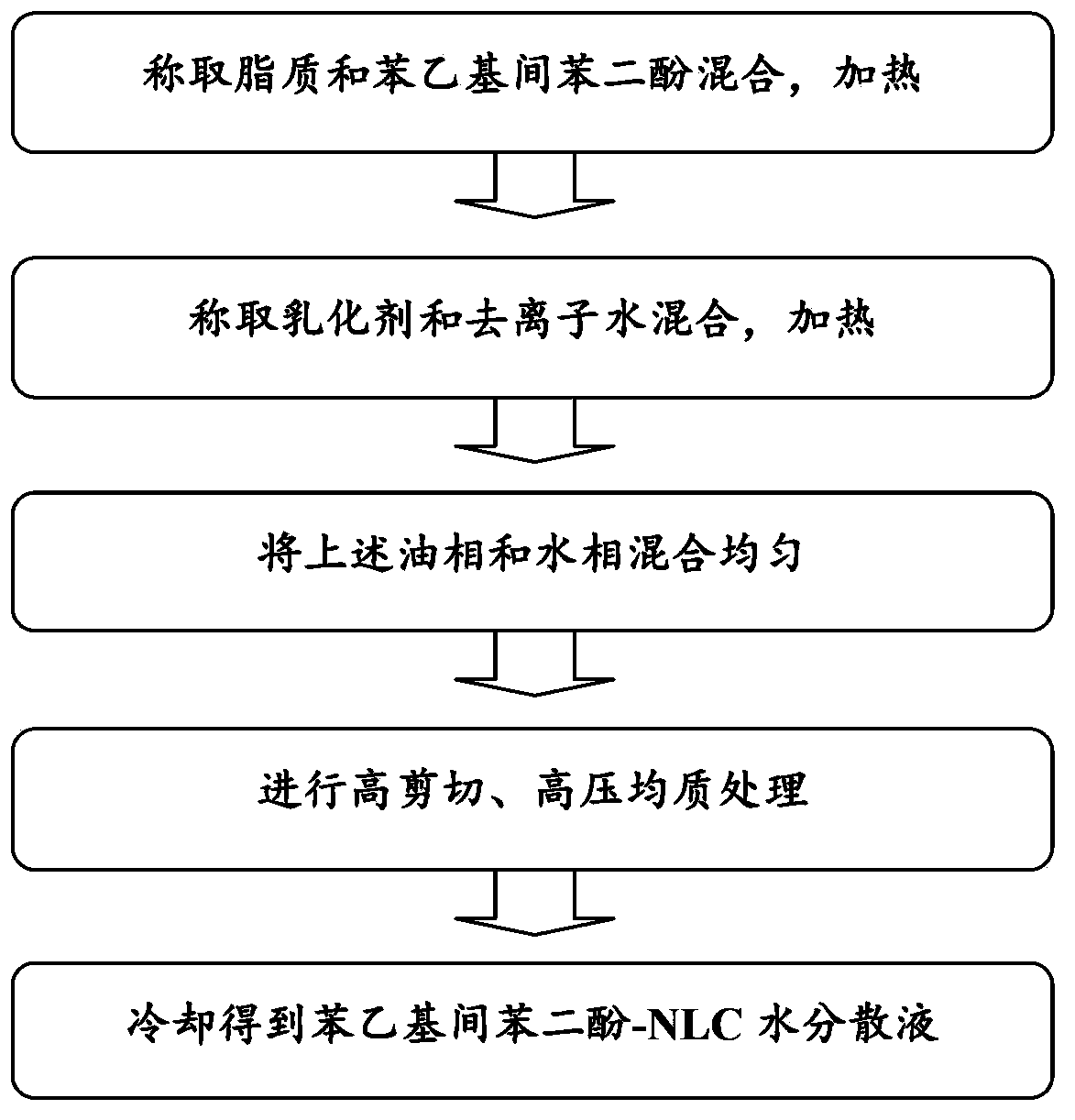

Nanostructured lipid carrier loaded with phenylethyl resorcinol, preparation method thereof and cosmetic containing same

InactiveCN103860389AImprove stabilityReduce leakageCosmetic preparationsToilet preparationsSolubilityActive component

The invention relates to nanostructured lipid carrier loaded with phenylethyl resorcinol. The carrier is loaded with the active component phenylethyl resorcinol (SymWhite 377) and is characterized in that the nanostructured lipid carrier comprises the following compositions in percent by weight: 0.5%-2% of phenylethyl resorcinol, 2%-5% of a nemulsifier, 5%-10% of a composite lipid material and 83%-92.5% of deionized water. The invention also relates to a preparation method of the nanostructured lipid carrier. The invention also relates to a skin-care product or a cosmetic containing the nanostructured lipid carrier. The nonostructured lipid carrier has excellent stability and water solubility, the preparation method is simple and controllable and good in repeatability, and is applicable to preparation of cosmetic containing phenylethyl resorcinol.

Owner:BEINONG BIOCHEM SUZHOU INDAL PARK +1

Plastic closure with enhanced performance

InactiveUS8485374B2Use minimizedEfficient and versatile useCapsClosure capsTamper resistanceEngineering

Owner:CLOSURE SYST INT INC

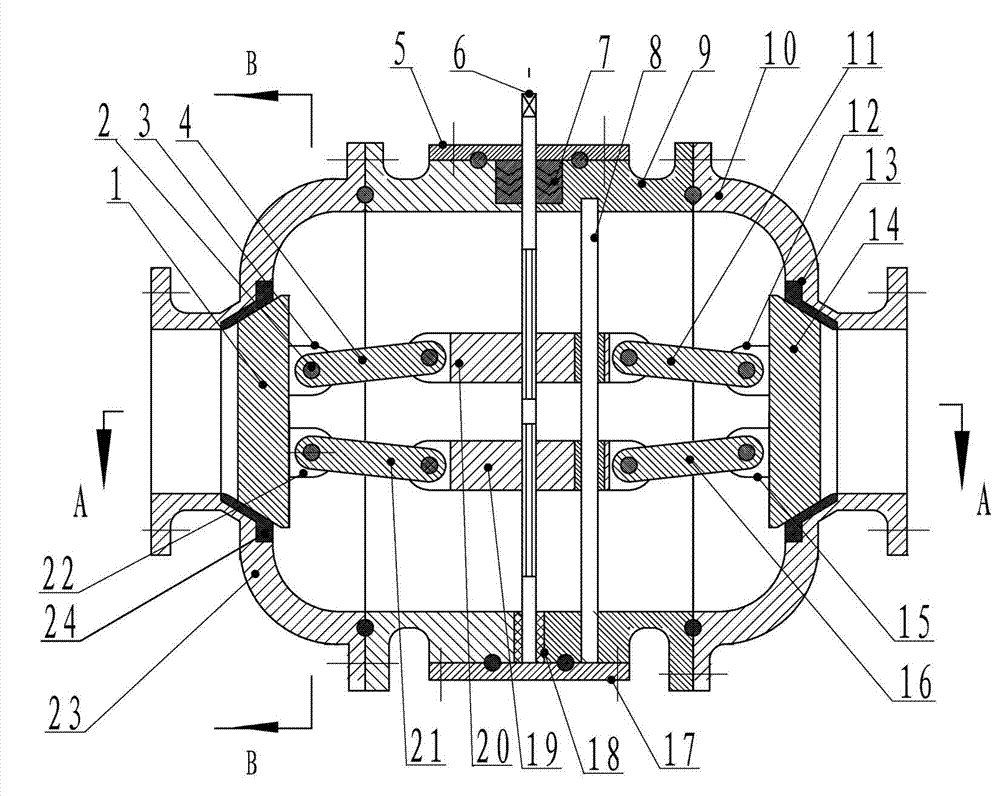

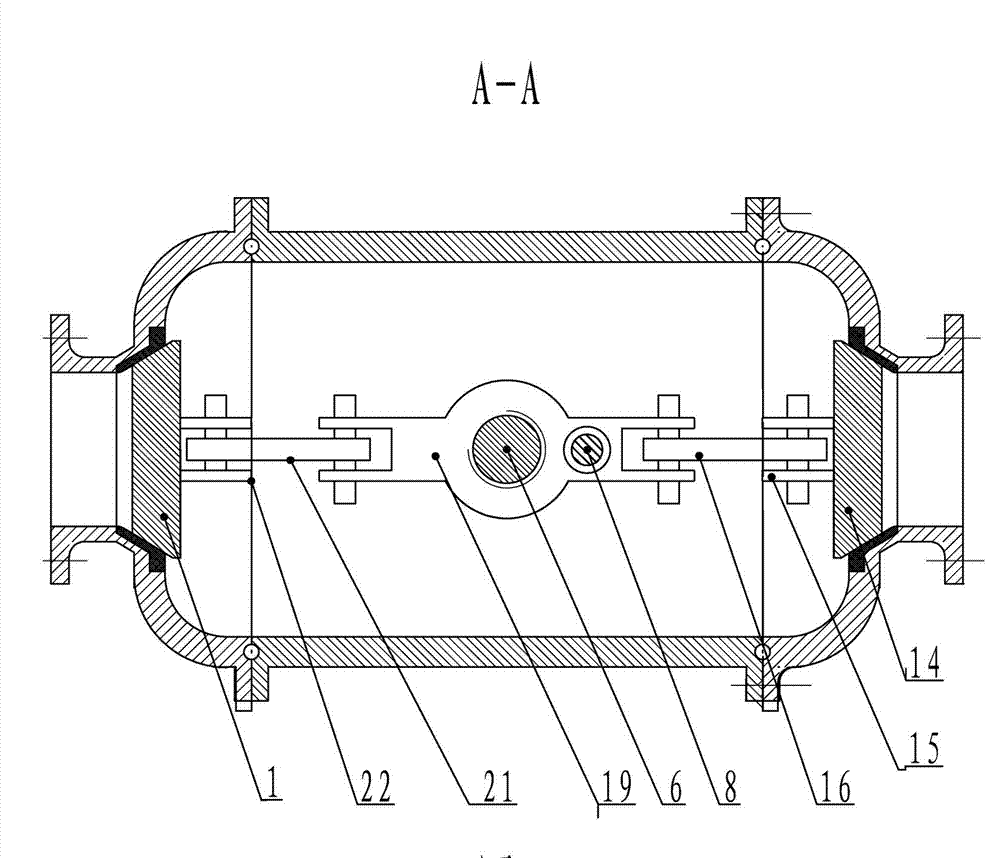

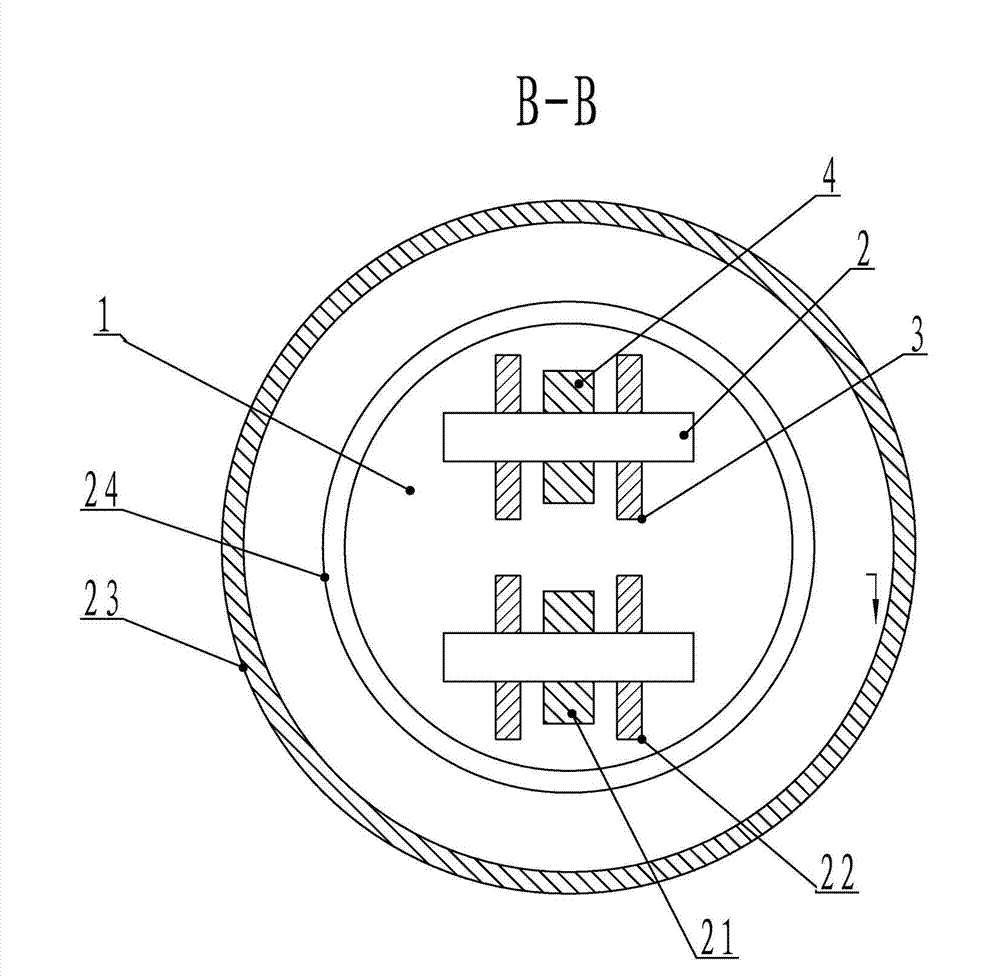

Sealing valve with double valve plates

InactiveCN102966745ASimple valve structureEasy to operateOperating means/releasing devices for valvesLift valveBall valveButterfly valve

The invention relates to a sealing valve with double valve plates, which comprises a left valve body, a middle valve body, a right valve body, a left valve plate, a right valve plate and a valve plate linkage mechanism, wherein the left valve body and the right valve body are respectively in sealing connection with the middle valve body; a sealing ring is arranged between the left valve plate and a medium inlet on a left valve body as well as the right valve plate and a medium outlet on the right valve body; and the valve plate linkage mechanism is respectively hinged with the left valve plate and the right valve plate. The sealing valve with double valve plates has the advantages as follows: (1), the valve structure is simple and compact; (2), the operation is convenient; (3), no leakage of poison gas when opening or closing the valve guarantees the safety of workers; (4), the closing effect of the valve is better, and the other valve plate supplies the guarantee in case that one valve plate leaks the gas; (5), the valve can replace existing various blind valves, butterfly valves, ball valves and sluice valves, and so on; and (6), the jacking press function of the valve plate linkage mechanism results in tighter closing and better sealing of the valve.

Owner:张家政

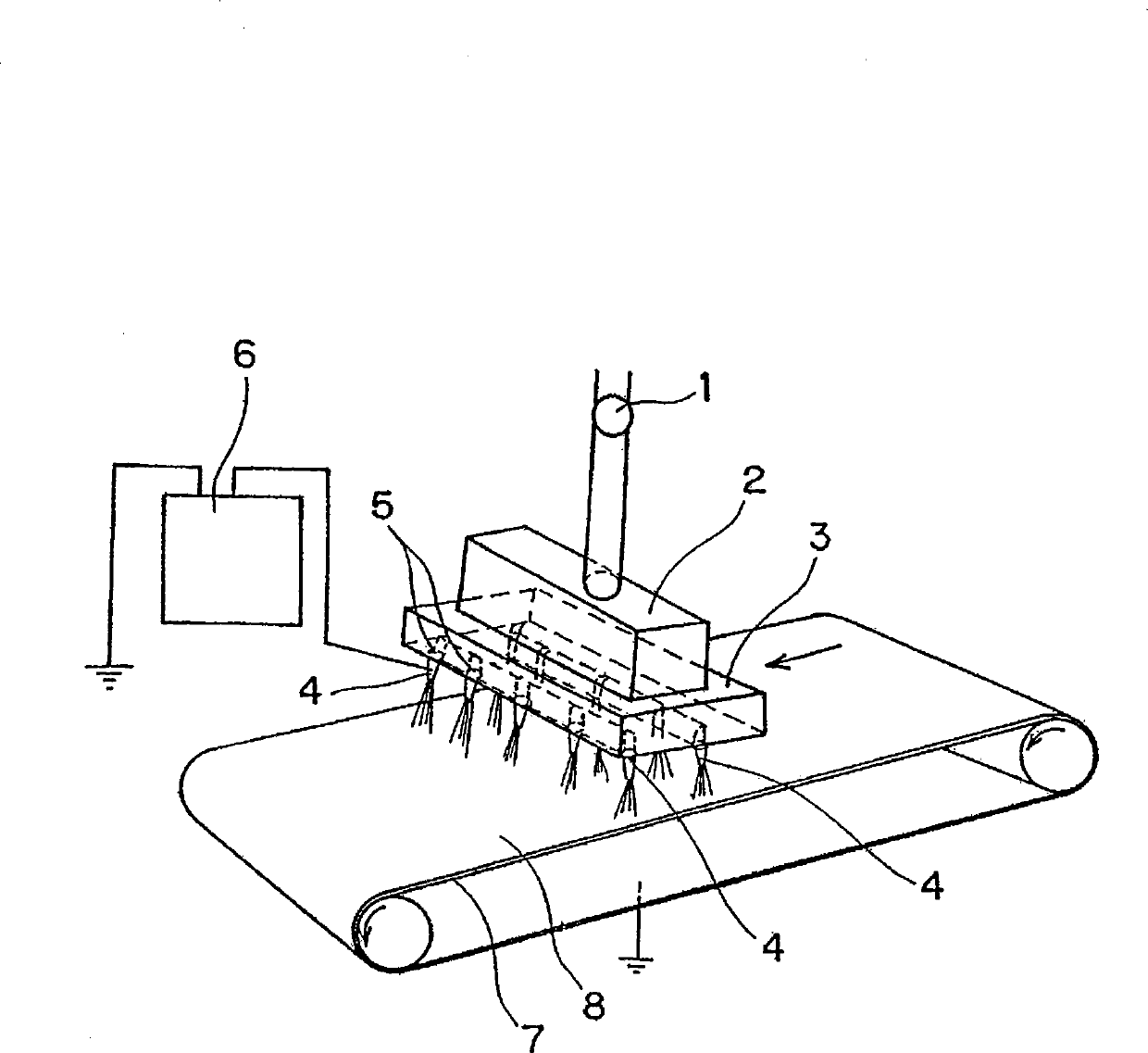

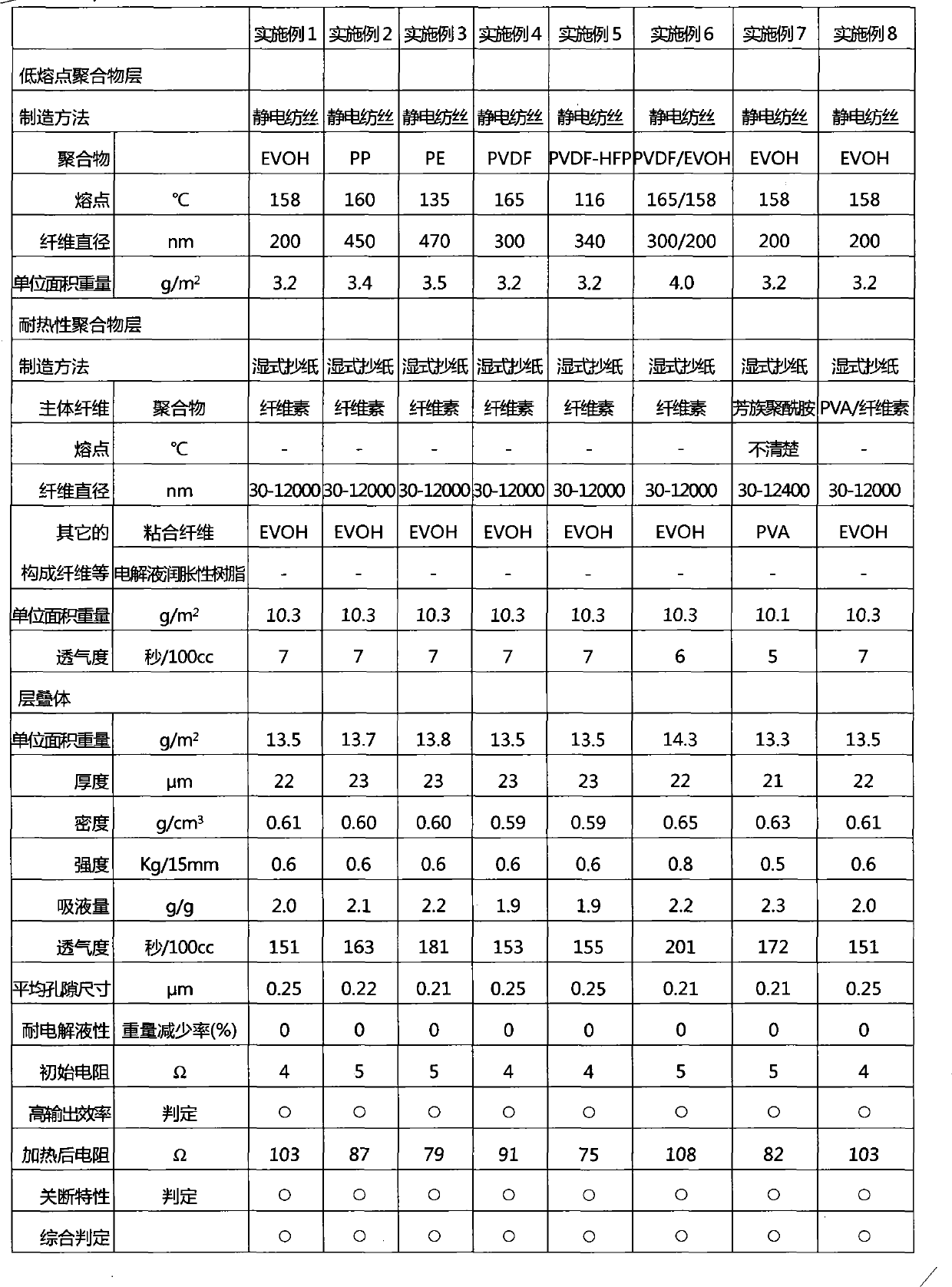

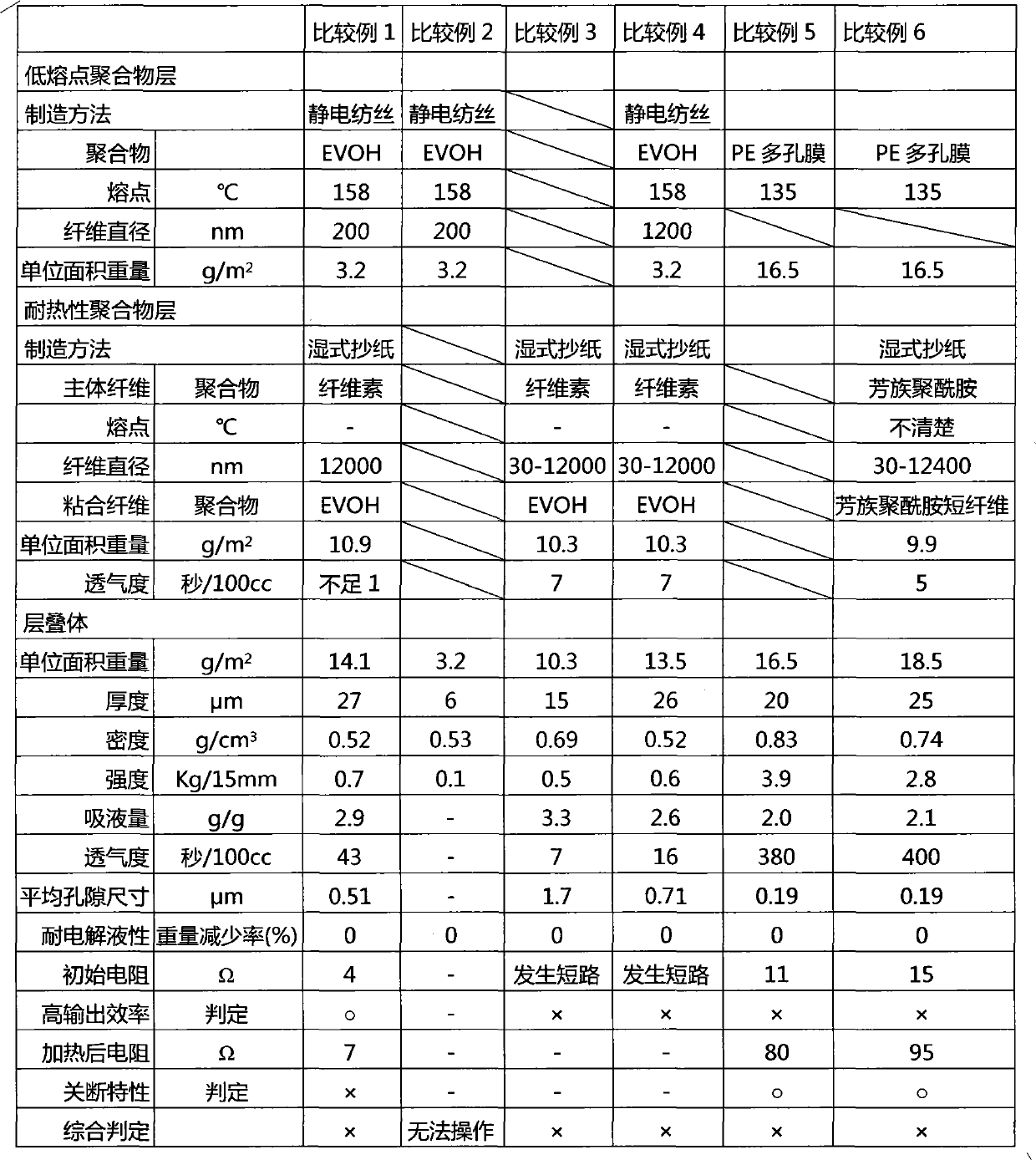

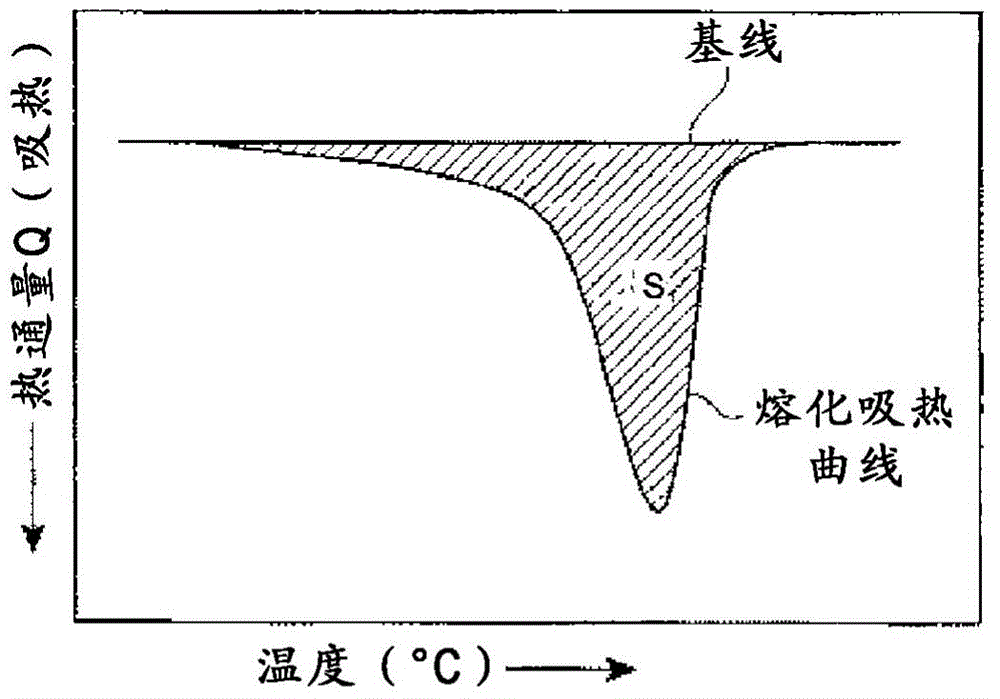

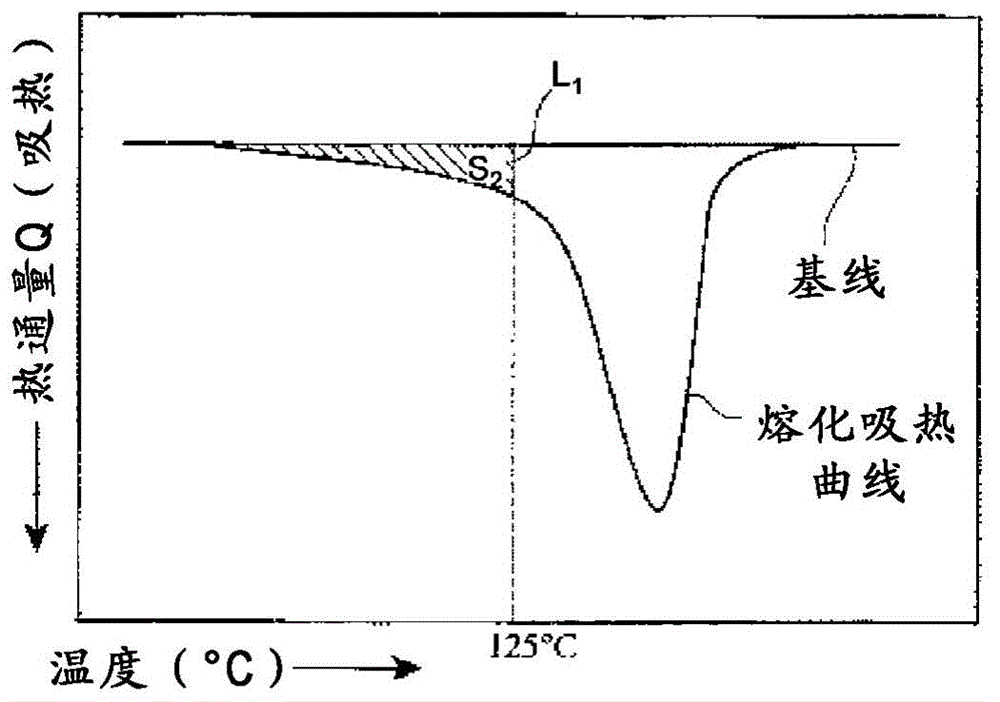

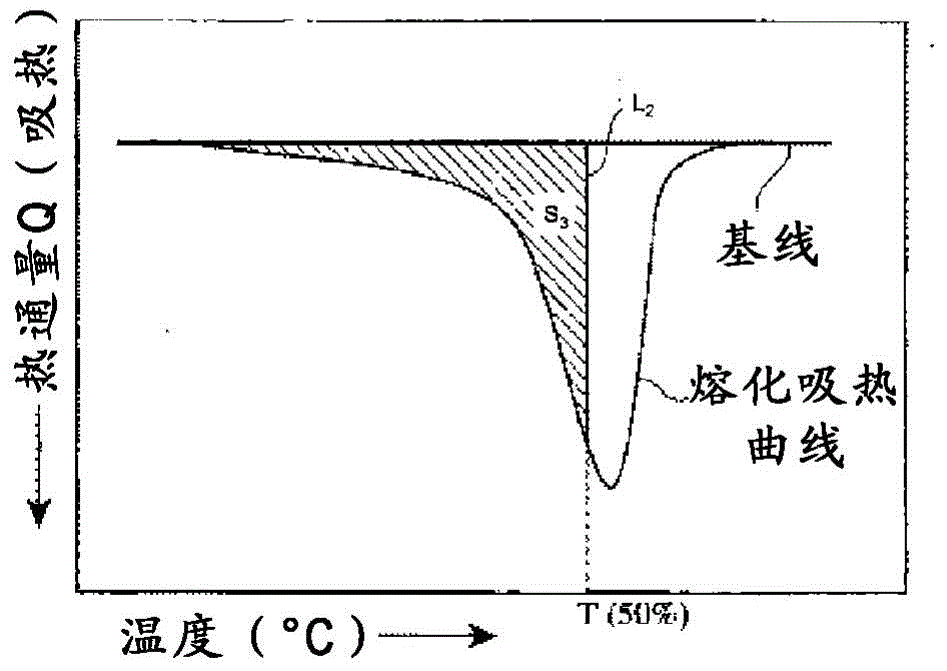

Separator for non-aqueous batteries, non-aqueous battery using same, and production method for separator for non-aqueous batteries

InactiveCN102498592ALower initial resistanceImprove output efficiencyNon-aqueous electrolyte accumulatorsCell seperators/membranes/diaphragms/spacersPolymer scienceElectrical battery

Disclosed is a separator for non-aqueous batteries which not only has a shutdown mechanism, but can also achieve a higher output and has short-circuit resistance. The separator is configured of a laminate which is provided with a low melting point polymer-fibre layer (A), formed of a low melting point polymer having a melting point of 100-200 DEG C, and a heat-resistant polymer-fibre layer (B), formed above the low melting point polymer-fibre layer (A) and formed of a heat infusible polymer or a high melting point polymer, having a melting point of over 200 DEG C. The low melting point polymer-fibre layer (A) includes low melting point polymer fibres having a fibre diameter not greater than 1000nm; the heat-resistant polymer-fibre layer (B) is formed from the heat resistant polymers and includes an amalgam of nanofibres and non-nanofibres.

Owner:KURARAY CO LTD

Separator for batteries and method for producing separator for batteries

ActiveCN104981921AImprove permeabilityImprove closing effectSynthetic resin layered productsSecondary cellsPolyolefinPolymer science

A separator for batteries, which is obtained by laminating a modified porous layer that contains a fluorine-based resin and inorganic particles or crosslinked polymer particles on one surface of a polyolefin microporous membrane having a thickness of 16 μm or less. This separator for batteries satisfies formula (1) and formula (2) described below, and the polyolefin microporous membrane is characterized in that (a) the shutdown temperature thereof is 135°C or less and (b) the air resistance change ratio thereof is 1 × 104 sec / 100 cc / °C or more. A method for producing this separator for batteries. 0.01 ≤ absT(1200) ≤ 0.30 (1) absT(1200): the absorbance per a thickness of 10 μm of the polyolefin microporous membrane of the absorption having a peak at around 1,200 cm-1 as determined by infrared spectrometry (a transmission method) in cases where the modified porous layer is separated from the polyolefin microporous membrane 0.001 ≤ absR(1200) ≤ 0.030 (2) absR(1200): the absorbance at the maximum peak at around 1,200 cm-1 as determined by infrared spectrometry (a reflection method) of a surface of the polyolefin microporous membrane, said surface being on the reverse side of the modified porous layer. Consequently, the present invention provides: a separator for batteries, which has good adhesion to an electrode, excellent shutdown performance and excellent electrolyte solution permeability, and which is suitable for high-capacity batteries; and a method for producing this separator for batteries.

Owner:TORAY IND INC

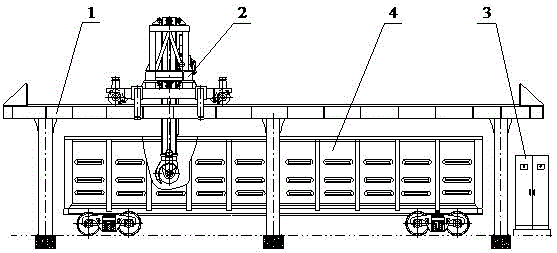

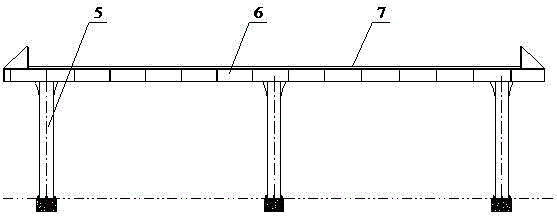

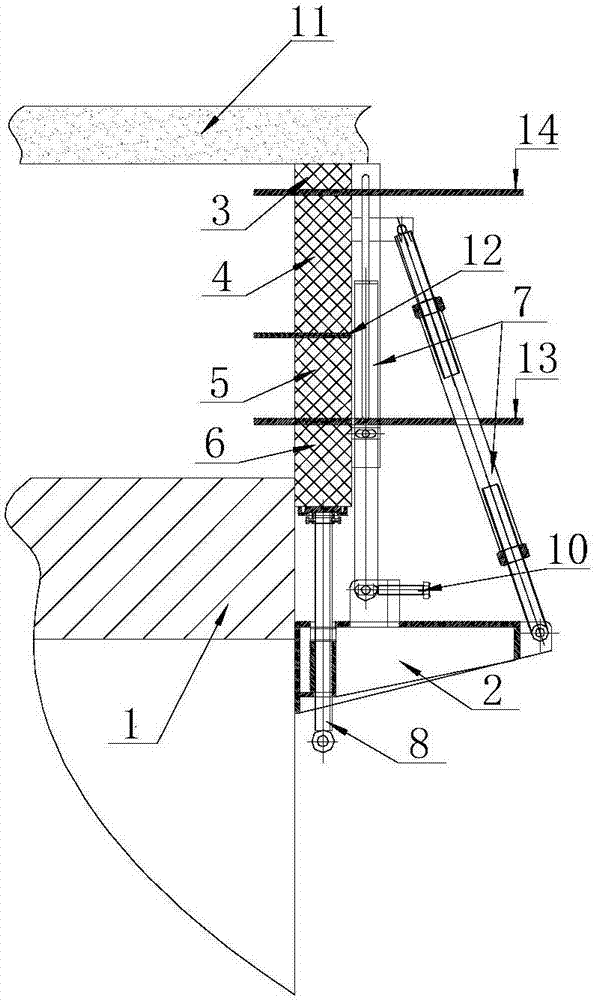

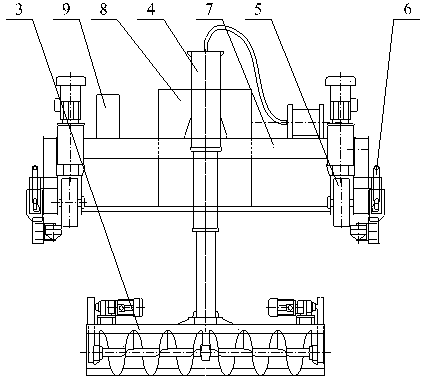

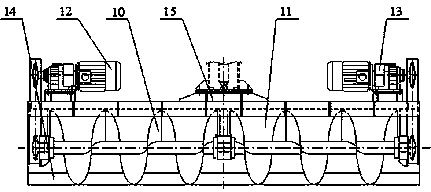

Overhead rail-mounted spiral high-efficiency flatting system

ActiveCN102976120ARealize scanning closing operationImprove efficiencyLoading/unloadingBridge typeElectrical control

The invention relates to an overhead rail-mounted spiral high-efficiency flatting system which comprises a bearing gantry and a track (1), a spiral flatting machine (2) and an electric control system (3), wherein the spiral flatting machine (2) comprises a spiral pushing mechanism, a lifting mechanism, a frame structure and a walking mechanism; and the spiral pushing mechanism serves as the main working mechanism of the flatting system to carry out flatting operation. The system adopts an operation method similar to that of a workshop bridge-type crane, the spiral flatting machine (2) walks on the high-altitude track which is borne by the bearing gantry, and the flatting operation is carried out to materials in a compartment from the upper part of the train compartment (4) through two groups of left screws and right screws which are lined in a 'linear' shape in parallel and scrapers on the side surfaces of the two groups of screws. According to the overhead rail-mounted spiral high-efficiency flatting system, leveling operation can be carried out to sharp-angled material piles which are distributed in the compartment randomly through the screws and the pushing of the scrapers, so that manual flatting operation is fully replaced, and the overhead rail-mounted spiral high-efficiency flatting system has the characteristics of good flatting effect, high efficiency, high adaptability, low energy consumption, safety, reliability and the like.

Owner:WUHAN K CRANE OCEAN ELEVATORING TECH

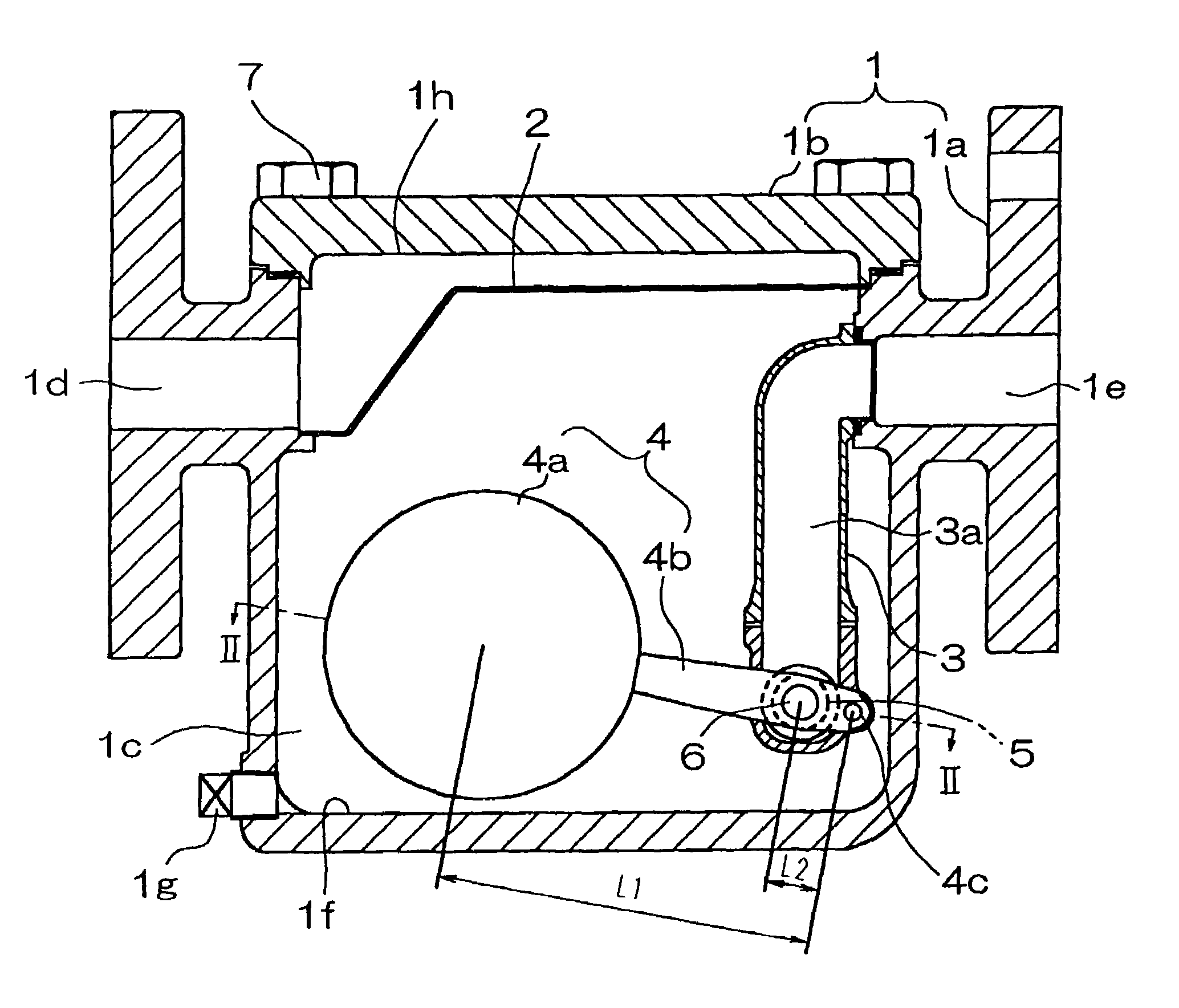

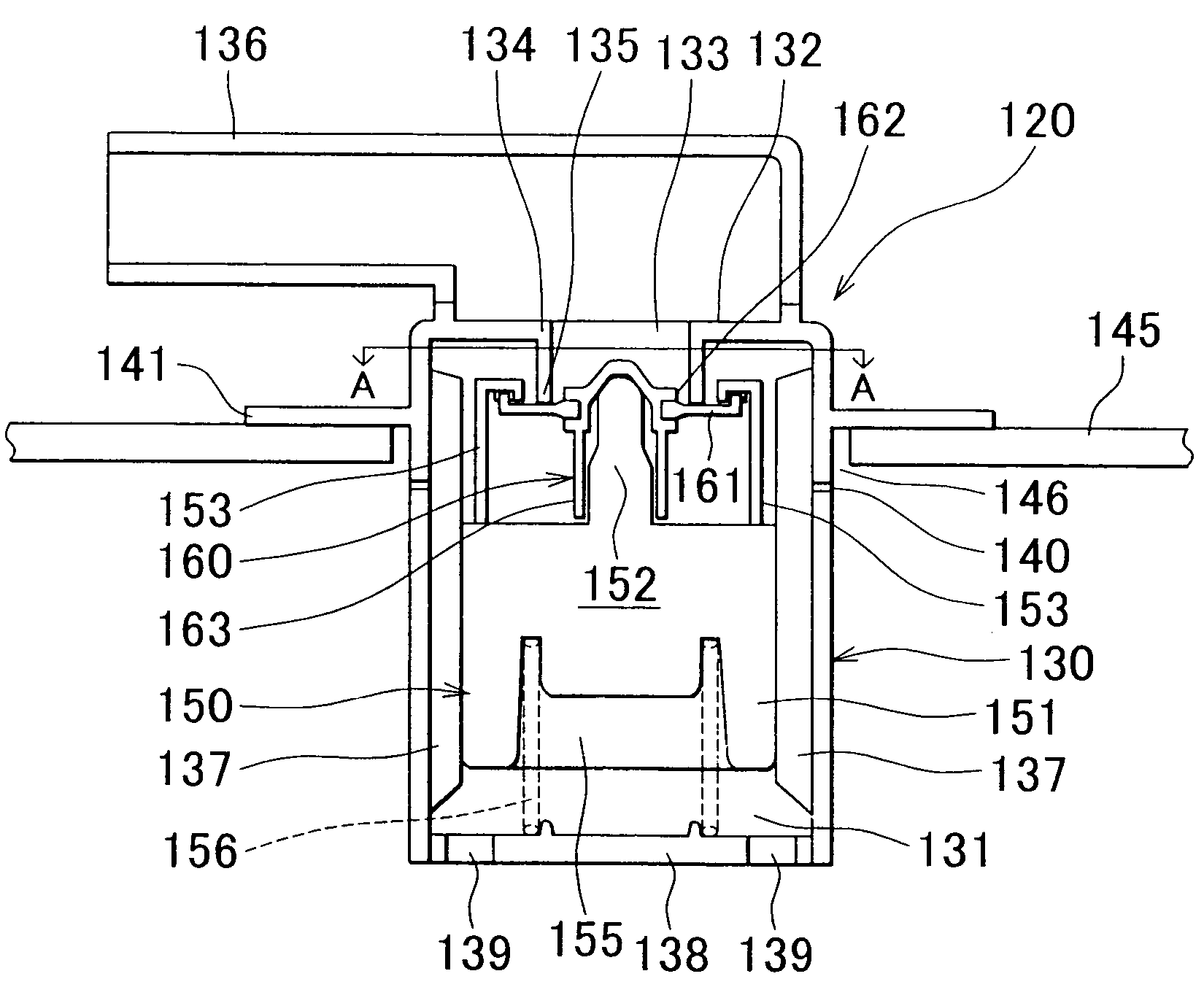

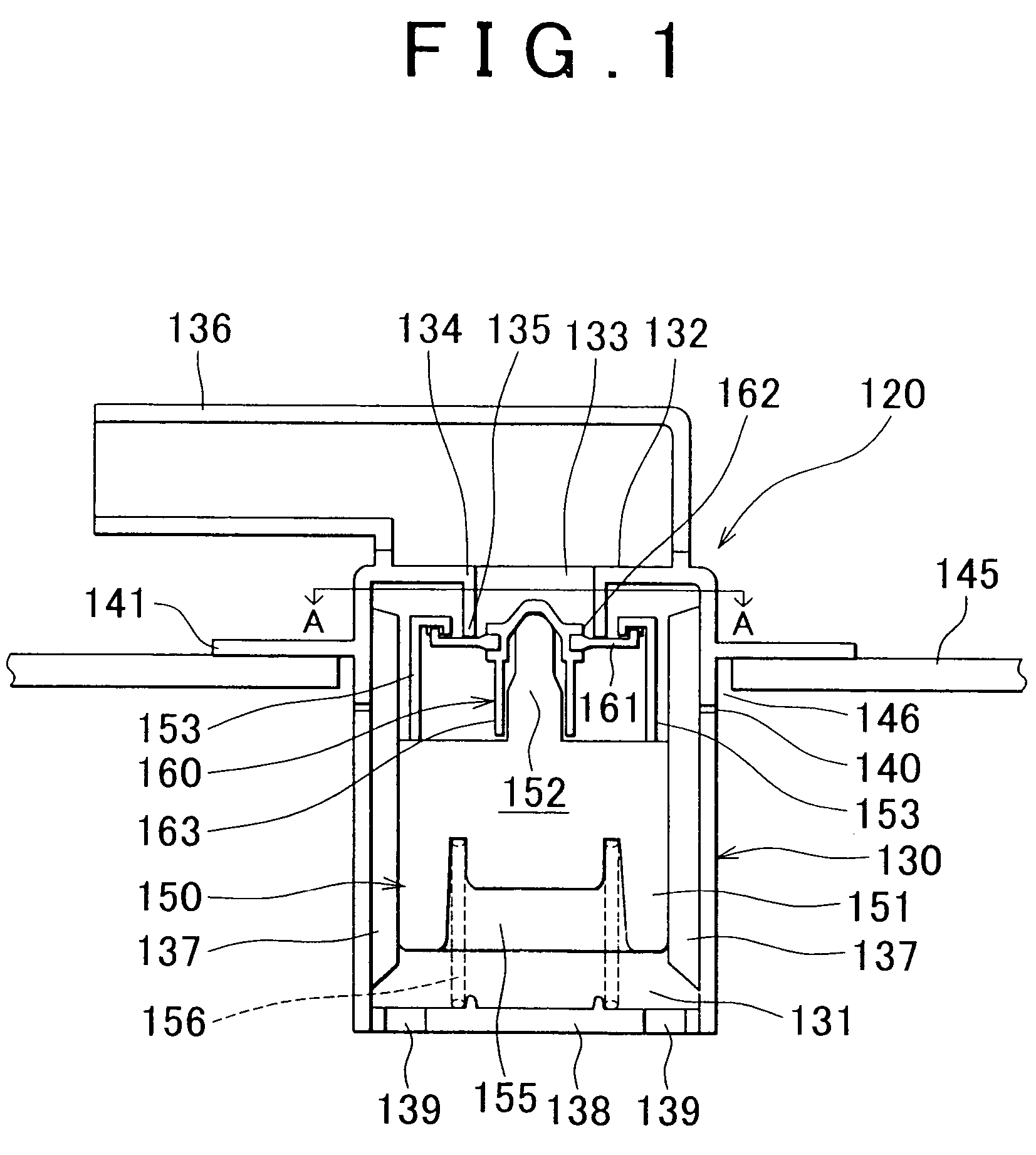

Float type steam trap

InactiveUS7096880B2Improve valve closing performanceReduce device sizeOperating means/releasing devices for valvesSteam trapsSteam trapValve seat

There is provided a float type steam trap having a casing having a float chamber formed with an inflow port and an outflow port. A holder has a flow path communicating with the outflow port. A valve seat on the holder communicates with the outflow port. A float has a float body and a lever with a valve element. One end of the lever is fixed to the float body, and the other end is supported by the holder. The valve element slides with the up-and-down movement of the float body to open and close the valve seat 5.

Owner:MOTOYAMASEISAKUSHO

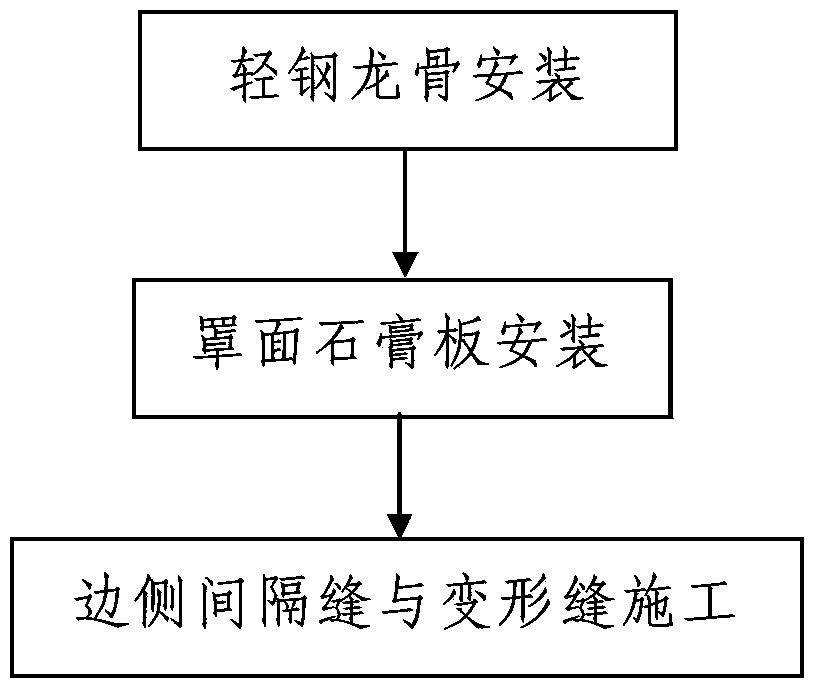

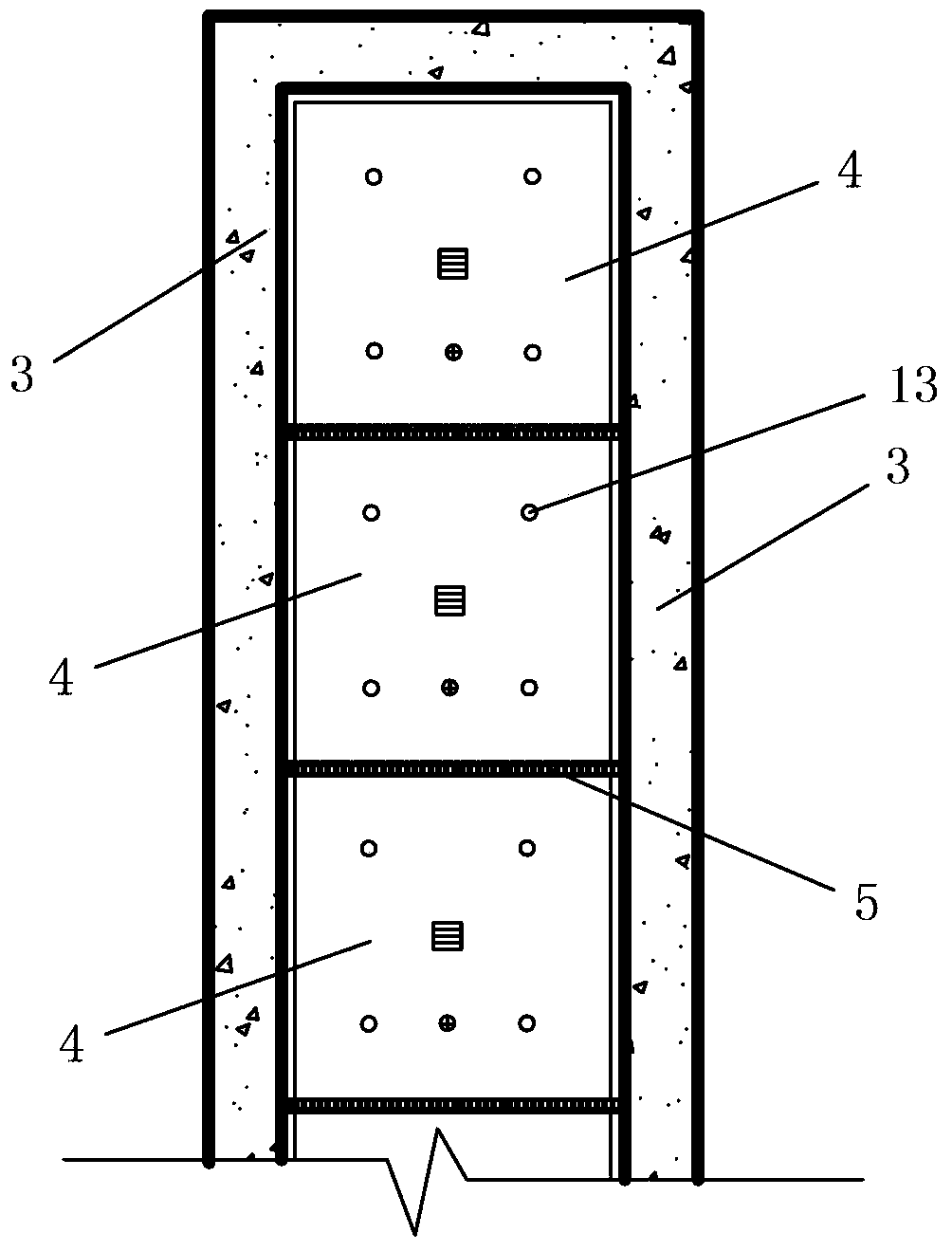

Construction method of architectural structure gypsum board with paper surface hung ceiling

The invention discloses a construction method of an architectural structure gypsum board with paper surface hung ceiling. The construction method comprises the following steps of:1, installing a light steel keel; 2, installing a top facing gypsum board, namely, installing the top facing gypsum board on the installed light steel keel; reserving side interval joints between side walls on the periphery of the top facing gypsum board and a wall body; forming multiple transverse deformation joints on the top facing gypsum board, and distributing the multiple transverse deformation joints from front to back along the long direction of the top facing gypsum board; and dividing the light steel keel into multiple light steel keel frames by taking the multiple transverse deformation joints as boundaries, and disconnecting the two front and back adjacent light steel keel frames; and 3, constructing the side interval joints and the deformation joints, namely, closing in the transverse deformation joints by adopting first aluminium alloy end caps, and meanwhile closing in the side interval joints by adopting second aluminium alloy end caps. The construction method is simple in steps, reasonable in design, and simple and convenient in construction and operation, has high working efficiency and good construction effect and can be used for solving the problems of ugly appearance, easiness in occurrence of cracks and deformation and the like existing in the conventional gypsum plaster board.

Owner:陕西建工集团有限公司 +1

Float valve structure

InactiveUS20070006919A1Improve sealingLow production costLarge containersVenting valvesEngineeringVALVE PORT

A float valve structure according to the invention includes a case; a valve seat that is formed at an end portion of the case, at a position near an upper opening of the case; a float that is arranged in a space formed in the case so as to be vertically movable; a valve support member that is arranged above the float and that can be inserted into the upper opening; a valve that is fitted to the valve support member and that can contact the valve seat; and a valve opening member that can vertically move together with the float and that opens at least one portion of the valve.

Owner:KYOSAN DENKI KABUSHIKI KAISHA

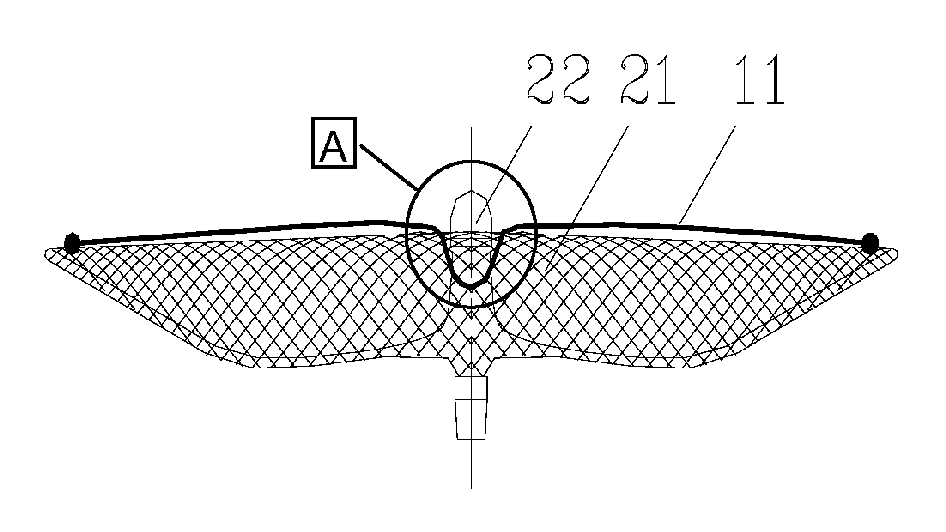

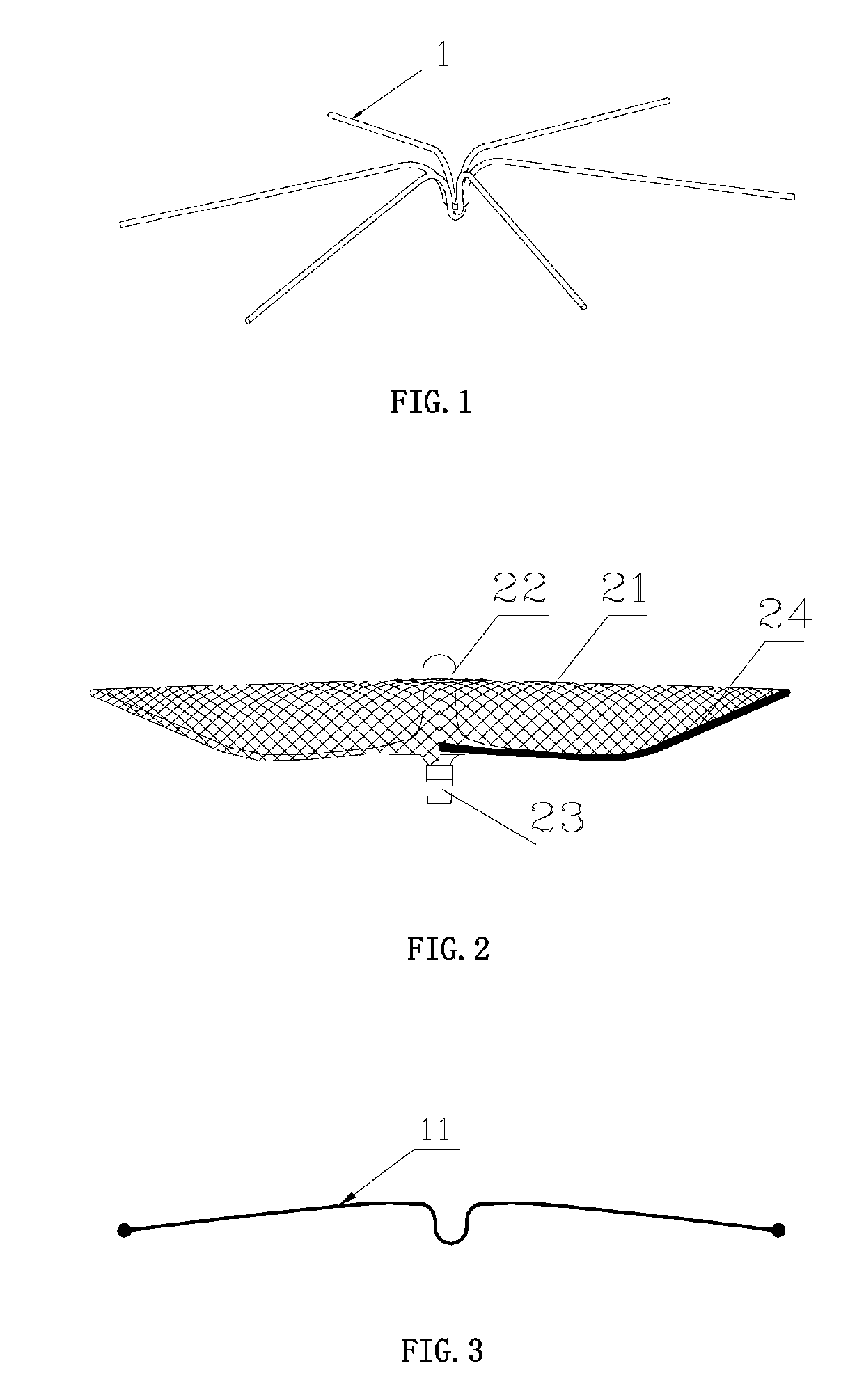

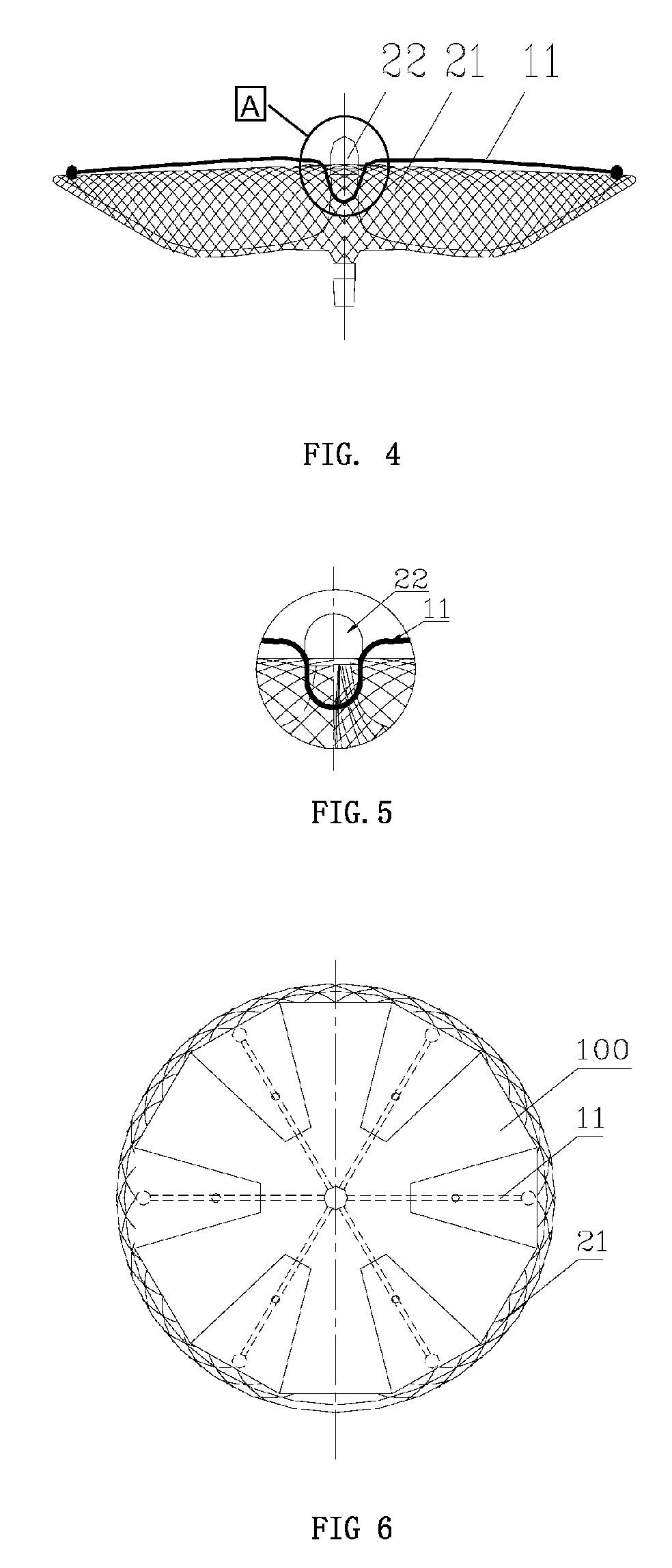

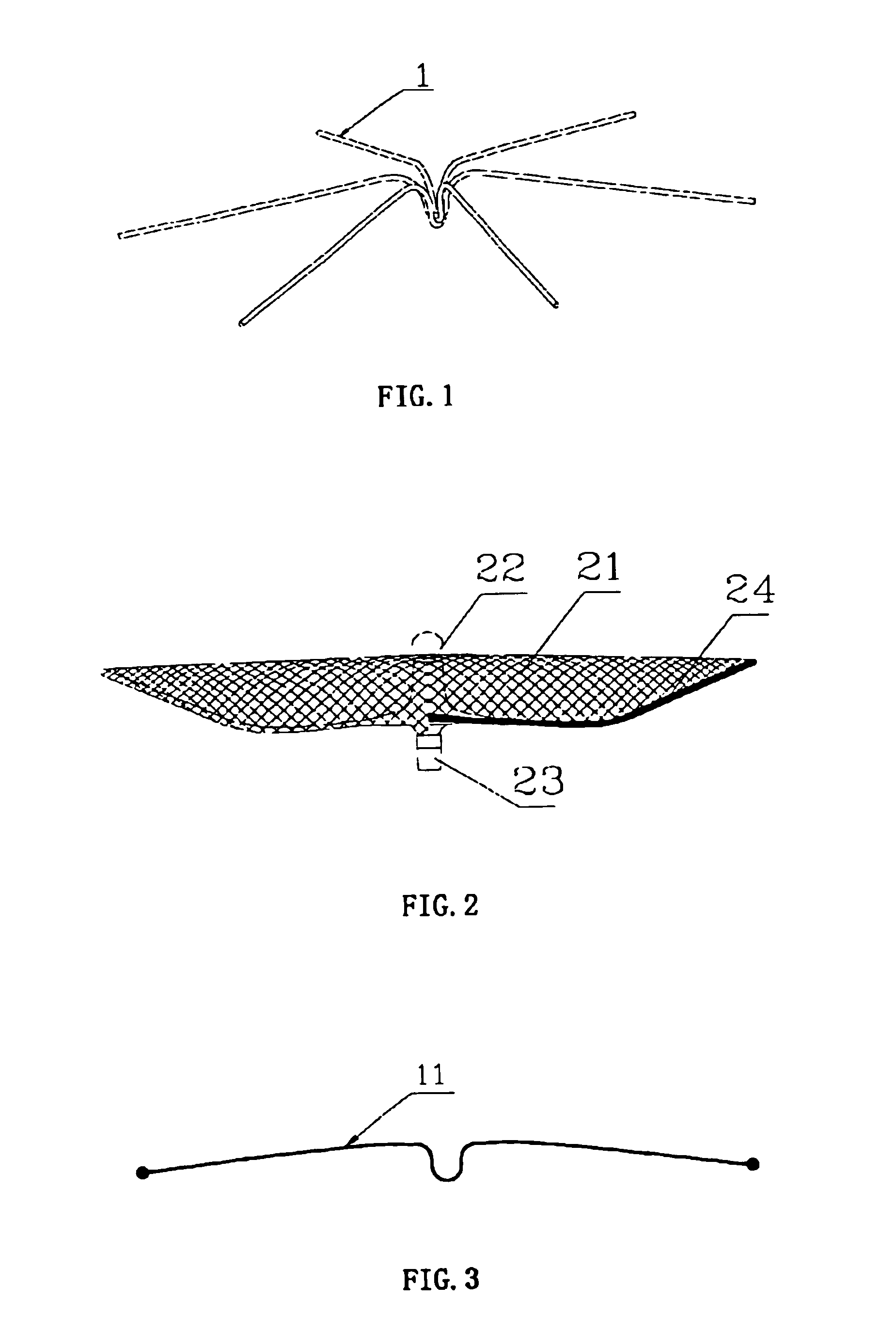

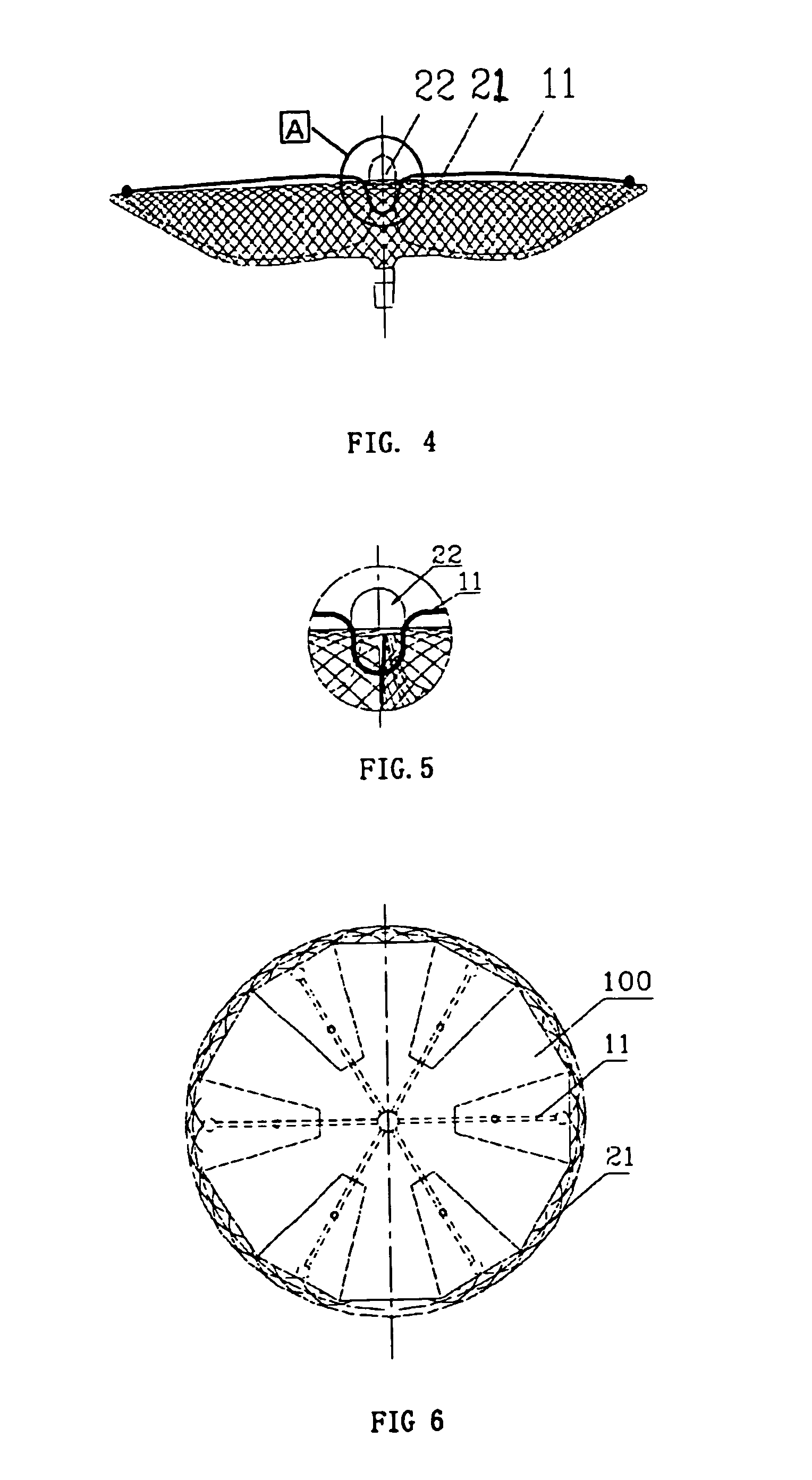

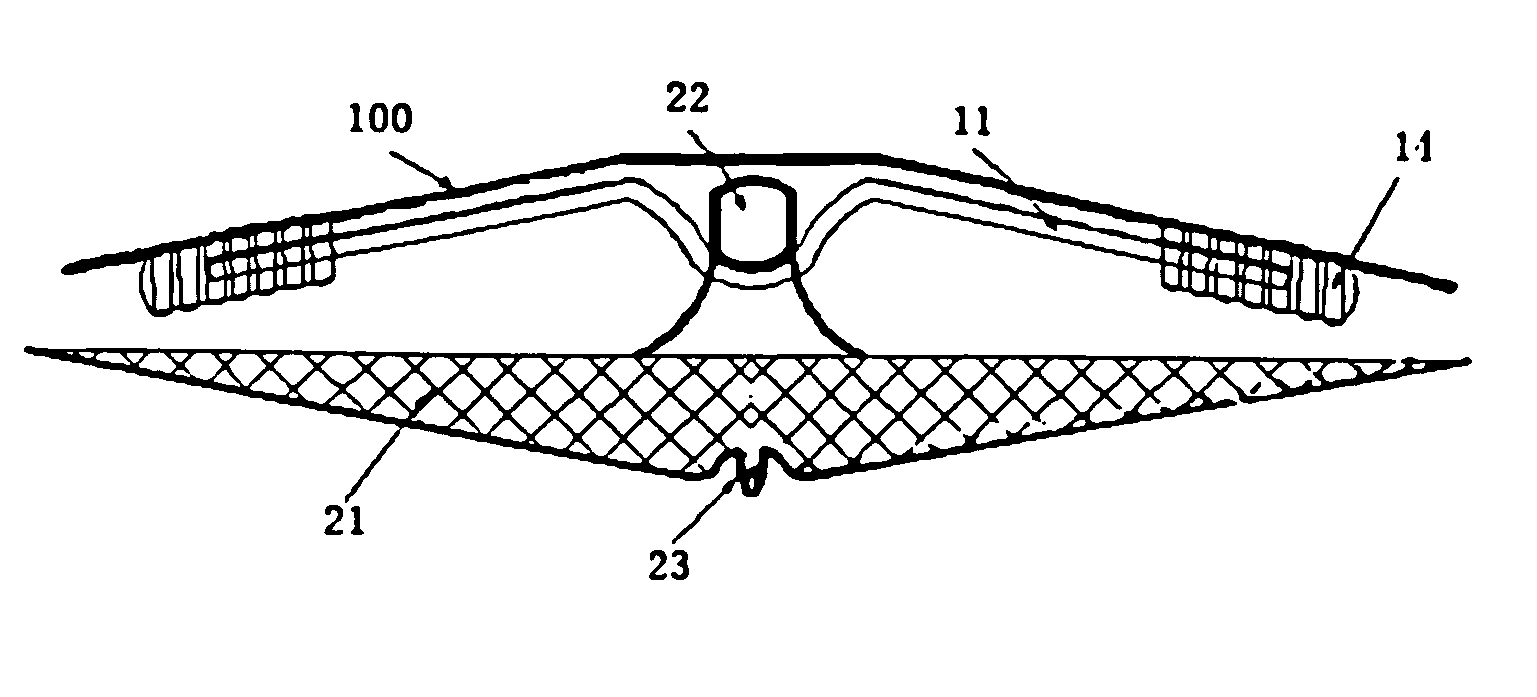

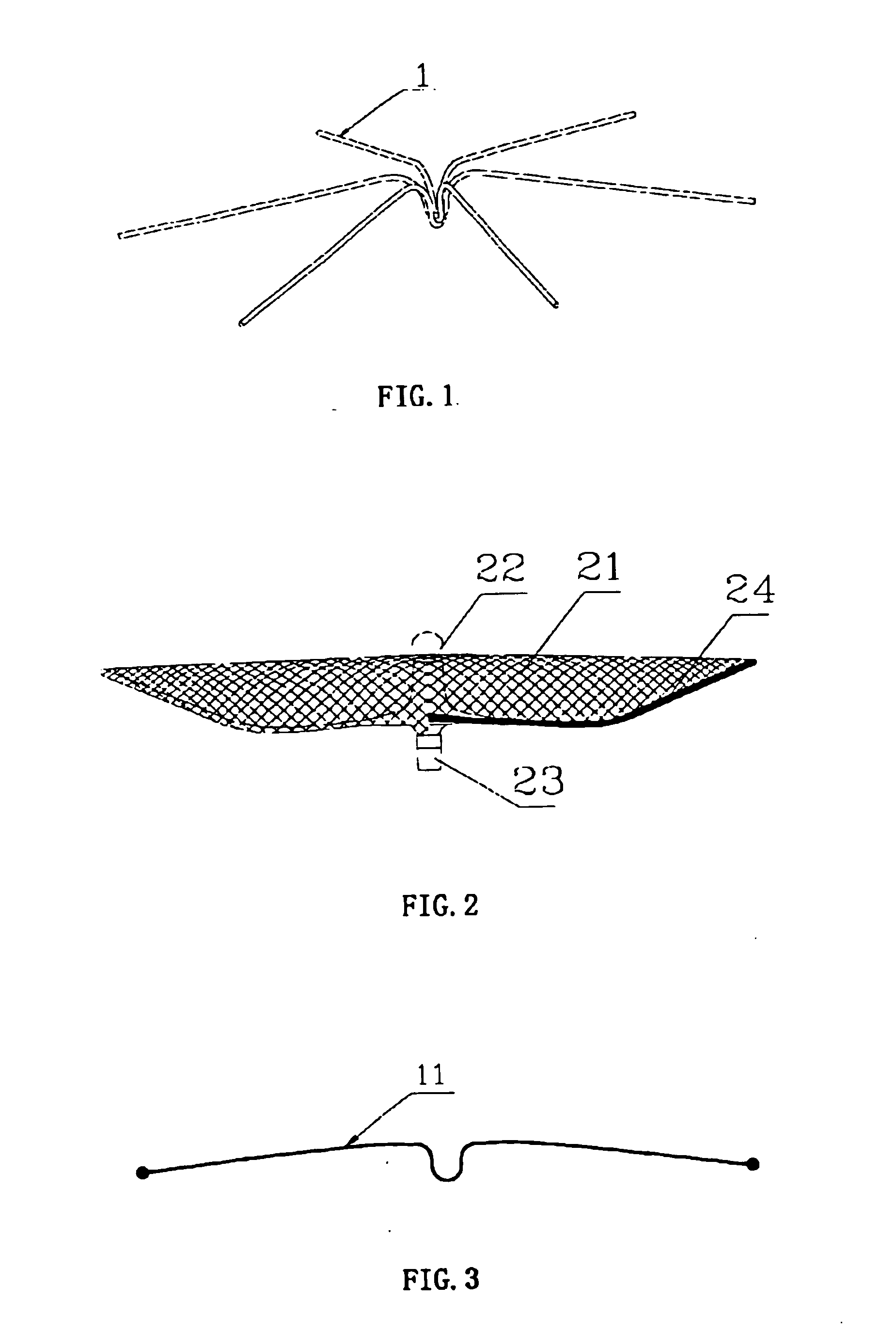

Heart septal defect occlusion devices with adjustable length tether adapting to the unique anatomy of the patient

ActiveUS7828818B2Improve closing effectThrombus can be reducedSurgical veterinaryWound clampsAnatomical structuresHeart septal defect

Owner:LIFETECH SCI

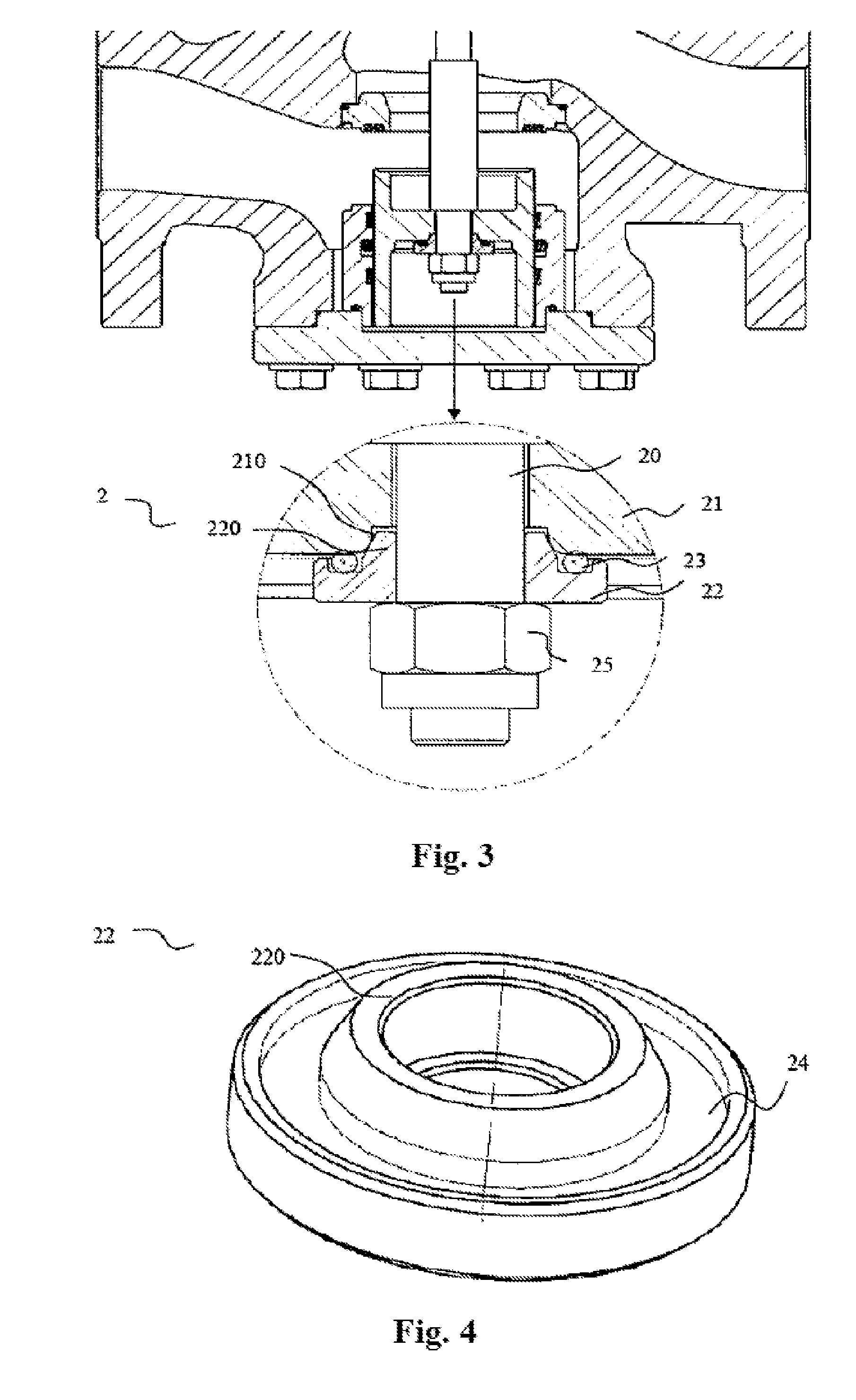

Valve Stem and Valve Core Assembly and Valve Comprising the Assembly

ActiveUS20150276078A1Improve closing effectMore flexibly moveLift valveValve housingsValve stemEngineering

The present invention relates to a valve stem and valve core assembly and a valve comprising the assembly. The valve core sleeves the valve stem, an adjusting device is arranged on the valve stem, an elastic element is arranged between the adjusting device and the valve core, and a clearance exists among the valve core, the valve stem and the adjusting device, so that the valve core can move relative to the valve stem and the valve can have a good closing performance.

Owner:EMERSON PROCESS MANAGEMENT REGULATOR TECH INC

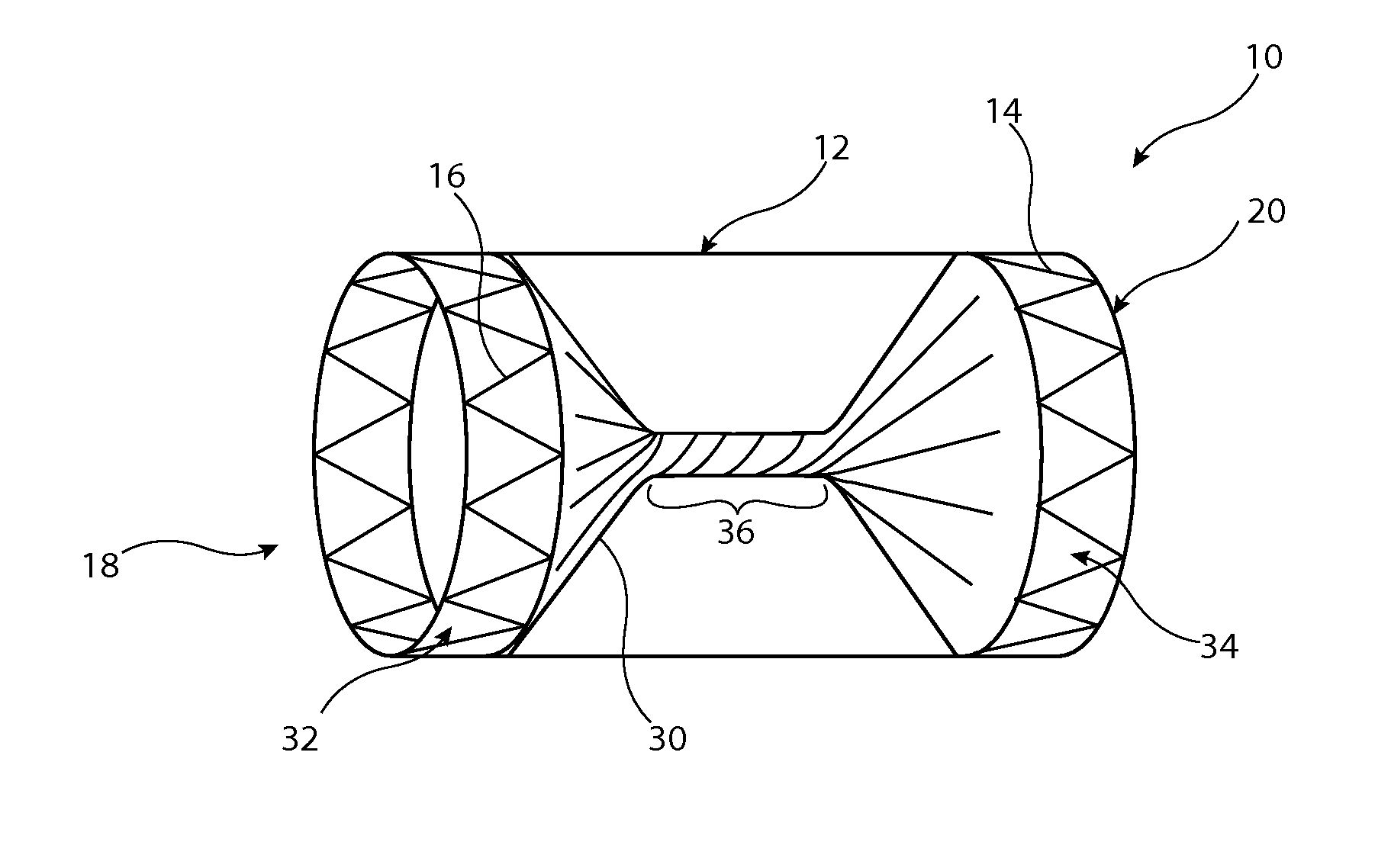

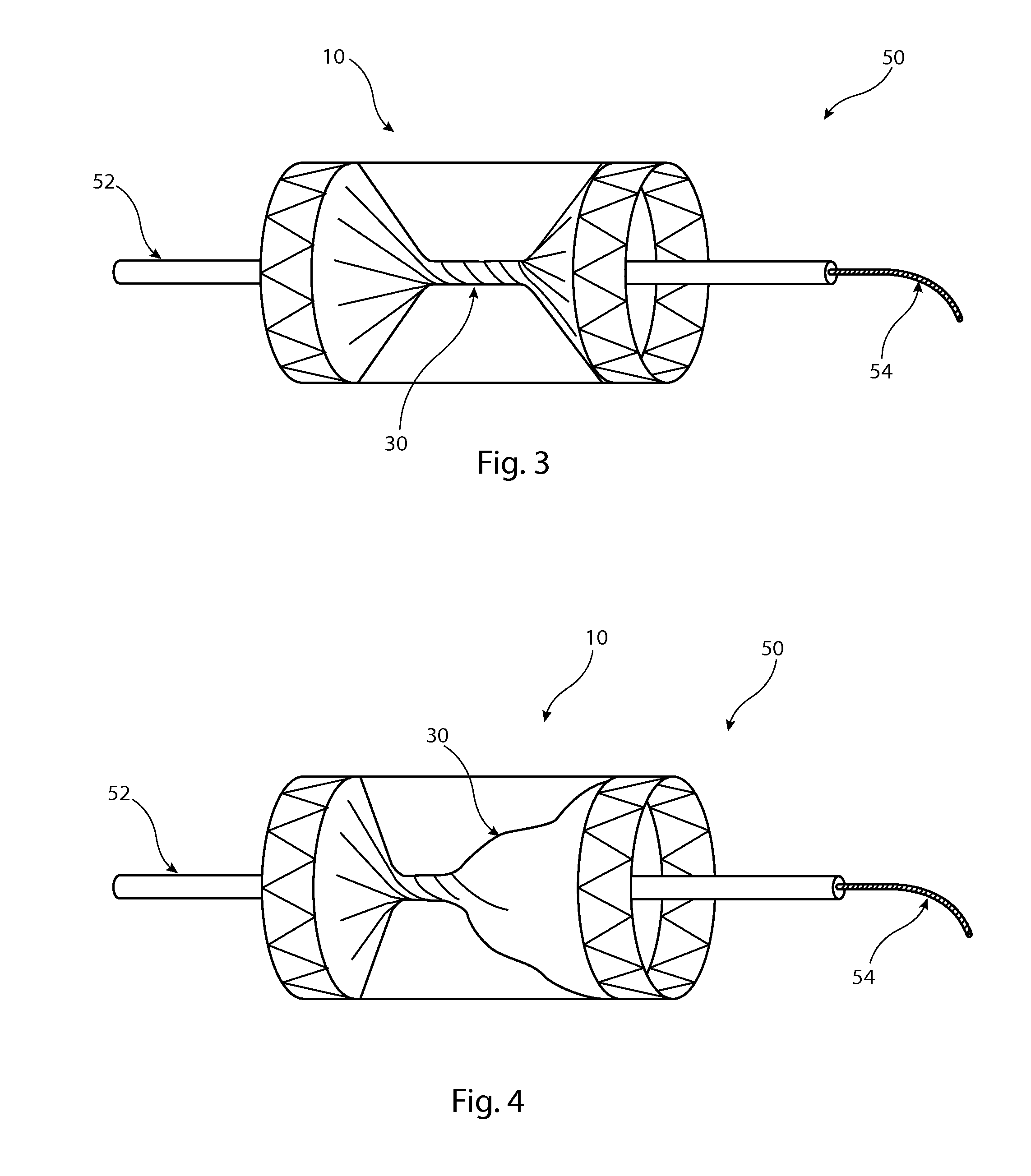

Implantable medical device with twisted element

ActiveUS20150313603A1Avoids risk of recanalizationOptimal procedureStentsDilatorsConstrictionGuide wires

A vascular occluder includes a tubular support element and a sleeve of occluding material disposed within the support element. The sleeve is twisted in the support creating a constriction which closes the lumen of the sleeve. The lumen of the sleeve can nevertheless be opened by a guide wire or cannula for over the wire delivery. Once the guide wire or cannula are withdrawn from the sleeve, the sleeve will close again by the action of blood pressure thereon. Blood pressure will act to maintain closing pressure on the sleeve, thereby avoiding or reducing the risk of recanalization.

Owner:COOK MEDICAL TECH LLC

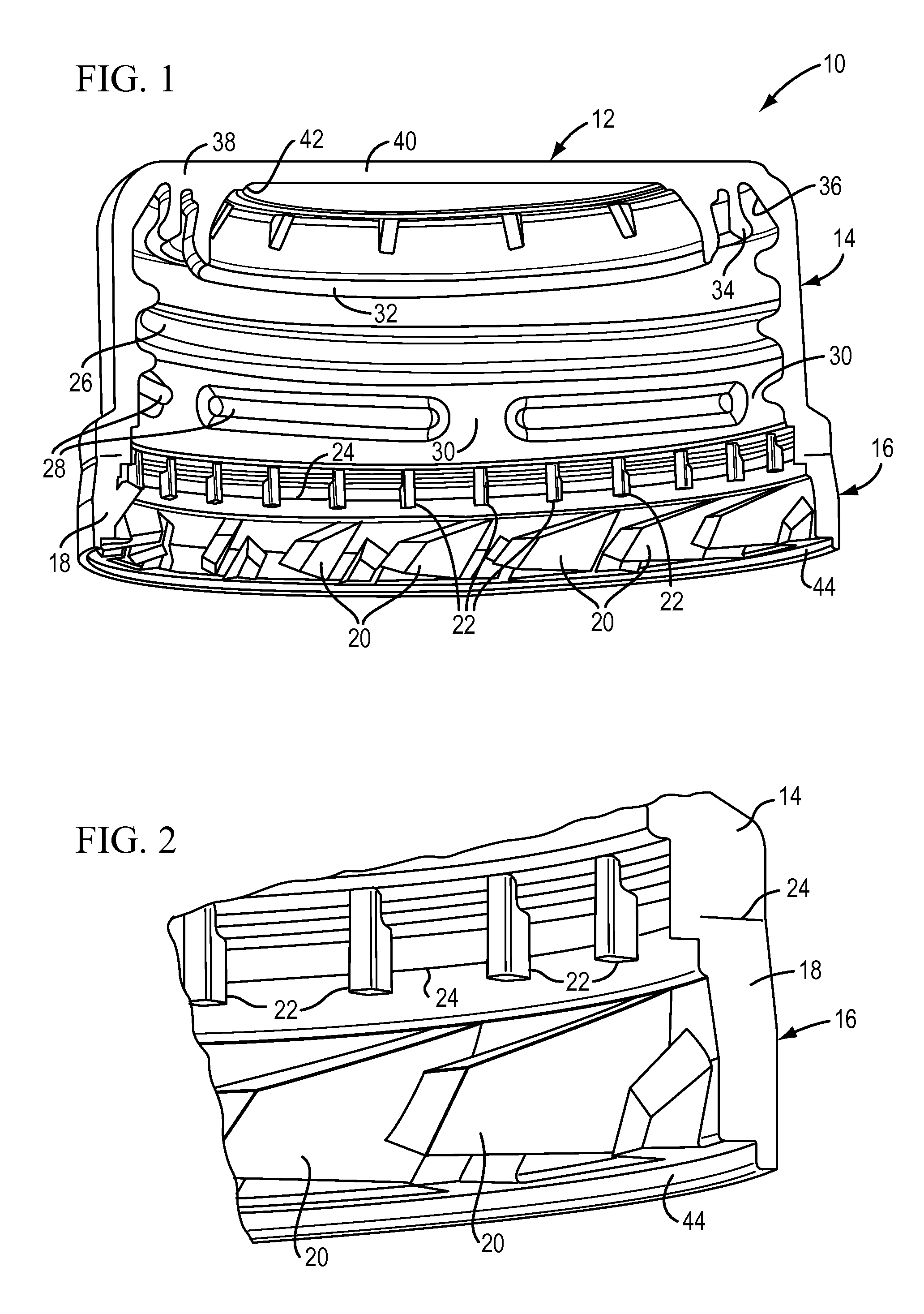

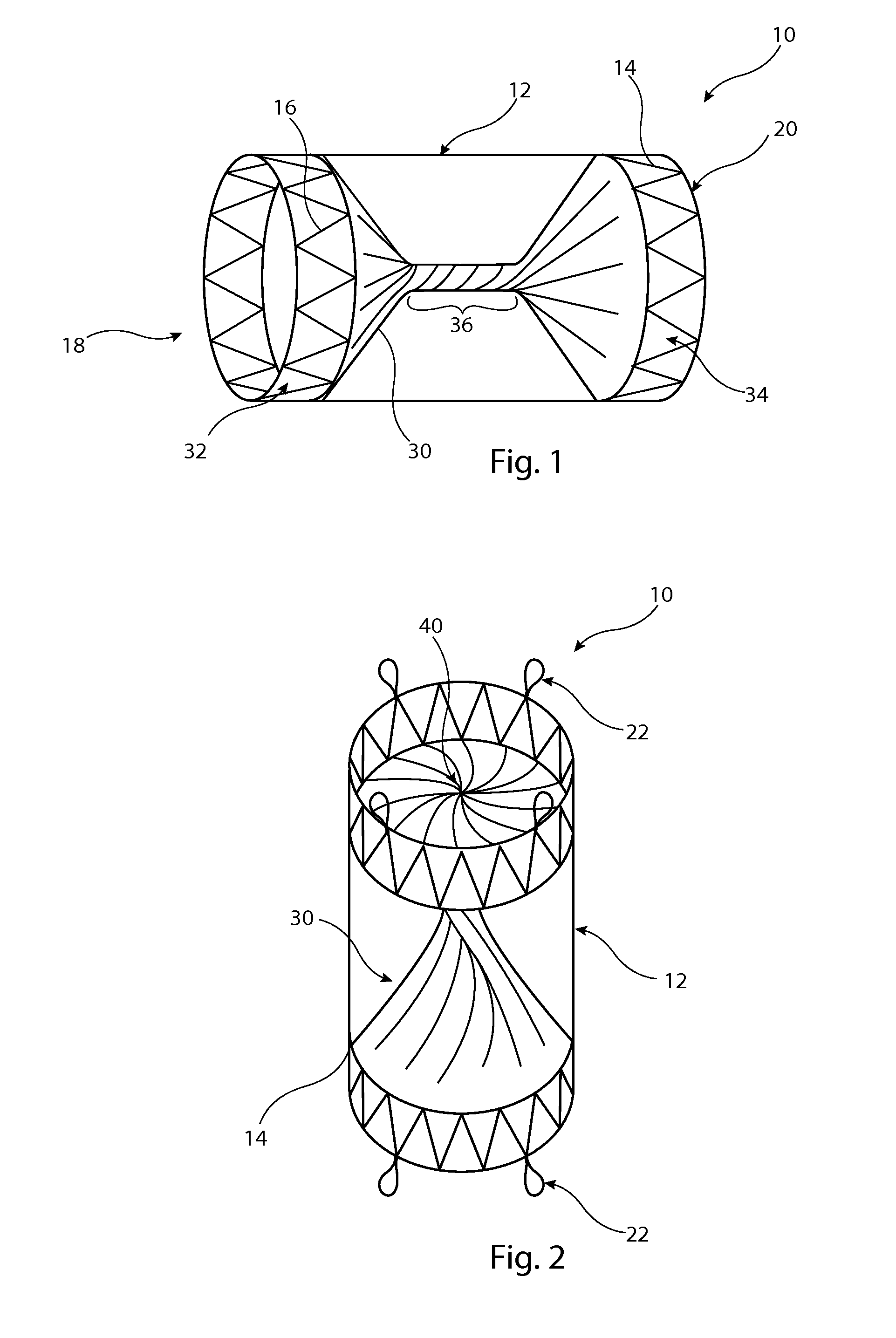

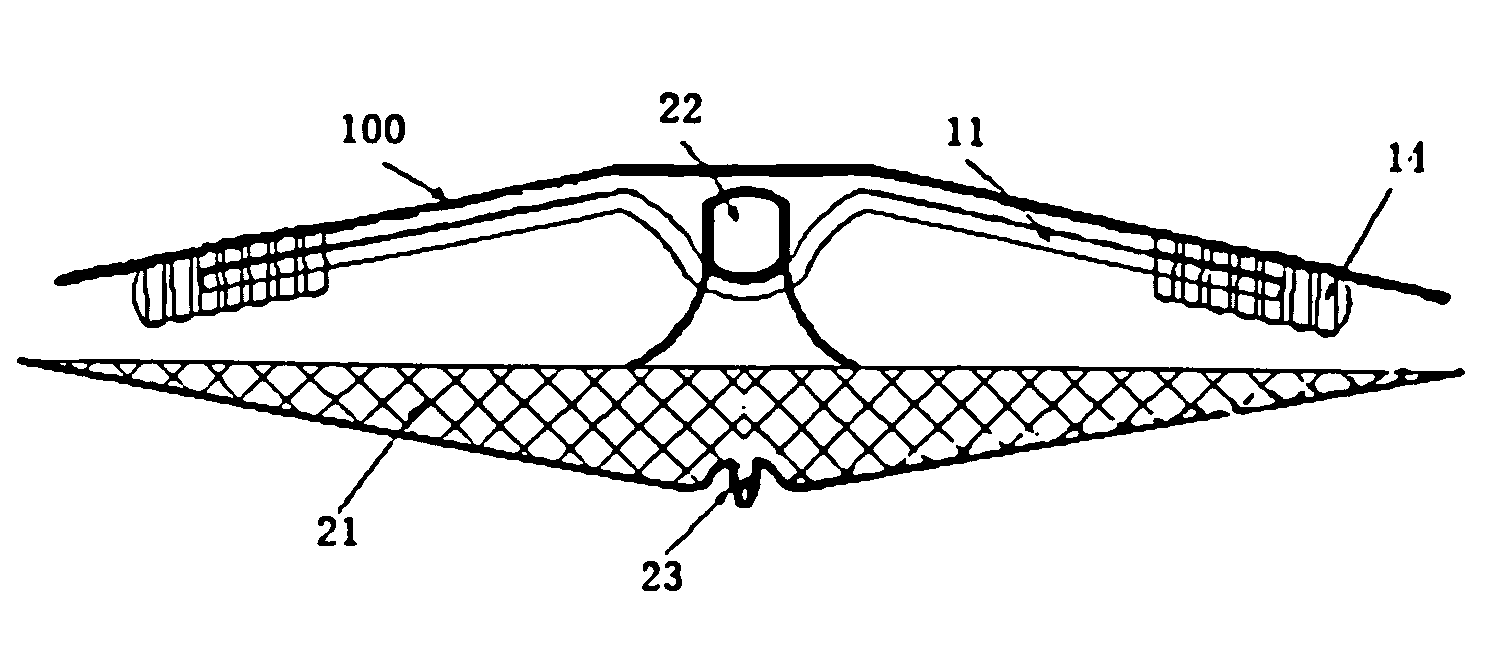

Heart septal defect occlusion device

ActiveUS8366743B2Improve closing effectThrombus can be reducedSurgical veterinaryWound clampsHeart septal defectMedicine

An occlusion device has a right disc made from a metal mesh having a plurality of openings, and a left disc having at least two skeletons that are covered by a membrane. Each skeleton passes through openings of the metal mesh to interlock the right and left discs, and a coil is wrapped around each opposing end segment of the skeletons. The skeletons can have a looped section where the skeleton is twisted or looped to cross or overlap itself. In addition, each skeleton can be formed from a braided strand of a plurality of wires.

Owner:LIFETECH SCIENTIFIC (SHENZHEN) CO LTD

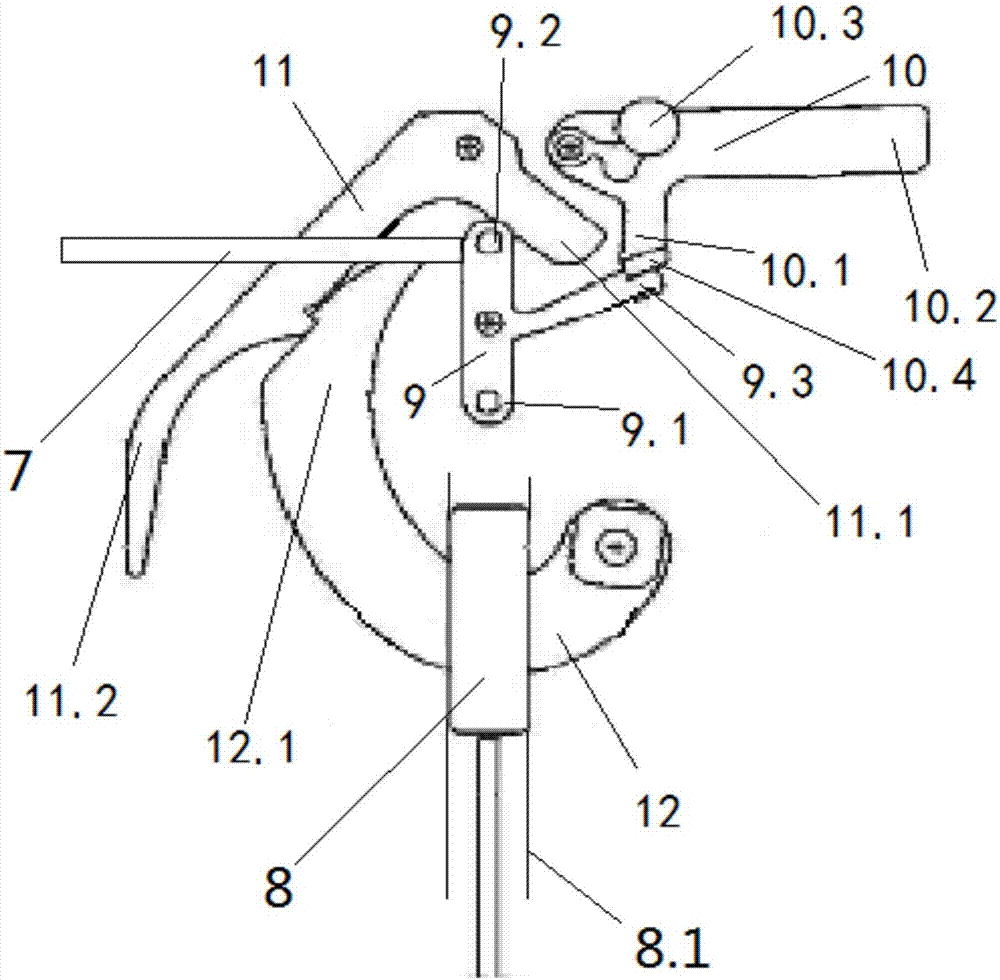

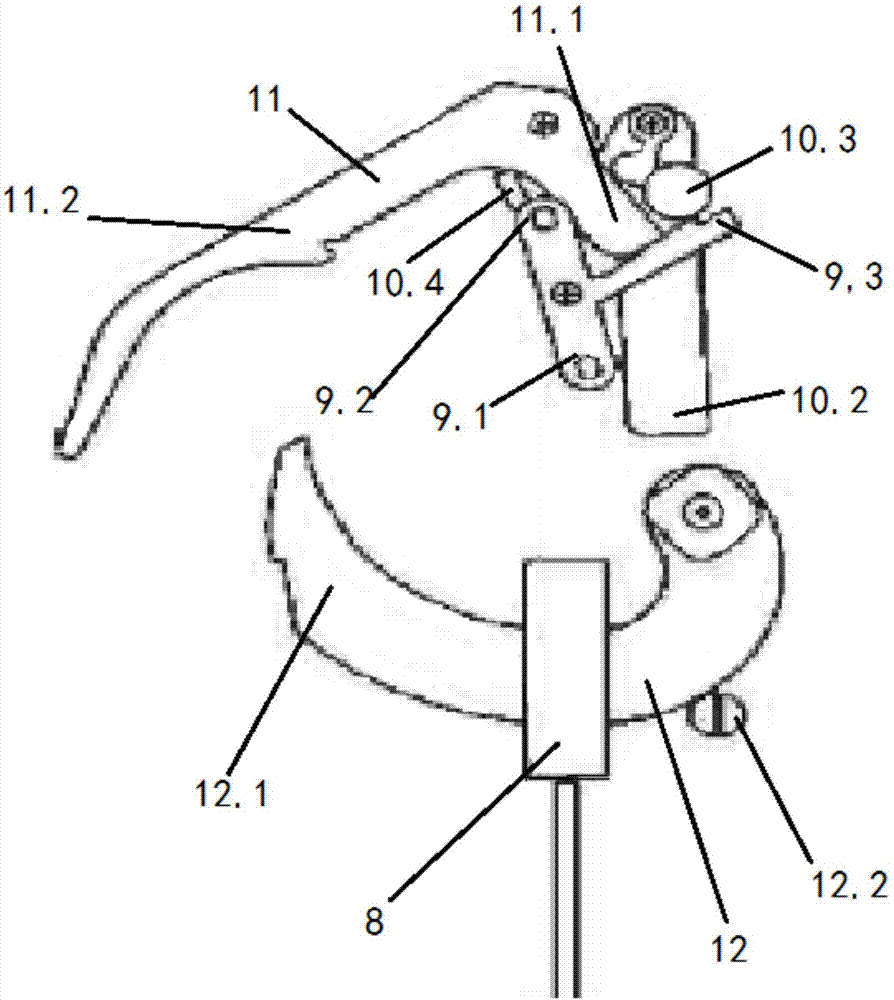

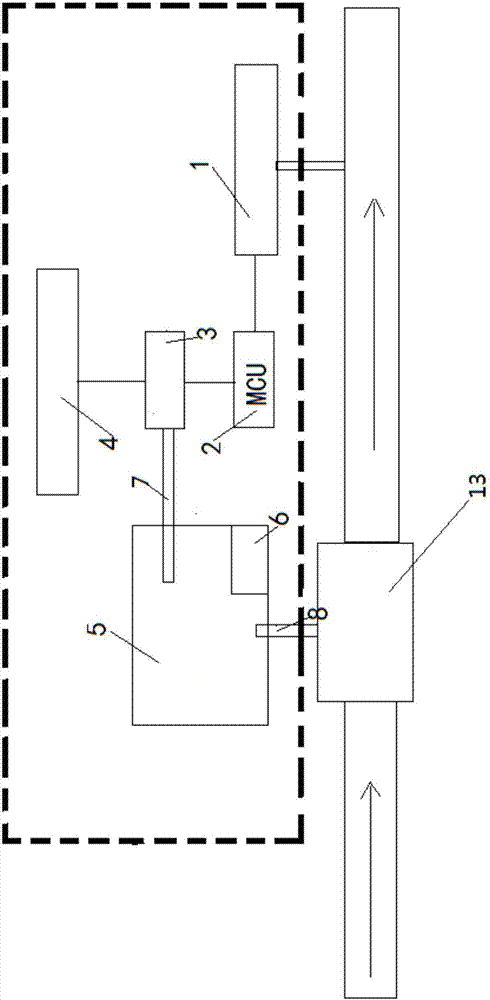

Latching device and gas transmission station pressure regulation safety cut-off valve

PendingCN107504235AThere will be no misoperationImprove seismic performanceOperating means/releasing devices for valvesEqualizing valvesControl theoryForce sensor

The invention relates to a latching device and a gas transmission station pressure regulation safety cut-off valve. The gas transmission station pressure regulation safety cut-off valve comprises the latching device, a pressure sensor, an MCU, an electromagnet and a gate valve body, wherein the pressure sensor is connected with the MCU; the MCU is electrically connected with the electromagnet; a control end of the electromagnet is connected with an ejector rod; the gate valve body is connected with a valve rod; and when pressure measured by the pressure sensor exceeds a threshold valve, the MCU sends out an electric signal, the electromagnet is energized, the electromagnet drives the ejector rod, the valve rod falls off, and the gate valve body is cut off. According to the latching device and the gas transmission station pressure regulation safety cut-off valve, when abnormities like overpressure and pressure loss of downstream pressure are detected, the safety cut-off valve can be quickly cut off; when emergency switching-off is executed, driving is carried out through the electromagnet, and the general service life reaches millions of times; besides, the electromagnet is energized, and the situation that an interlock driving device performs mistaken action is avoided; and the shock resistance is high, closing performance is good, and real-time feedback of the valve state can be achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Heart septal defect occlusion device

ActiveUS20110066180A1Reliable and reliableImprove closing effectSurgical veterinaryWound clampsMetal meshWrap around

An occlusion device has a right disc made from a metal mesh having a plurality of openings, and a left disc having at least two skeletons that are covered by a membrane. Each skeleton passes through openings of the metal mesh to interlock the right and left discs, and a coil is wrapped around each opposing end segment of the skeletons. The skeletons can have a looped section where the skeleton is twisted or looped to cross or overlap itself. In addition, each skeleton can be formed from a braided strand of a plurality of wires.

Owner:LIFETECH SCIENTIFIC (SHENZHEN) CO LTD

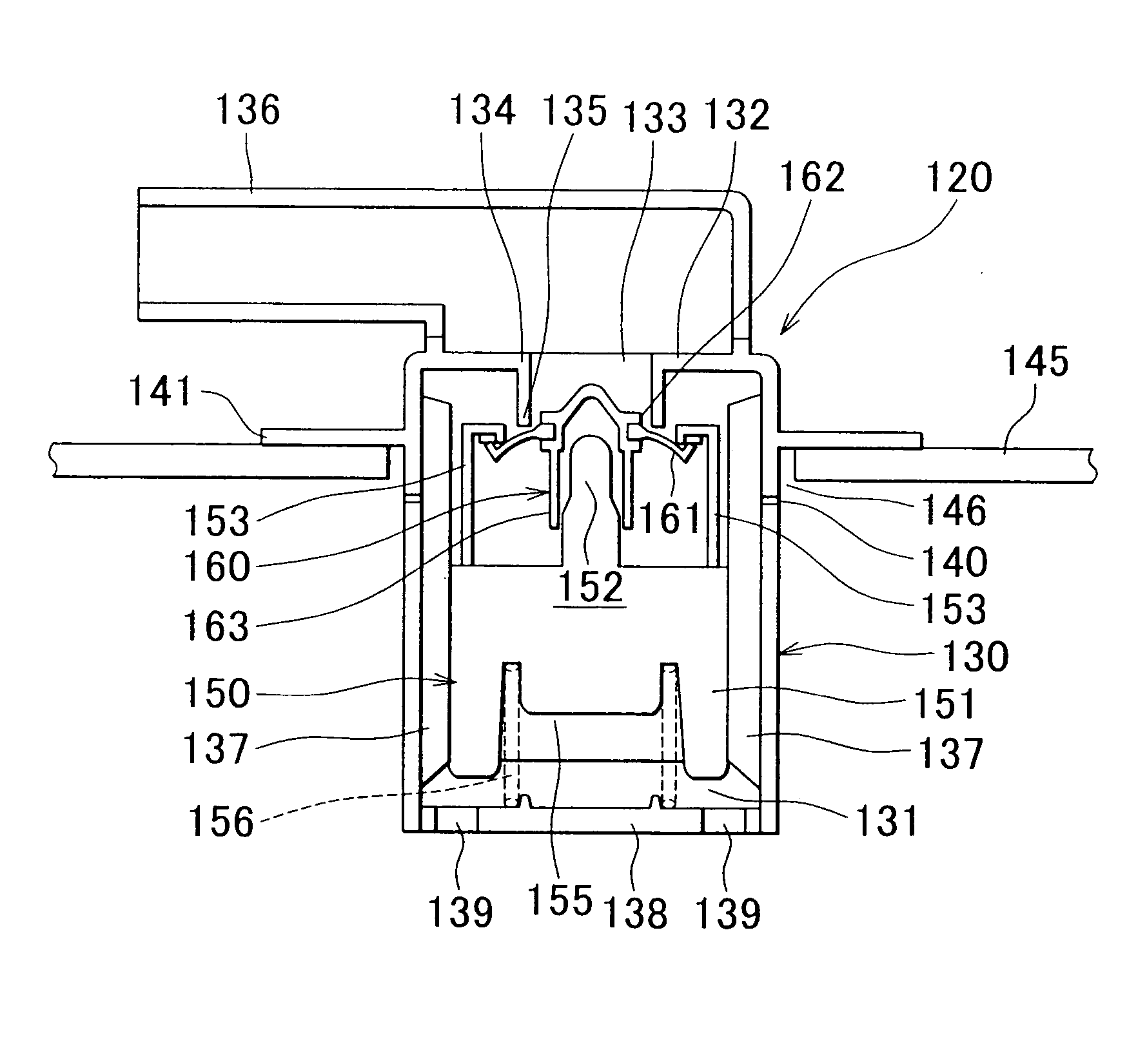

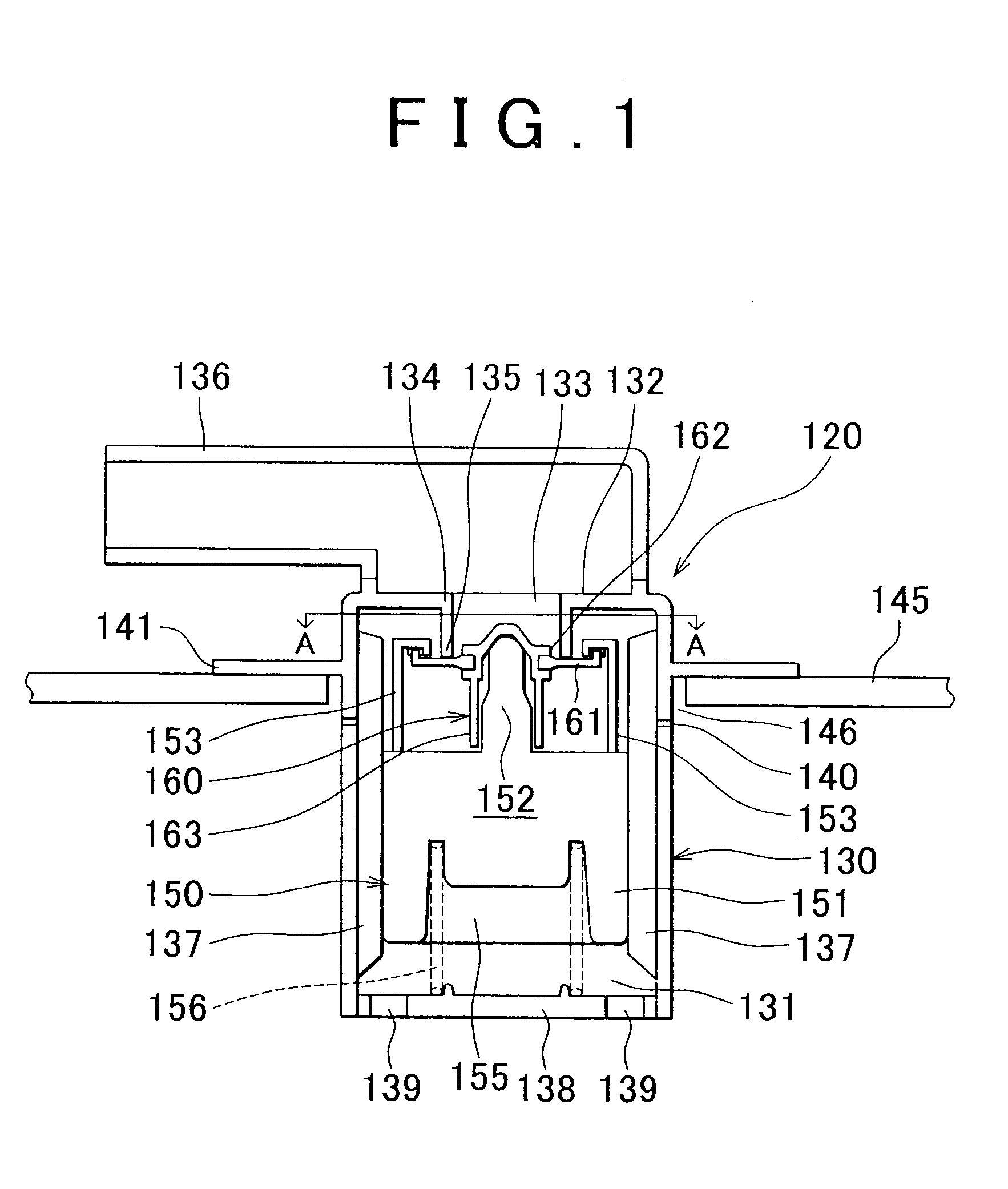

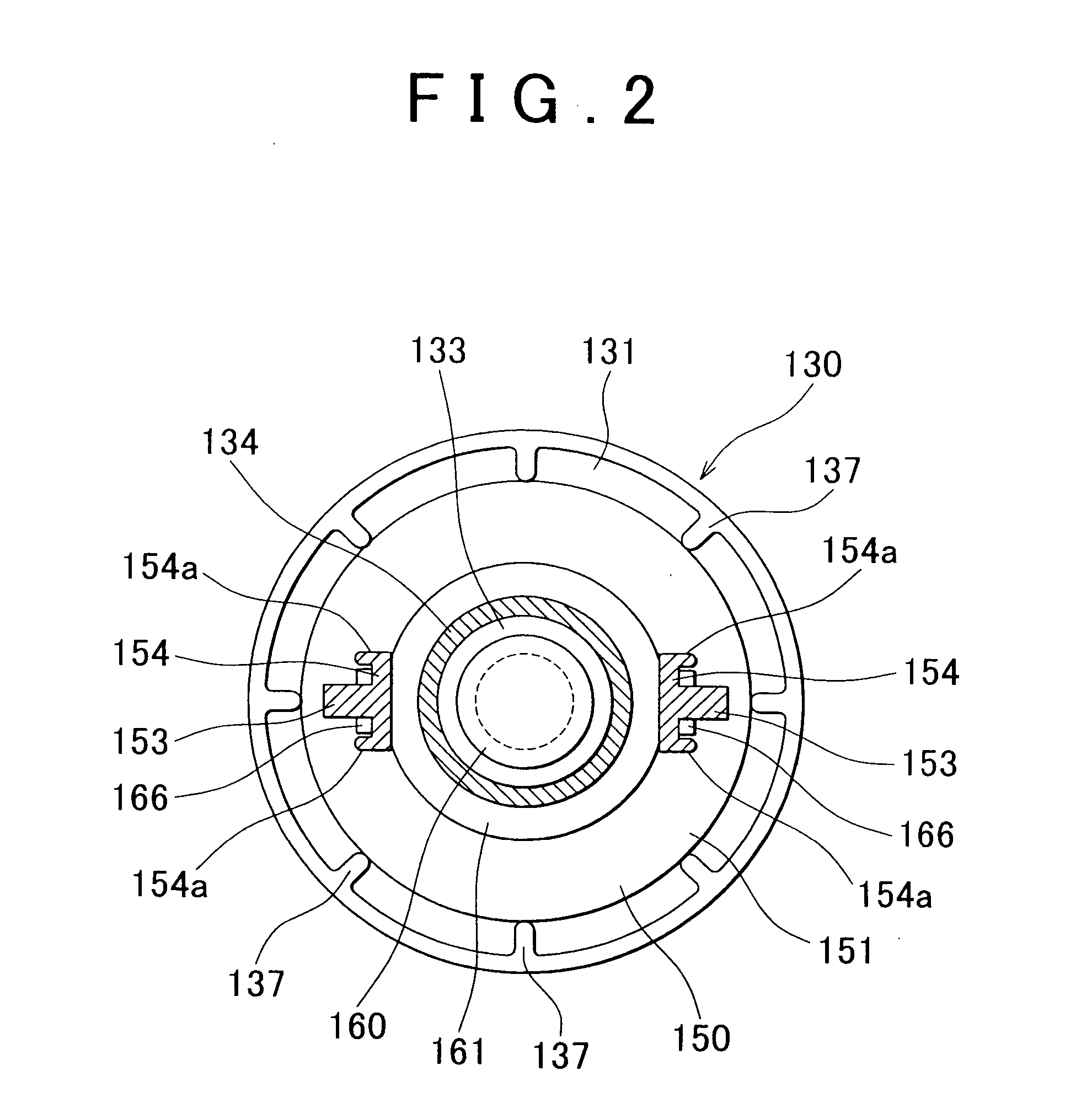

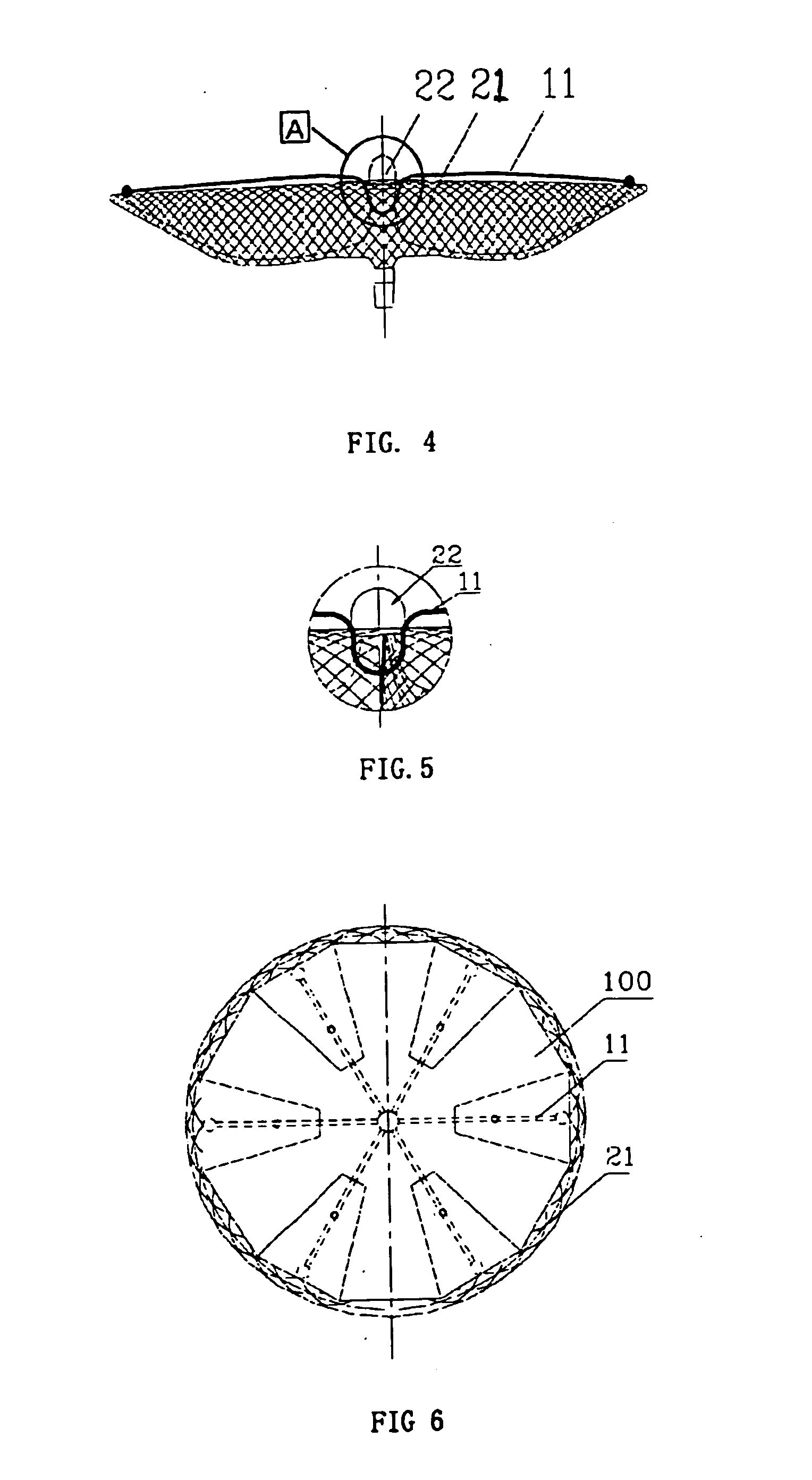

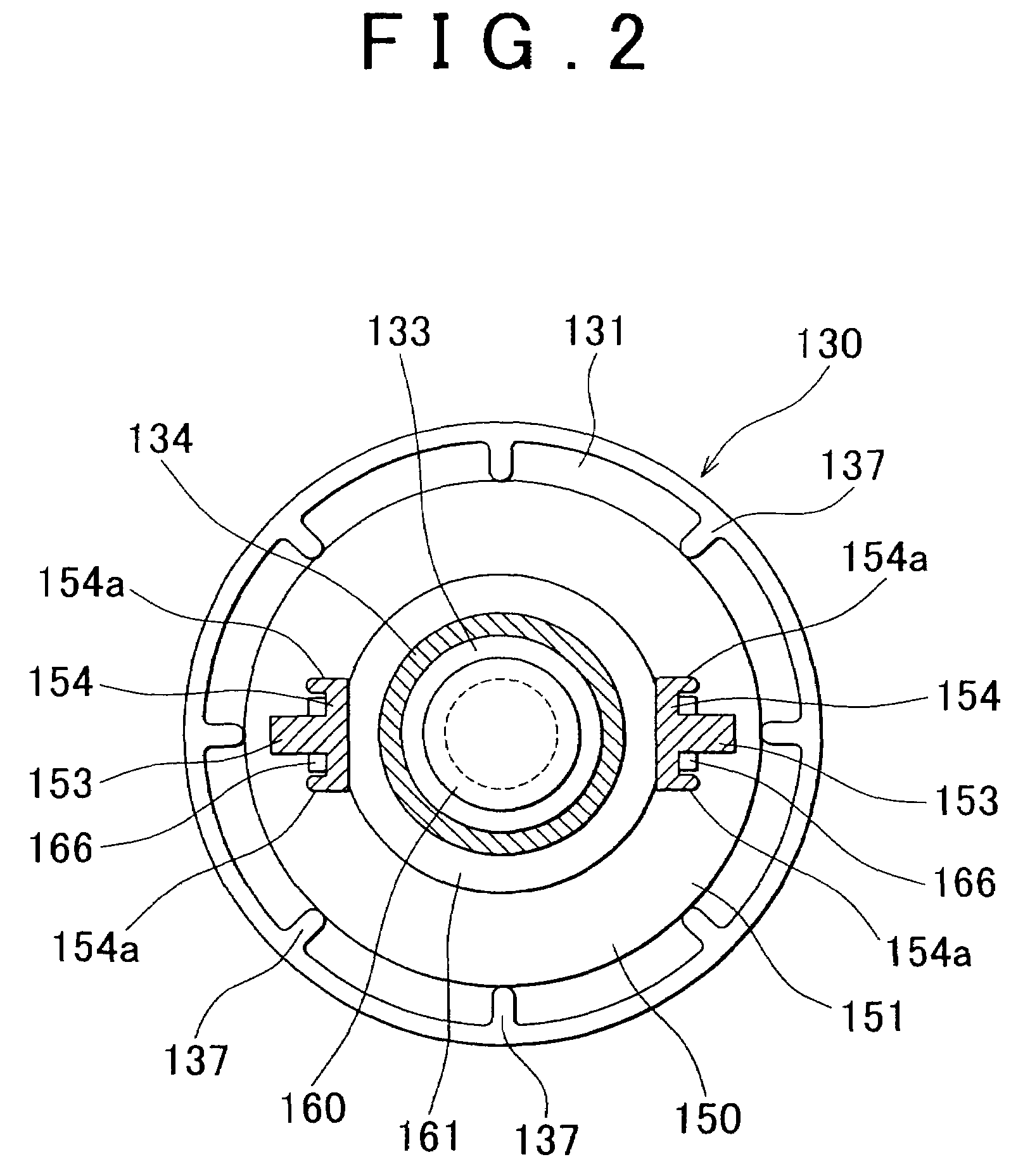

Valve drive device, its control method and pump

InactiveUS20070181838A1Improve performanceImprove closing effectSpindle sealingsDiaphragm valvesDiaphragm valveVALVE PORT

A valve drive device may include a motor, a rotational member rotated by the motor, a linearly moving member engaged with the rotary member, a converting mechanism for converting rotation of the rotational member into linear movement of the linearly moving member, a diaphragm valve for opening or closing an opening part by linearly moving member, and an urging member for closing the opening part through the diaphragm valve. The linearly moving member is linearly moved by the rotational member and the opening part is closed by the diaphragm valve in a state that the rotational member and the linearly moving member are in a non-engagement state. The valve drive device may be mounted on a pump having an inflow path and a plurality of outflow paths.

Owner:SANKYO SEIKI MFG CO LTD

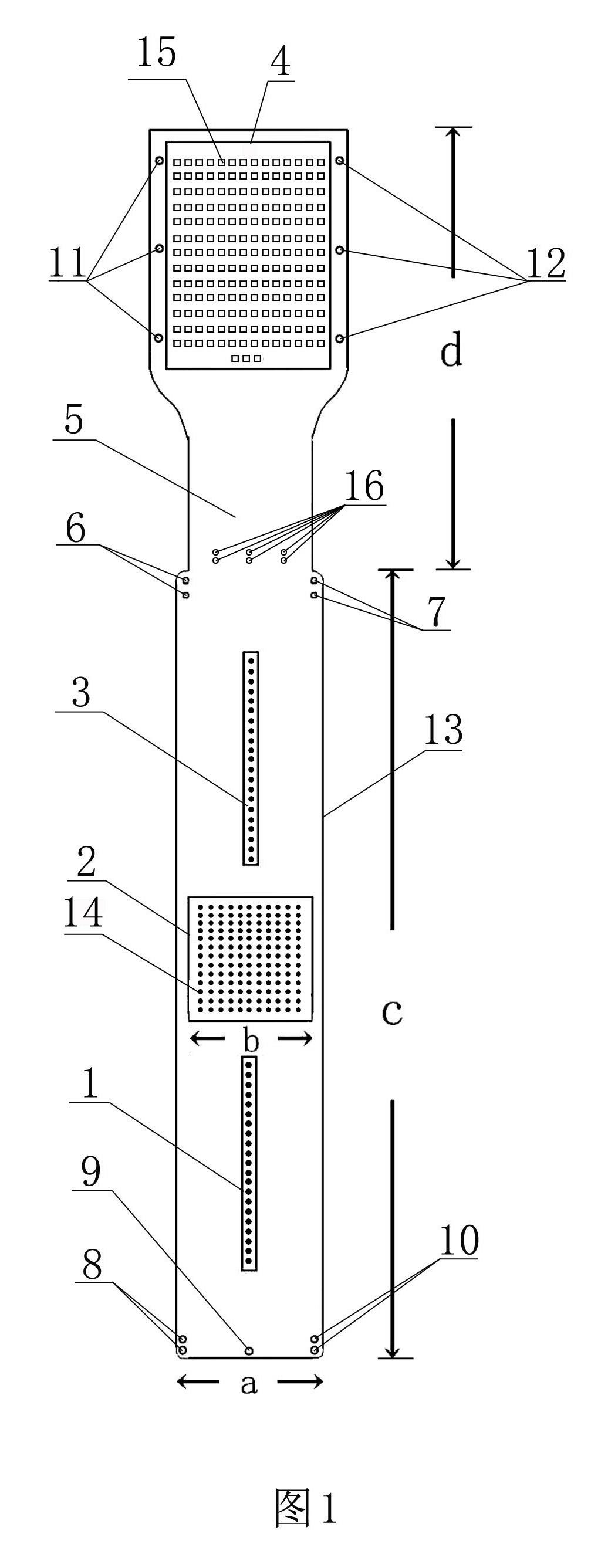

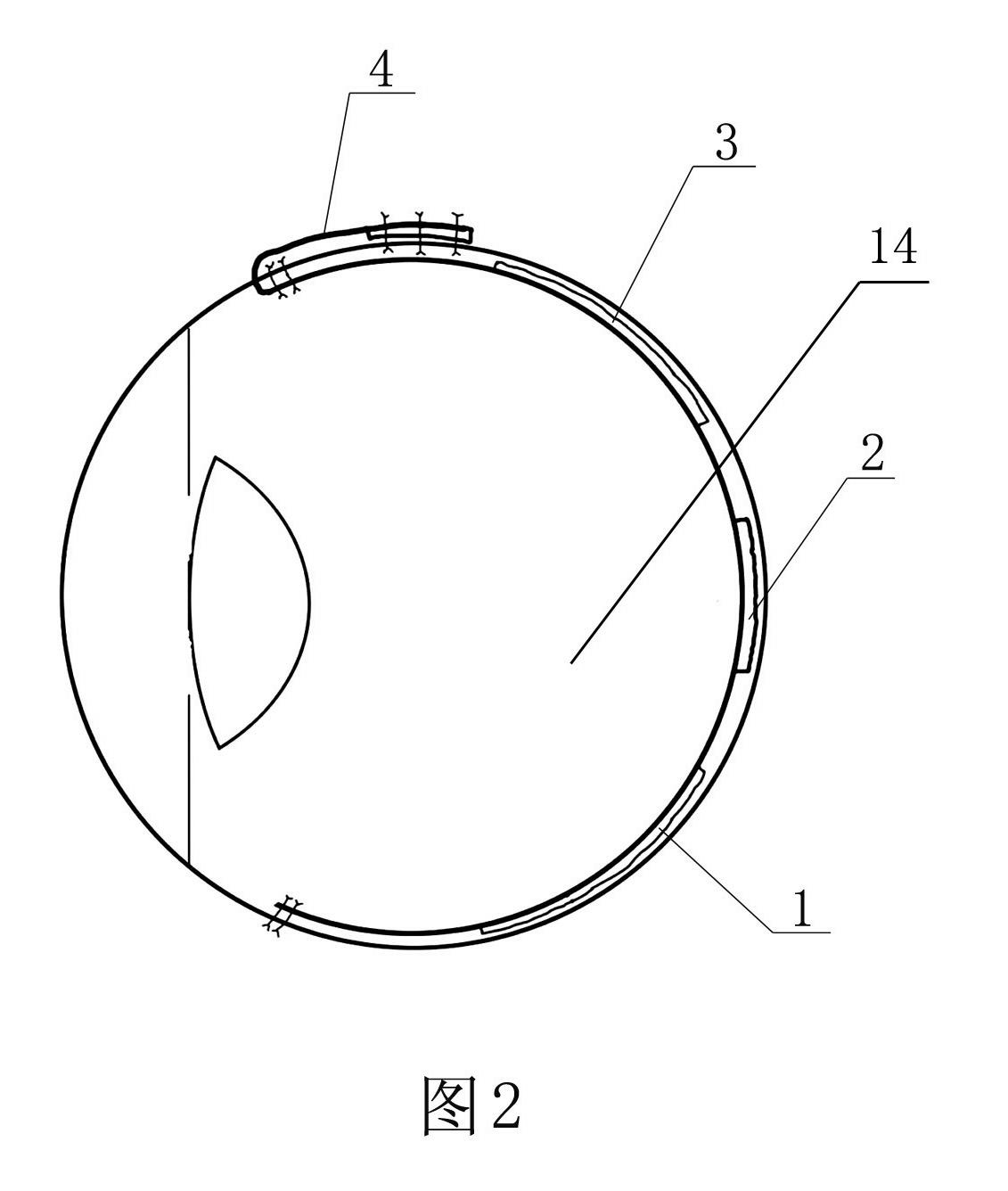

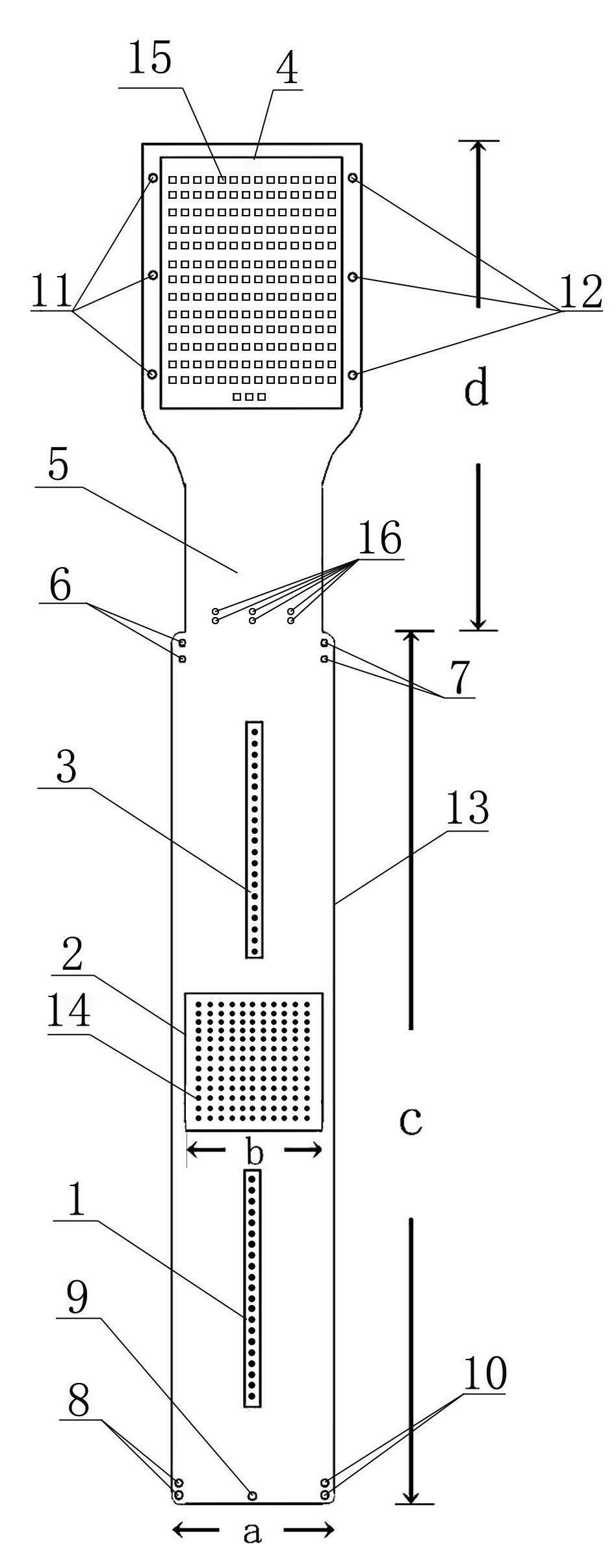

Micro-electrode array chip before retina in field of artificial vision

The invention discloses a micro-electrode array chip before retina in the field of artificial vision. The micro-electrode array chip comprises a chip substrate, a lead buried in the chip substrate and micro-electrodes protruding the surface of the substrate and forming an array. The edge of the lower end of the chip substrate is provided with at least two lower suture line preformed holes; a micro-electrode arrangement lower area, a micro-electrode arrangement middle area, a micro-electrode arrangement upper area, a substrate reduction area and a substrate expansion area are sequentially arranged on the chip substrate from bottom to top; the substrate expansion area contains contacts corresponding to the electrode arrangement areas, and are connected with the micro-electrodes through the lead buried in the chip substrate; the chip substrate close to the lower end of the substrate reduction area is provided with at least three groups of two sclera cut suture line preformed holes, and two edges are respectively provided with at least two upper suture line preformed holes; and two sides of the substrate expansion area are provided with eye external suture line preformed holes. The micro-electrode array chip can stimulate retinal ganlion cells of the blind to recover partial vision of the blind, and avoids rhegmatogenous retinal detachment, choroidal hemorrhage and sympathetic ophthalmia caused by iatrogenic retinal breaks.

Owner:PEOPLES HOSPITAL PEKING UNIV

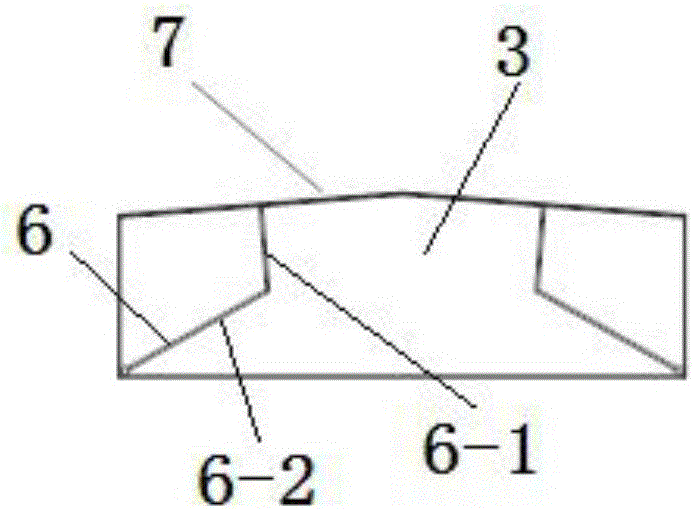

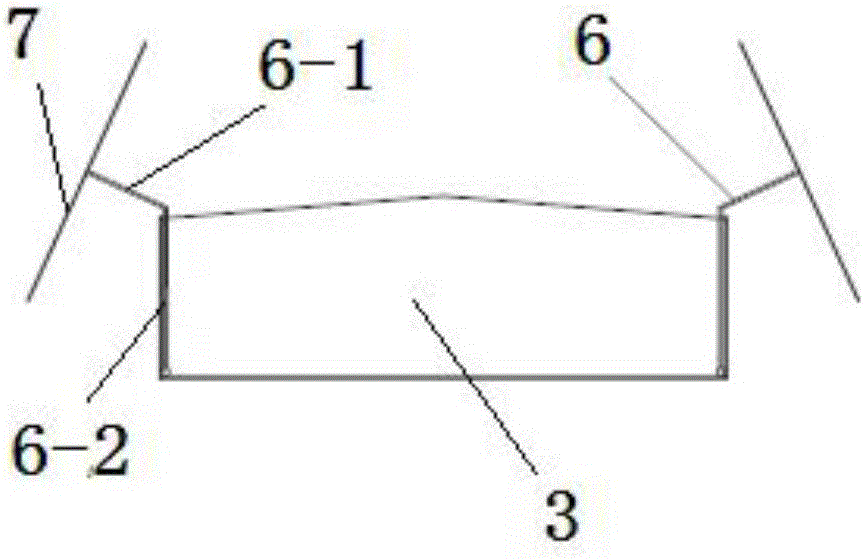

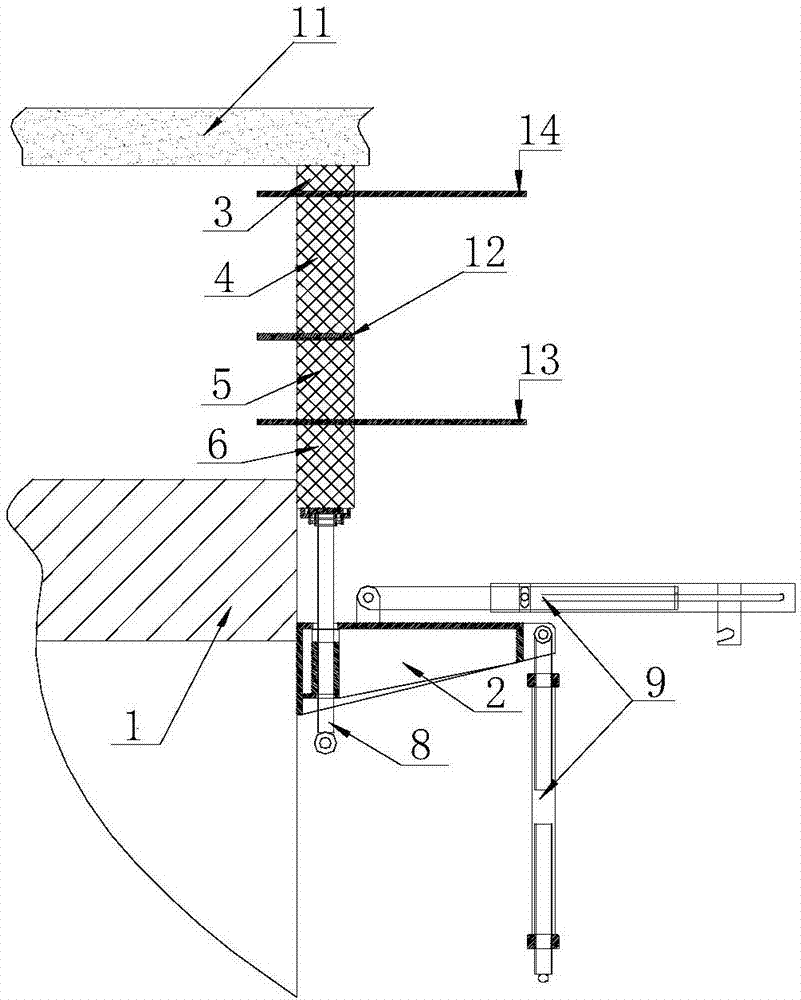

Composite rubber vertical rod telescopic plug plate and use method thereof

ActiveCN107060828AReduce gapAvoid misalignmentUnderground chambersLifting devicesWater leakageSlurry

The invention discloses a composite rubber vertical rod telescopic plug plate and a use method thereof and belongs to the technical field of tunnel construction. By adoption of the composite rubber vertical rod telescopic plug plate and the use method thereof, the hidden dangers such as water leakage and slurry leakage of a tunnel are avoided. The telescopic plug plate comprises a trolley, a supporting base and rubber baffles. A back pasting type watertight strip is arranged between the tunnel roof and the uppermost layer rubber baffle. A watertight strip and / or a steel bar layer is arranged between every two adjacent rubber baffles. The supporting base is connected with a hoisting mechanism which is connected with the lowermost layer rubber baffle. The use method adopts the telescopic plug plate, and a lifting telescopic rod of a lifting mechanism is rotated, so that the connecting end of the lifting telescopic rod acts on the back pasting type watertight strip, and the back pasting type watertight strip is tightly attached to the tunnel roof to enable the watertight strips and the back pasting type watertight strip to be smoothly located between the second rubber baffle and the third rubber baffle as well as between the first rubber baffle and the tunnel roof correspondingly.

Owner:SICHUAN HAODESI NEW MATERIAL TECH CO LTD

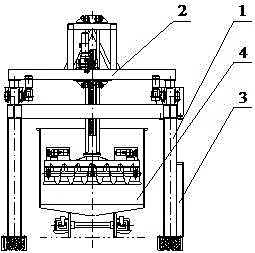

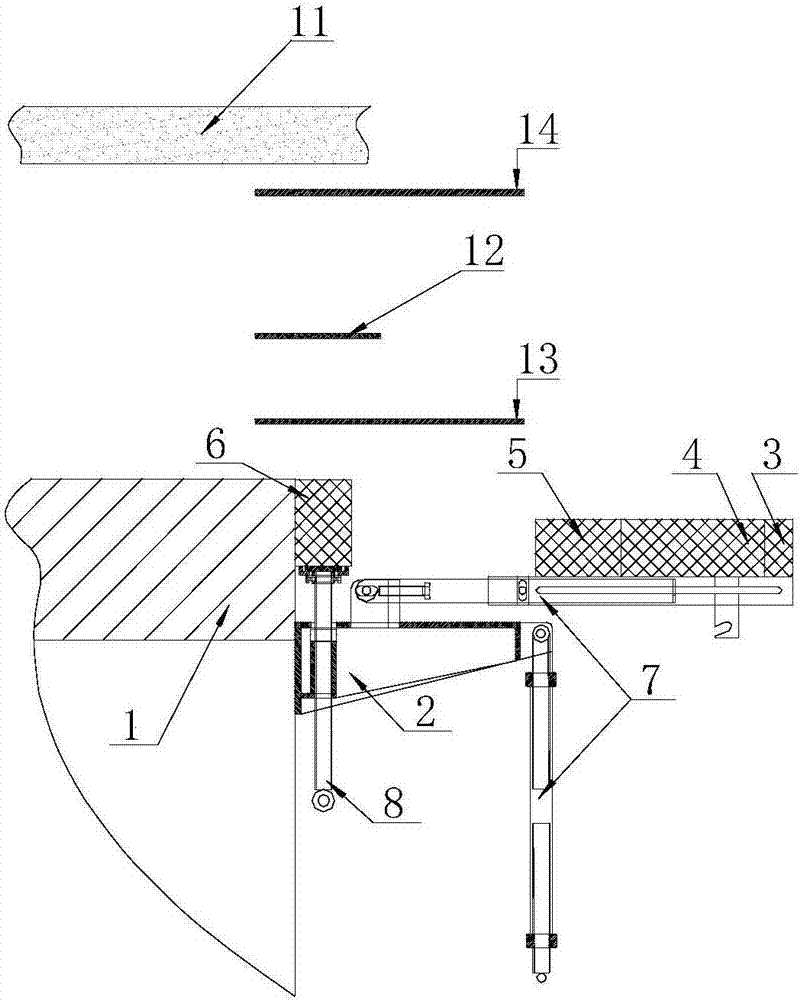

Flowing type efficient spiral material leveling machine

ActiveCN103738748ALower center of gravityEnsure normal walkingLoading/unloadingLeveling effectElectrical and Electronics engineering

The invention discloses a flowing type efficient spiral material leveling machine. When the flowing type efficient spiral material leveling machine operates, travelling mechanisms are horizontally arranged on bilateral sideboards in the width direction of a train; a plurality of groups of incline proof mechanisms are connected to external sides of the travelling mechanisms through bolts; incline proof lateral rolling wheel groups which are arranged on external sides of the sideboards play roles in preventing the material leveling machine travelling from deorbiting; lifting mechanism supports are fixedly connected to symmetrical bases which are arranged at end beams at upper ends of the travelling mechanisms; ladder-shaped structures of the lifting mechanism supports are formed due to the fact that two short square steel are symmetrically welded to the middle of two long square steel perpendicularly; lifting mechanisms perpendicularly penetrate frame-shaped areas which are defined by the two short square steel and the long square steel; spiral material pushing mechanisms which are connected under the lifting mechanisms are perpendicular to rails in the length direction. According to the flowing type efficient spiral material leveling machine, power is supplied through a built-in power device, travelling and carriage crossing are directly performed on a carriage with the train sideboards serving as the rails, and scanning type cabin leveling operation of all carriages of the integral train is achieved. The flowing type efficient spiral material leveling machine has the advantages of completely replacing manual cabin leveling operation, meanwhile satisfying cabin leveling tasks at any places, being good in cabin leveling effect, high in efficiency, strong in adaptability, safe and reliable and the like.

Owner:WUHAN K CRANE OCEAN ELEVATORING TECH

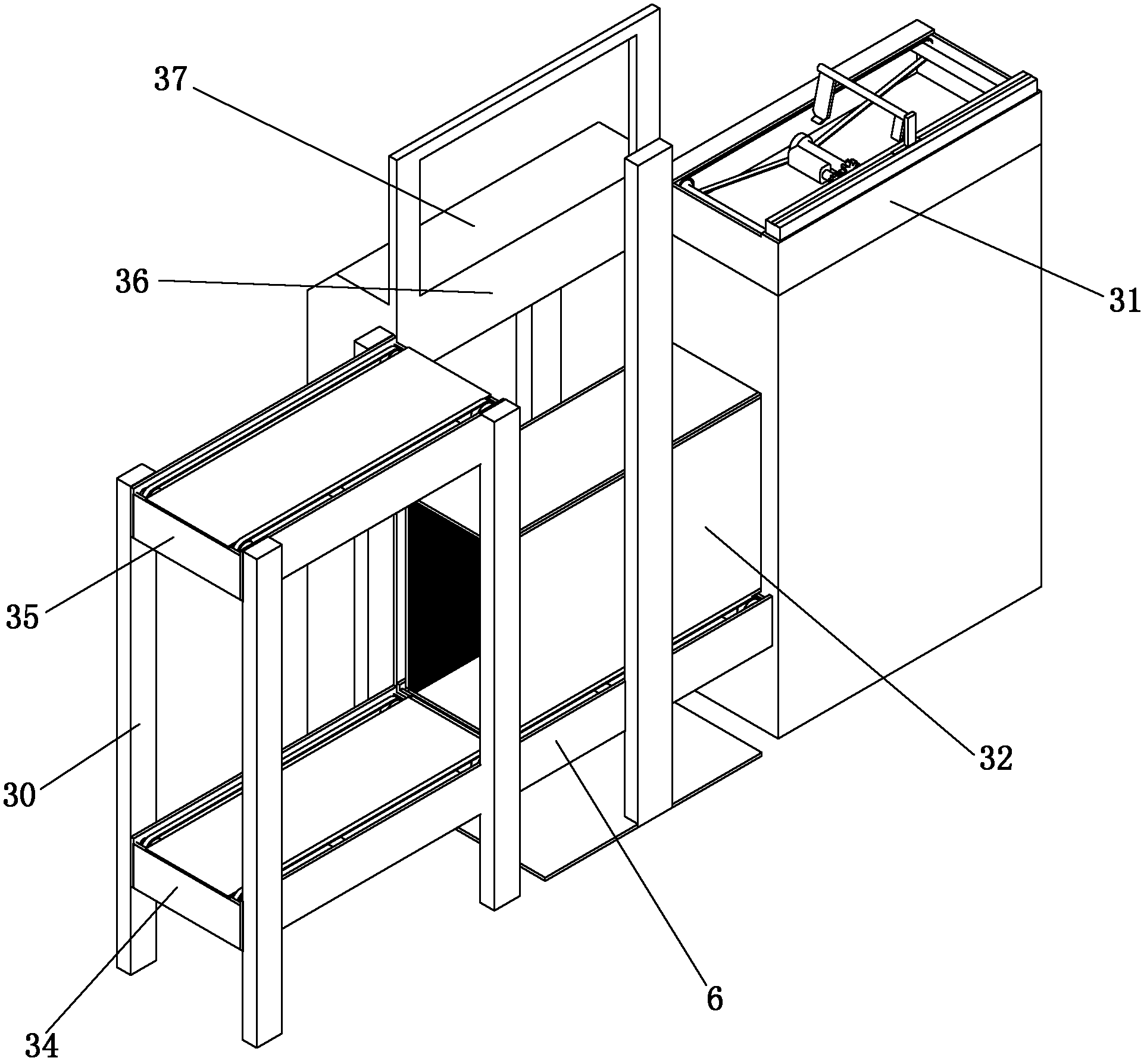

Full-automatic printed circuit board (PCB) stacker

InactiveCN103130010ASmooth transmissionSimple structurePrinted circuit manufacturePile receiversRight-to-leftPrinted circuit board

The invention discloses a full automatic printed circuit board (PCB) stacker which comprises a PCB staking frame, a board pushing mechanism, a lifting mechanism and a combined type transmission device, wherein the board pushing mechanism is used for pushing a PCB into the PCB staking frame, the lifting mechanism is used for achieving lifting motion of the PCB staking frame and transmitting the PCB staking frame, and the combined type transmission device is used for transmitting the PCB staking frame. The board pushing mechanism, the lifting mechanism and the combined type transmission device are sequentially arranged from right to left. The full automatic PCB stacker is simple in structure, reasonable in design, simple and convenient to use and operate, capable of stably transmitting the PCB and the PCB staking frame to proper positions, simultaneously high in automation, capable of repeatedly working for a long time, and good in stacking effect, and saves a large amount of manpower labor.

Owner:SHAANXI ZIZHU ELECTRON

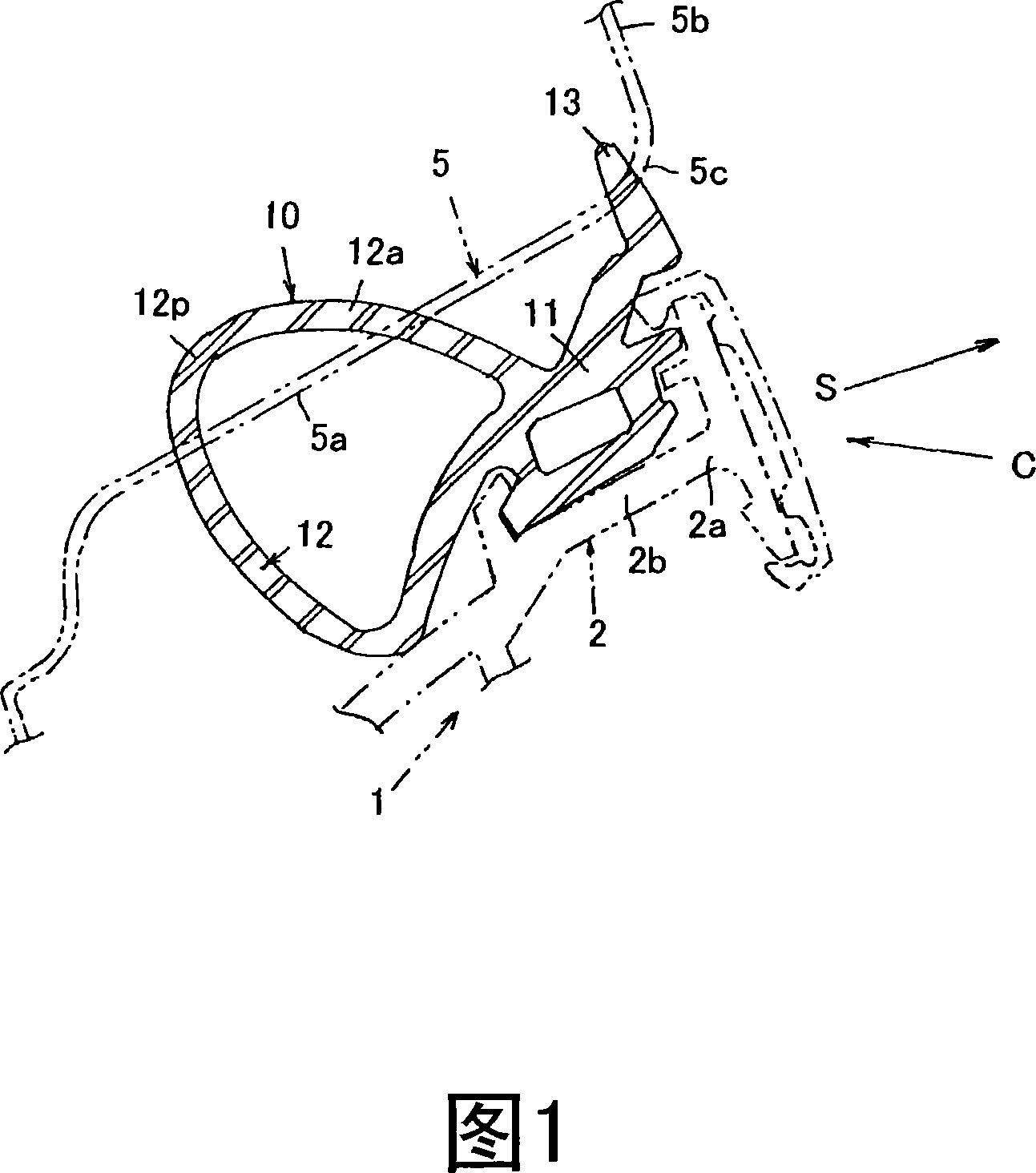

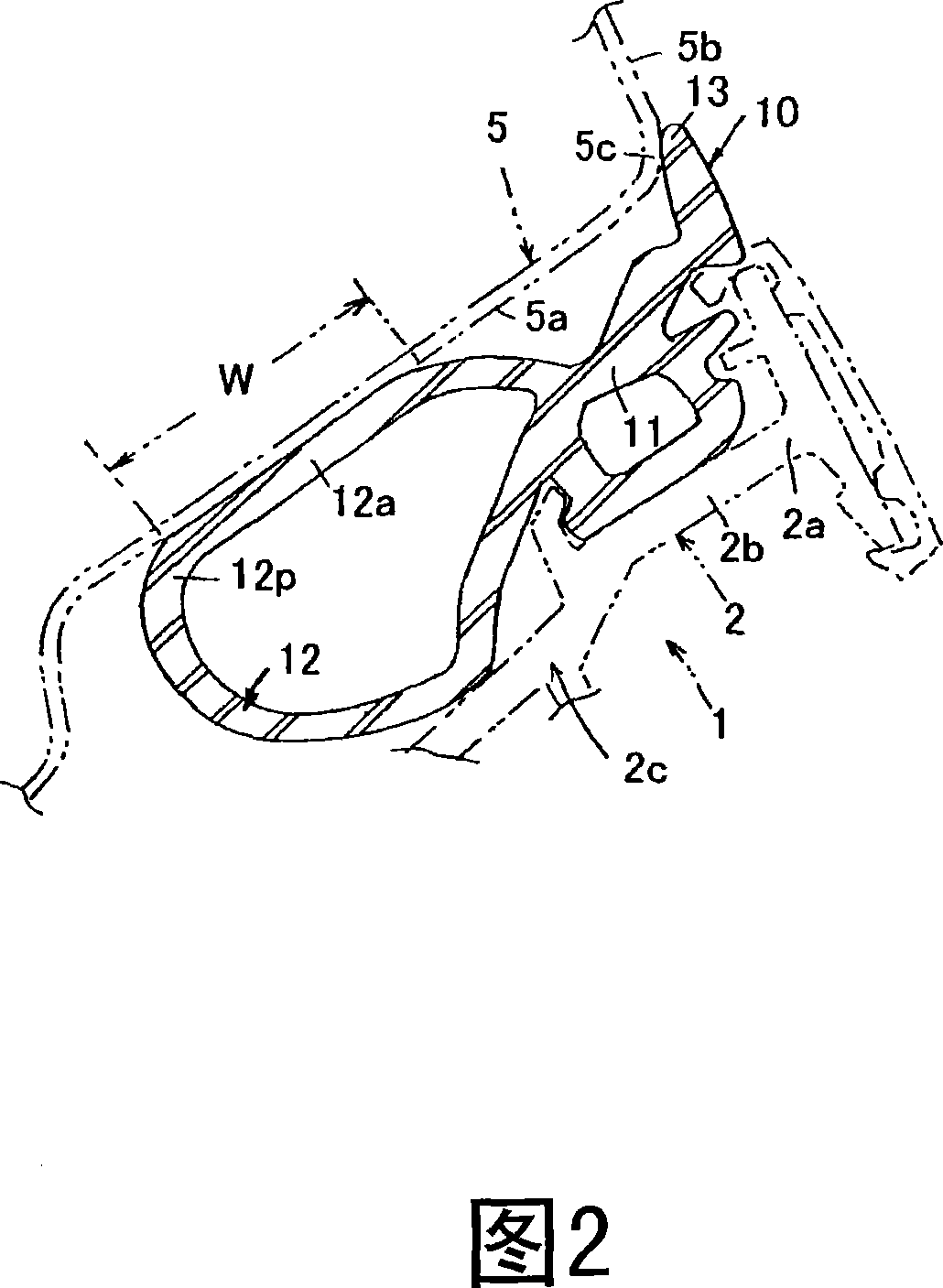

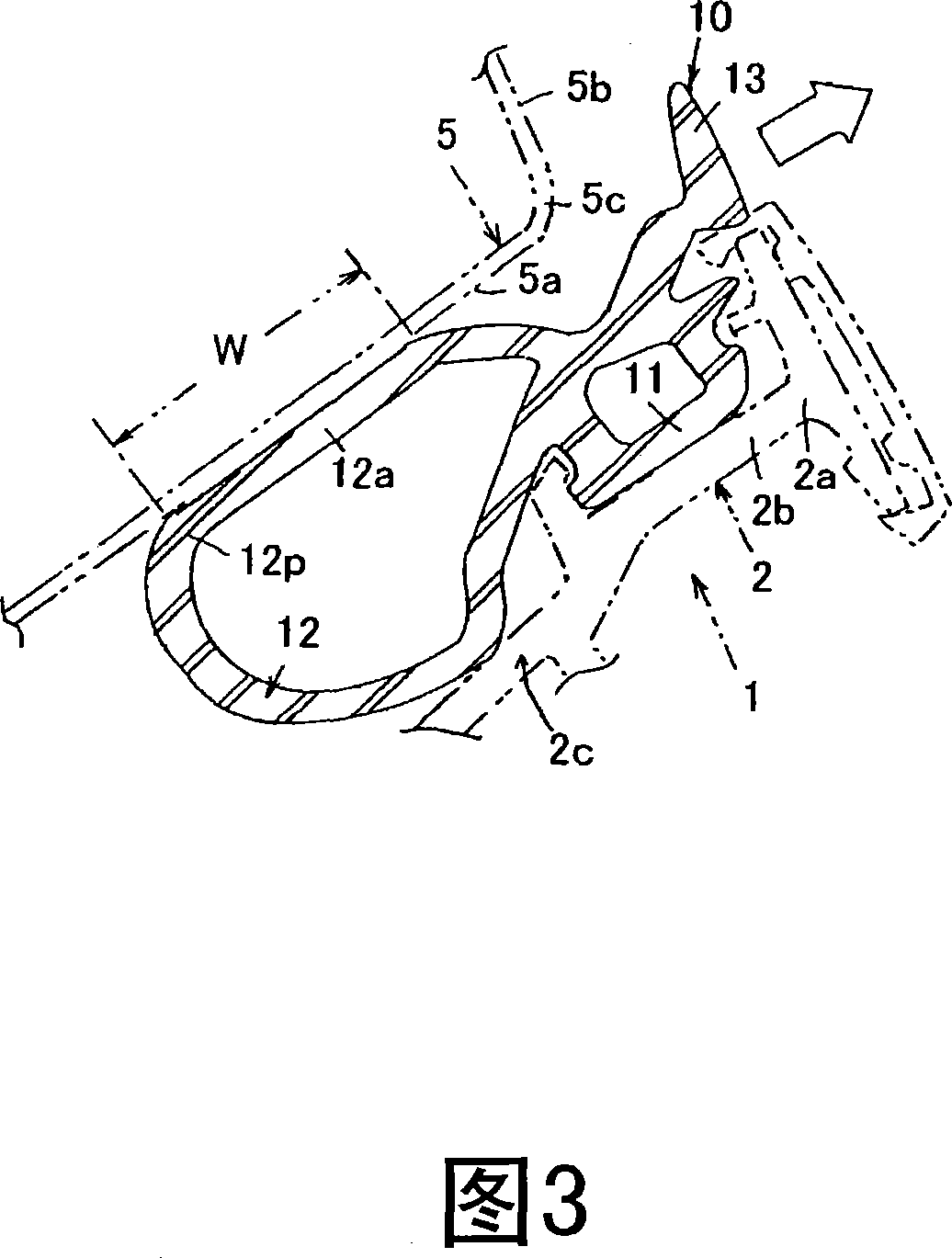

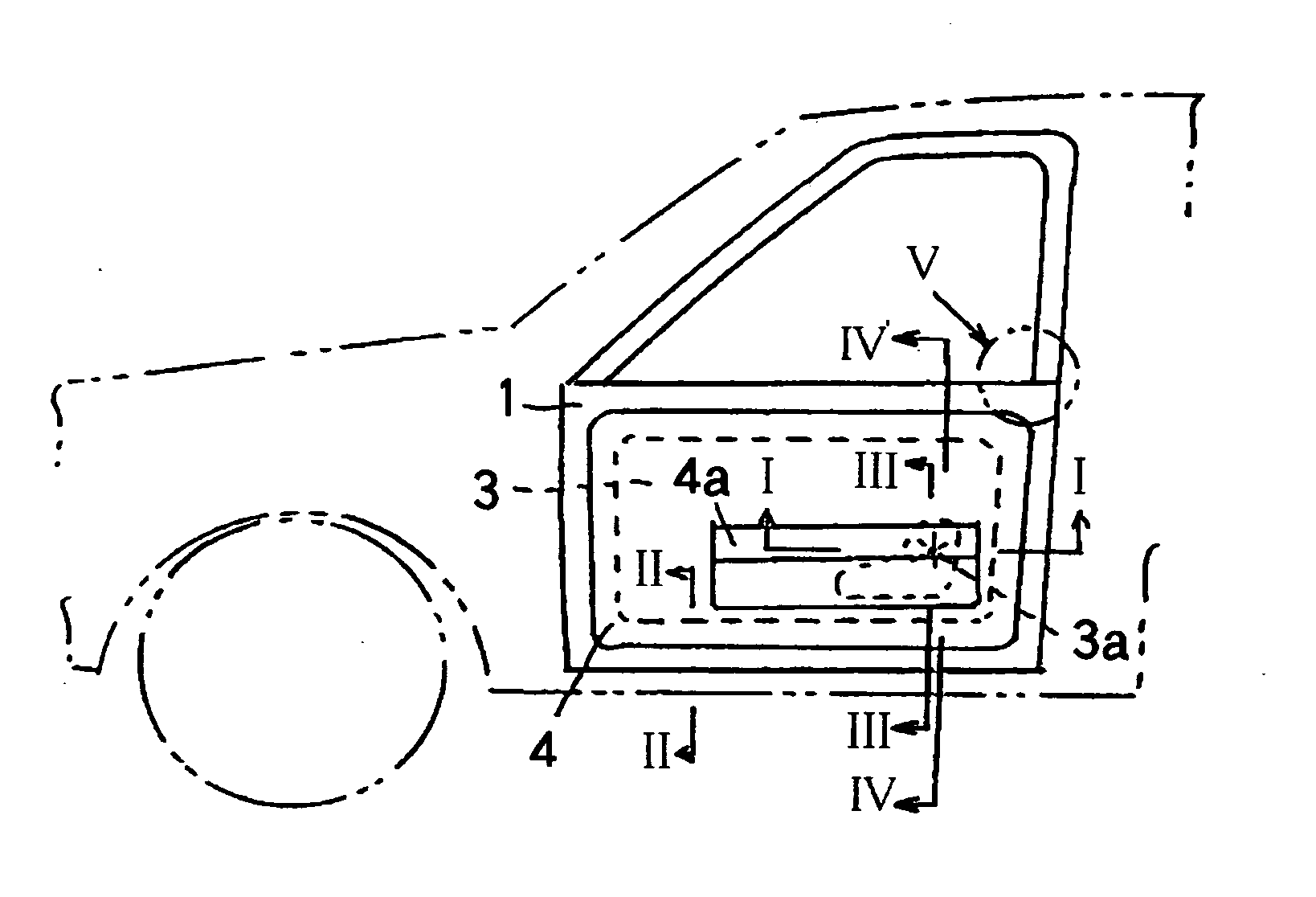

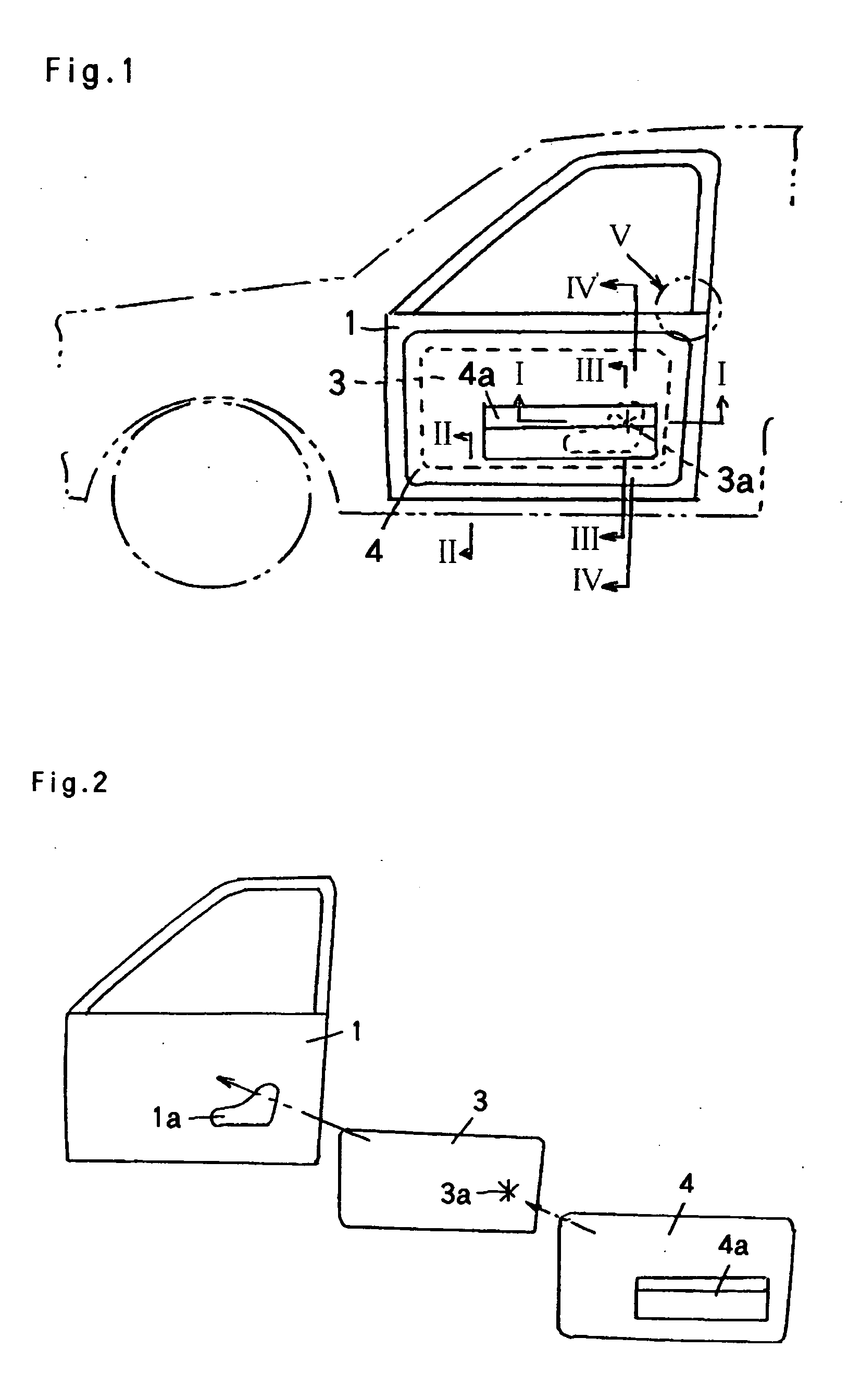

Attachment structure of door weather strip for vehicle

InactiveCN101062653AImprove sealingClosed retentionEngine sealsVehicle sealing arrangementsTravel modeEngineering

The invention provides a car door weather strip mounting structure capable of maintaining the high sealability even when a door is sucked outside a car when the car is traveling while maintaining the good door closability. The door weather strip 10 has a mounting base part 11 mounted on a retainer part 2a of a door sash 2, and a hollow seal part 12 which is integrated with the mounting base part 11 and elastically brought into contact with a body panel 5 when the door is closed. A part of the body panel 5 with the hollow seal part 12 elastically brought into contact therewith forms a flat parallel seal face 5a which is formed parallel or substantially parallel to the sucking direction S of a door 1 in a traveling mode.

Owner:NISHIKAWA RUBBER +1

Float valve structure

InactiveUS7717126B2Improve closing effectOpen fullyLarge containersVenting valvesEngineeringValve seat

A float valve structure that includes a case; a valve seat that is formed at an end portion of the case, at a position near an upper opening of the case; a float that is arranged in a space formed in the case so as to be vertically movable; a valve support member that is arranged above the float and that can be inserted into the upper opening; a valve that is fitted to the valve support member and that can contact the valve seat; and a valve opening member that can vertically move together with the float and that opens at least one portion of the valve.

Owner:KYOSAN DENKI KABUSHIKI KAISHA

Screen door for preventing mosquitoes and flies from entering rooms

The invention discloses a screen door for preventing mosquitoes and flies from entering rooms, which belongs to household sanitation fittings. The screen door comprises a rectangle gauze and soft doors leafs which consist of edge sealing cloths packed into the periphery of the rectangle gauze; the bottom edge of each soft door leaf is provided with a balance; the screen door is characterized in that: the folding edge of each two adjacent soft door leafs is provided with a rigid plastic strip; and mutual attractive permanent magnet blocks are arranged on the rigid plastic strip at interval. The screen door has the advantages of simple structure, convenient use, excellent closing effect and low cost.

Owner:刘中富

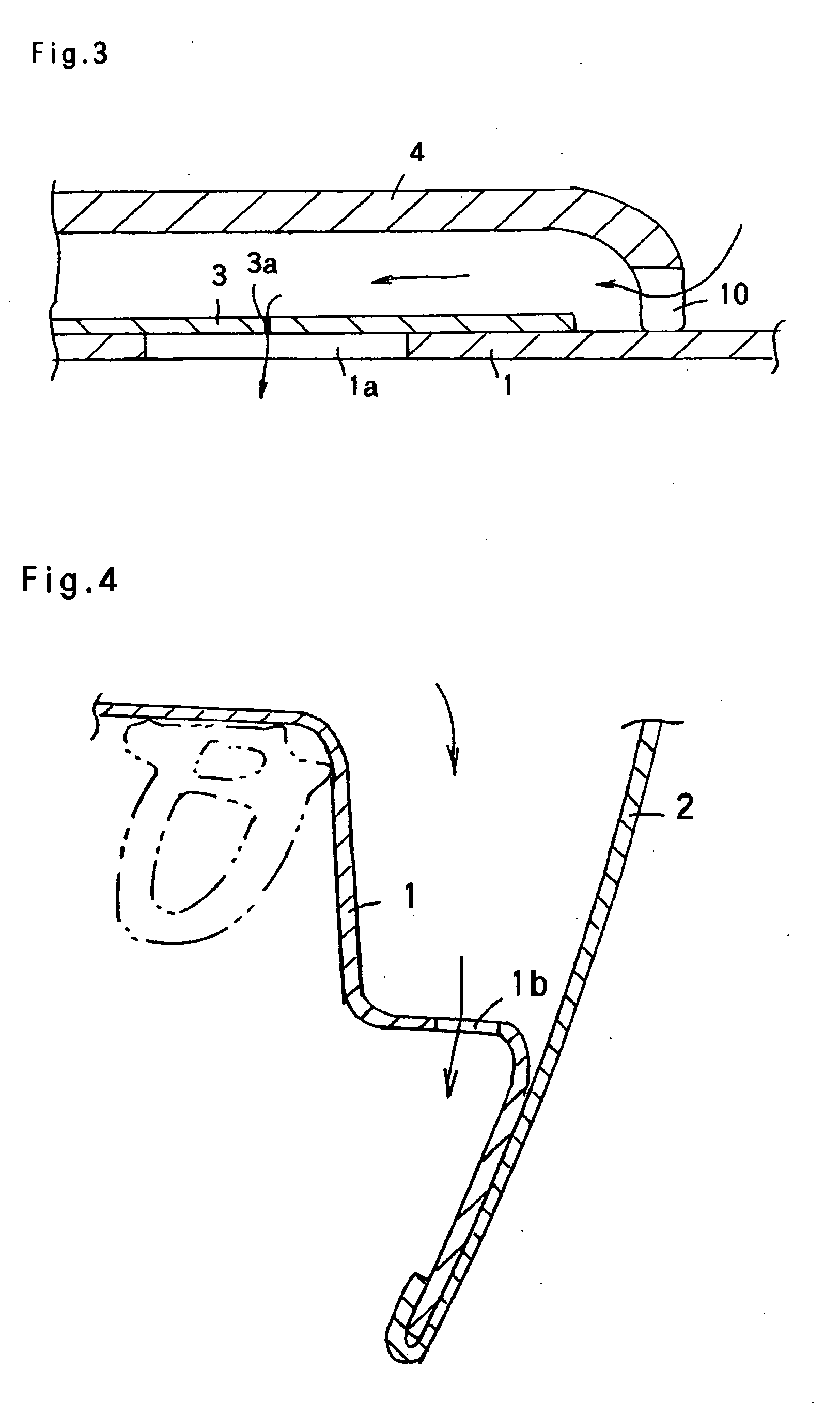

Ventilation structure of automobile door

InactiveUS20060012215A1Improve closing effectIncrease production capacityVehicle seatsWindowsEngineeringElectrical and Electronics engineering

Owner:NISHIKAWA RUBBER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com