A kind of in-tube growth doped state or filled mesoporous polyaniline gas sensor and its preparation method

A gas sensor, polyaniline technology, used in instruments, scientific instruments, measuring devices, etc., can solve the problems of slow generation rate, small specific surface contact area, recovery time, stability gap, etc., and achieve proton mobility and oxidation degree. The effect of improving, large contact specific surface area, and reducing initial resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

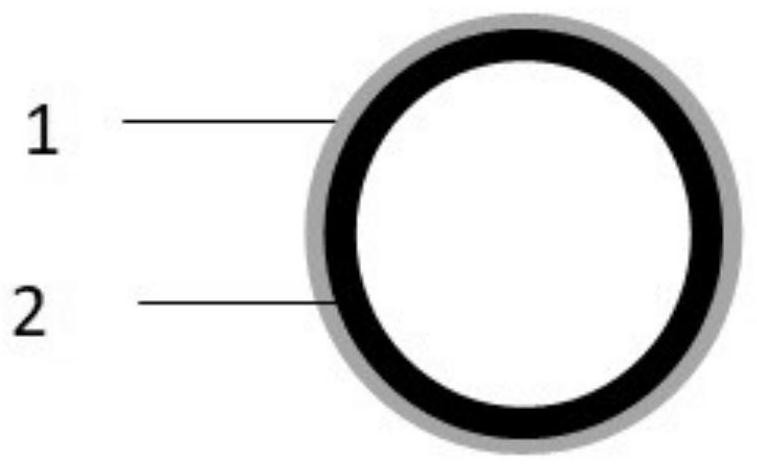

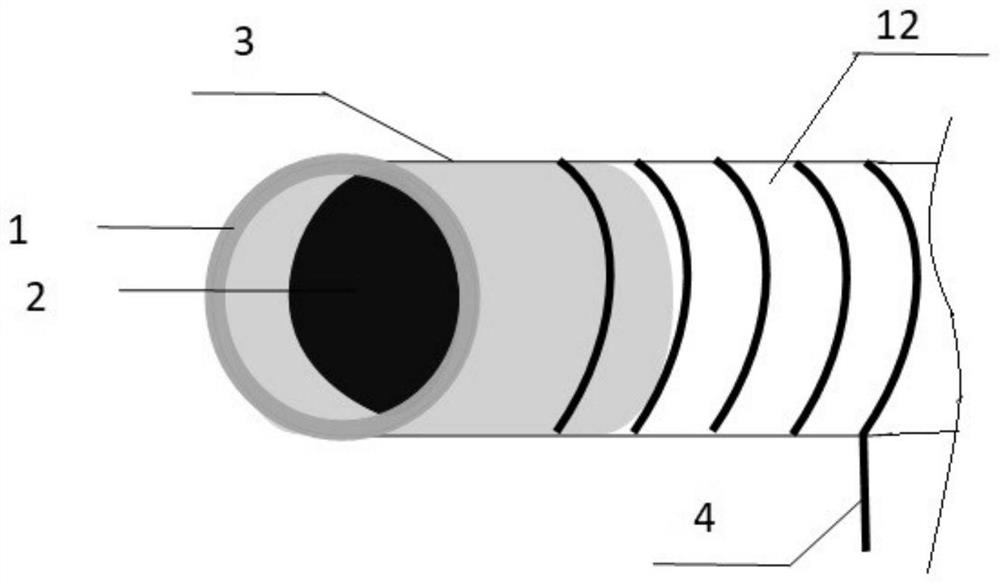

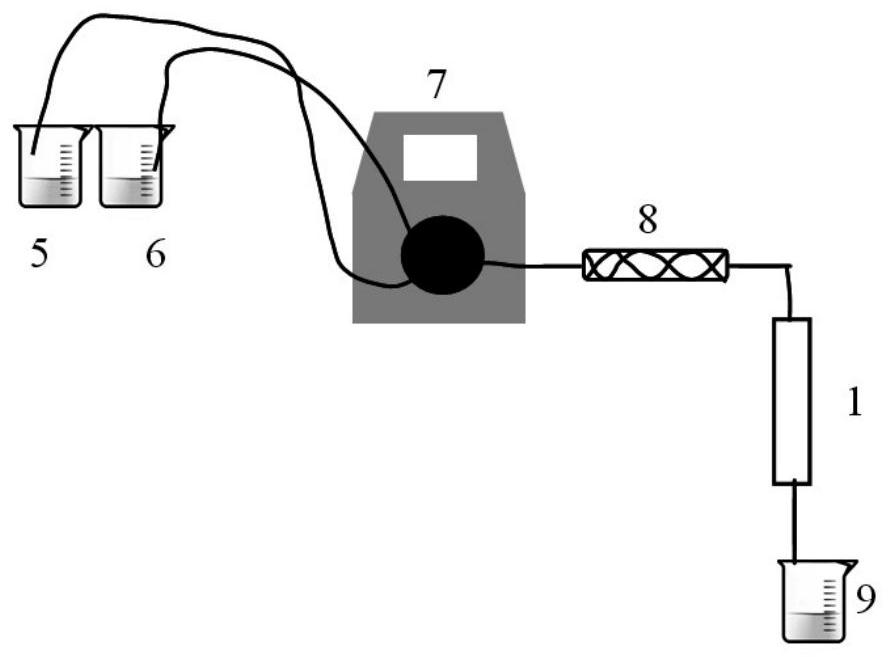

[0047] Prepare a sulfosalicylic acid / hydrochloric acid doped polyaniline gas sensor based on a glass capillary with a diameter of 1 mm and a length of 7.5 cm, including:

[0048] 1) Cleaning and pretreatment of 1mm glass capillary

[0049] A1: Purchase a glass capillary with an inner diameter of 1mm and a wall thickness of 0.6mm, and clean the inner wall surface with deionized water at a flow rate of 10 / min for 3 minutes;

[0050] A2: Amination treatment, continuously pass through 5wt% sodium ethoxide solution at a flow rate of 0.02ml / min for 20 minutes, then pass through 0.3wt% ammonium persulfate (APS) acetone solution for 1min, then pass through acetone for 1min, at 20ml / min Ventilate and dry;

[0051] A3: Carboxylation treatment, cleaning the inner wall of the base tube after amination with absolute ethanol, passing through a saturated solution of succinic anhydride in absolute ethanol at 0.02ml / min for 4 hours, finally cleaning with absolute ethanol, and connecting to an...

Embodiment 2

[0060] Fabrication of a filled mesoporous polyaniline gas sensor based on a glass capillary with a diameter of 1.5 mm and a length of 5 cm

[0061] Step 1: Dispersion of Mesoporous Polyaniline

[0062] A1: Take 400mg of mesoporous polyaniline, put it in 2ml of absolute ethanol, and ultrasonicate for 2 hours after sealing, among which, the pore diameter of mesoporous polyaniline is 14nm;

[0063] A2: Stand and cool to room temperature 25°C;

[0064] A3: Ethanol was volatilized at room temperature for 5 minutes to prepare a 90wt% mesoporous polyaniline dope;

[0065] Step 2: Cleaning of the glass capillary

[0066] B1: With a 1.5mm diameter glass capillary as the substrate, clean the inner wall surface with deionized water at a flow rate of 15ml / min for 1min;

[0067] Step 3: Filling the glass capillary with mesoporous polyaniline

[0068] C1: Pump the mesoporous polyaniline concentrate into the tube at a flow rate of 1ml / min, and fill it up to prepare a packed column;

[0...

Embodiment 3

[0074] Preparation of camphorsulfonic acid (CSA) / titanium dioxide (TiO2) doped cluster polyaniline gas sensor based on glass capillary with 530um diameter and 12cm length

[0075] Step 1: Cleaning and pretreatment of the substrate

[0076] A1: Use a glass capillary tube with a diameter of 530um and a length of 12cm as the base, and clean the surface of the inner wall with deionized water at a flow rate of 10ml / min for 1min;

[0077] A2: Amination treatment, continuously pass through 10wt% sodium ethoxide solution at a flow rate of 0.02ml / min for 10 minutes, then pass through 0.3wt% ammonium persulfate (APS) acetone solution for 1min, then pass through acetone for 1min, at 10ml / min Ventilate and dry;

[0078] A3: Carboxylation treatment, clean the inner wall of the aminated glass capillary tube with absolute ethanol, pass through a saturated solution of succinic anhydride in absolute ethanol at 0.01-ml / min for 2 hours, finally wash with absolute ethanol, and connect to air fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com