Patents

Literature

168 results about "Liquid bubble" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A bubble is a globule of one substance in another, usually gas in a liquid. Due to the Marangoni effect, bubbles may remain intact when they reach the surface of the immersive substance.

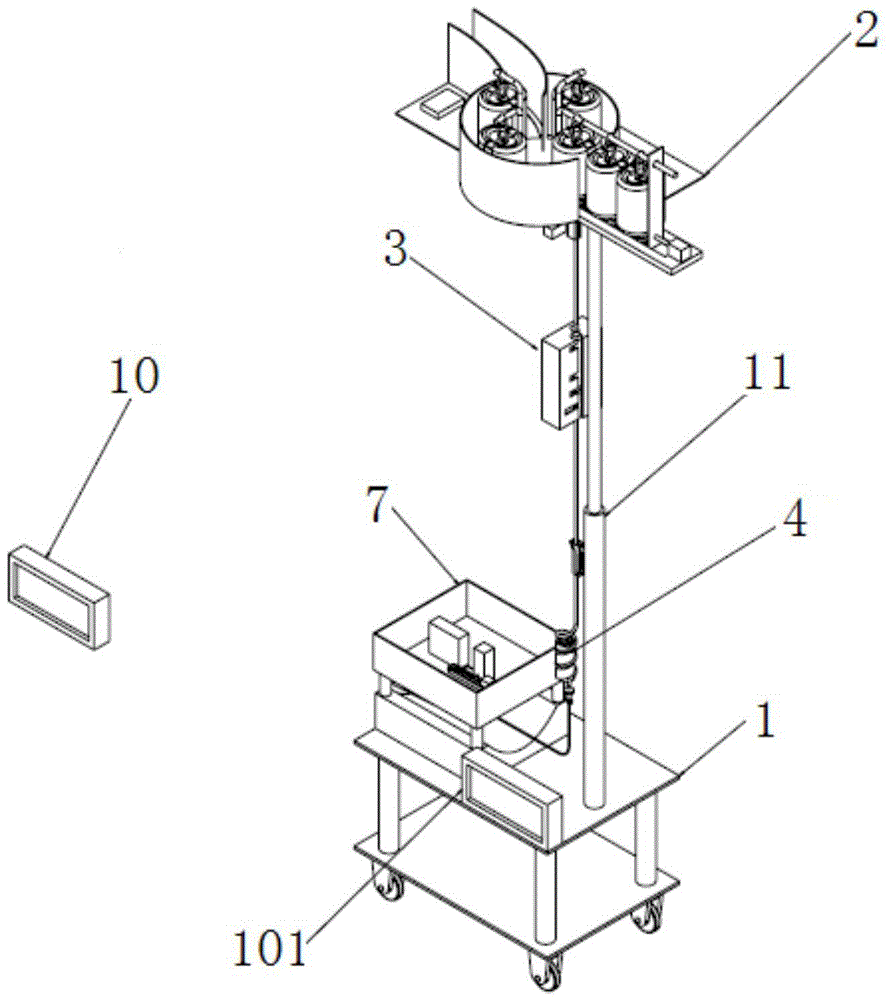

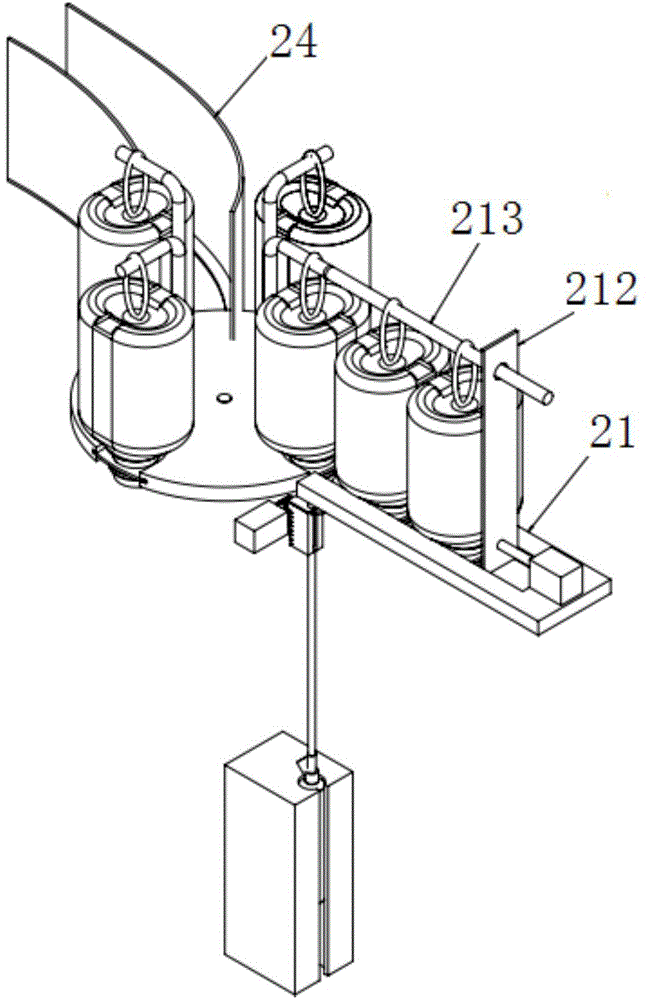

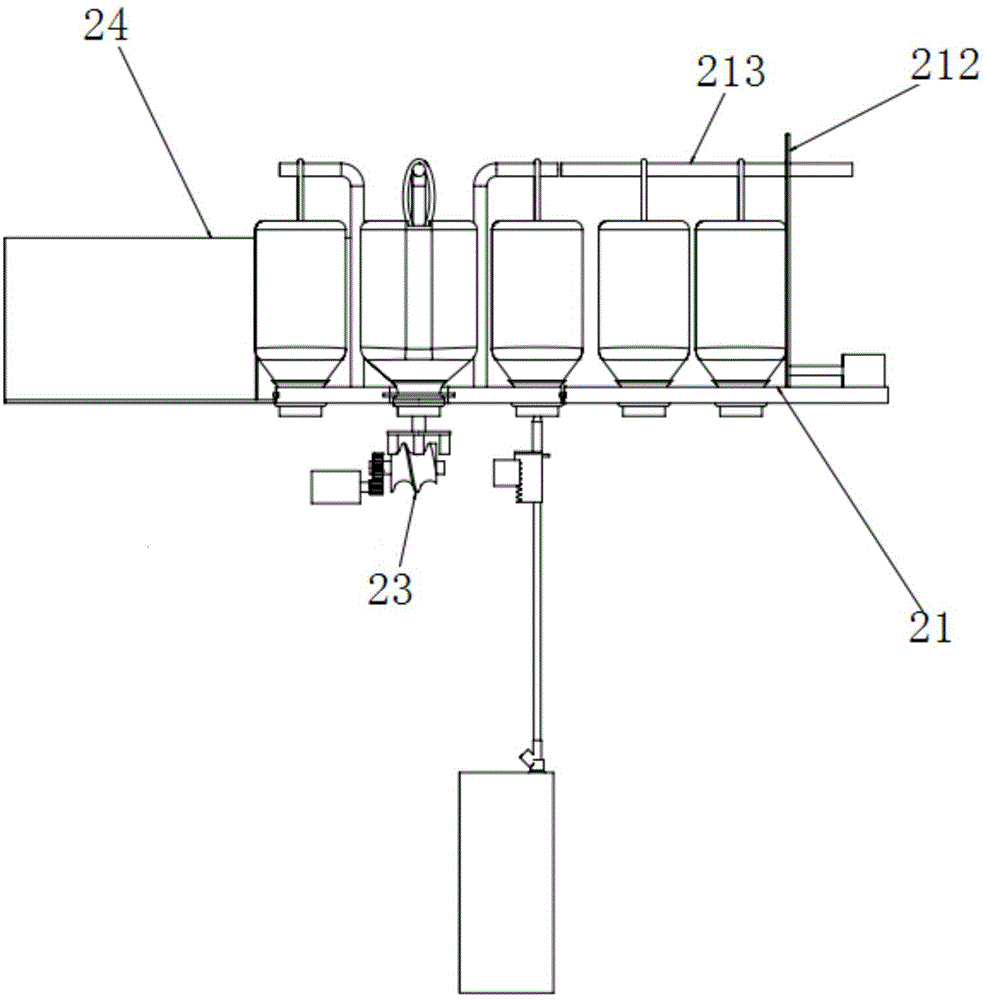

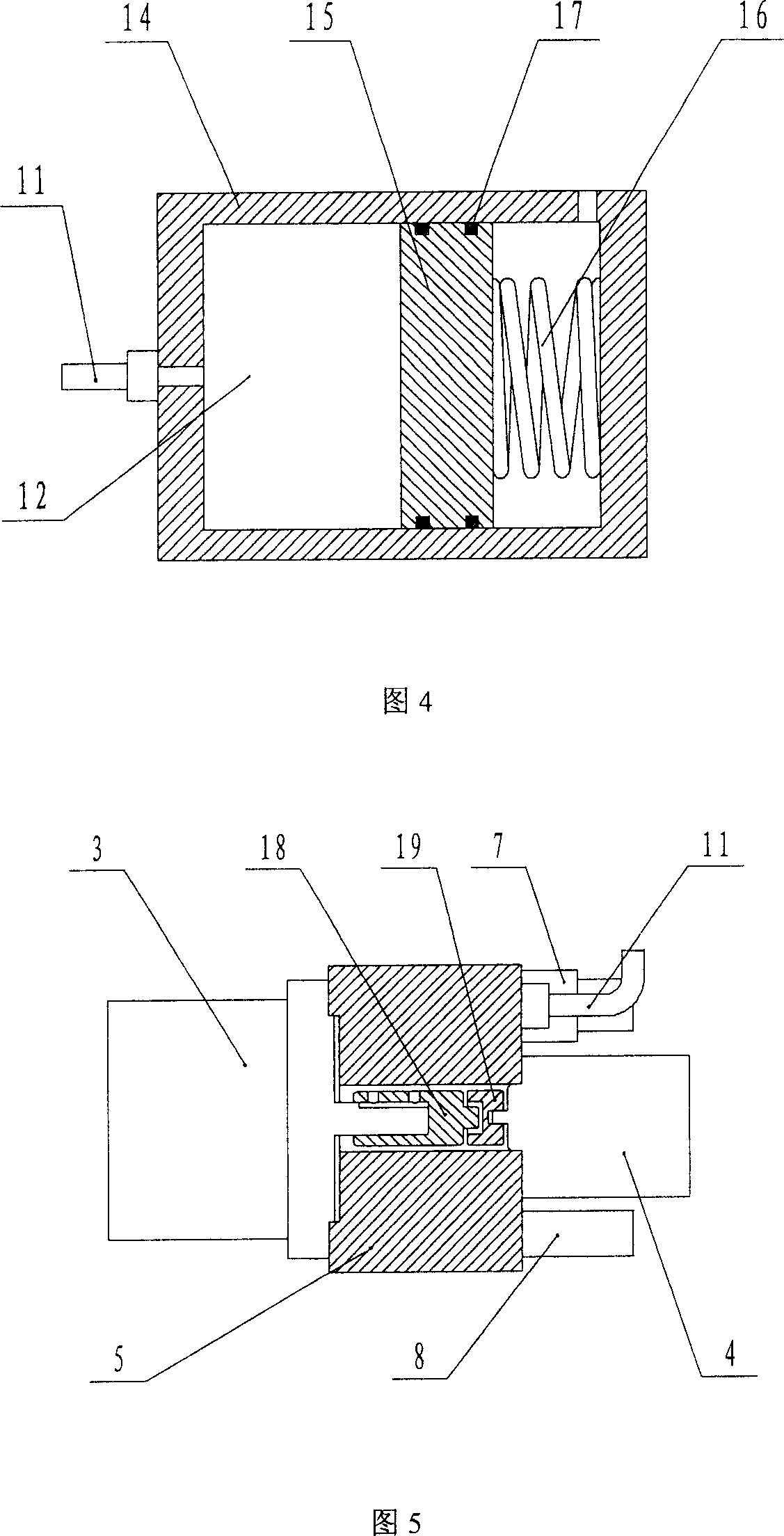

Intelligent infusion device

ActiveCN104784771AMonitor drop rateRealize automatic integrationFlow monitorsLiquid temperatureAutomatic control

The invention discloses an intelligent infusion device. The intelligent infusion device comprises an infusion bottle control mechanism, a puncture outfit mechanical arm mechanism, an infusion liquid dynamic monitoring mechanism, an infusion liquid temperature control mechanism, an automatic needle plugging and unplugging mechanism, a central control station and a central control unit. The central control unit corresponds to the puncture outfit mechanical arm mechanism, the liquid dynamic monitoring mechanism, the liquid temperature control mechanism and the automatic needle plugging and unplugging mechanism. The intelligent infusion device has the advantage that automatic integration in the infusion process can be achieved, which is concretely embodied in that an infusion bottle can be automatically changed; infusion dripping speed, flowing speed and liquid bubbles are monitored, the infusion dripping speed and flowing speed are controlled, and the bubbles are eliminated in time; in the infusion process, an infusion tube is heated, and heating temperature is automatically controlled; through control of mechanical arms, automatic needle plugging and unplugging are achieved; the central receiver controls controllers of all units, so that control over all stages in the infusion process is achieved.

Owner:深圳文健医疗科技有限公司

Method for cleaning hollow tubing and fibers

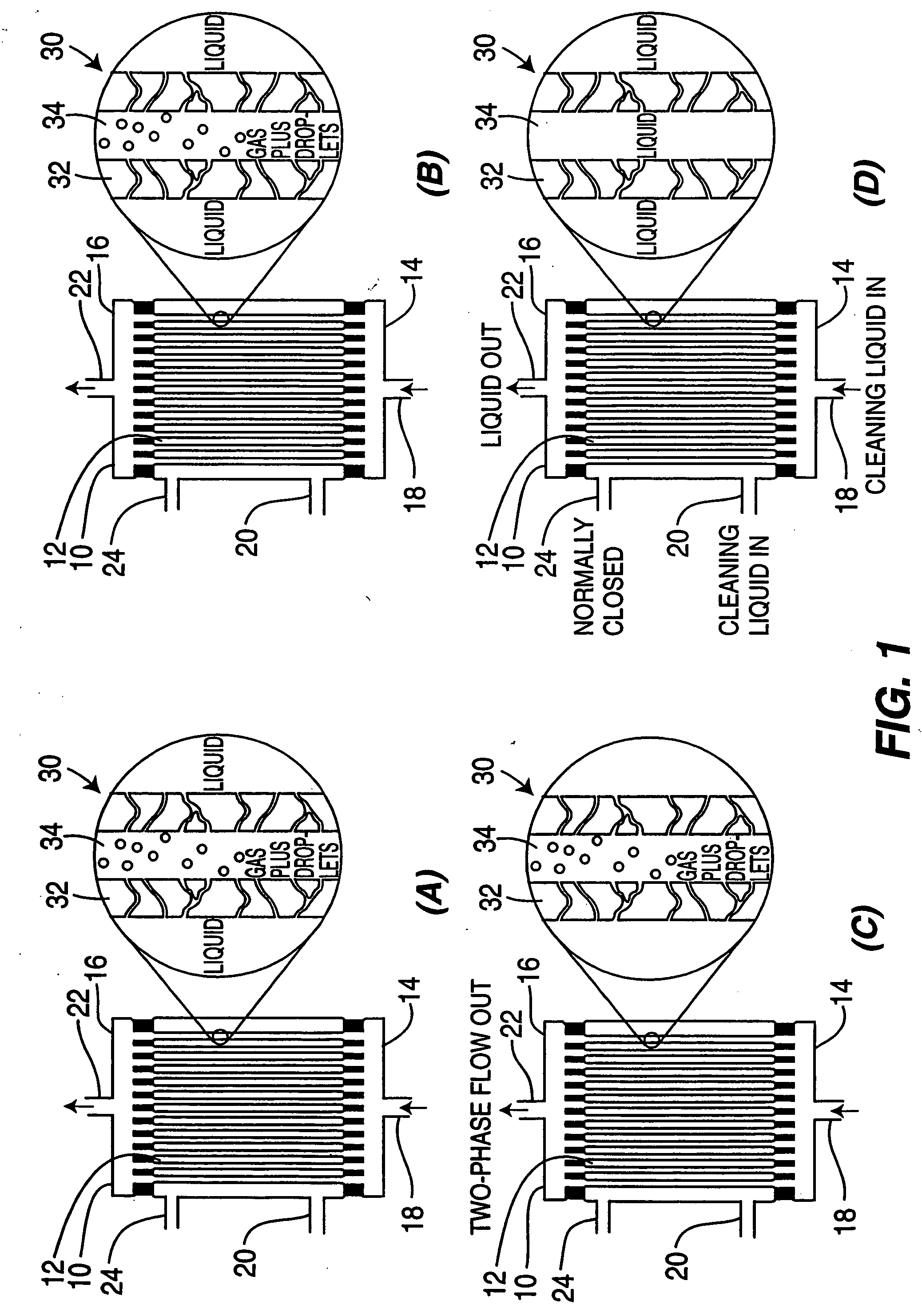

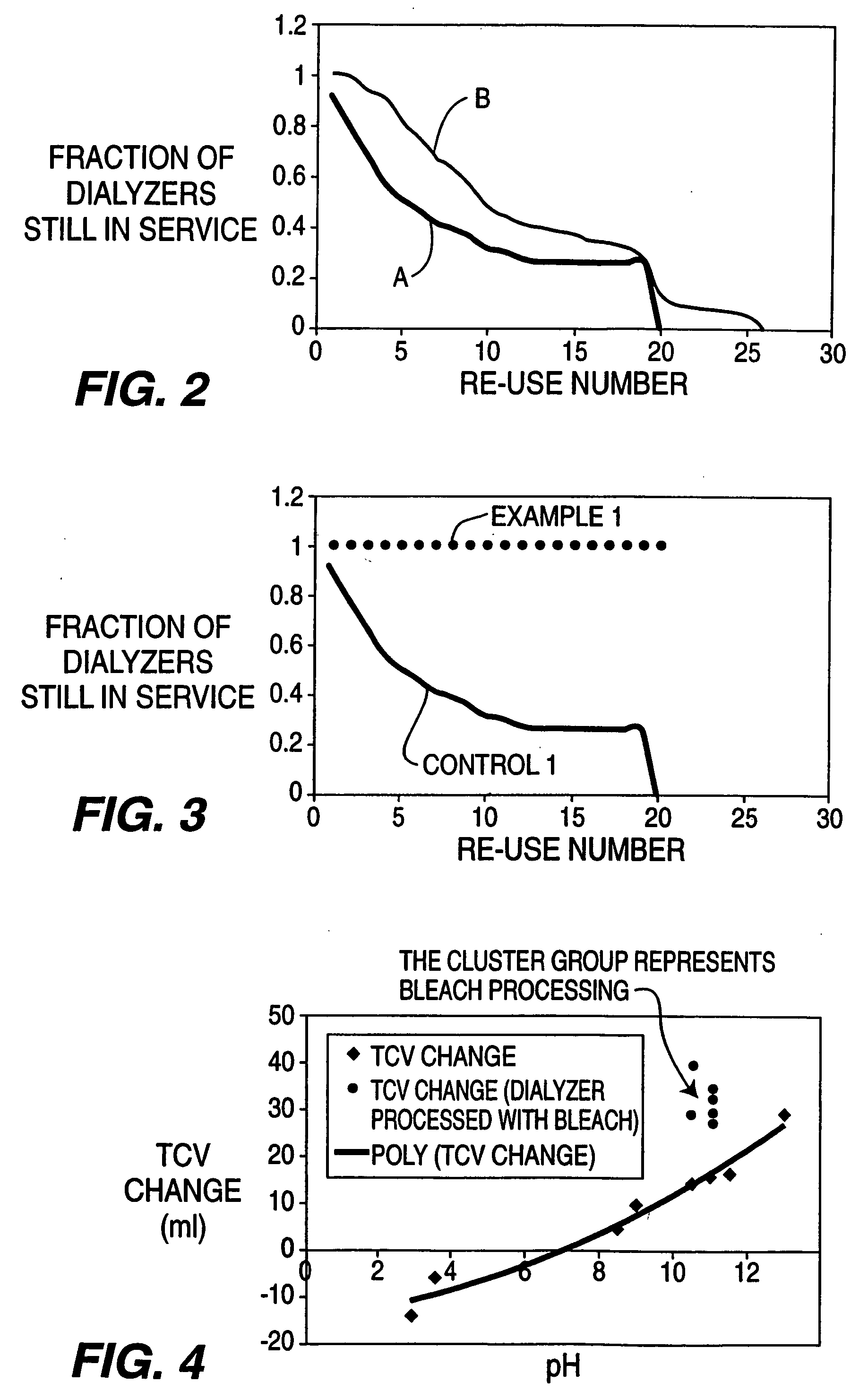

InactiveUS20050150831A1High aspect ratioReadily flushed awayInorganic/elemental detergent compounding agentsSemi-permeable membranesHollow fibreLiquid bubble

Hollow porous fibers containing adhered contaminants are cleaned to remove the contaminants by backflushing a liquid to fill the pores, and adding a flow of gas so as to form a two-phase mixture of gas and bubbles of liquid that can scrub the fibers, loosening the contaminants and allowing them to be flushed from the hollow fibers. The method is particularly useful for cleaning hemodialyzers used for dialysis and hollow fiber modules used in water treatment and separations. The two phase flow method is specifically effective in cleaning piping systems having high length to diameter (l / d) ratios.

Owner:NOVAFLUX INC

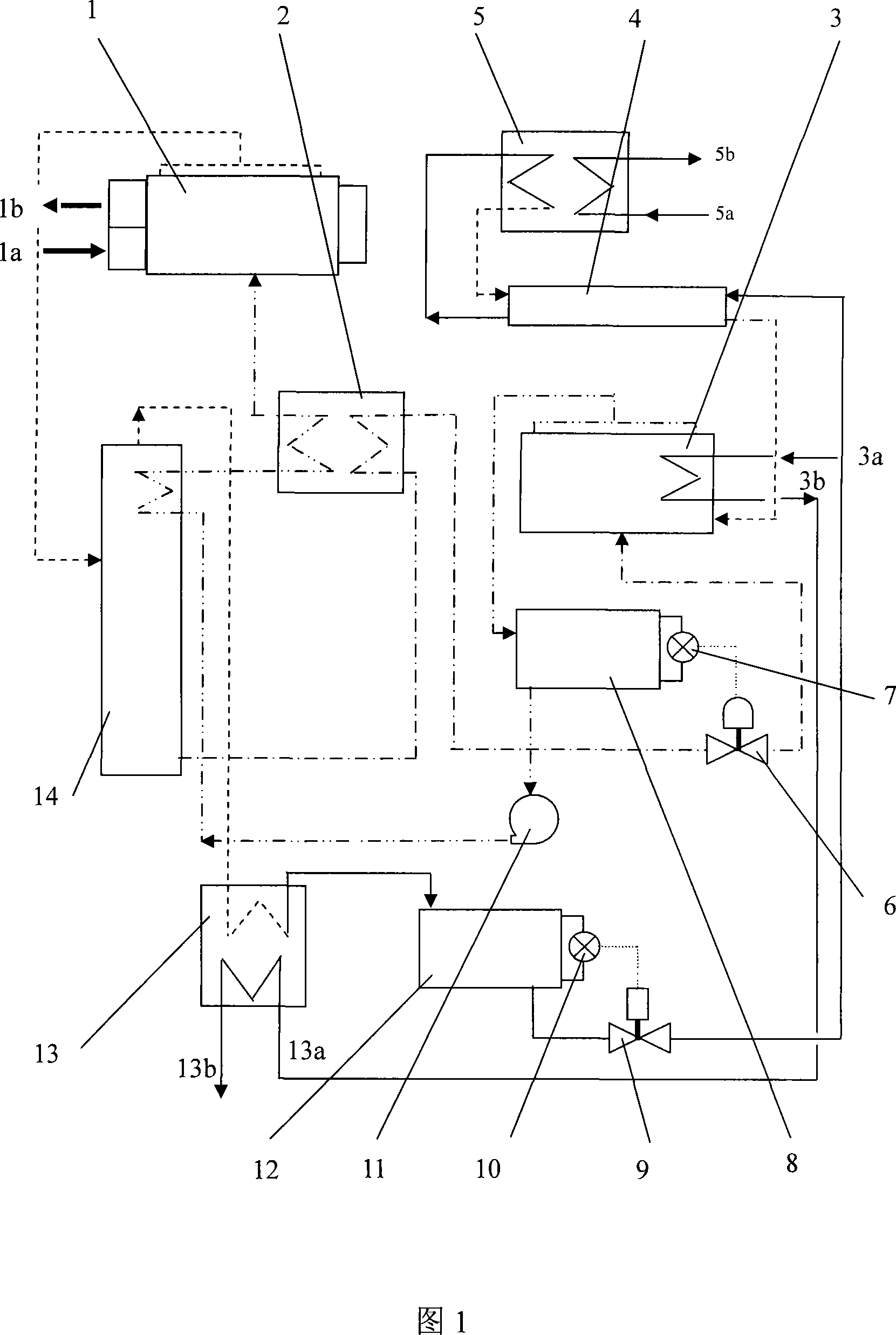

Ammonia water absorption refrigerator used in boat and drove by residual heat of ship engine exhaust

ActiveCN101033898ASave fuelLow costClimate change adaptationMachines using waste heatDifferential pressureEngineering

The invention is a kind of marine ammonia liquor absorption refrigerator which relates to technology field of refrigeration by excess heat. it is characterized in that making use of ship craft exhausting excess heat to heat generator full use of ammonia liquor; free ammonia and liquor flows into gas-liquid separator all together, the separated free ammonia containing water or moisture is partly purified by dephlegmator and condensates in the condensator; ammonia liquor evaporates in the casing evaporator and produces cold energy, cold free ammonia and marine ammonia which does not evaporate exchange heating the coil subcooler, and enters full liquid bubble absorber under gravity and differential pressure; free ammonia bubble is absorbed by dilute solution of marine ammonia from gas-liquid separator and cooled by solution heat exchanger , dense dilute solution of marine ammonia flows into marine ammonia tank and driven into full liquid generator by solution pump. The effect and benefit of the invention is that making use of excess heat can work under incline, swing and bump; it can save energy and protect environment, the operation cost is low, it is especially fit for refrigeration, ice-making and air- of different shipping.

Owner:TAISHAN GROUP

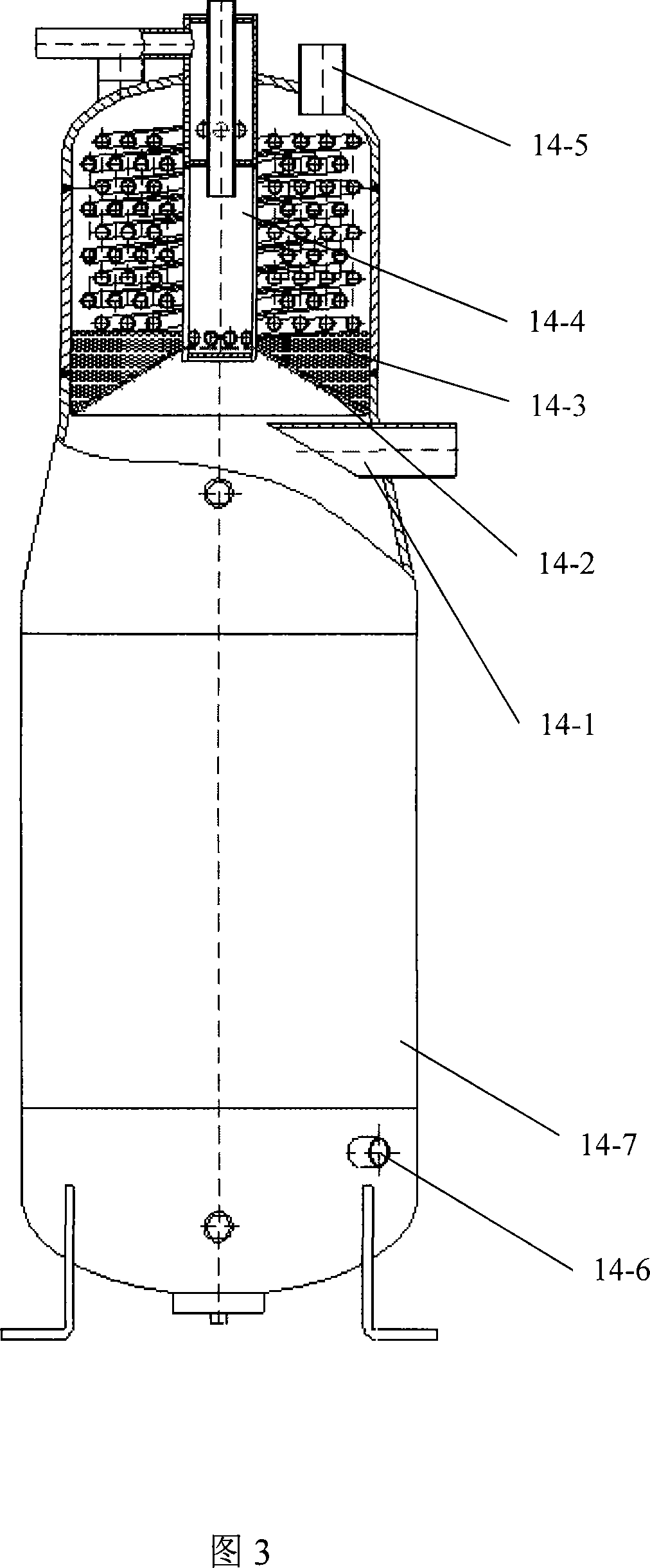

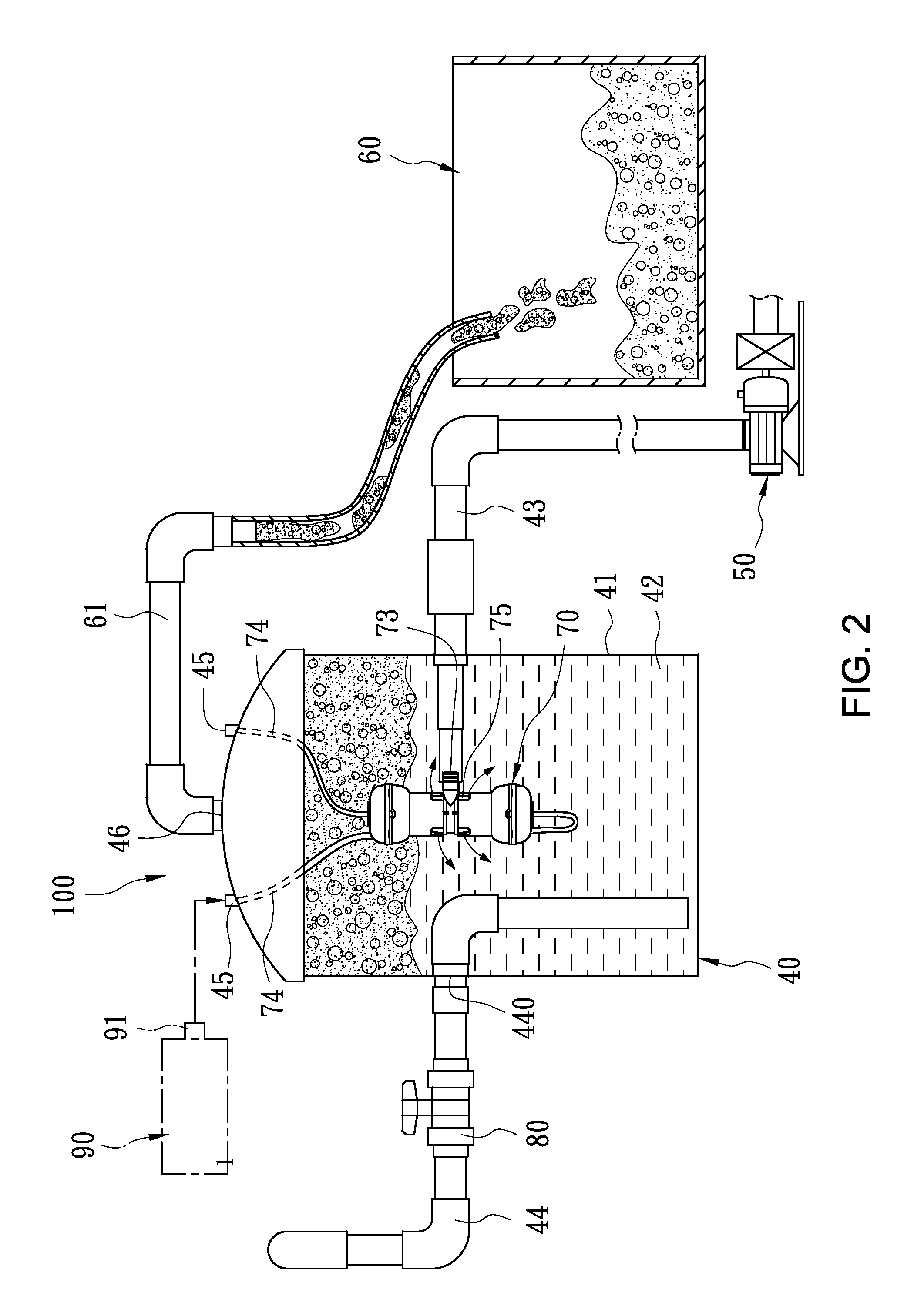

Liquid bubble separator of circulating water system

InactiveUS20160113249A1Extended service lifeImprove survival rateTreatment using aerobic processesSpecific water treatment objectivesMicro bubbleEngineering

A liquid bubble separator of a circulating water system contains: a cylindrical tank, a pump, a bubble collection tank, and at least one micro bubble generating unit. The cylindrical tank included a water chamber defined by an inner wall, an inlet pipe, an outlet pipe, at least one air orifice, and a bubble discharging hole. The pump is coupled with the inlet pipe to pump treated water into the inlet pipe via the nitrification tank. The bubble collection tank is mounted on one side of the cylindrical tank and includes a collecting tube. Each micro bubble generating unit is disposed in the water chamber and includes a body, a first mixing room, an inlet, at least one air tube coupling with the at least one air orifice and corresponding to the inlet, and a plurality of backflow apertures formed around the body and communicating with the first mixing room.

Owner:KUO CHI TSE

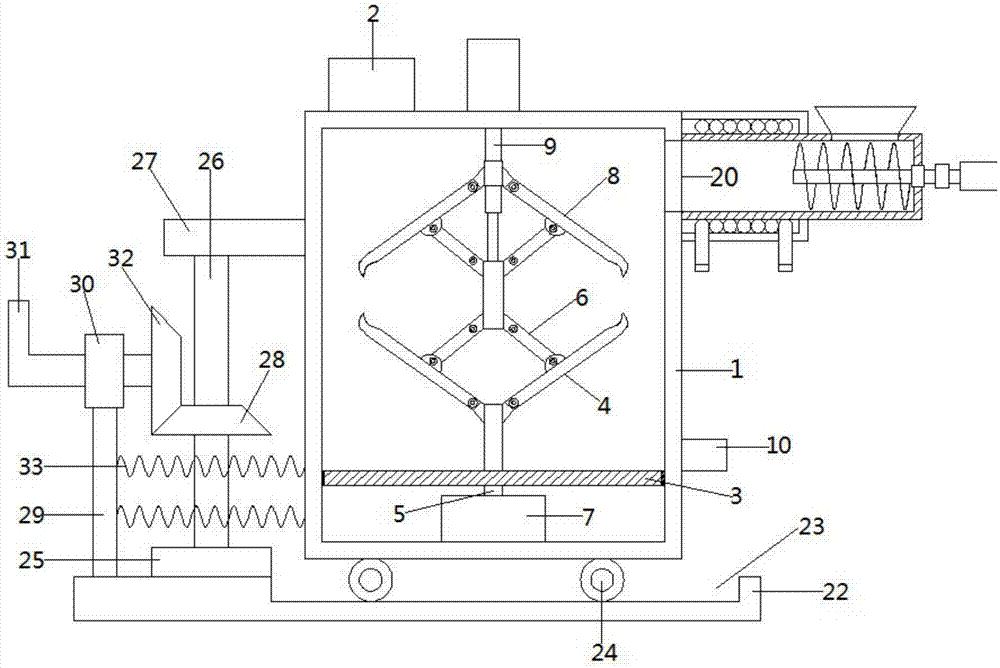

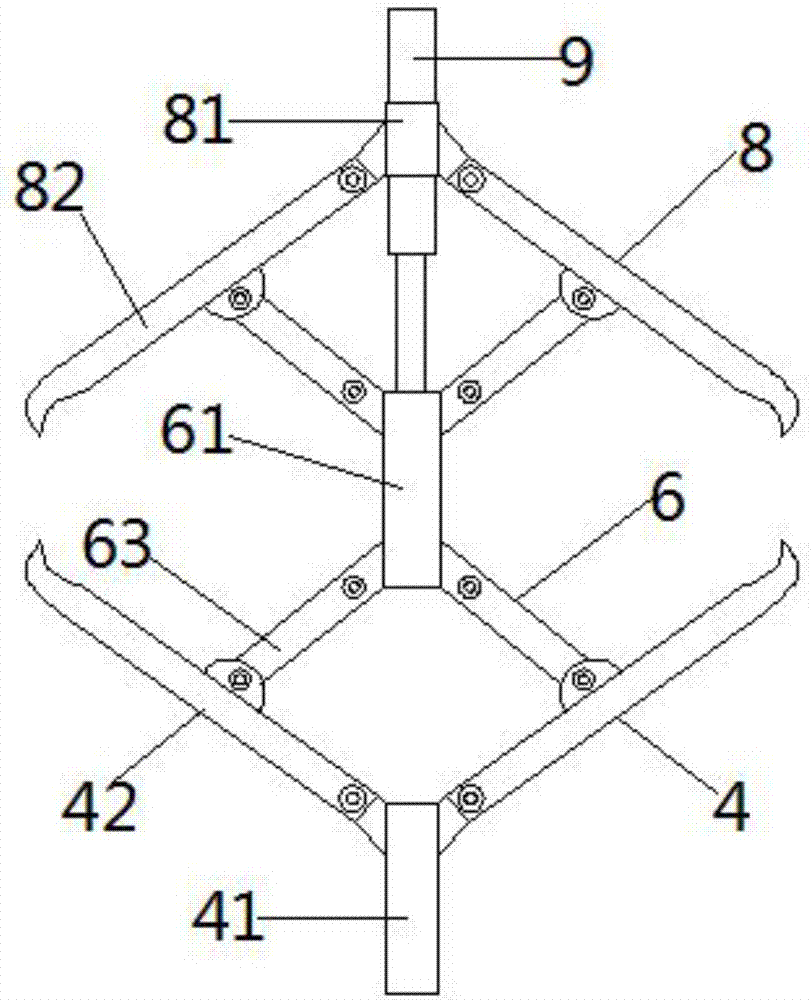

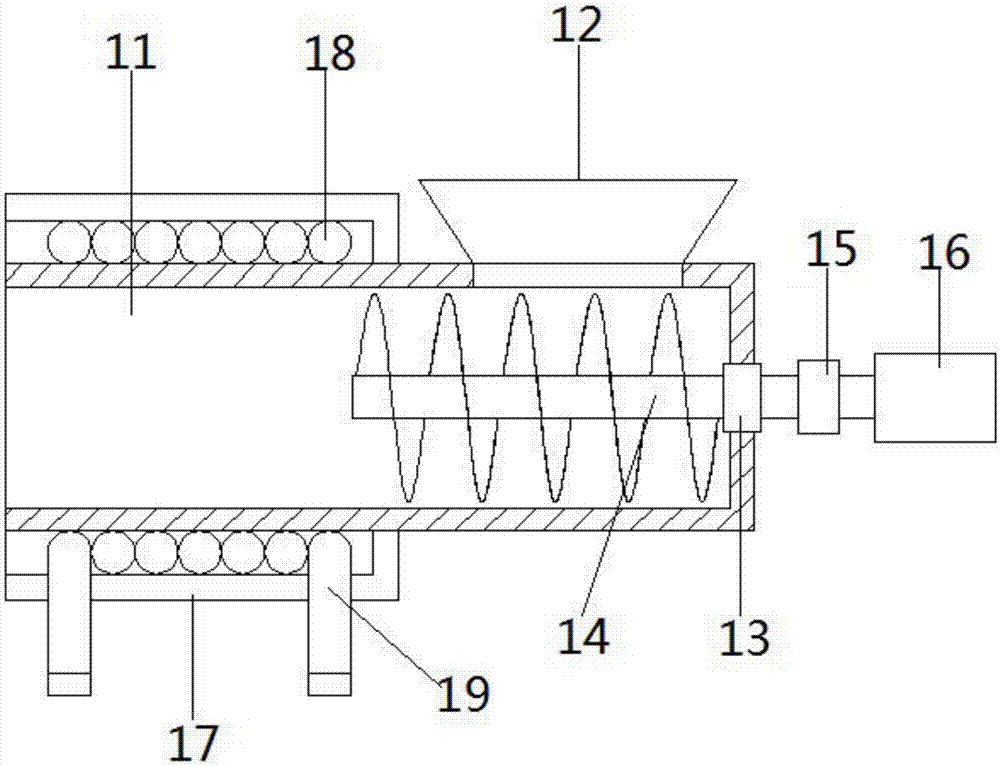

Liquid mixing device capable of rapidly mixing materials

InactiveCN107349852AExtended range of mixingChange fixed mixShaking/oscillating/vibrating mixersRotary stirring mixersEngineeringDrive motor

Owner:林红英

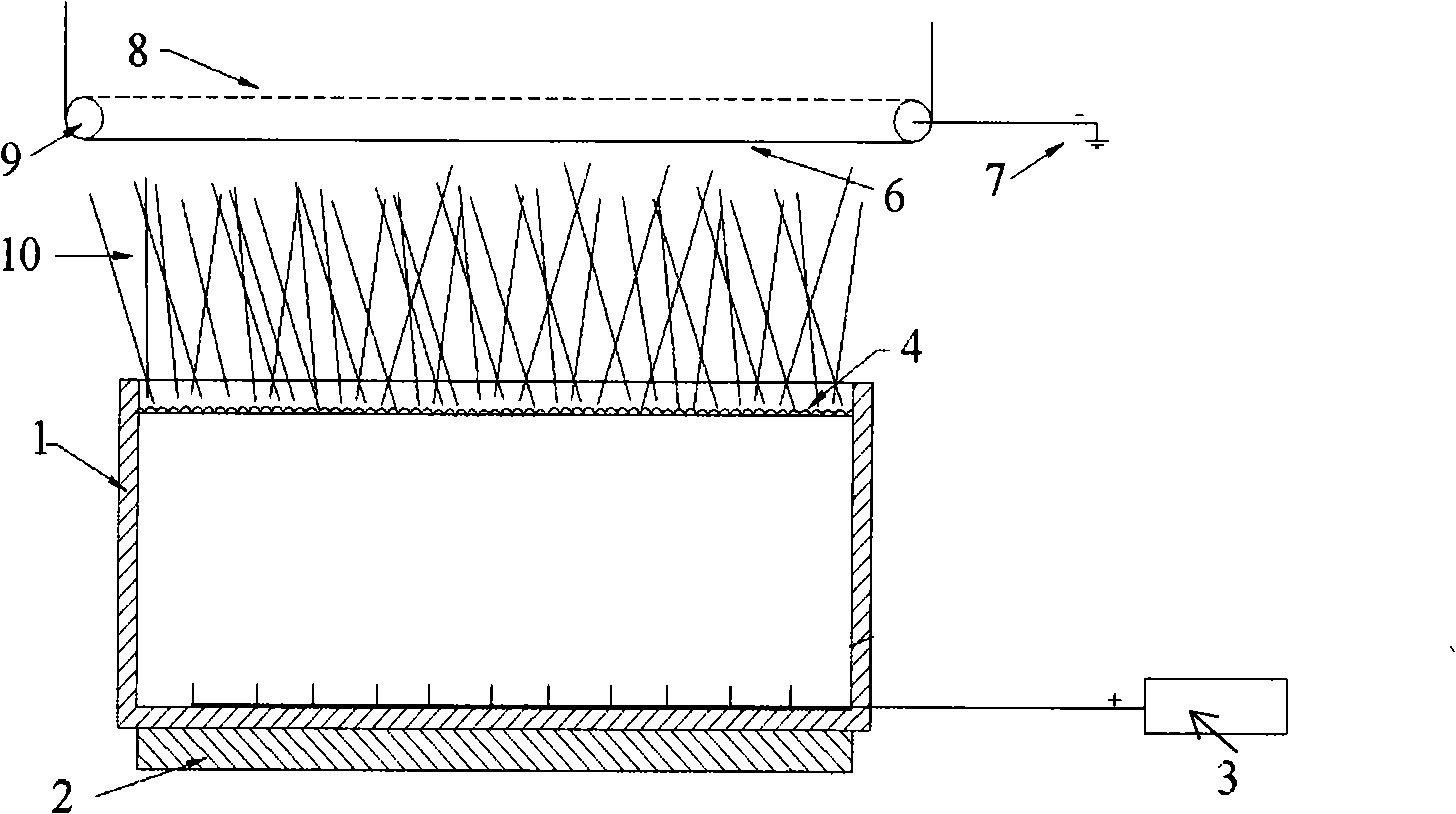

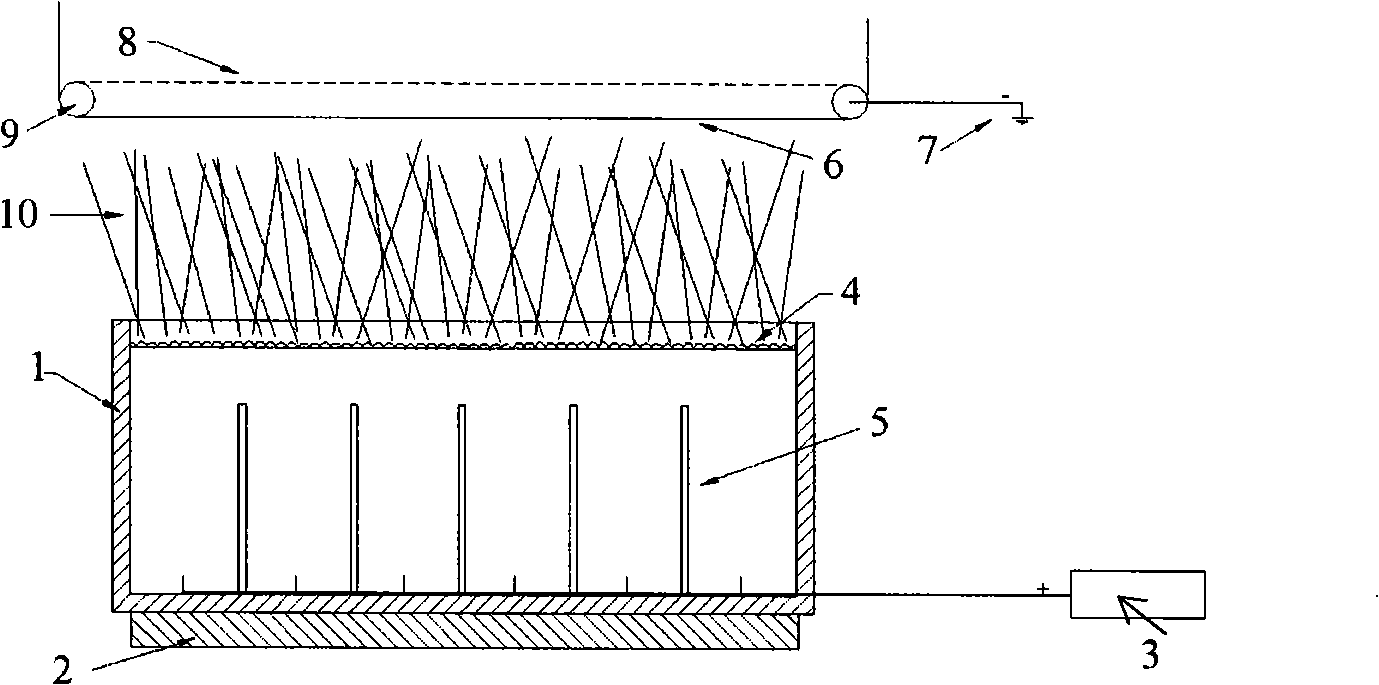

Thermal bubble spinning method and device for nano-fiber production

InactiveCN101275299ASimple spinning mechanismEasy production controlArtificial thread manufacturing machinesFilament/thread formingFiberMetallic electrode

Owner:DONGHUA UNIV

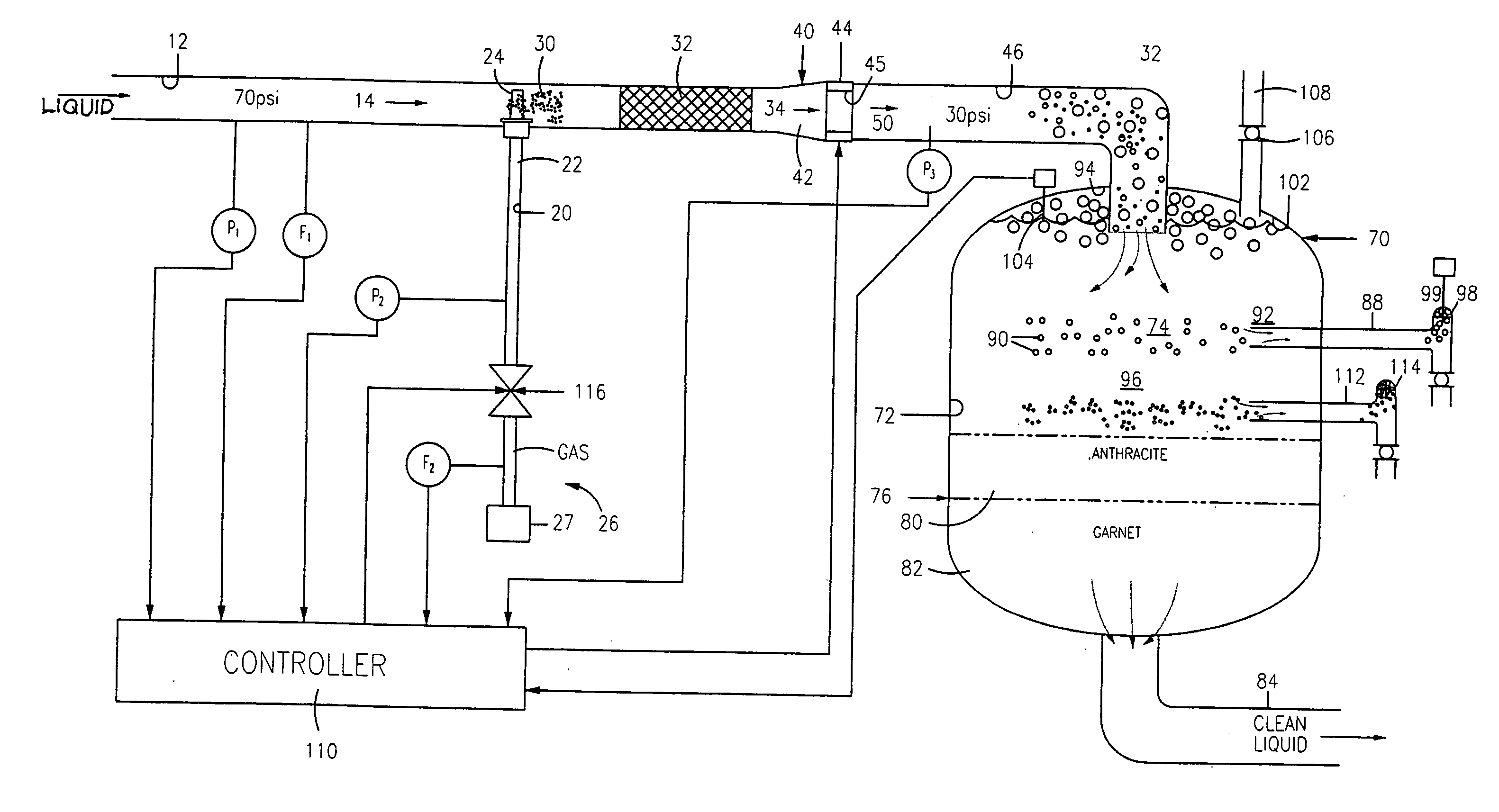

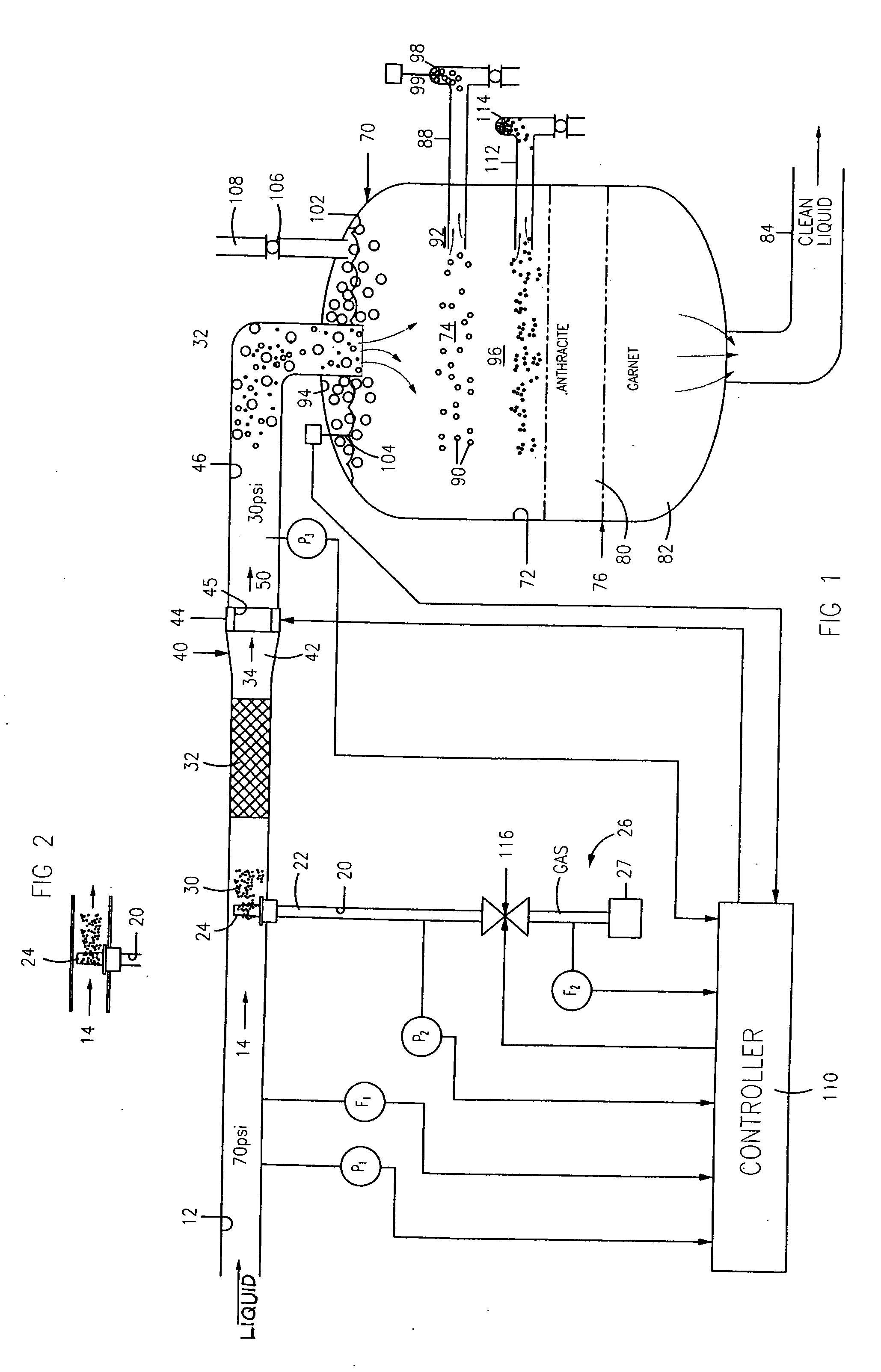

Gas bubble generation for coalescing

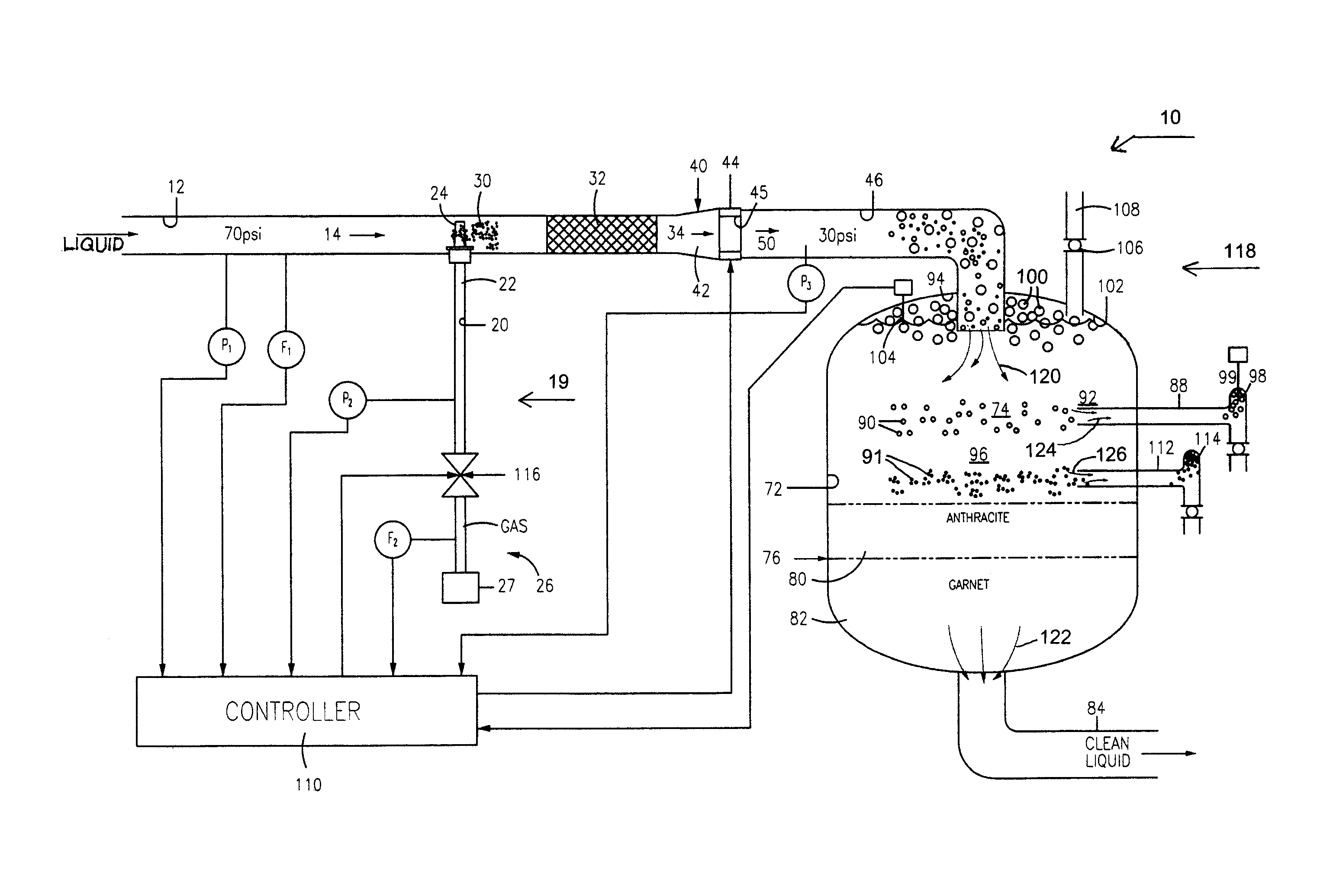

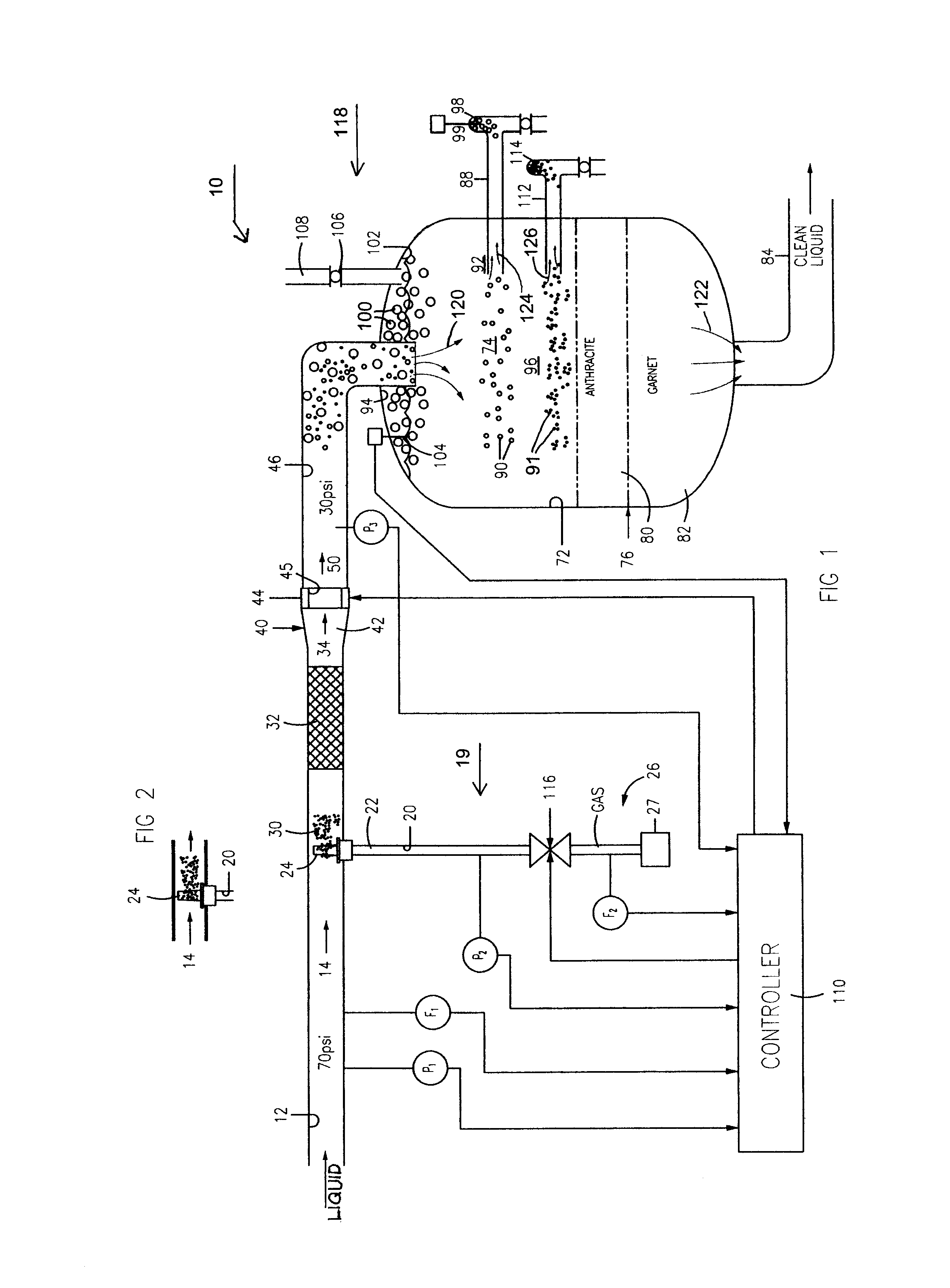

InactiveUS20110168640A1High proportionReduce pressureWater treatment parameter controlFlow mixersEngineeringLiquid bubble

Apparatus is provided for introducing gas bubbles 30 (usually air bubbles) into a liquid stream 14 to coalesce material such as unwanted bits, or particles, of hydrocarbons that lie in the liquid stream along with wanted dissolved bits of metal, for removal of the hydrocarbons. The apparatus is constructed to produce a large number of bubbles of an optimum range such as 60 to 100 μm which best coalesce the hydrocarbons. A controller (110) receives the outputs of sensors such as pressure and flow rate sensors (P, F) and uses them to make changes in other parameters such as the pressure of air introduced (at 116) into the liquid stream and the pressure in a third conduit 46 of the liquid-bubble stream.

Owner:SPINTEK FILTRATION

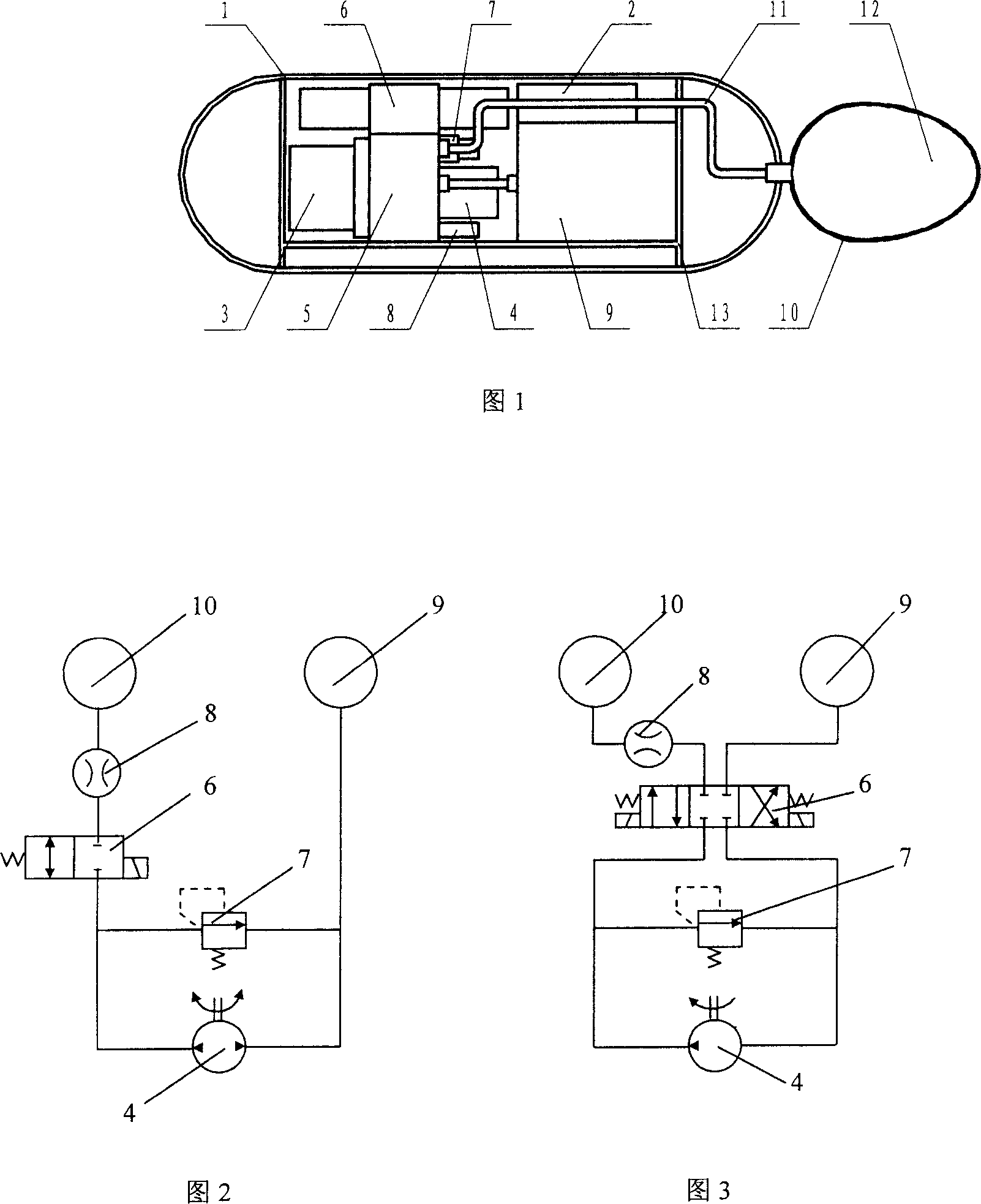

Enclosed type electric and hydraulic floating force driving system

InactiveCN1951762ACompact structureReduce volumeUnderwater vesselsUnderwater equipmentLiquid mediumHydraulic pump

The invention relates to a sealed electric hydraulic driving system. Wherein, it comprises sealed pressure-resistance frame, inner liquid tank, and outer liquid bubble; the liquid tank are in the frame; the outer liquid bubble is outside the frame; the inner liquid tank and the outer liquid bubble are connected by liquid tube; the tube has hydraulic pump, stop electromagnetic steering valve, overflow valve and flux meter, integrated on the hydraulic block; said hydraulic block is integrated with direct-current motor; the motor and the hydraulic pump are connected; the direct-current power is connected to the motor. The invention has simple structure and high efficiency.

Owner:SHENYANG POLYTECHNIC UNIV

Oriented film composed of thermoplastic polymer with particulate hollow bodies, a process for its production and its use

InactiveUS6124029AGood mechanical and homogeneous optical propertyIncrease stiffnessSynthetic resin layered productsThin material handlingParticulatesPolymer science

An oriented film composed of thermoplastic polymers is described which comprises at least one vacuole-containing layer. The vacuole-containing layer comprises particulate hollow bodies which are essentially composed of a polymer which is incompatible with the thermoplastic polymer. A process for producing the film is also described.

Owner:TICONA GMBH

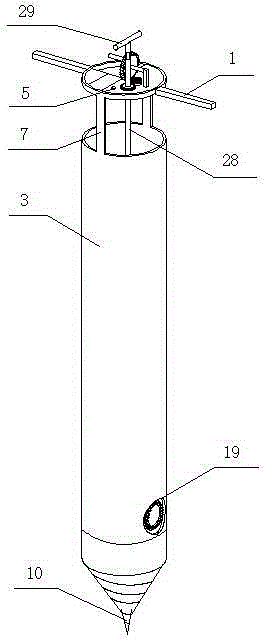

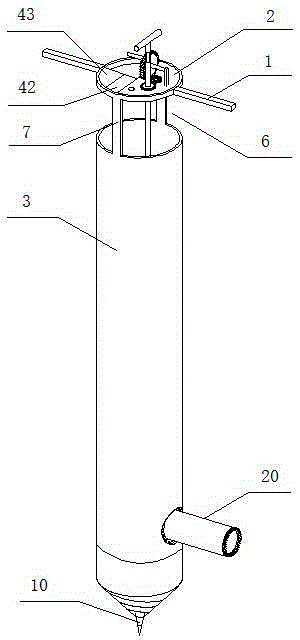

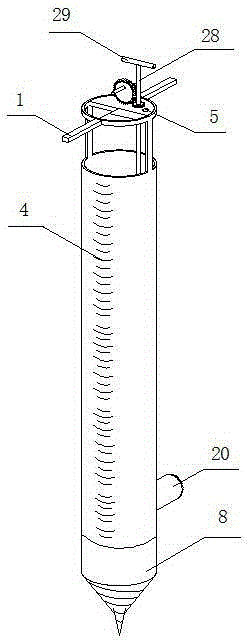

Sampler

ActiveCN105388039AReduce disturbanceGuaranteed spot samplingWithdrawing sample devicesData displayEngineering

The invention relates to a sampler, and belongs to the technical field of sampling. The sampler comprises a handle, an operating platform, an external drilling barrel, height scales, a small horizontal liquid bubble, a sample discharging groove, a vertical shaft, a drill bit, a drill bit sampling hole, a rotating buckle, a longitudinal sampling ring knife, a lug clamping groove, a transverse sampling hole, a transverse sampling ring knife, sawteeth, a piston-type tail piece, a tail portion lug, a thread, a bottom rotating gear, a bottom control gear, a bottom rotating gear fixing shaft, a sampling rod, a sampling rod handle, a sampling rod moving groove, a sliding key, a spring ball, a spring ball clamping groove, a turning gear, a transverse control gear, a longitudinal adjusting gear, a longitudinal adjusting gear handle, a longitudinal adjusting gear fixing shaft, a compaction sensor, a humidity sensor, a wire, a data display setup screen, a battery and a sample pushing needle. By the adoption of the sampler, spot sampling can be guaranteed, and disturbance to surrounding samples is reduced; transverse sample discharging and longitudinal sample discharging are independent of each other, and sample discharging is thorough. The sampler has the advantages of being reasonable in structure, convenient to operate and capable of saving time and labor.

Owner:KUNMING UNIV OF SCI & TECH

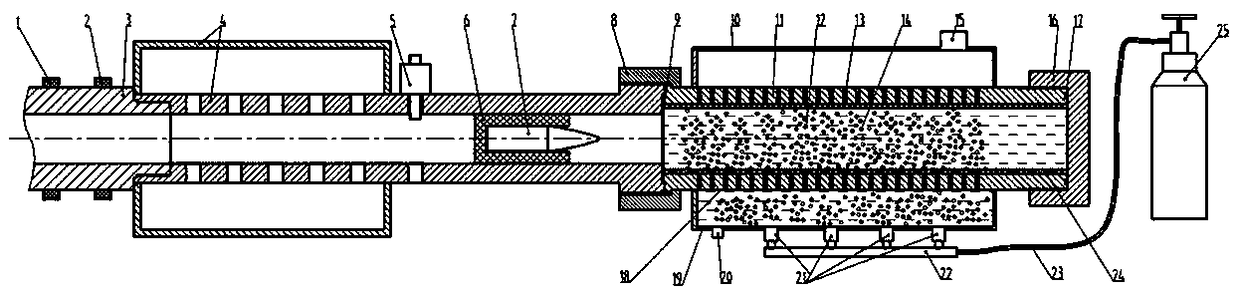

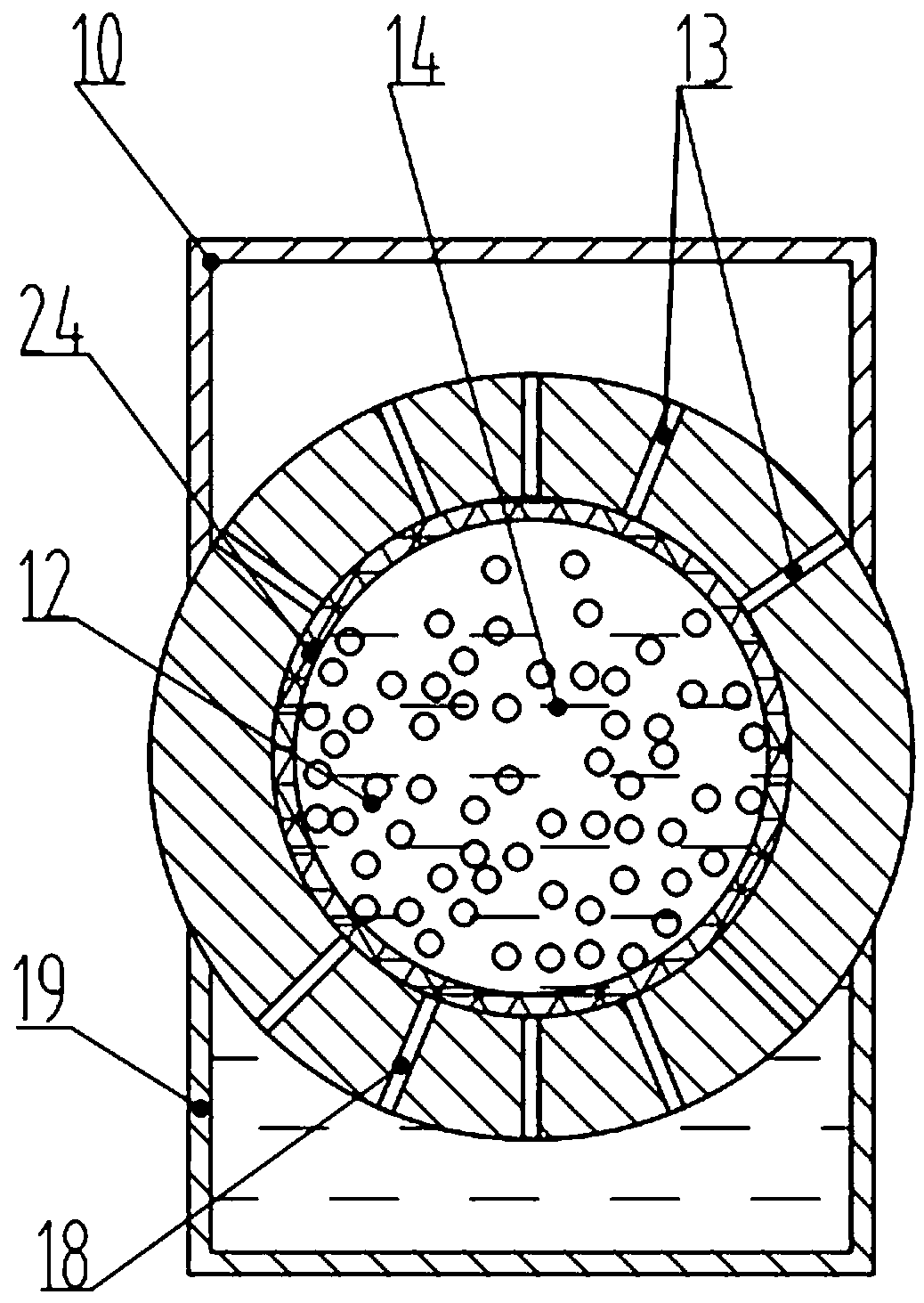

Test projectile recovery device

The invention belongs to the field of projectile tests and experiments, and particularly relates to a test projectile recovery device. Partial liquid is filled in a recovery capsule, a large number ofliquid bubbles can be formed through the links such as a high-pressure air pipe, a metal air pipe, a one-way valve, an air inlet hole and an open cell foam inner cylinder by utilizing high-pressure gas in a gas cylinder, the liquid bubbles enter the recovery capsule, and the liquid containing the large number of liquid bubbles becomes compressible liquid. When a test projectile rushes into the liquid containing the large number of liquid bubbles at high speed, by utilizing the compressibility of the air bubbles and the damping characteristic of the liquid, the damage of the projectile causedwhen the projectile enters water is prevented, a speed reducing function of the projectile is realized, and a high-speed test projectile recovery function is realized. The test projectile recovery device provided by the invention overcomes the defects of sand box recovery, mechanical buffer recovery, foamed aluminum recovery, water damping recovery and gas recovery, provides a new method for the recovery problem of the projectile experiment process, has a certain value on recovery during the projectile experiment, and is worth to be popularized in the projectile recovery technology.

Owner:ZHONGBEI UNIV

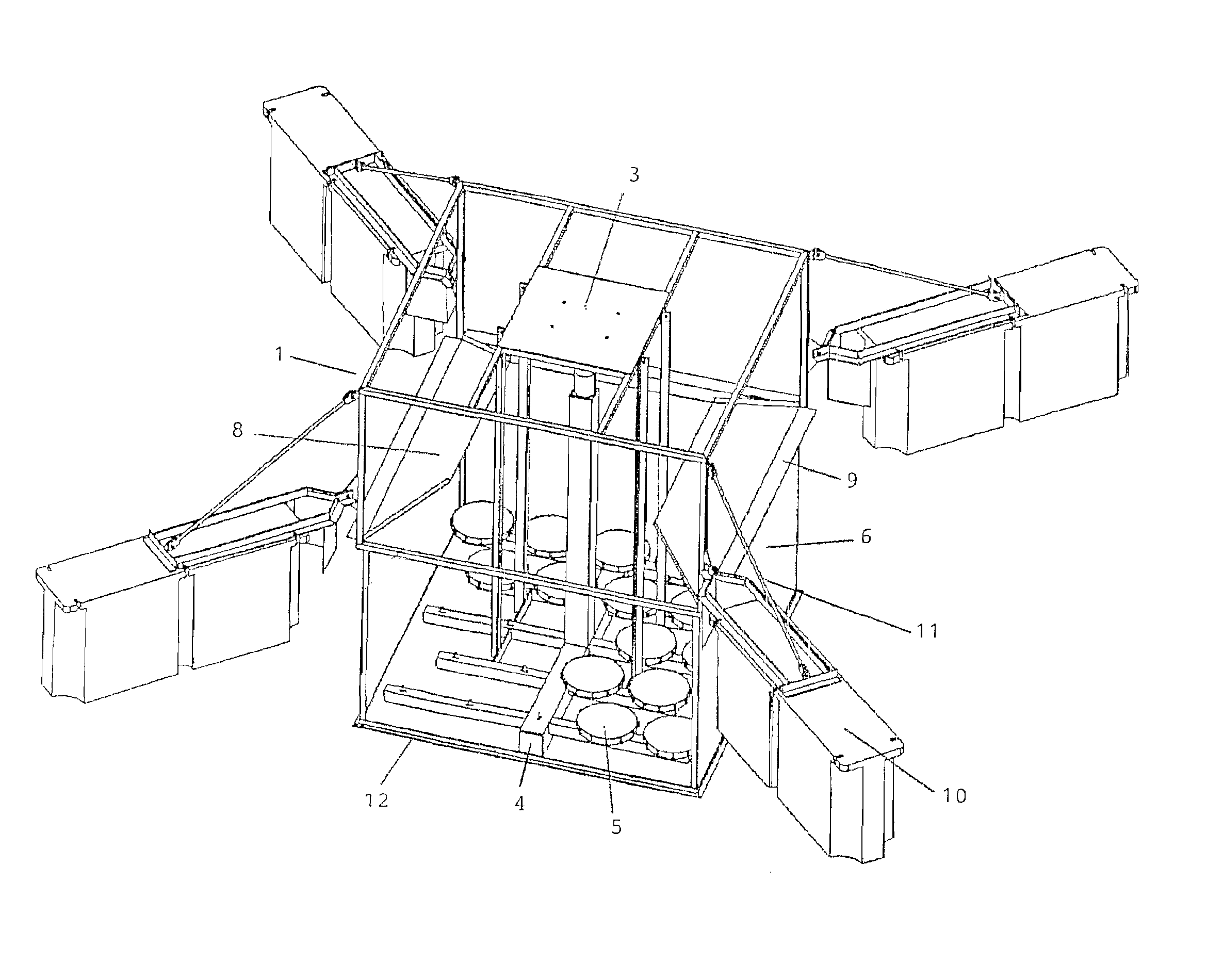

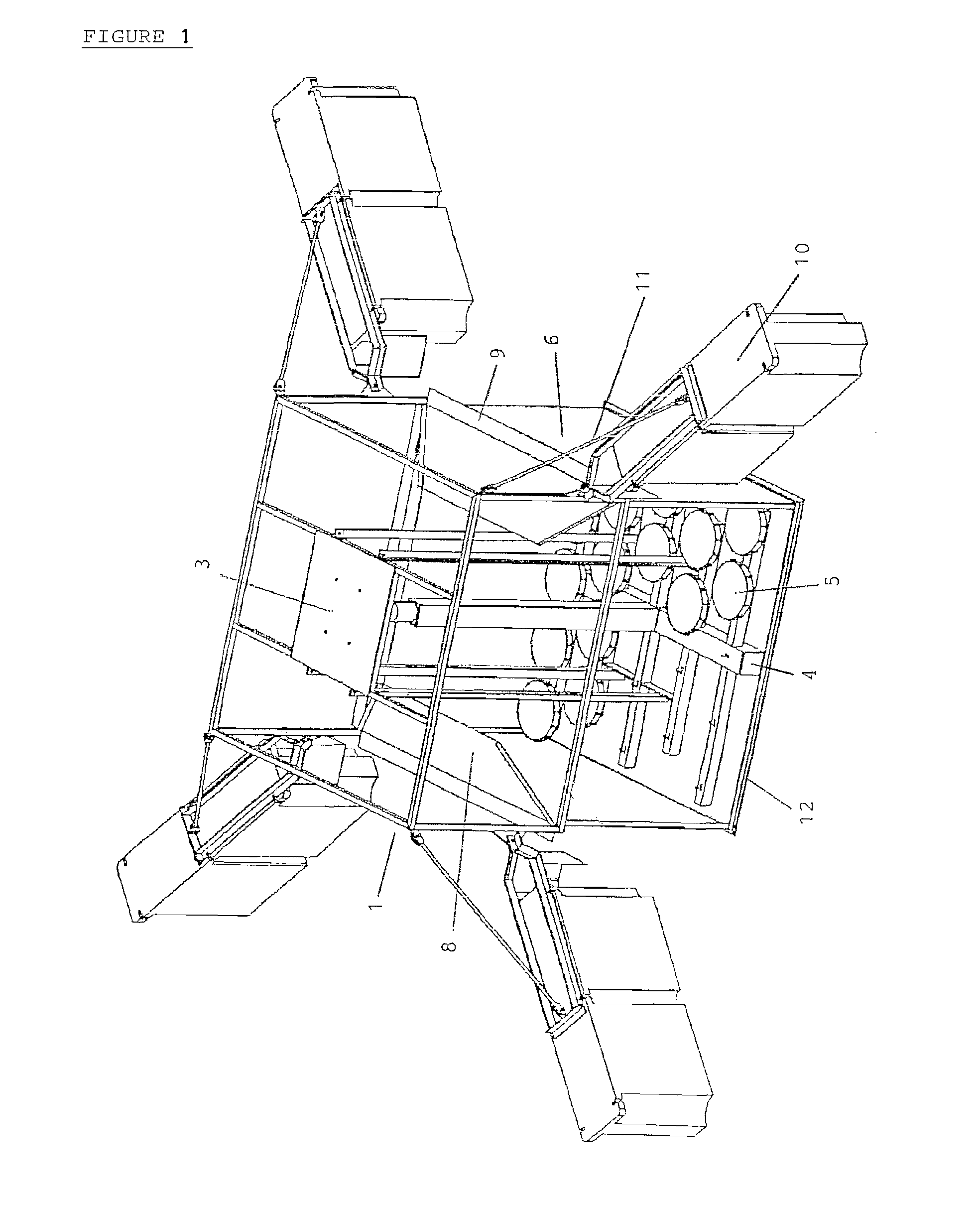

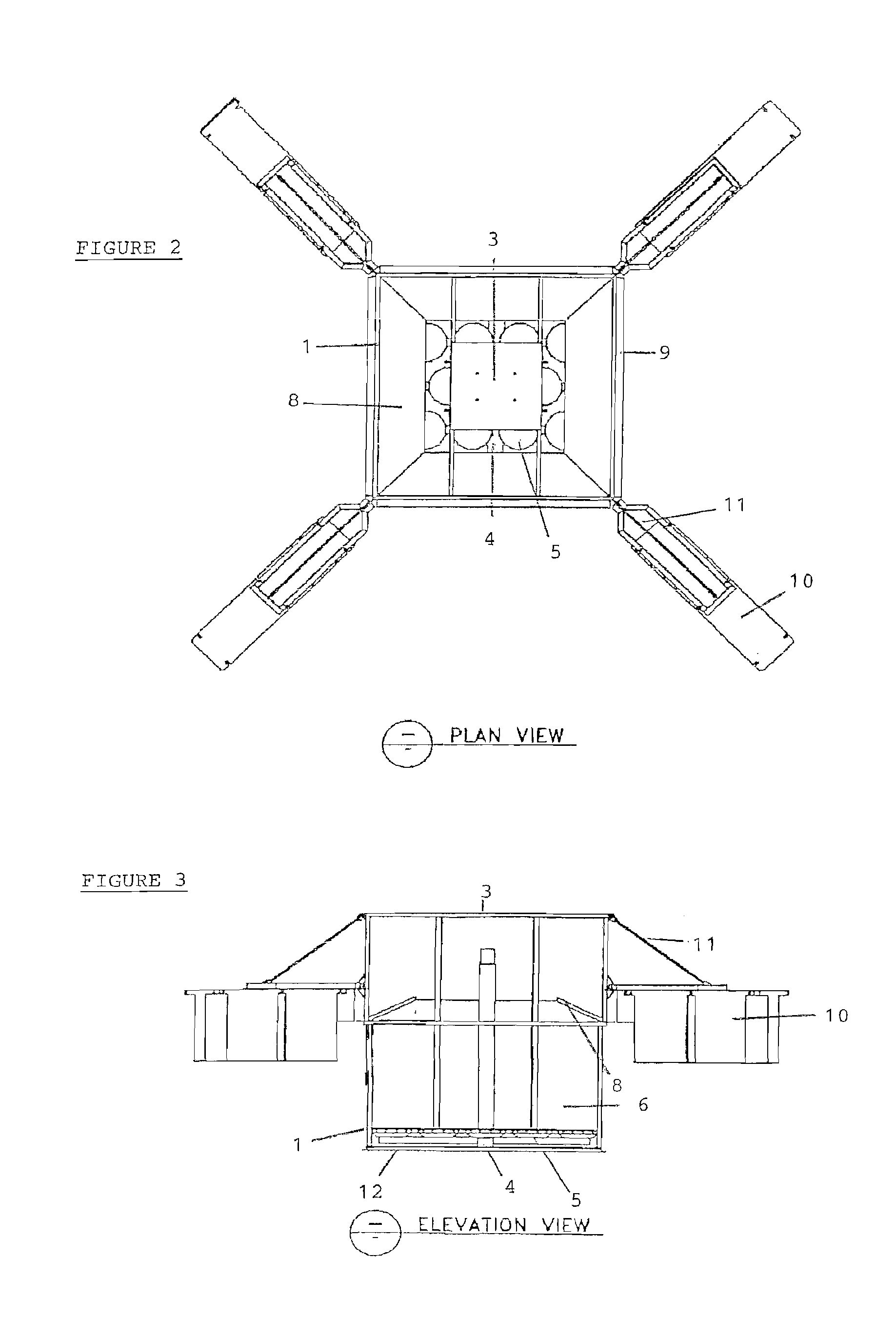

Floating diffused air aerator

InactiveUS7520493B1Conserve energy inputImprove performanceCarburetting airWater cleaningLiquid wasteAtmospheric air

An aerator for mechanically inducing near laminar flow and controlled turbulence in a liquid waste treatment lagoon or pond. A blower, blower mount platform, diffuser modules, aeration manifold, aeration chamber, an adjustable, telescoping aeration chamber extension, baffles, and buoyancy apparatuses attach to a frame. The diffusers are located beneath the surface of the body of liquid at a predetermined, fixed depth. The blower supplies air to the diffusers and liquid-bubble mixture is released into an aeration chamber where artificial aeration is maximized. The mixture then rises through the aeration chamber. Bubble dissipation and flow conditioning baffles force bubbles to coalesce and vertically dissipate into the atmosphere. The liquid flows over the top of the baffles and a flow manipulation rim to radiate outward and parallel to the pond surface with minimum turbulence at an optimum flow discharge rate. The aerator provides optimized oxygen transfer at low energy costs.

Owner:HALDANE WILLIAM J

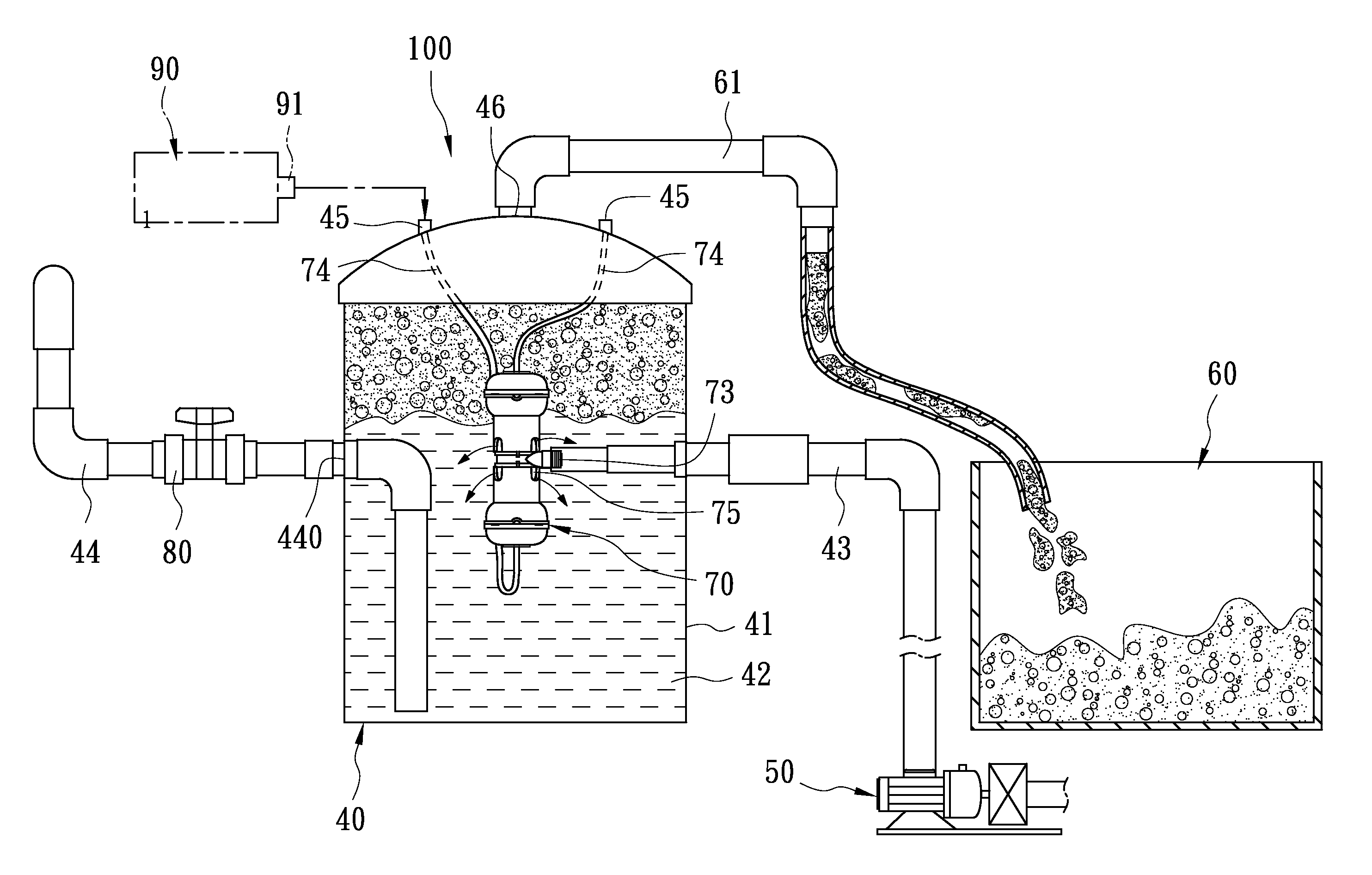

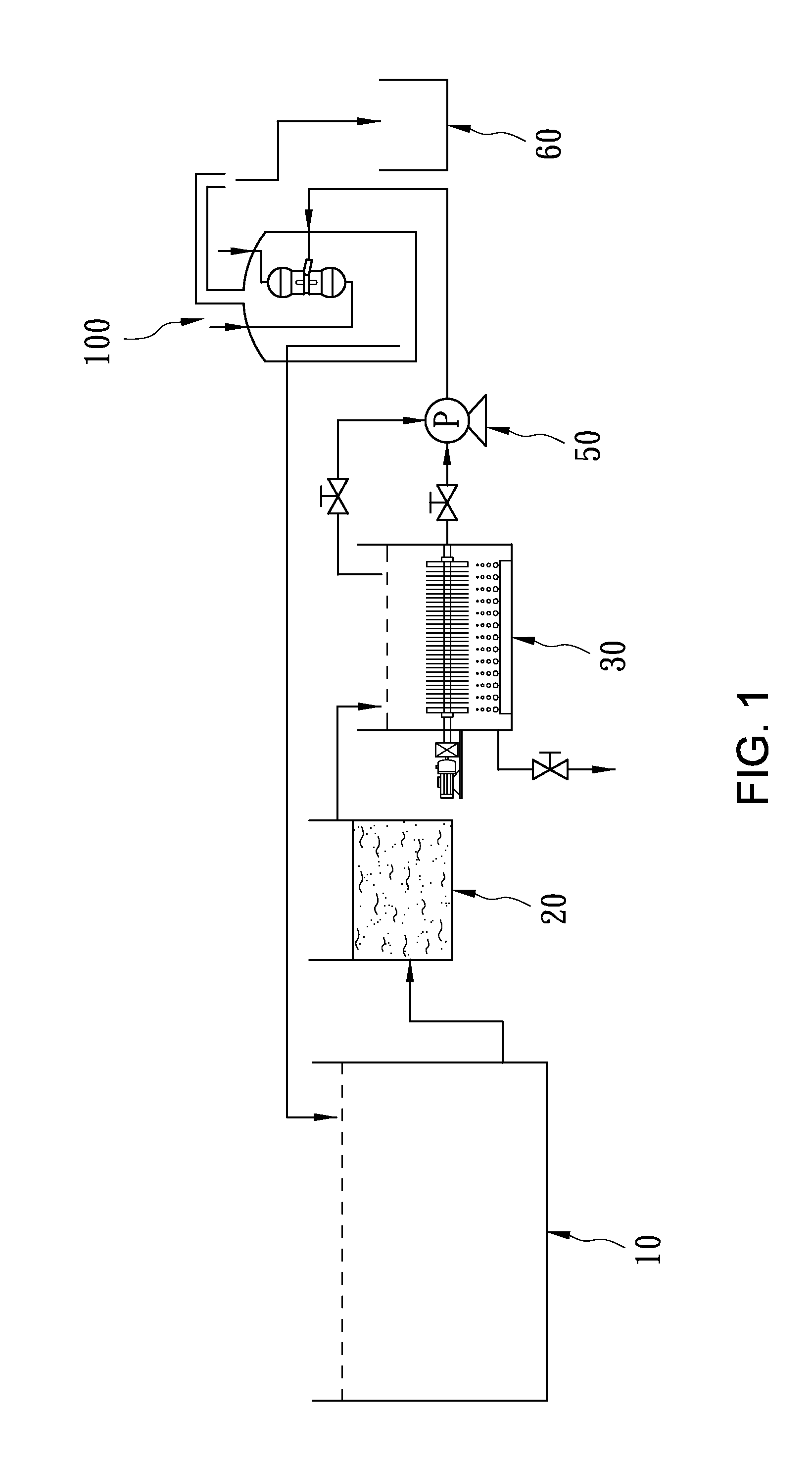

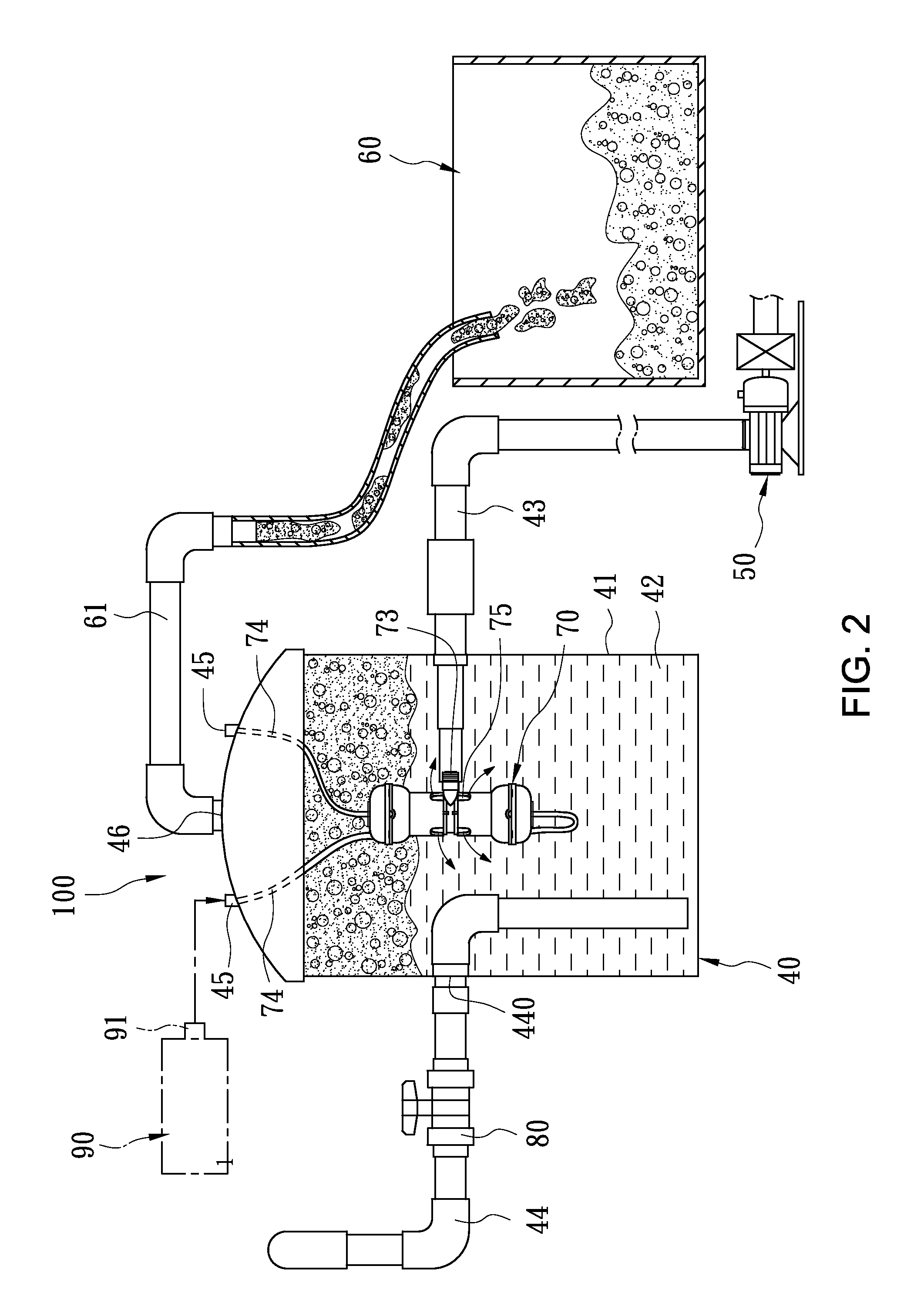

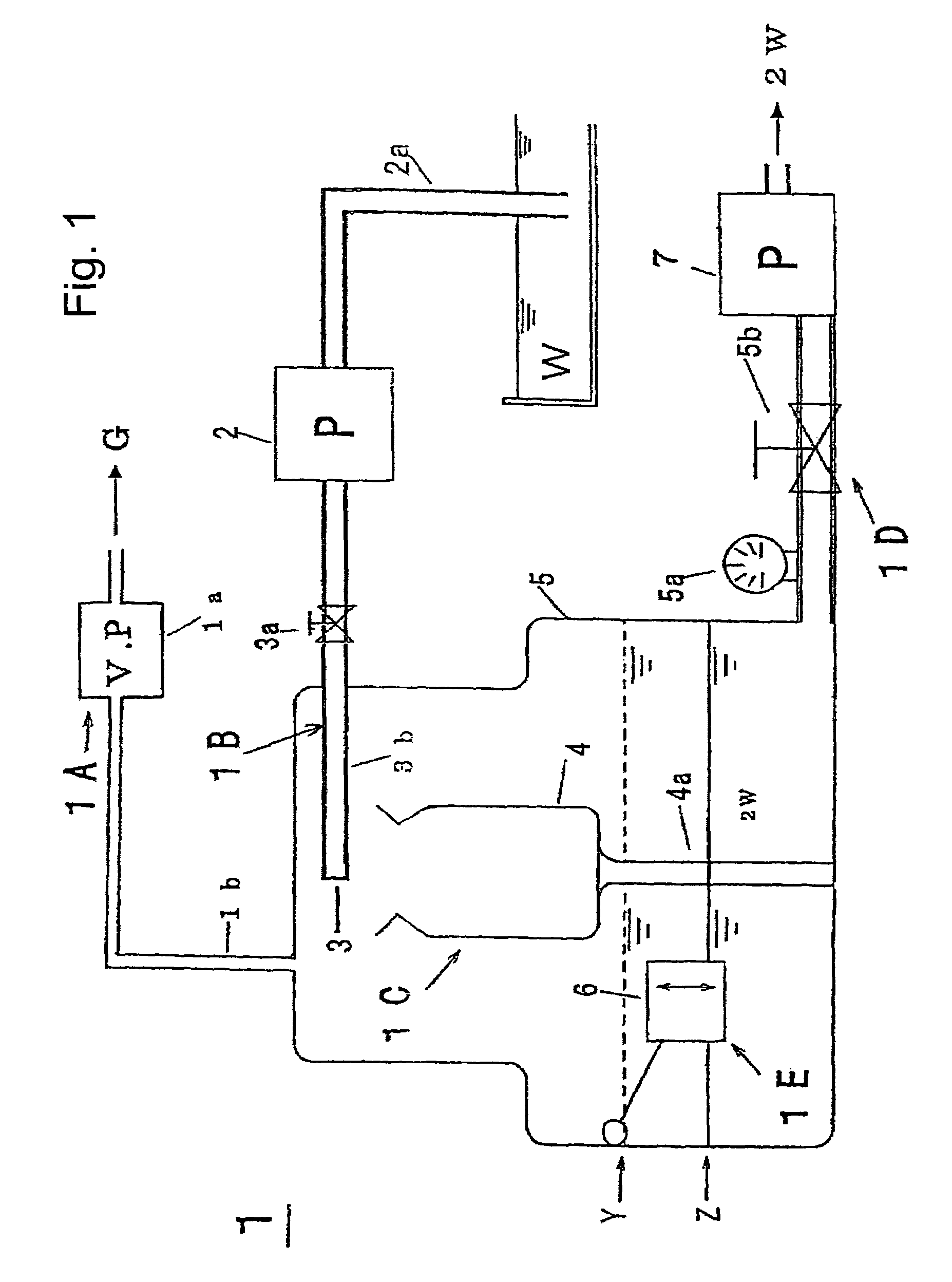

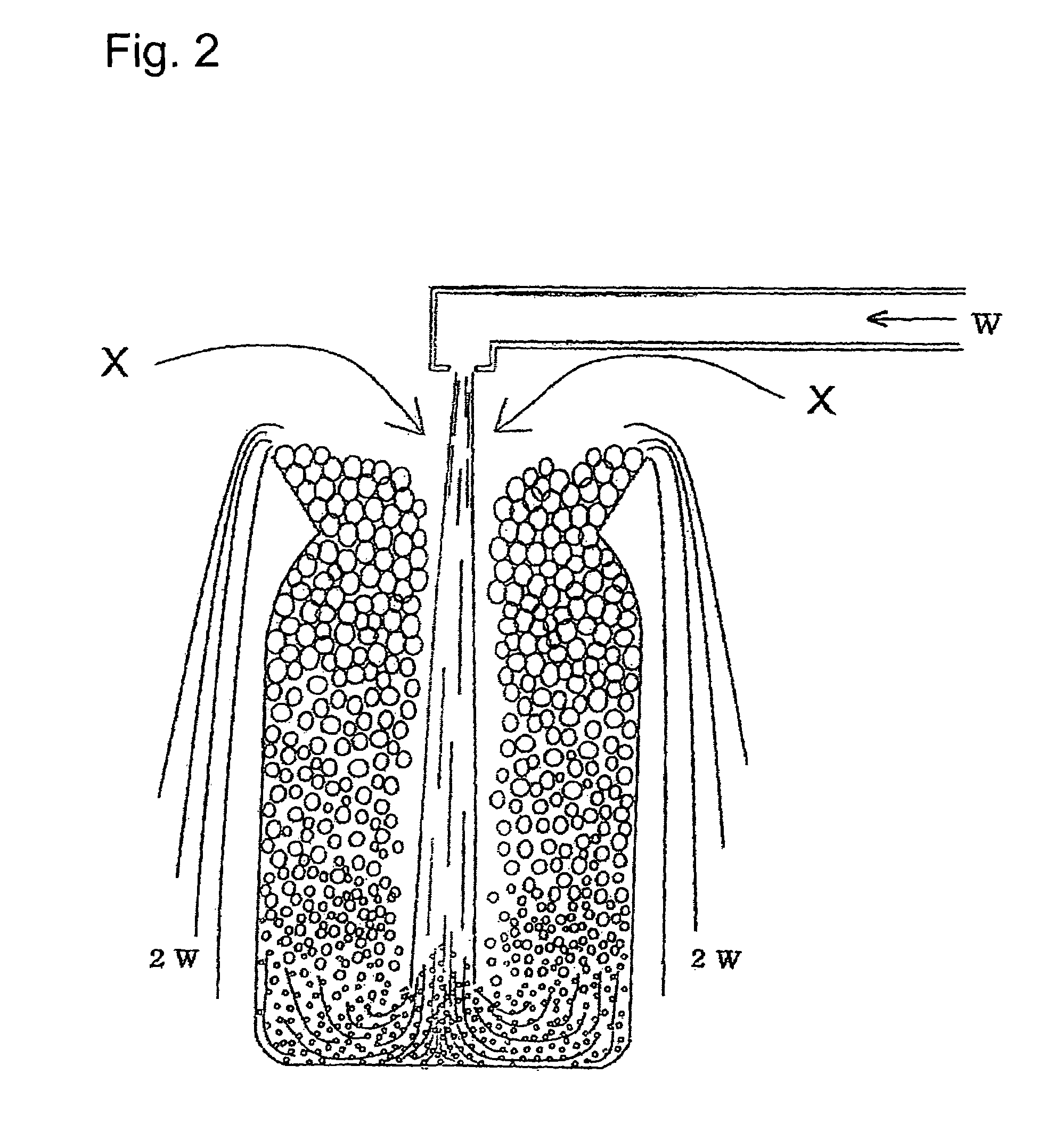

Method, device, and system for controlling dissolved amount of gas

InactiveUS7494534B2Reduce resistanceIncrease gas spaceLiquid degasification with auxillary substancesFlow mixersEngineeringProduct gas

A device for controlling a dissolved amount of gas. The device is formed of: a pressure reducing part constructed by connecting a hole provided at an upper part of a closed tank to a vacuum pump through a pipe; an injection supply part for injecting fluid to be treated pressurized by a pressurizing pump from the upper part of the tank; a liquid foam generating container where the injected fluid to be treated is received, then gas of the reduced pressure space is involved in, and an air bubble group rises along an inner peripheral wall and is separated from the liquid, and then changes into liquid bubbles in an upper region; a recovery pump part for allowing the liquid bubbles having overflowed from the container; and a tank water level sensor part for maintaining a water level of the treated fluid.

Owner:TETABUHIKO FUJISATO +1

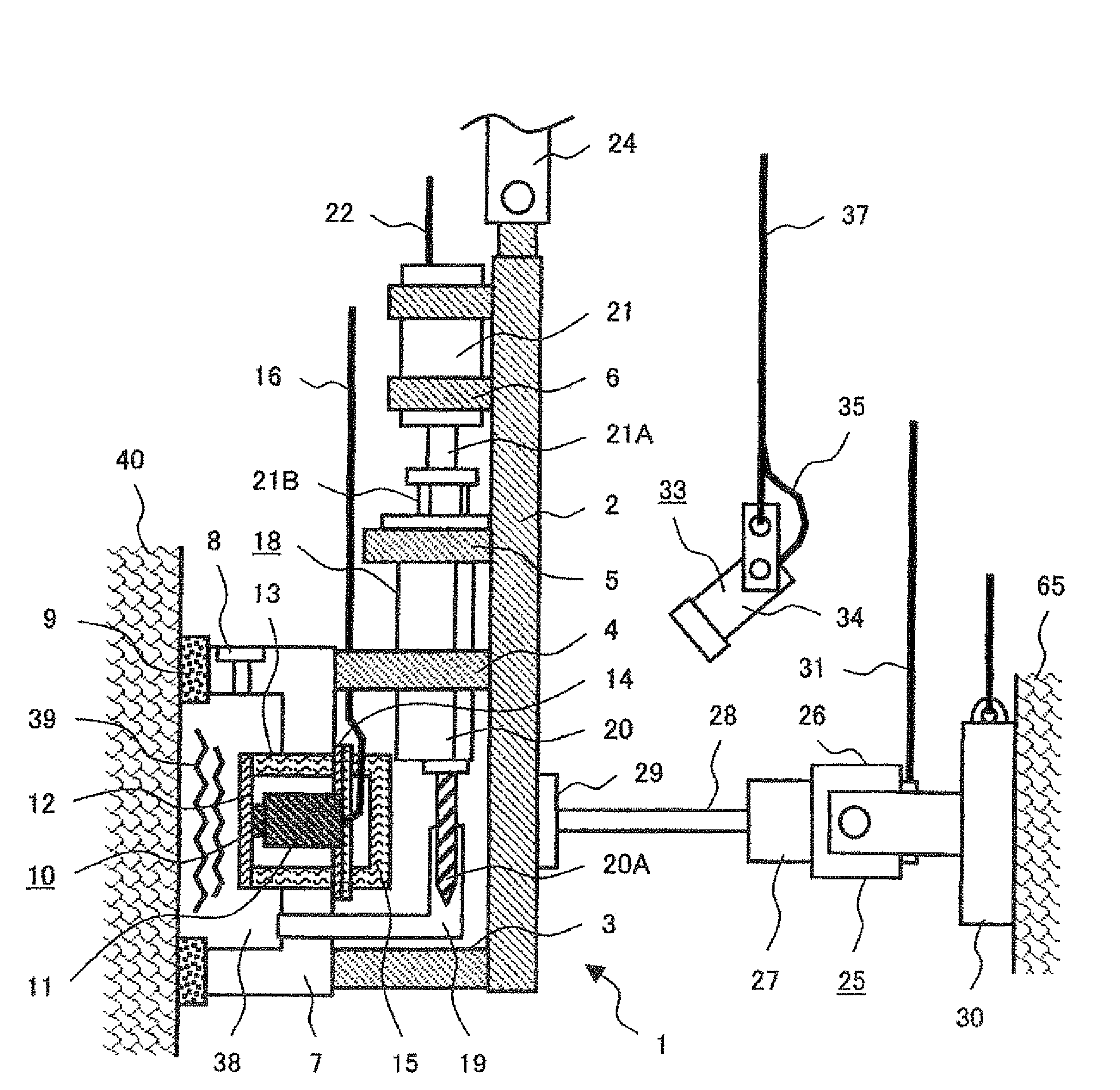

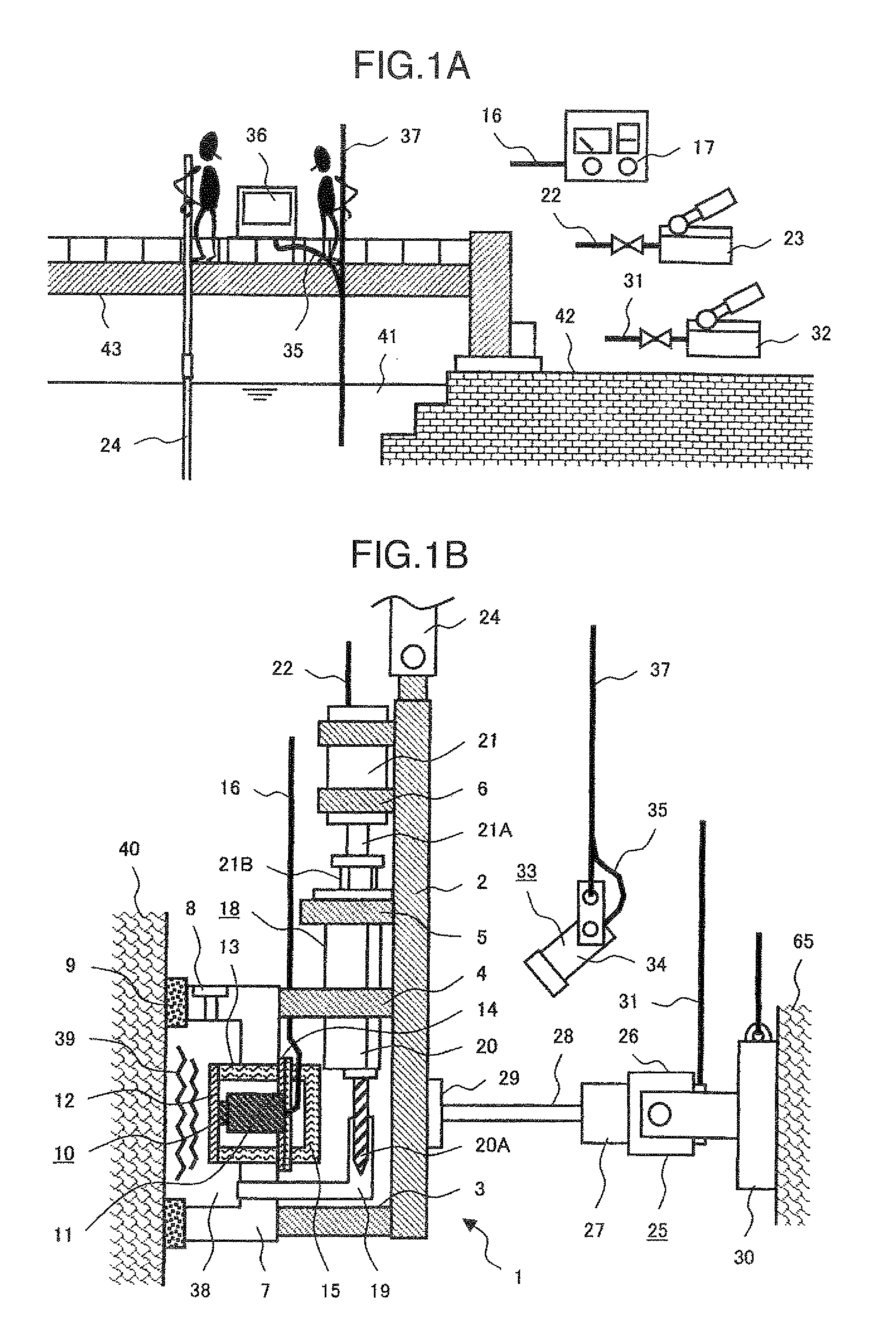

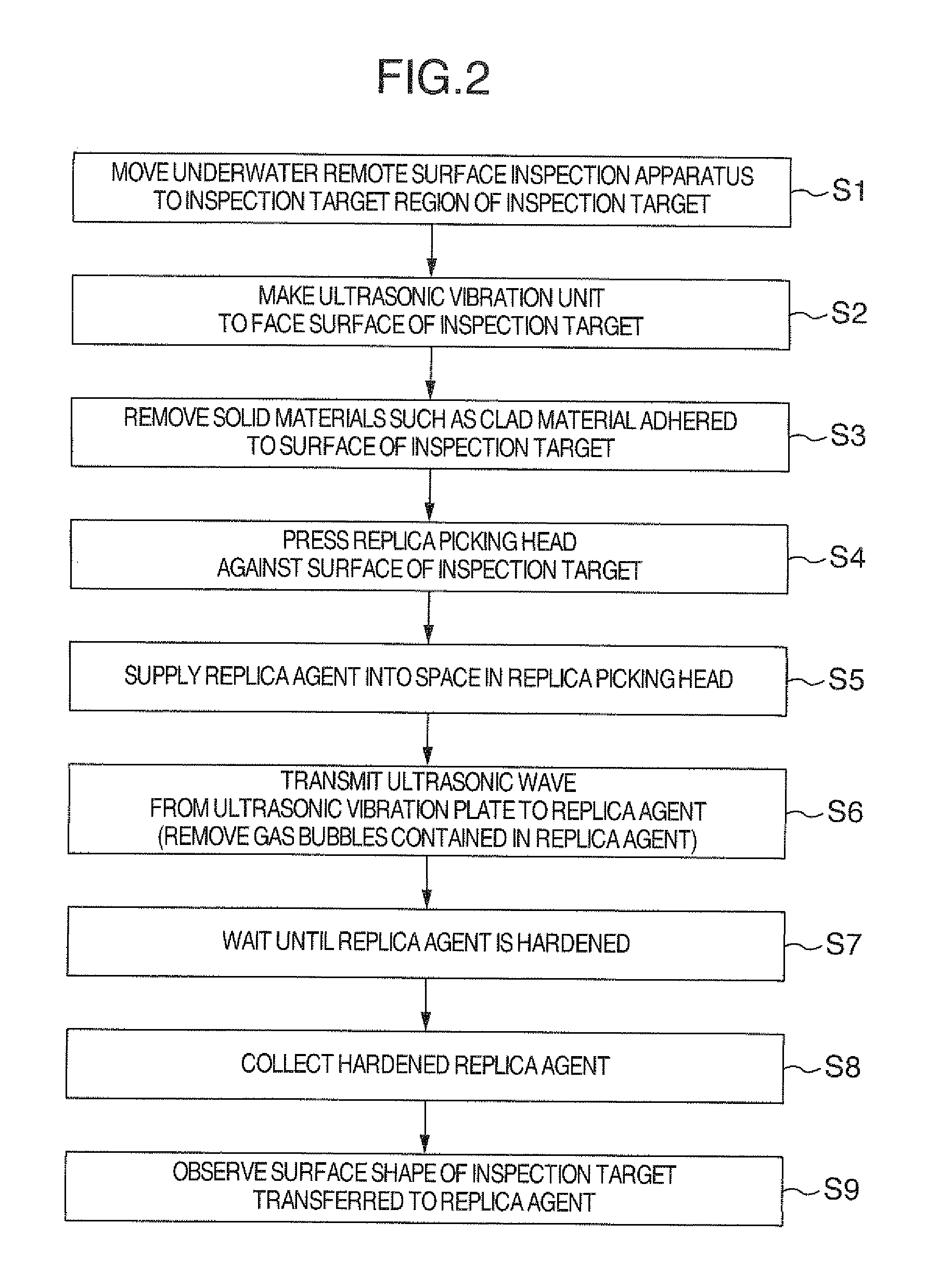

Underwater remote surface inspection method and apparatus for reactor constituting member

InactiveUS20100089164A1High precisionReduce the amount requiredAnalysing solids using sonic/ultrasonic/infrasonic wavesNuclear energy generationUnderwaterLiquid bubble

In an underwater remote surface inspection method for a reactor constituting member, in order to improve the precision of an operation of inspecting a surface shape of the reactor constituting member, an underwater remote surface inspection apparatus includes a replica picking head, an ultrasonic vibrator, and a replica agent cartridge. The replica picking head is pressed against a surface of core internal structure as an inspection target. A replica agent is supplied from the replica agent cartridge into the replica agent supply region formed inside the replica picking head and contacting with the surface of the core internal structure. After the operation of supplying the replica agent ends, an ultrasonic wave is transmitted from an ultrasonic vibrator to the replica agent inside the replica agent supply region. Accordingly, gas bubbles or liquid bubbles existing inside the replica agent supply region rise up so as to be discharged to the outside of the replica picking head through an air extracting hole. As a result, the gas bubbles or the liquid bubbles do not remain in the surface of the replica agent contacting with the surface of the core internal structure.

Owner:HITACHI-GE NUCLEAR ENERGY LTD

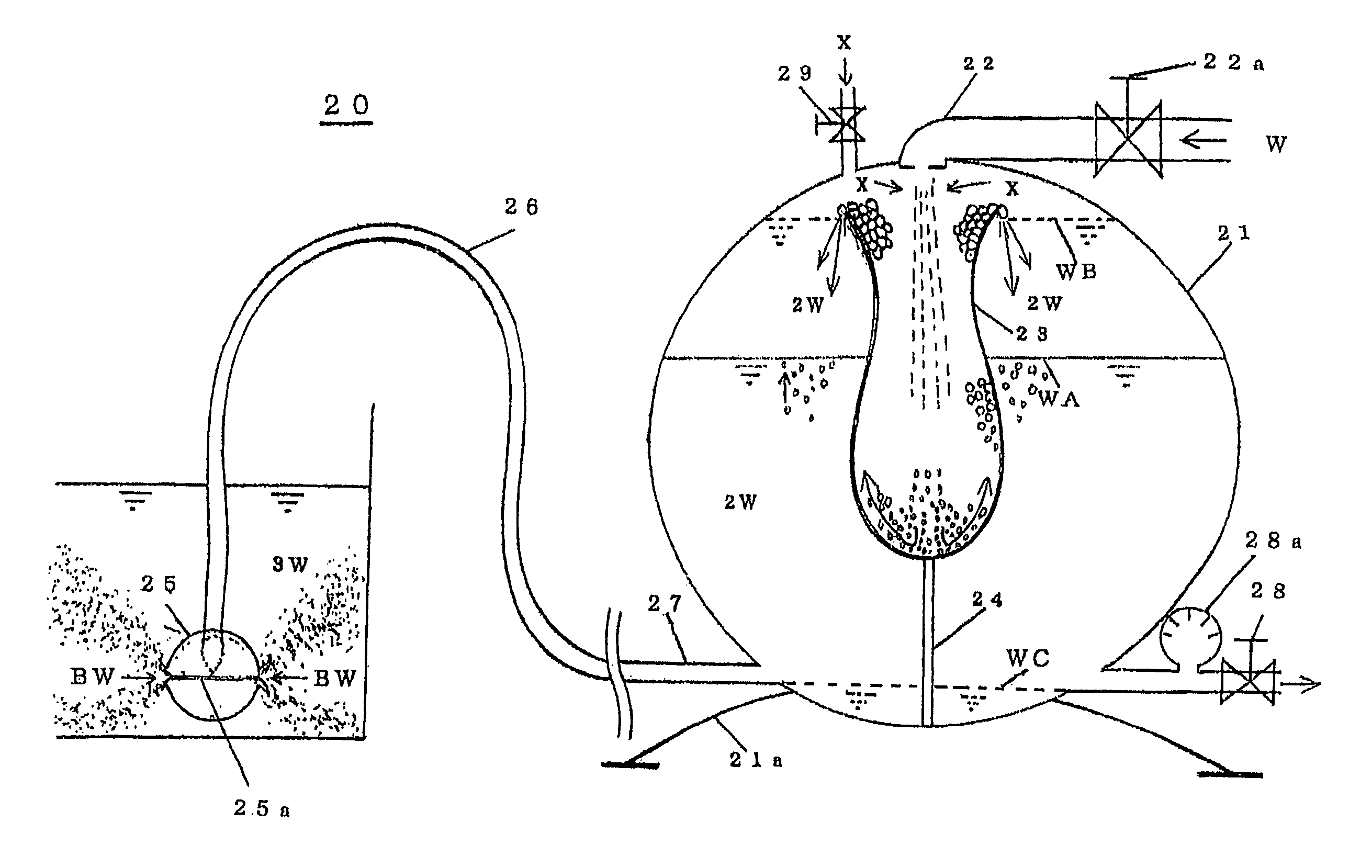

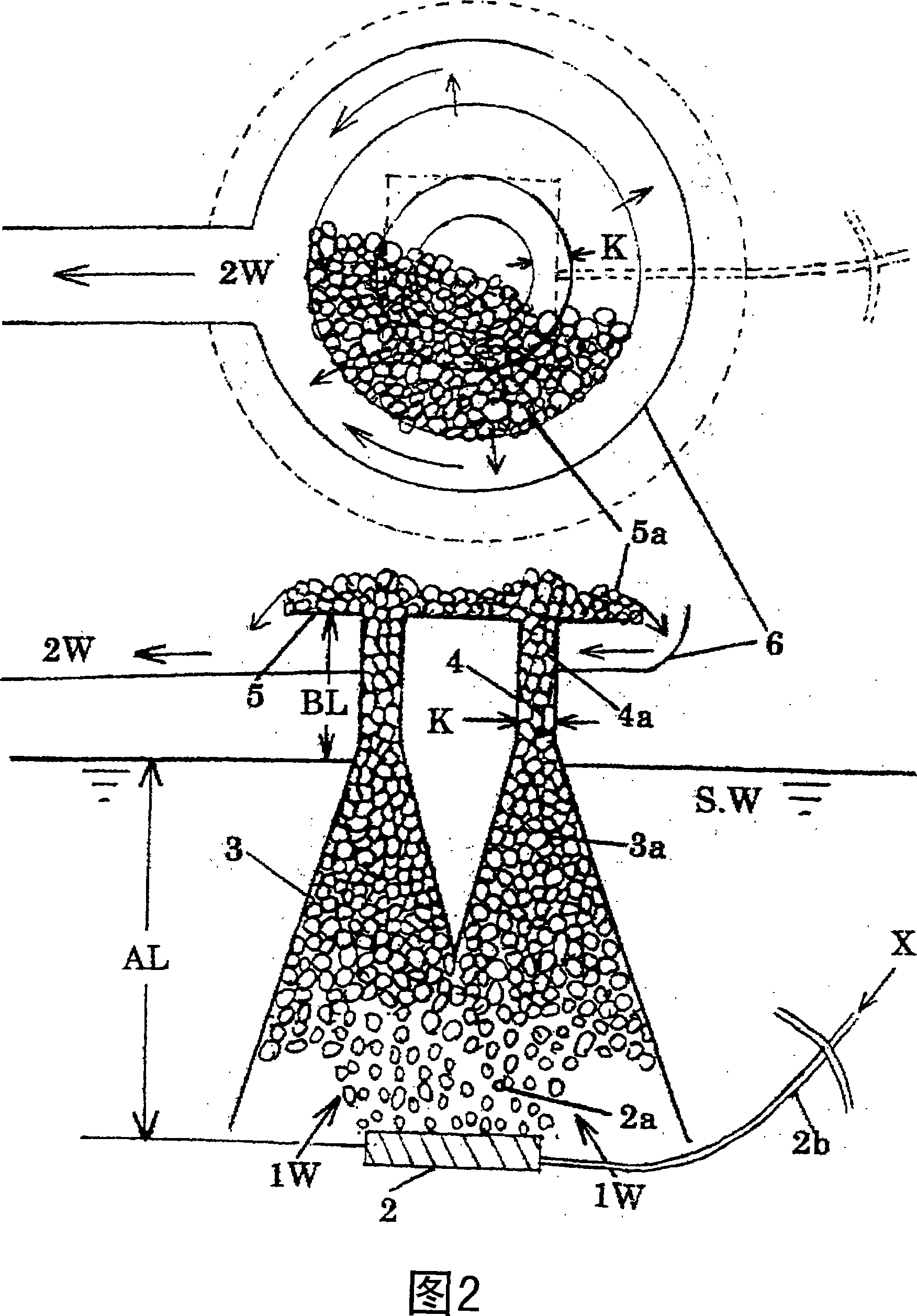

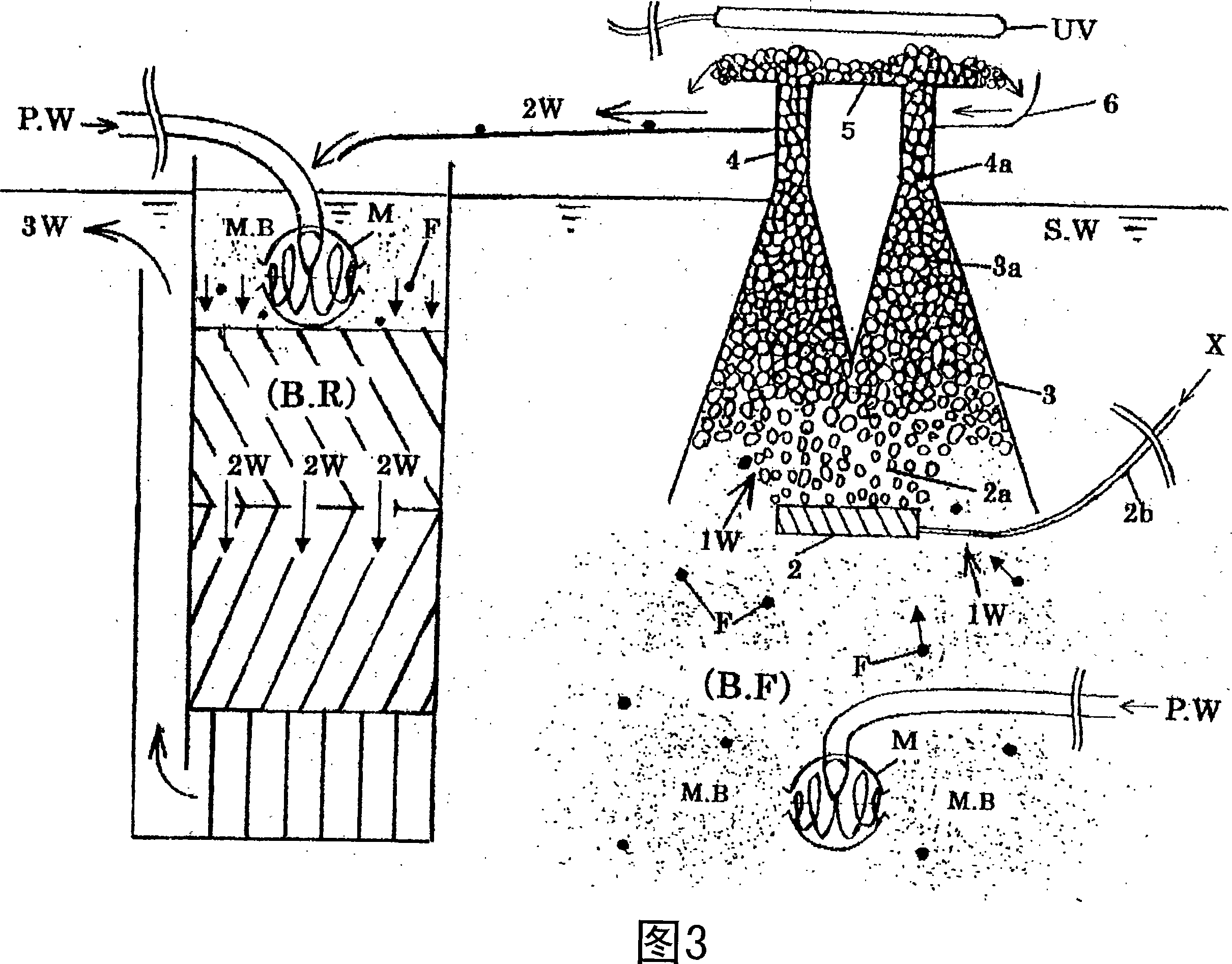

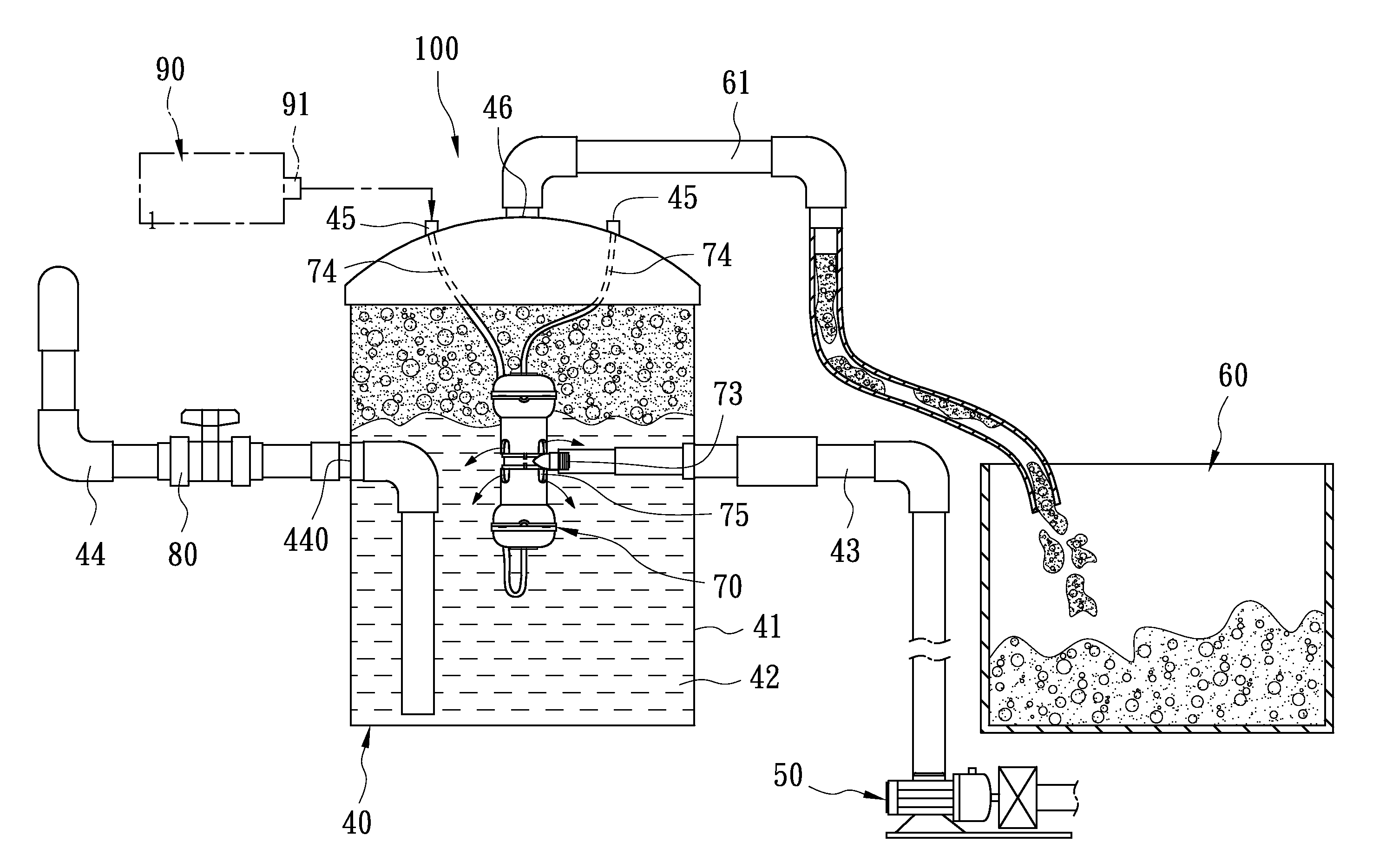

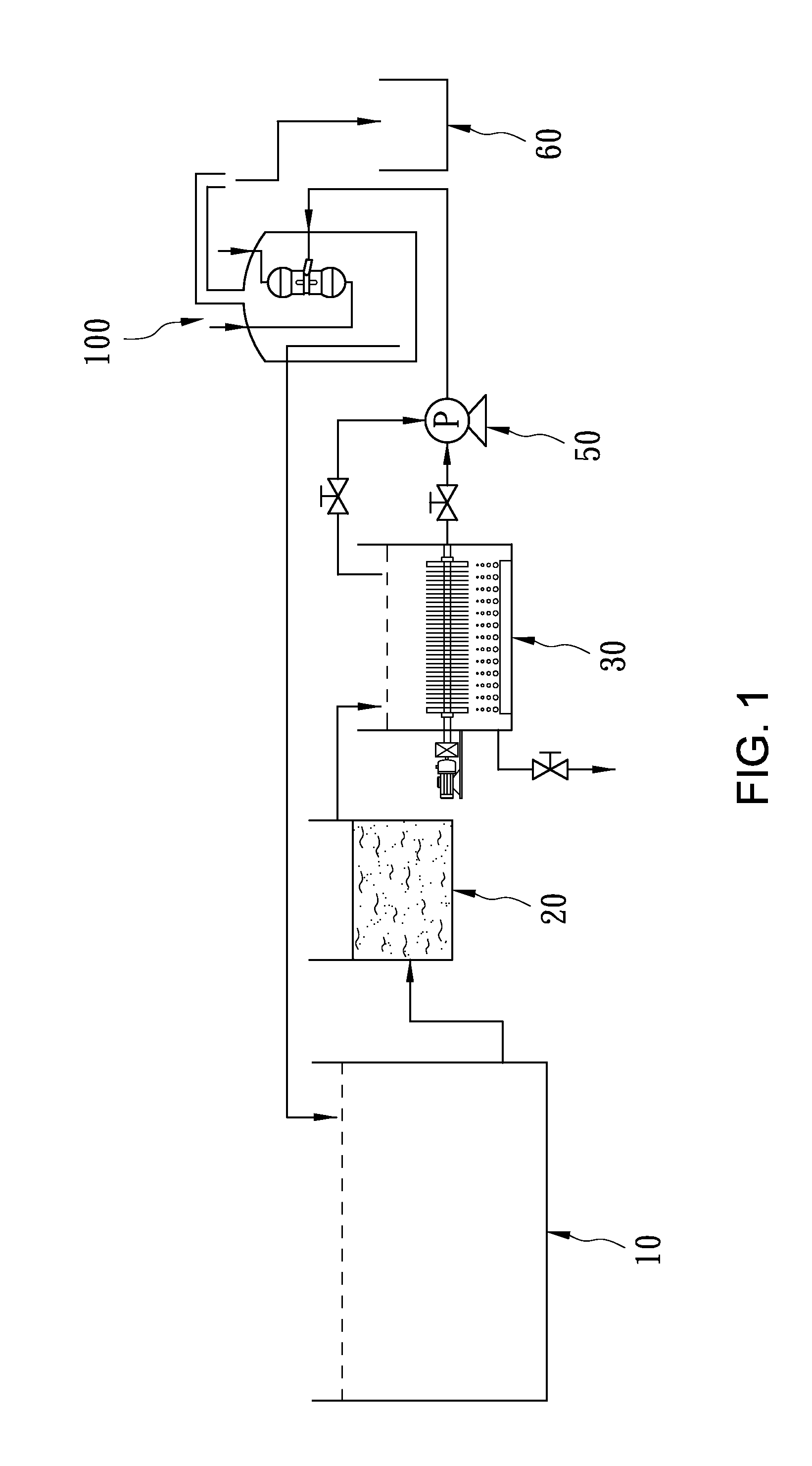

Aeration method, its apparatus and its system

InactiveCN101018742AGood dissolution efficiencyImprove utilization efficiencyTreatment using aerobic processesWater aerationAeration systemEnvironmental engineering

Provided are an aeration method, an aeration apparatus and an aeration system which allow, in a sewage disposal plant, a nursery for fish and shellfish and a closed water area in an ocean or the like, the highly efficient dissolution of an gas into the water to be treated and the transfer of the resultant treated water to another place by a water head difference by the use of a conventional apparatus for supplying a gas. An aeration apparatus, which comprises an gas spraying section (22) for generating gas bubble particles in the water to be treated (1W), a bubble rise section (3P) for allowing a mass of the gas bubble particles generated above to move upwards, a passage section (4P) for the rise of gas bubble particles, wherein the above gas bubble particles are pushed up to a position above a water surface and are changed into liquid bubbles, to thereby convert the water to be treated (1W) to a liquid film, and a liquid bubble transfer section (5P) wherein the treated water (2W) can be transferred by a water head difference.

Owner:池田 好明 +5

Method for making nano-powder through ultrasonic atomization-microwave pyrolysis

InactiveCN103588175AEasy to collectFast heatingMaterial nanotechnologyTin compoundsCavitationLiquid bubble

The invention relates to a method for making nano-powder through ultrasonic atomization-microwave pyrolysis, and belongs to the technical field of inorganic nano-materials. The method comprises the following steps: processing a soluble labile metal salt with a water-ethanol mixed solution to prepare a precursor solution, and carrying out ultrasonic atomization of the obtained precursor solution to obtain droplets; and carrying the droplets to microwaves under the action of a carrying gas or a fan for rapid drying pyrolysis to prepare the nano-powder which is a nanometer shell metal oxide or composite oxide powder. The method utilizes the combination of respective advantages of ultrasonic waves and the microwaves, the ultrasonic waves make a large amount of tiny bubbles generated because of cavitation in a liquid to form the droplets on the surface of the liquid, each of the droplets has a spherical hollow small vacuole structure, and the microwave heating has the advantages of uniform outward heating, selective heating, fast heating speed and easy control.

Owner:KUNMING UNIV OF SCI & TECH

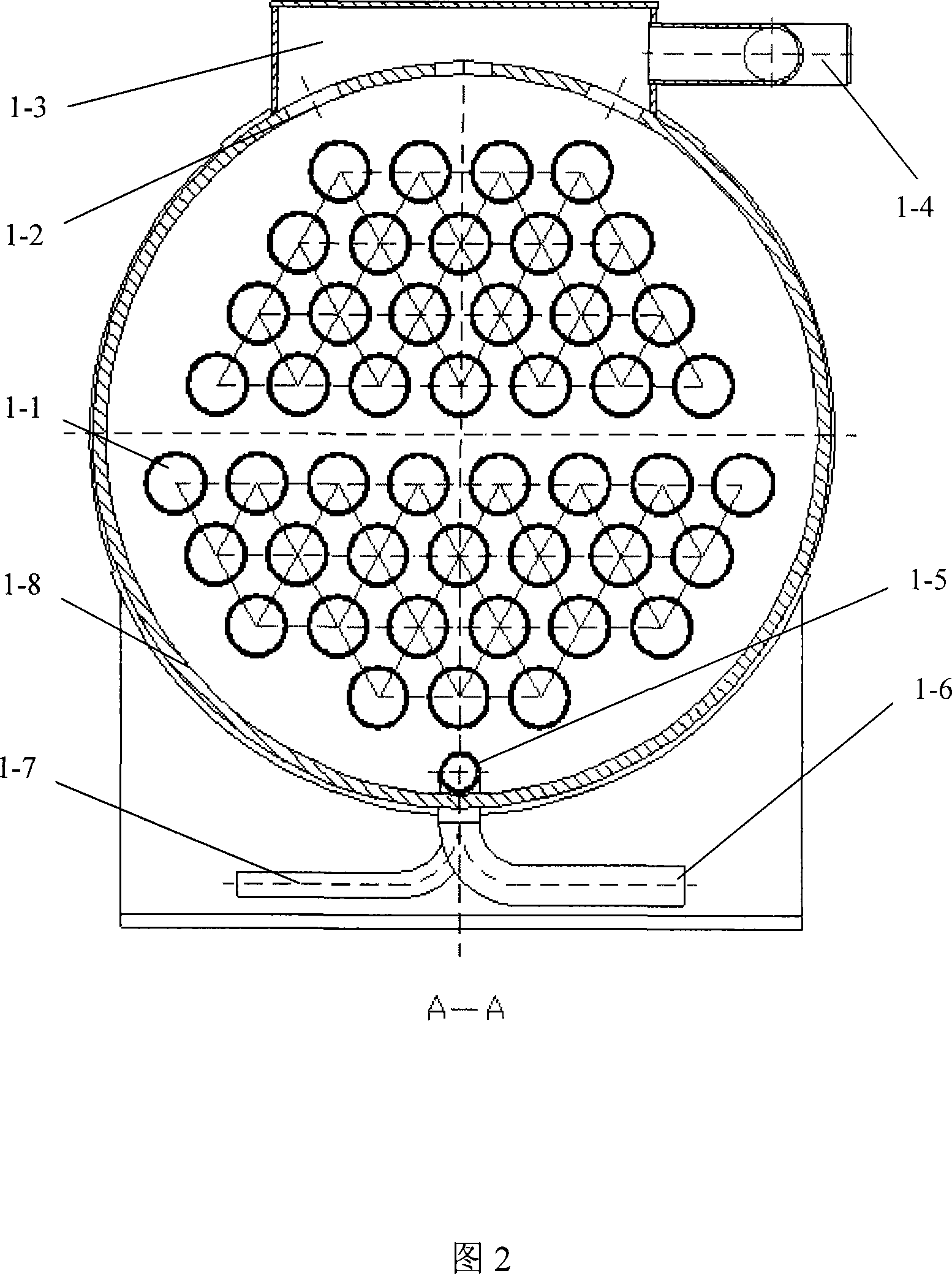

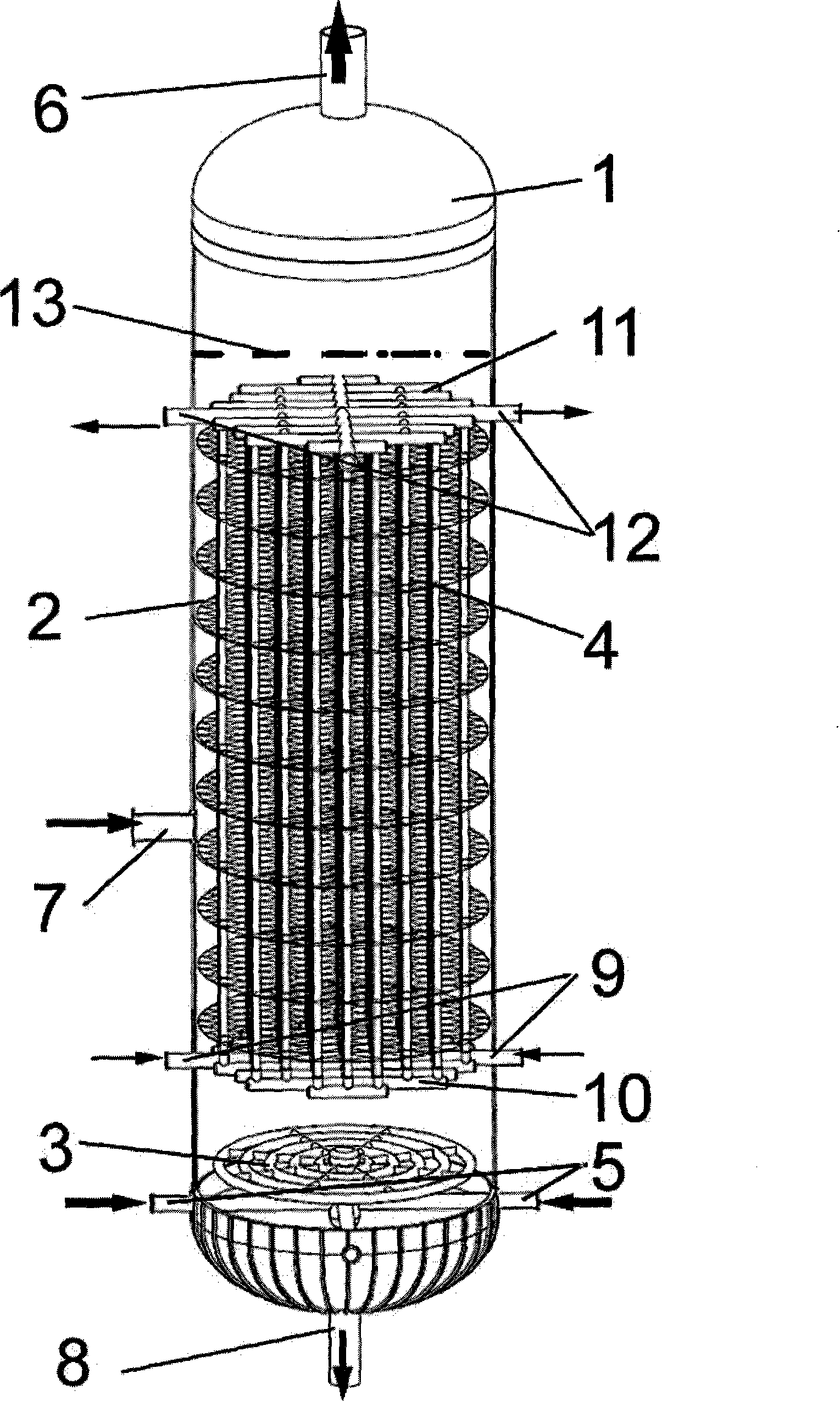

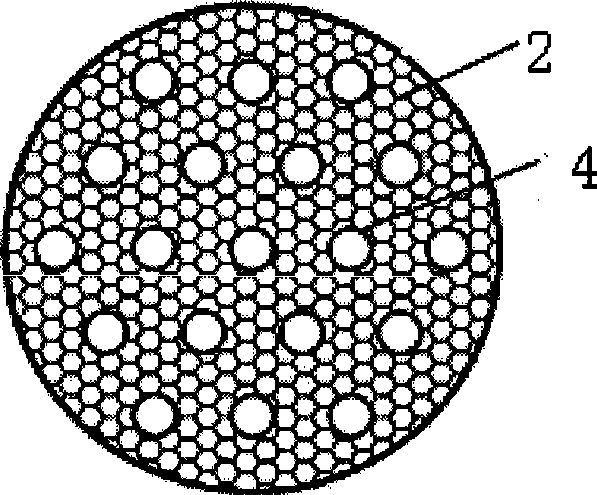

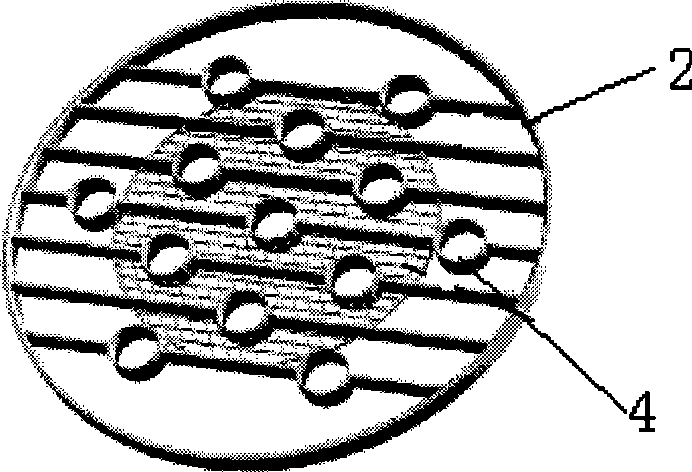

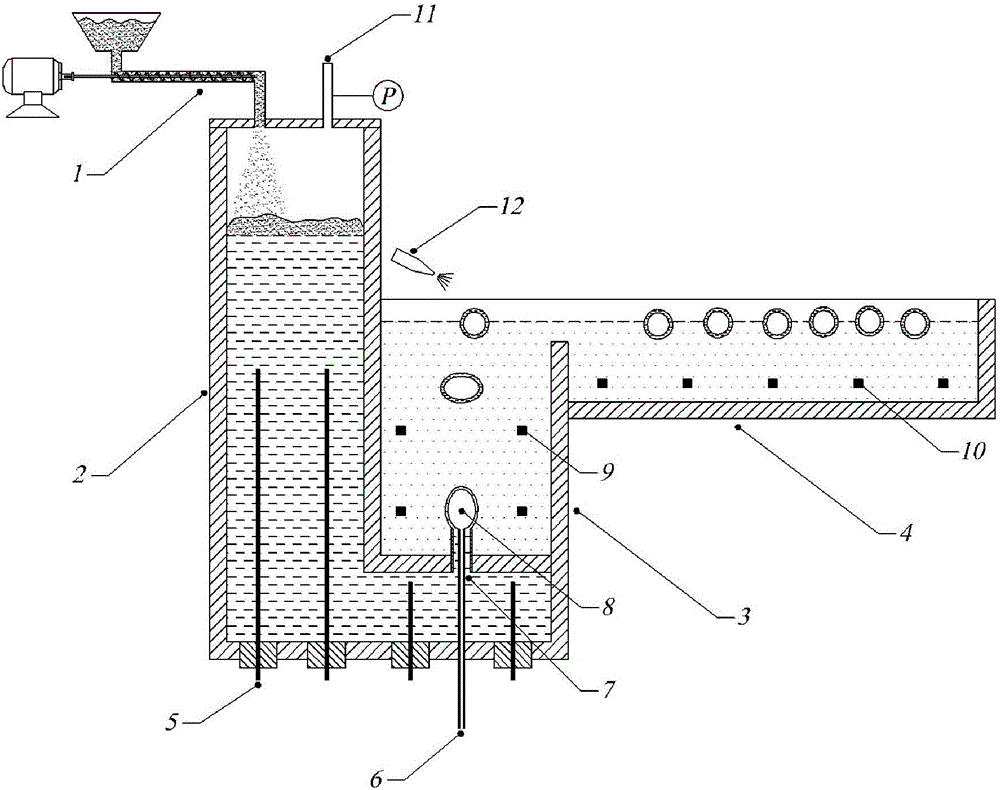

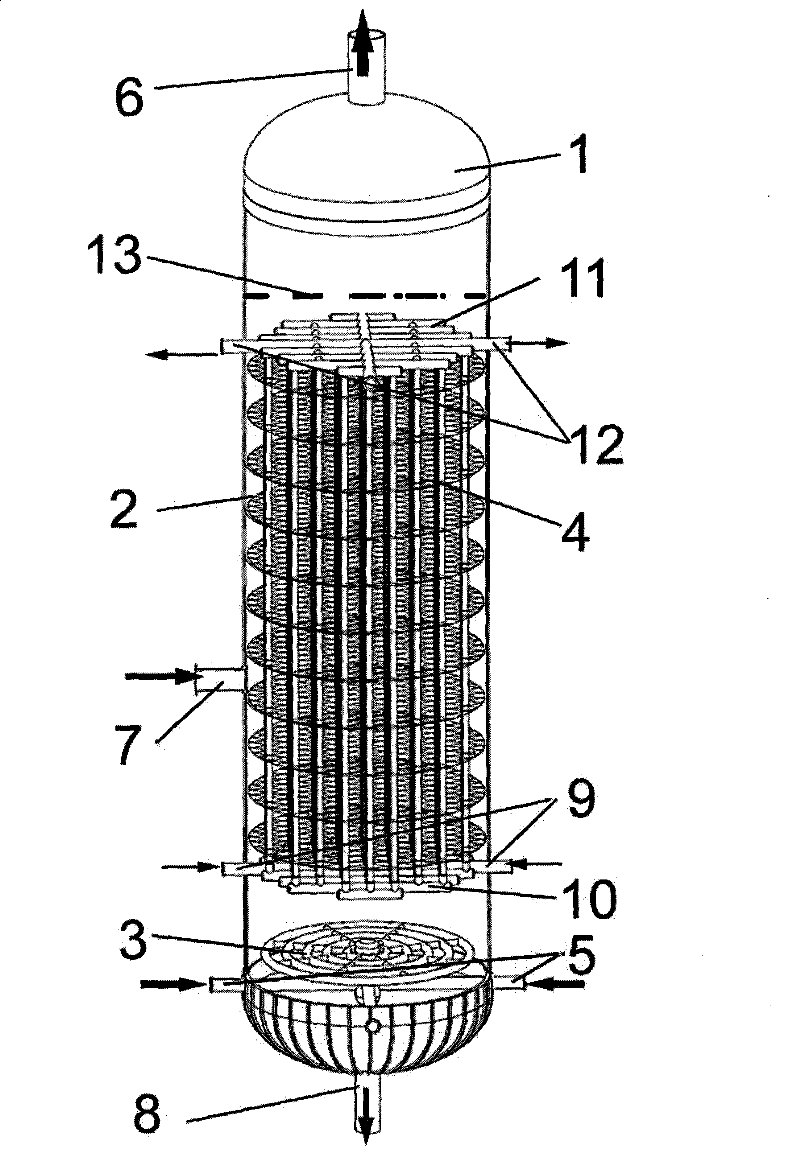

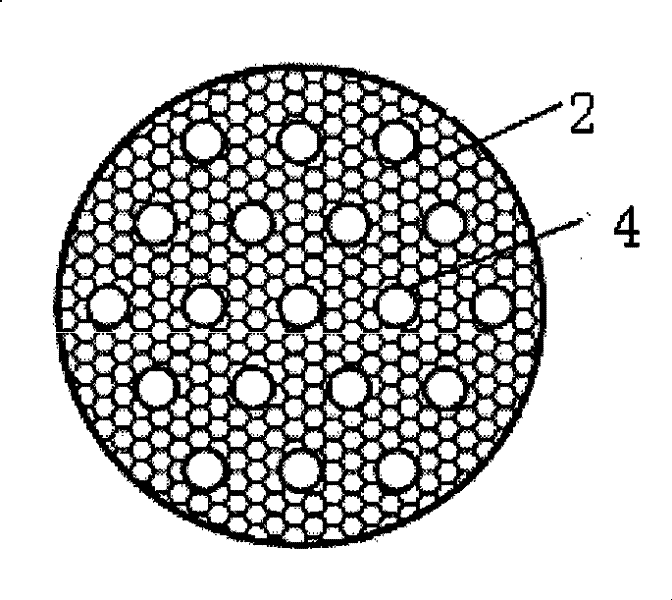

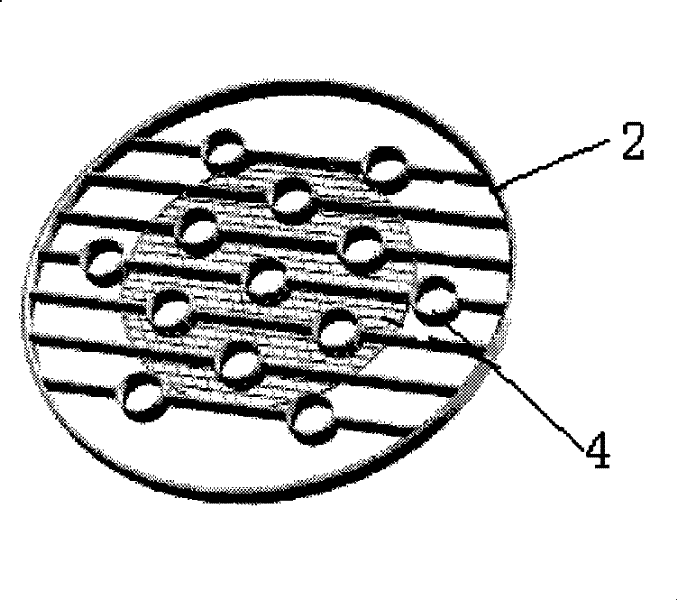

Method and device for improving flow character of gas liquid bubble column with row tubes

InactiveCN101417220AImprove flow characteristicsImprove responseLiquid-gas reaction processesSlurry reactorBubble column

The invention discloses a method and a device used for improving the flowing characteristic of the slurry bubble tower with row tubes; the device comprises a tower body, a gas distributor and a vertical heat exchanging row tube bundle; the lower end of the vertical heat exchanging tube bundle is connected with a liquid distributor which is fixed at the lower part of the tower body and the upper end thereof is connected with a liquid collector which is fixed at the upper part of the tower body; a plurality of layers of horizontal grid-typed damp internal components are arranged between the liquid distributor and the liquid collector; the heat exchanging row tube bundle vertically passes through the horizontal grid-typed damp internal components; each layer of the grids is fixed on the tower wall and the row tubes; and by arranging the horizontal grid-typed damp internal components in the slurry bubble tower which is provided with vertical row tube bundles; and the horizontal damp internal components block the flowing of the slurry and air bubbles in the tower, inhibit the flowing craggedness effect caused by the row tube bundle, and reduce the returned mixing of the fluid, thus improving the flowing characteristic of the slurry reactor.

Owner:ZHEJIANG UNIV

Liquid bubble separator of circulating water system

InactiveUS9451759B2Avoid cloggingIncrease ratingsTreatment using aerobic processesSpecific water treatment objectivesMicro bubbleTreated water

A liquid bubble separator of a circulating water system contains: a cylindrical tank, a pump, a bubble collection tank, and at least one micro bubble generating unit. The cylindrical tank included a water chamber defined by an inner wall, an inlet pipe, an outlet pipe, at least one air orifice, and a bubble discharging hole. The pump is coupled with the inlet pipe to pump treated water into the inlet pipe via the nitrification tank. The bubble collection tank is mounted on one side of the cylindrical tank and includes a collecting tube. Each micro bubble generating unit is disposed in the water chamber and includes a body, a first mixing room, an inlet, at least one air tube coupling with the at least one air orifice and corresponding to the inlet, and a plurality of backflow apertures formed around the body and communicating with the first mixing room.

Owner:KUO CHI TSE

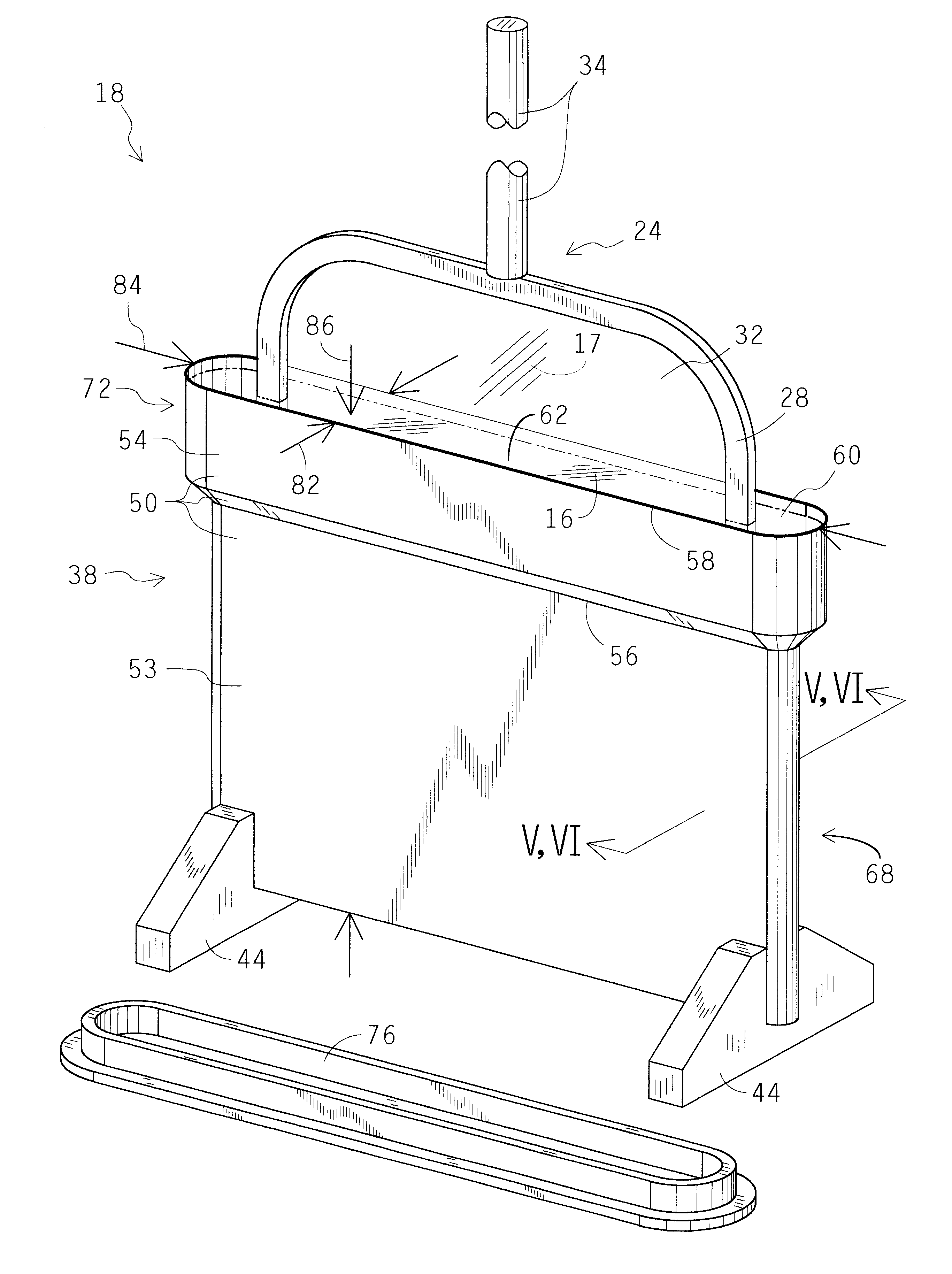

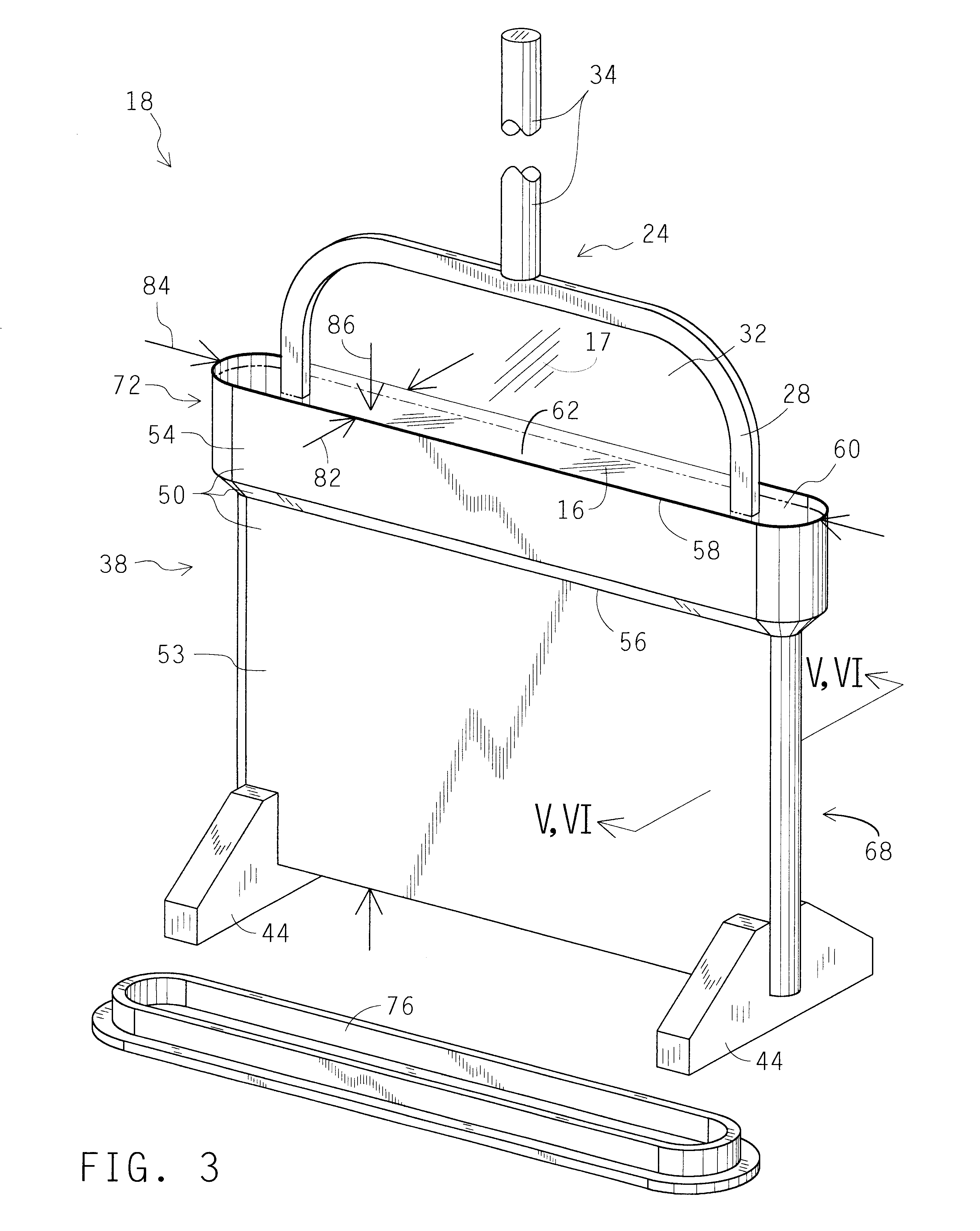

Vertically disposed bubble maker

A vertically disposed bubble maker comprising a specially designed container for reducing the amount of a bubble solution required for dipping a large, vertically oriented, bubble forming loop in bubble solution for blowing bubbles. A wand comprises a handle attached to the loop, and there is a loop opening inside the loop. The container retains a liquid bubble solution, is open at the top, and is large enough so that the loop opening can be fully submerged in bubble solution when the loop is vertically oriented and when the container is full. The container has a shape that is substantially conformal to the shape of the vertically oriented loop when both the loop and the container are viewed from above. In the preferred embodiment, the container comprises a lower and an upper section, the lower section is the holster, the upper section is the reservoir. In this embodiment, the width of the reservoir is greater than the width of the holster, and the vertical cross-sectional area of the reservoir is greater than the vertical cross-sectional area of the holster. The bubble maker may also include a lid for covering the container, which would better allow the container to be stored with the bubble solution still inside. The lid would serve to prevent dirt and debris from entering the bubble solution during storage. The lid may also seal the container to prevent the bubble solution from leaking or spilling when the container is moved or tipped.

Owner:PORTWINE WAYNE K

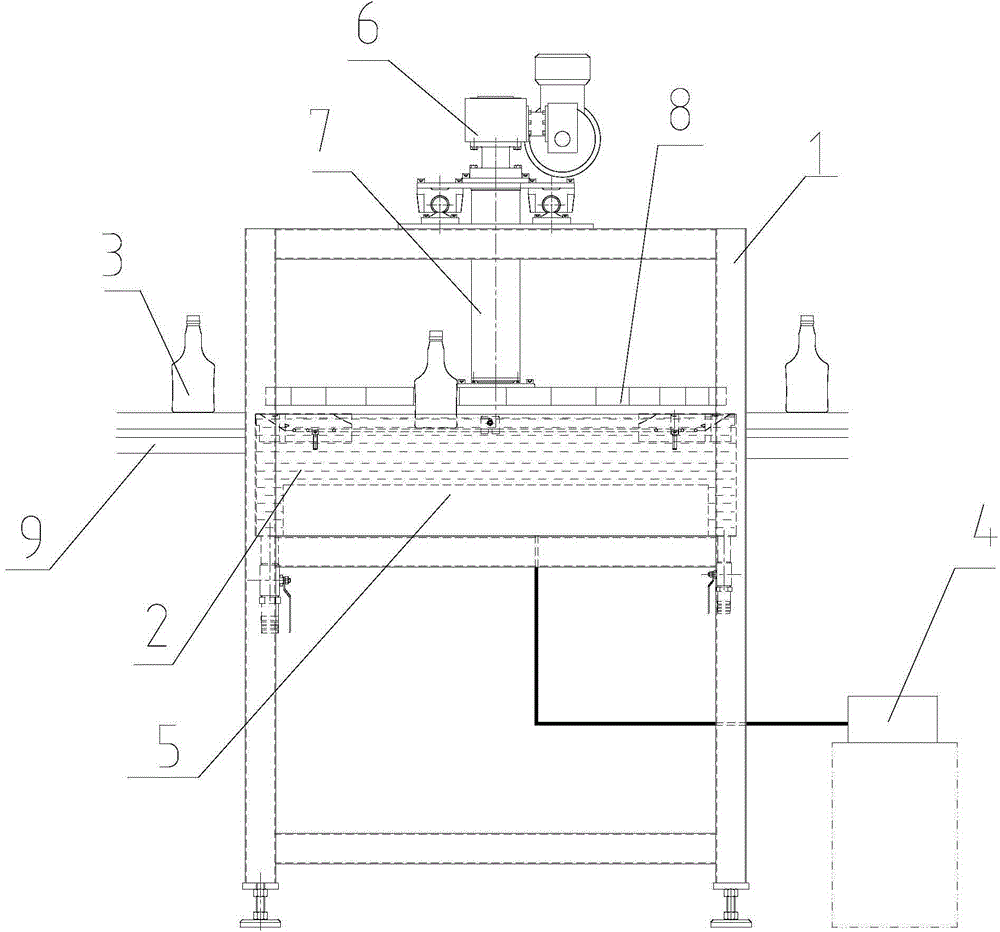

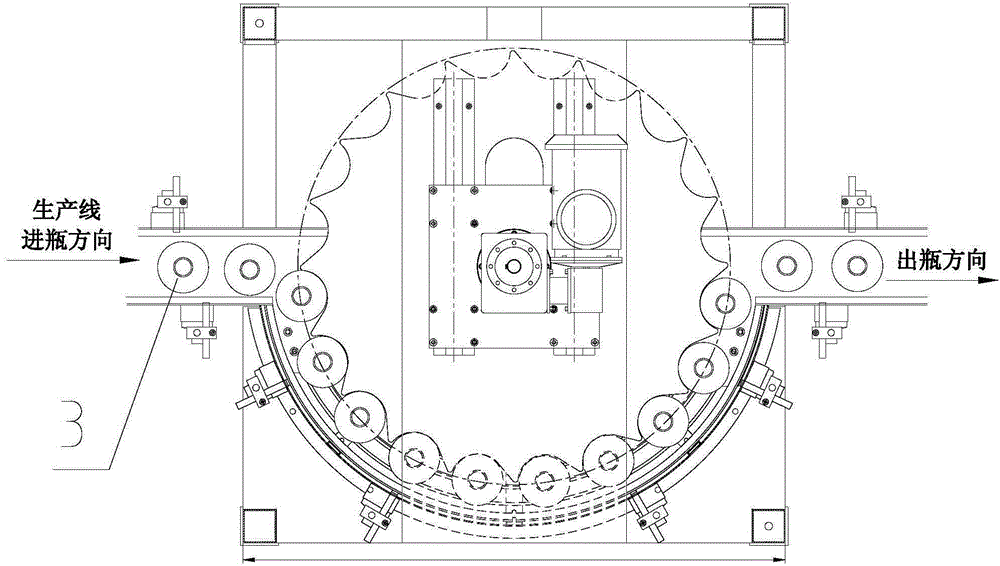

Defoaming device before bottled liquid light inspection and defoaming method of defoaming device

InactiveCN105983381AEliminate Bubble ProblemsSmall footprintEnergy based chemical/physical/physico-chemical processesFoam dispersion/preventionLiquid mediumEngineering

The invention provides a defoaming device before bottle liquid light inspection and a defoaming method of the defoaming device. The defoaming device comprises a rack, a liquid containing container, a conveying device and an ultrasonic device, the liquid containing container is located on the upper portion of the rack and filled with a liquid medium, the conveying device and the ultrasonic device are both partially arranged in the liquid containing container, and the conveying device does not make contact with the ultrasonic device; the conveying device can convey bottles and enable the bottles to be immersed in the liquid medium. The defoaming method comprises the steps that the ultrasonic device is started, and meanwhile the conveying device is started; filled bottles enter the conveying device, the conveying device lowers the bottles to below the liquid level of the liquid medium, the ultrasonic device sends out an ultrasonic oscillation signal to remove liquid bubbles in the bottles, and the conveying device conveys the bottles to the light inspection process. The defoaming device can thoroughly remove the bubbles in the bottle liquid and can be arranged on a production line without separately occupying a production space.

Owner:CHENGDU HONGRUI TECH

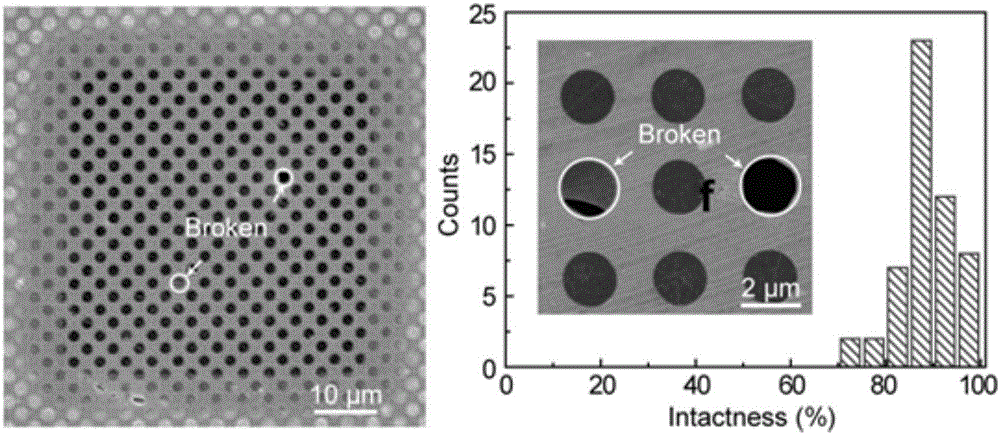

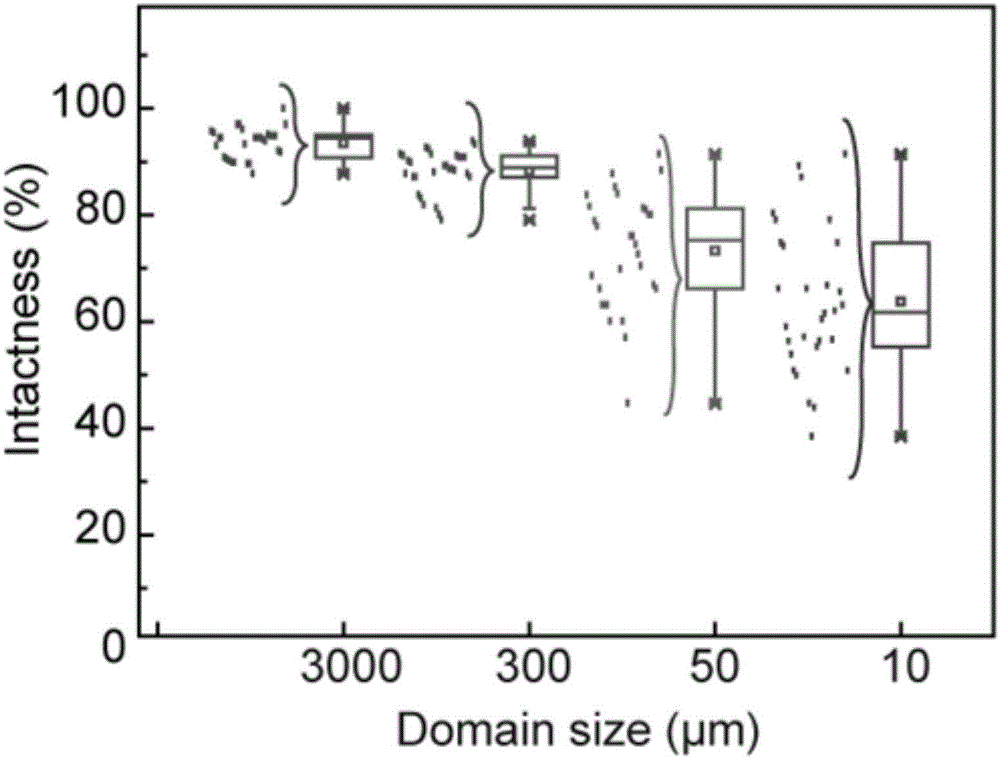

Method used for realizing high-efficiency liquid packaging using graphene monocrystal support membrane grid

ActiveCN106769287AImprove integrityImprove cleanlinessElectric discharge tubesPreparing sample for investigationLiquid cellElectron microscope

The invention discloses a method used for realizing high-efficiency liquid packaging using graphene monocrystal support membrane grid. The method comprises following steps: two slices of graphene grow on different growth substrates are transferred onto a transmission substrate, liquid to be packaged is dropped onto the surface of one of the two graphene slices, and the graphene slice is coated with the other graphene slice so as to realize packaging, and obtain a large amount of liquid bubbles for in-situ characterization under a transmission electron microscope. The process is simple; repeatability is high; controllability is high; compatibility is high; thousands of liquid cells packaged with graphene on a sample with a size of several millimeters are prepared in a short time for in-situ characterization under a transmission electron microscope, so that the possibility of study of reaction mechanism on atomic scale is increased greatly.

Owner:PEKING UNIV

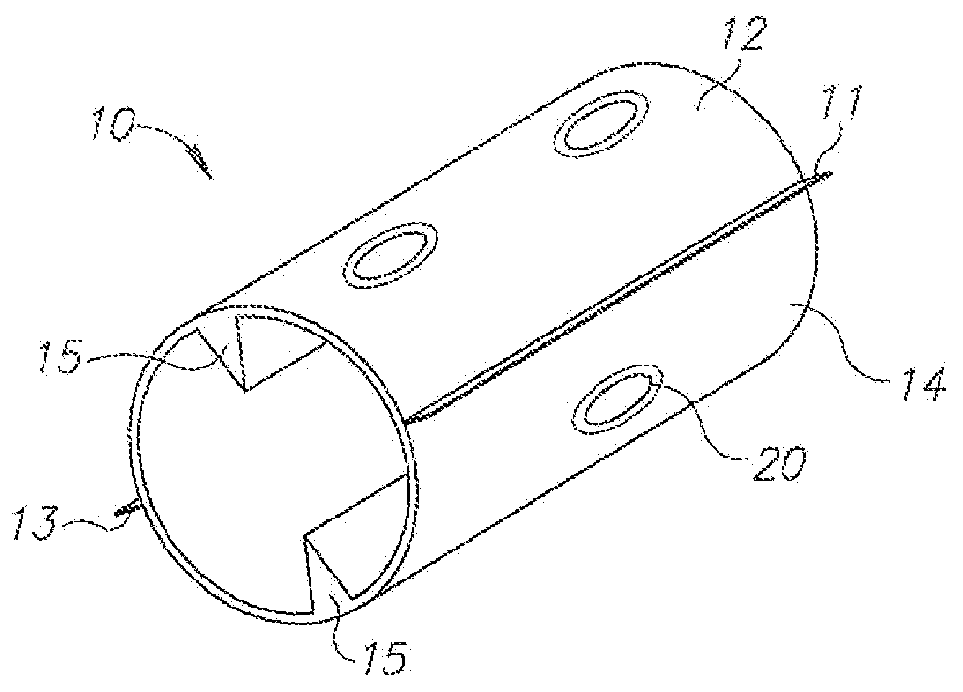

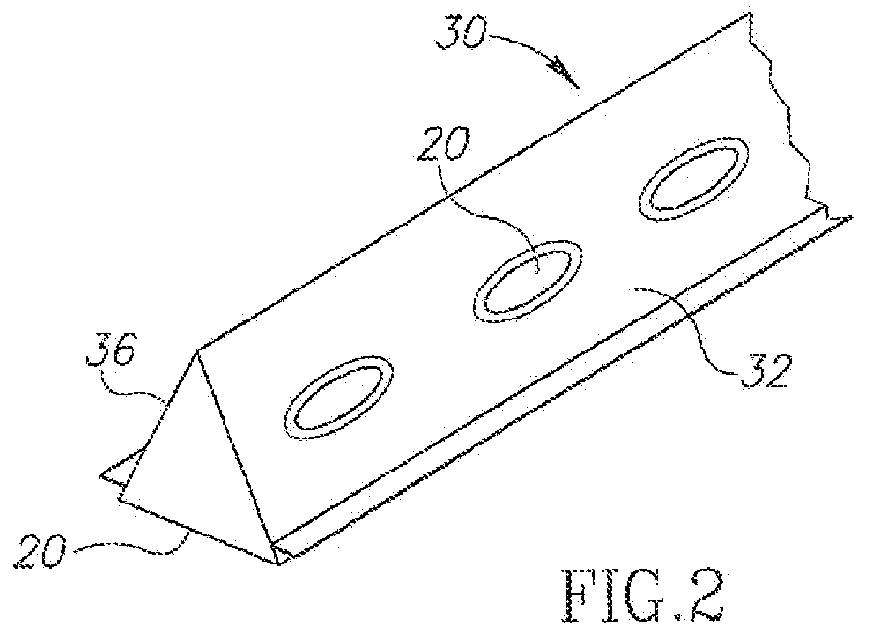

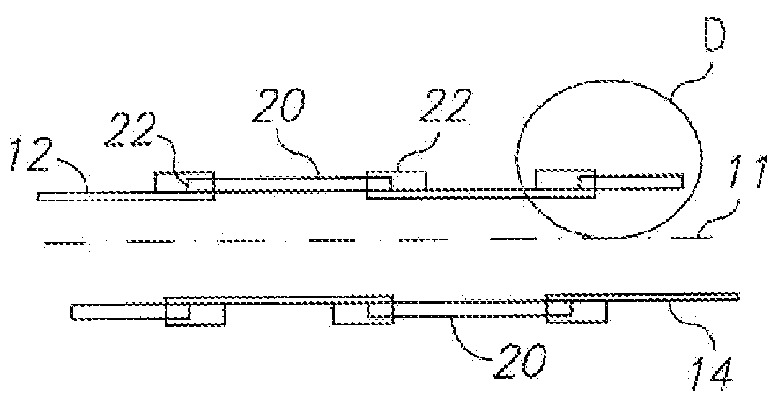

Irrigation conduit and system

InactiveUS20120107048A1Resistant to cloggingEasy to deployAgriculture tools and machinesConstructionsEngineeringCatheter

An irrigation conduit for sub ground irrigation, methods for fabrication the conduit and irrigation systems comprising the same. The irrigation conduit comprises one or more elongated water-impermeable plastic strips joined to form a sleeve, wherein at least one of the strips comprises a plurality of water transmitting ceramic windows spaced along its length. The water transmitting ceramic windows are having an internal structure comprising vacuoles and a network of channels connecting between the vacuoles.

Owner:KIBUTZ YOTVATA

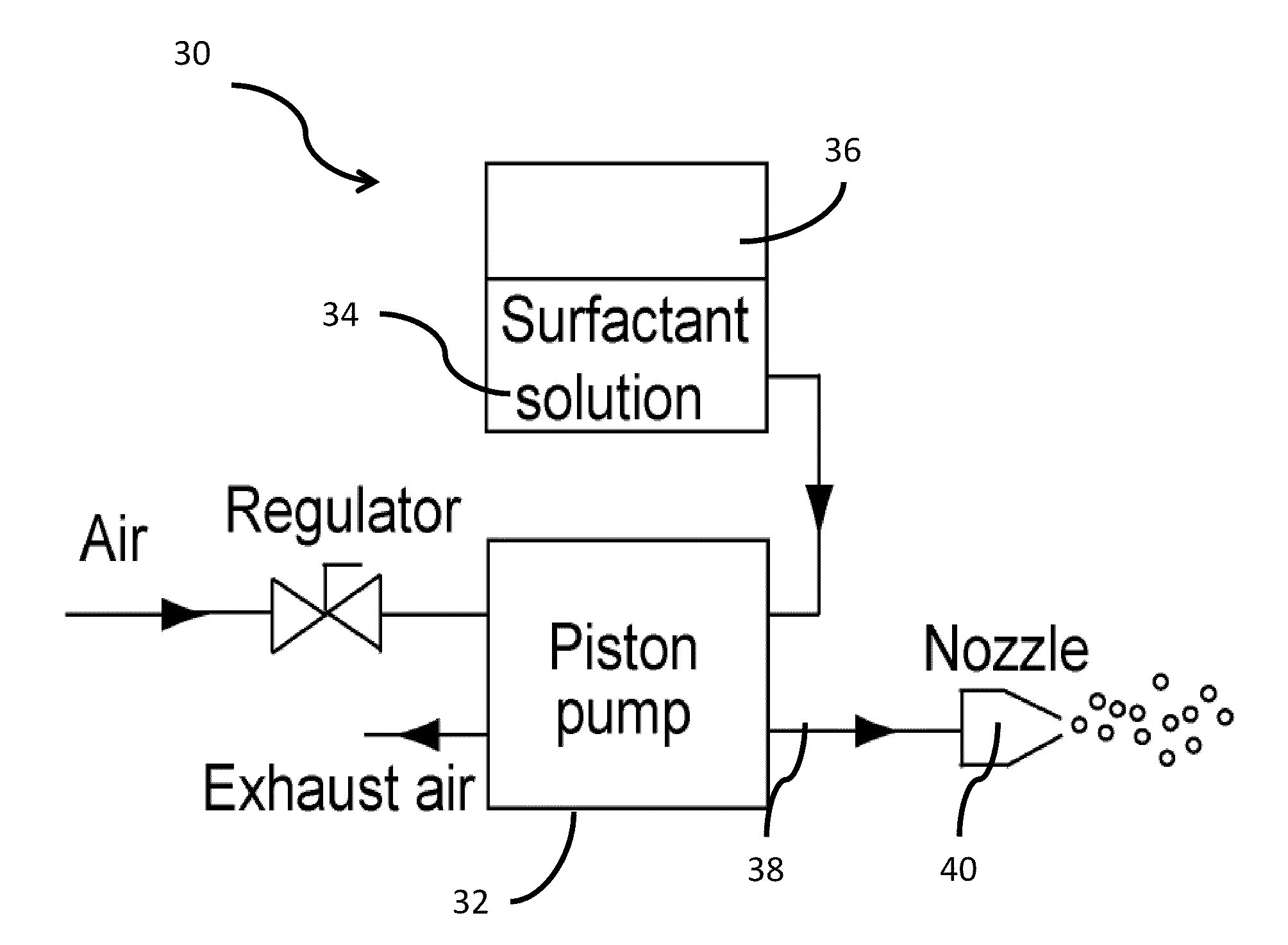

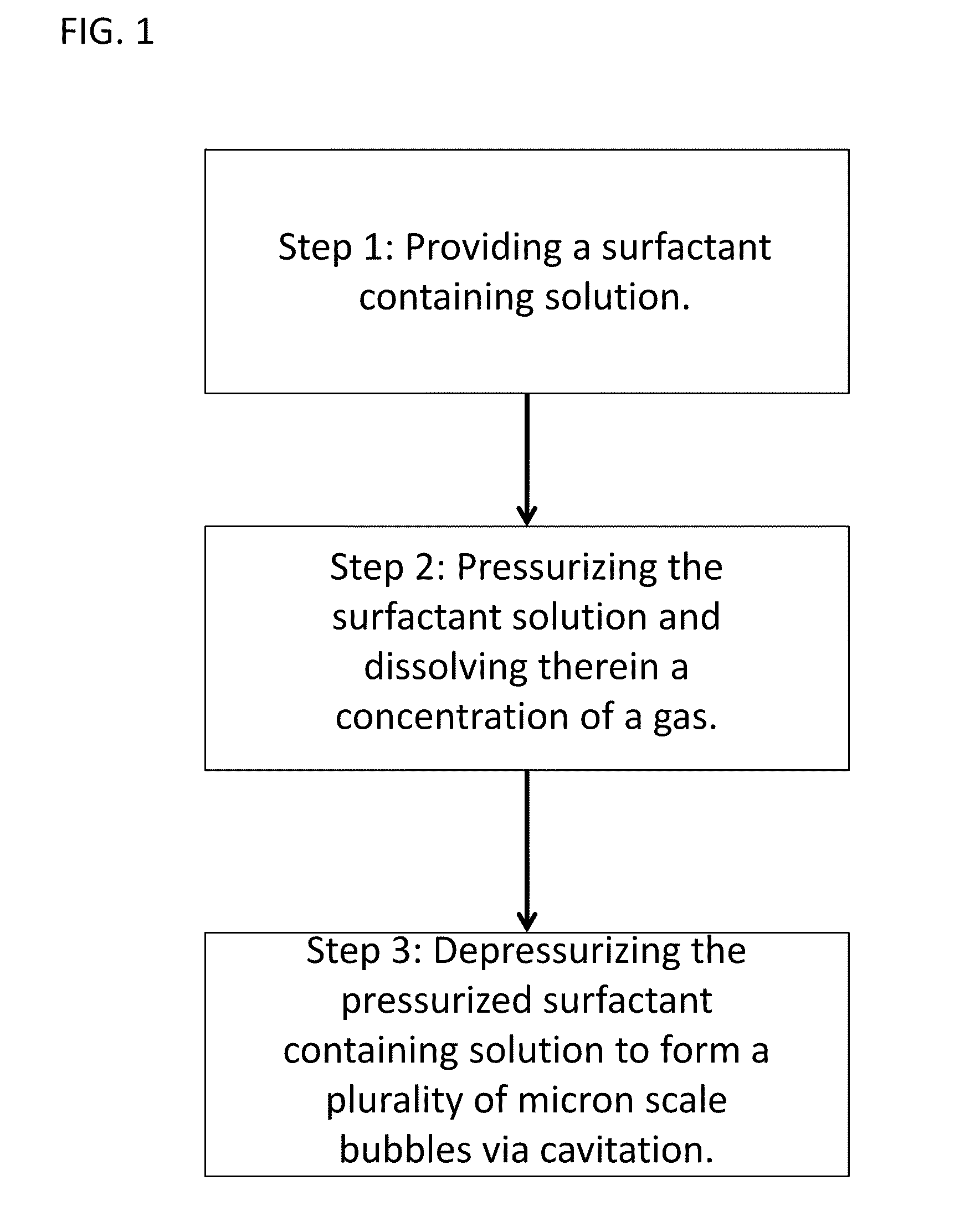

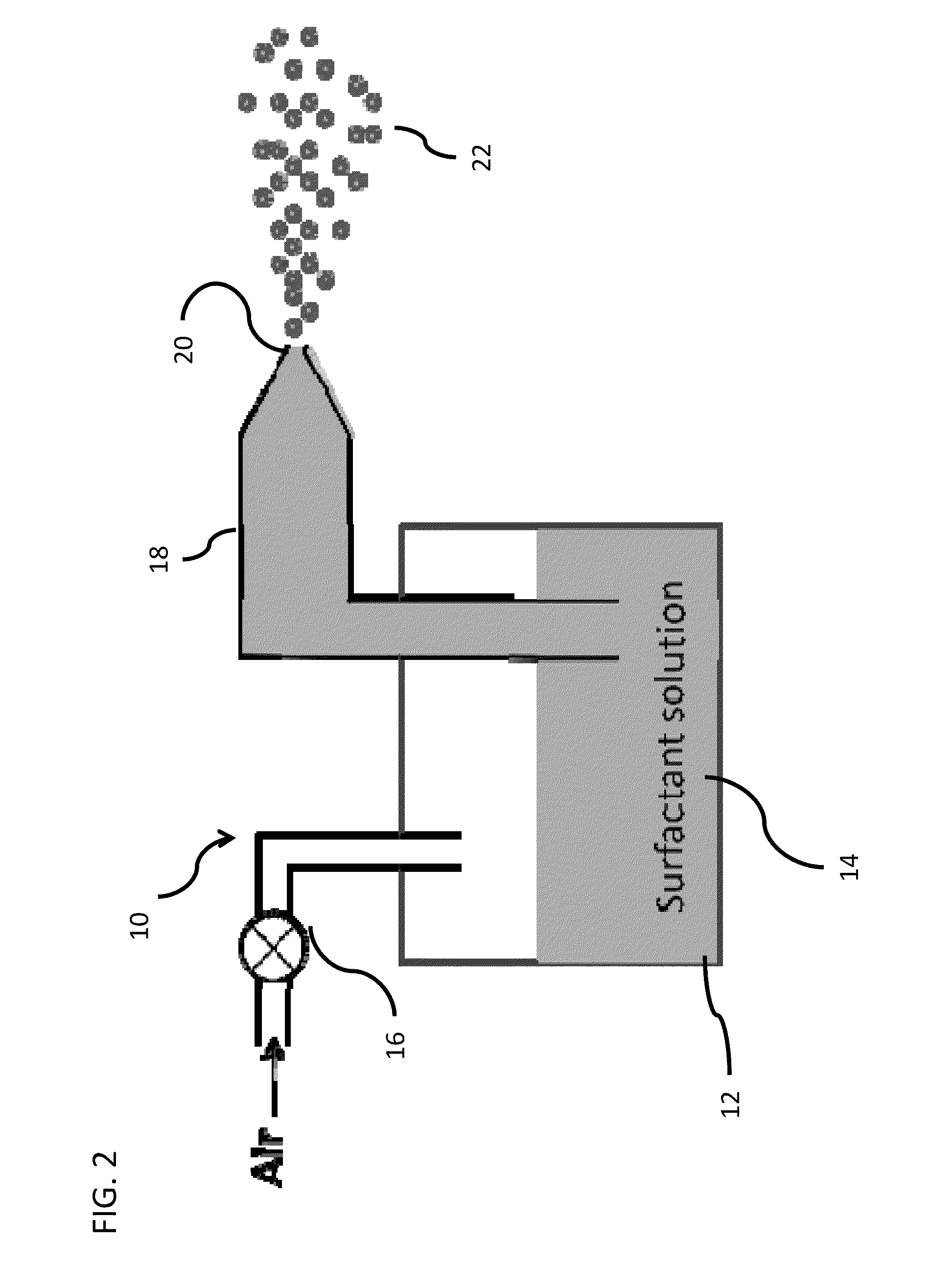

Method to generate micro scale gas filled liquid bubbles as tracer particles or inhaler mist for drug delivery

A method and apparatus that enables the production of micron-scale free-standing bubbles made of liquids containing surfactants are provided. The method and apparatus of the invention overcomes the limitations of conventional bubble forming techniques by using a controlled cavitation process in a liquid media.

Owner:CALIFORNIA INST OF TECH

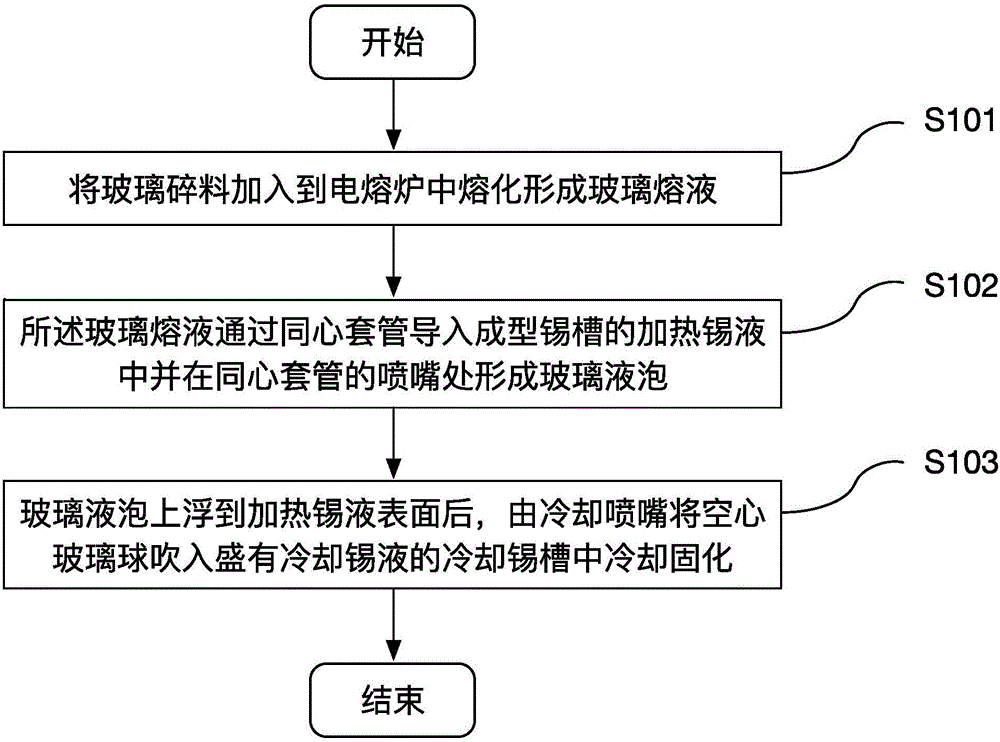

Tin liquid bubbling production process and tin liquid bubbling production apparatus for hollow glass spheres

ActiveCN105906192AImprove protectionEasy to recycleGlass shaping apparatusGlass productionGlass spheresLiquid bubble

The invention discloses a tin liquid bubbling production process and a tin liquid bubbling production apparatus for hollow glass spheres. The production process includes the steps of: (A) adding a crushed glass material into an electric melting furnace to melt the material into molten glass; (B) feeding the molten glass through a concentric sleeve tube bubbler into a shaping tin trough, wherein molten glass bubbles are naturally formed on a nozzle of the concentric sleeve tube bubbler; (C) after the molten glass bubbles are floated to the surface of the heated tin liquid, blowing the molten glass bubbles into a cooling tin trough by means of a cooling nozzle to cool and solidify the glass spheres. The production apparatus includes an L-shaped electric melting furnace which is formed by a vertical channel and a horizontal channel. A pressure control device and a material adding device are arranged on the top of the vertical channel. The concentric sleeve tube bubbler is disposed on the top wall of the horizontal channel. The shaping tin trough is arranged above the horizontal channel. The nozzle of the concentric sleeve tube bubbler is located in the shaping tin trough. The cooling nozzle is arranged above the shaping tin trough. The cooling tin trough is arranged in the gas flow jet direction of the cooling nozzle. The shaping tin trough and the cooling tin trough are communicated with each other. The process and the apparatus are beneficial to protection of environment and recycling of resources.

Owner:CHINA TRIUMPH INT ENG

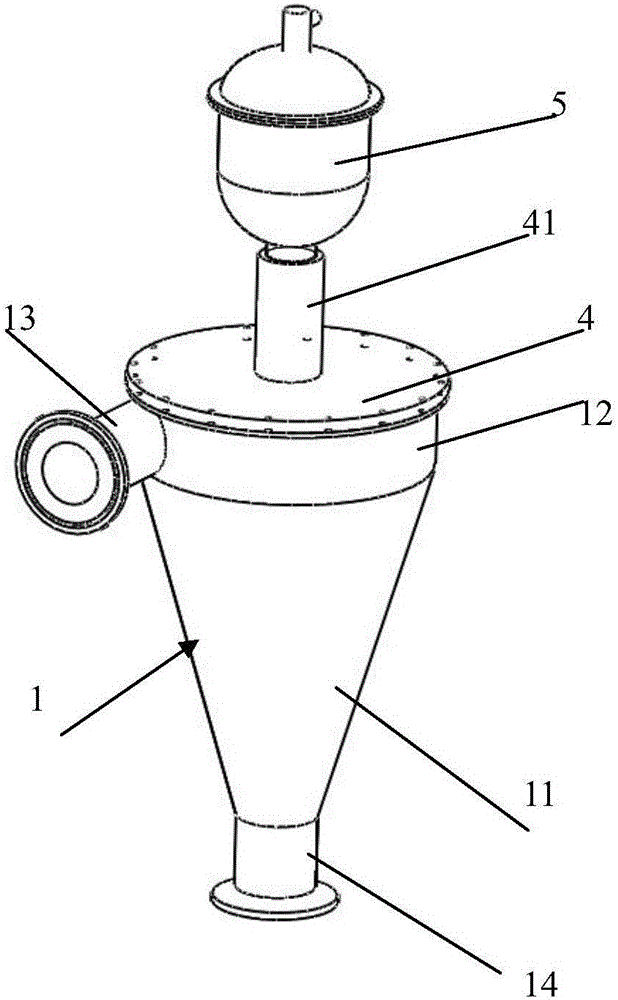

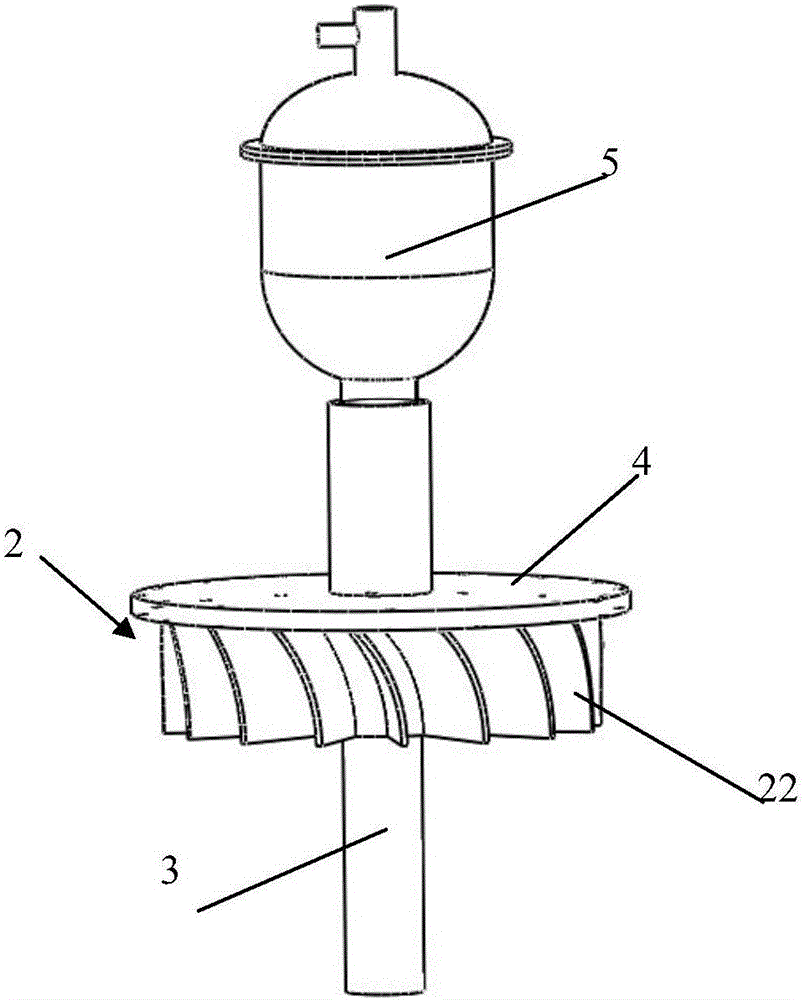

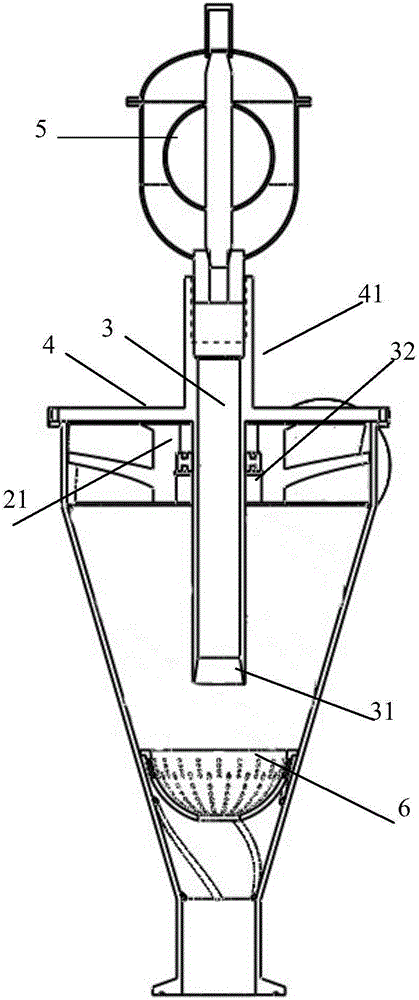

Combined type online oil liquid bubble removal device

InactiveCN106224331AImprove agglomerationEasy to separateFluid-pressure actuator componentsImpellerExhaust valve

The invention discloses a combined online oil liquid bubble removal device. The combined online oil liquid bubble removal device comprises an oil-gas separation cylinder, a guide impeller, an exhaust pipe, an upper cover for sealing an opening of the oil-gas separation cylinder and an exhaust valve fixedly connected with the upper end of the exhaust pipe. The oil-gas separation cylinder comprises a cylindrical rotating cavity on the upper portion and a separation cavity coaxially and integrally formed at the bottom of the rotating cavity. An oil inlet pipe is arranged on one side of the rotating cavity in the tangential direction. An oil drainage opening is formed in the bottom of the oil-gas separation cylinder. The guide impeller is rotationally arranged in the rotating cavity. A filtering portion is arranged on the lower portion of the oil-gas separation cylinder. Filtering holes are formed in the filtering portion. By the adoption of the online bubble removal device, a purely-mechanical structure can be achieved, no power is needed, the online bubble removal device operates along with running of oil liquid, and bubble gathering can be accelerated quickly; and the oil-gas separation mechanism of the two levels of rotating separation and filtering separation is adopted, and the overall separation effect is improved greatly.

Owner:TIANJIN CHENGKE MECHANICAL & ELECTRICAL TRANSMISSION TECH

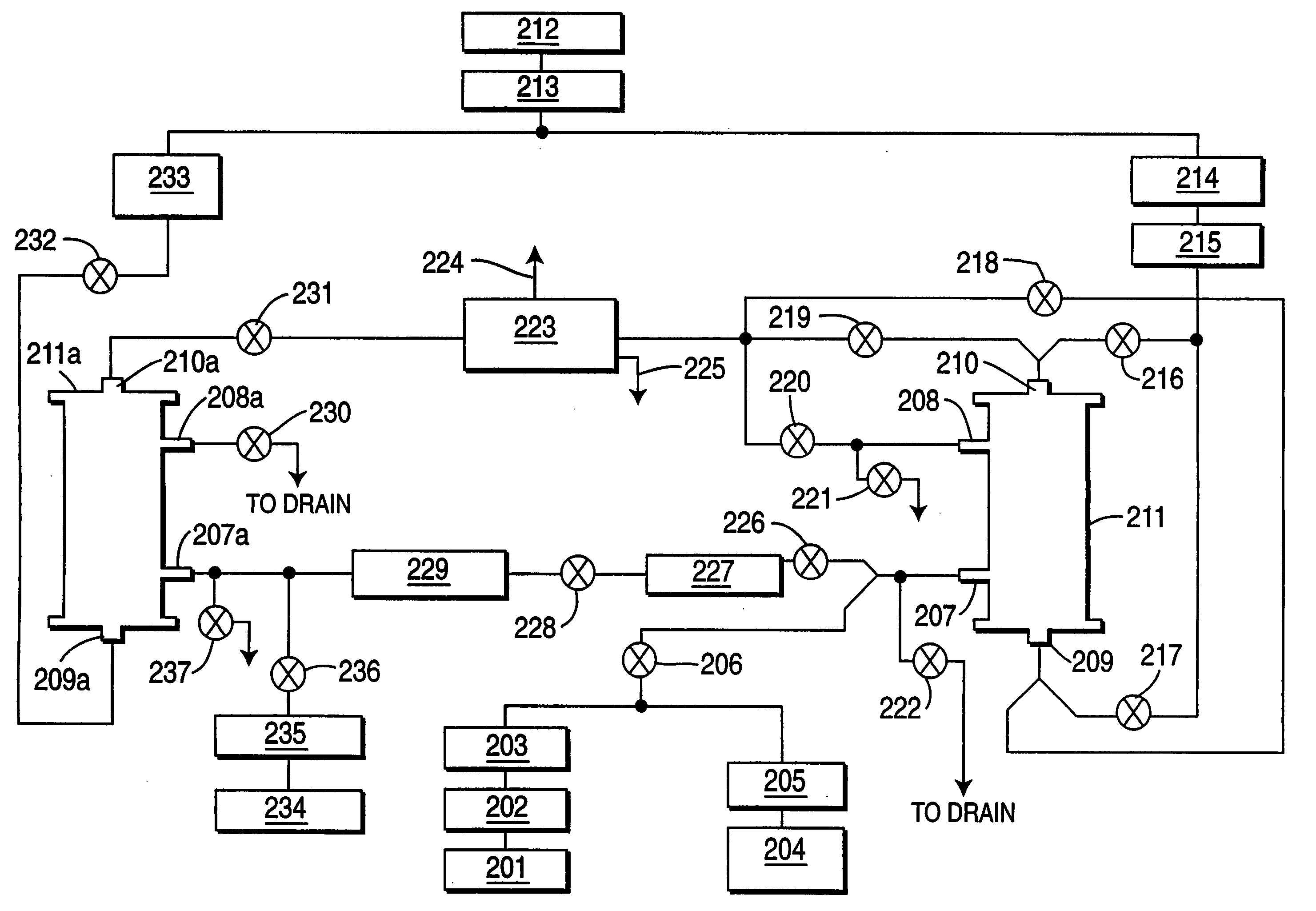

Gas bubble generation for coalescing

InactiveUS9115006B2Reduce cloggingHigh proportionWater treatment parameter controlFlow mixersFlow transducerEngineering

A system is provided for introducing gas bubbles (usually air bubbles) into a liquid stream to coalesce material such as unwanted bits, or particles, of hydrocarbons that lie in the liquid stream along with wanted dissolved bits of metal, for removal of the hydrocarbons. The system is constructed to produce a large number of bubbles of an optimum range such as 60 to 100 μm which best coalesce the hydrocarbons. A controller receives the outputs of sensors such as pressure and flow rate sensors (P, F) and uses them to make changes in other parameters such as the pressure of air introduced into the liquid stream and the pressure in a third conduit of the liquid-bubble stream.

Owner:SPINTEK FILTRATION

Method and device for improving flow character of gas liquid bubble column with row tubes

InactiveCN101417220BImprove responseReduce the difficulty of zooming inLiquid-gas reaction processesSlurry reactorBubble column

The invention discloses a method and a device used for improving the flowing characteristic of the slurry bubble tower with row tubes; the device comprises a tower body, a gas distributor and a vertical heat exchanging row tube bundle; the lower end of the vertical heat exchanging tube bundle is connected with a liquid distributor which is fixed at the lower part of the tower body and the upper end thereof is connected with a liquid collector which is fixed at the upper part of the tower body; a plurality of layers of horizontal grid-typed damp internal components are arranged between the liquid distributor and the liquid collector; the heat exchanging row tube bundle vertically passes through the horizontal grid-typed damp internal components; each layer of the grids is fixed on the tower wall and the row tubes; and by arranging the horizontal grid-typed damp internal components in the slurry bubble tower which is provided with vertical row tube bundles; and the horizontal damp internal components block the flowing of the slurry and air bubbles in the tower, inhibit the flowing craggedness effect caused by the row tube bundle, and reduce the returned mixing of the fluid, thus improving the flowing characteristic of the slurry reactor.

Owner:ZHEJIANG UNIV

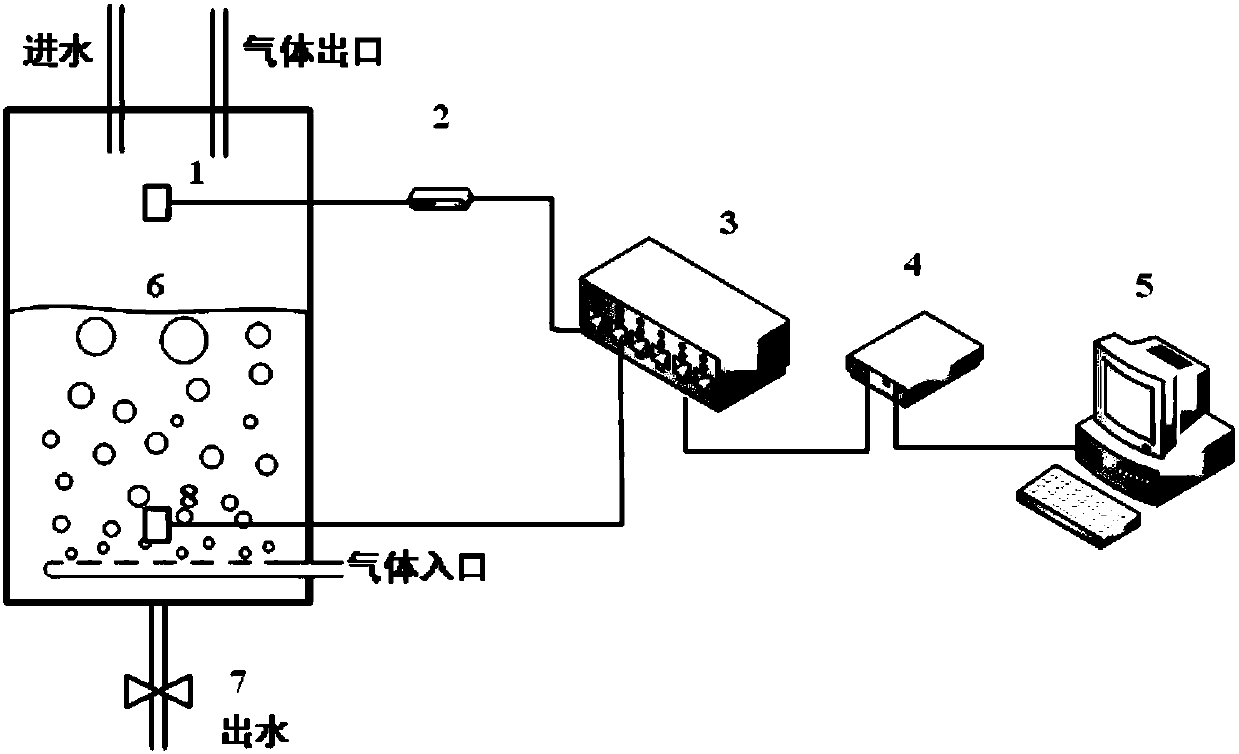

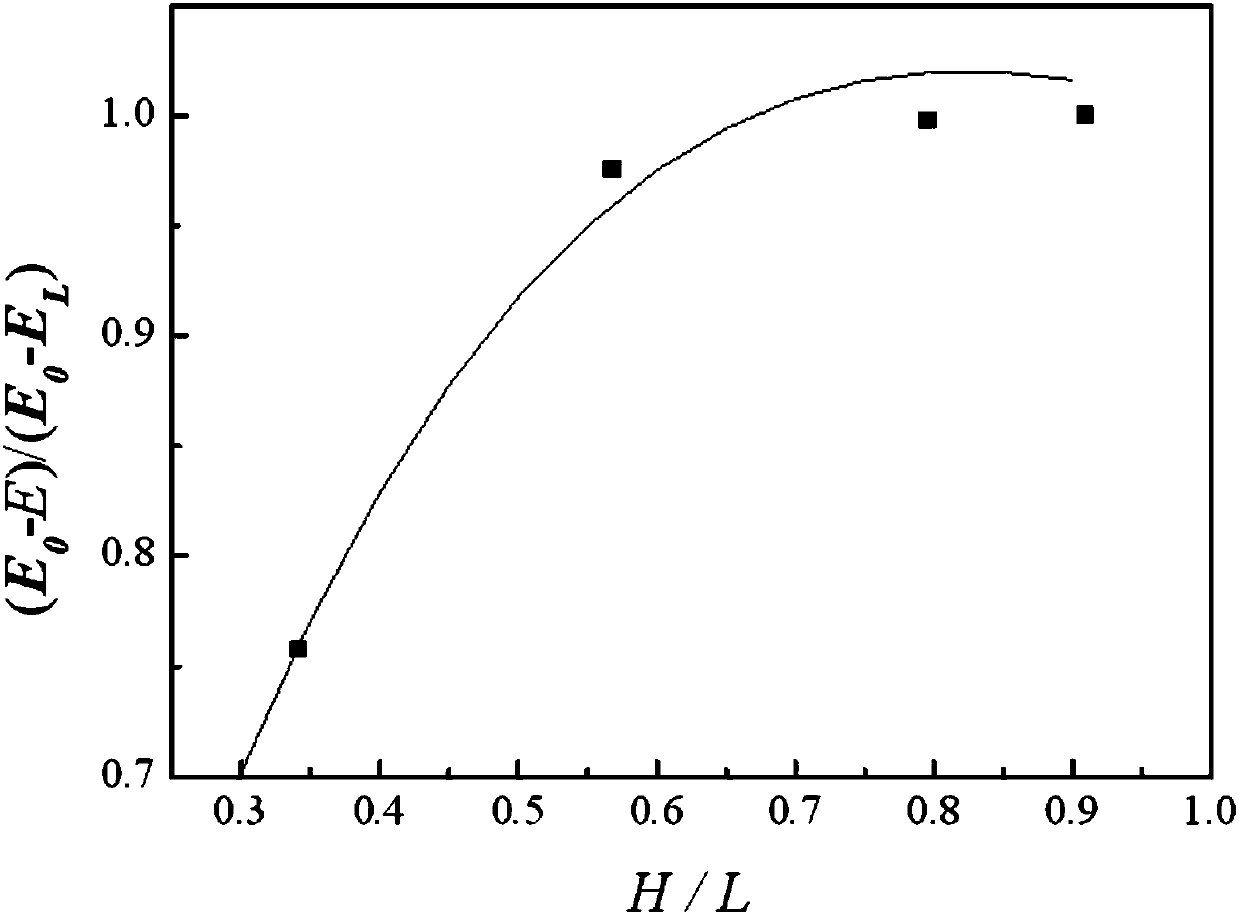

Ultrasonic liquid level measurement method and device

InactiveCN107741264AAccurate detectionStable detectionMachines/enginesLevel indicatorsUltrasound attenuationGas bubbler

The invention discloses an ultrasonic liquid level measurement method and device, comprising: step 1, installing the transmitting probe of the signal transmitting system on the lower part of the side wall of the gas-liquid bubbling device, converting the signal generated by the signal generator into an ultrasonic signal; 2. Install the receiving probe of the signal acquisition system on the side wall of the gas-liquid bubbling device to receive the ultrasonic signal, convert the ultrasonic signal into an electrical signal and transmit it to the acquisition card and computer; step 3, according to the principle of amplitude attenuation of the ultrasonic signal And the principle of shock absorption, establish the ultrasonic damping attenuation liquid level detection model; step 4, according to the ultrasonic damping attenuation liquid level detection model, establish the correlation between the received signal and the liquid level, and detect the liquid level. The invention can adapt to various measurement environments such as liquid level fluctuations, mist entrainment, complicated internal components, etc., and can accurately and stably detect the liquid level.

Owner:王涵青

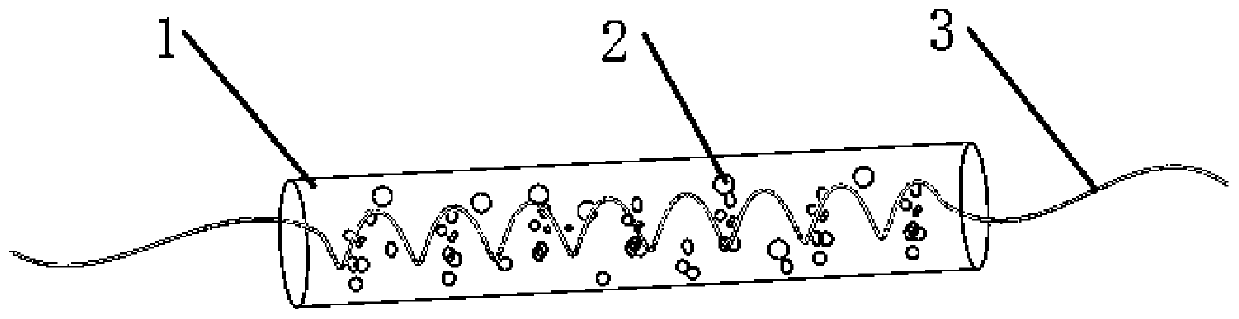

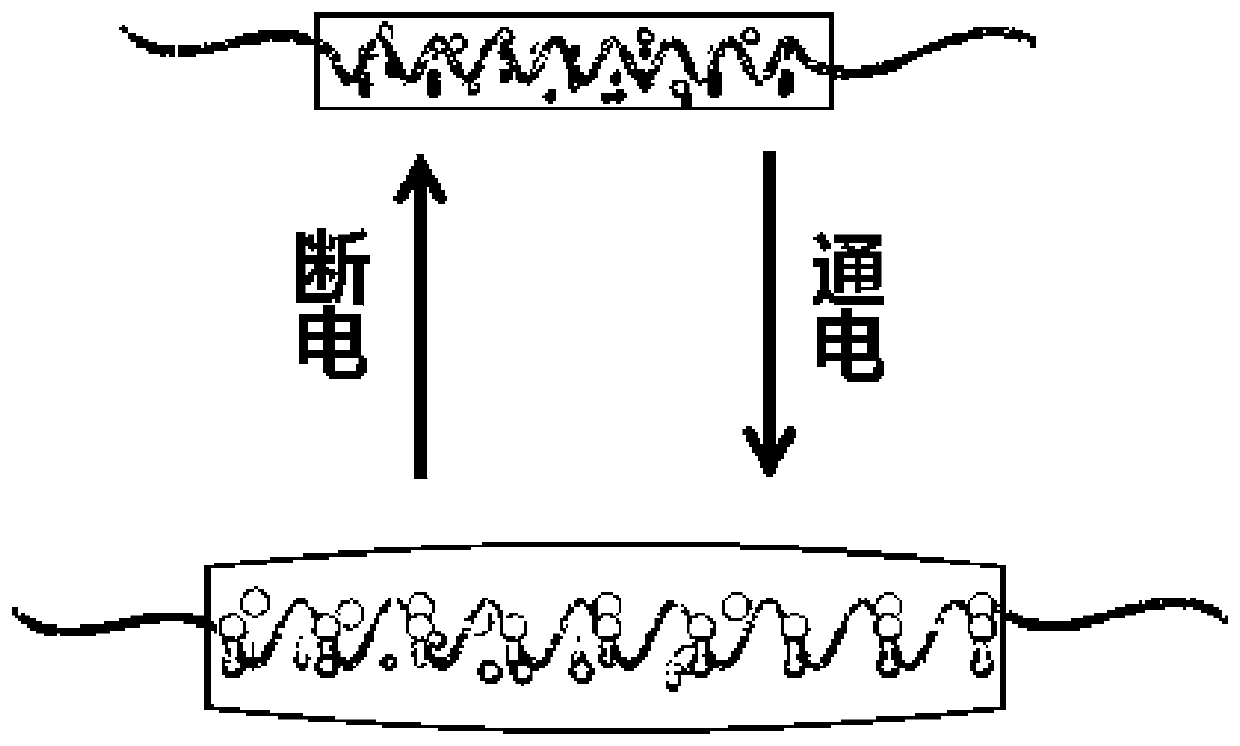

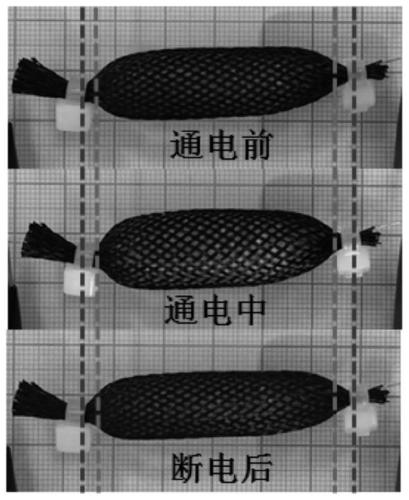

Flexible phase change type artificial muscle material and preparation method thereof

InactiveCN109968571AAchieve shrinkageAchieve expansionHeat-exchange elementsMaterial DesignMuscle contraction

The invention relates to a flexible phase change type artificial muscle material and a preparation method thereof. The flexible phase change type artificial muscle material comprises a flexible silicagel substrate, phase change liquid, a heat conductivity enhancing additive, a resistive heater and an outer-layer nylon net. The phase change liquid is evenly distributed in the flexible silica gel substrate in a liquid bubble manner, the heat conductivity enhancing additive is evenly dispersed in the flexible silica gel substrate, and the flexible silica gel substrate is wrapped by the nylon woven net. The phase change liquid is absolute ethyl alcohol, and the heat conductivity enhancing additive is oxidized graphene or gold nano-particles. The motion pattern of muscle contraction and relaxation is simulated, flexible composite material design and mechanical structure design are organically integrated, and the flexible phase change type artificial muscle material which is capable of working under the low-pressure condition, flexible, small in size and large in deformation is provided.

Owner:JILIN UNIV

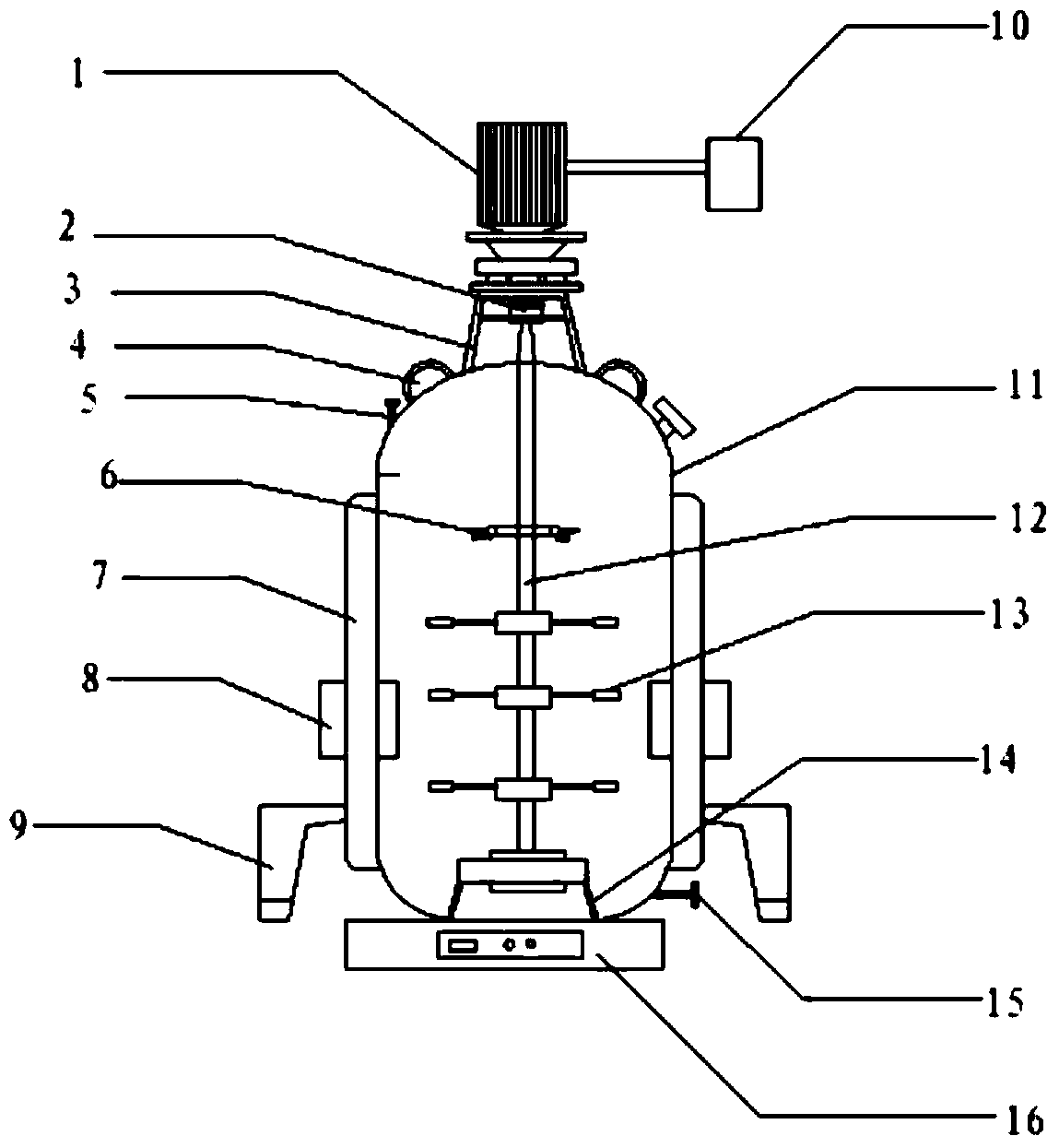

Material mixing and fermenting device

InactiveCN103468562AAdjust the speedIncrease speedBioreactor/fermenter combinationsBiological substance pretreatmentsFrequency changerElectric machine

The invention relates to a material mixing and fermenting device. The material mixing and fermenting device comprises a tank body, a temperature measuring device, a rotating shaft, blades, a defoaming device, three tank body supports, an electric stove plate, a motor, a shaft coupling, a frequency converter and a motor support. The top of the tank body is provided with a feed port, a lifting lug and a manhole, the tank bottom is in a flat bottom structure, a discharge port is formed in the tank bottom, the temperature measuring device is positioned on the side wall of the tank body, and the temperature measuring device can directly observe a temperature value in the tank from the outside of the tank; the top of the rotating shaft is connected with the shaft coupling, and the bottom of the rotating shaft is articulated with a support seat on the bottom surface in the tank body; the blades are crisscross arranged on the rotating shaft; the defoaming device is positioned on the rotating shaft and can timely eliminate liquid bubbles produced by stirring; the three tank body supports are uniformly distributed on the side wall of the tank body; one end of the shaft coupling is connected with the rotating shaft, and one end of the shaft coupling is connected with the motor; the frequency converter is connected with the motor and can adjust the rotational speed of the motor; the material mixing and fermenting device has the advantages of simple heating structure, low cost, convenience in maintenance, uniformity in material mixing, safety and reliability.

Owner:TIANJIN CITY BINHAI NEW AREA JURONG TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com