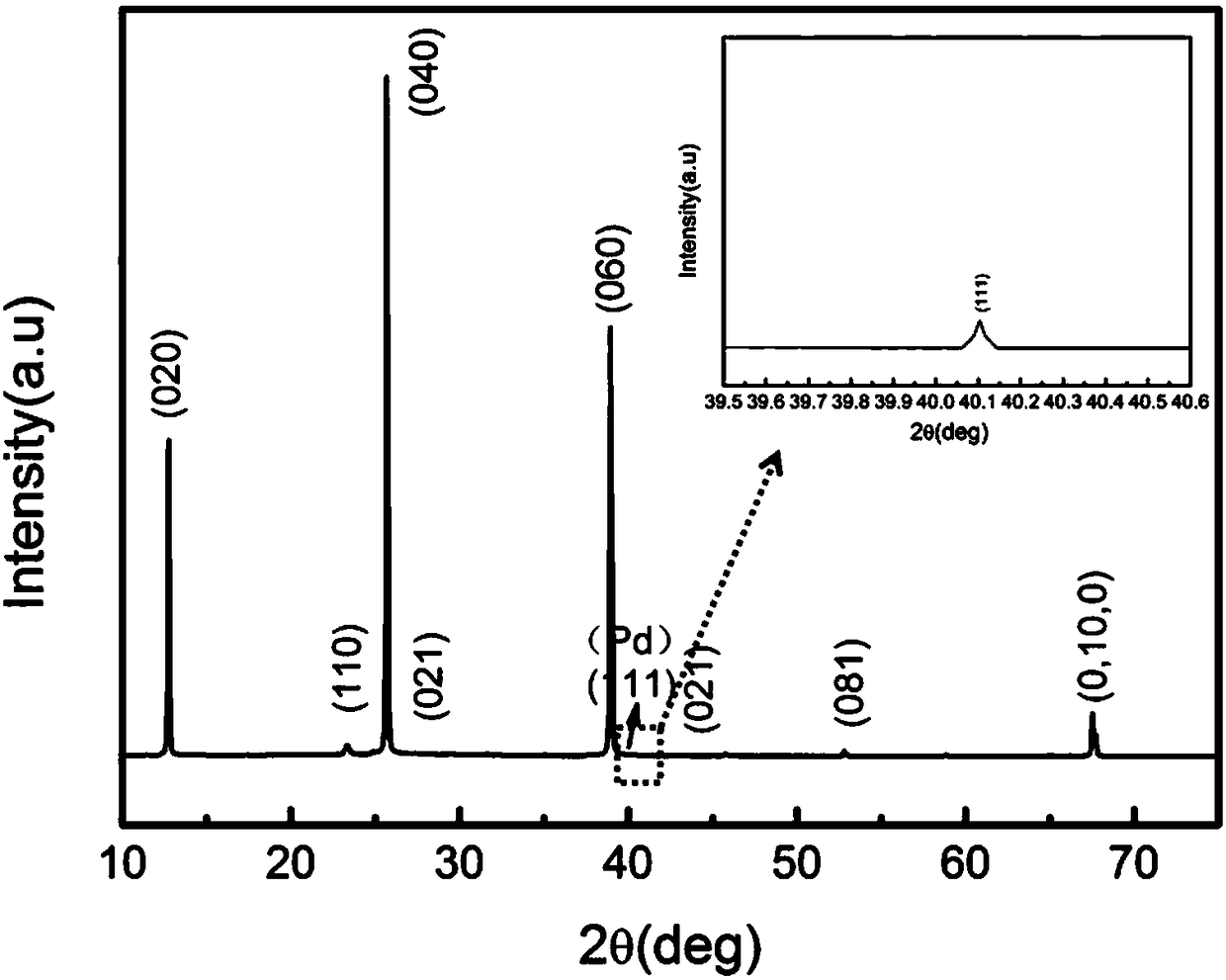

Preparation method of molybdenum oxide nanofiber paper containing pd quantum dot modification

A technology of nanofibers and quantum dots, which is applied in the field of molybdenum oxide nanofiber paper preparation, can solve problems such as the production method of molybdenum oxide nanofiber paper, and achieve the effects of short response time, small initial resistance, and improved sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method for preparing molybdenum oxide nanofiber paper modified with Pd quantum dots, said method comprising the steps of:

[0039] (1) Dissolve 2.42g of sodium molybdate dihydrate in 30.0ml of deionized water to obtain a sodium molybdate solution, and then add dropwise 6.25ml of a concentrated solution with a concentration of 70% and a purity greater than 99% to the sodium molybdate solution. Nitric acid, magnetically stirred for 30 minutes under sealed conditions, and obtained solution A after stirring evenly;

[0040] (2) Under normal temperature and pressure conditions, dissolve 150.0ml of absolute ethanol in 1350.0ml of deionized water, and stir magnetically for 15 minutes under sealed conditions. After stirring evenly, a mixed solution B of alcohol and deionized water is obtained;

[0041] (3) Under normal temperature and pressure conditions, transfer the solution A obtained in step (1) to a clean polytetrafluoroethylene reactor, then place the reactor in an electr...

Embodiment 2

[0047] The difference between the preparation method of molybdenum oxide nanofiber paper modified with Pd quantum dots in this example and Example 1 is that the temperature in the drying oven in step (3) of this example is 260 ° C, and the molybdenum oxide nanofiber paper in step (6) The drying temperature of the fiber paper was 80° C., and the other conditions were the same as in Example 1 to prepare the molybdenum oxide nanofiber paper modified with Pd quantum dots.

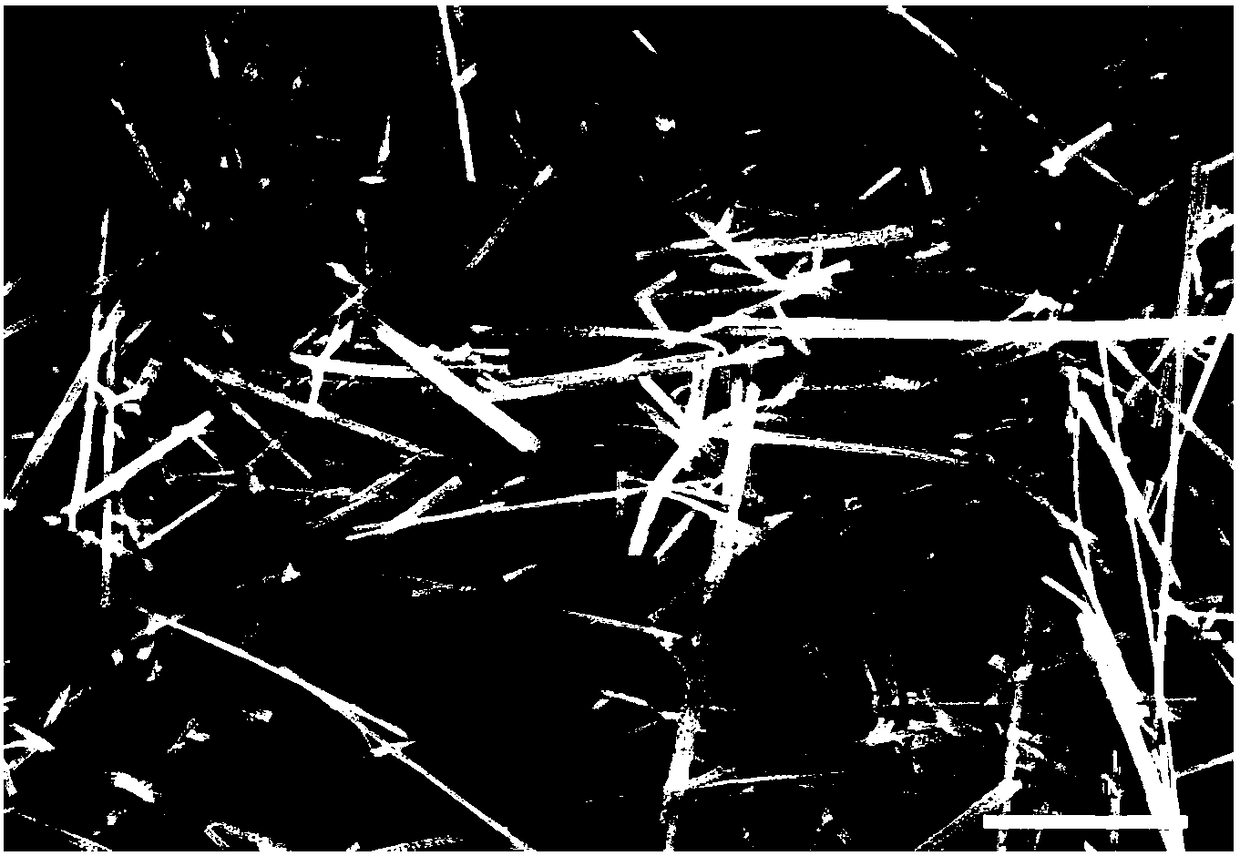

[0048] The SEM image of the molybdenum oxide nanofiber paper modified with Pd quantum dots prepared in this example image 3 As shown, the actual picture is as figure 2 shown.

Embodiment 3

[0050] A method for preparing molybdenum oxide nanofiber paper modified with Pd quantum dots, said method comprising the steps of:

[0051] (1) Dissolve 2.42g of sodium molybdate dihydrate in 30.0ml of deionized water to obtain a sodium molybdate solution, and then add dropwise 15.0ml of sodium molybdate solution with a concentration of 70% and a purity greater than 99%. Concentrated nitric acid, stirred magnetically for 30 minutes under sealed conditions, and obtained solution A after stirring evenly;

[0052] (2) Under normal temperature and pressure conditions, dissolve 150.0ml of absolute ethanol in 1350.0ml of deionized water, and stir magnetically for 15 minutes under sealed conditions. After stirring evenly, a mixed solution B of alcohol and deionized water is obtained;

[0053] (3) Under normal temperature and pressure conditions, transfer the solution A obtained in step (1) to a clean polytetrafluoroethylene reactor, then place the reactor in an electric blast drying ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quantum dot | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com