A Pull Sensitive Sensor with Positive Resistance Effect

A sensor and pull-sensing technology, applied in the field of pull-sensing sensors, can solve the problems that cannot be used in fields with large deformation variables, complex structures, and high manufacturing costs, and achieve excellent resistance recovery performance, broad application prospects, and low manufacturing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

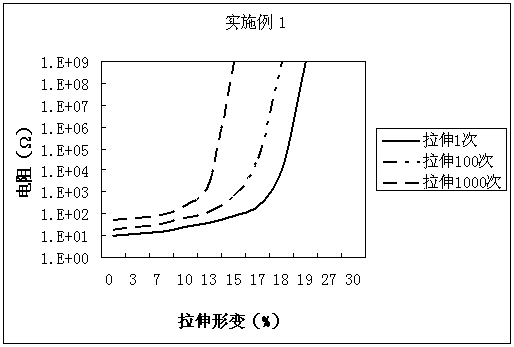

Embodiment 1

[0026] The pull-sensitivity sensor with positive resistance effect of this embodiment uses conductive rubber as the pull-sensitivity material, and the manufacturing method is as follows:

[0027] The composition ratio and production method of conductive rubber are as follows:

[0028] In the following order, 100 parts by mass of methyl vinyl silicone rubber (brand 110-1, molecular weight 450,000-700,000, vinyl content 0.13-0.22%, Nanjing Dongjue Silicone Co., Ltd.), 2 parts by mass of diphenyl Silicon glycol, 180 parts by mass of silver-plated aluminum powder (particle size 10-20 μm), 15 parts by mass of fumed silica (AEROSIL 150, Evonik Degussa), 2 parts by mass of double 25 vulcanizing agent (2, 5-Dimethyl-2,5-bis(tert-butyl peroxide)hexane), added to the double-roll mill for mixing, the temperature of the mill was set at 45°C, and after the components were mixed evenly, Thin slices.

[0029] Put the well-mixed silicone rubber into a mold with a cavity size of 112mm×200mm×...

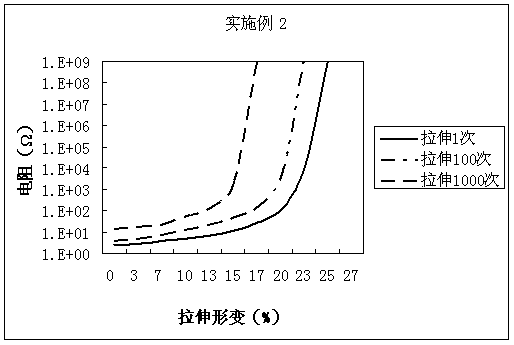

Embodiment 2

[0056] According to the pull-sensitivity sensor of making positive resistance effect according to the same method as embodiment 1, but replace the silver-coated aluminum powder (particle diameter 10 μm) of 180 mass parts in embodiment 1 with the silver-coated aluminum powder (particle diameter 10 μ m) of 210 mass parts -20μm). Test the law and repeatability of the resistance of the pull-sensing sensor of the positive resistance effect with the stretching deformation in the same manner as described in Example 1, the results are as follows figure 2 shown. The composition of the conductive rubber formulation of this embodiment and the test data of the pull-sensitive sensor are listed in Table 1.

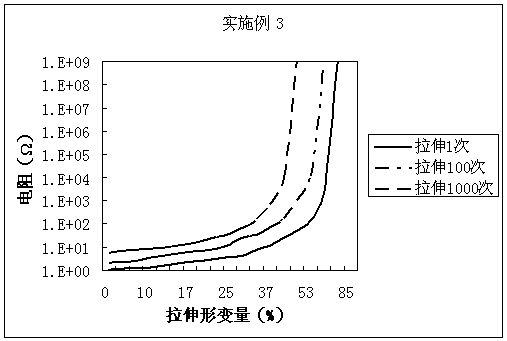

Embodiment 3

[0058] According to the same method as embodiment 1, the pull-sensitivity sensor of positive resistance effect is manufactured, but the silver-coated aluminum powder (particle diameter 10-20 μ m) of 240 mass parts replaces the silver-coated aluminum powder (particle diameter 10 μm) of 180 mass parts in embodiment 1 -20μm). Test the law and repeatability of the resistance of the pull-sensing sensor of the positive resistance effect with the stretching deformation in the same manner as described in Example 1, the results are as follows image 3 shown. The composition of the conductive rubber formulation of this embodiment and the test data of the pull-sensitive sensor are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com