Patents

Literature

111results about How to "Increase the specific surface area of contact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

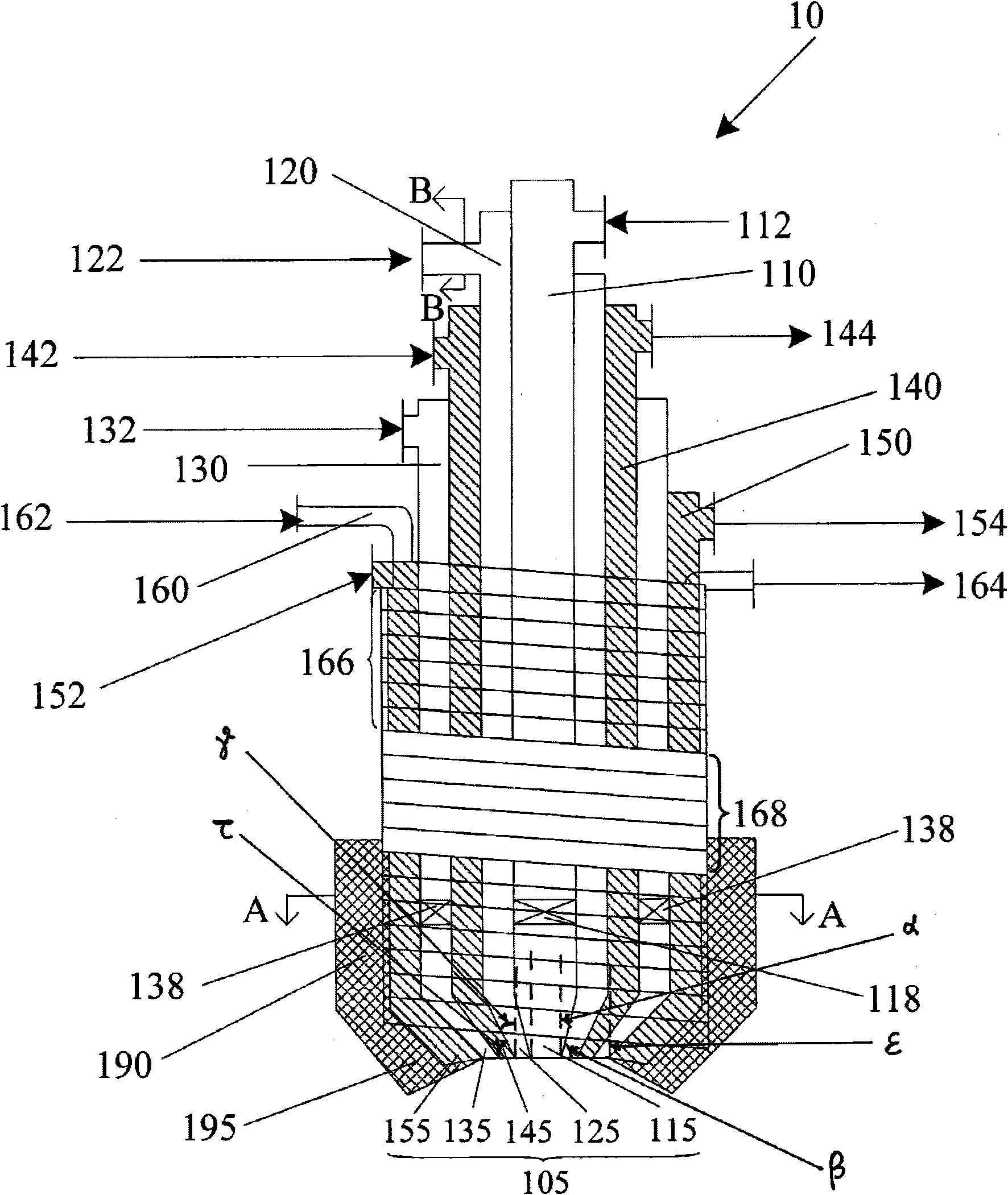

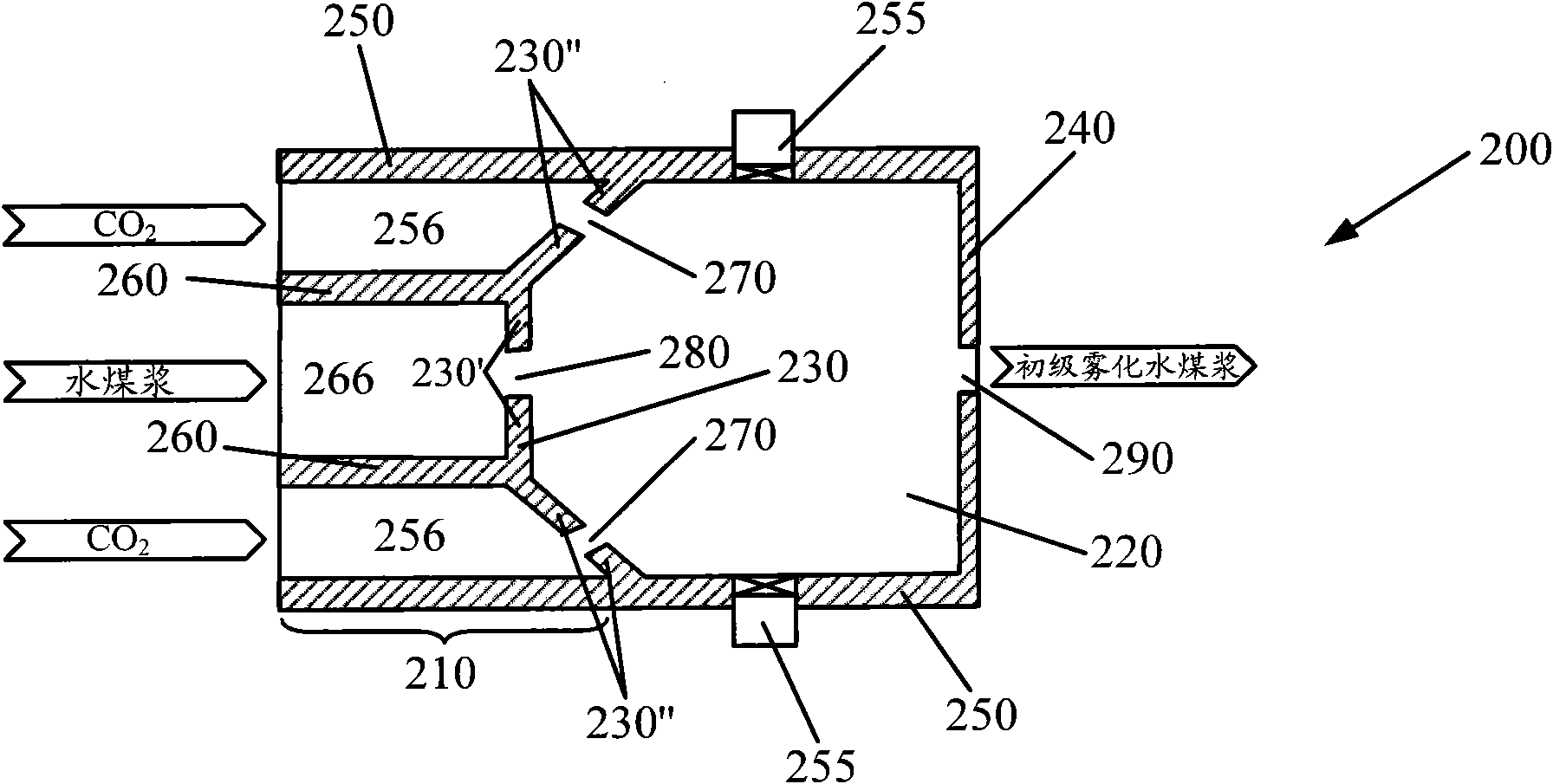

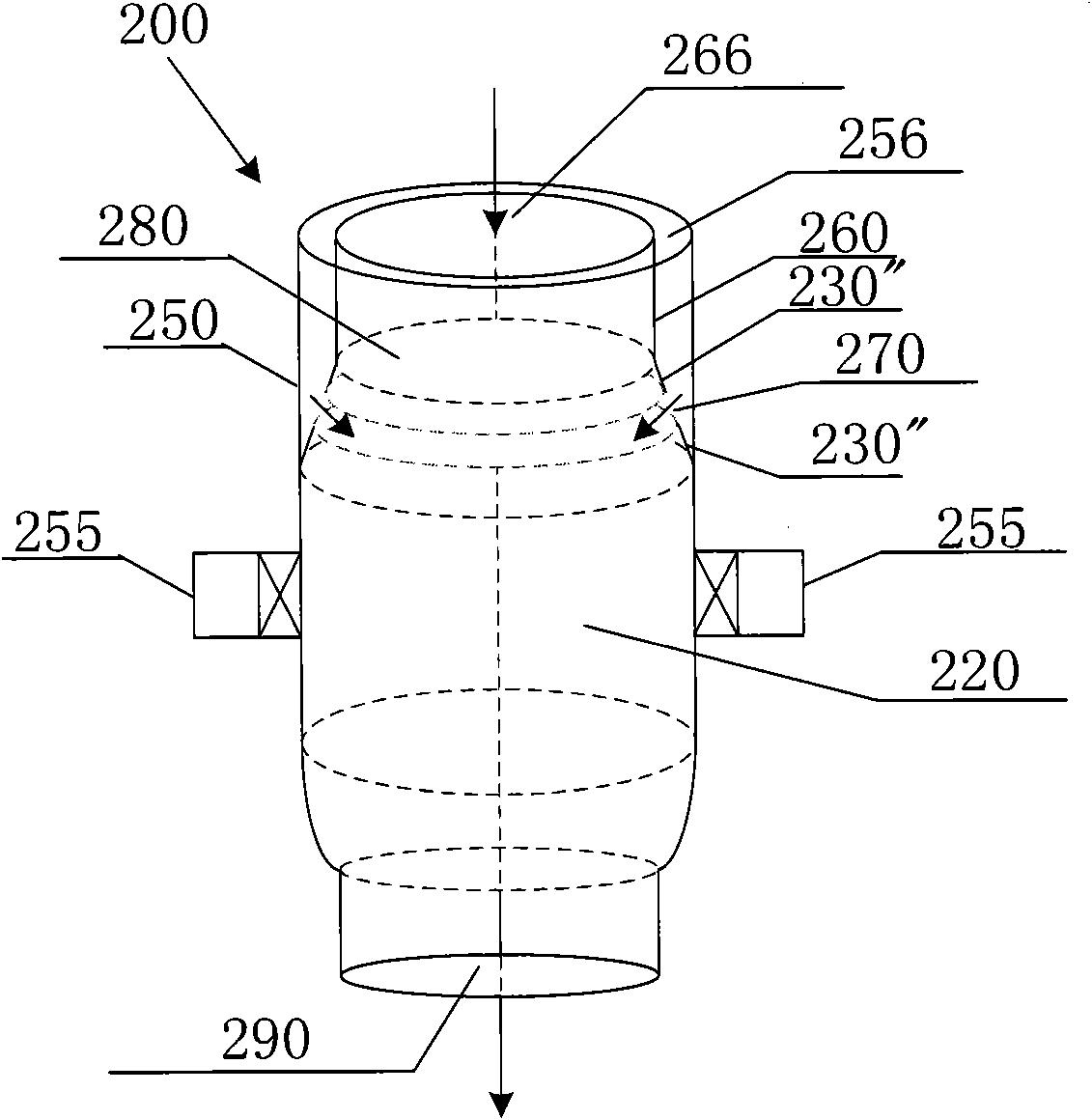

Process nozzle and system for gasifying water coal slurry and application thereof

ActiveCN102031152AEffective protectionImprove cooling effectLiquid spraying apparatusGranular/pulverulent flues gasificationCoal slurryWater jacket

The invention provides a process nozzle and a system for gasifying water coal slurry. The process nozzle comprises a first oxygen channel, a water coal slurry channel, a second oxygen channel, a first cooling water jacket and a cooling water coil, wherein the first oxygen channel comprises a first oxygen channel inlet and a first oxygen channel outlet; the water coal slurry channel comprises at least one water coal slurry channel inlet and a water coal slurry channel outlet; the second oxygen channel comprises a second oxygen channel inlet and a second oxygen channel outlet; the first cooling water jacket comprises a first cooling water jacket inlet and a first cooling water jacket outlet; and the cooling water coil comprises a cooling water coil inlet and a cooling water coil outlet. The process nozzle is characterized in that: the first oxygen channel is positioned at the central position of the process nozzle; the water coal slurry channel is positioned between the first oxygen channel and the second oxygen channel and surrounds the periphery of the first oxygen channel; and the second oxygen channel surrounds the periphery of the water coal slurry channel. The process nozzle reduces the length of combustion flame more effectively, reduces the ablation of flame on a refractory brick, promotes the mixing and atomization of water coal slurry and oxygen and improves gasification efficiency.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

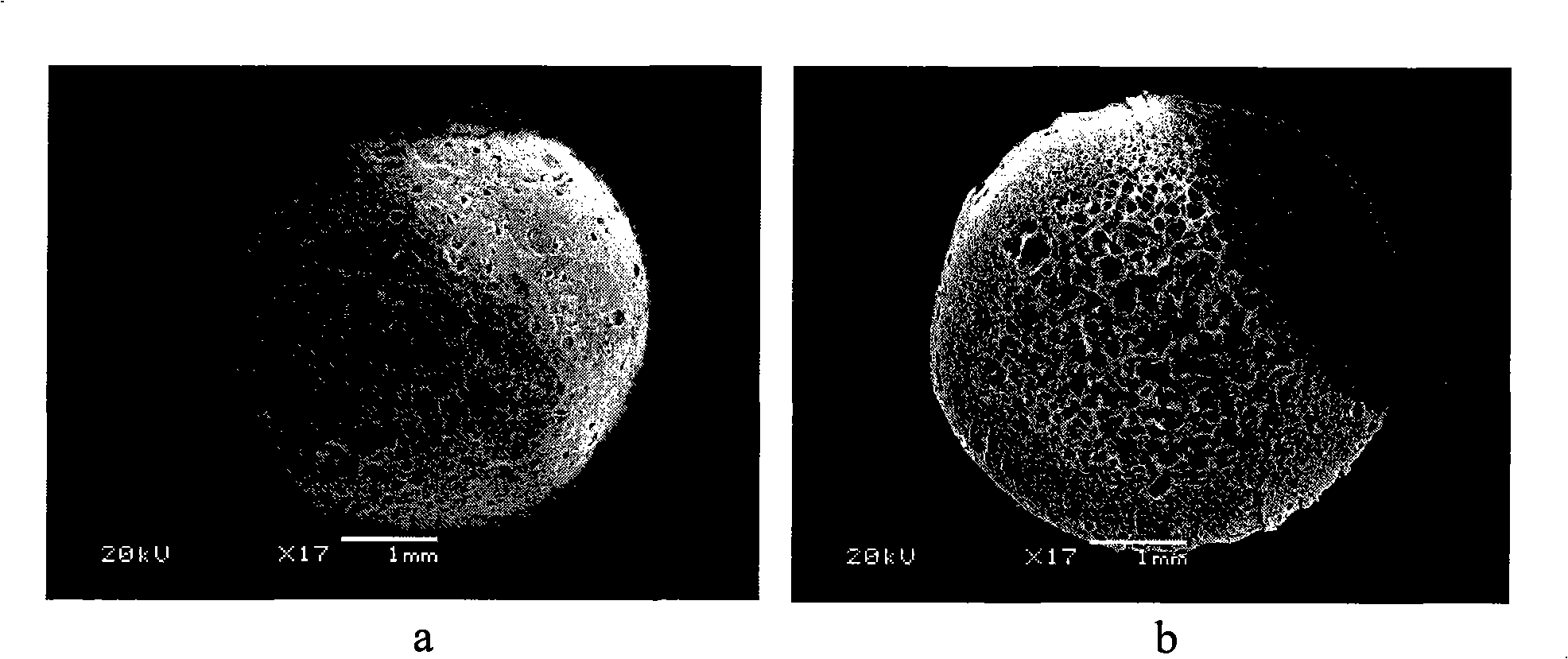

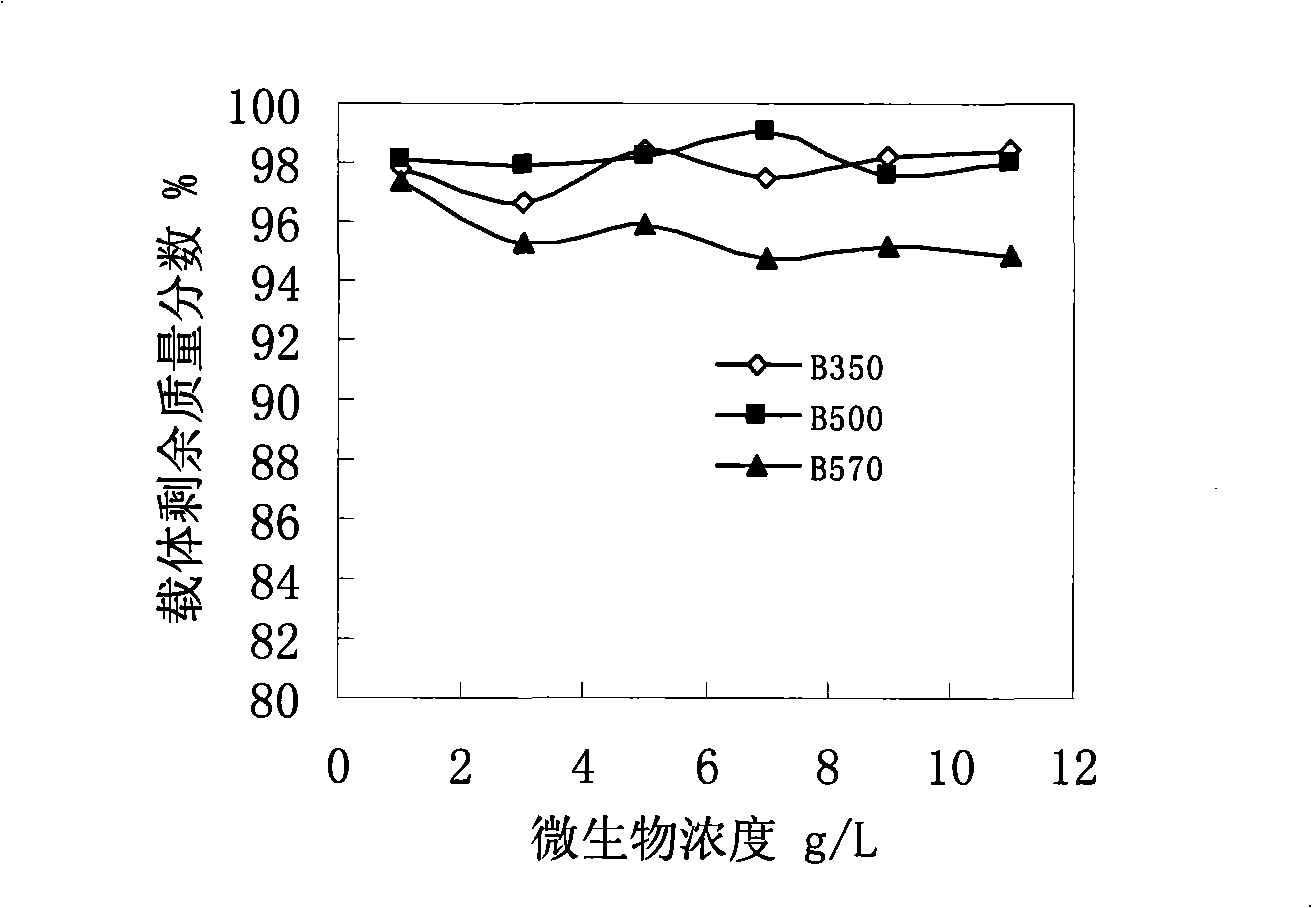

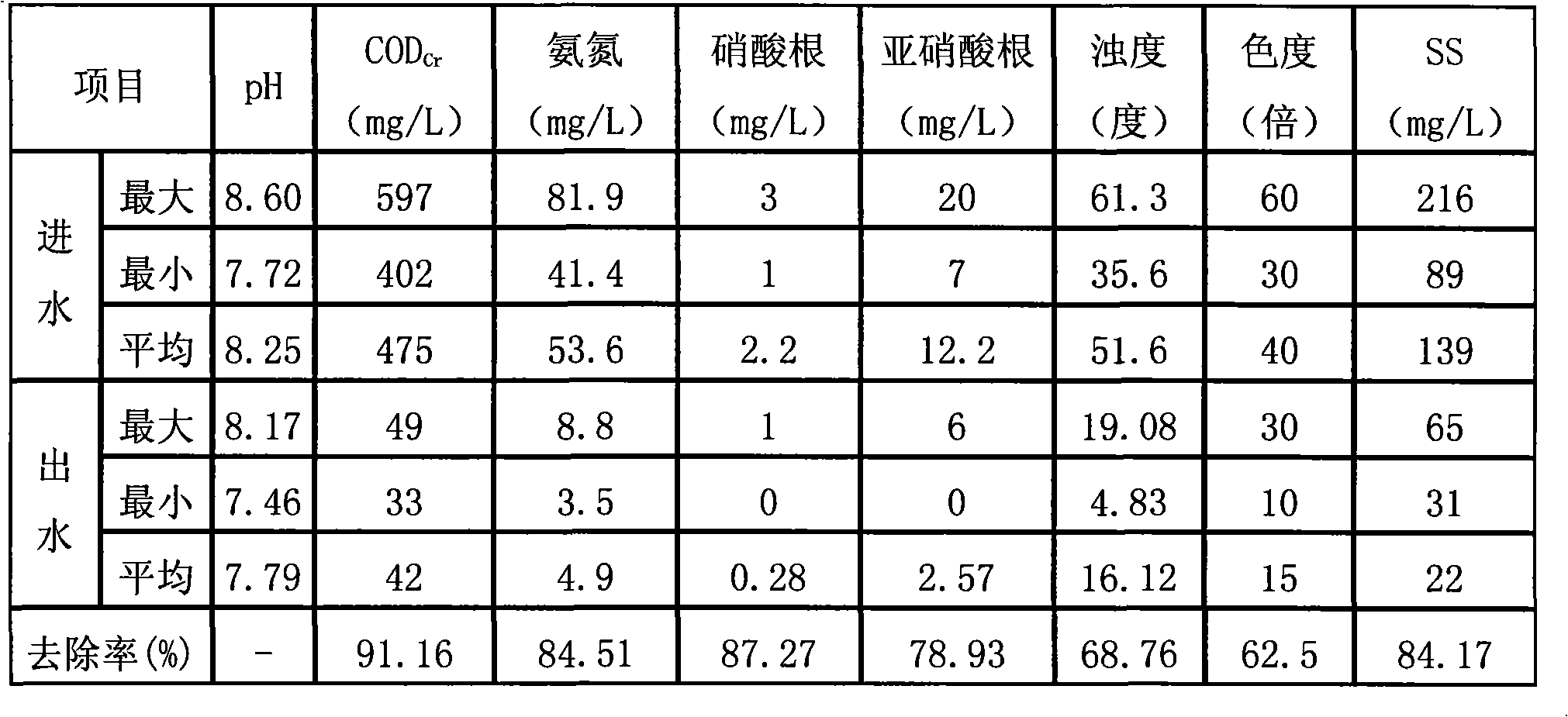

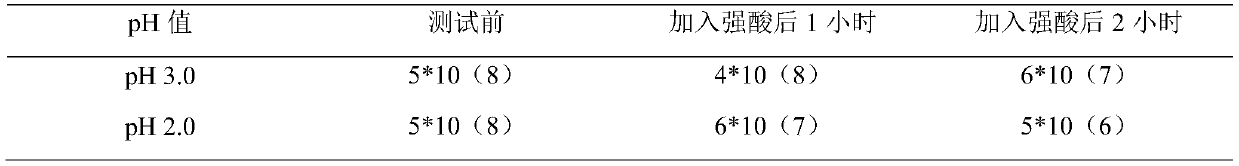

Macroreticular polyvinyl alcohol bead carrier and preparation thereof

InactiveCN101348782AIncrease the specific surface area of contactIncrease chance of contactOn/in organic carrierPeristaltic pumpDissolution

The invention provides a method for preparing a macroporous reticulated polyvinyl alcohol spherical vector. The method comprises the following steps: firstly, polyvinyl alcohol, calcium carbonate, sodium alginate and water are mixed in a certain mass proportion, and stirring is performed for full dissolution of the polyvinyl alcohol and uniform mixture, and then white PVA sol is obtained; secondly, the sol obtained is added into saturated boric acid solution containing 3 percent of calcium chloride by a peristaltic pump, and PVA gel beads are formed, cleaned by water and then placed into diluted hydrochloric acid solution for dipping until no air bubble is generated; thirdly, a spherical vector is thrown into glutaral pentanedial water solution and adjusted into acidity so as to generate crosslinking reaction to form a more stable crosslinking structure; and fourthly, the spherical vector is dipped into water and cleaned into neutrality, and then the white macroporous reticulated PVA spherical vector with elasticity is obtained. The macroporous reticulated polyvinyl alcohol vector prepared by the method has stable macroporous reticulated structure and good hydrophilicity, physical and chemical stability and anti-biological degradability, is suitable for immobilized enzymes and microorganisms so as to form a plurality of bed-shaped bioreactors, and is used in the modern bioengineering field such as sewage treatment and so on.

Owner:LANZHOU UNIVERSITY

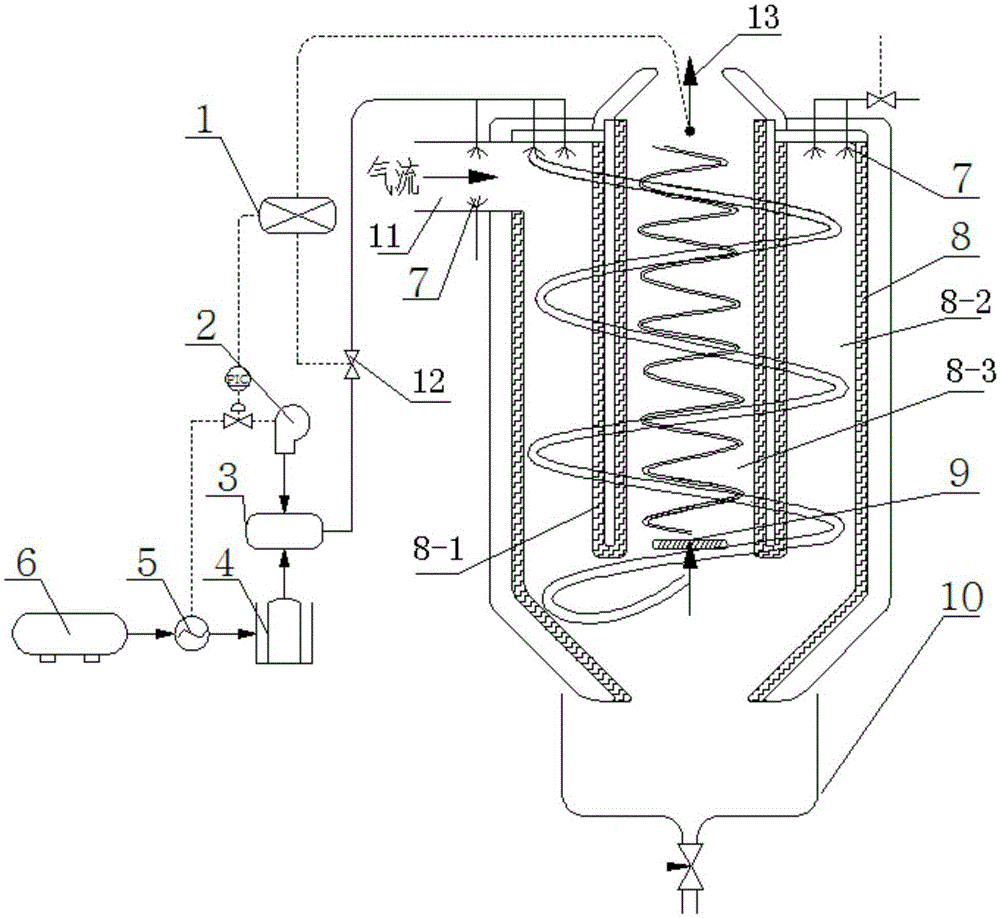

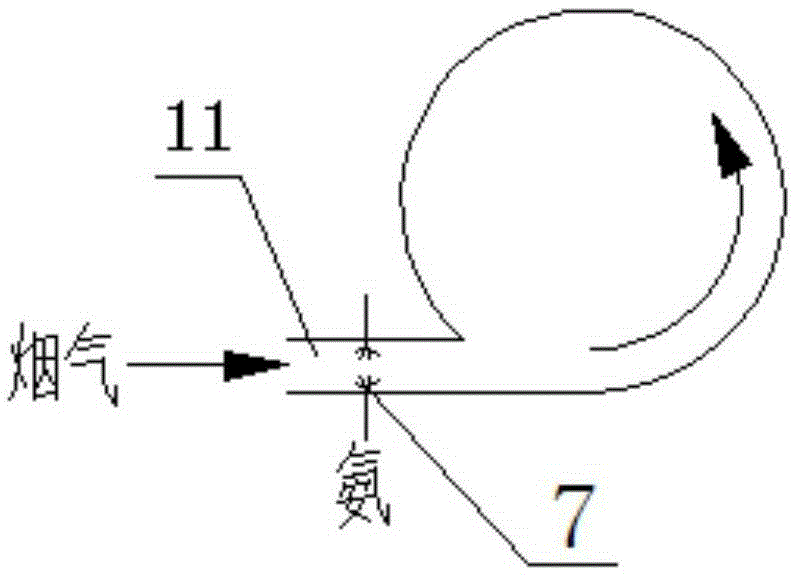

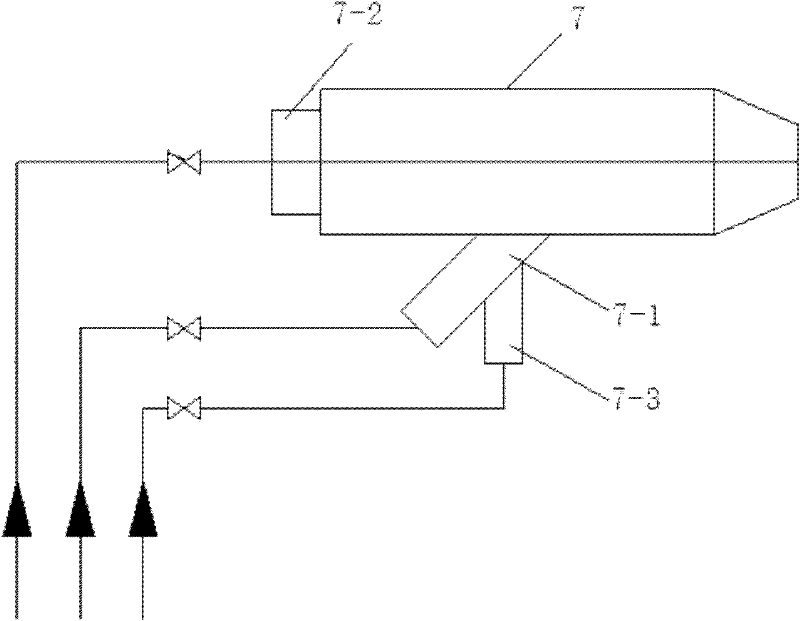

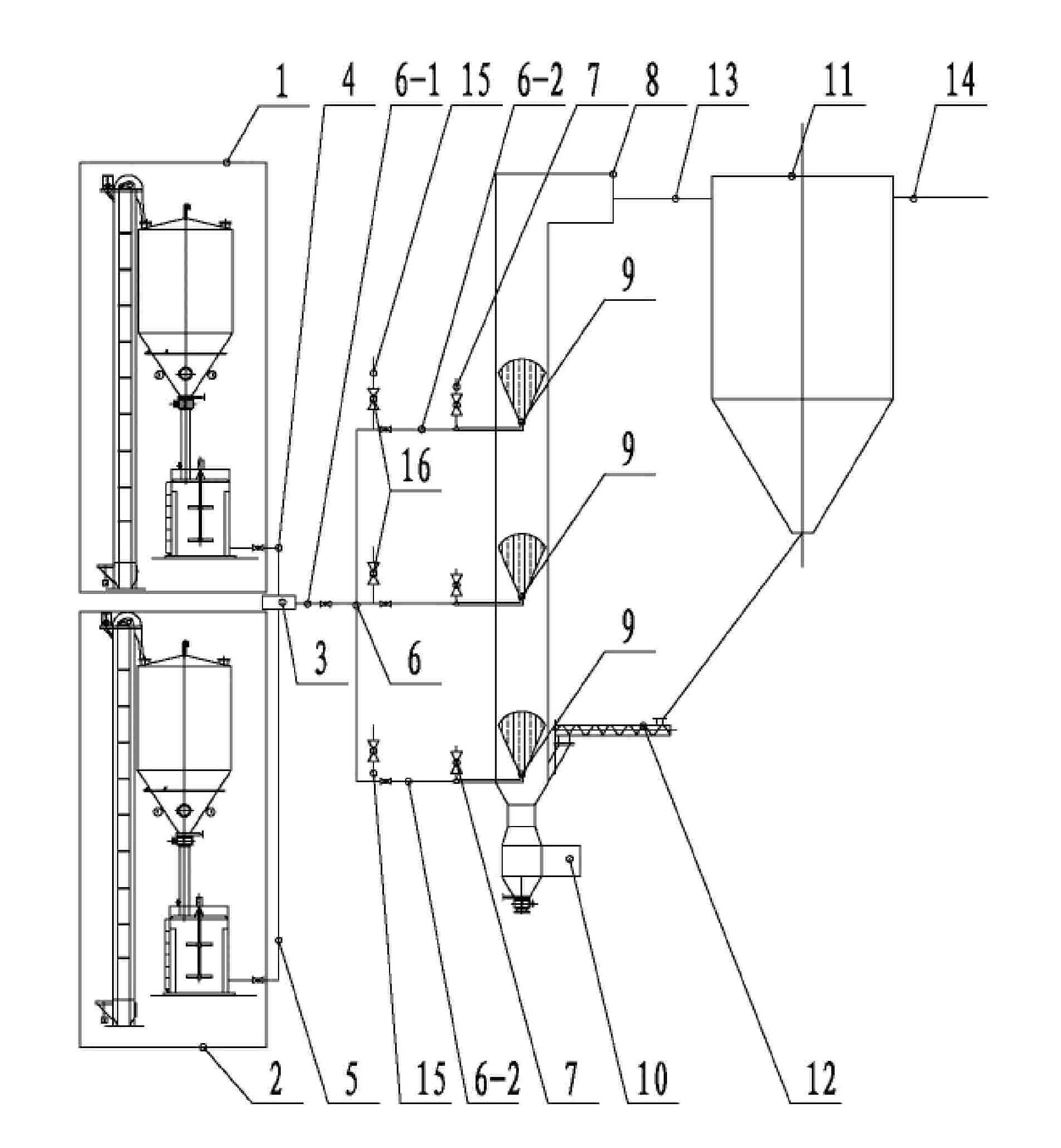

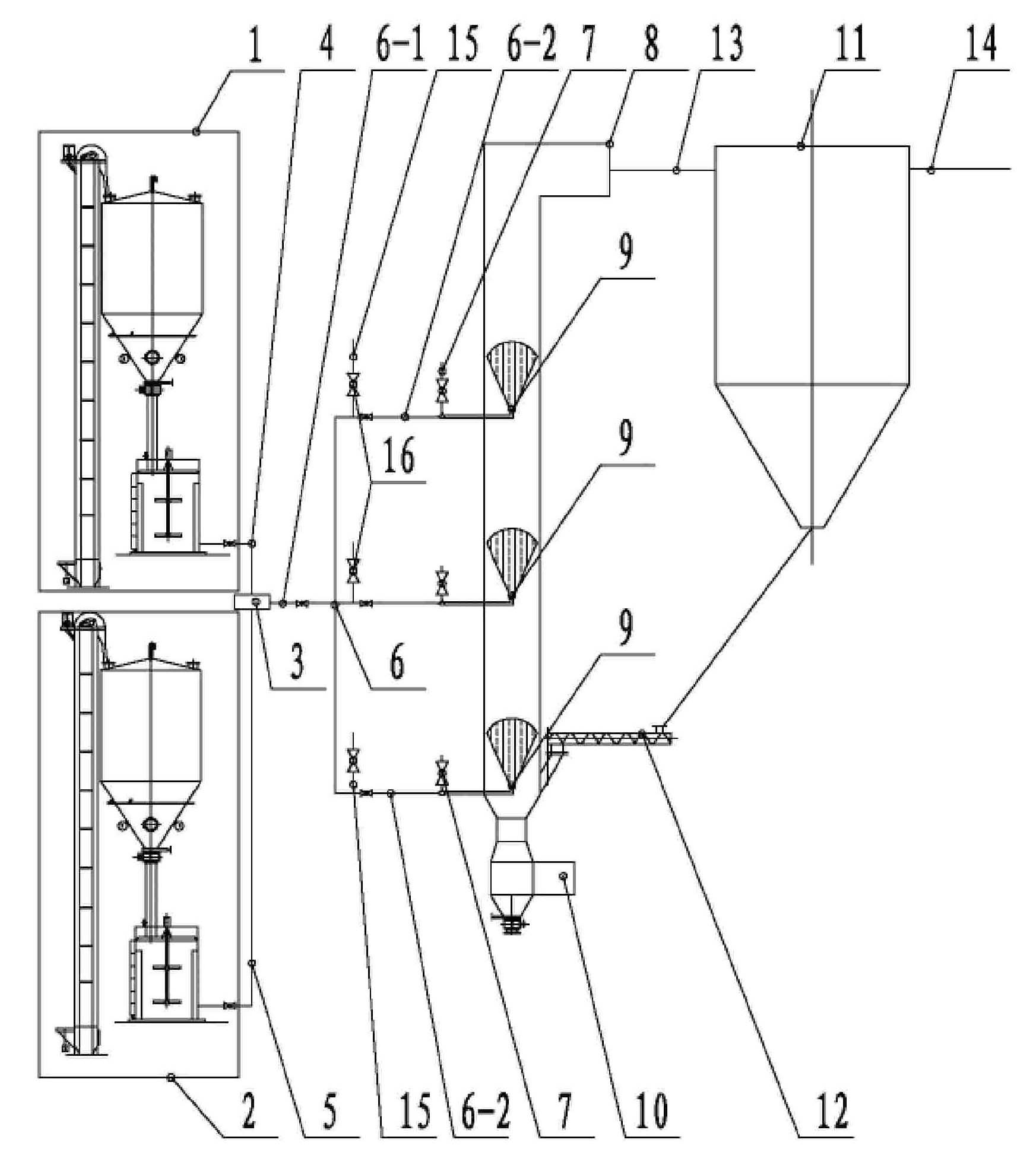

Double-rotation SCR denitration method and apparatus thereof

ActiveCN105289301AImprove denitrification efficiencyIncrease contact timeDispersed particle separationCycloneFlue gas

The invention discloses a double-rotation SCR denitration method and an apparatus thereof. According to the invention, a first eddy flow catalytic reaction chamber and a second eddy flow catalytic reaction chamber are arranged along a denitrating tower body; a flue gas introduction pipeline is arranged on a sidewall of the denitrating tower body; several eddy flow atomizing nozzles are respectively arranged on inner periphery of the flue gas introduction pipeline and the inner periphery at top of the first eddy flow catalytic reaction chamber; when flue gas is introduced into the flue gas introduction pipeline, the flue gas and ammonia gas injected by the eddy flow atomizing nozzle are mixed, and a mixture enables spiral sinking along circumference of the first eddy flow catalytic reaction chamber from up to down in a tangent circle mode, under effect of a cyclone, and then the mixture enable spiral rise along circumference of the second eddy flow catalytic reaction chamber from down to up in the tangent circle mode. Under prerequisite that high efficiency denitration is ensured, catalyst amount is less, operation of technical means is simple and easy, compared with the prior art, a denitrating tower structure is simple, cost of the apparatus is low, denitration efficiency is high, energy consumption is low, escapement ratio of ammonia is reduced, denitration cost is greatly reduced, and economic benefit is obviously increased.

Owner:SOUTH CHINA UNIV OF TECH

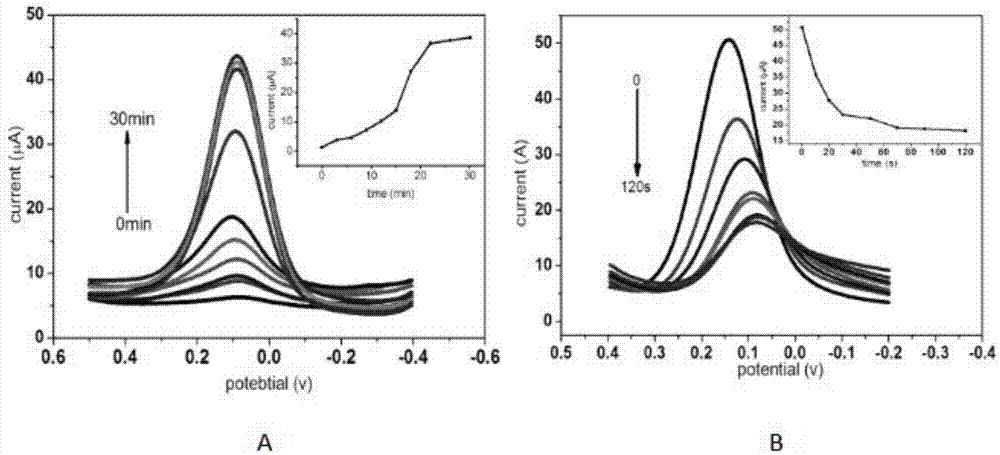

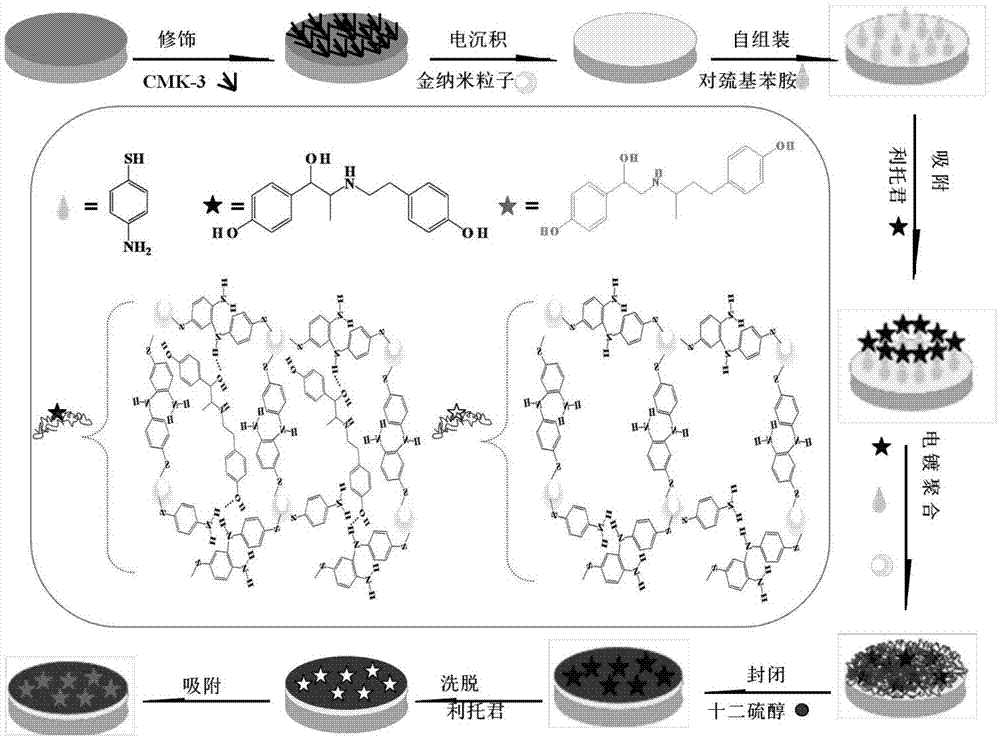

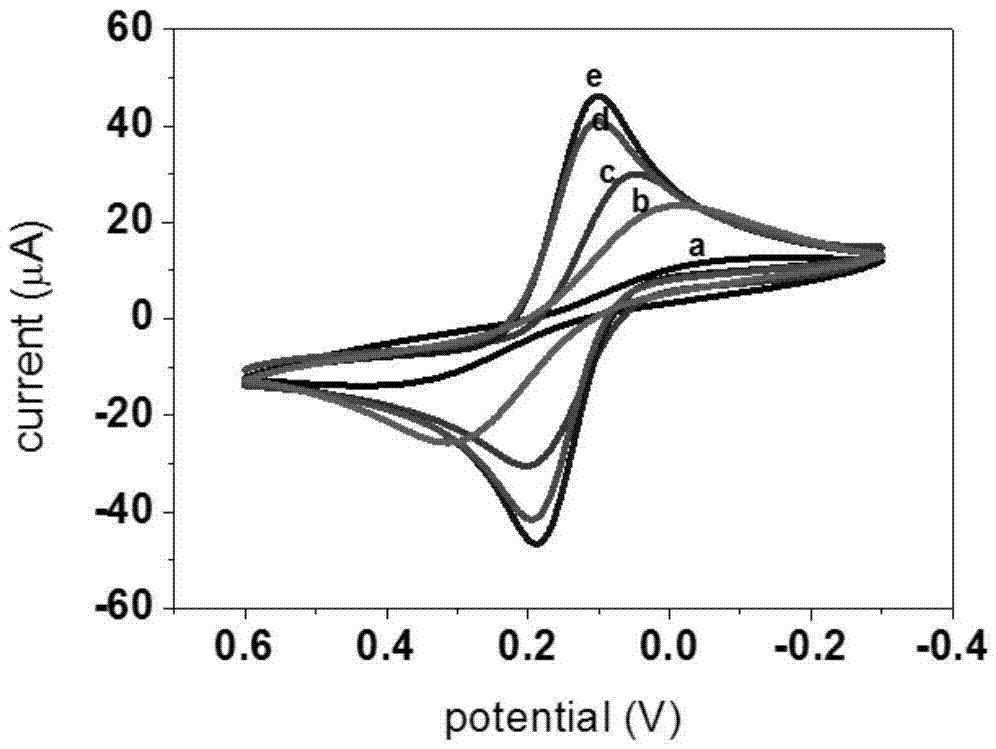

Portable ractopamine molecular imprinted silk-screen printed electrochemical sensor

ActiveCN105445356ALarge specific surface areaHigh selectivityMaterial electrochemical variablesElectrochemical detectorPeak value

The invention discloses a portable ractopamine molecular imprinted silk-screen printed electrochemical sensor, and belongs to the technical field of fast detection. 60-100 [mu]L of an electric conductance solution contains a to-be-detected sample is dropwise added to the surface of a ractopamine molecular imprinted silk-screen printed electrode, the standing adsorption time is 50-200 s, then the ractopamine molecular imprinted silk-screen printed electrode is horizontally inserted into a clamping slot of a portable electrochemical detector, a current peak value during scanning is recorded, calculation is performed according to a standard curve between the ractopamine concentration and the current peak value I([mu]A)=-14.944logC([mu]M)+0.2641 (R<2>=0.9923); and finally, the detected concentration of ractopamine in the sample is displayed on an LED screen. The sensor has the advantages of high precision, high stability and high repeatability.

Owner:JIANGNAN UNIV

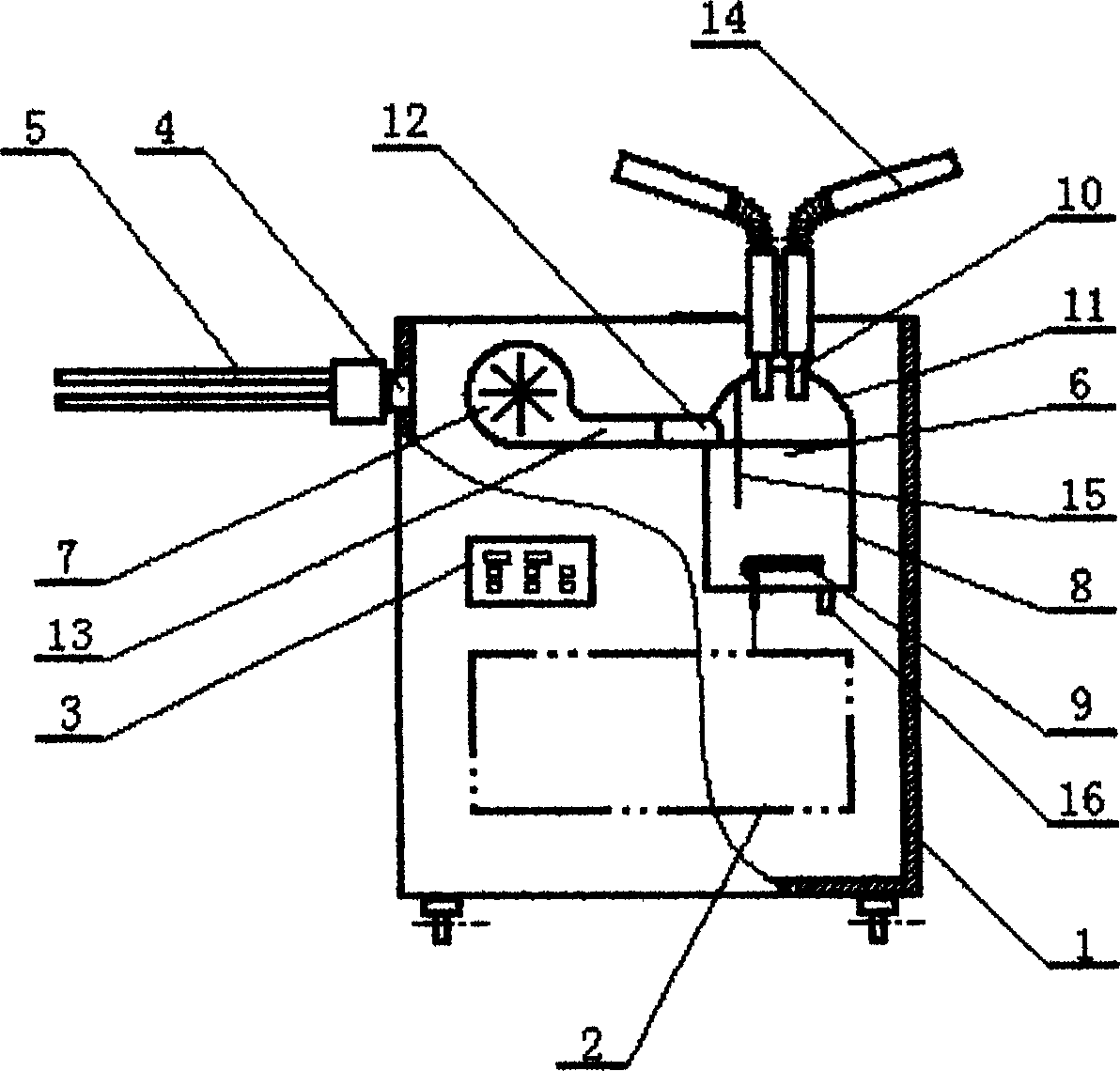

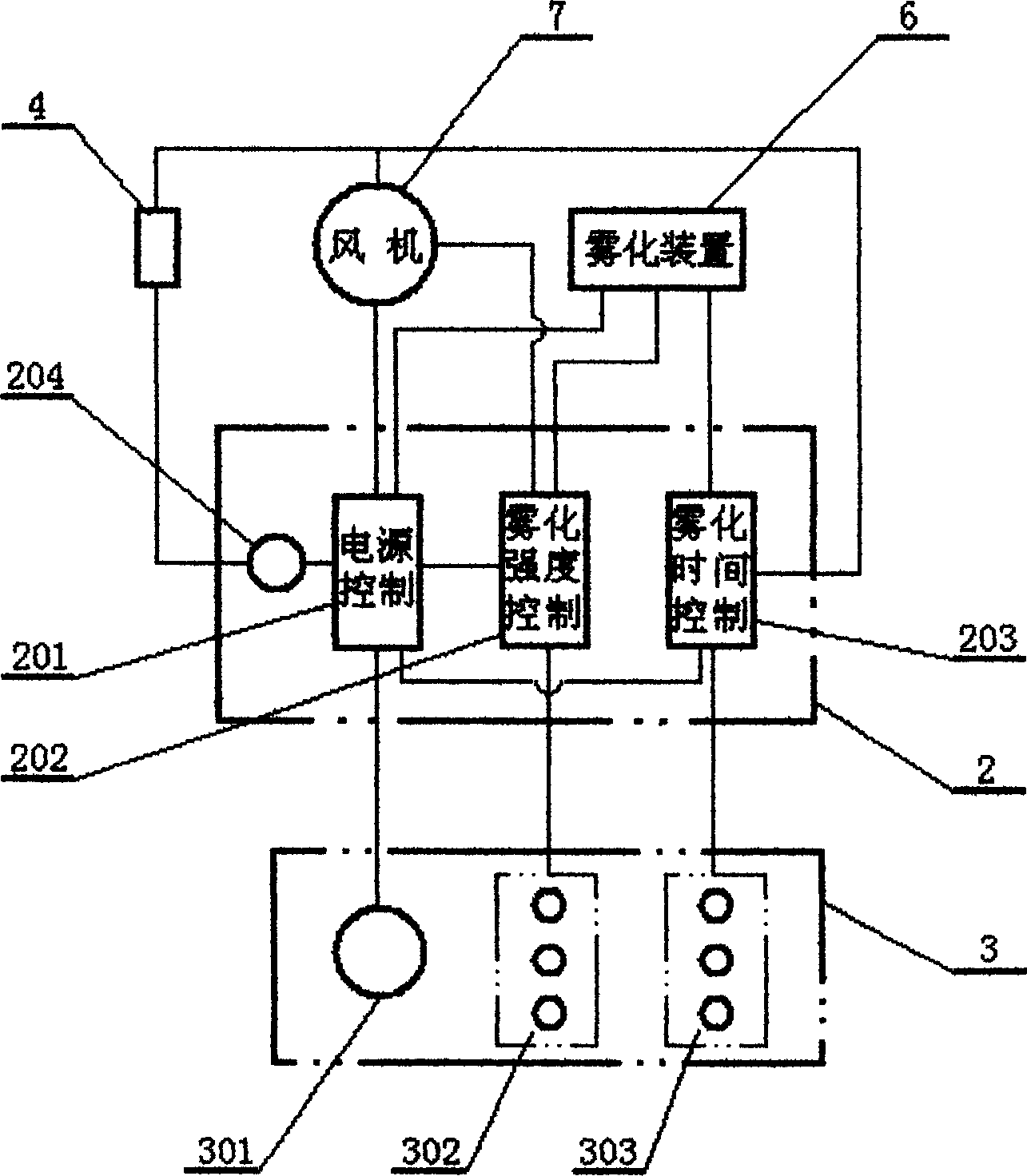

Method and apparatus for purifying indoor air

InactiveCN1763446AImprove purification effectIncrease the specific surface area of contactLighting and heating apparatusDispersed particle separationOxygen ionsAir cleaning

The invention relates to an indoor air purifying method and device, which comprises the following steps: adapting air purifying disposing liquid within photocatalytic agent; atomizing the disposing liquid into tiny particle mist material; spreading the mist disposing liquid into the polluted space through fan; activating the photocatalytic agent to catalyze the water and oxygen in the air into large amount of oxyhydrogen free radical and negative oxygen-ion. The device contains box, fan, operation panel, electric control pod, ultraviolet radiation lamp and ultrasonic atomizing device, wherein the electric control component is composed of power control mode, atomizing strength control mode and atomizing time control mode. The invention can finish air purifying disposal in a short time, which sustains the air purifying function for a long time.

Owner:黄志军

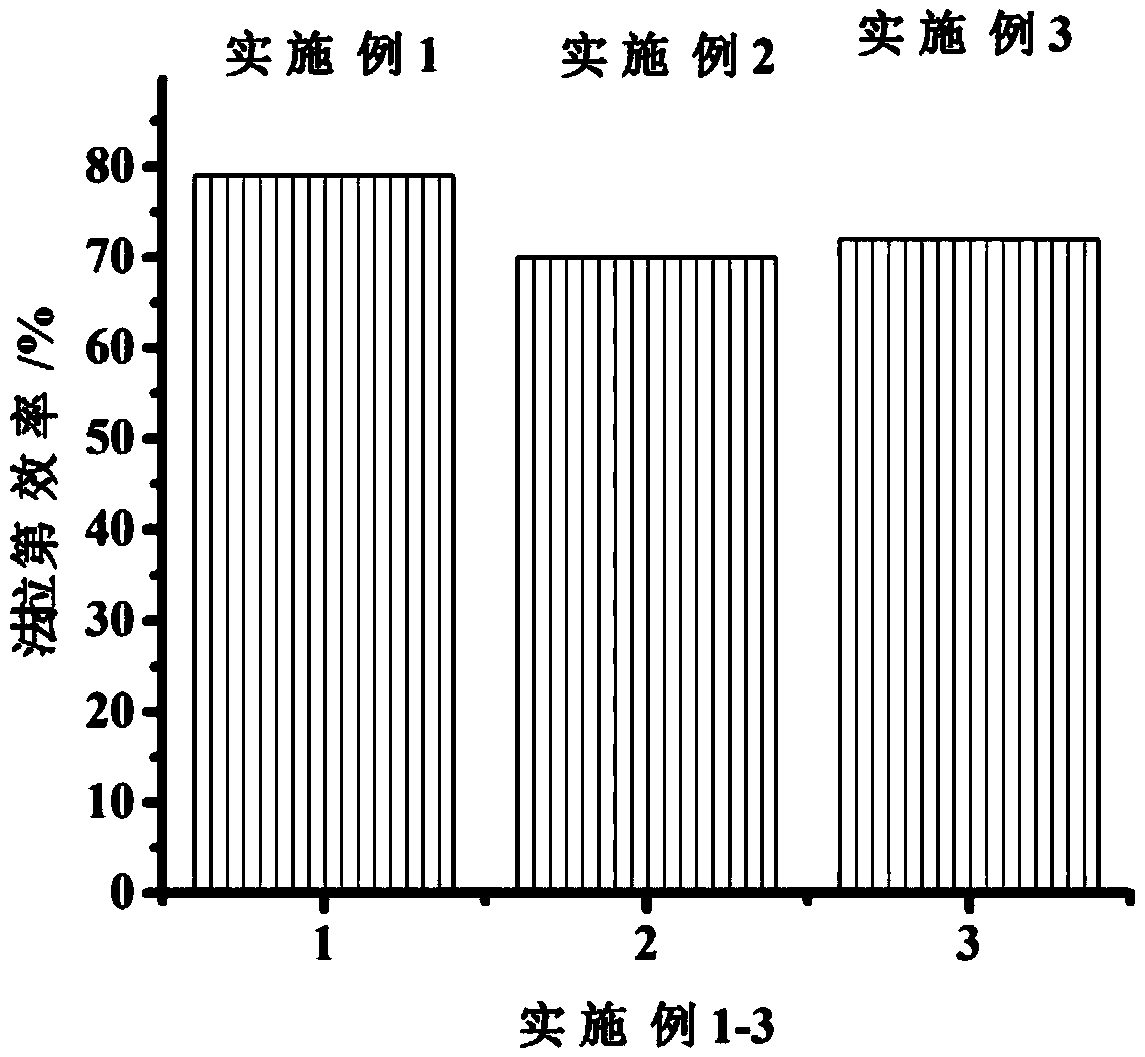

Process for preparing porous catalytic filling for internal electrolysis

The invention relates to a process for preparing porous catalytic filling for internal electrolysis which consists of, adding by proportion multiple component noble metal including palladium, chromium into the conventional electrolyzation filler, press forming in die arrangement, elevating the temperature, obtaining porous inner electrolyzation filler with specific shapes through combustion, wherein porous catalytic material comprises the components (by weight percentage) of iron powder 30-40%, carbon powder 30-40%, super macromolecular polyethylene 10-15%, palladium 1-2.5%, chromium 1-2.5%.

Owner:SHANGHAI UNIV +1

Rotational flow plate type SCR denitration tower and denitration method thereof

ActiveCN105289300AExtended stayThe catalytic reduction reaction is fullyDispersed particle separationFlue gasEscape rate

The invention discloses a rotational flow plate type SCR denitration tower and a denitration method thereof. The denitration tower comprises a denitration tower body and a corrugated plate type catalyst layer arranged along the inner circumference face of the denitration tower body, and the corrugated plate type catalyst layer forms a flue gas channel. A plurality of layers of rotational flow atomizing nozzles performing jetting in the contact circle direction are distributed on the circumference face of the corrugated plate type catalyst layer from bottom to top. When flue gas enters the flue gas channel from the bottom of the denitration tower body, and the flue gas encounters ammonia gas jetted by the whirlwind atomizing nozzles, the flue gas and the ammonia gas are mixed in an entrainment mode and spirally raises in the inner circumference direction of the flue gas channel in a contact circle mode because the ammonia gas is jetted in a rotational flow mode in the contact circle direction. On the premise that efficient denitration is guaranteed, the catalyst use amount of the denitration tower is small, the technical means is easy and convenient to use. Compared with the prior art, the denitration tower is simple in structure, low in manufacturing cost, high in denitration efficiency and low in energy consumption, reduces the ammonia escape rate, makes denitration cost greatly reduced, and remarkably improves economic benefits.

Owner:SOUTH CHINA UNIV OF TECH

Catalyst for carbon dioxide reduction through electrocatalysis and preparation method thereof

InactiveCN110280283ALarge specific surface areaIncrease the specific surface area of contactPhysical/chemical process catalystsElectrolytic organic productionIndiumZinc sulfide

The invention belongs to the technical field of carbon dioxide reduction through electrocatalysis, and particularly relates to a catalyst for carbon dioxide reduction through electrocatalysis and a preparation method thereof. The catalyst is an indium zinc sulfide-MXene composite material. The catalyst has high electrocatalytic activity and selectivity on the carbon dioxide reduction, and significantly improves the energy efficiency for carbon dioxide utilization.

Owner:INT ACAD OF OPTOELECTRONICS AT ZHAOQING SOUTH CHINA NORMAL UNIV

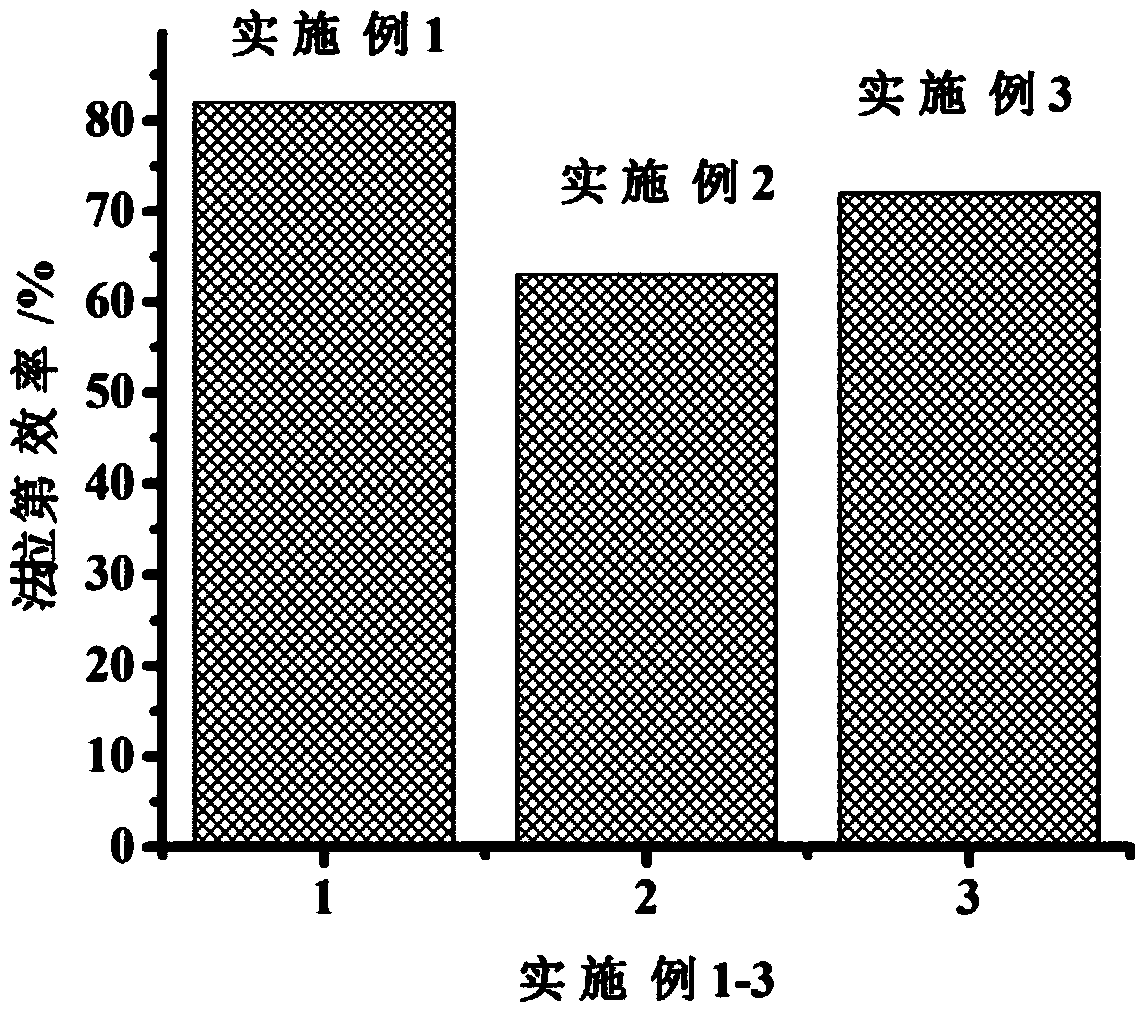

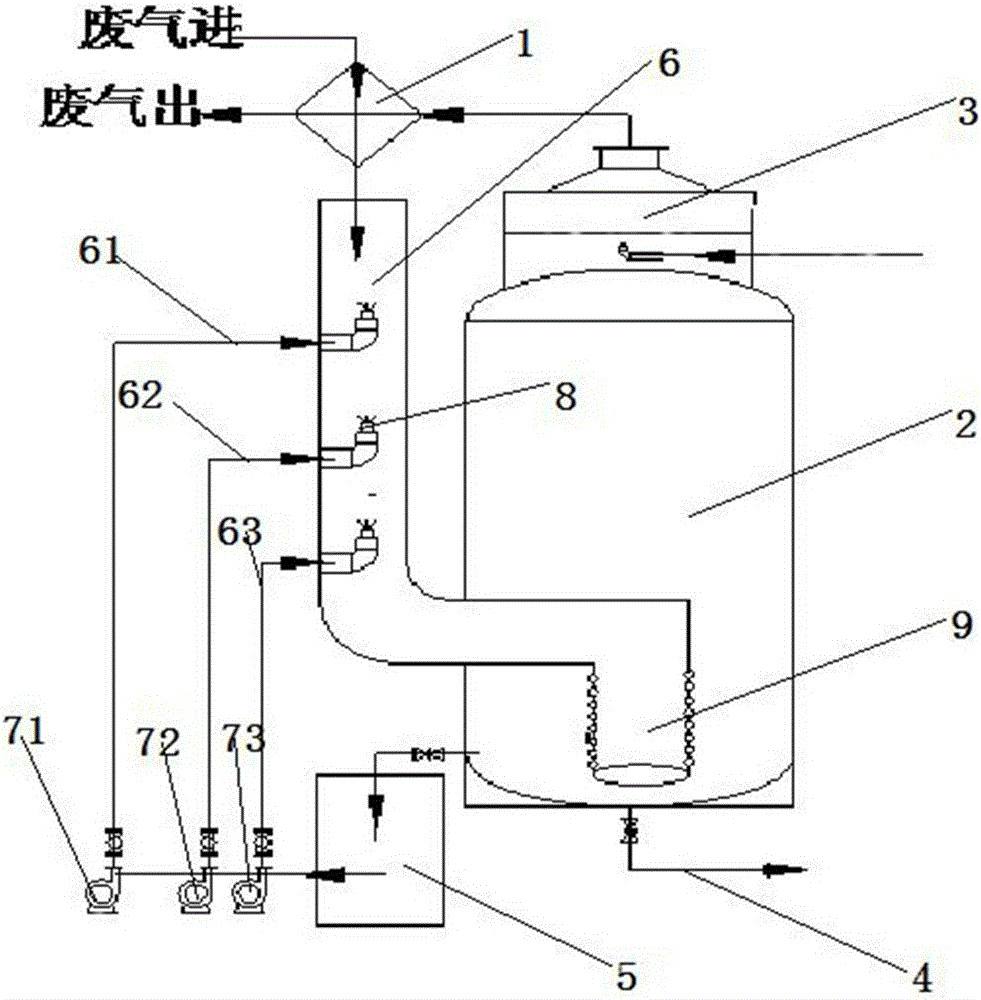

Waste gas treatment process and device adopting reverse flow counter-impact turbulence washing tower

InactiveCN106139866APollution controlImprove the environmentGas treatmentUsing liquid separation agentHeat exchangerTower

The invention provides a waste gas treatment process and device adopting a reverse flow counter-impact turbulence washing tower. The process includes following steps: enabling waste gas to pass a heat exchanger and enter a reverse spray washing pipe of the reverse flow washing tower to contact with a first-stage reverse spray, second-stage reverse spray or third-stage reverse spray absorbing liquid circulating system which sprays flow upwards to obtain mixed absorbing liquid, and forming a gas-liquid turbulence foam washing area; enabling the mixed absorbing liquid to enter the bottom of the reverse flow washing tower along the flow and enter a holed pipe to form a gas-liquid or liquid-liquid bubble washing area, enabling the waste gas after going through the bubble washing area to pass a defoamer and then an outlet of the heat exchanger, and discharging the waste gas after being purified. The waste gas treatment process and device has the advantages that gas-liquid counter-impact is utilized to increase contact specific surface area of the waste gas and the absorbing liquid to form the turbulence foam washing area, and the three reverse spray absorbing liquid circulating systems are designed creatively; natural gravity of the reverse spray absorbing liquid is utilized, and pipe wall hole diameter of 1-20mm is designed at the bottom of the reverse spray washing pipe creatively to form the bubble washing area.

Owner:浙江海牛环境科技股份有限公司

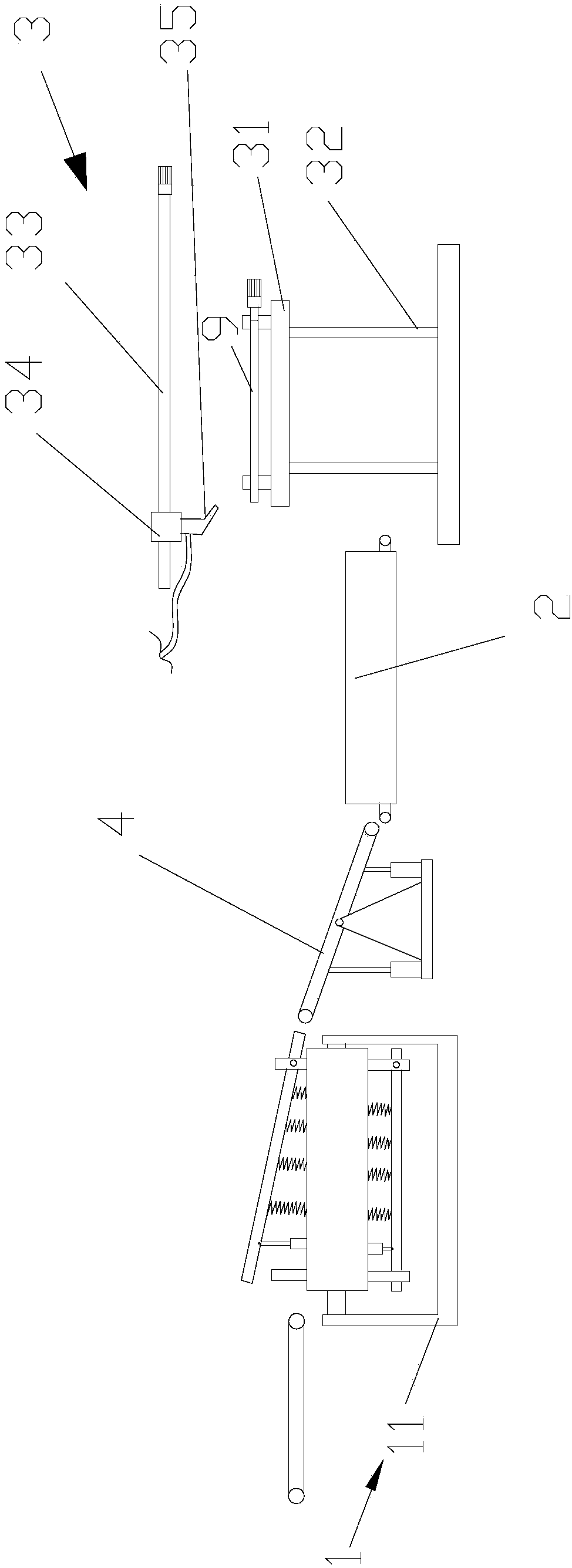

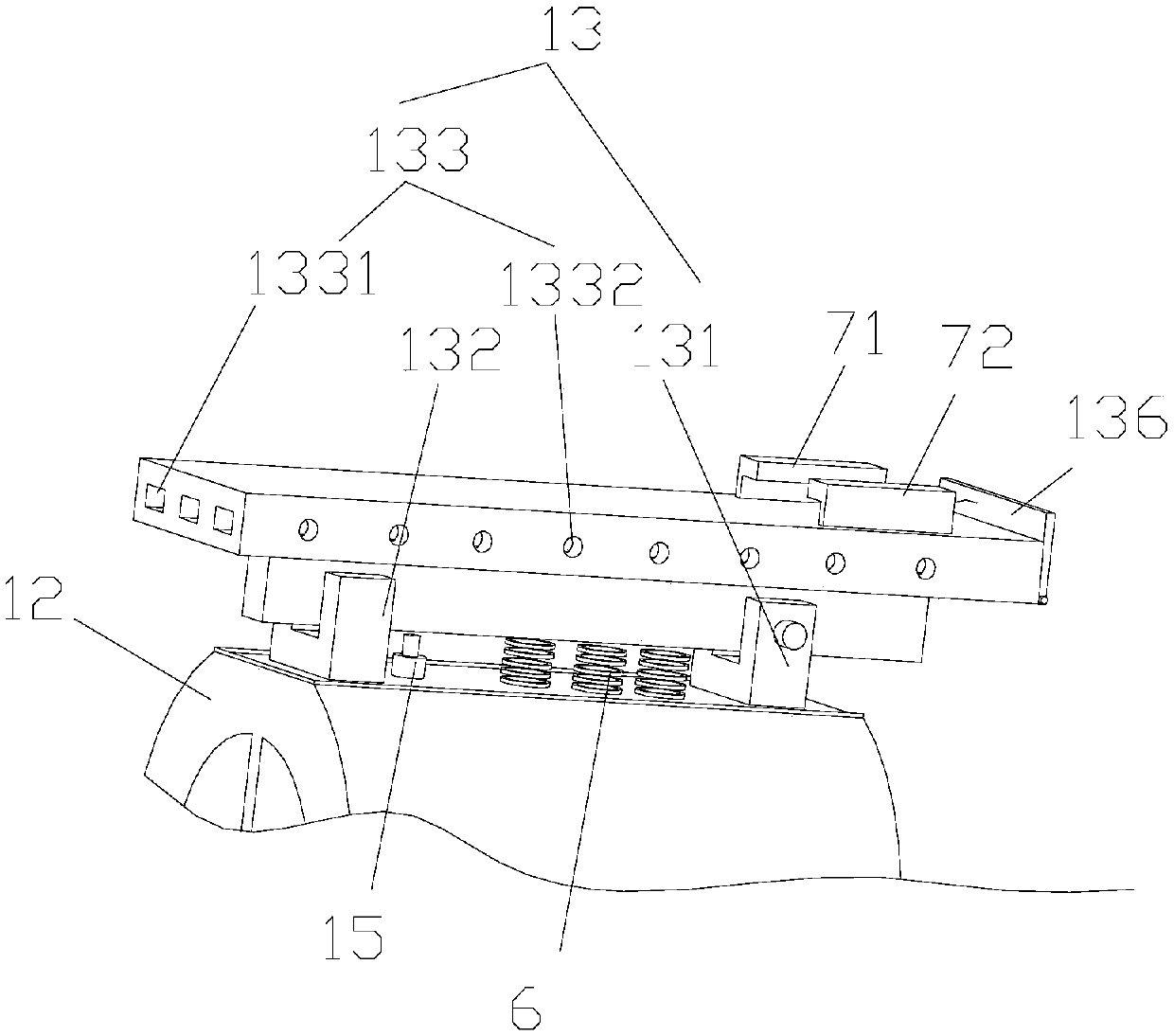

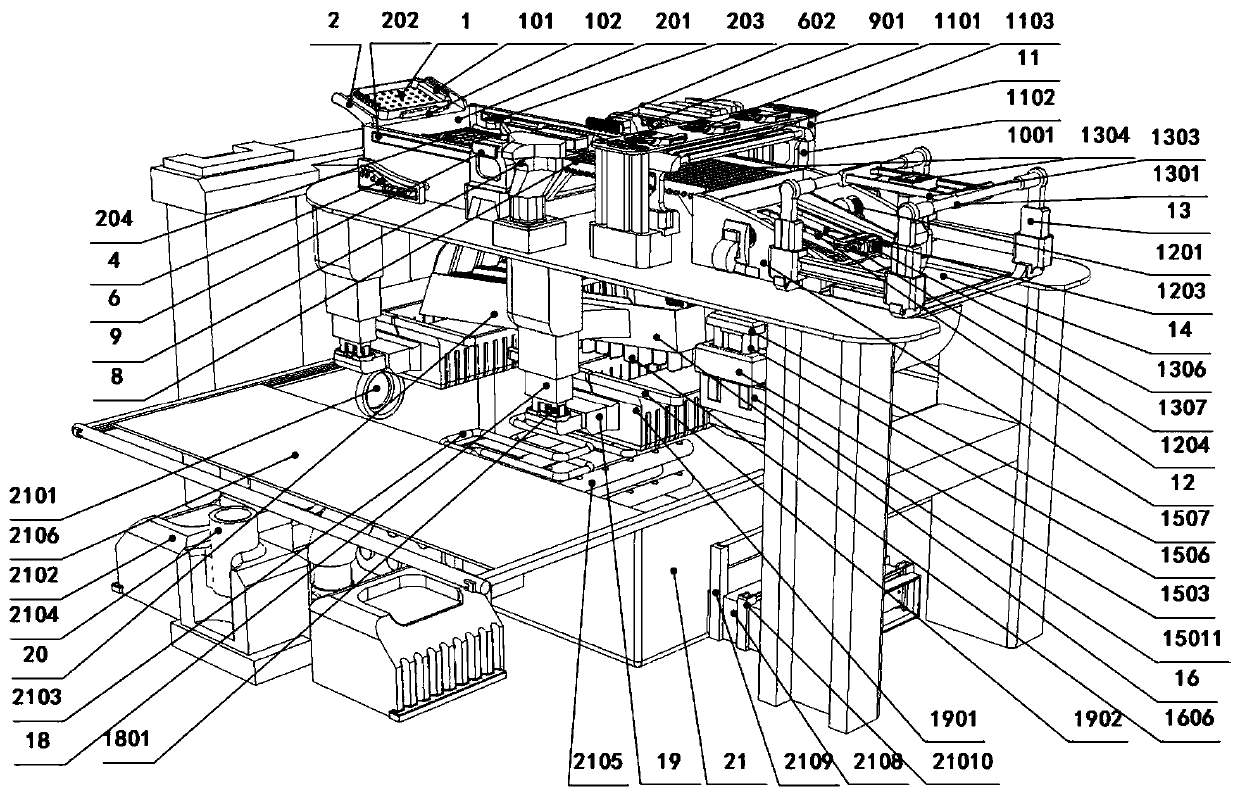

Aluminium sectional material spraying system and spraying method thereof

ActiveCN107649325AScattered spatial locationAdd storage pointsPretreated surfacesCoatingsMaterials scienceAluminium

The invention discloses an aluminium sectional material spraying system which comprises a cleaning / oxidizing tank, a drying box and a spraying device, wherein the cleaning / oxidizing tank is used for carrying out cleaning and oxidizing treatment on the surface of aluminium sectional material; the drying box is used for drying the aluminium sectional material after cleaning and oxidizing treatment;the spraying device is used for spraying the dried aluminium sectional material; and the aluminium sectional material spraying system further comprises a rotating type conveying mechanism. The invention further discloses an aluminium sectional material spraying method by adopting the aluminium sectional material spraying system. The aluminium sectional material spraying system has the advantages of high cleaning efficiency and spraying uniformity.

Owner:奋安铝业股份有限公司

Method for preparing multi-stage SnO2 nanotubular gas sensitive material and application of method

The invention discloses a method for preparing a multi-stage SnO2 nanotubular gas sensitive material. The method comprises the following steps: (1) stirring PVP (Polyvinyl Pyrrolidone) in ethylene glycol, and carrying out ultrasonic treatment so as to obtain a solution a; (2) uniformly dispersing molybdenum oxide nanorods into the solution a so as to obtain a solution b; (3) putting a stannous chloride solution and a thioacetamide solution into the solution b, stirring, transferring into a reaction kettle, and carrying out constant-temperature hydrothermal treatment for 10-14 hours; (4) cooling, carrying out centrifugal collection with absolute ethyl alcohol, transferring obtained precipitate into a flask by using the absolute ethyl alcohol, adding ammonia water, stirring for 1-2 hours, carrying out centrifugal collection, and drying the obtained precipitate so as to obtain SnS2; (5) calcining the obtained SnS2 in a tubular furnace, thereby obtaining the multi-stage SnO2 nanotubular gas sensitive material. The method is cheap and easy in raw material obtaining, simple in operation method, low in energy consumption, good in repeatability, high in yield and applicable to on-scale production, and in addition, the prepared multi-stage SnO2 nanotubular gas sensitive material can be used as materials of sensors, catalysts, catalyst carriers and the like, and has good application prospects.

Owner:GUANGXI UNIV

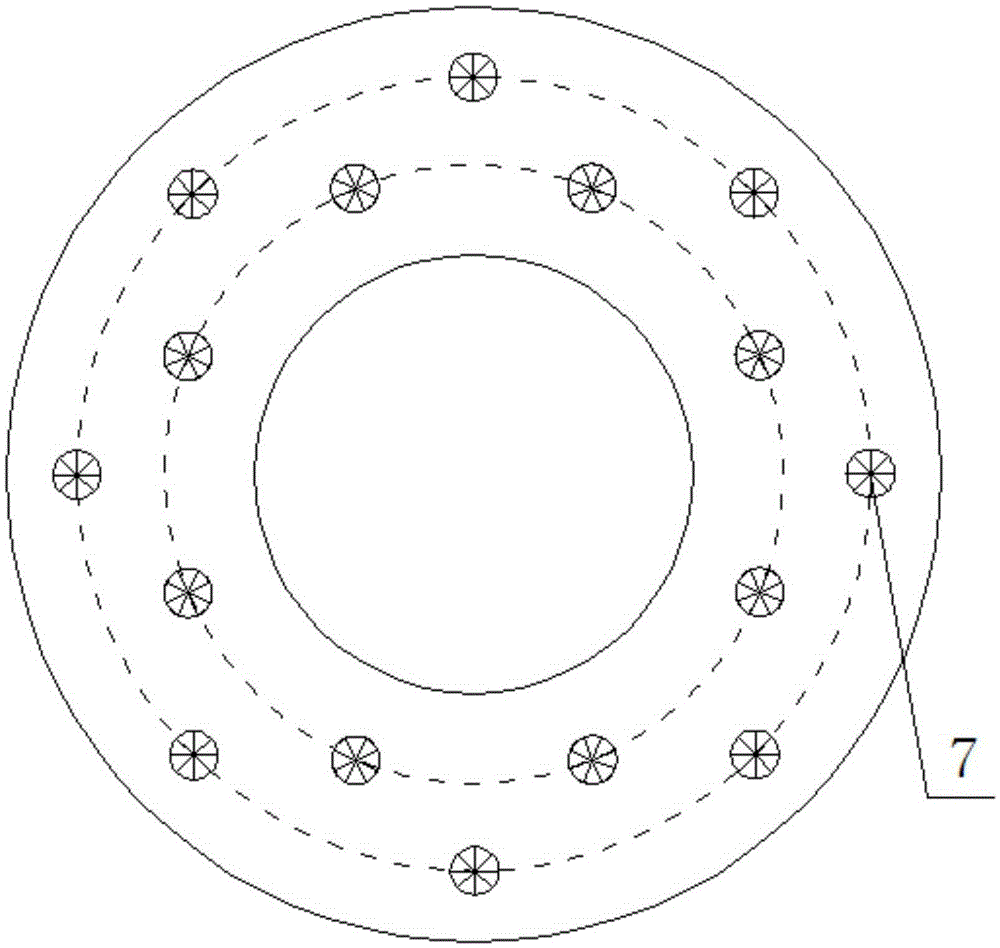

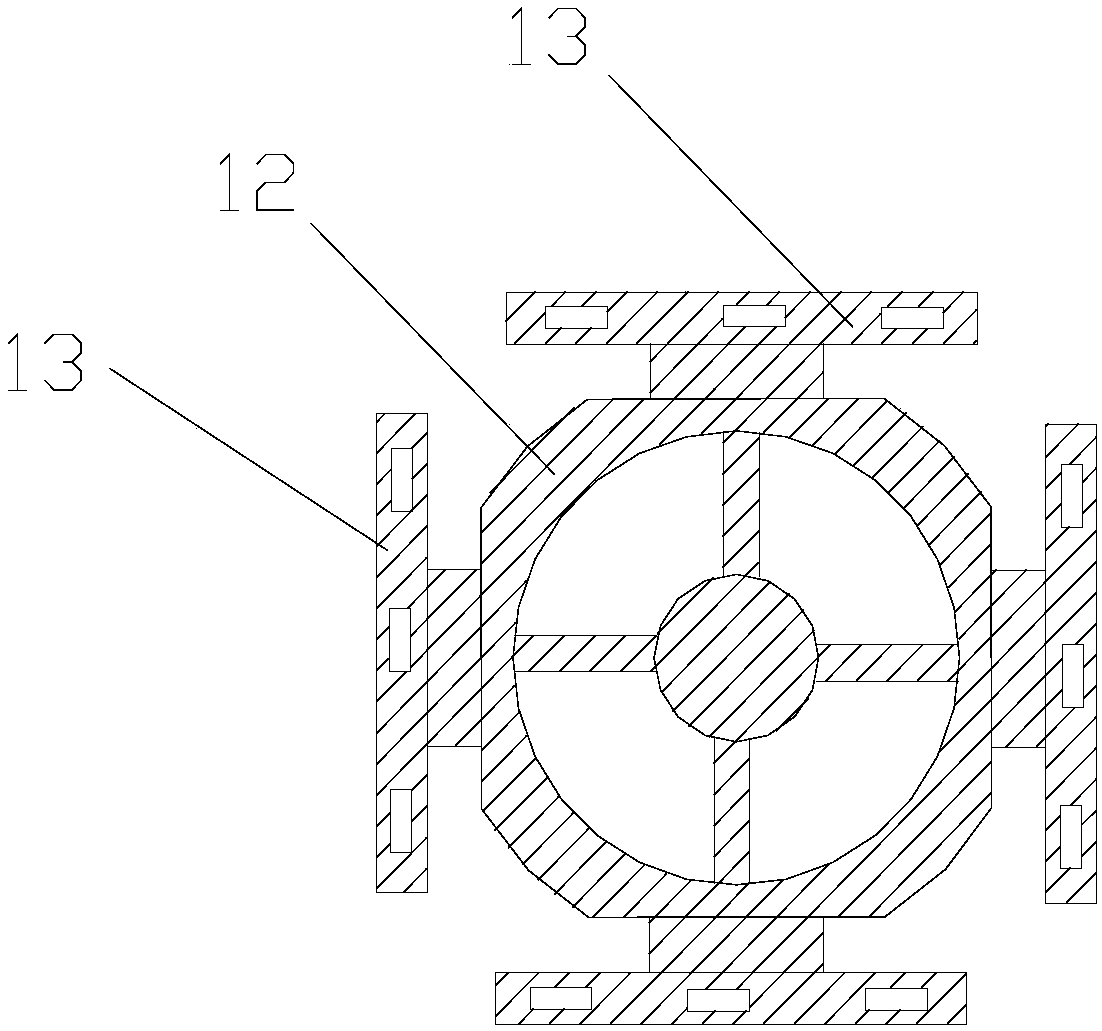

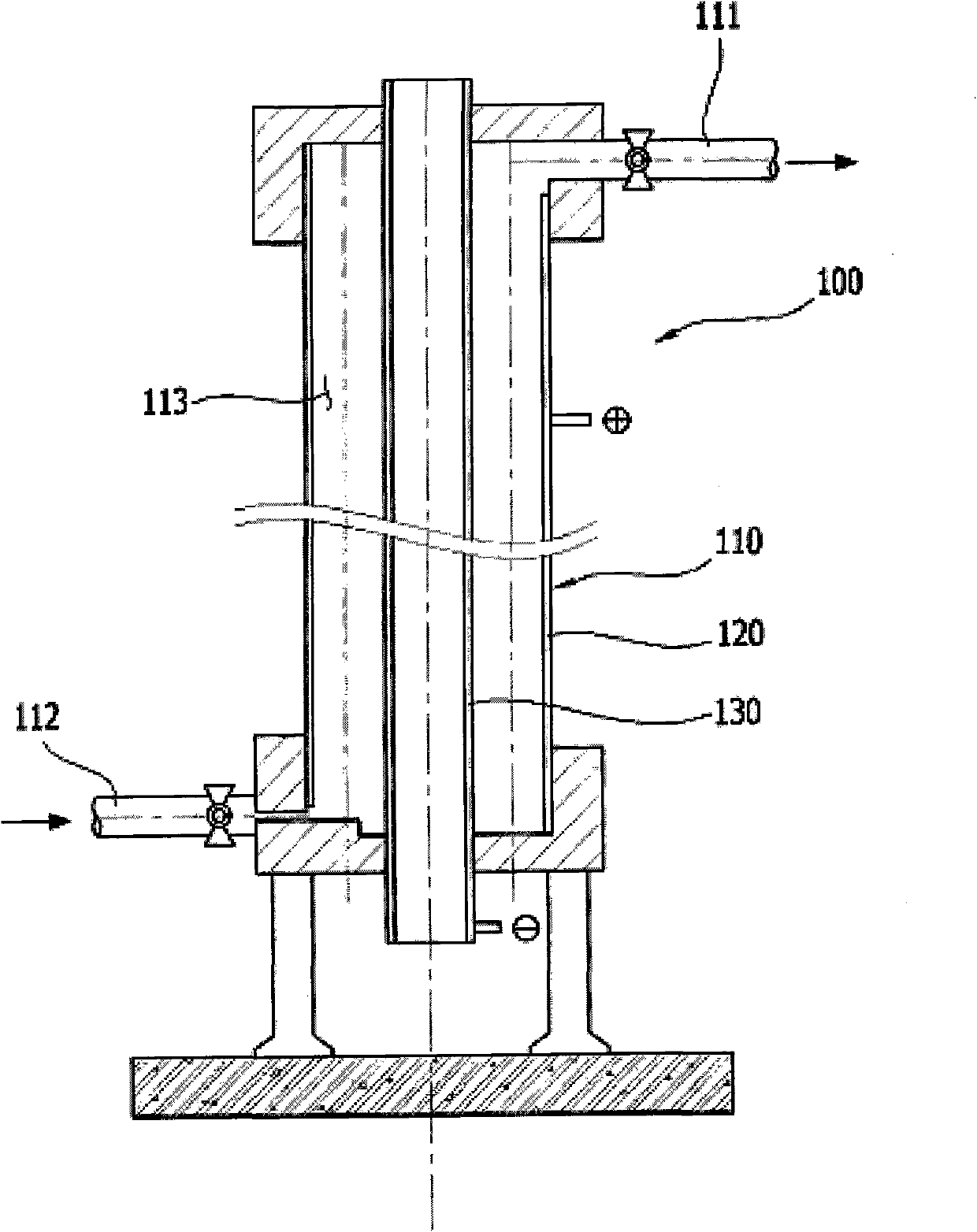

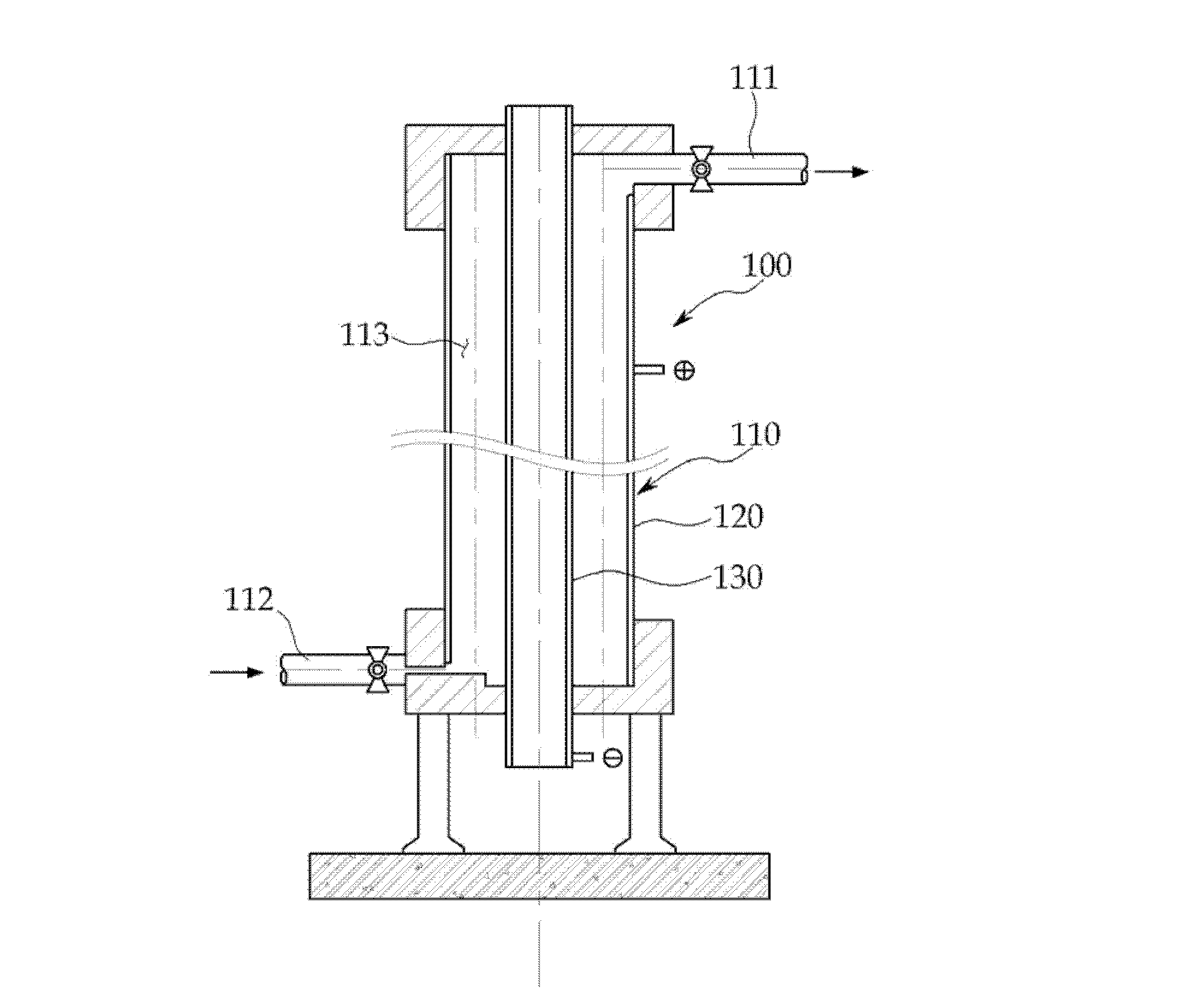

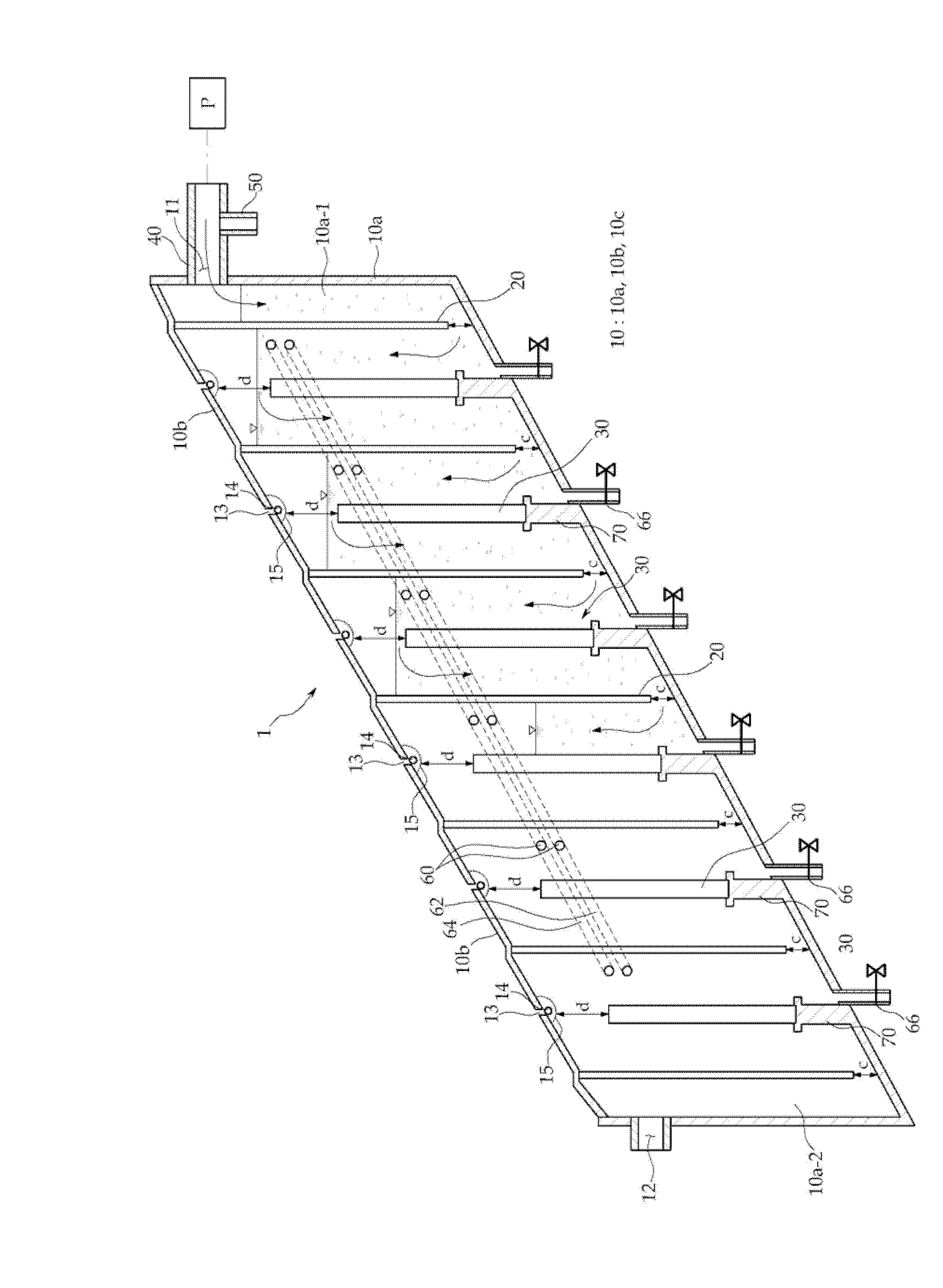

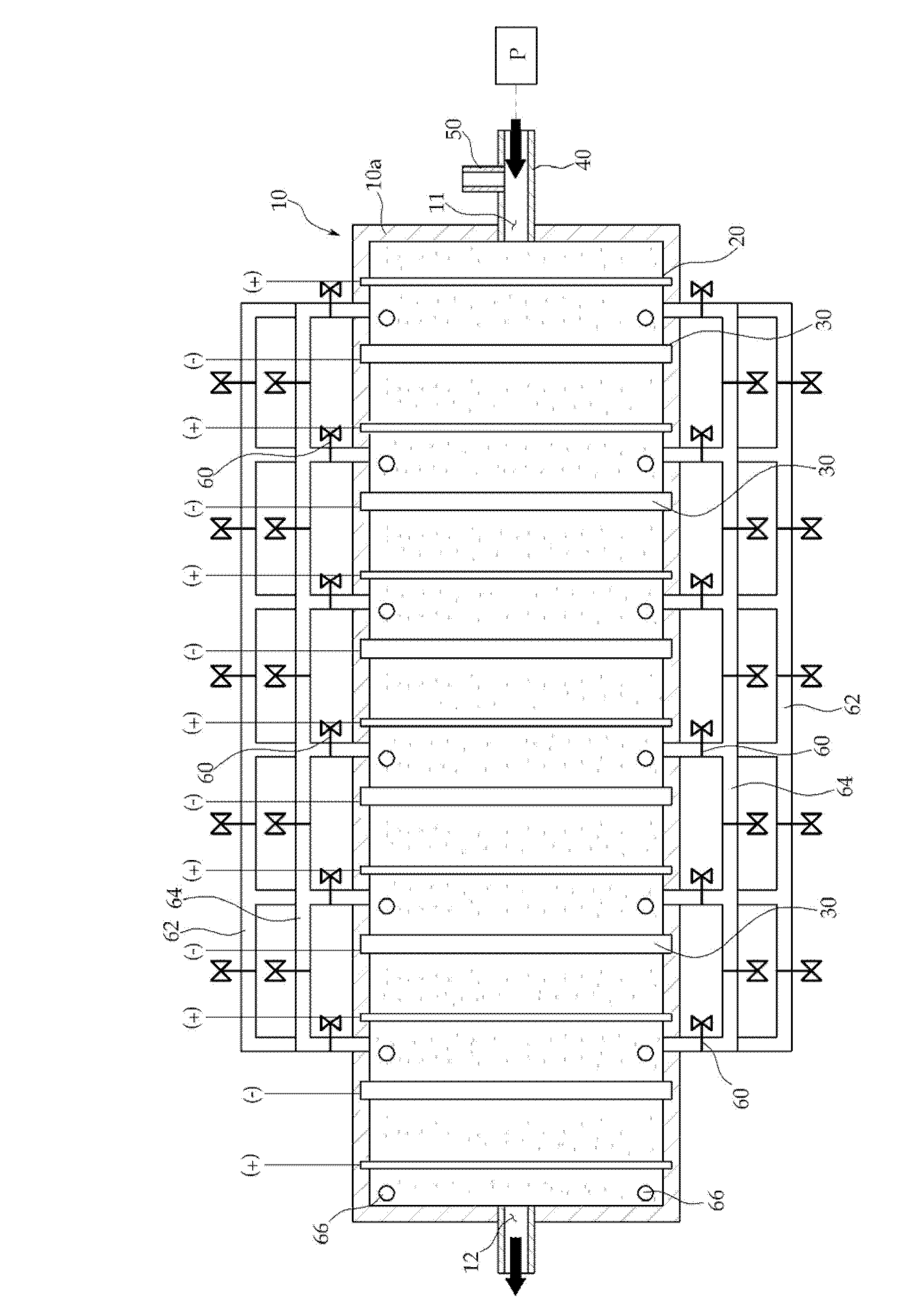

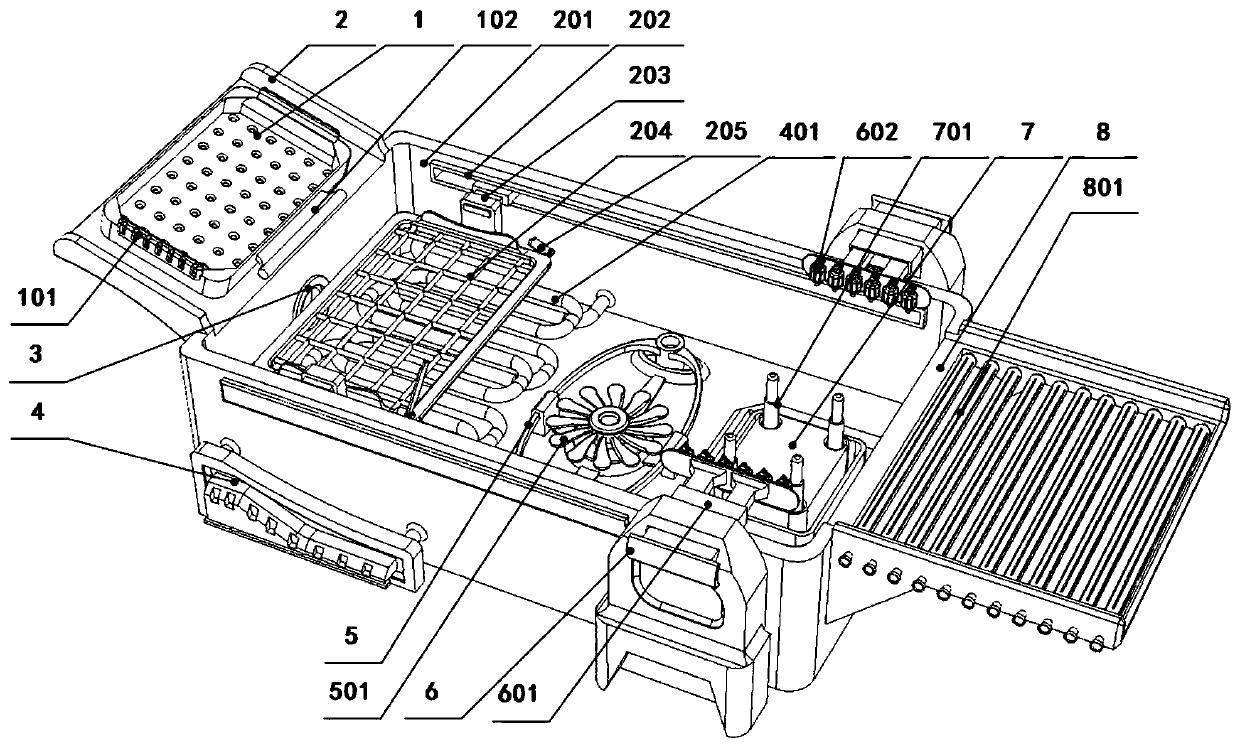

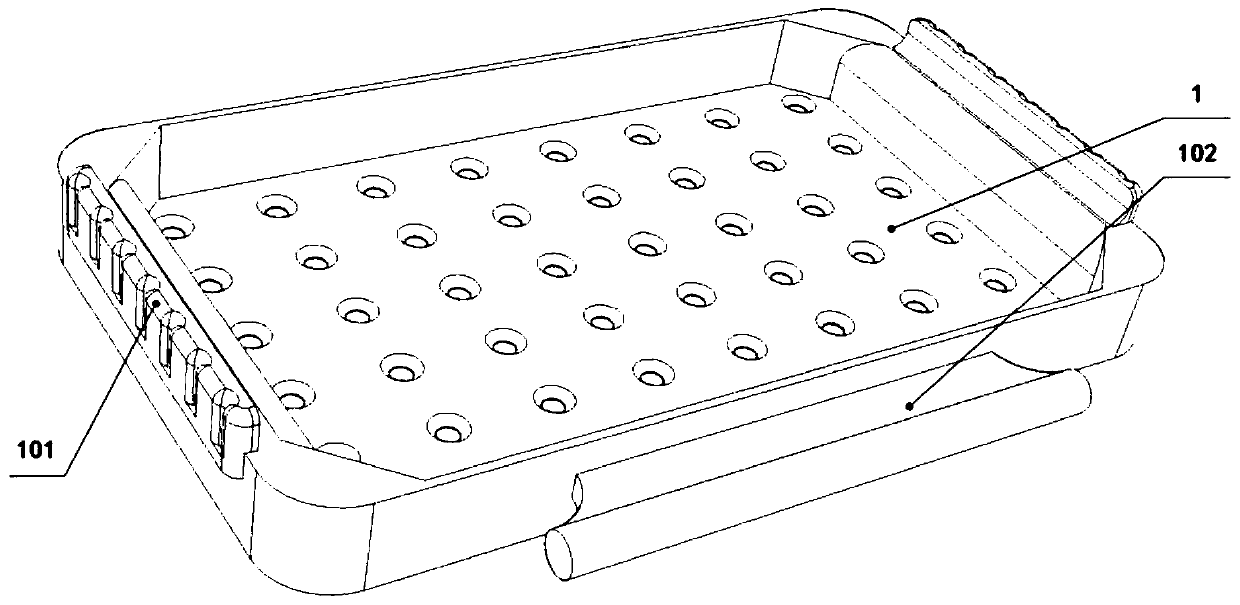

Electrolytic cell with large contact specific surface area for valuable metal recovery

InactiveCN102021609AIncrease the specific surface area of contactImprove electrolysis efficiencyElectrodesElectricityWastewater

The invention relates to an electrolytic cell which can effectively electrodeposit recyclable valuable metal in gold-plated wastewater or valuable metal-containing wastewater for recovery, in particular to an electrolytic cell with a large contact specific surface area for valuable metal recovery, which increases the specific surface area of an electrode contacted by the electrolyzed wastewater to the greatest extent, improves the electrolysis efficiency, expands the electrolysis space and effectively electrodeposits and recovers the valuable metal in low-concentration wastewater. In the electrolytic cell for eletrodepositing the valuable metal in the wastewater through electrolytic reaction by using a cathode and an anode, a shell, an anode assembly and a cathode assembly are arranged, wherein the shell is provided with a flow inlet, a flow outlet and an exhaust hole and has an internal space; the anode assembly covers the internal space and is provided with a plurality of anodes; the cathode assembly is arranged between the anodes by covering the internal space and partitions the internal space into two electrolysis spaces; and ball-like cathode steel wires are arranged on one side of each electrolysis space so as to increase the specific surface area contacted by the wastewater. The wastewater flowing in from the flow inlet passes through a plurality of electrolysis spaces in turn, the valuable metal is electrodeposited on the cathode assembly for coagulating the cathode steel wires to be recovered, and gas is discharged out of the exhaust hole, and the wastewater is discharged to the exterior through the flow outlet.

Owner:石尚烨

Composite type wet-method flue gas desulfurizing device

InactiveCN102363094AImprove desulfurization efficiencyReduce energy consumptionDispersed particle separationFlue gasSpray nozzle

The invention discloses a composite type wet-method flue gas desulfurizing device which comprises a absorption tower, wherein a mist spraying layer, a conventional spraying layer and a demisting layer are sequentially arranged in the absorption tower from bottom up; downward ultrasonic atomizing spray nozzles are arranged on the mist spraying layer in an array manner; the conventional spraying layer comprises a plurality of columns of mechanical spray nozzles distributed in an array manner; the demisting layer is a demister; and a slurry storage zone and a slurry recovery zone are arranged at the bottom in the absorption tower. By adopting the device, the desulfurizing liquid-gas ratio can be greatly reduced; the number of slurry pumps and the atomizing spray nozzles is reduced; the volume of a desulfurizing spraying tower is reduced; and the desulfurizing system cost and the desulfurizing energy consumption are reduced. The composite type wet-method flue gas desulfurizing device can be widely applied to flue gas desulfurizing systems in industries such as power, petrification, metallurgy, cement and the like.

Owner:SOUTH CHINA UNIV OF TECH

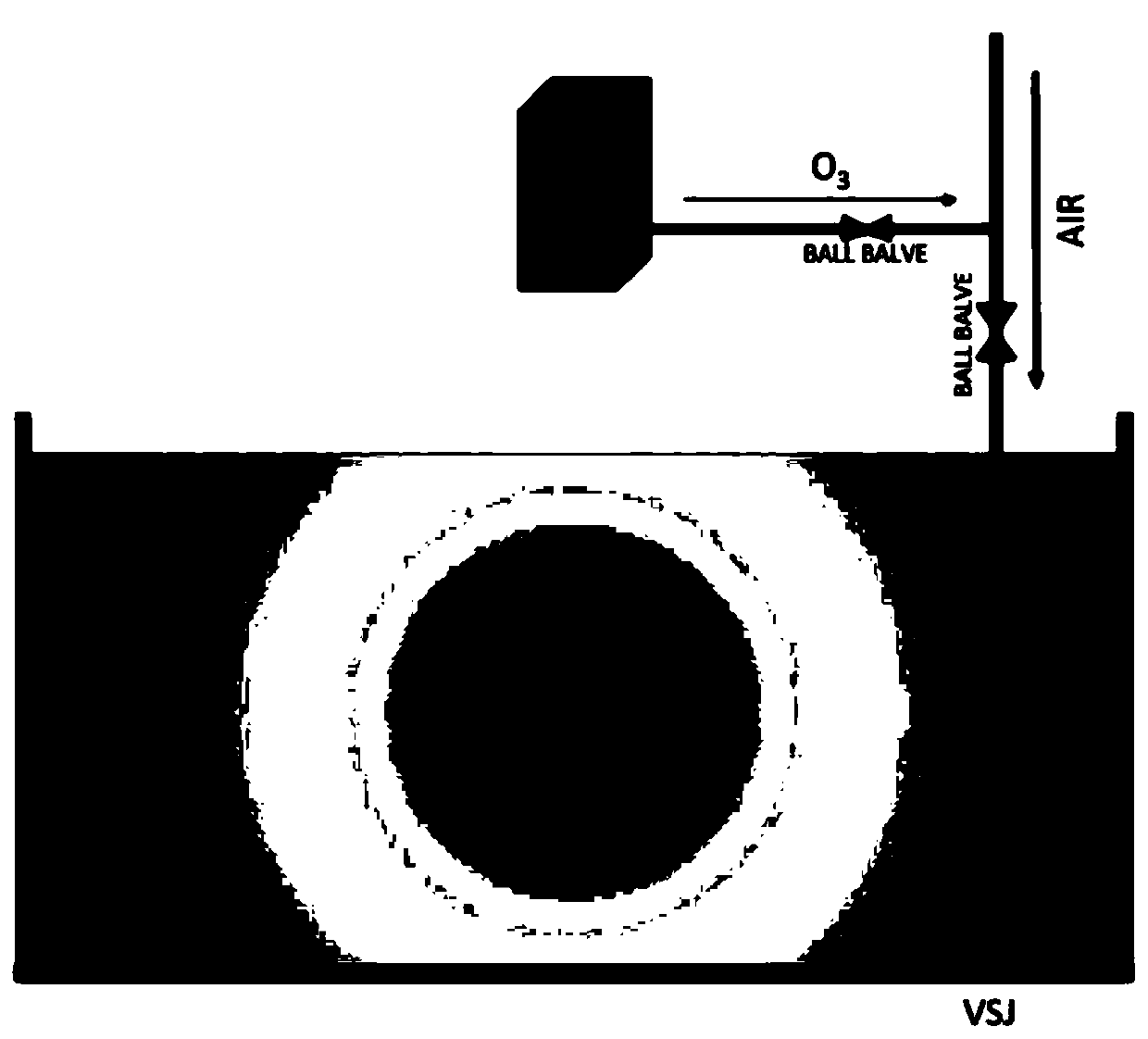

Mixed treatment process of feces and urine

InactiveCN110156276AIncrease dissolved oxygen concentrationImprove the ability to decompose organic matterTreatment using aerobic processesTreatment with aerobic and anaerobic processesMicro nanoFeces

The invention discloses a mixed treatment process of feces and urine, and belongs to the field of feces and urine treatment. The treatment process comprises the following steps: 1) introducing feces and urine into a biochemical treatment tank for aerobic biological treatment, periodically adding a microbial bacterial liquid to the biochemical treatment tank, and simultaneously performing micro-nano aeration treatment; 2) introducing the treated water body in the step 1) into a sedimentation tank for solid-liquid separation; and 3) introducing the obtained supernatant liquid after treatment inthe step 2) into a deep treatment tank, introducing a small amount of ozone to generate a large amount of hydroxyl radicals by using a micro-nano aeration apparatus in the deep treatment tank, performing high-efficiency oxidation, and simultaneously performing micro-nano aeration treatment on the water body. The microbial bacterial liquid added in the step 1) comprises lactobacillus QV1, lactobacillus QV1 is deposited in the General Microbiology Center of the China Microbial Culture Collection Management Committee, and the preservation number is CGMCC No.16350. The treatment process has high treatment efficiency, and the discharge can meet the standard after two weeks of treatment.

Owner:浙江亲水园生物科技有限公司

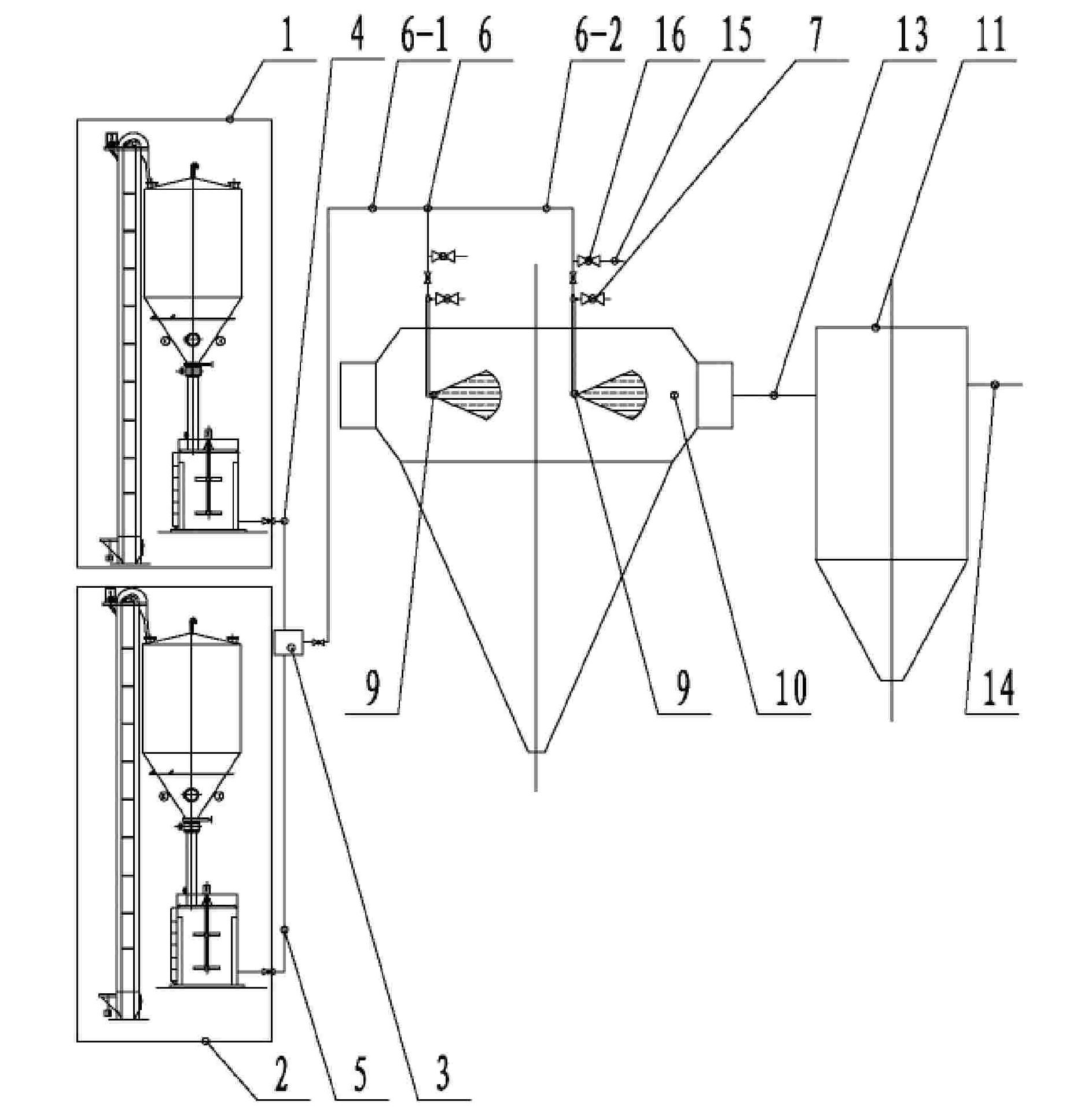

Double-alkaline semi-dry flue gas desulfurization device and technique thereof

ActiveCN101874975AReduce consumptionGood water solubilityDispersed particle separationParticulatesFlue gas

The invention provides a double-alkaline semi-dry flue gas desulfurization device and a technique thereof, and relates to a double-alkaline flue gas desulfurization device and a technique thereof. The invention aims at solving the problems of high operating cost of the existing double-alkaline flue gas desulfurization technology and low desulfurization efficiency of the existing semi-dry flue gas desulfurization technology. A first desulfurization device is provided with an atomizing nozzle which is arranged inside a desulfurizing tower, and solid particles in a dust-removing device is sent back into the desulfurizing tower by a material transmission device; a first desulfurization technique adopts the first desulfurization device and leads the desulfurization process to be carried out in the desulfurizing tower; a second desulfurization device is provided with an atomizing nozzle which is arranged inside a flue gas discharge pipeline, and the solid particles are precipitated in the dust-removing device; and a second desulfurization technique adopts the second desulfurization device and leads the desulfurization process to be carried out in the flue gas discharge pipeline. The invention realizes the desulfurization efficiency of 85-90%, ensures the consumption quantity of sodium hydroxide to be less than 15%, and has low operating cost.

Owner:HARBIN INST OF TECH

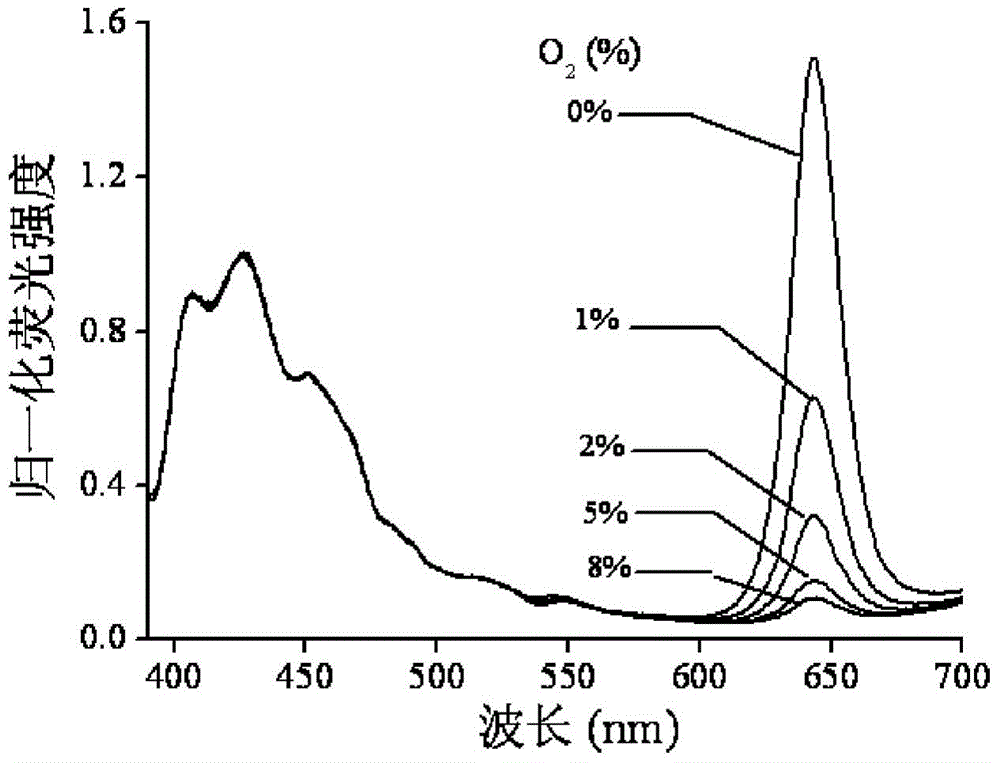

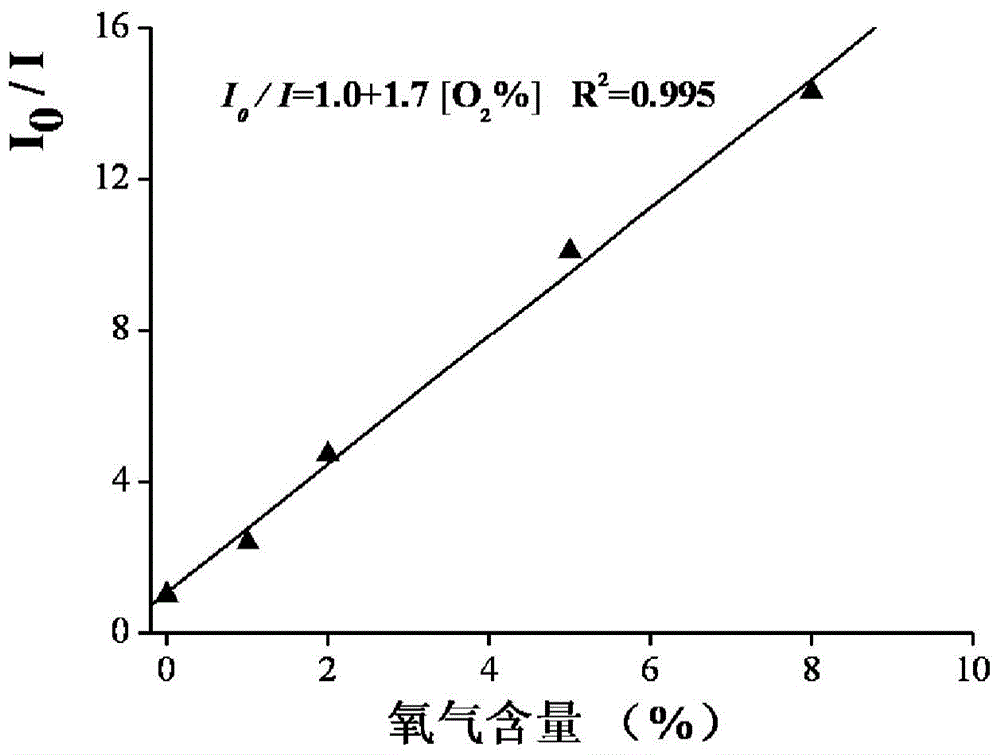

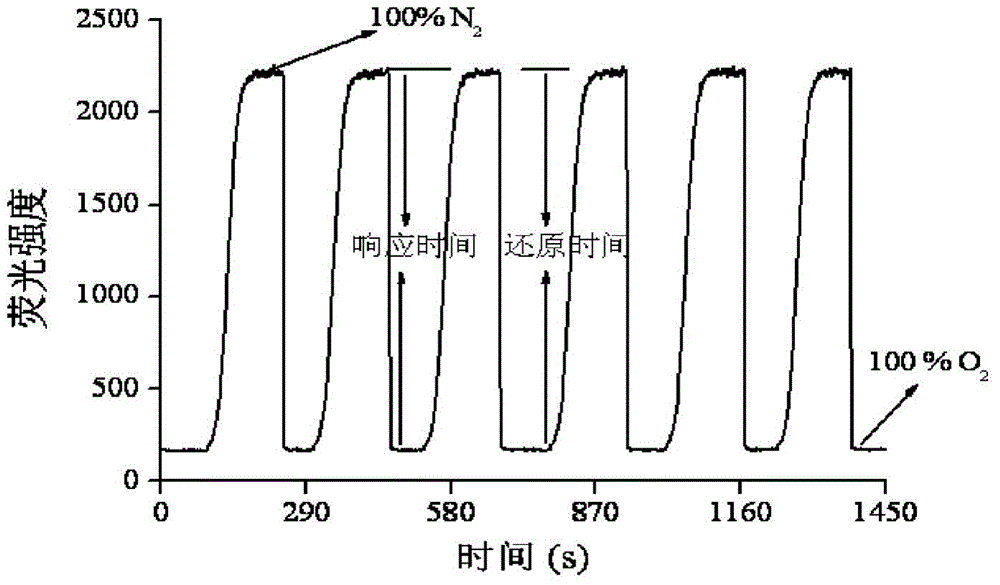

Preparation and application of ratio--type fluorescent oxygen sensing film

ActiveCN105277520ALong excitation lifetimeHigh Luminescence Quantum YieldFluorescence/phosphorescenceFluorescence ratioLength wave

The invention discloses a sol-gel method for fixing two light-emitting substances in a sensing film at the same time, wherein the two light-emitting substances are capable of being excited by fluorescence having save wavelength; PtFTPP is sensitive to oxygen concentration change and can serve as a probe, while a fluorescent brightening agent BBS can serve as a reference substance since the fluorescent brightening agent BBS is not obviously responsive to the oxygen and is light-stable; so that a the ratio type fluorescent oxygen sensing film is constructed. By means of the oxygen sensing film, a fluorescence ratio detection method is employed for detecting oxygen and dissolved oxygen concentration; the sensing film has good sensitivity, accuracy and stability and a quick responsiveness.

Owner:XIAMEN MEDICAL COLLEGE

Preparation method of wool-cashmere anti-bacterial blended knitting yarn

InactiveCN111472076AFully adsorbedIncrease the specific surface area of contactBiochemical fibre treatmentDyeing processYarnFiber

The invention relates to the technical field of wool-cashmere anti-bacterial blended knitting yarns, in particular to a preparation method of a wool-cashmere anti-bacterial blended knitting yarn. Theyarn is produced through carrying out loose fiber dyeing and anti-bacterial finishing on a blended raw material and then utilizing a semi-worsted process, wherein the blended raw material is formed by10 to 15 percent of cashmere and 85 to 90 percent of mercerized wool; in the loose fiber dyeing process, a low temperature dyeing auxiliary LTD and a wool protective auxiliary HTW are added; and anti-bacterial finishing is carried out after accomplishing loose fiber dyeing. The preparation method of the wool-cashmere anti-bacterial blended knitting yarn obtained through the invention has the advantages that main anti-bacterial factors of an anti-bacterial agent are silver ions, the contact specific surface area of the silver ion anti-bacterial components and a fiber can be increased through the method, fibers are fully adsorbed, the surface silver content of a final finished-product fabric can range from 15 to 50ppm, and an anti-bacterial effect and the durability are improved.

Owner:浙江中鼎纺织股份有限公司

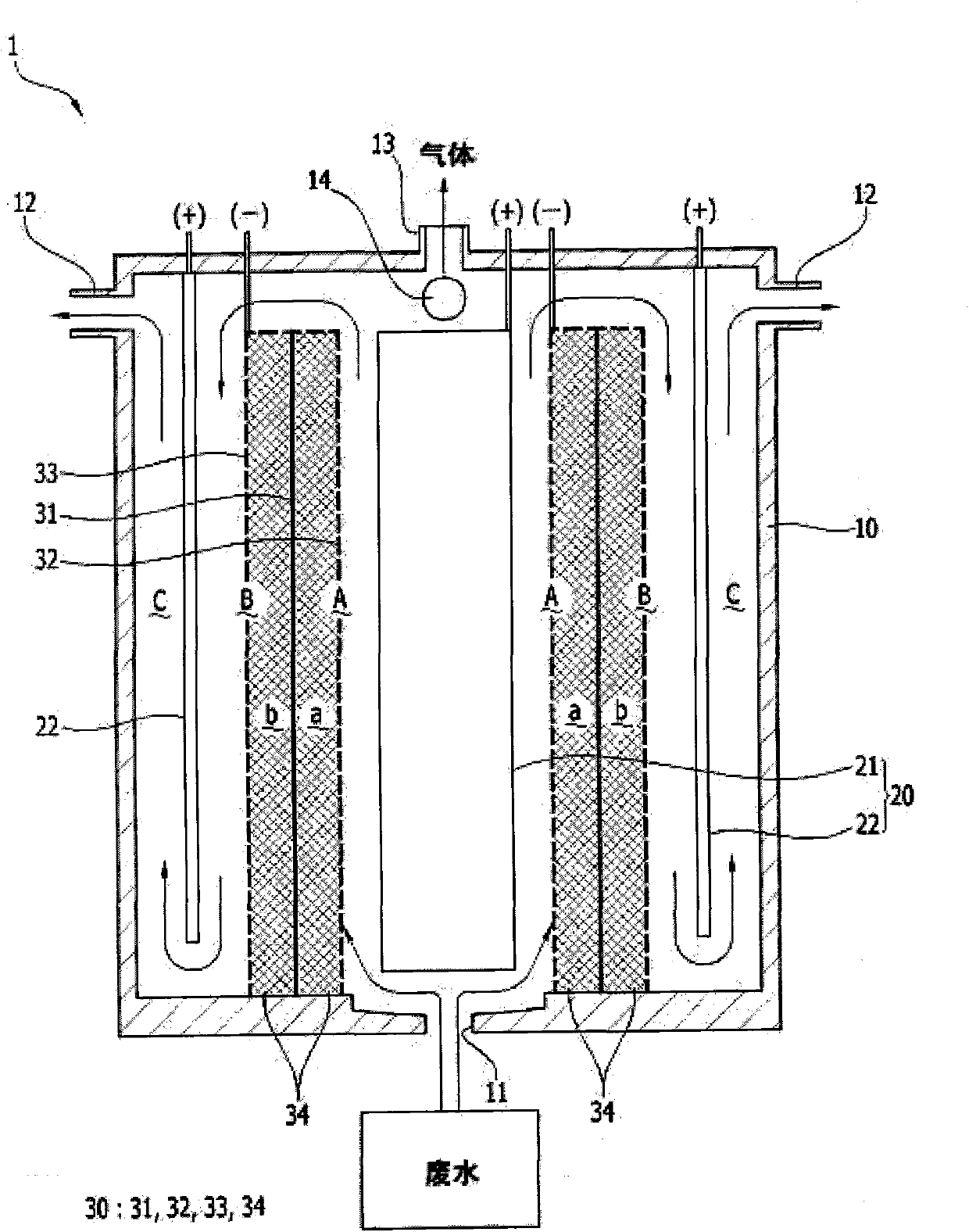

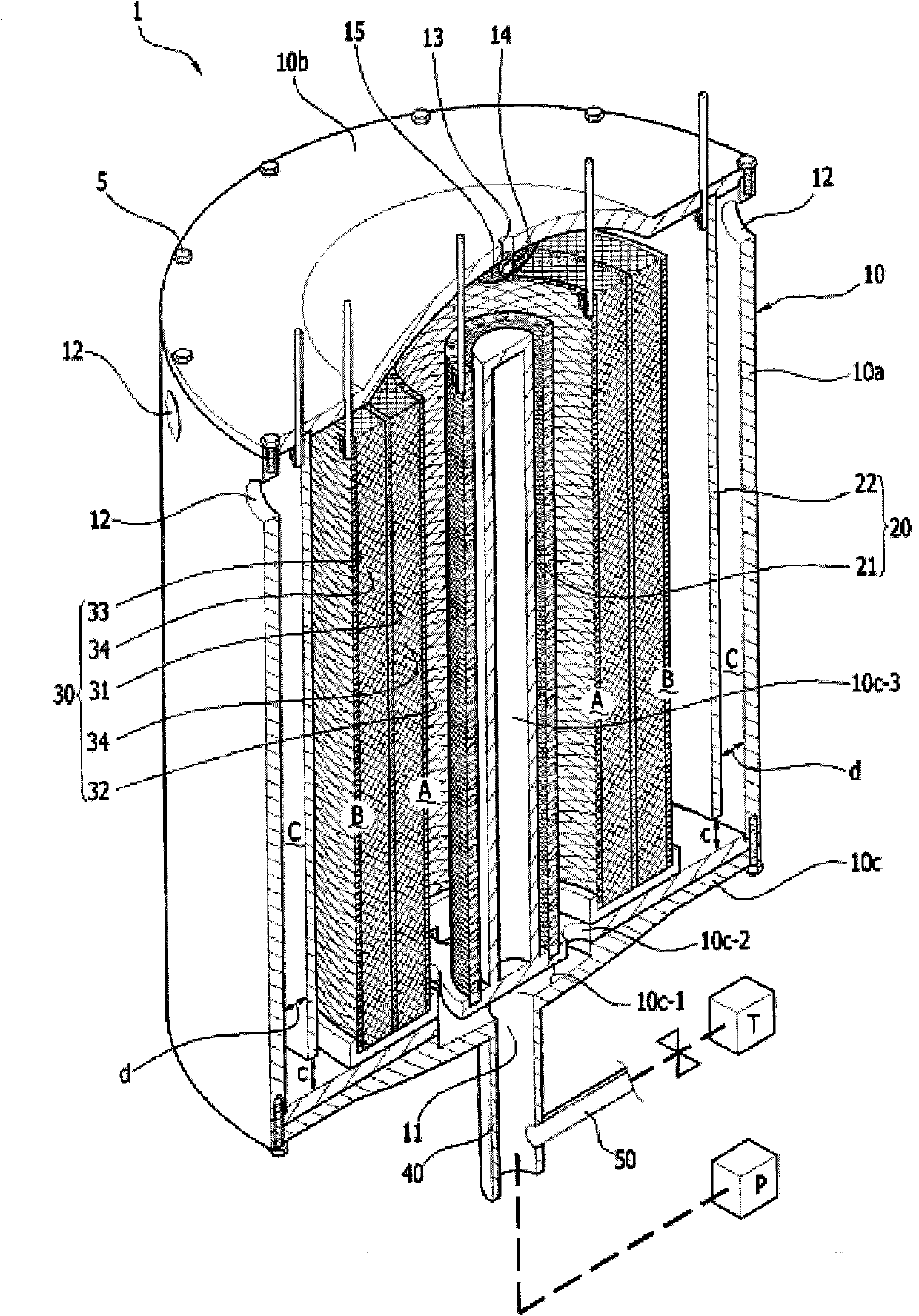

Electrolyzer having increased contact specific surface area for the recovery of valuable metals

InactiveCN102575365AIncrease the specific surface area of contactImprove stabilityCellsProcess efficiency improvementElectricityInterior space

It is an object of the present invention to provide an electrolyzer having increased contact specific surface area for the recovery of valuable metals, wherein the electrolyzer comprises: a housing having a rear end with an inlet port and a front end with an outlet port, and having an internal space with a downwardly inclined bottom; a plurality of anodes arranged within the housing such that each of the anodes divides the internal space of the housing in a widthwise direction; and a plurality of cathode units interposed between the anodes to divide the space between the adjacent anodes into two electrolytic spaces. The wastewater introduced through the inlet port sequentially passes through the plurality of electrolytic spaces such that valuable metals are electro-deposited to the cathode units and recovered. Subsequently, the wastewater is discharged through the outlet port.; The electrolyzer having increased contact specific surface area for the recovery of valuable metals according to the present invention is advantageous in that each of the cathode units has a second cathode, a first cathode, a third cathode, and cathode wires which fill the spaces among the first, third and second cathodes, to increase the contact specific surface area of the wastewater introduced into the electrolyzer so that valuable metals can be easily electro-deposited and recovered even from the wastewater containing a small amount of valuable metals.

Owner:石尚烨

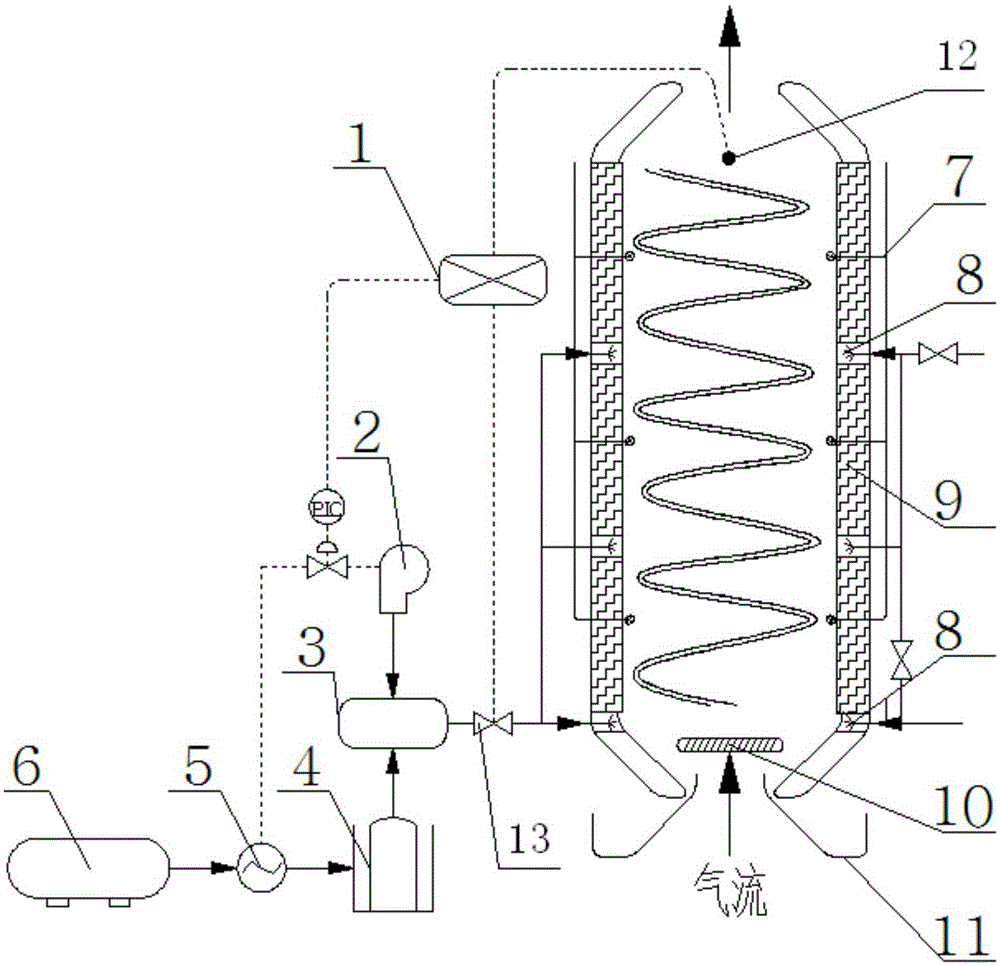

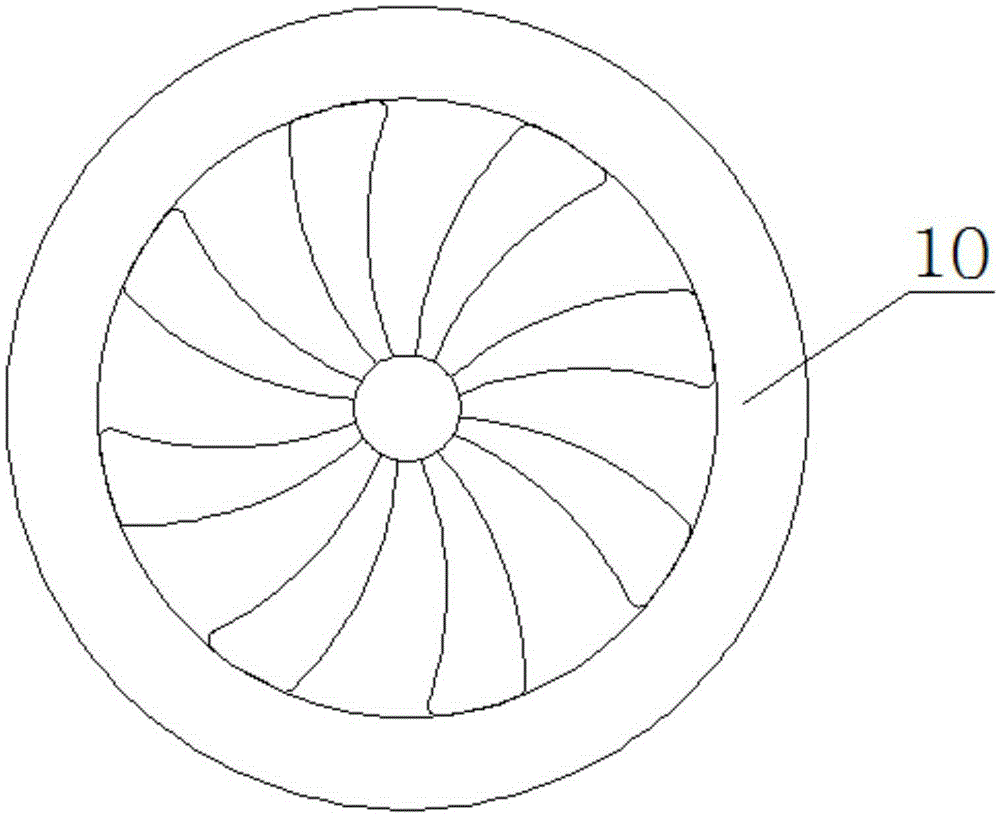

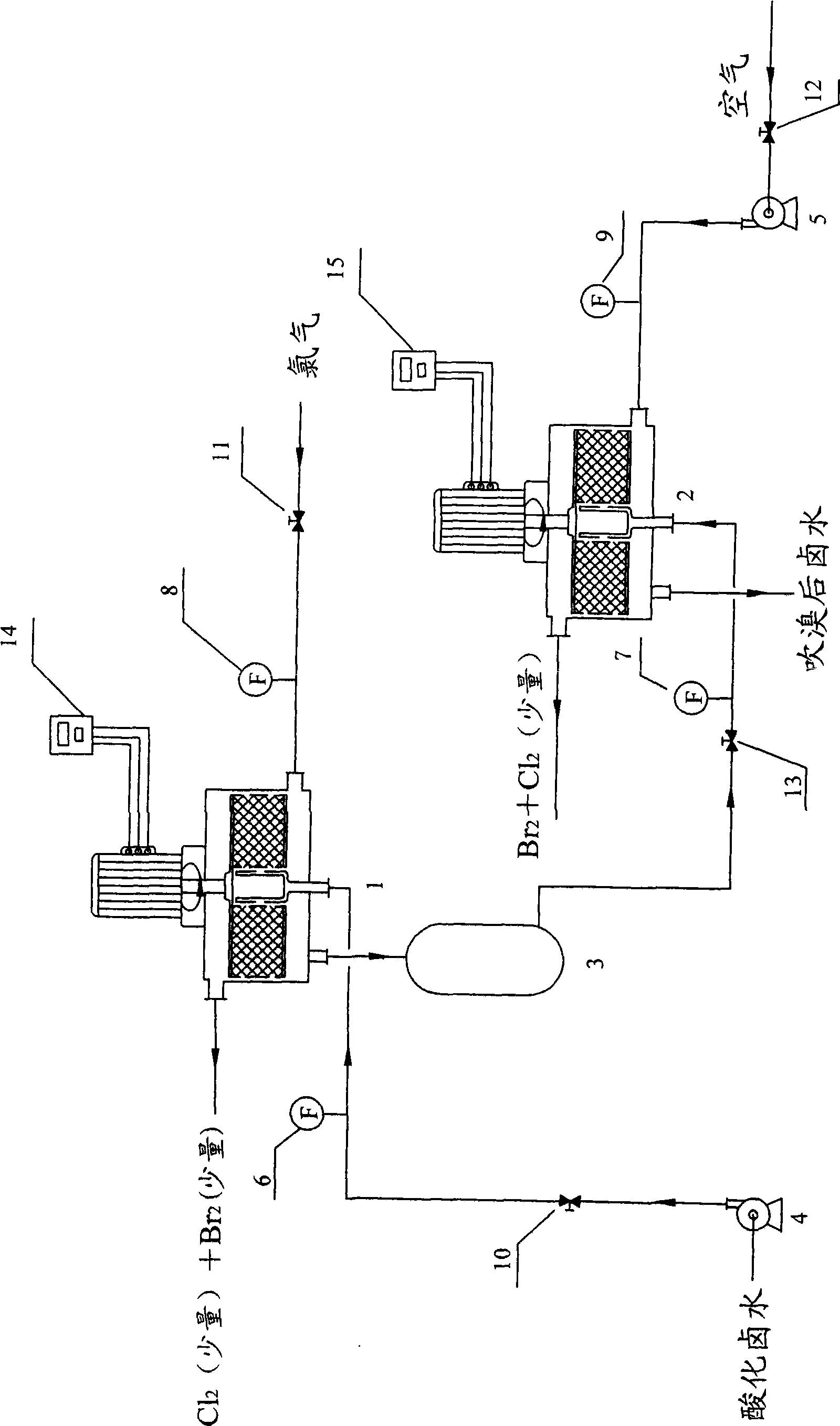

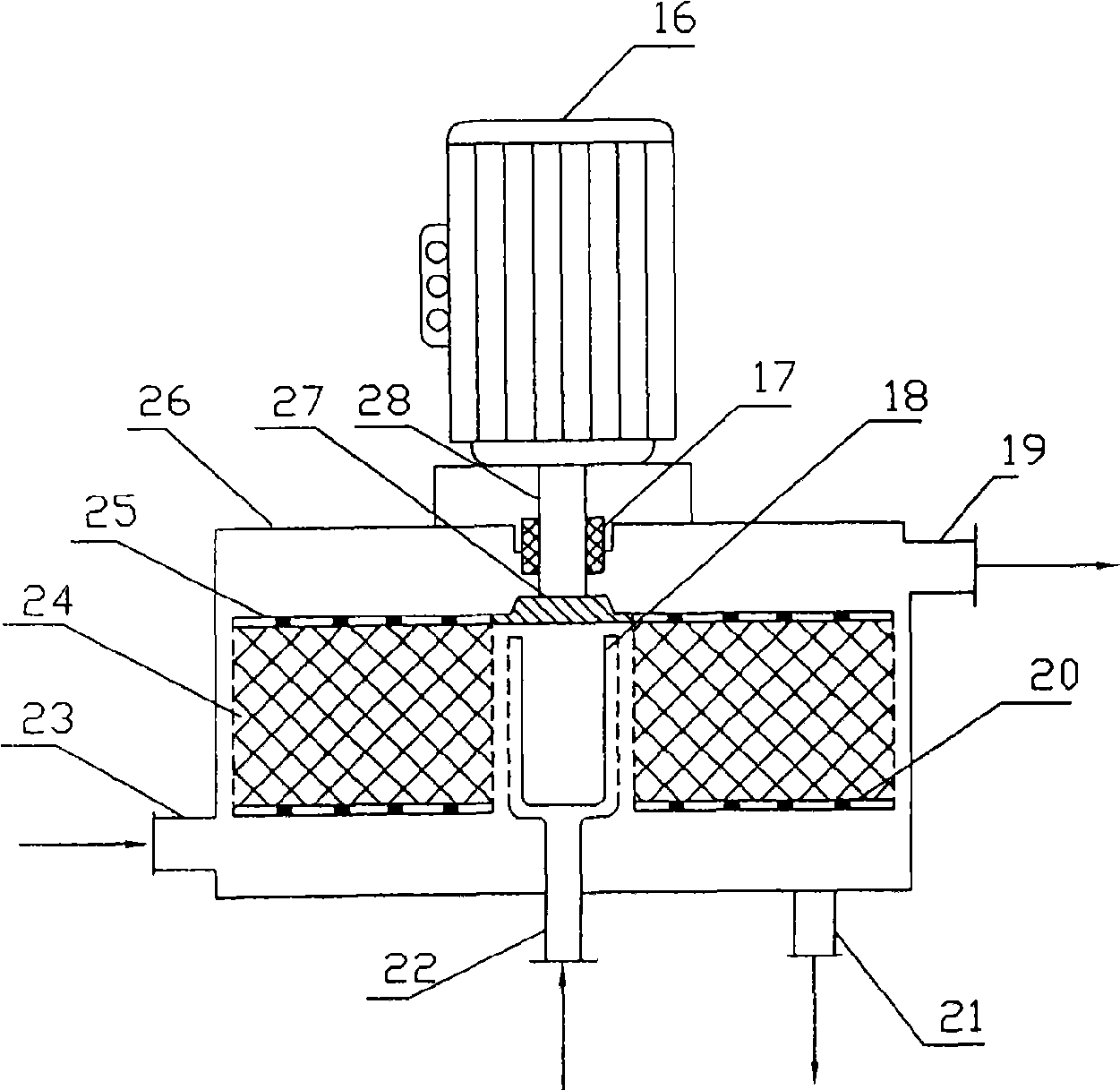

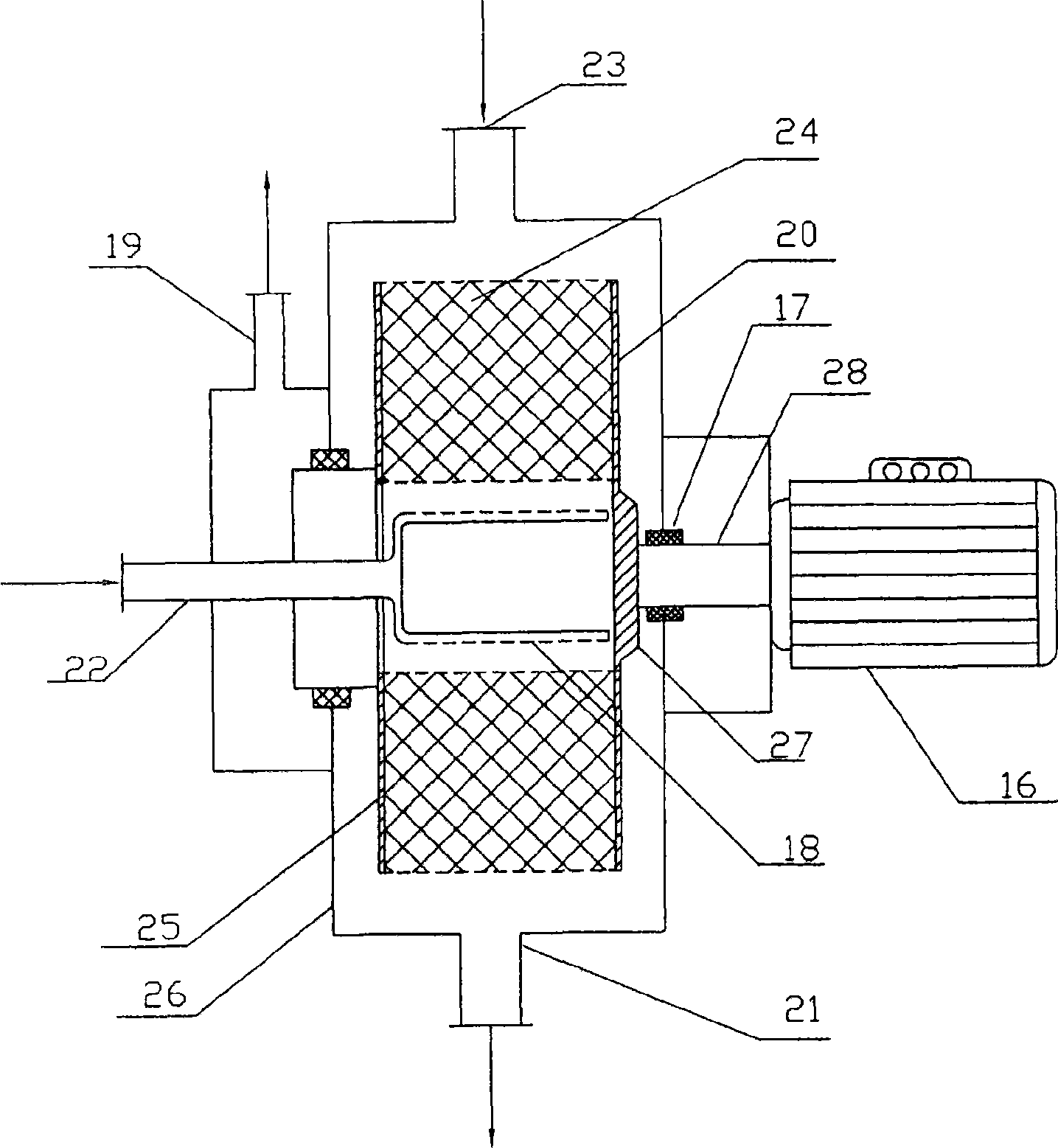

Oxidation and blowout technological process and apparatus for bittern bromine process

ActiveCN101486445AIncrease the specific surface area of contactEnhanced mass transferBromine/hydrogen-bromideLiquid ratioBromine

The invention pertains to the technical field of extraction of bromine from brine, more particularly relates to the technique of oxidation and blow-out during the process of extraction of bromine from brine, and a device thereof, which improve the oxidation rate and blow-out rate of bromine during the extraction process and reduce energy consumption. The method is as follows: acid brine and chlorine are introduced into a rotating packed bed I, and the formed oxidation solution and air enter a rotating packed bed II to blow out free bromine. The device comprises two rotating packed beds, the liquid inlet of the rotating packed bed I is connected with a pump and the gas inlet thereof is connected with a chlorine pipe; the rotating packed bed I and the rotating packed bed II are connected by a storage tank; and the gas inlet of the rotating packed bed II is connected with a fan. The method has the advantages of improving the oxidation rate of bromonium ions, the utilization ratio of chlorine and the blow-out rate of free bromine, and reducing chlorine adding ratio, chlorine consumption amount, the causticity of the device during the process after the extraction of bromine and the process of salt extraction, gas-liquid ratio and operation cost; and the device occupies less land and is easy to be start and shut off and maintained.

Owner:ZHONGBEI UNIV

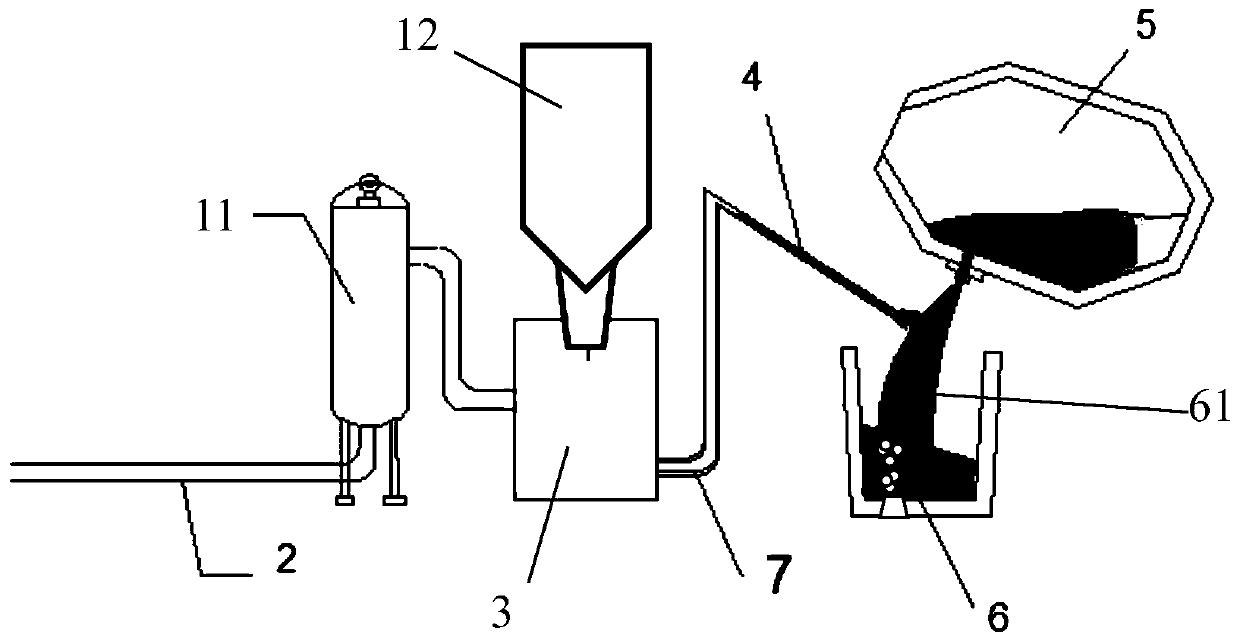

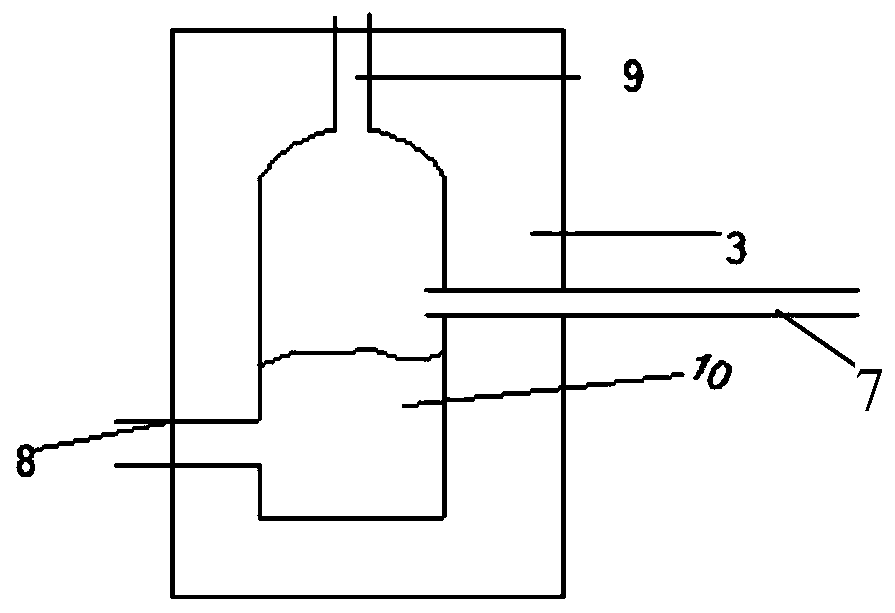

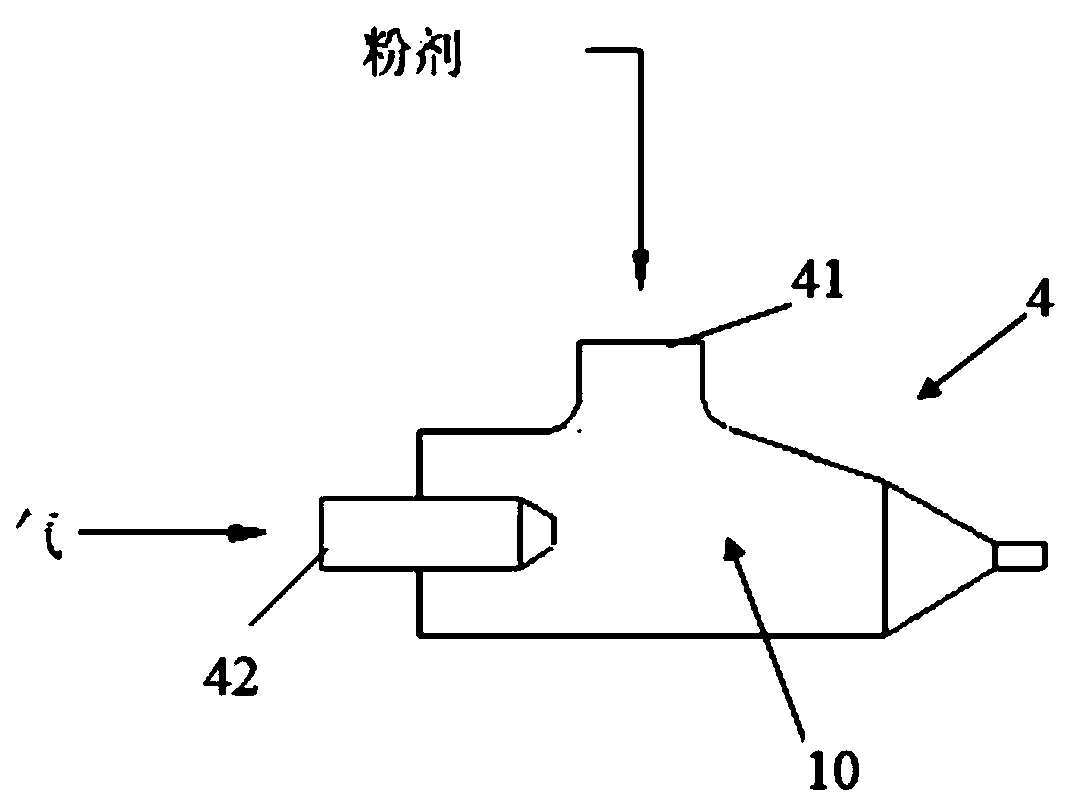

Converter tapping injection refining desulfurization method and device

The invention provides a converter tapping injection refining desulfurization method and device. In the converter tapping process, with Ar (or N2) as powder spraying carrier gas, a spraying gun injects powdery desulfurization agents to molten steel streams in the tapping process, so that the powdery desulfurization agents are fed in a ladle with the molten steel streams; and the full mixing is realized under the effect of bottom blowing argon stirring of the ladle, so that the contact specific surface area of the powdery desulfurization agents and molten steel is increased, the inter-phase mass transfer speed and the molten steel desulfurization reaction speed are accelerated, the effective utilization efficiency of the powdery desulfurization agents is improved, the desulfurization refining production takt is accelerated, and the continuous stable efficient refining is realized. The defects in a traditional desulfurization process can be overcome; and the quick and efficient smeltingcan be realized. The powdery desulfurization agents can be replaced by carbon powder, desulfurization powder agents, desulfurization powder agents or alloy powder agents; and the multifunctional refining can be realized. The device and the method are not only suitable for molten steel desulfurization refining processes, but also suitable for other refining processes.

Owner:NORTHEASTERN UNIV

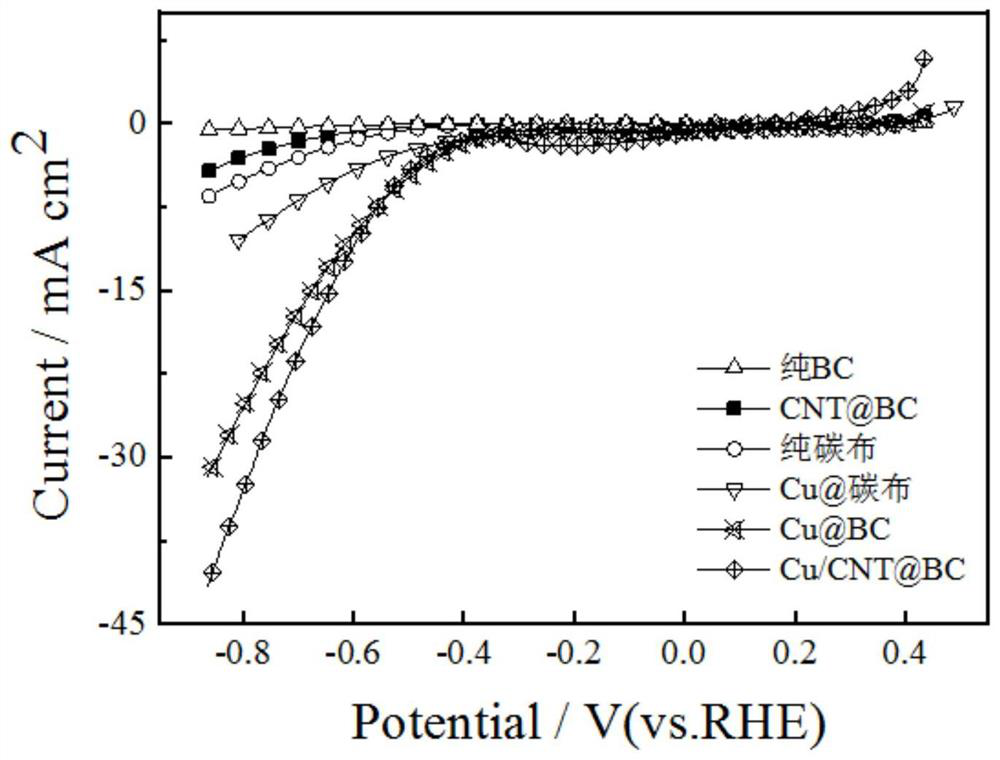

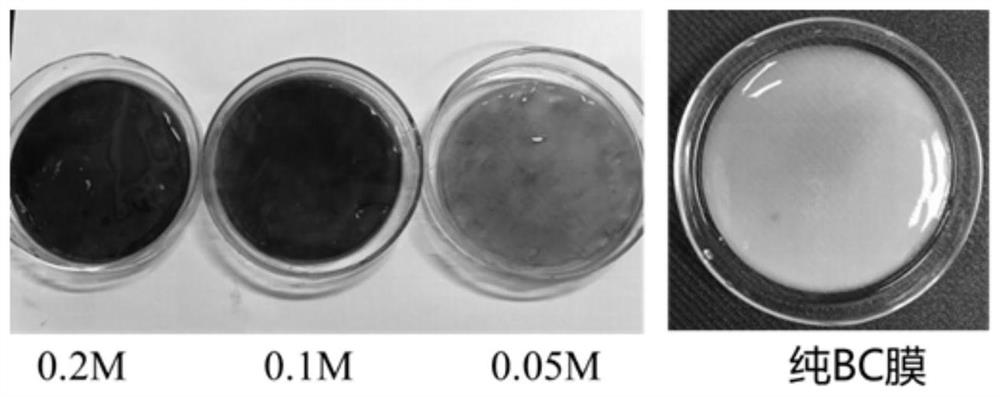

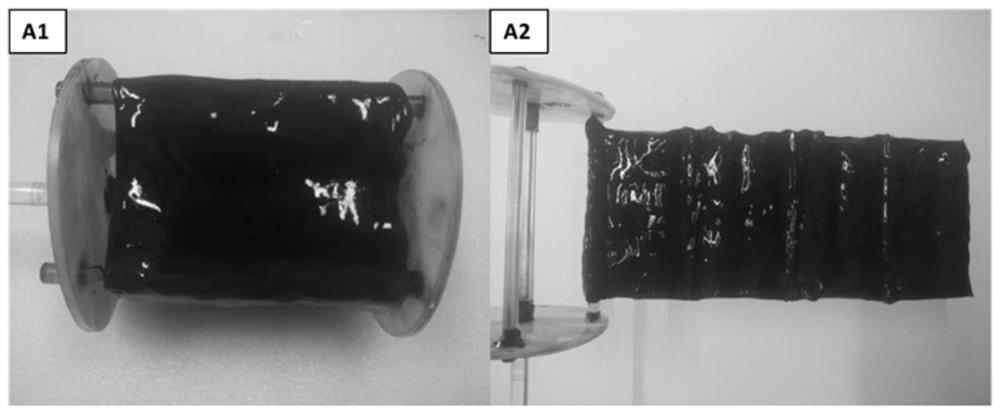

Copper/silver-based electrode taking conductive bacterial cellulose composite film as substrate

ActiveCN112194818AReduce the occurrence of hydrogen evolution reactionLower overpotentialCell electrodesOrganic-compounds/hydrides/coordination-complexes catalystsChemistryPhoto catalysis

The invention relates to a copper / silver-based electrode taking a conductive bacterial cellulose composite film as a substrate, and the electrode is obtained by taking the composite film as the substrate and carrying out Cu / Ag ion in-situ chemical reduction, catalytic reduction or hydrothermal synthesis. Compared with a traditional electrode taking carbon cloth as a substrate, the catalytic electrode prepared by the invention has higher catalytic efficiency and longer electrode service life due to a three-dimensional nanofiber network structure, a high specific surface area and high conductivity. The preparation method is environmentally friendly, simple in process and short in preparation time. The electrode has good application prospects in the fields of carbon dioxide electrocatalytic reduction, fuel cells, photocatalysis, biocatalysis and the like, and has important significance in environmental protection, energy cyclic utilization and the like.

Owner:DONGHUA UNIV

Supergravity SCR denitrification device and denitrification technology thereof

ActiveCN108479380AIncrease the specific surface area of contactReduce contact timeGas treatmentDispersed particle separationCentrifugal pumpUrea

The invention belongs to the technical field of SCR denitrification, solves the problems that potential safety hazards exist in the liquid ammonia gasification process in the SCR denitrification technology, the operating cost of the urea pyrolysis technology is relatively high and a dilution fan is needed for diluting ammonia concentration and is large in energy consumption, and provides a supergravity SCR denitrification device and a denitrification technology thereof, so that the ammonia producing concentration reaches the ammonia required concentration of the SCR denitration technology, andthe ammonia producing concentration realizes precision numerical control. A gas inlet is communicated with a blast blower, a gas outlet is connected with an SCR reactor through an ammonia spraying grating, a liquid inlet is communicated with an ammonia water raw material tank through a centrifugal pump, a liquid outlet is connected to a waste liquid tank, a frequency changer is arranged on the motor of a supergravity rotating filler bed, and an ammonia concentration detector, a liquid flow sensor, a gas flow sensor, the frequency changer and a nitric oxide concentration detector are connectedto a control system. The problems such as the dangerousness of the liquid nitrogen gasification process and high operating cost of the urea pyrolysis technology are solved; the ammonia escape rate isreduced, so that secondary pollution on the environment caused by extremely high ammonia escape rate is avoided.

Owner:ZHONGBEI UNIV

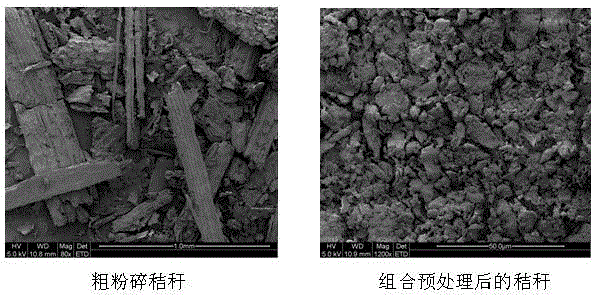

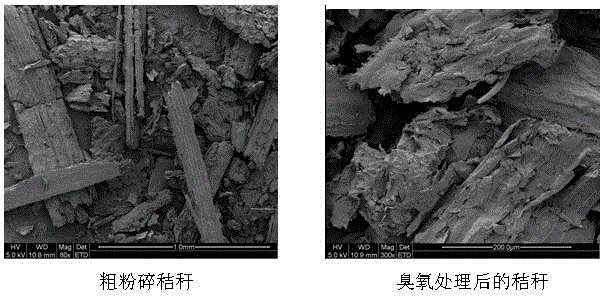

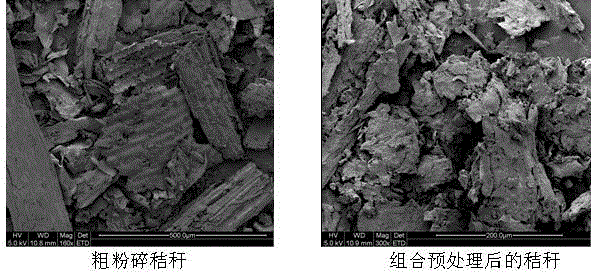

Efficient combined preprocessing method for straws

ActiveCN104131050APromote digestionMild treatment conditionsFermentationPretreatment methodCellulase

An efficient combined preprocessing method for straws employs an ozone processing method combined with a ball milling method to perform efficient combined pretreatment on straws, and concretely comprises two parts: (1) firstly performing ozone pretreatment on crushed straws, and then performing ball milling pretreatment; and (2) firstly performing ball milling pretreatment on crushed straws and then performing ozone pretreatment. After straws are subjected to combined pretreatment, water-washing acid removal and compound cellulase enzymolysis, the glycation rate is substantially improved.

Owner:JIANGNAN UNIV

Fresh ginger juice production device

InactiveCN110226759AEfficient killingImprove cleanlinessJuice extractionFood treatmentEngineeringImpurity

The present invention relates to a fresh ginger juice production device. The fresh ginger juice production device comprises a loading system, a water washing system, an air drying system, a material pouring system, a material cutting system, a screening system, two material loading systems, a material crushing system and a juice squeezing system. Fresh gingers are subjected to high-temperature cooking and soaking in the water washing system, so that dust, residues and other materials on surfaces of the fresh gingers are washed away together, at the same time, various harmful micro-organisms carried on the surfaces of the fresh gingers are effectively killed in a large amount, at the same time, during a drying process, taken-away water takes fine residues and impurities away together, and finally, a shaking work of the drying system ensures that the whole fresh gingers are clean and free of impurities. The fresh gingers are successively treated by the material cutting system, screeningsystem and material crushing system into fresh ginger blocks of a same uniform size range and a small size, which maximally increases a contact specific surface area of the fresh ginger raw material,at the same time also enables the fresh ginger raw material not to produce unnecessary deterioration due to excessive processing to affect subsequent products.

Owner:王兴翠

Direct steel making alloying metal oxide core-spun yarn and manufacturing method thereof

The invention discloses a direct steel making alloying metal oxide core-spun yarn and a manufacturing method thereof, and belongs to the technical field of direct steel making alloying process. In the core-spun yarn, core powder thereof mainly adopts metal salt particles, with high stability, formed by performing high-temperature calcining for balls; and the balls are dryly pressed by metal oxides and alkaline earth metal carbonate. The manufacturing method of the core-spun yarn comprises the following steps: heavy metal oxides and alkaline earth metal carbonate are respectively crushed to proper particle sizes; then, a bonding agent is added for mixing to form balls for calcining; metal salt obtained through calcining is crushed, screened and classified; and after the obtained metal salt particles are uniformly mixed with a reducing agent according to a mass ratio, a core-spun yarn cover is used for coating to obtain the core-spun yarn. The core-spun yarn, manufactured by the method, alloys molten steel, so that the yield of the steel can be prominently improved, and the stability of the yield is guaranteed.

Owner:MAANSHAN XINGDA METALLURGICAL NEW MATERIAL

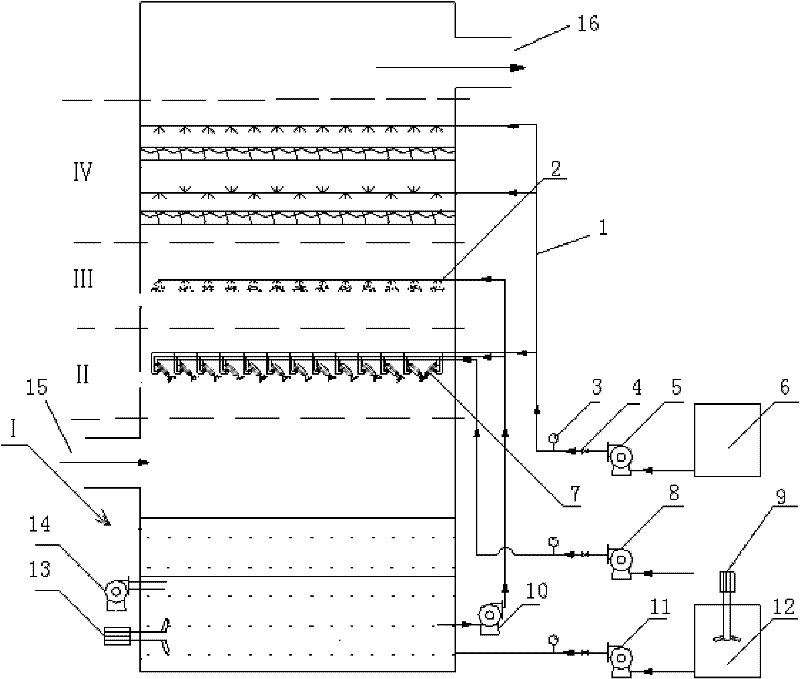

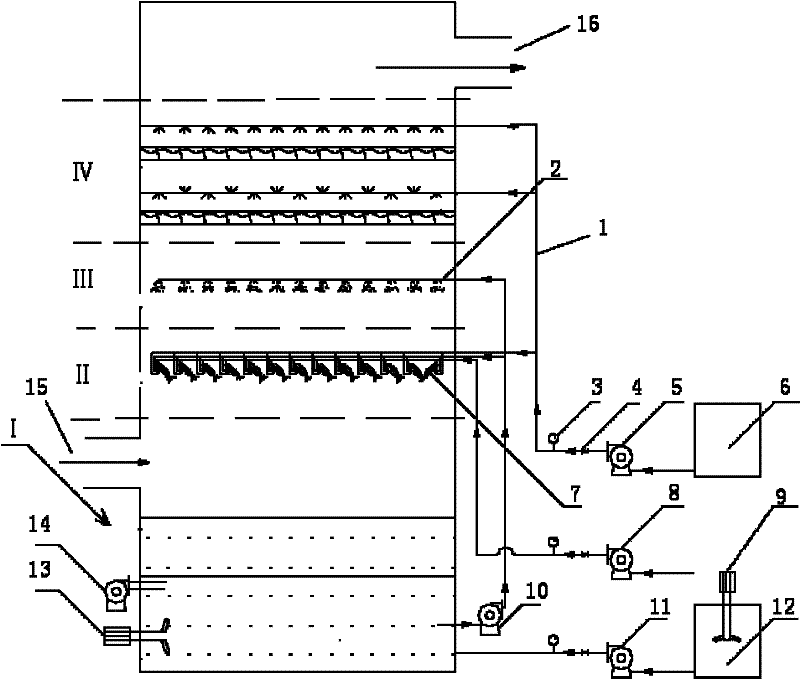

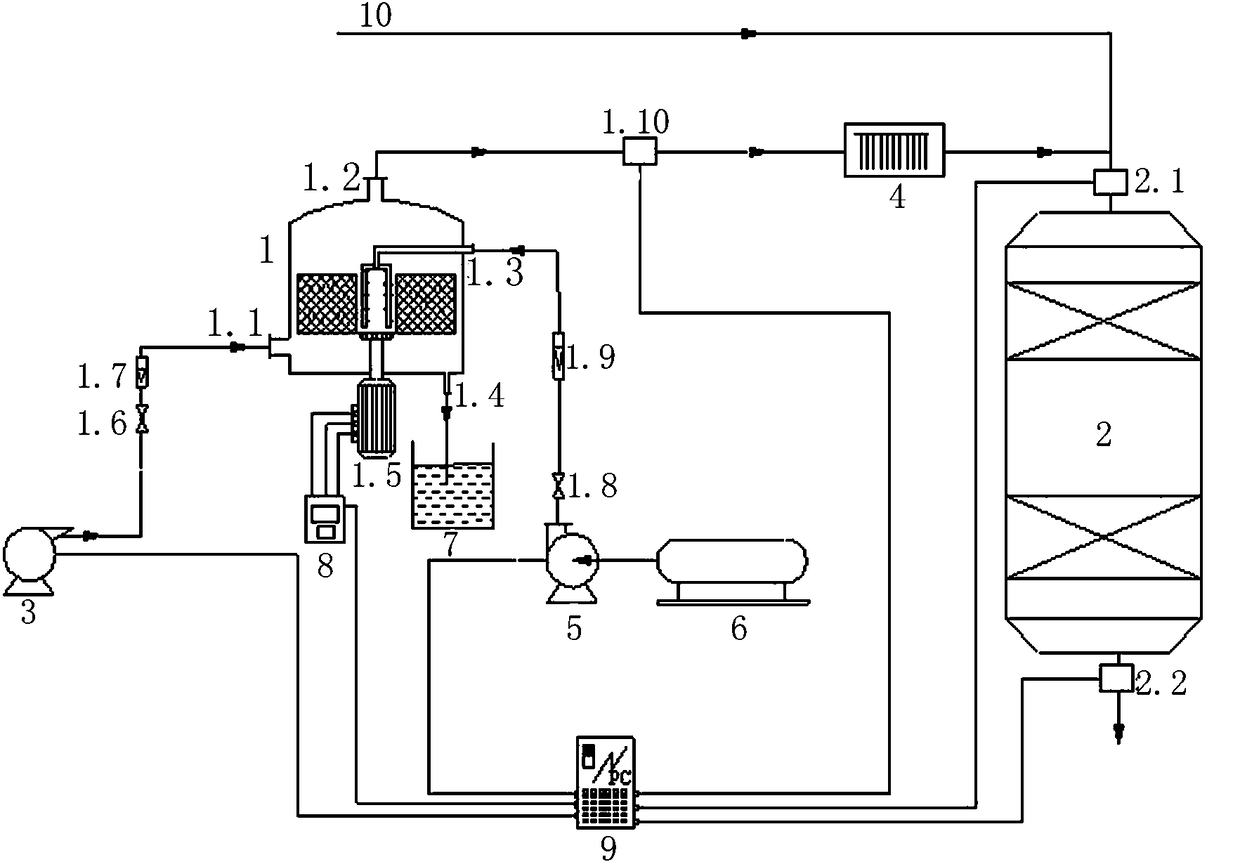

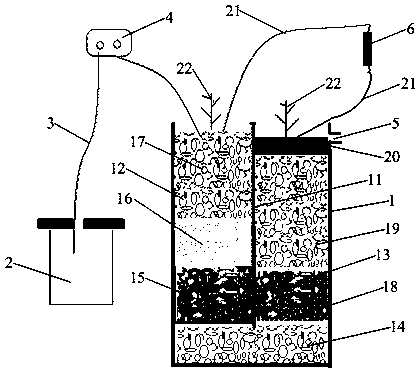

Artificial wetland and microbial fuel battery wastewater treatment coupling device

ActiveCN108033567ARich abilityStable strain activityTreatment by combined electrochemical biological processesTreatment with aerobic and anaerobic processesMicrobial fuel cellPeristaltic pump

The invention provides an artificial wetland and microbial fuel battery wastewater treatment coupling device including a double-chamber cuboid board box, a water distribution tank, a water feeding pipe, and a water feeding peristaltic pump, wherein the water distribution tank, the water feeding pipe, the water feeding peristaltic pump and the double-chamber cuboid board box are successively connected. A separation board is arranged in the center of the double-chamber cuboid board box to divide the box into an anode chamber and a cathode chamber, which are communicated with each other at the bottom of the double-chamber cuboid board box. A gravel communicating layer is arranged on the bottom of the double-chamber cuboid board box. An anode downward active carbon filler layer, an anode middle conductive filler layer and an anode surface packing layer are successively arranged in the anode chamber from bottom to top, and a cathode upward active carbon filler layer, a cathode upward gravelfiller layer and a cathode top packing conductive layer are successively arranged in the cathode chamber from bottom to top. The artificial wetland and microbial fuel battery wastewater treatment coupling device has simple structure and is convenient to use.

Owner:JIANGXI SCI & TECH NORMAL UNIV

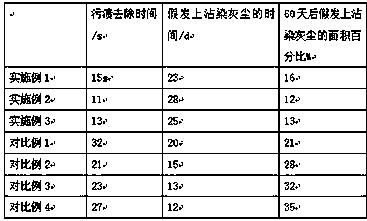

Preparation method of easy-to-clean hydrophilic and anti-fouling wig

ActiveCN110331590AEasy to removeImprove hydrophilicityStain/soil resistant fibresWigsFiberHydrotalcite

The invention discloses a preparation method of an easy-to-clean hydrophilic and anti-fouling wig. The preparation method specifically comprises the following steps: 1), sulfonation modification of polyether sulfone; 2), modification of polyether sulfone with polydopamine; 3) graft modification of N,N'- dimethylethylenediamine; 4) preparation of a modified polyether sulfone hybrid base film on thesurface of wig fiber. The easy-to-clean hydrophilic and anti-fouling wig is characterized in that the modified polyether sulfone / hydrotalcite-like hybrid base film is formed on the surface of the wigfiber, so that hydrophilicity of the wig and smoothness of the surface are improved, interception and aggregation of pollutants on the surface of the wig are reduced, anti-fouling performance of thewig is improved, and the wig has broad popularization and application prospects.

Owner:龙山冠美美发用品有限公司

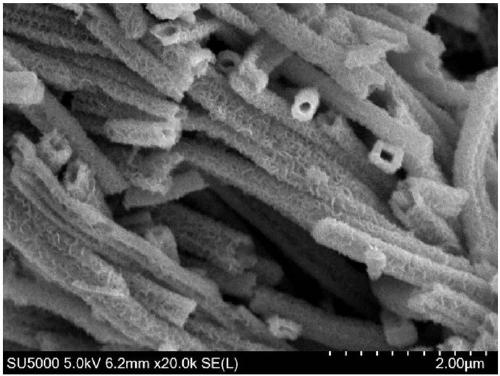

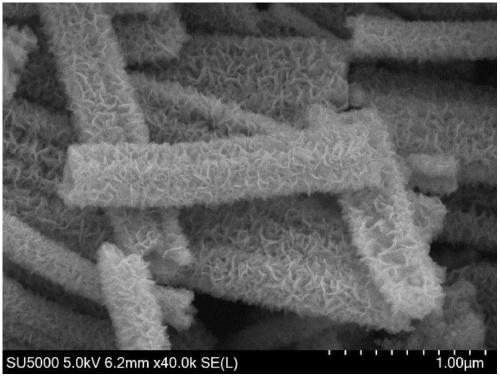

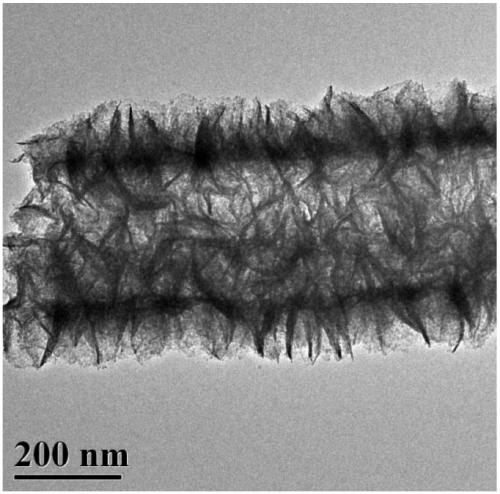

Catalyst for carbon dioxide reduction through electrocatalysis and preparation method thereof

InactiveCN110280294AIncrease the specific surface area of contactImprove Faraday efficiencyPhysical/chemical process catalystsChemical industryNanofiberIron sulfide

The invention belongs to the technical field of carbon dioxide reduction through electrocatalysis, and particularly relates to a catalyst for carbon dioxide reduction through electrocatalysis and a preparation method thereof. The catalyst is nitrogen-doped carbon nanofiber composite iron sulfide particles. The catalyst has high electrocatalytic activity and selectivity on the carbon dioxide reduction, in particular, can significantly improve the energy efficiency for carbon dioxide utilization; in addition, the preparation method of the catalyst has the advantages of simple operation, environmental friendliness, high yield, and broad application prospects.

Owner:INT ACAD OF OPTOELECTRONICS AT ZHAOQING SOUTH CHINA NORMAL UNIV

Method for preparing ethylene carbonate by using CO gas phase method

InactiveCN102649758AHigh selectivityMild reaction conditionsOrganic compound preparationCarbonic/haloformic acid esters preparationMethyl carbonateGas phase

The invention relates to a method for preparing ethylene carbonate by using a CO gas phase method and mainly solves the technical problems of low nitric oxide or ethylene carbonate utilization rate and low selectivity existing in the prior art. With the adoption of the technical scheme that the method for preparing the ethylene carbonate by using the CO gas phase method comprises the following steps that: a), the ethylene carbonate, water, methanol and sulfuric acid or nitric acid firstly enter a reactor I, and an effluent II containing methyl nitrite is obtained after a generated effluent is separated; and b), the effluent II and CO gas enter a coupling reactor, a generated NO-contained effluent IV is reacted with the methanol and oxygen in a reactor II, and an effluent VI containing the methyl nitrite obtained after the generated effluent is separated flows back and is continuously reacted with the effluent II and the CO gas in the coupling reactor, wherein the reactor I and the reactor II are rotary super-gravity reactors, so the problems are better solved. The method can be used in the industrial production for preparing the ethylene carbonate by using the CO gas phase method.

Owner:CHINA PETROLEUM & CHEM CORP +1

Stainless steel acid pickling sludge briquette, as well as preparation method and application thereof

The invention discloses a stainless steel acid pickling sludge briquette, as well as a preparation method and application thereof. The stainless steel acid pickling sludge briquette is characterized by being prepared from the components in parts by weight: 70 to 80 parts of stainless steel acid pickling sludge, 20 to 30 parts of framework material, and 2 to 5 parts of compound cellulose type binding agent; the water content of the briquette is less than or equal to 5 percent; and the breaking strength is larger than or equal to 100 kgf. The preparation method comprises the following steps of filter pressing, drying, preparing of the briquette, drying and screening. The stainless steel acid pickling sludge briquette is used as an auxiliary material so as to be applied to top-blown stirringand desulfurizing, auxiliary materials such as the stainless steel acid pickling sludge briquette and lime are stirred in a steel ladle by utilizing top blowing, a white slag with favorable fluidity and reducibility is used for desulfurizing, and low S steel water for smelting high-quality steel is provided for refining furnace argon oxygen decarburization (AOD) after slagging off. The stainless steel acid pickling sludge briquette, as well as the preparation method and the application thereof provided by the invention have the advantages that the stainless steel acid pickling sludge briquetteis high in strength, alloy components in the stainless steel sludge are effectively utilized, and the harm of the sludge on the application field is reduced.

Owner:ZHANGJIAGANG POHANG STAINLESS STEEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com