Cathode active material, method for preparing same, and lithium secondary battery comprising same

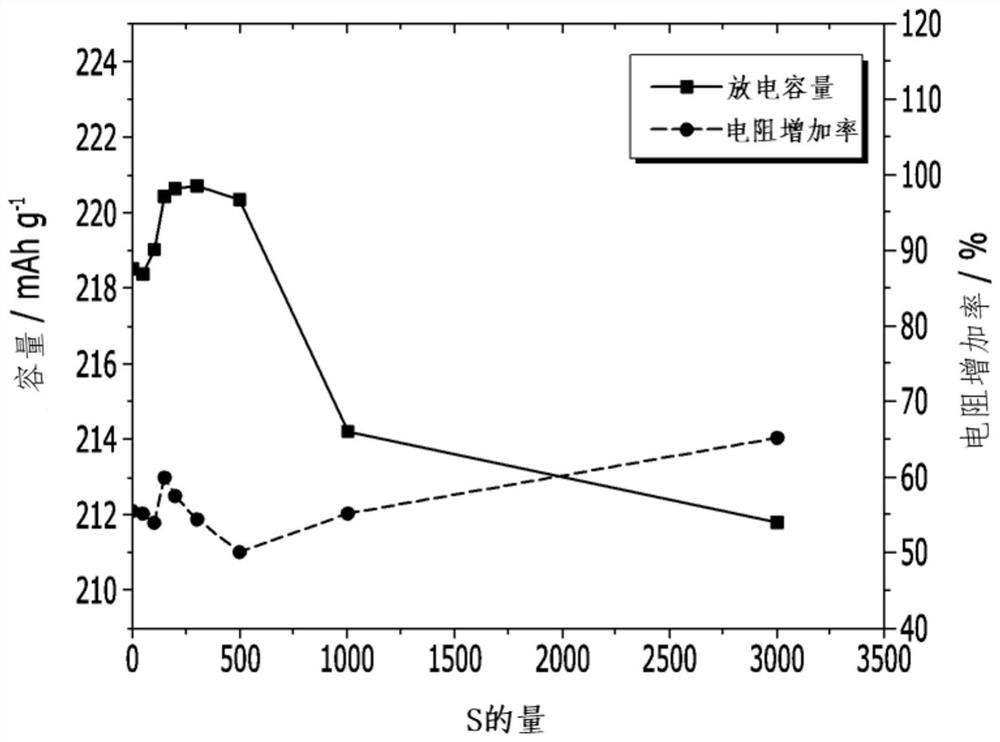

A cathode active material, lithium secondary battery technology, applied in secondary batteries, lithium storage batteries, active material electrodes, etc., can solve the problems of low thermal stability, difficult commercialization, structural collapse, etc., to reduce the initial resistance and Resistance increase rate, excellent high temperature life characteristics, high capacity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] According to another embodiment, a method for preparing a positive electrode active material includes: placing an aqueous metal salt solution into a co-precipitation reactor to obtain a metal precursor; mixing the metal precursor, a lithium raw material, and a doping raw material , to prepare a mixture; a step of cooling the mixture after a heat treatment; and washing and drying the product of the cooling step, mixing it with a coating-forming substance, and then performing a second heat treatment. The coating-forming substance may contain boron compounds, LiOH and Li 2 SO 4 .

[0050] First, the following steps are carried out: the aqueous metal salt solution is put into a coprecipitation reactor to obtain a metal precursor.

[0051] More specifically, the metal raw materials such as nickel raw materials, cobalt raw materials, manganese raw materials, etc. that form lithium metal oxides are mixed with distilled water to prepare a metal salt aqueous solution, and then...

preparation example 1

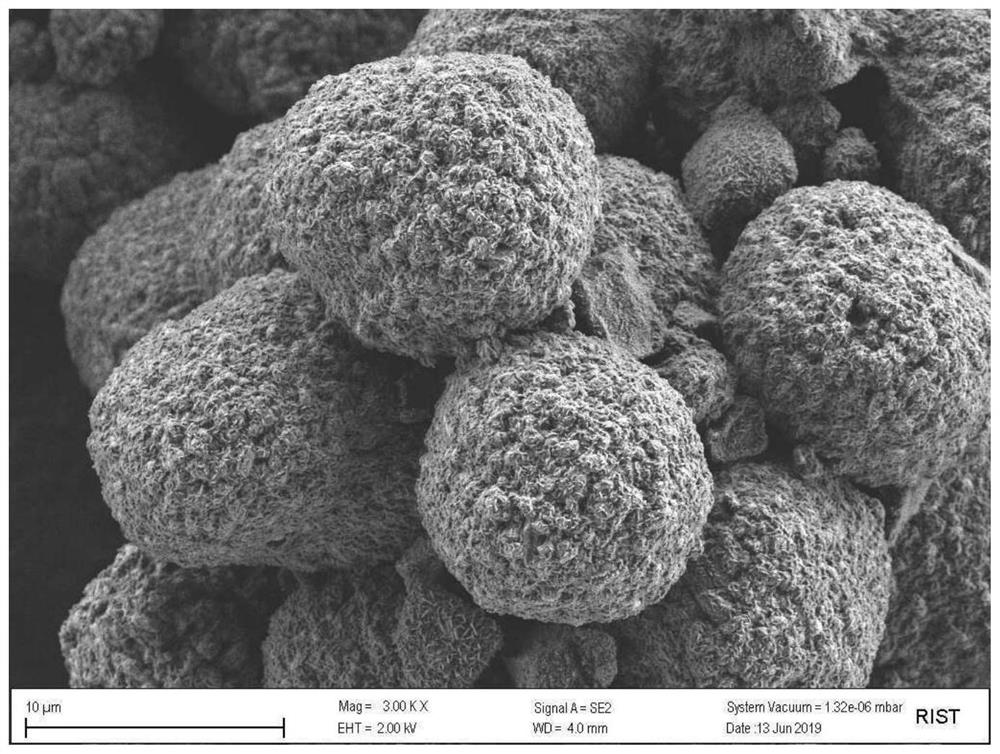

[0091] Preparation Example 1 - Preparation of Cathode Active Material Precursor

[0092] prepared by a general co-precipitation method with (Ni 0.92 Co 0.04 Mn 0.04 )(OH) 2 component precursors.

[0093] Specifically, NiSO was used as the nickel raw material 4 ·6H 2 O, CoSO was used as cobalt raw material 4 ·7H 2 O, MnSO was used as manganese raw material 4 ·H 2 O. These raw materials were dissolved in distilled water to prepare an aqueous metal salt solution.

[0094] Next, after preparing the coprecipitation reactor, in order to prevent the oxidation of metal ions during the coprecipitation reaction, N 2 Purging was carried out and the reactor temperature was maintained at 50°C.

[0095] NH is added to the co-precipitation reactor 4 (OH) was used as a chelating agent and NaOH was used to adjust the pH.

[0096] The precipitate obtained according to the co-precipitation process was filtered, washed with distilled water, and dried in an oven at 100° C. for 24 hou...

Embodiment 1

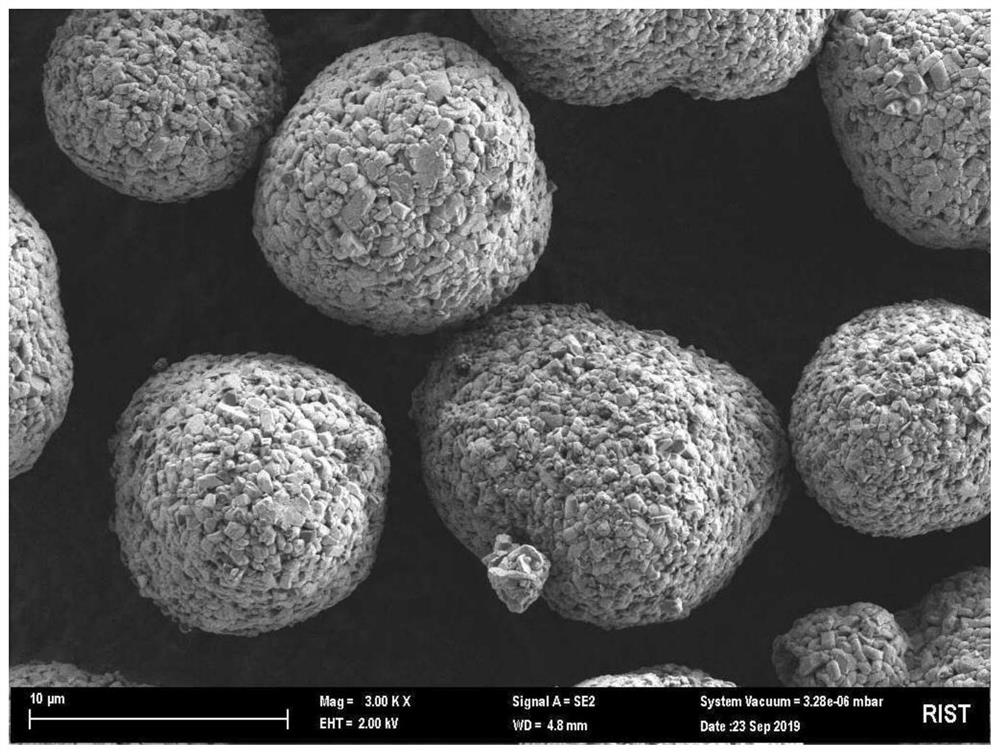

[0108] Example 1 - Preparation with 500 ppm B, 1700 ppm LiOH, 3000 ppm Li 2 CO 3 , 10ppm Li 2 SO 4 Ni is 90% cathode active material

[0109] The cooled product was washed with distilled water, filtered and dried, followed by dry mixing of 500 ppm of H 3 BO 3 , 250ppm LiOH and 10ppm Li 2 SO 4 After the second heat treatment was performed, the same method as in Comparative Example 2 was used to prepare a surface containing 500 ppm of B, 1700 ppm of LiOH, and 3000 ppm of Li formed on the surface. 2 CO 3 , 10ppm Li 2 SO 4 The coated cathode active material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain | aaaaa | aaaaa |

| Pressed density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com