Flexible phase change type artificial muscle material and preparation method thereof

An artificial muscle and phase change technology, applied in the field of artificial muscle materials and its preparation, can solve the problems of large size, difficulty in meeting the requirements of robot development, and limited working conditions, etc., and achieve the effect of small size, large deformation, and realization of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

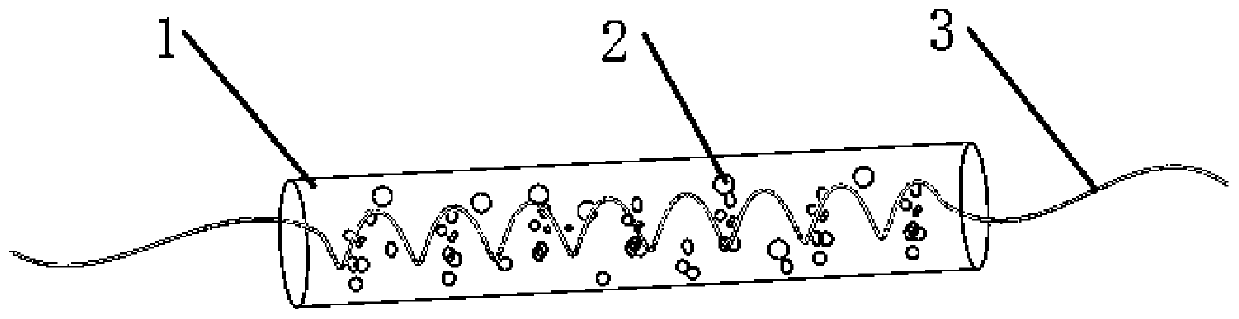

[0027] see Figure 1-4 Shown:

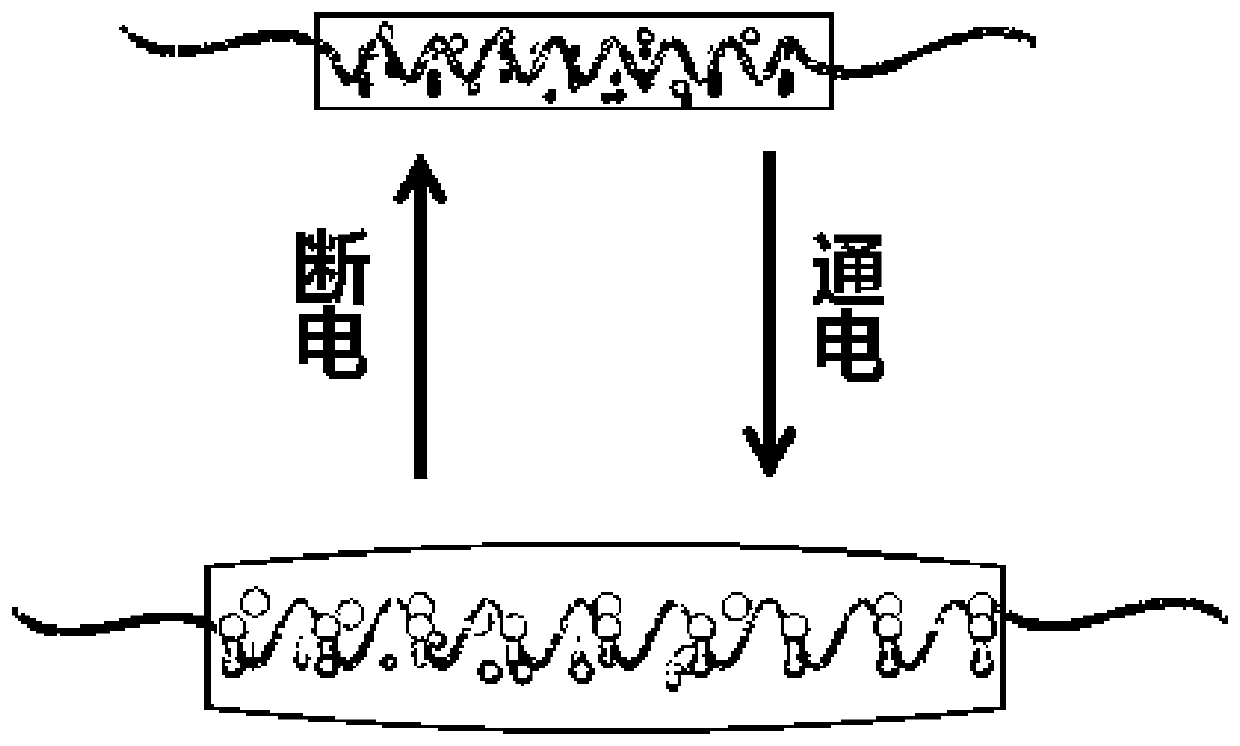

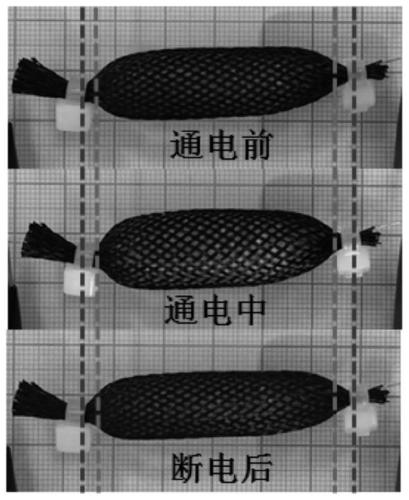

[0028] A flexible phase-change artificial muscle material, comprising a flexible silica gel matrix 1, a phase-change liquid 2, a thermal conductivity enhancer, a heating resistance wire 3 and an outer nylon mesh, wherein the flexible silica gel matrix 1 contains nano-dispersed ions, and the The phase change liquid 2 is evenly distributed in the flexible silica gel matrix 1 in the form of vacuoles, and the thermal conductivity enhancing additive is evenly dispersed in the flexible silica gel matrix 1. After the material is manufactured, the nylon braided mesh is wrapped outside, and the resistance wire is energized to generate heat change. As a result, the phase change fluid 2 produces a liquid-vapor phase transition, and the material expands. After the power is turned off, the phase change fluid 2 produces a vapor-liquid phase transition, and the material shrinks, such as figure 2 As shown, the artificial muscle can produce muscle-like recipro...

Embodiment 2

[0046]The difference between this example and Example 1 is that the thermal conductivity enhancer is different, a flexible phase-change artificial muscle material, including flexible silica gel matrix 1, phase-change fluid 2, thermal conductivity enhancer, heating resistance wire 3 and outer nylon mesh , the flexible silica gel matrix 1 contains thermal conductivity enhancing additives, the phase change liquid 2 is evenly distributed in the flexible silica gel matrix 1 in the form of bubbles, and the thermal conductivity enhancing additives are evenly dispersed in the flexible silica gel matrix 1. Nylon braided mesh is wrapped on the outside, and the resistance wire is energized to generate heat change, which causes the phase change liquid 2 to undergo a liquid-vapor phase change, and the material expands. After the power is turned off, the phase change liquid 2 undergoes a vapor-liquid phase change, and the material shrinks, such as figure 2 As shown, the artificial muscle ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com