Separator for non-aqueous batteries, non-aqueous battery using same, and production method for separator for non-aqueous batteries

一种电池、非水的技术,应用在非水电解质蓄电池、非水电解质、电池组零部件等方向,能够解决电解液起火性担忧、电池温度升高、设备热损坏等问题,达到操作性良好、初始电阻低、耐热性优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

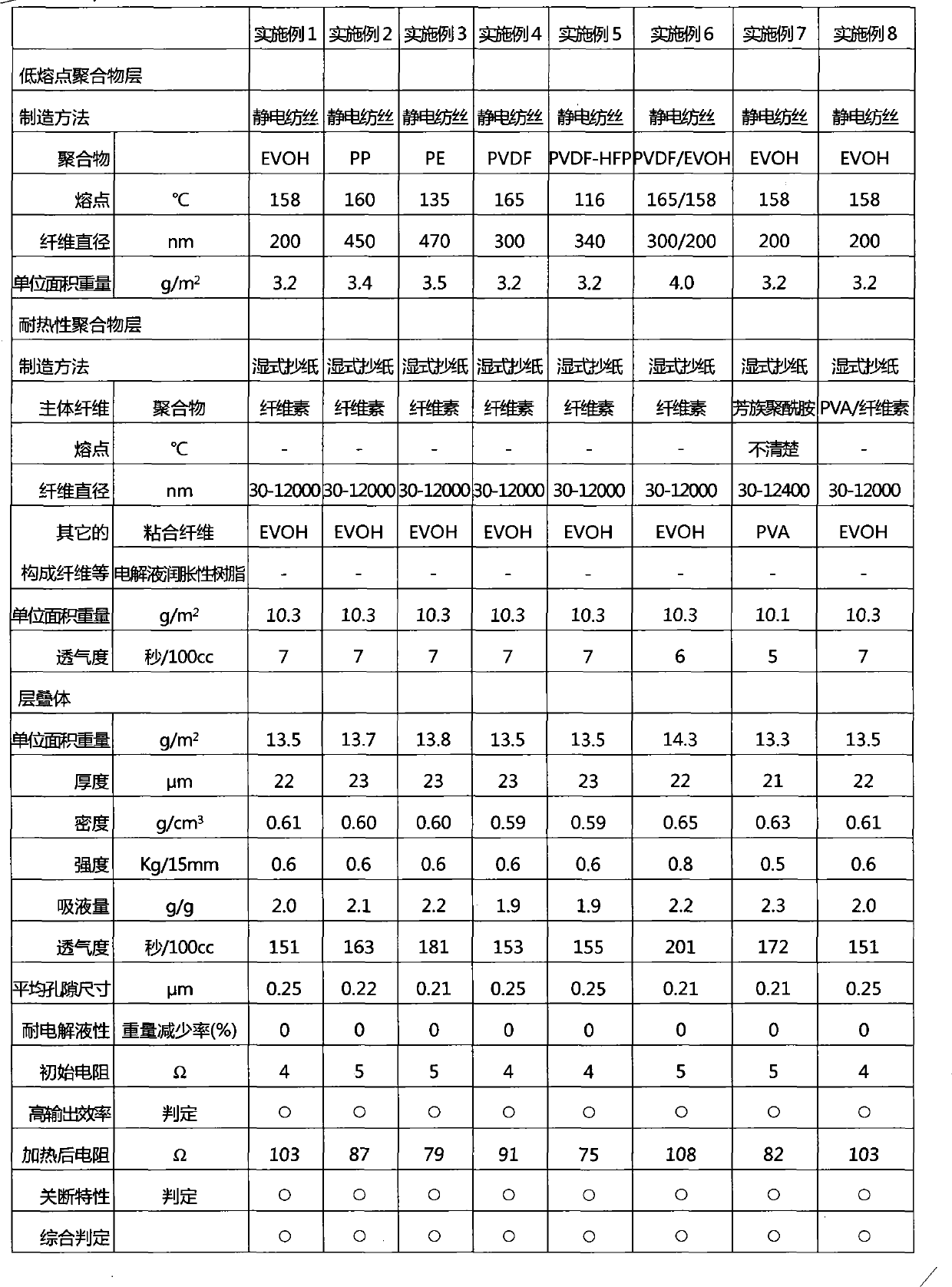

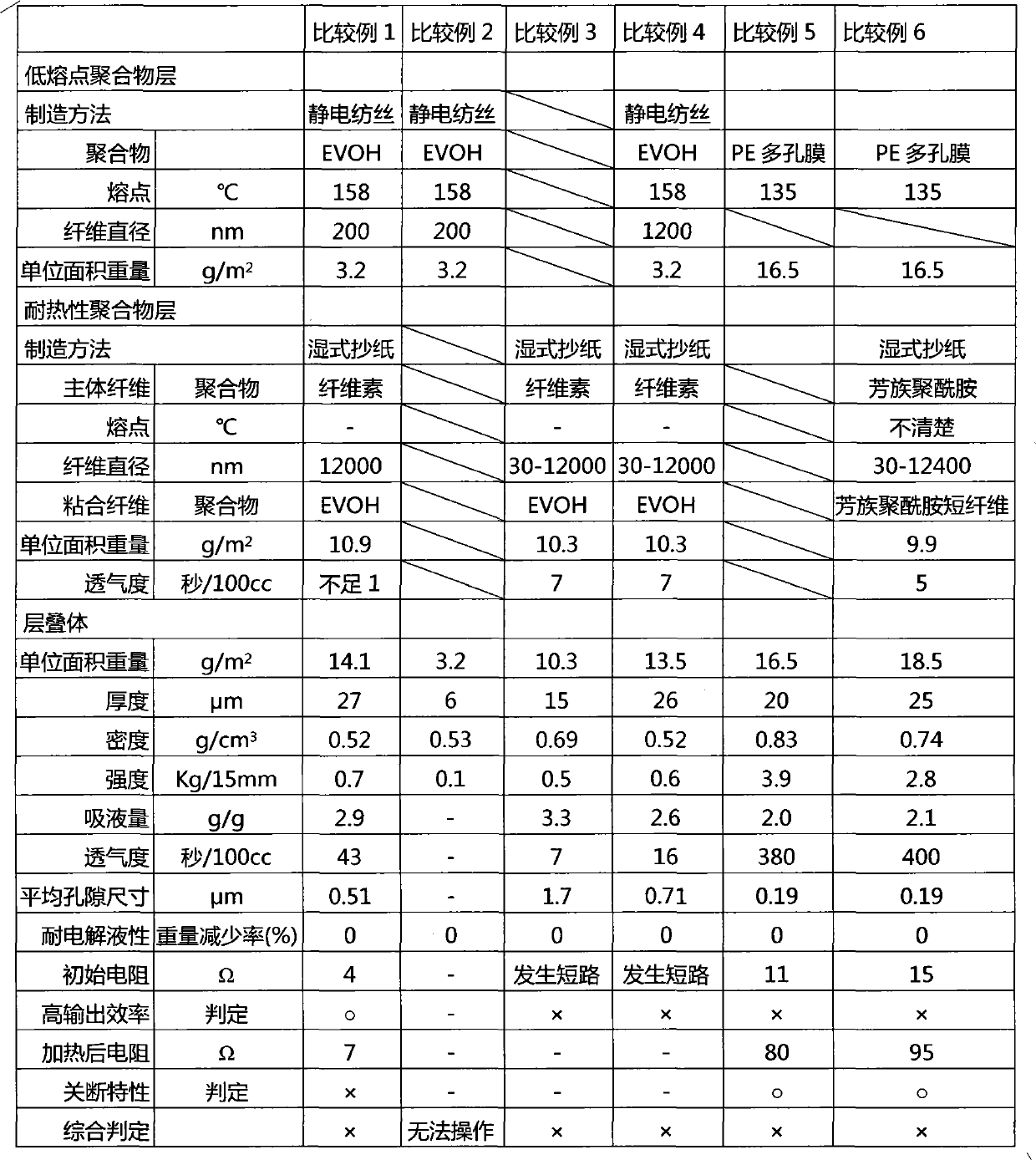

Embodiment 1

[0136] (1) Production of heat-resistant polymer fiber layer (B)

[0137] Solvent-spun cellulose fibers of 1.7 dtex and 3 mm in length (manufactured by Cotoluses, Tencel) were beaten by a fiberizer and a pulper to obtain a CSF0 ml fibrillated product. This fiber was used as the main fiber, and ethylene-vinyl alcohol fiber (manufactured by Kuraray Co., Ltd., "S030") was added as the binder fiber in such an amount that the mass ratio of main fiber: binder fiber was 80:20. the slurry.

[0138] Use a cylinder paper machine to make paper from this slurry, dry it at a dryer temperature of 130°C, and produce a weight per square meter of 10.9g / m 2 , A heat-resistant polymer fiber layer with a thickness of 15 μm.

[0139] (2) Formation of low melting point polymer fiber layer (A)

[0140] First, an ethylene-vinyl alcohol copolymer (EVOH: EVAL-G manufactured by Kuraray Co., Ltd.) was put into a DMSO solvent so as to be 14% by mass, and then left to dissolve at 25° C. to obtain a spinn...

Embodiment 2

[0144] It produced similarly to Example 1 except having used polypropylene instead of the ethylene-vinyl alcohol copolymer as the low-melting-point polymer which forms the low-melting-point polymer fiber layer of Example 1 mentioned above.

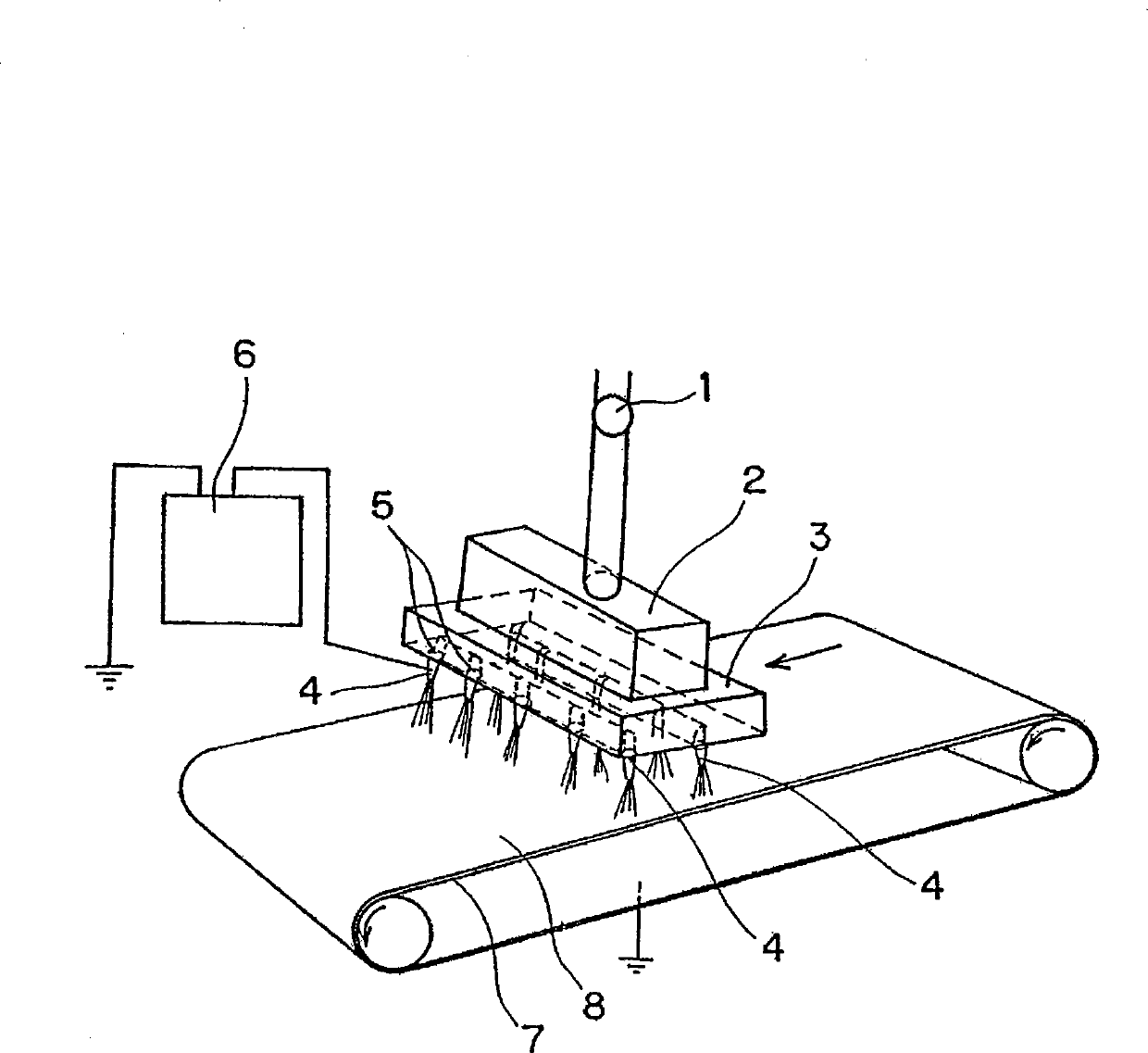

[0145] Specifically, when producing low-melting nanofibers, a polypropylene resin (manufactured by Grand Polymer Co., Ltd.: B101) was melt-kneaded at 300° C. using a twin-screw extruder to obtain a spinning stock solution. figure 1 The spinning device was used for electrospinning.

[0146] In the spinning device, a needle with an inner diameter of 0.3 mm was used as the metal mouth 4, and the distance between the metal mouth 4 and the forming sheet take-up device 7 was 6 cm. In addition, the heat-resistant polymer fiber layer obtained in (1) of Example 1 was wound up on the forming sheet take-up device 7 . Then, the stock solution is extruded from the metal port with a conveyor speed of 0.1m / min and a prescribed supply amount, and a 40kV ...

Embodiment 3

[0148] It produced similarly to Example 2 except having changed the low melting point polymer of the low melting point polymer fiber layer of Example 2 into polyethylene (Mitsui Chemicals: 5202B). Table 1 shows the performance of the obtained separator.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com