Patents

Literature

173results about How to "Adjust the speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method, system and device for power fail safeguard of data

InactiveCN106354241AAdjust the speedReduce power consumptionPower supply for data processingElectricityManagement unit

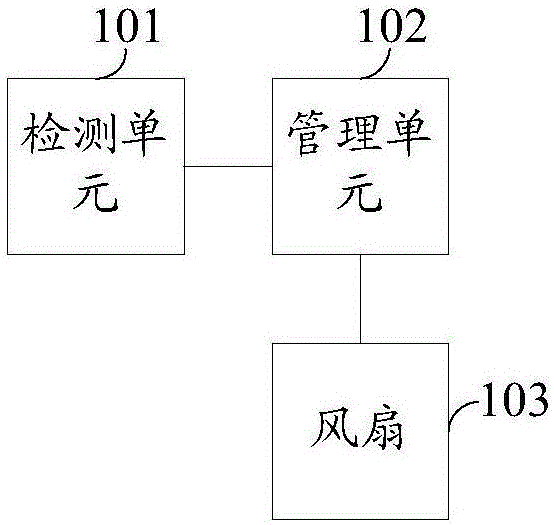

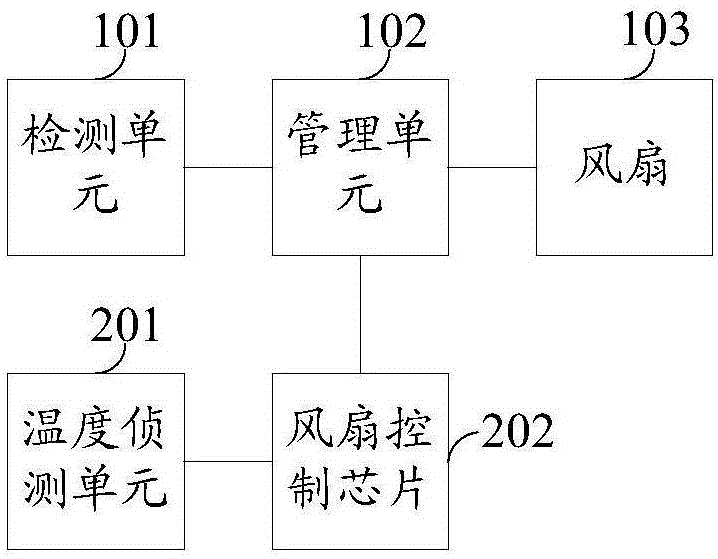

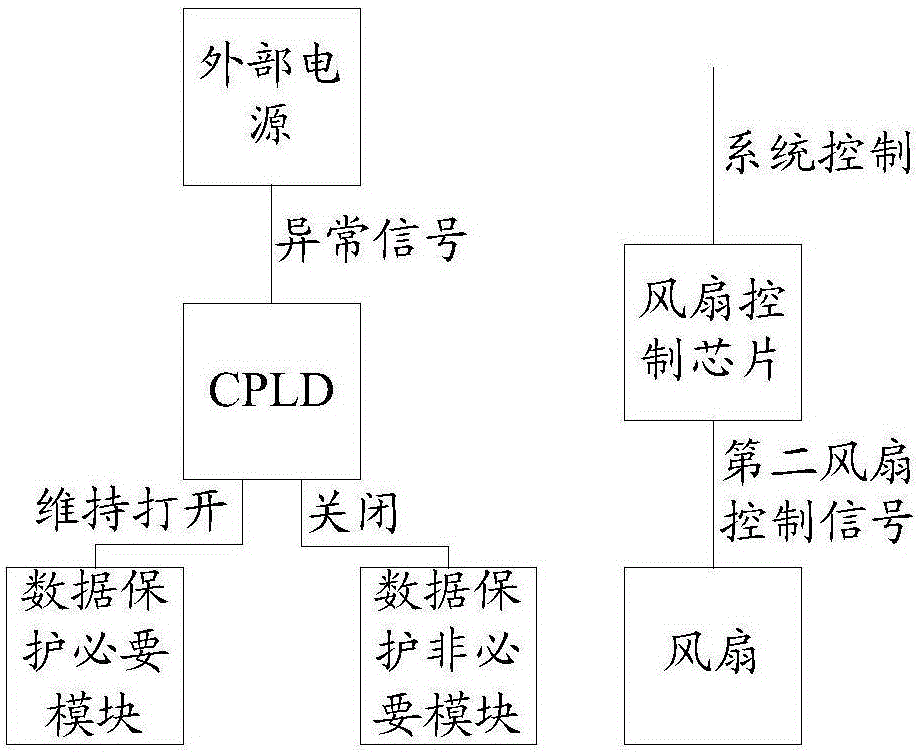

The invention provides a method, a system and a device for power fail safeguard of data. The device comprises a detection unit, a management unit and a fan. The detection unit is used for sending abnormality signals to the management unit after abnormality of an external power source is detected in real time. The management unit is used for generating a target duty ratio carrying first fan control signal and sending the first fan control signal to the fan after the abnormality signals sent by the detection unit are received. The fan is used for adjusting a rotation speed according to the target duty ratio carrying first fan control signal. The method, the system and the device for power fail safeguard of data have the advantage that system power consumption can be quickly reduced after power failure.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

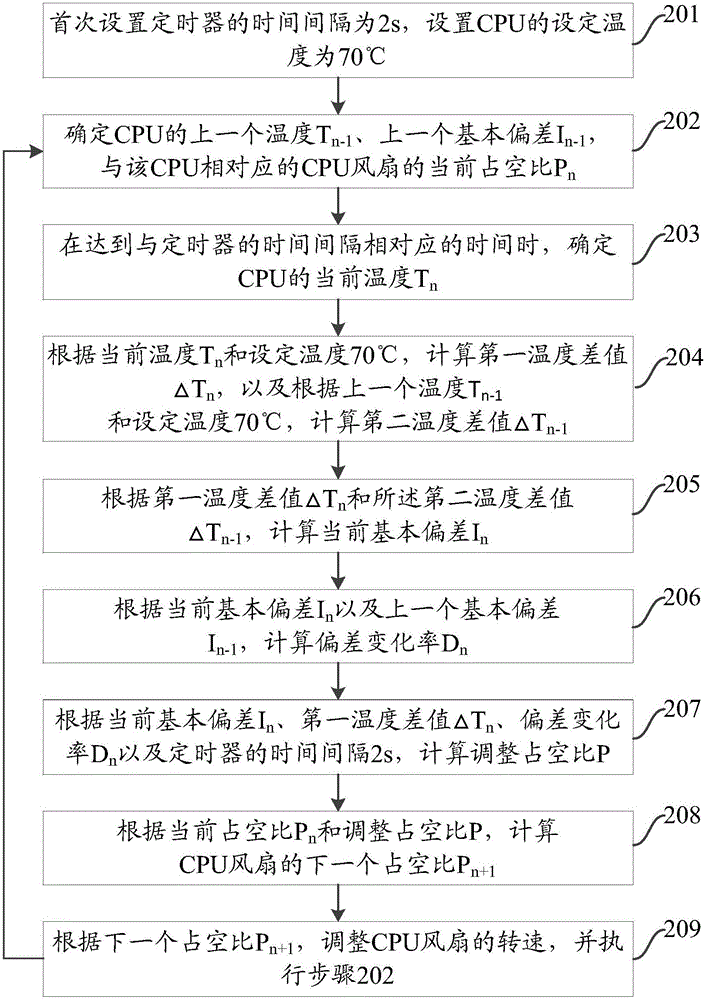

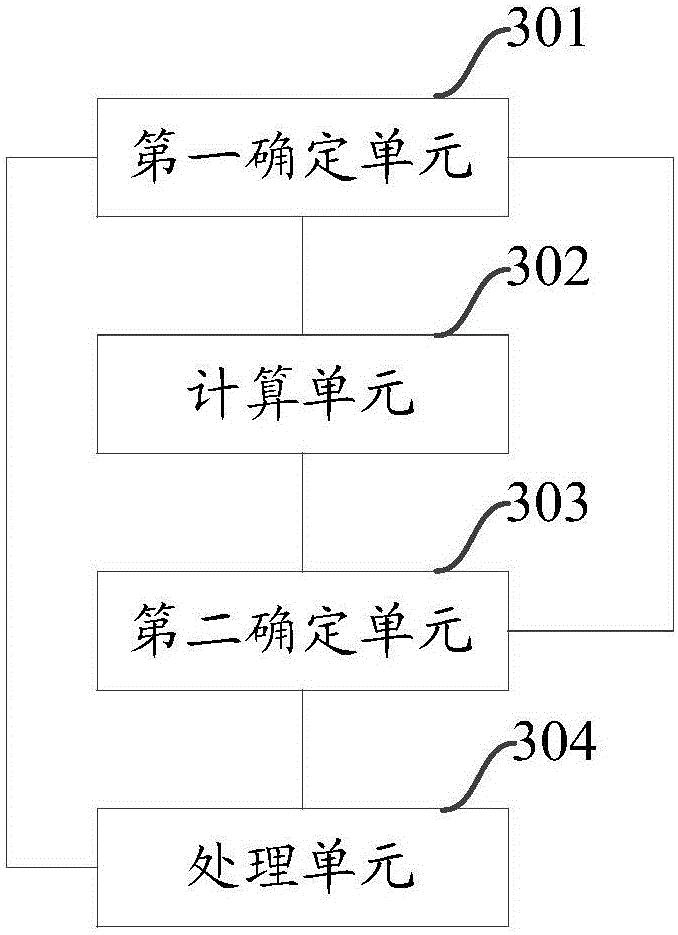

Speed regulation method and device for server fan and 64-CPU server

InactiveCN105822580AImprove stabilityAdjust the speedDigital data processing detailsEngine controlControl theoryDuty cycle

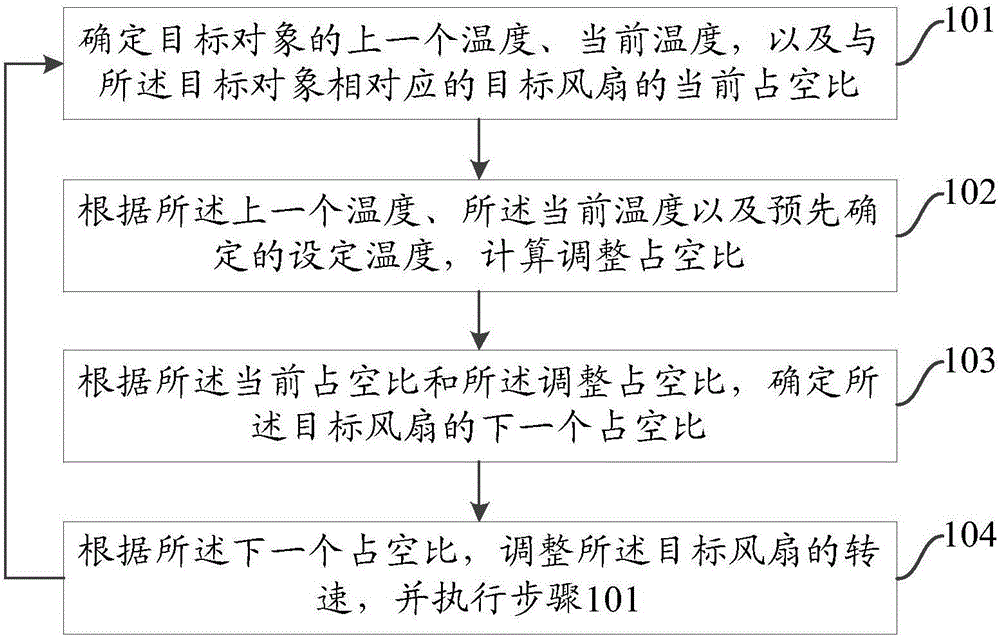

The invention provides a speed regulation method and device for a server fan and a 64-CPU server. The method comprises the steps that the last temperature, the current temperature and the set temperature of a target object and the current duty ratio of the corresponding target fan are firstly determined, the duty ratio is calculated and regulated on this basis, and therefore a corresponding new duty ratio is determined; and then the rotating speed of the target fan is regulated according to the determined new duty ratio, the process circulates in this manner, and therefore real-time and accurate regulation of the rotating speed of the fan based on temperature changes of the target object is achieved. Thus, according to the scheme, the speed regulation stability of the server fan can be improved.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

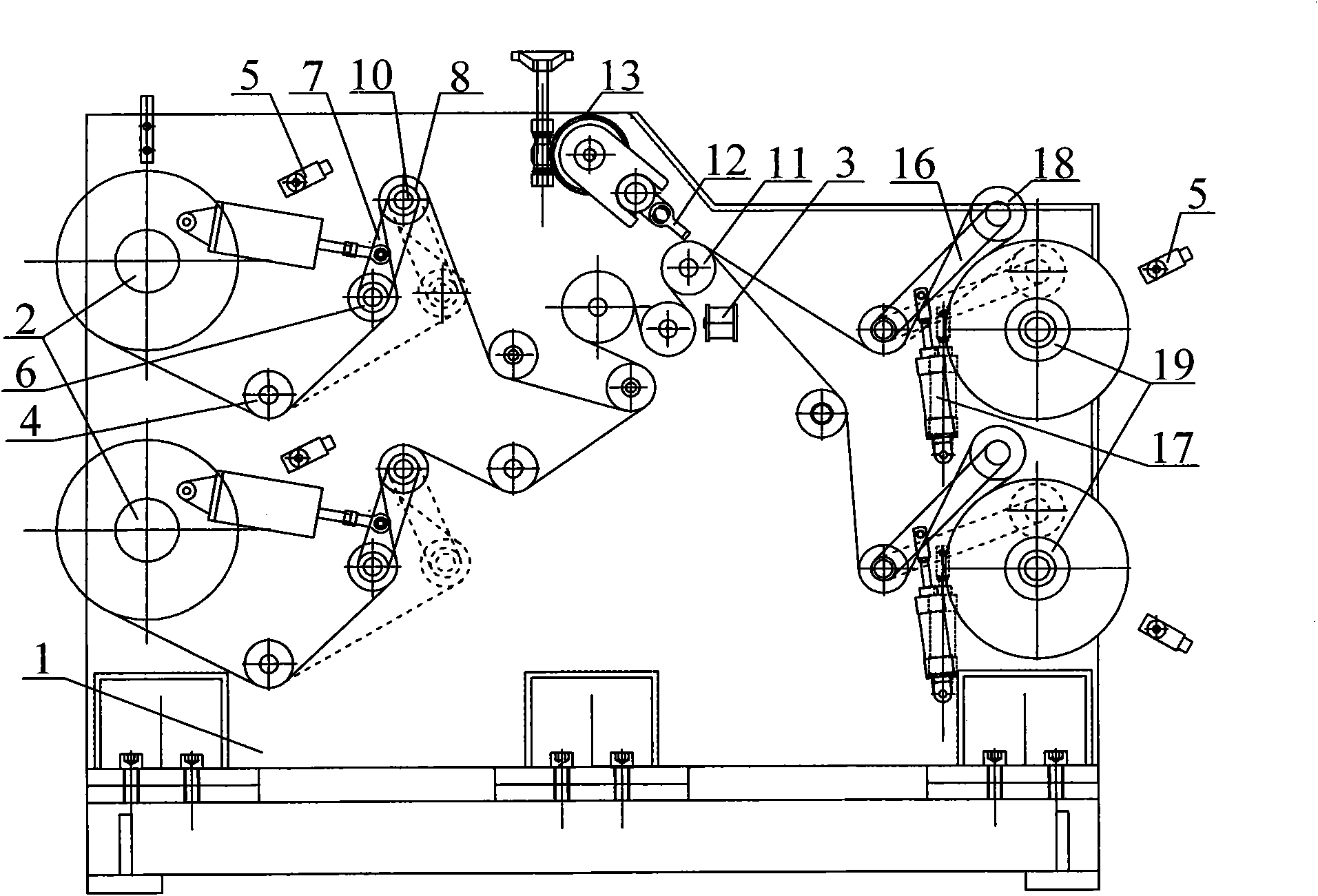

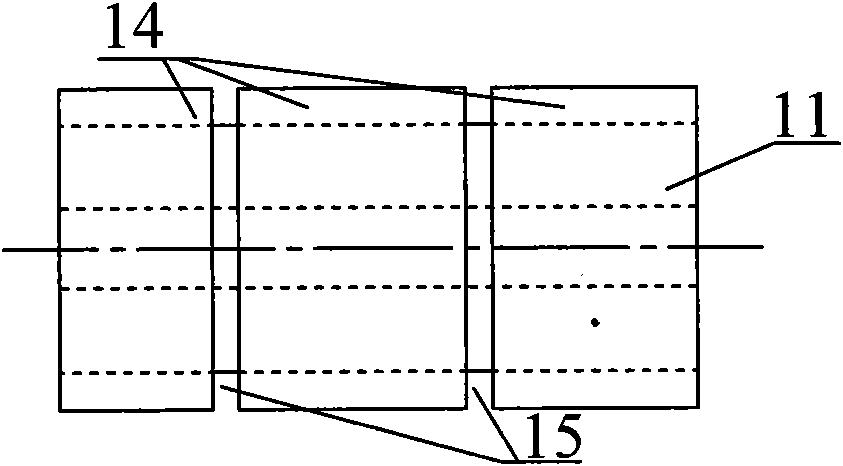

Micro-tension rewinding splitting machine

InactiveCN101837903AAdjust the speedAdjust the braking torqueWebs handlingElectric machineryFree state

The invention relates to a micro-tension rewinding splitting machine, which comprises a frame, an active unwinding shaft, a splitting mechanism and a winding mechanism. The splitting machine is characterized in that: the active unwinding shaft is connected with an unwinding motor and a brake; a tension micro-metering mechanism is arranged between the active unwinding shaft and the splitting mechanism; a suction fan is arranged below the splitting mechanism; guide rollers are arranged between every two of the active unwinding shaft, the tension micro-metering mechanism, the splitting mechanism and the winding mechanism and are fixed to the frame; and a diameter gauge is arranged over against the active unwinding shaft. Due to the arrangement of the tension micro-metering mechanism, the rotating speed of the unwinding motor and the braking moment of the brake can be sensitively adjusted, so that a novel plastic diaphragm material is always conveyed in an approximately free state; since the suction fan is arranged below the splitting mechanism, offcut produced in a splitting process can be recovered in time without specially arranging an offcut winding mechanism and the cost is saved; and a slip inflatable shaft is arranged in the winding mechanism, so the winding tension can be adjusted and the flatness of the winding roll material is ensured.

Owner:SHANDONG ZHENGHUA MEMBRANE TECH +1

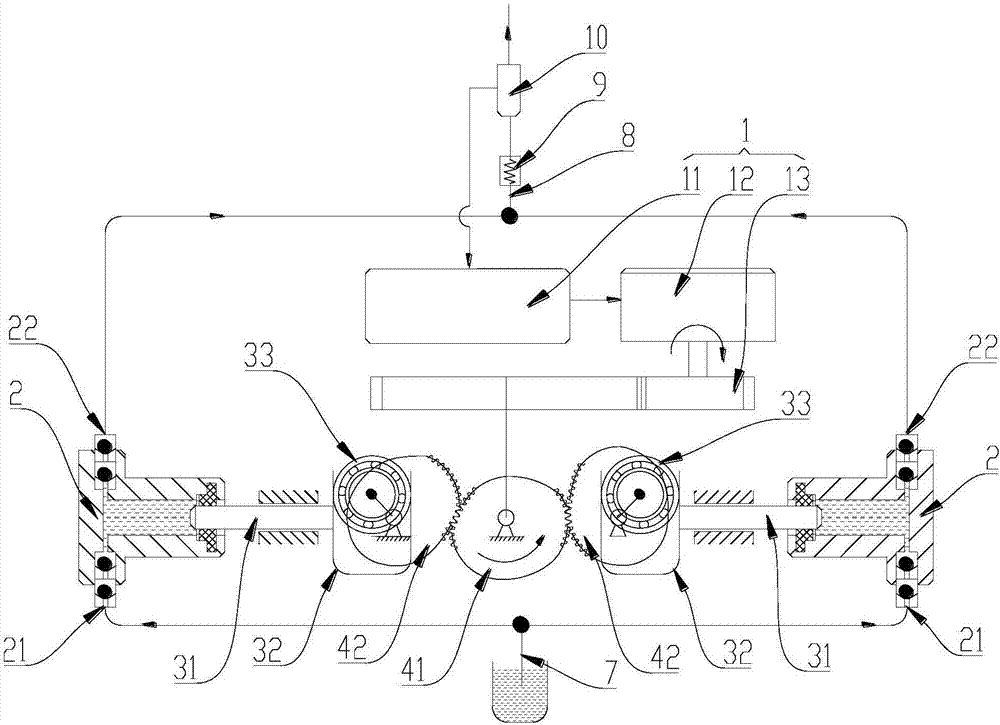

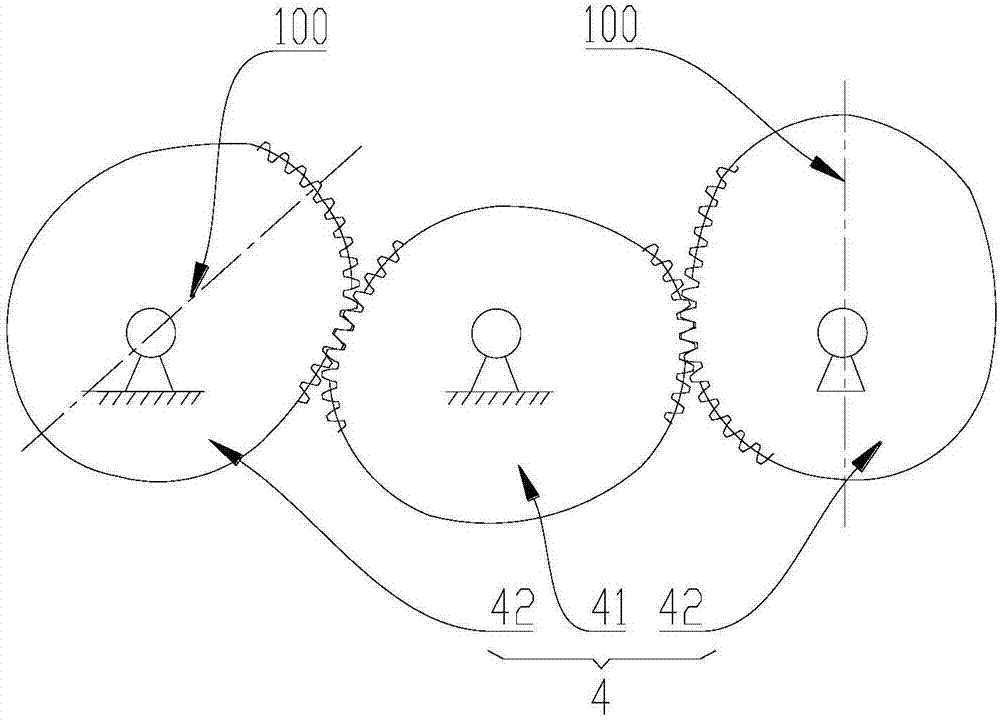

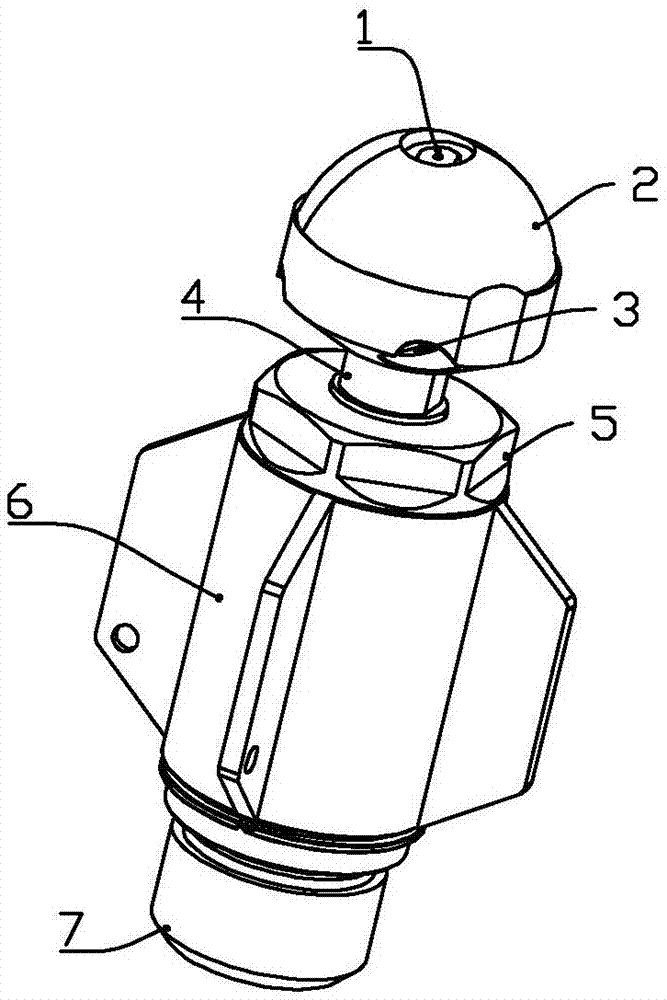

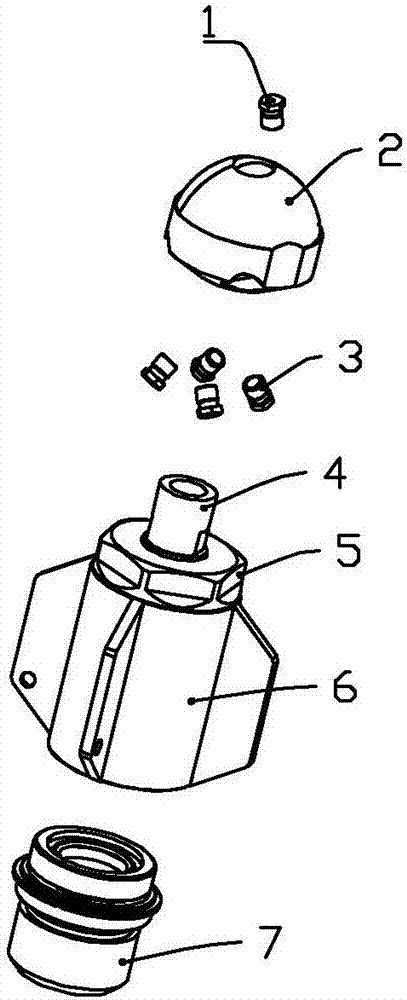

Novel plunger pump

InactiveCN107327382AMovement speed is stableExtended service lifeGearingPump controlReciprocating motionEngineering

The present invention relates to a new type of plunger pump, which includes a driving device, a pump body, a power actuator assembly, and a power transmission assembly; the power actuator assembly includes a guide rod, a chute, and a swing plate that reciprocate in the pump body; The chute is fixedly mounted on one end of the guide rod protruding from the pump body, and the inner side of the chute has two parallel and opposite working planes, the working planes are perpendicular to the guide rod; The power transmission assembly includes an active non-circular gear and a passive non-circular gear meshing with each other, the passive non-circular gear is in transmission connection with the oscillating plate, the active non-circular gear is connected with the driving device, and is driven by the driving device its spinning. The plunger pump can realize the transmission of the sinusoidal mechanism, the pressure angle can be realized by the rotation of the chute and the oscillating disk, and the non-circular gear can realize the smooth movement speed of the guide rod. The equipment is driven by non-circular gears, which can greatly overcome many shortcomings of the cam mechanism, and has a long service life and is not easy to wear.

Owner:殷图源

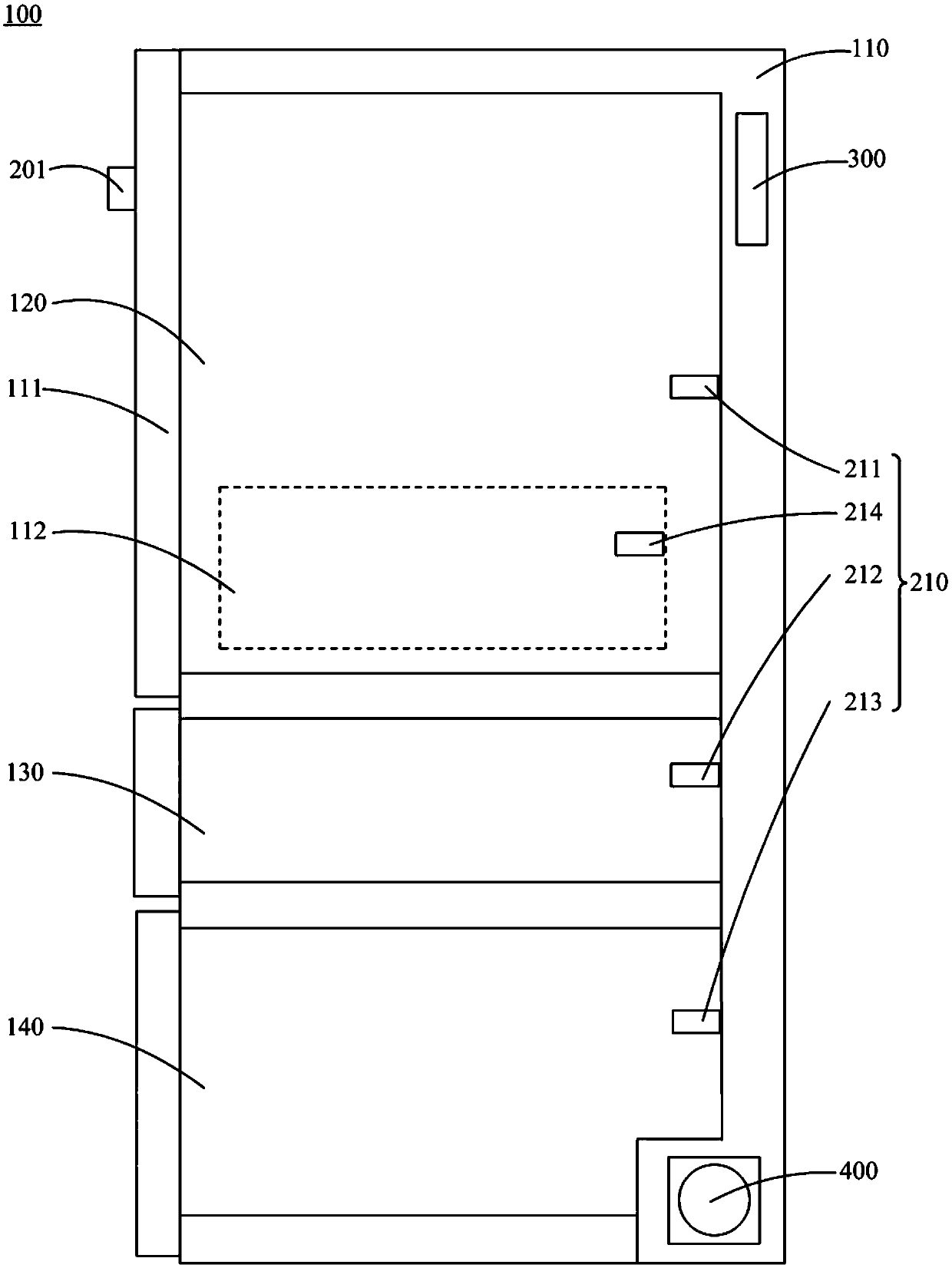

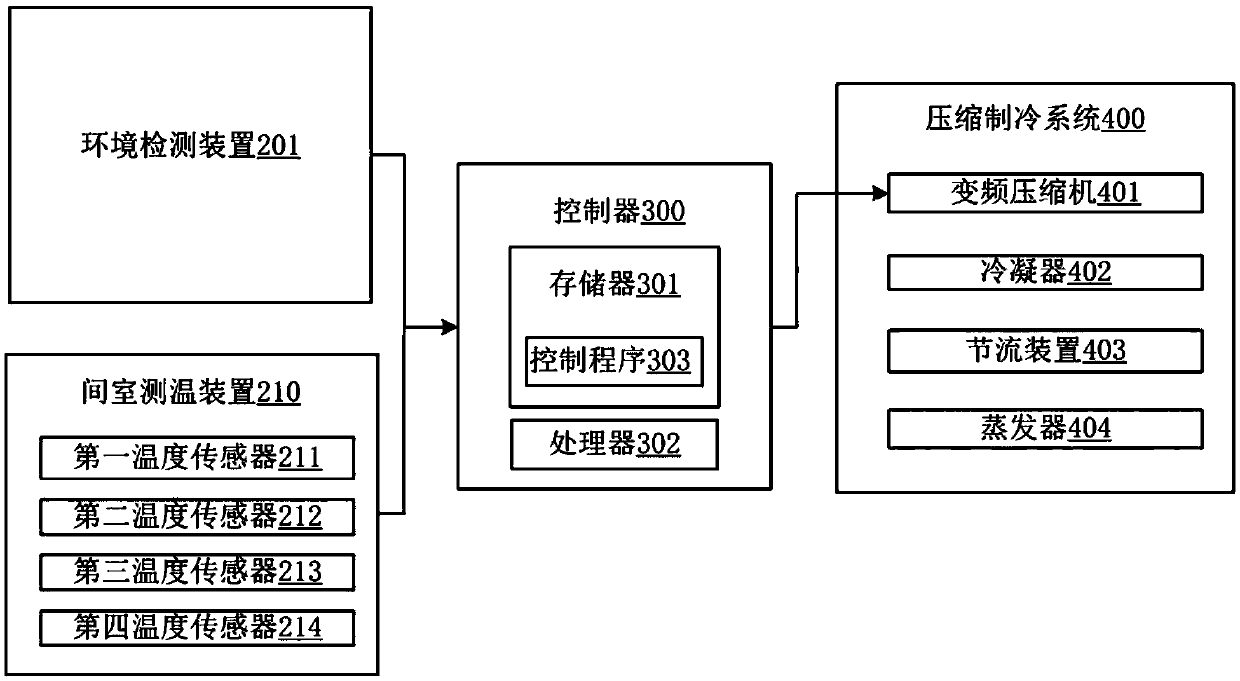

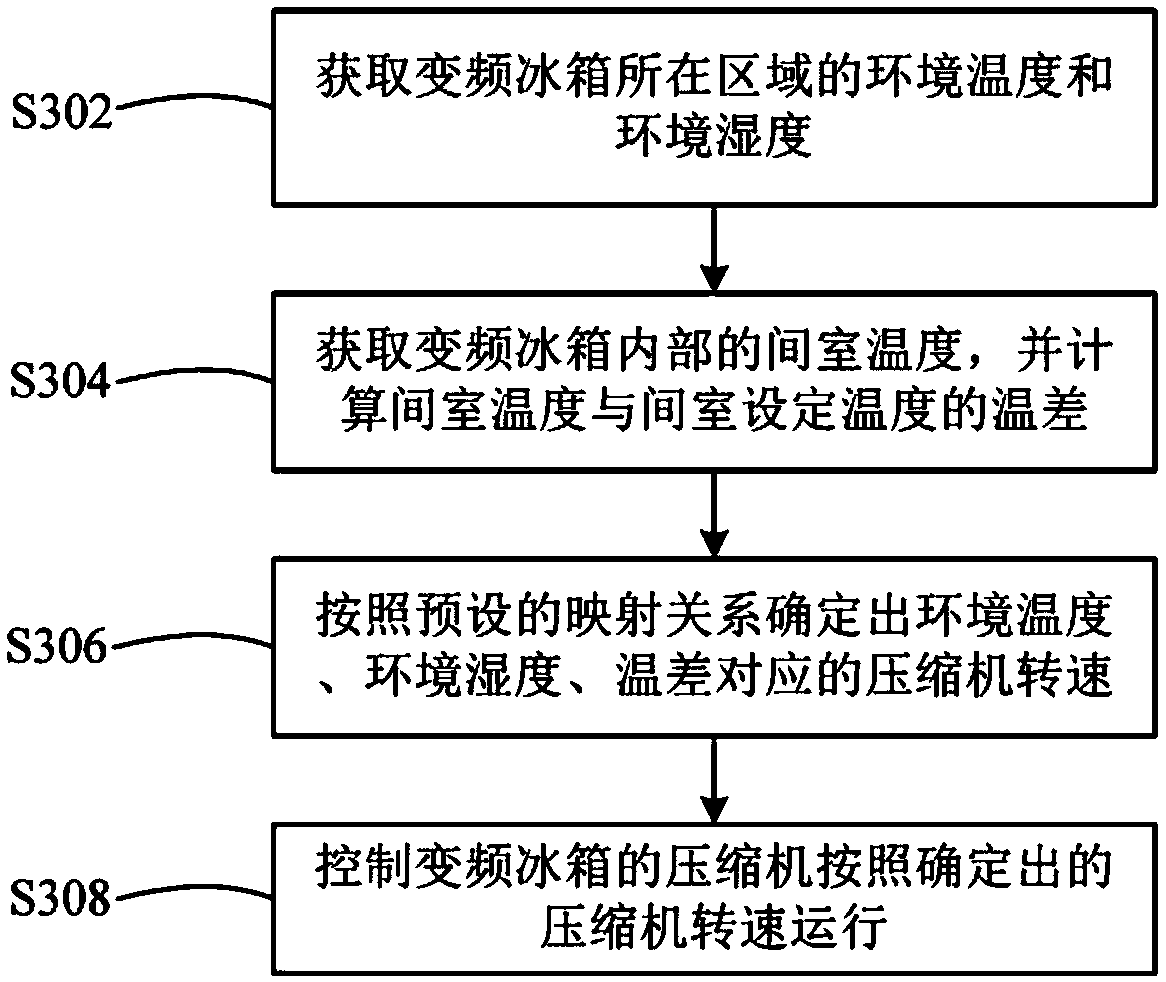

Refrigerator and control method thereof

ActiveCN110953792AImprove efficiencyReduce energy consumptionLighting and heating apparatusDomestic refrigeratorsPhysicsMechanical engineering

The invention provides a control method for an inverter refrigerator. The control method comprises the steps: the environment temperature and the environment humidity of an area where the inverter refrigerator is located are obtained; the temperature of a chamber in the inverter refrigerator is obtained, and the temperature difference between the temperature of the chamber and the set temperatureof the chamber is calculated; the compressor rotating speed corresponding to the environment temperature, the environment humidity and the temperature difference is determined according to a preset mapping relationship, wherein the mapping relationship specifies rotating speed values corresponding to an environment temperature numerical range, an environment humidity numerical range and a temperature difference numerical range; and the compressor of the inverter refrigerator is controlled to operate according to the determined rotating speed of the compressor. The invention further provides arefrigerator.

Owner:HAIER SMART HOME CO LTD

Automatic winding machine

InactiveCN102074349AAdjust the speedCorrect accumulated differences at any timeControl without using feedbackCoils manufactureElectricityWinding machine

The invention relates to an automatic winding machine. The automatic winding machine comprises a stand, and a flat cable mechanism, a fixing mechanism, a winding mechanism, a shifting mechanism and a programmable logic control (PLC) automatic control system which are arranged on the stand, wherein the flat cable mechanism comprises a bracket, a guide rod which is arranged on the bracket and a correction sensor roller which is arranged on the guide rod; the fixing mechanism comprises a fixed main shaft and a mounting and fixing block which is arranged on the fixed main shaft; the shifting mechanism comprises a shifting motor and a correction sensor roller shaft shifting piece which is connected with the shifting motor and into which a copper wire is inserted; both a winding motor and the shifting motor are electrically connected with the PLC automatic control system; the shifting mechanism is provided with a correction sensor which is connected with the PLC automatic control system; and under the coordination of the PLC automatic control system, the rotation speed of the winding motor and the shifting motor can be adjusted, the accumulative difference which is generated by a flat cable and a wound wire during multi-turn multi-layer winding can be randomly corrected, the flat cable is precise and attractive, and the working efficiency is improved.

Owner:冯曙光

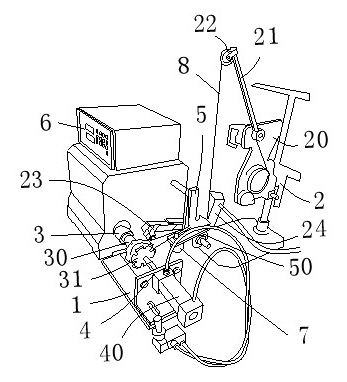

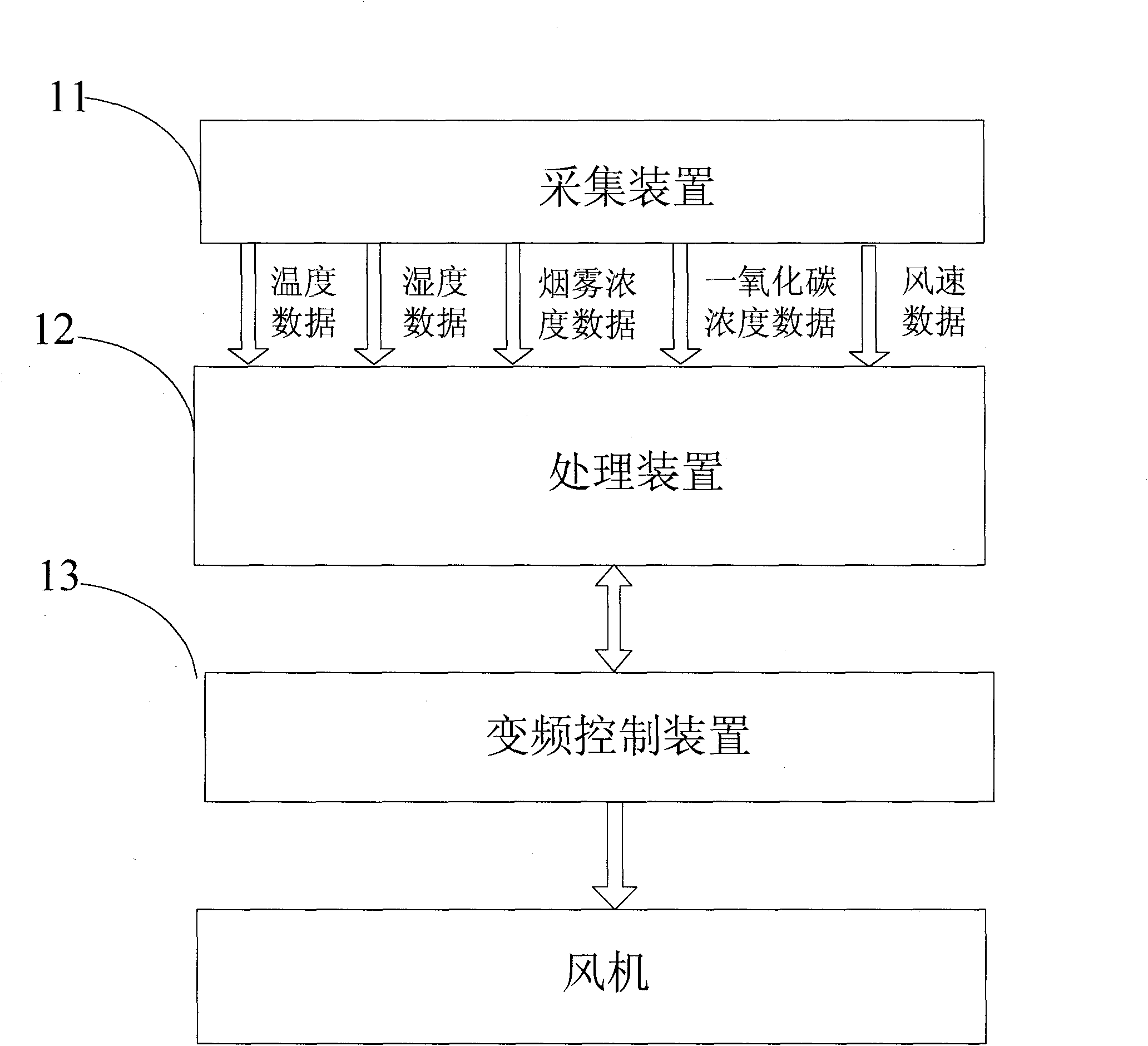

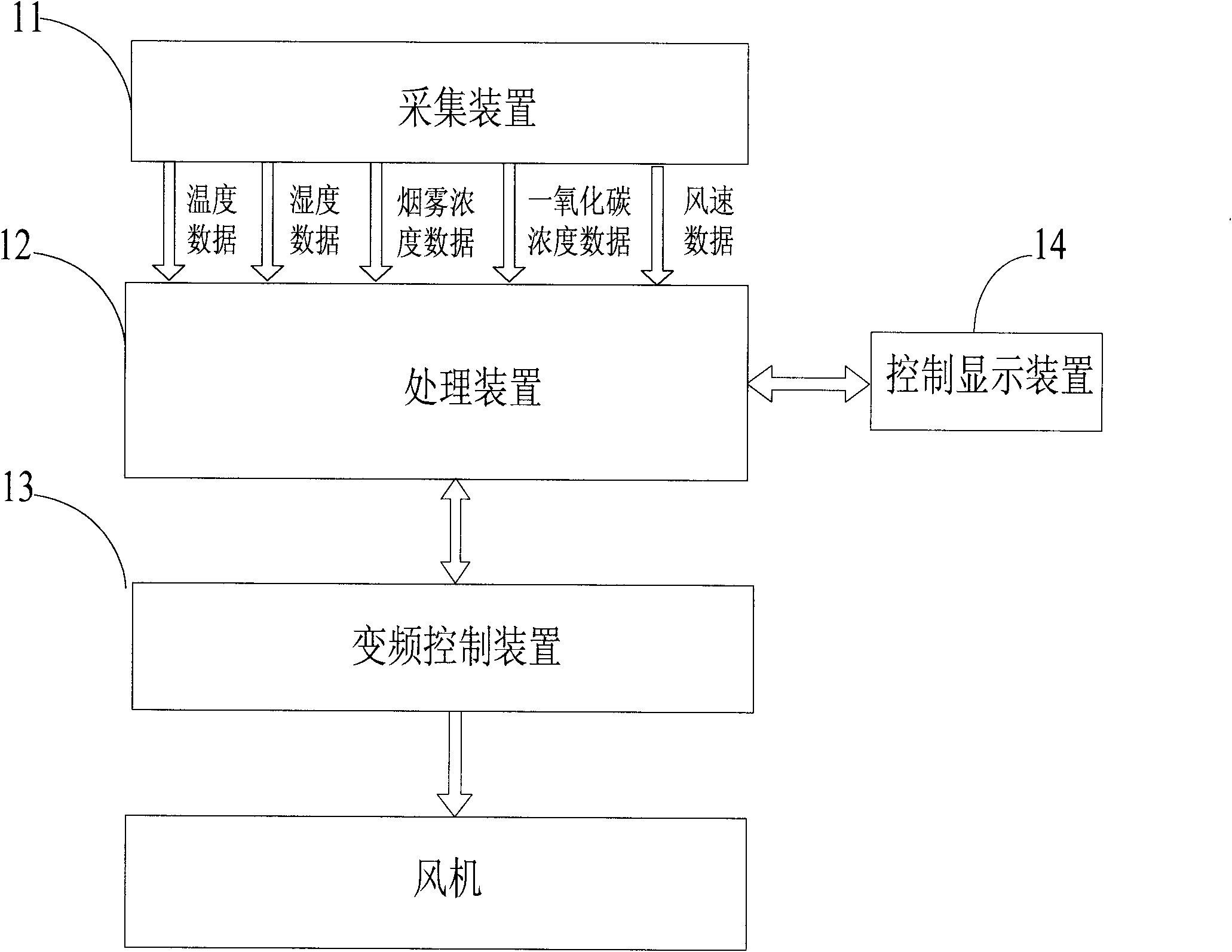

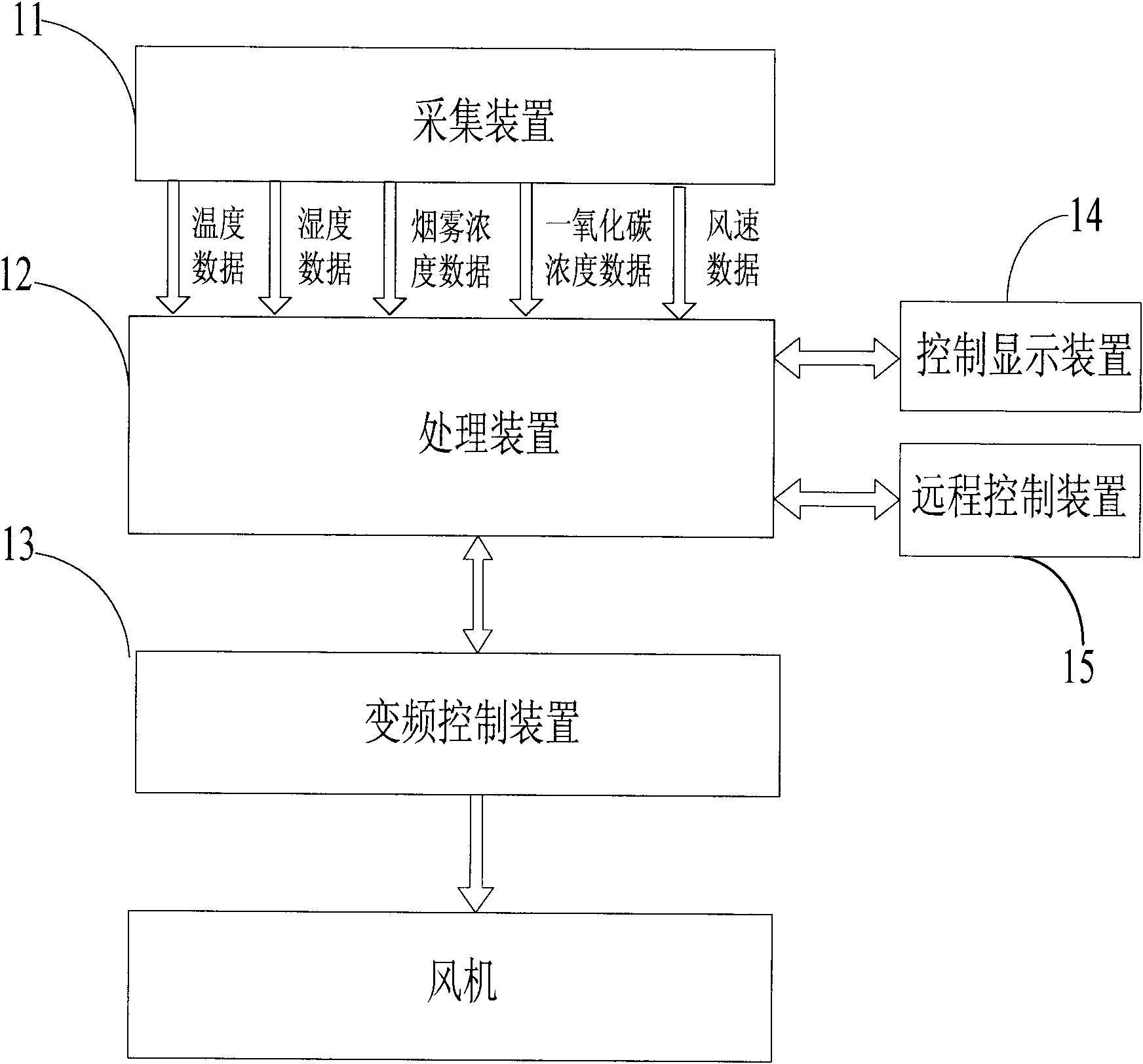

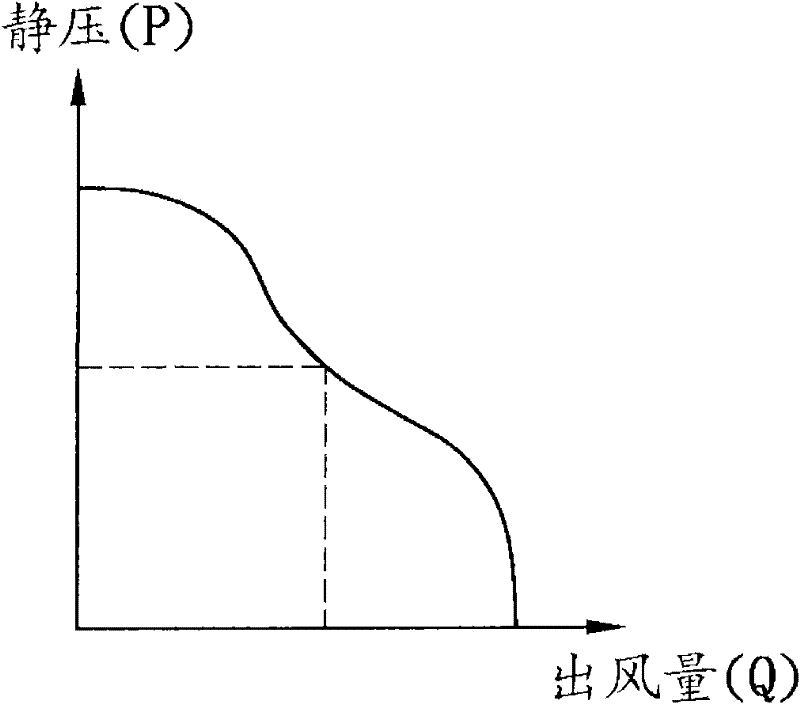

Energy saving system for jet fan

InactiveCN101787980AAdjust the speedReduce energy consumptionPump controlNon-positive displacement fluid enginesHigh energyVariable frequency control

The invention discloses an energy saving system for a jet fan, which comprises an acquisition device, a processing device and a frequency conversion control device. The acquisition device comprises a temperature acquisition unit, a humidity acquisition unit, and an air quality acquisition unit for acquiring air quality data when the jet fan is used and sending the acquired date to the processing device; the processing device comprises a data processing unit which is used for analyzing and calculating the received data, generating a control signal according to the analysis and calculation results, and then sending the control signal to the frequency conversion control device; and the frequency conversion control device comprises a frequency conversion control unit which is used for adjusting the rotating speed of the jet fan according to the control signal. By using the technical scheme, the system adjusts the rotating speed of the jet fan according to the air quality data when the jet fan is used, solves the problems that the conventional system cannot adjust the rotating speed of the jet fan according to the air quality data when the jet fan is used and has high energy consumption.

Owner:重庆汉宾光电节能技术有限公司

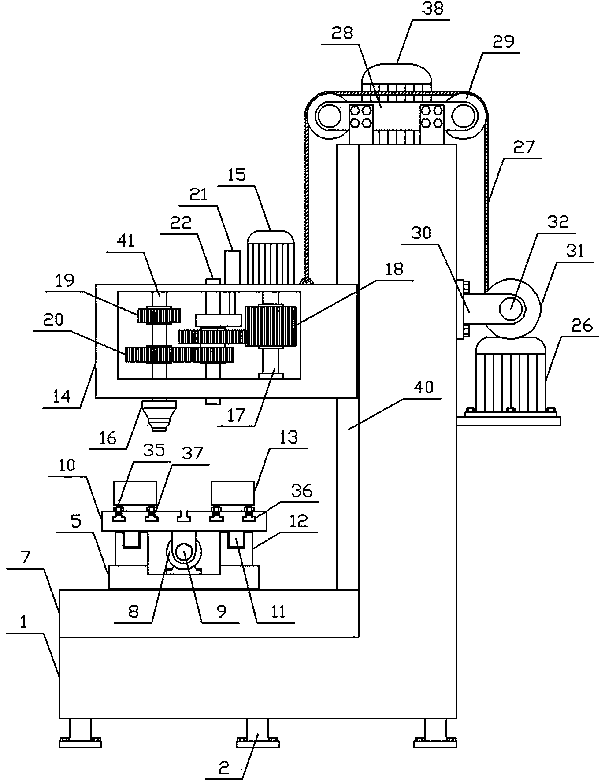

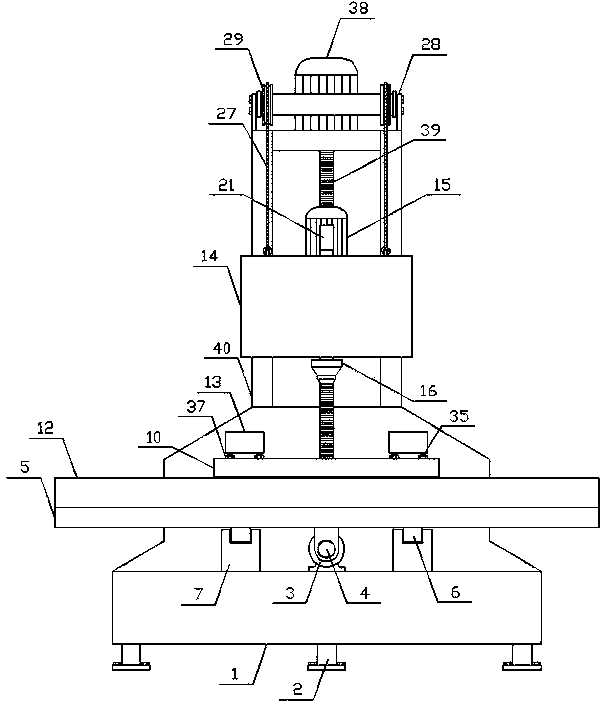

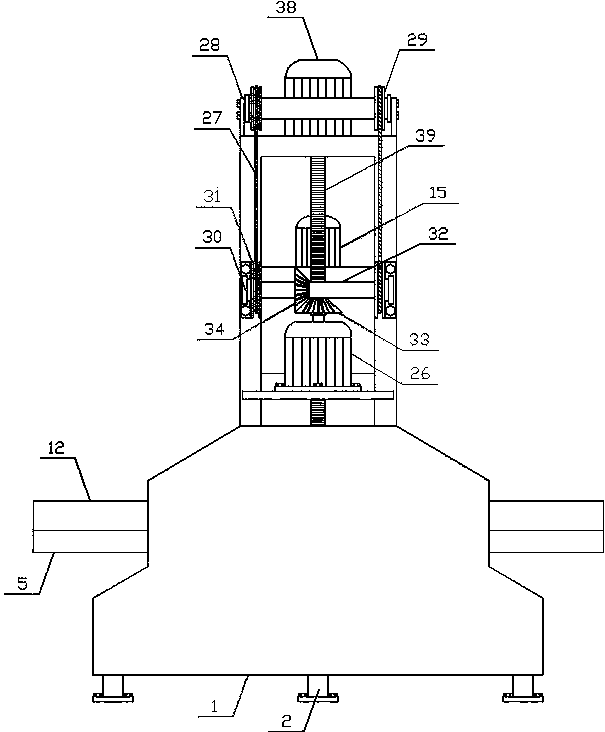

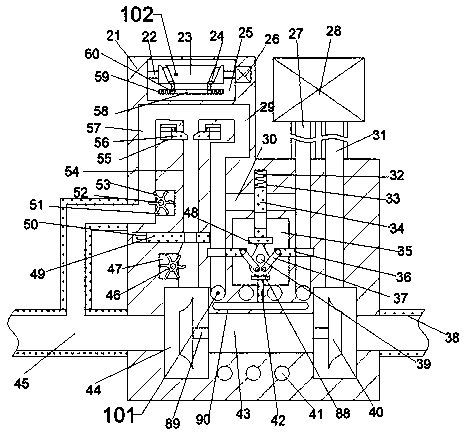

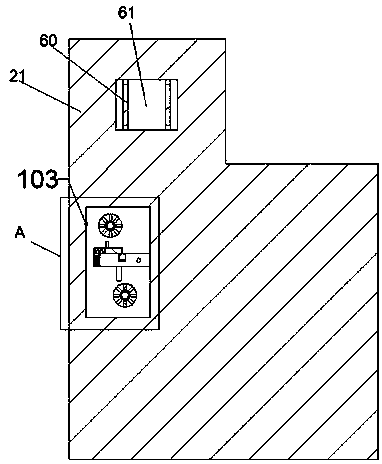

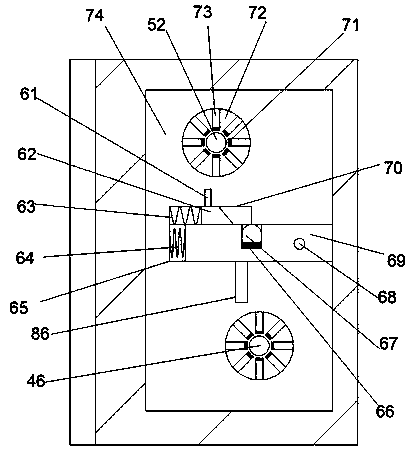

Vertical machining device

InactiveCN104369044AEfficient processingImprove processing efficiencyFeeding apparatusLarge fixed membersEngineeringMachine tool

The invention discloses a vertical machining device and belongs to the technical field of machining. The vertical machining device comprises a main support, a workpiece fixing mechanism and a machining mechanism. The workpiece fixing mechanism is horizontally arranged on the main support, the machining mechanism is horizontally arranged above the workpiece fixing mechanism, and the workpiece fixing mechanism comprises a lower horizontal-moving mechanism, an upper horizontal-moving mechanism and a fixing clamp. The machining mechanism comprises a machining case, a machining motor and a machining tool. The machining case is horizontally arranged on the upper side of the main support, a lifting mechanism is vertically arranged on one side of the machining case, the machining motor is vertically arranged downwards on the upper side of the machining case, an input shaft is vertically arranged in the machining case, and a connecting mechanism is vertically arranged in the machining case. One side of the connecting mechanism is provided with an output shaft, the machining tool is arranged below the output shaft, and the main support is provided with a lifting fixing mechanism. The vertical machining device is simple in structure, convenient to operate and capable of fast, efficiently and accurately machining a workpiece and meeting the requirements of production.

Owner:TONGXIANG SHENGHUI PRECISION MACHINERY

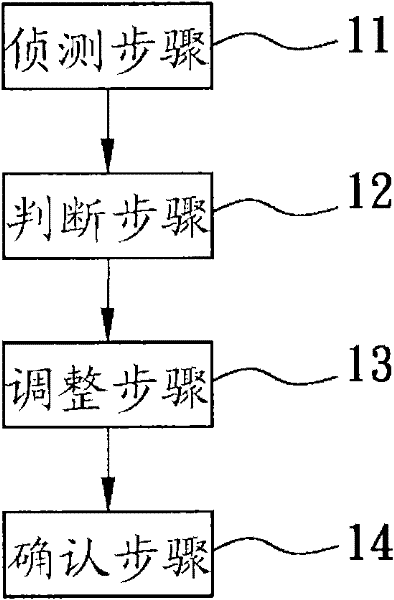

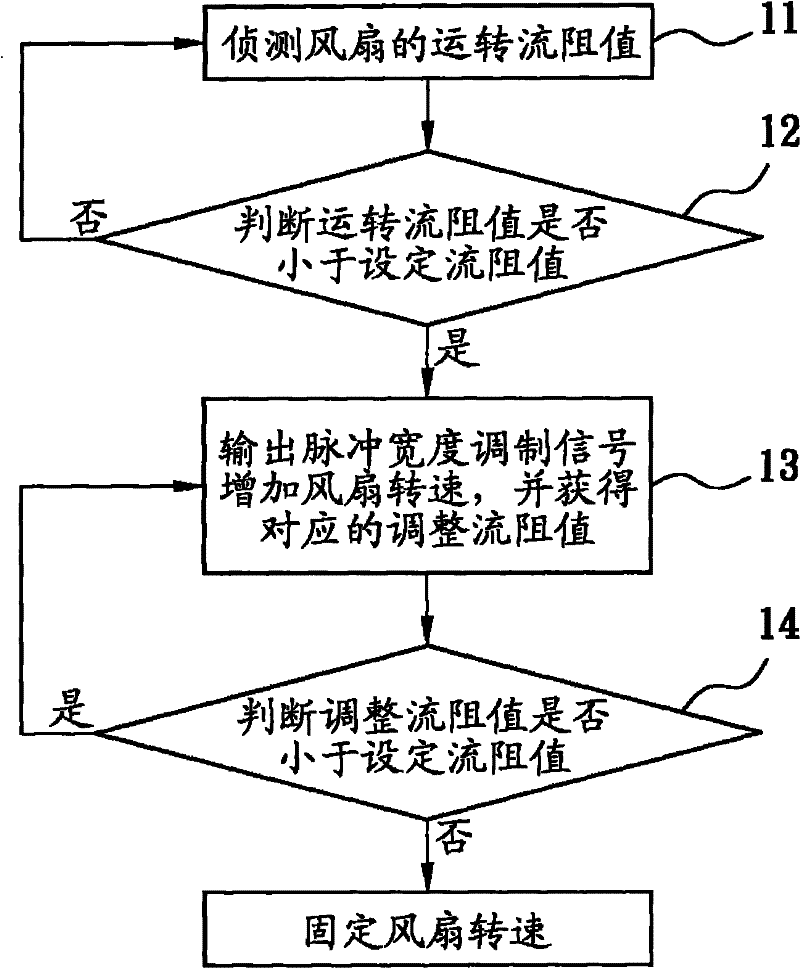

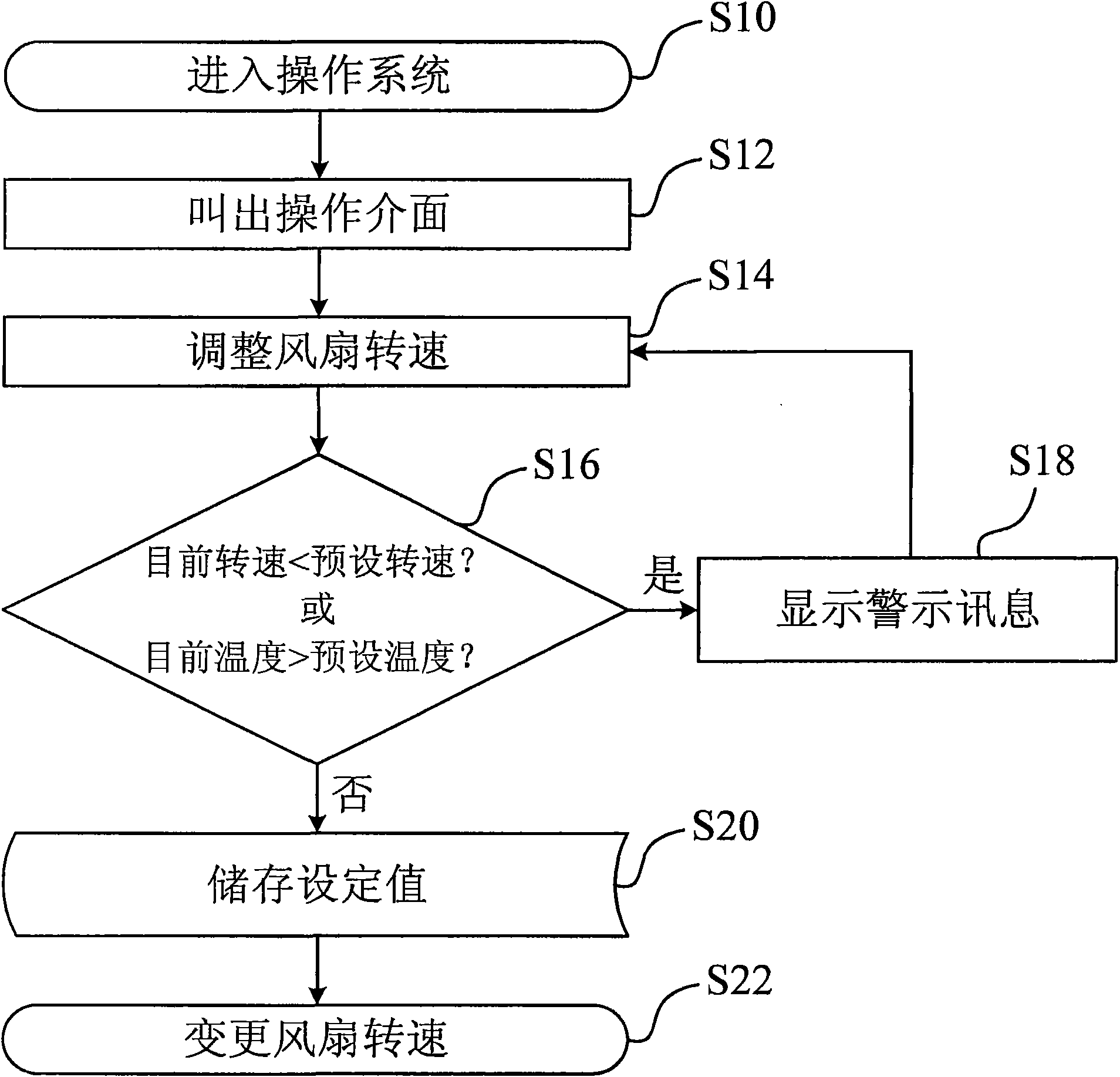

Method for controlling the rotation speed of fan

InactiveCN102192174AAdjust the speedPump controlNon-positive displacement fluid enginesControl theory

Owner:YEN SUN TECH CORP

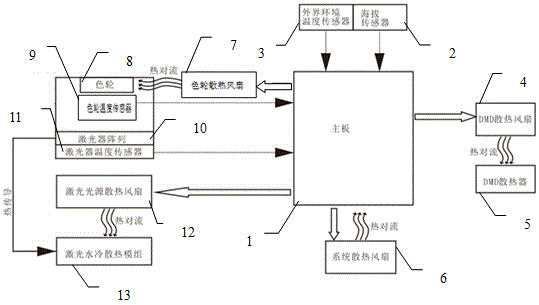

Heat management system of laser projector

ActiveCN105467731AAdjust the speedAutomatic and effective heat dissipationProjectorsHeat managementLaser array

The invention discloses a heat management system of a laser projector. The system comprises a mainboard, and further comprises an altitude sensor, an external environment temperature sensor, a DMD cooling fan, a laser light source and a laser light source cooling fan which are connected with the mainboard, wherein the laser light source comprises a color wheel and a laser array; a color wheel temperature sensor connected with the mainboard is arranged in a position 1cm away from the disc surface of the color wheel; a laser temperature sensor connected with the mainboard is attached to the heat exchange surface of the laser array; and the laser array is connected with a laser water-cooling heat dissipation module. According to the system, a control system automatically adjusts and changes corresponding parameters at different external environment temperatures and altitudes; and the control system accurately adjusts the rotational speed of each corresponding fan in real time in combination with the parameters according to data detected and sent by each temperature detection sensor to finally realize automatic and effective heat dissipation.

Owner:AVANZA

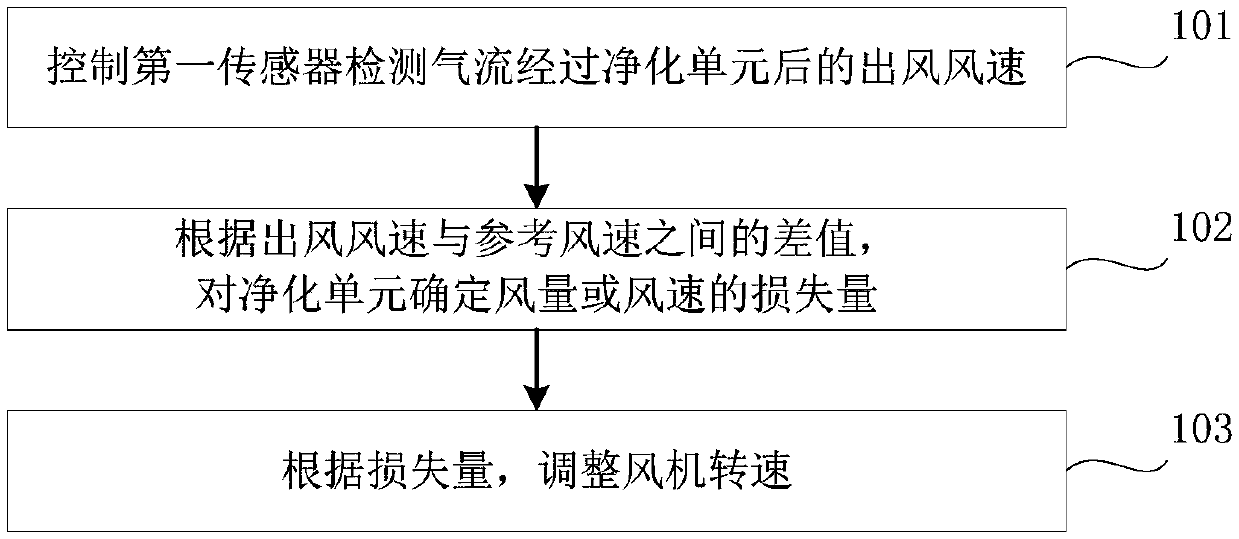

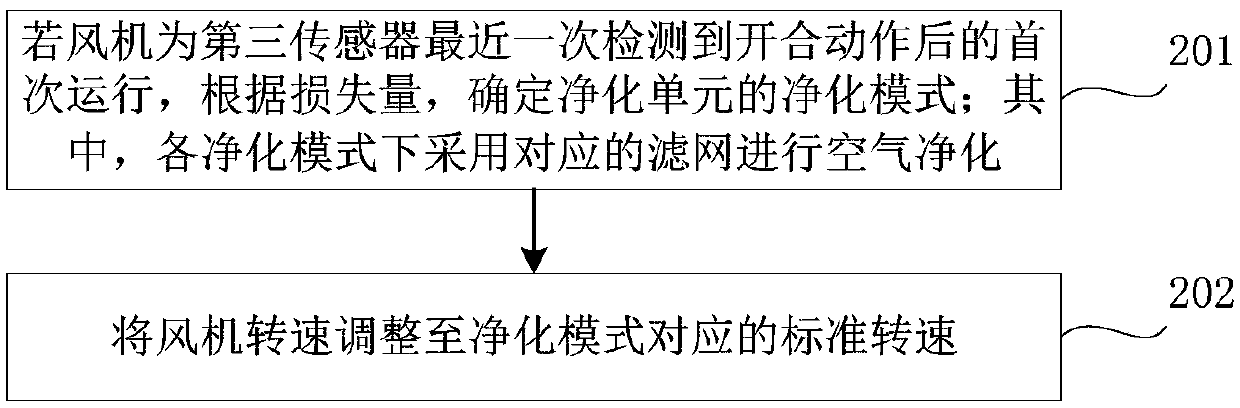

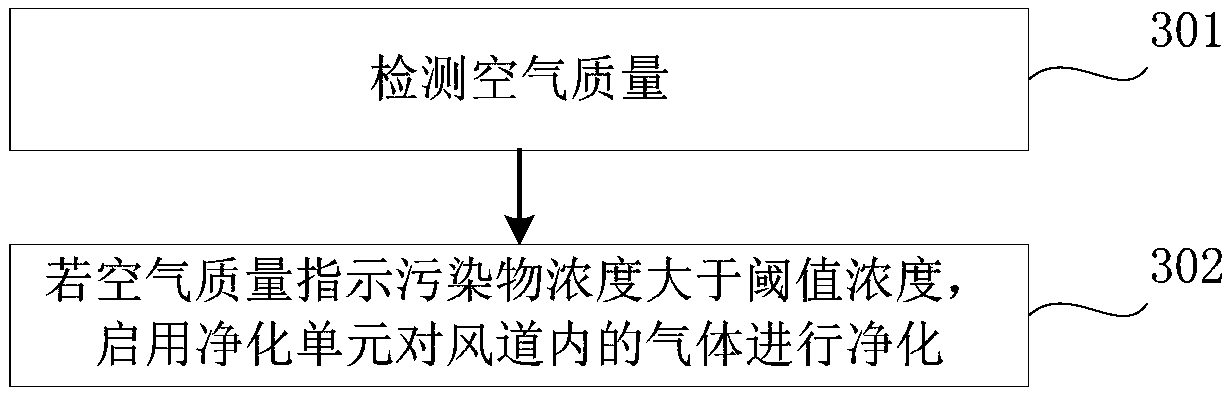

Air conditioning device control method, device and air conditioning device

ActiveCN109668261AWind speed adjustmentAdjust the speedMechanical apparatusSpace heating and ventilation safety systemsHigh energyAir conditioning

The invention provides an air conditioning device control method, a device and an air conditioning device. According to the air conditioning device control method, the device and the air conditioningdevice, an indoor unit of the air conditioning device is provided with an air outlet, an air passage communicating with the air outlet is internally provided with an air fan and a purifying unit for purifying air flow output by the air fan, and air outlet is further provided with a first sensor for detecting the air speed. The method comprises the steps that the first sensor is controlled to detect the air outlet speed of the air flow after passing through the purifying unit; the air quantity or the air speed loss quantity of the purifying unit is confirmed according to the difference value between the air outlet speed and the reference air speed; and the rotating speed of the air fan is adjusted according to the loss quantity. By means of the air conditioning device control method, the fact that the rotating speed of the air fan is adjusted automatically according to the air quantity or the air speed loss quantity can be realized, adjustment of the purifying air quantity can be realized, and the purifying efficiency and effect are guaranteed; and in addition, the rotating speed of the air fan changes along with change of the loss quantity, occurrence of the situation of high energy consumption caused by the air fan running at a high rotating speed all the time can be avoided, and the energy consumption can be effectively reduced.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

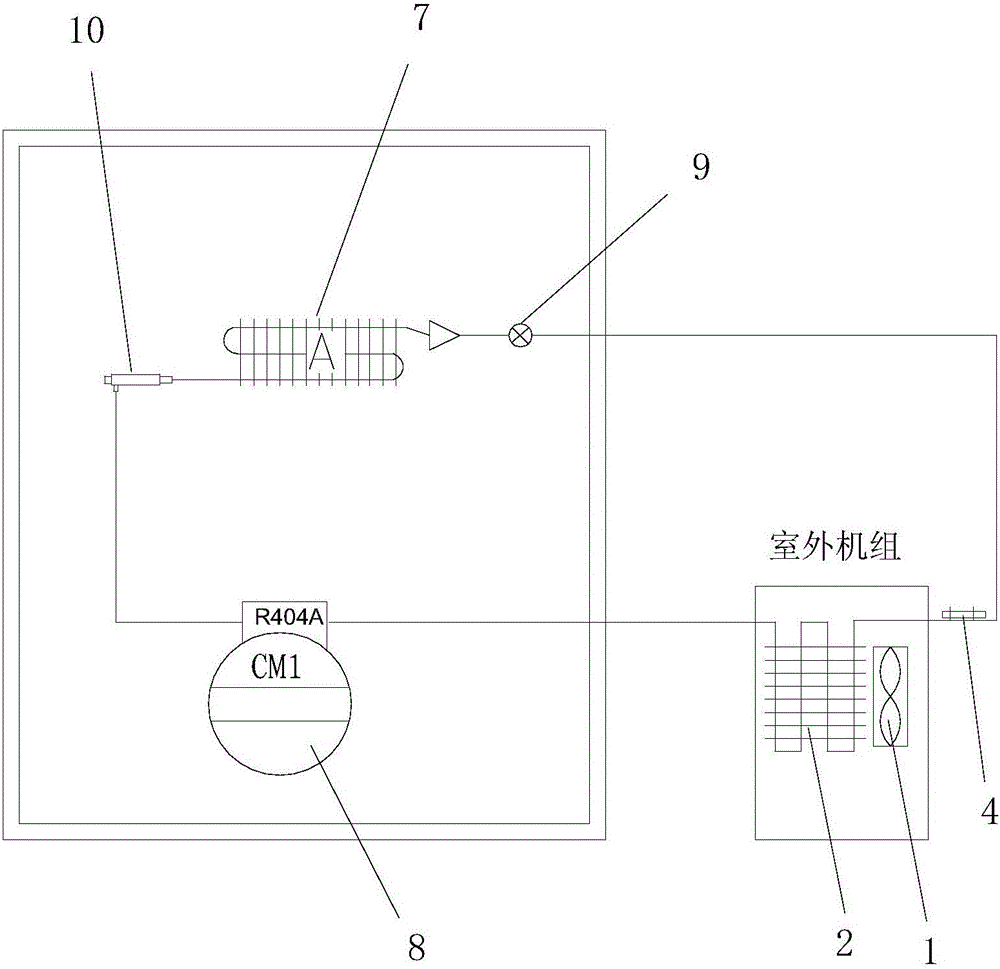

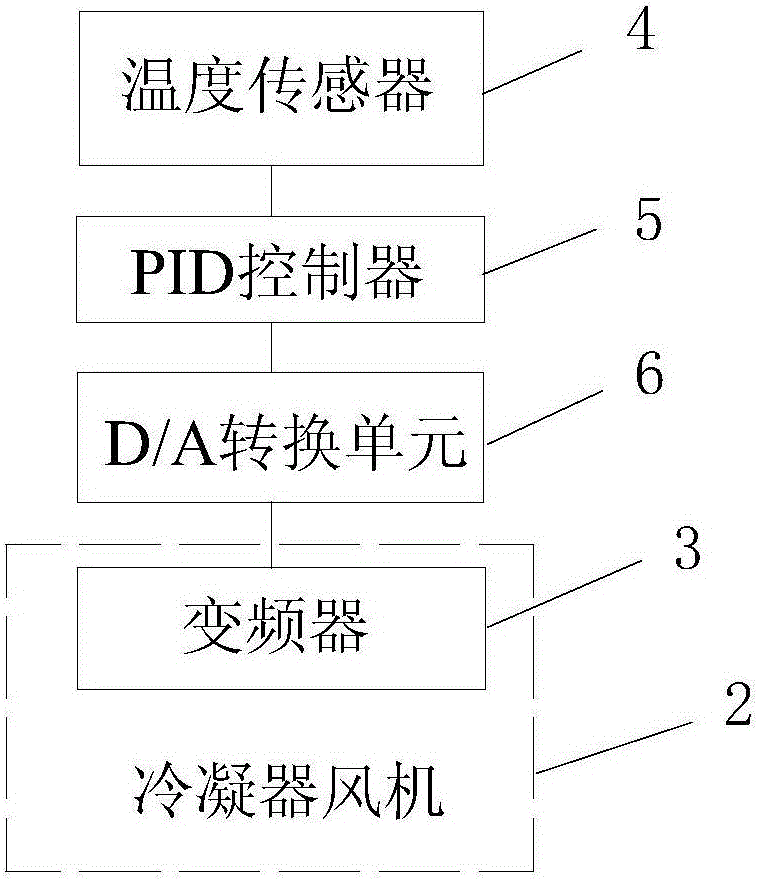

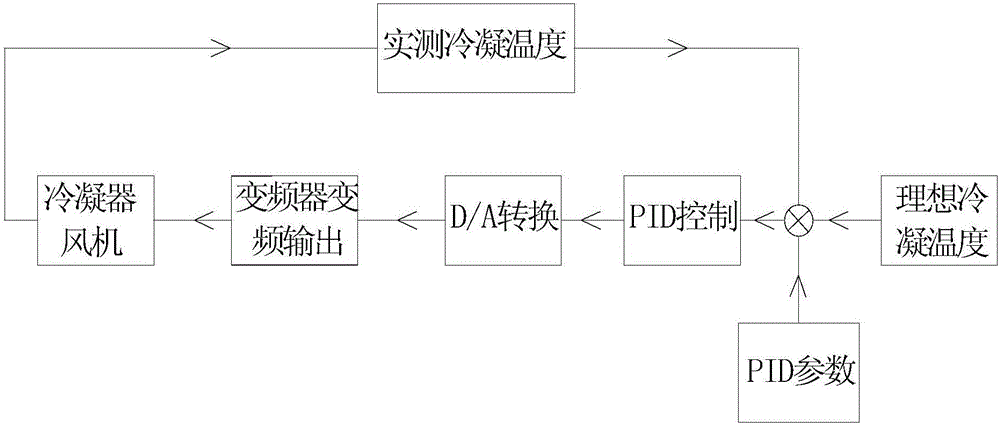

Frequency conversion control system and method for constant temperature and humidity device

ActiveCN106052031AAdjust the speedGuaranteed uptimeMechanical apparatusSpace heating and ventilation safety systemsFrequency changerControl system

The invention discloses a frequency conversion control system and method for a constant temperature and humidity device. The frequency conversion control system comprises a temperature sensor, a PID controller, a D / A conversion unit and a frequency converter. The temperature sensor is used for measuring the actual condensing temperature of a condenser. The PID controller is used for calculating the frequency value of the frequency converter, needing to be executed, through a PID calculation method according to the difference between the measured actual condensing temperature and the set ideal condensing temperature. The D / A conversion unit is used for converting the frequency value, obtained through the calculation of the PID controller, of the frequency converter into an analog signal capable of being recognized by the frequency converter. The frequency converter is used for regulating the rotational speed of a fan according to the corresponding analog signal to control the condensing temperature of the condenser in a real-time manner to enable the condenser to reach the ideal condensing temperature and the condensing pressure to be higher than the evaporation pressure limit. The frequency conversion control system is reasonable in design, and perennial stable operation of the constant temperature and humidity device can be realized.

Owner:DONGGUAN CITY SIMPLEWELL TECH

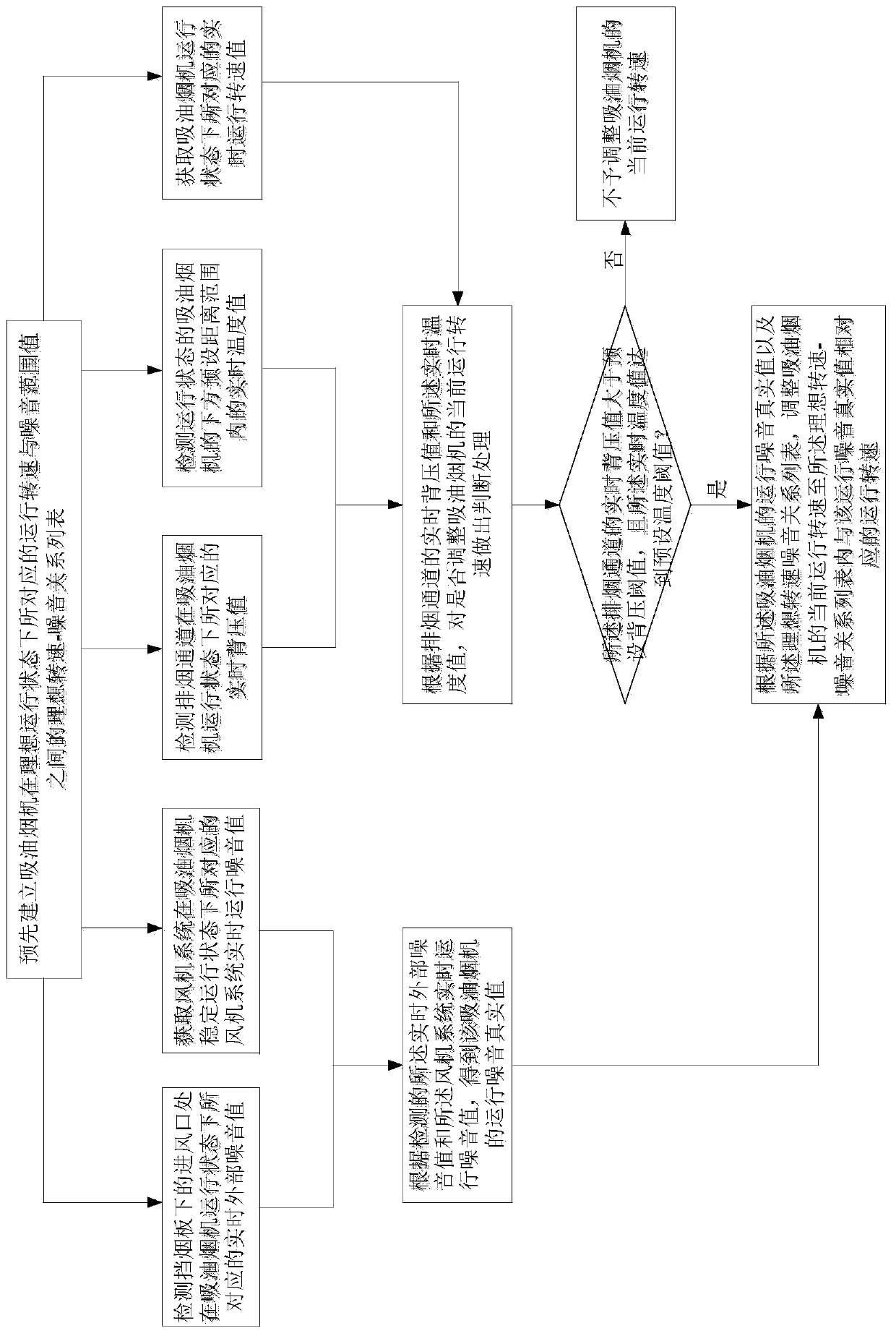

Intelligent adjusting method for noise of extractor hood

ActiveCN111043637AAvoid affecting the user experienceAdjust real-time running speedDomestic stoves or rangesPump componentsInternal noiseEngineering

The invention relates to an intelligent adjusting method for noise of an extractor hood. An ideal rotating speed-noise relation list between the corresponding operating rotating speed and the noise range value of the extractor hood in an ideal operating state is established in advance; the real-time external noise value at the air inlet of the extractor hood and the real-time operation noise valueduring stable operation of the extractor hood are detected and the actual operation noise value of the extractor hood under the actual noise condition is accurately obtained in a manner of combiningthe internal noise and the external noise of the extractor hood; the current running rotating speed of the extractor hood is adjusted to the running rotating speed corresponding to the running noise true value in the ideal rotating speed-noise relation list when presence of the user below the extractor hood is determined according to the detection of the real-time back pressure value of the smokeexhaust channel and the temperature in the preset distance range below the range hood so that the rotating speed of the extractor hood during operation can be adjusted along with the generated noise and the noise of the extractor hood during operation is adjusted to the noise range in the ideal state and the influence on the use experience of the user is prevented.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

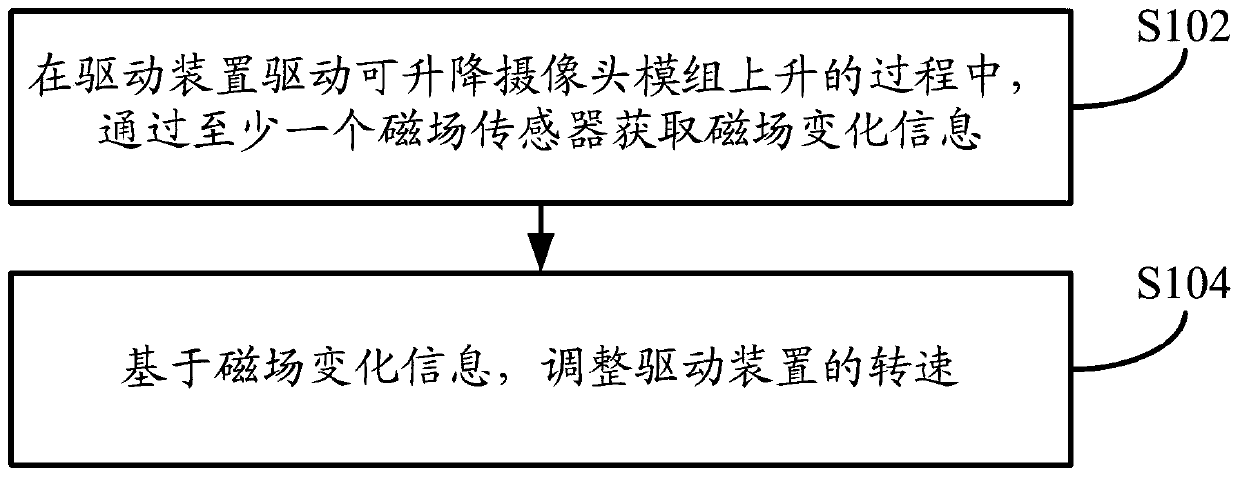

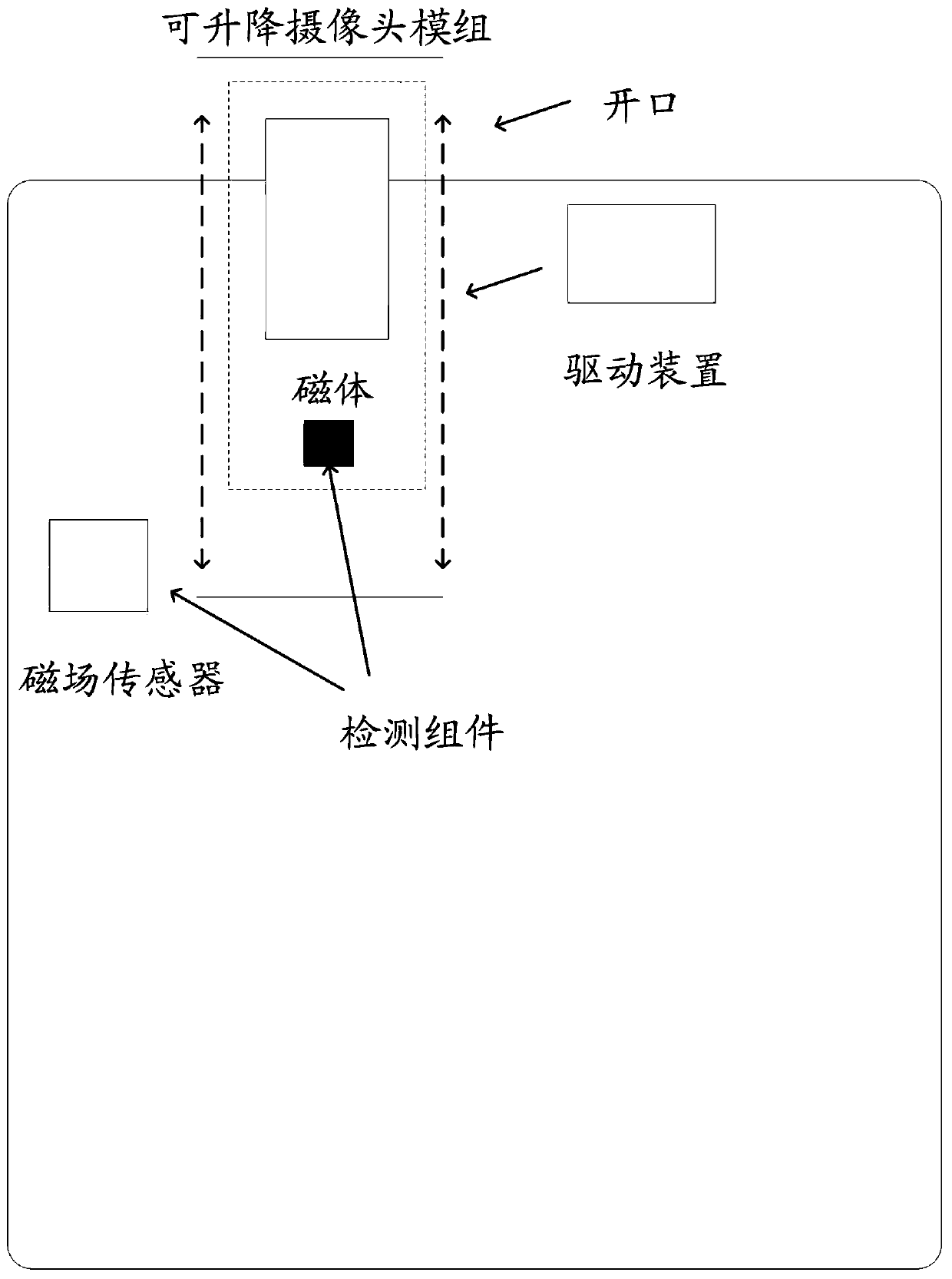

Control method and device and electronic equipment

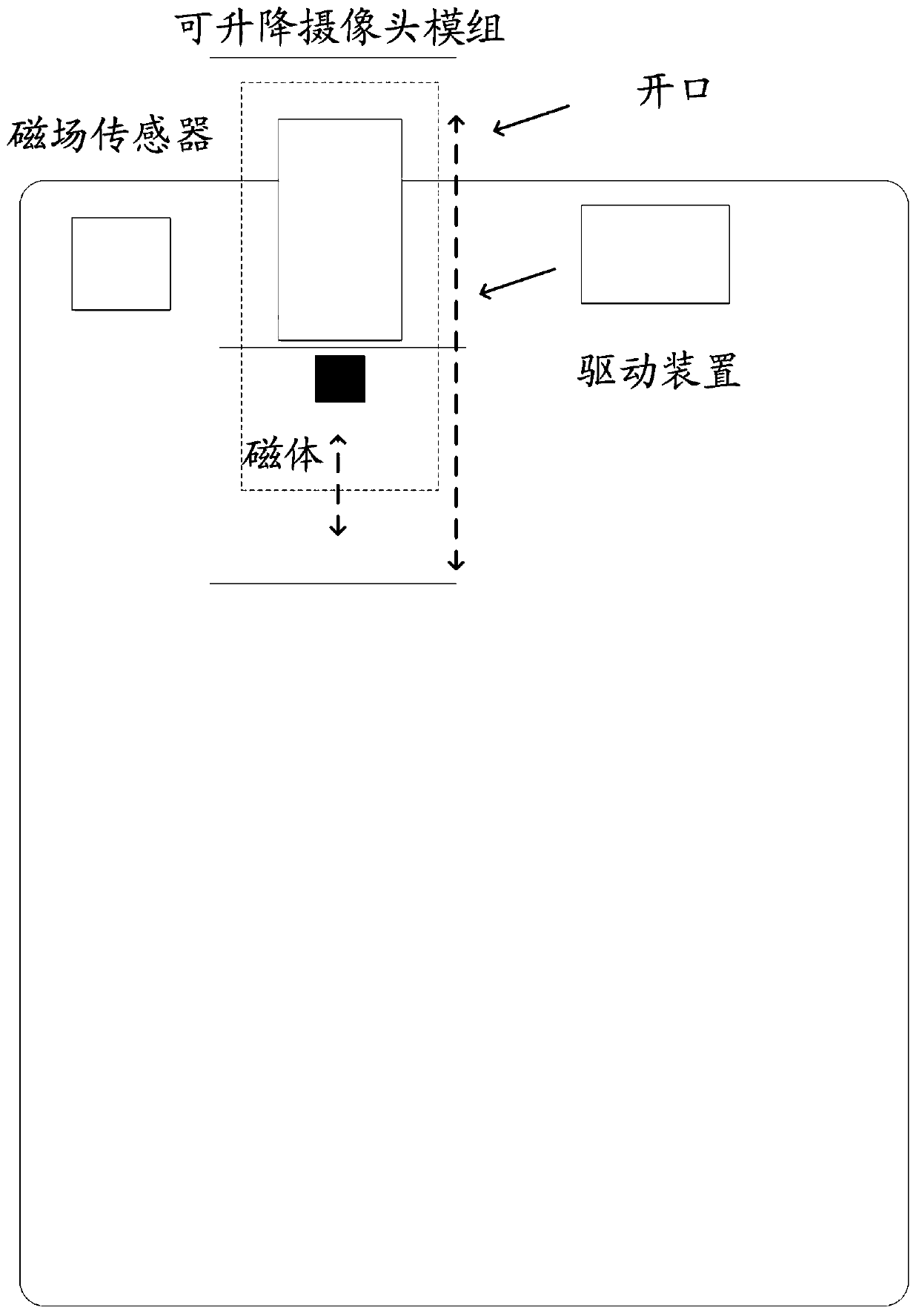

ActiveCN111246085AAvoid the problem of self-shrinkageAdjust the speedTelevision system detailsColor television detailsCamera moduleControl theory

The embodiment of the invention discloses a control method and device and electronic equipment, which are applied to the electronic equipment. The electronic equipment is internally provided with a liftable camera module, a detection assembly and a driving device; the detection assembly comprises at least one magnetic field sensor and a magnet. The magnet is fixedly connected with the liftable camera module. The method is characterized by comprising the following steps: in the process that the driving device drives the liftable camera module to ascend, acquiring magnetic field change information through the at least one magnetic field sensor, and adjusting the rotating speed of the driving device based on the magnetic field change information. Through the method, the rotating speed of thedriving device for driving the liftable camera module can be adjusted on the basis of the detected magnetic field change information, so the problem that the liftable camera shrinks automatically dueto long-time high-rotating-speed stalling of the driving device is avoided.

Owner:VIVO MOBILE COMM HANGZHOU CO LTD

Rotation speed control method for air conditioner compressor

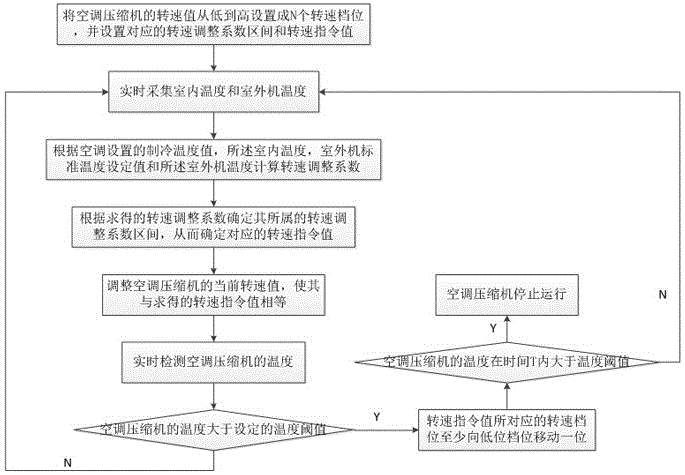

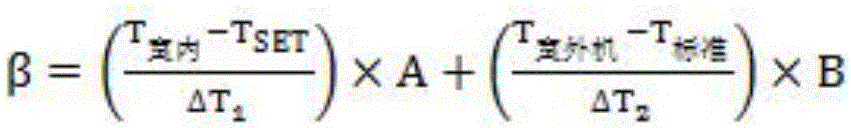

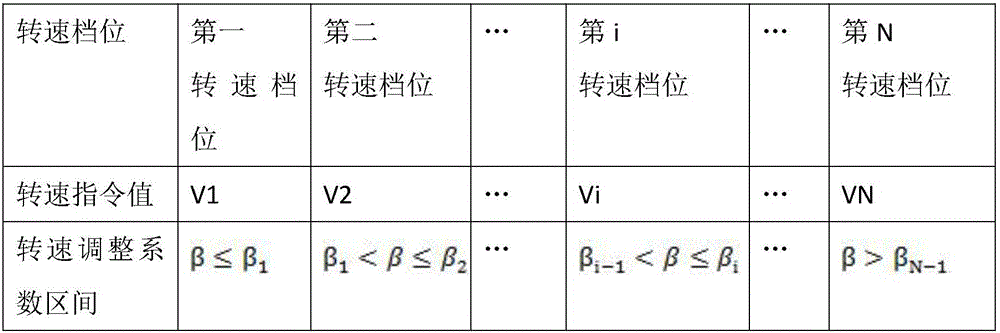

ActiveCN106839319AAdjust the speedAvoid long-term high-speed operationMechanical apparatusSpace heating and ventilation safety systemsValue setCooling effect

The invention relates to a rotation speed control method for an air conditioner compressor, which comprises the following steps: setting the rotation speed value of an air conditioner compressor into N rotation speed shifts from low to high, and setting a corresponding rotation speed adjusting coefficient interval and a rotation speed instruction value; acquiring indoor temperature and outdoor machine temperature in real time; according to a cooling temperature value set for an air conditioner, the indoor temperature, an outdoor machine standard temperature setup value and the outdoor machine temperature, calculating a rotation speed adjustment coefficient; according to the calculated rotation speed adjustment coefficient, confirming the rotation speed adjustment coefficient interval, confirming a corresponding rotation speed instruction value; adjusting a current rotation speed value of the air conditioner compressor to be equal to the calculated rotation speed instruction value. By adopting the rotation speed control method for the air conditioner compressor, the service life of the air conditioner compressor can be prolonged, and the cooling effect of the air conditioner compressor can be improved.

Owner:KEHUA DATA CO LTD

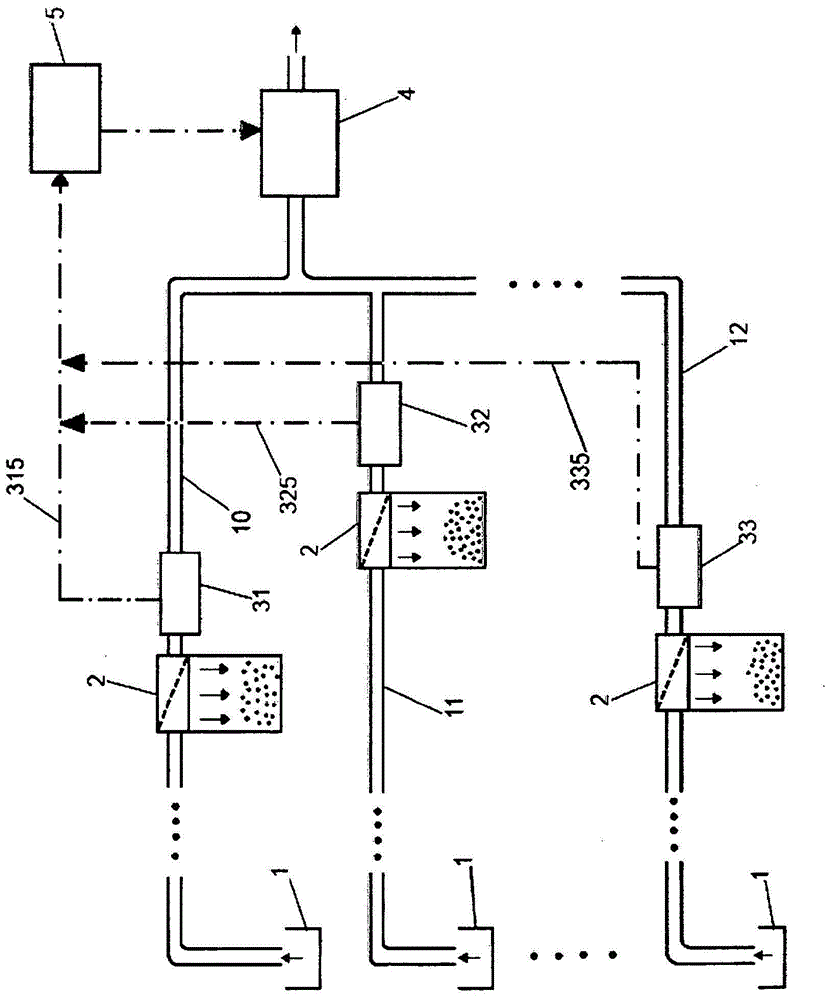

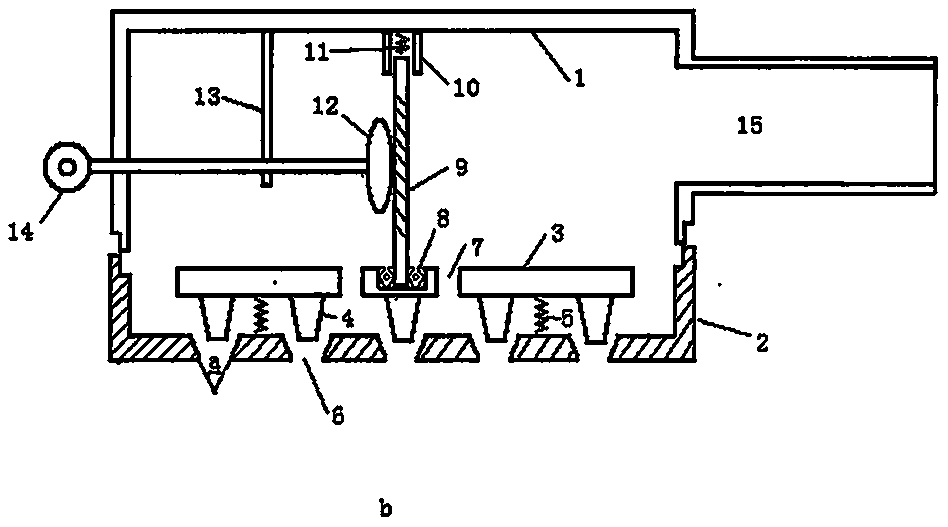

Pneumatic conveying installation

Disclosed is a pneumatic conveying installation, in particular a cut tobacco conveying installation, for conveying a material to be conveyed, in particular cut tobacco, in a gas stream, comprising a plurality of conveying lines (10, 11, 12) that are filled with material to be conveyed in the gas stream, in particular the air steam, and comprising at least one separating device (2) for each of the conveying lines (10, 11, 12). The separating device (2) is integrated into each of the conveying lines (10, 11, 12) and is designed so as to separate the material to be conveyed and to further conduct the remaining gas stream that has been substantially separated from the material to be conveyed in the conveying line. A regulation unit (31, 32, 33) is arranged downstream of each separating device (2) in the conveying line, which regulation unit comprises and regulates a throttle device so as to set a predefined conveying speed in the respective conveying line (10, 11, 12) by setting a throttle level above or equal to a predefined minimum value (Rmin), wherein the conveying installation has a common conveying device for conveying the material to be conveyed through the conveying lines (10, 11, 12). The conveying installation comprises a control and regulation device (5), which communicates with the conveying device (4) and which is designed to record the momentary throttle levels of the throttle devices and to vary the conveying power of the conveying device (4). The control and regulation device (5) is further designed to vary the conveying power of the conveying device (4) such that the throttle level of at least one throttle device lies, in each case, in the range of the minimum throttle level (Rmin).

Owner:RIEDEL FILTERTECHNIK GMBH

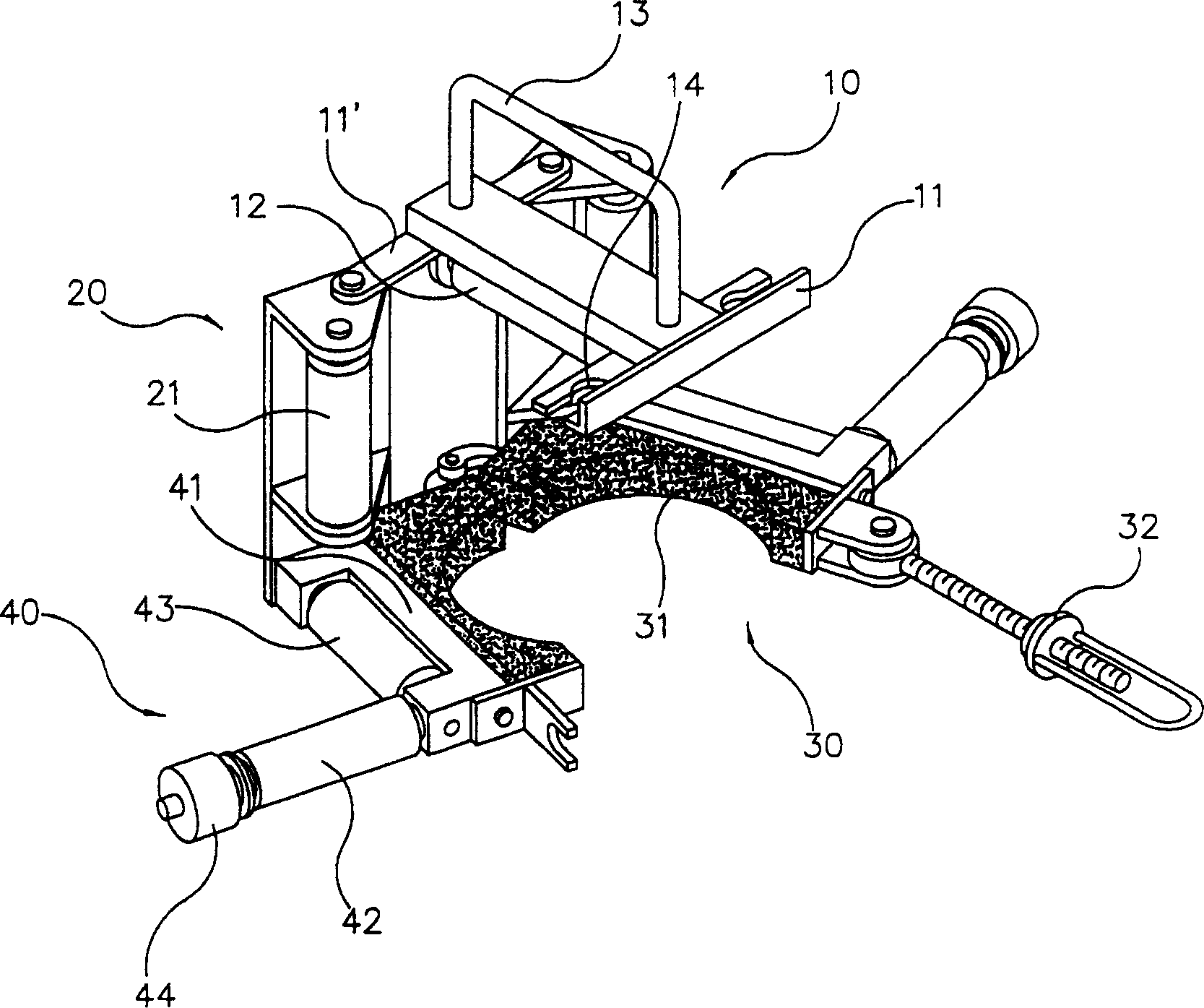

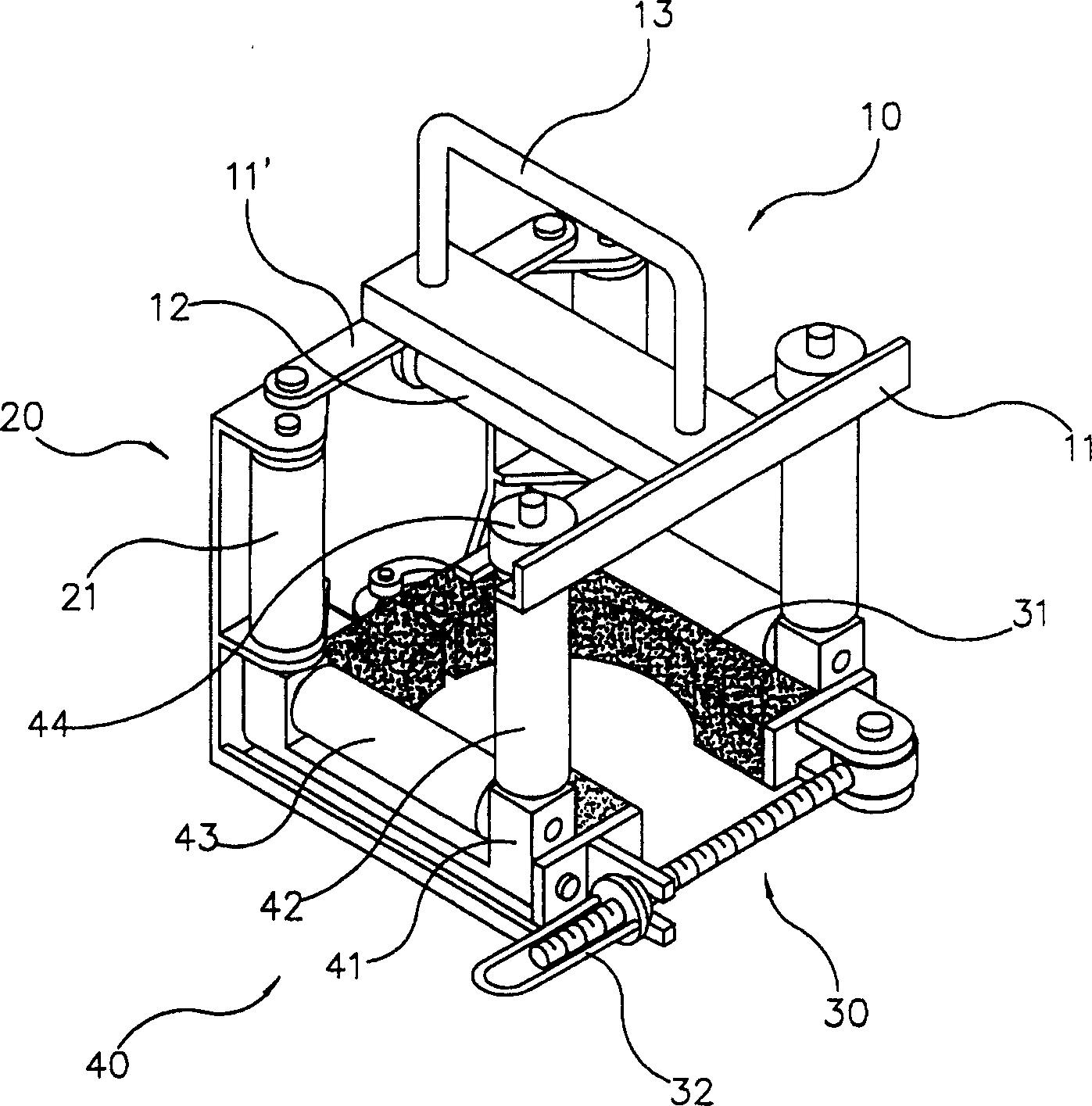

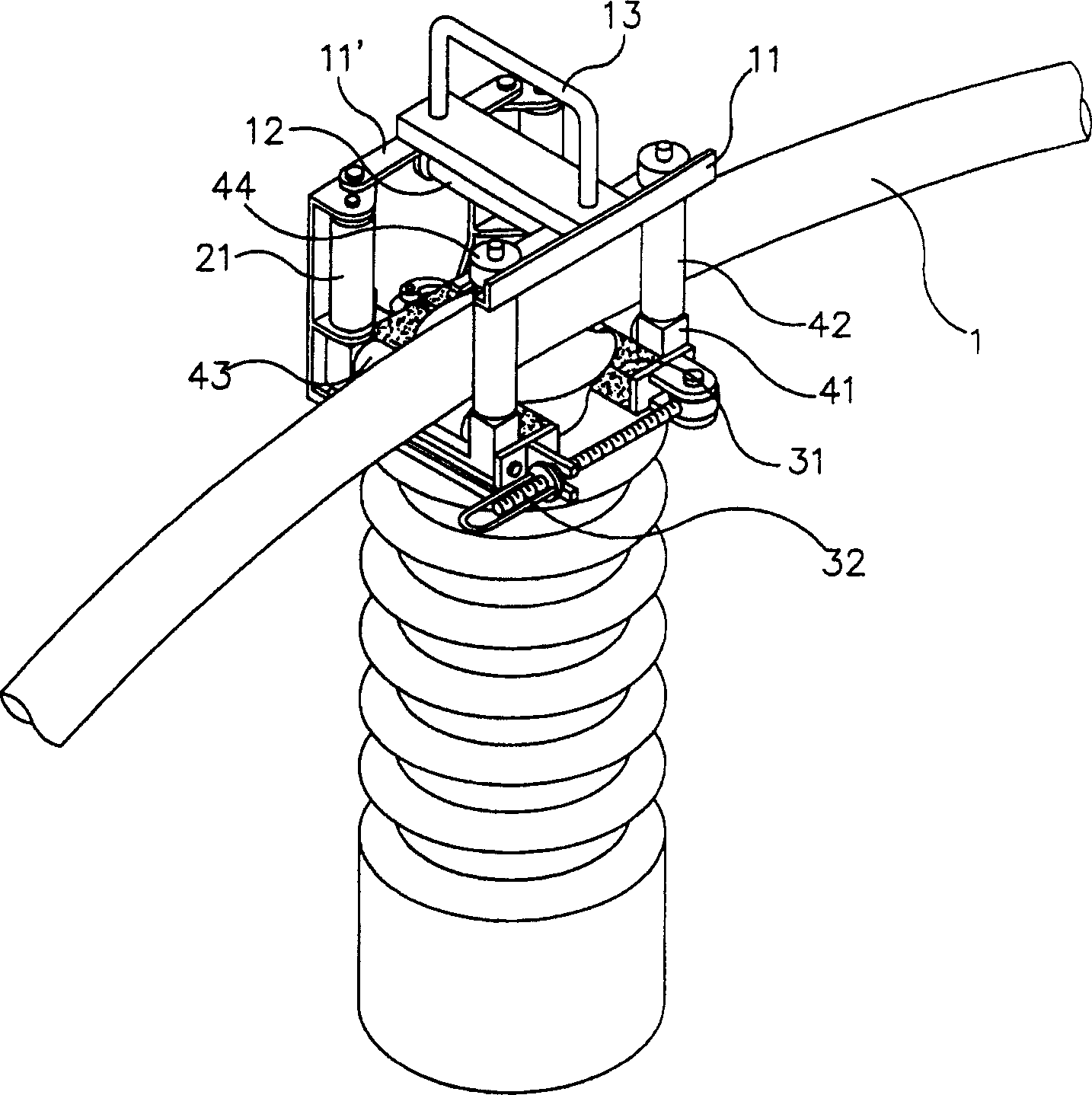

Electric wire removing roller for LP insulator and power distribution method of construction

InactiveCN1513223AEasy to operateReduce construction costsOverhead installationApparatus for overhead lines/cablesDistribution methodEngineering

The present invention discloses a wire stranding roller and a new method for the same, in a LP insulator being mounted at a cross arm of pin long column and insulating and supporting a high voltage wire, which drastically improves workability and greatly reduces construction cost because the location of a wire don't need to be changed after the stranding and wire pulling, which is easy to work with and is very effective in reducing labor cost and preventing a safety accident because it can easily perform wiring and removing works no matter how large the weight of the wires would be, which is capable of precisely adjusting a dip(degree in which the wire hangs down) because the wire are placed on an insulator, which is to be mounted, during a wire pulling work and also which can solve the problem of securing a work space when carrying out the work applying an uninterruptible method by forming a open-and-shut roller capable of wire insertion and a wire stranding roller consisting of an insulator coupling opening and directly coupling them on the upper surface of the LP insulator.

Owner:DAEWON ELECTRONICS CO LTD

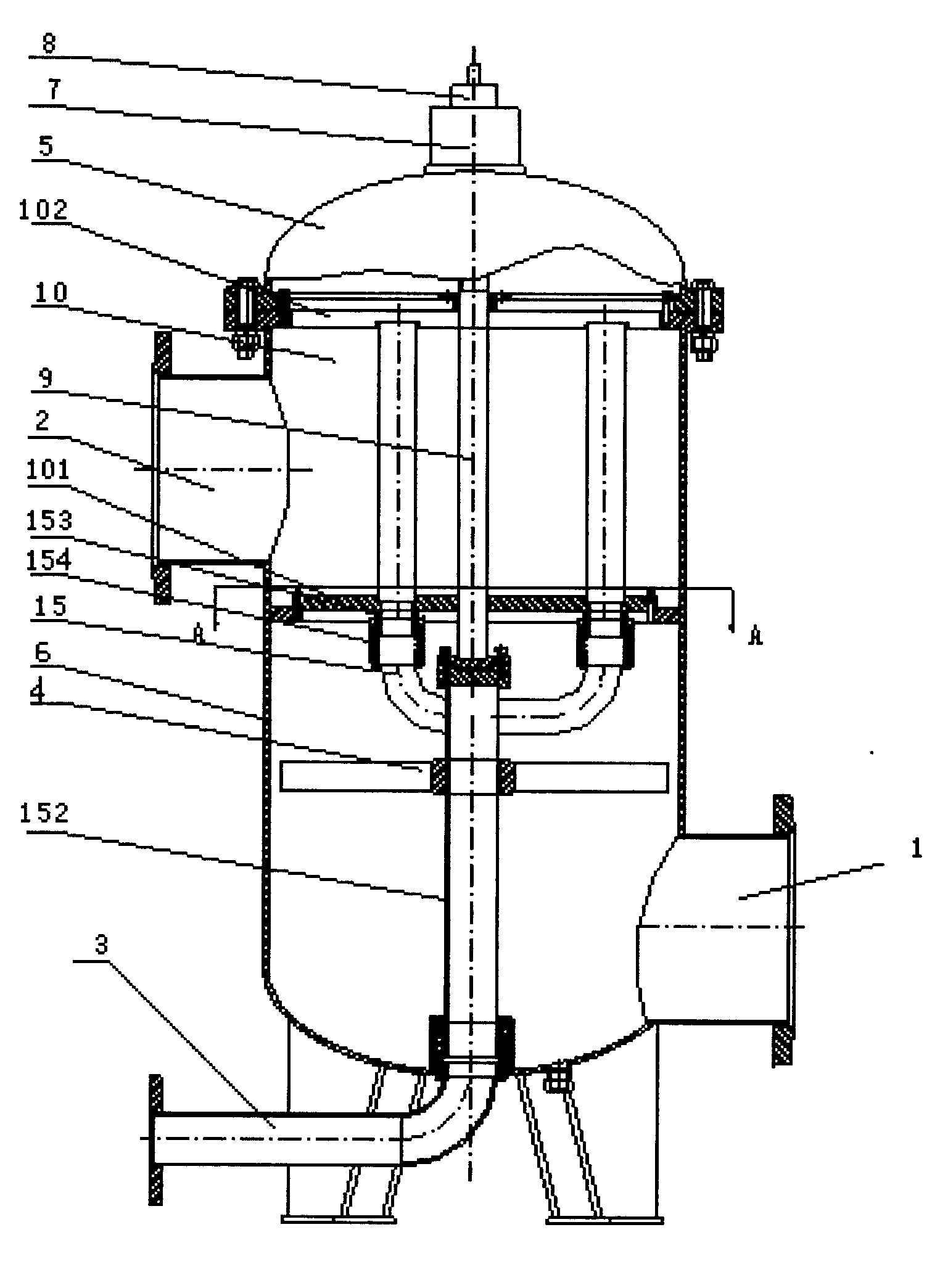

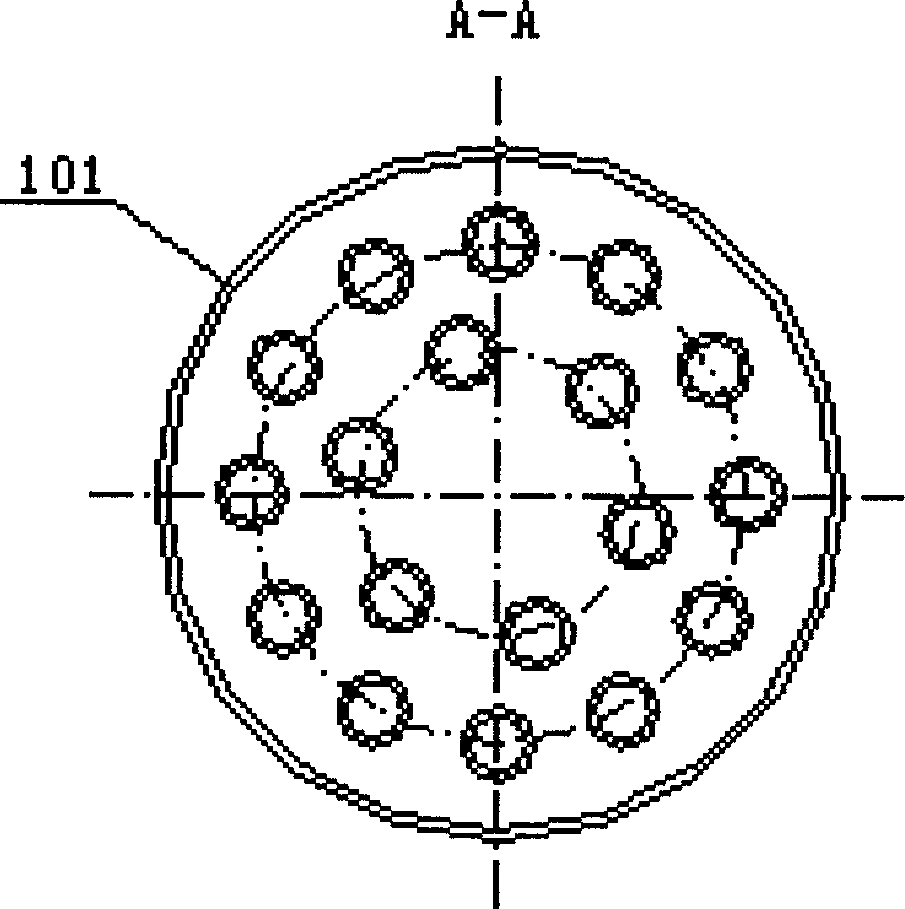

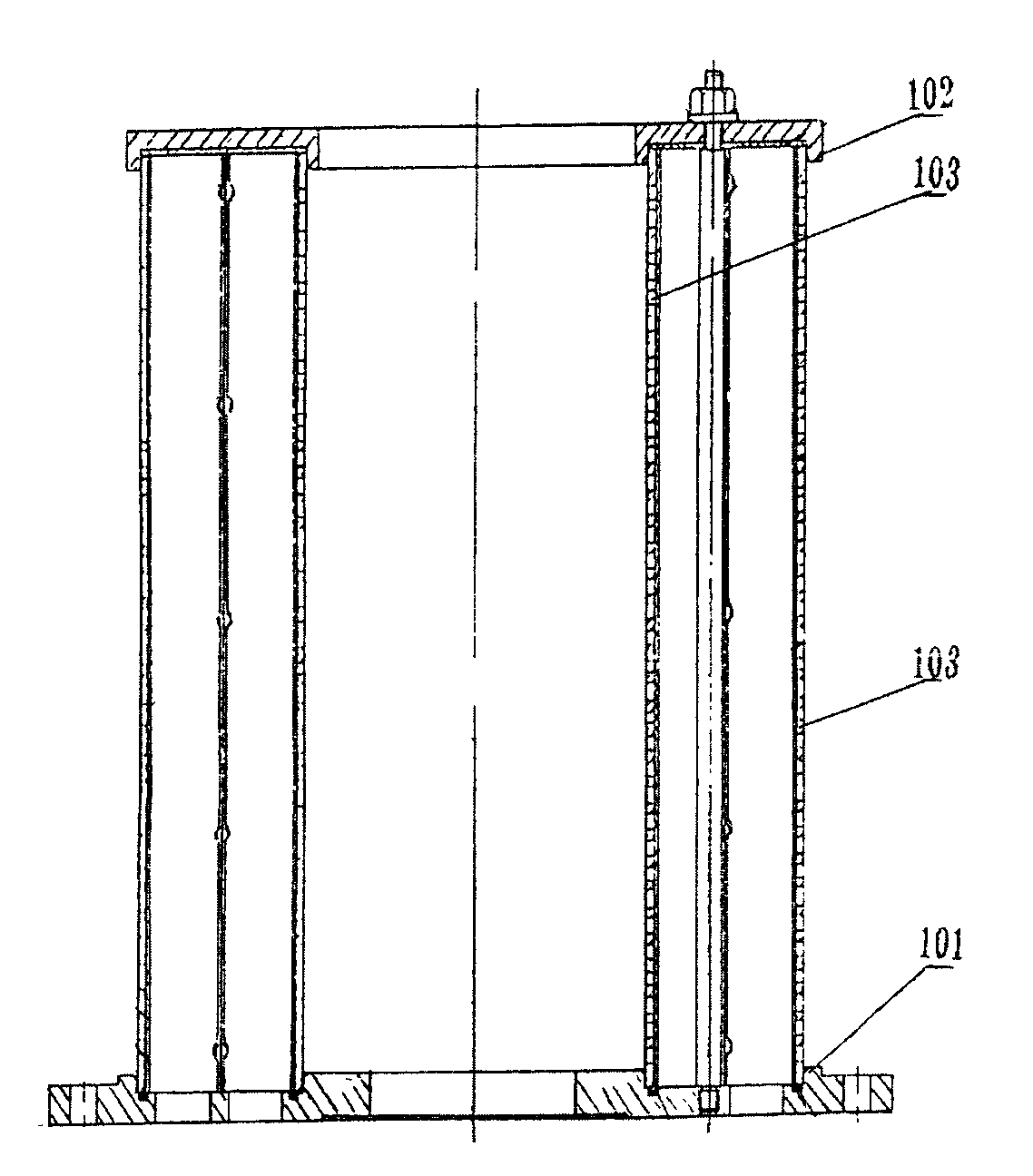

Self-driven sewage cleaning water filter

InactiveCN103055571ARealize the function of automatic sewage dischargeAdjust the speedStationary filtering element filtersImpellerWater filter

The invention relates to a self-driven sewage cleaning water filter, which comprises an upper casing, a lower casing, an impeller speed adjuster, a rotating speed annunciator, a balance shaft, a filter screen component, a sewage discharge branch pipe, a micro-impeller and a sewage discharge pipe. According to the self-driven sewage cleaning water filter, the self-driven sewage cleaning and discharging function is realized; during sewage discharging, a sewage discharge valve on a sewage discharge pipe 3 is opened, so that the water filter is in a sewage cleaning and discharging working condition; a sewage discharge branch pipe 15 is driven by the impeller 4 to rotate, so that pipe orifices on two arms of the sewage discharge branch pipe 15 are sequentially communicated with the washed filter screens of units, sewage attached to the filter screens are backwards washed by clean water, and effluent is discharged through the sewage discharge pipe 3, so that automatic sewage cleaning and discharging function is realized; and when the sewage valve is closed, the branch pipe is full of static pressure water, the sewage cleaning and discharging working condition is ended, and the water filter is recovered to the normal filtering working condition. According to the self-driven sewage cleaning water filter, redundant water energy in the water filter is fully utilized to drive the micro-impeller to realize self-driving, so that the technical effects of saving energy and simplifying structure are achieved.

Owner:苏九逵

Massage shower for brushing back

PendingCN109317320AAdjust the speedRealize the massage functionBathroom accessoriesSpray nozzlesMassageWater flow

The invention relates to a massage shower for brushing the back. The massage shower comprises an upper cover, a lower cover, a protrusion plate, a worm wheel and a worm; the worm wheel and the worm are matched, so that a rotary handle adjusts the worm wheel to rotate to drive the worm to move up and down; protrusions can be hidden inside the shower and can also protrude out of the lower surface ofthe lower cover, so that the length of the parts, extending out of water outlet holes, of the protrusions can be adjusted, and the functions of back brushing and massaging can be realized; and meanwhile, based on the condition that the taper angle a of the water outlet holes is larger than the taper angle b of the protrusions, so that when the protrusions move downwards, gaps between the protrusions and the water outlet holes become smaller, the water flow speed is increased, and the function of adjusting the water flow speed can be simultaneously achieved.

Owner:WUHAN TECHN COLLEGE OF COMM

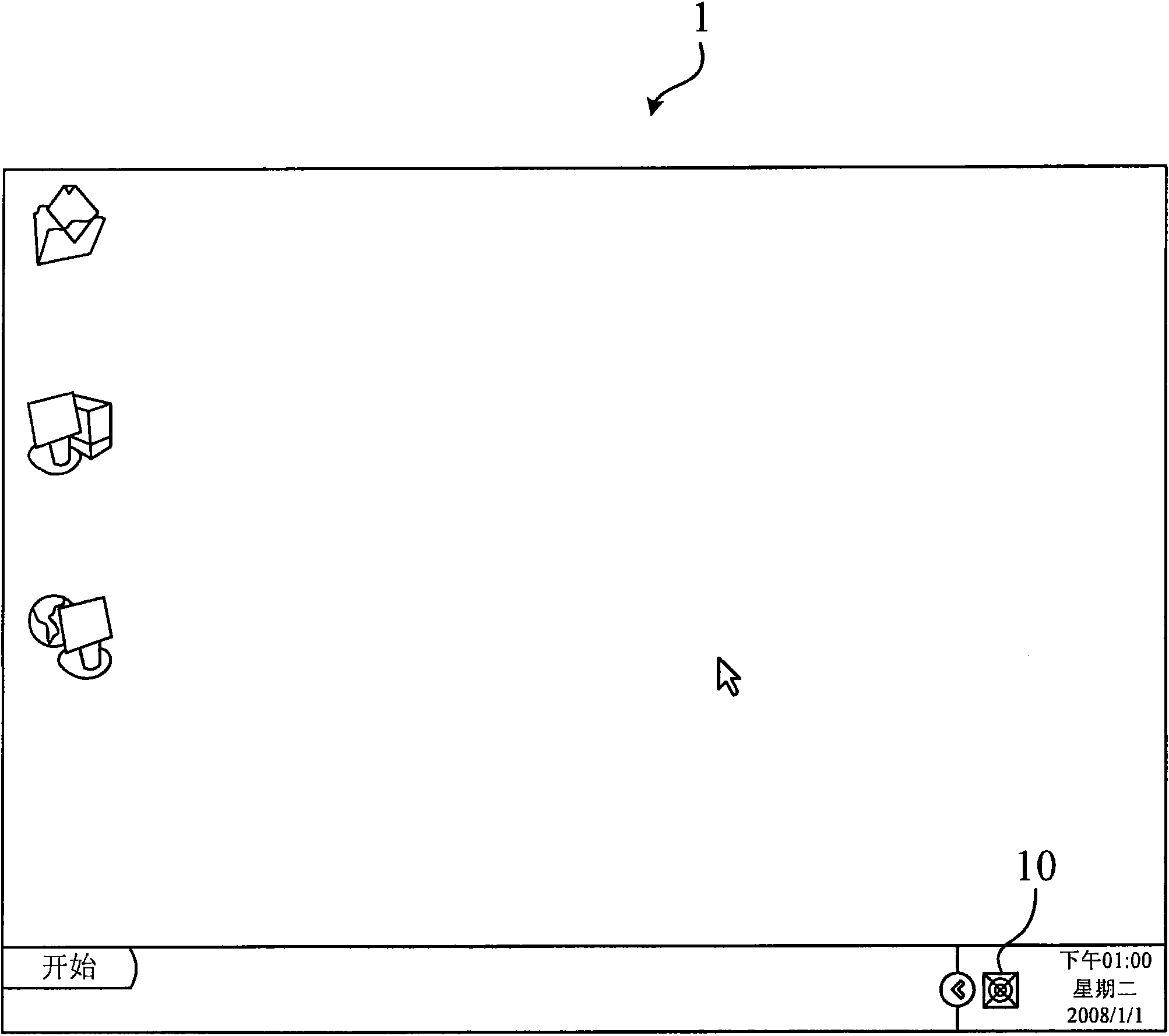

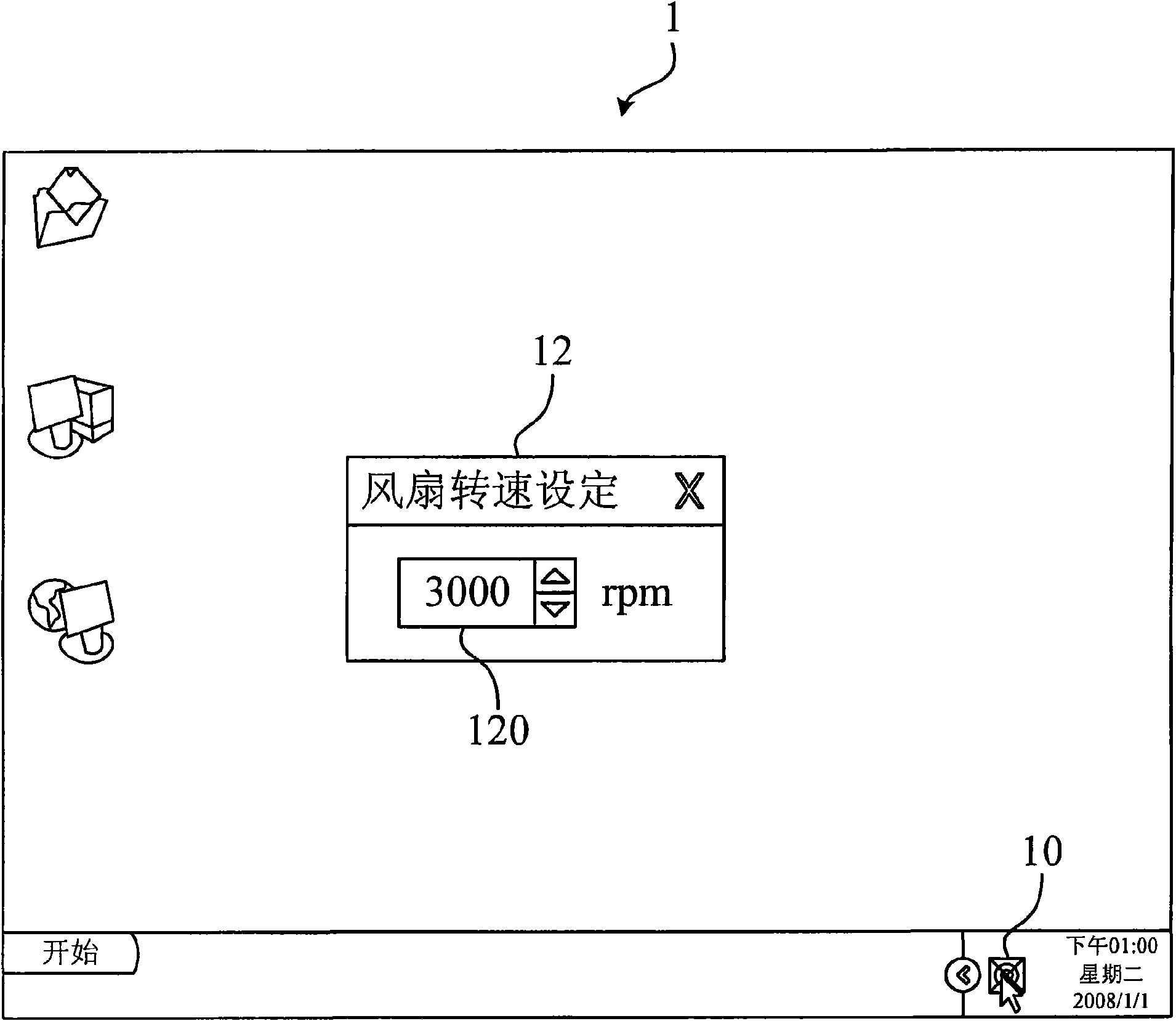

Method for controlling rotating speed of fan and computer system

InactiveCN101561703AReduce noiseEasy to adjustDigital data processing detailsHardware monitoringElectronic componentComputer science

The invention discloses a method for controlling the rotating speed of a fan and a computer system used for executing the method. The method includes the following steps: a, providing an operation interface in an operation system so as to adjust the current rotating speed of the fan; b, displaying warning information in the operation system when the current rotating speed is lower than a preset rotating speed or the current temperature is higher than a preset temperature; and c, continuously executing processing programs after the current rotating speed is readjusted. The invention enables a user to directly adjust and lower the rotating speed of the fan to reduce the noise. When the current rotating speed of the fan can not effectively lower the temperature of an electronic component, the invention can use the warning information to inform the user of the current state and a preset value and forces the user to achieve the purpose that the current work can only be continued after the rotating speed of the fan is adjusted, therefore, the electronic component can be prevented from being damaged by overheating. Besides, the invention also provides the hotkey function so that the user can conveniently adjust the rotating speed of the fan under the operation system.

Owner:ASUSTEK COMPUTER INC

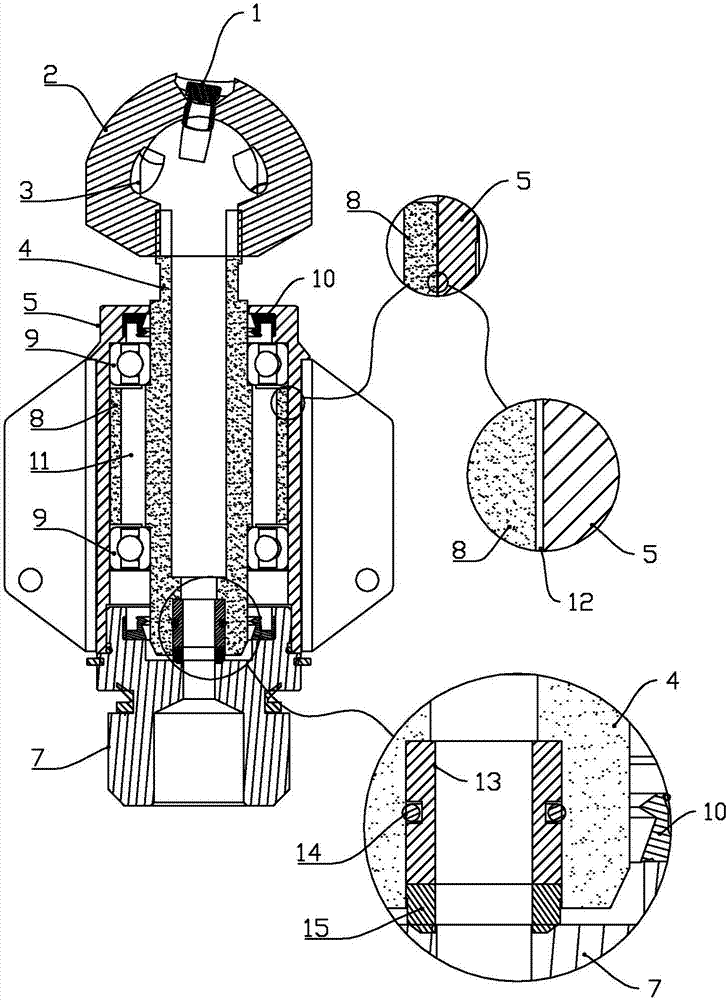

Auto-rotating sprayer

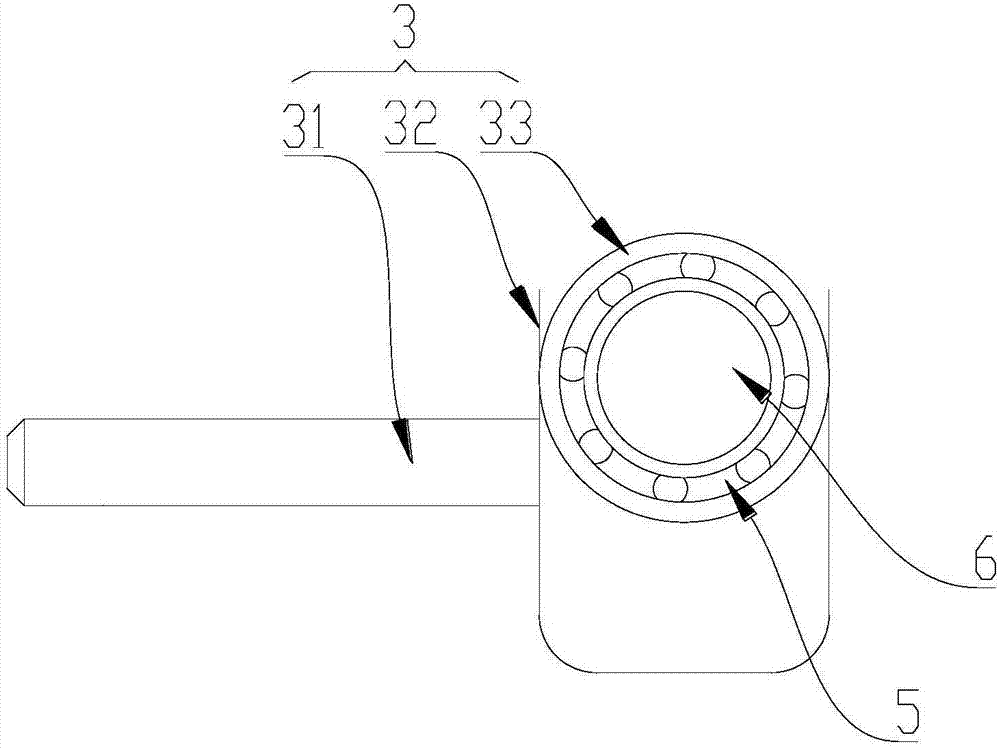

PendingCN107457098AHas a lubricating effectAdjust the speedMovable spraying apparatusEngineeringNozzle

Disclosed is an auto-rotating sprayer. The auto-rotating sprayer comprises a hollow rotating shaft, a rotator connected to the head of the rotating shaft, a case arranged on the circumference of the rotating shaft in a sleeving mode, and a connecting nut threadedly connected at the tap of the case; thrust spray nozzles are circumferentially distributed at the lower end of the rotator and obliquely and eccentrically arranged relative to the central axis of the rotator; the top of the rotator is obliquely provided with a cutting nozzle, and the thrust spray nozzles and the cutting nozzle are communicated with a water supply channel; the middle of the rotating shaft is provided with a damping ring unit, a damping slit is formed between the damping ring unit and the inner wall of the case; two bearings are matched between the rotating shaft and the case and on both sides of the damping ring unit; oil seals are arranged outside the bearings, and damping oil is filled between the two oil seals of the inner cavity of the case. According to the auto-rotating sprayer, the damping oil achieves lubricating effects as well as the aim of adjusting the rotating speed; a rotary sealing design breaks through the limitation of pressure insufficiency of the auto-rotating sprayer, and a 60 Mpa ultrahigh-pressure cleaning function can be achieved.

Owner:浙江博拓里尼机械股份有限公司

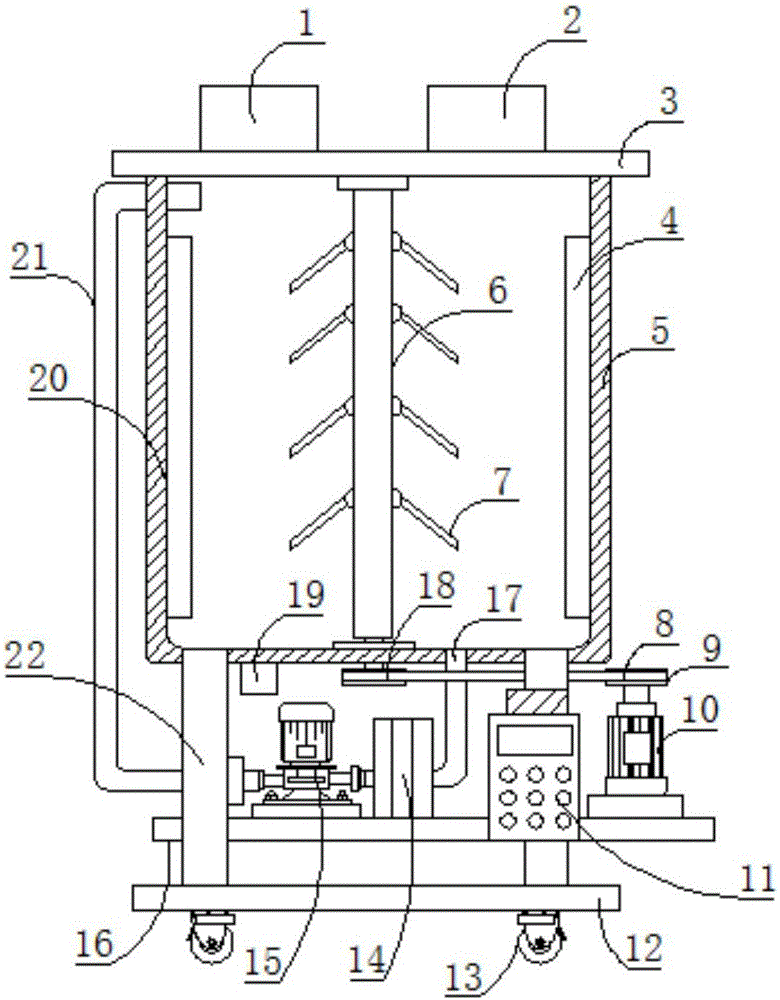

Efficient dyeing equipment convenient to control

InactiveCN107435201AFully contactedImprove dyeing efficiencyTextile treatment containersTextile treatment machine arrangementsRotation - actionEngineering

The invention discloses efficient dyeing equipment convenient to control. The efficient dyeing equipment comprises a body shell. A mounting plate is arranged on the upper side of the body shell, a material feed inlet is formed in the upper side of the mounting plate, a water feed inlet is formed in a side of the material feed inlet, a connecting shaft is mounted inside the body shell, stirring paddles are symmetrically mounted on two sides of the connecting shaft and comprise fixing shafts, bearing blocks, through holes and stirring paddle bodies, and the corresponding bearing blocks are symmetrically arranged at two ends of each fixing shaft. The efficient dyeing equipment has the advantages that the stirring paddles are symmetrically arranged on the two sides of the connecting shaft, the through holes are uniformly formed in the stirring paddle bodies of the stirring paddles, the stirring paddle bodies are rotationally connected with the connecting shaft by the fixing shafts and can rotate by different angles under the conditions of different rotational speeds, accordingly, dye inside the efficient dyeing equipment can be turned over inside the body shell in the up-down directions under the rotation actions of the stirring paddle bodies and can be in sufficient contact with materials required to be dyed, and the dyeing efficiency can be improved.

Owner:CHANGXING DEHONG MACHINERY CO LTD

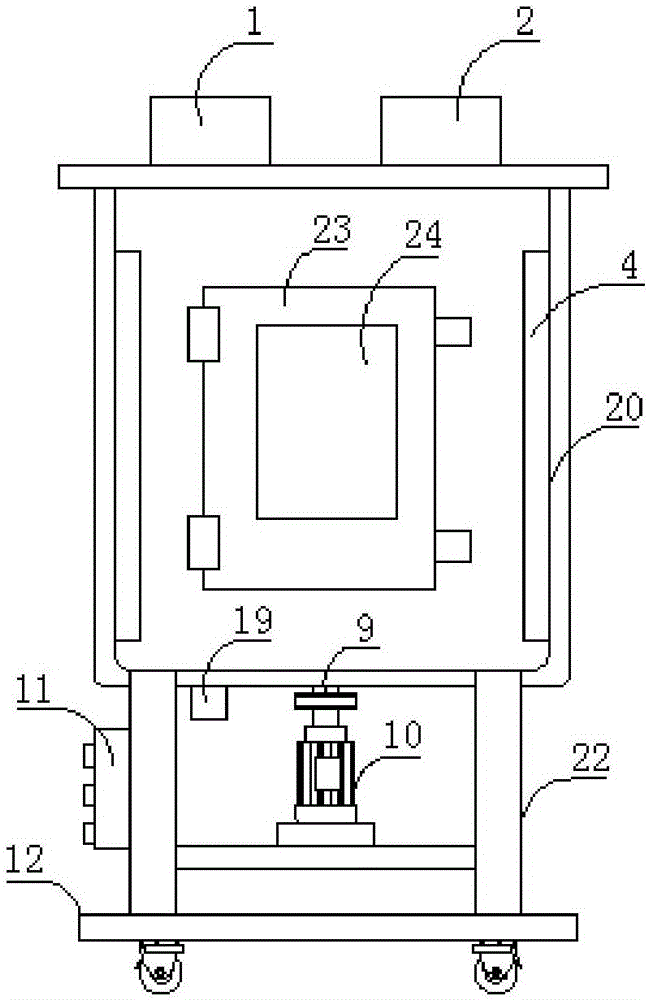

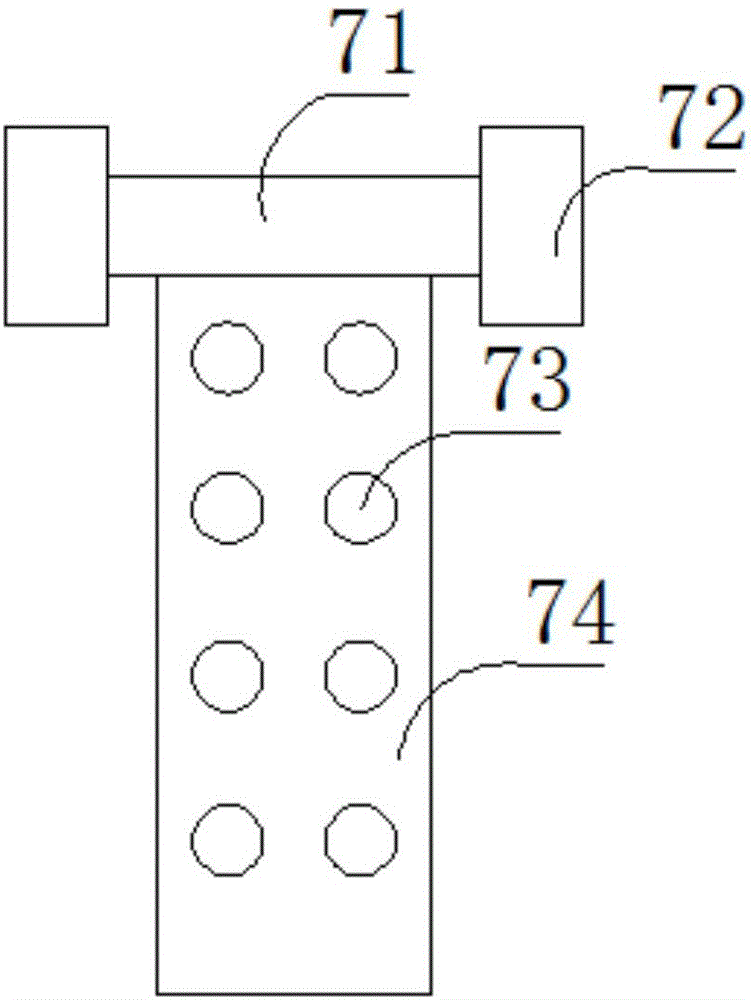

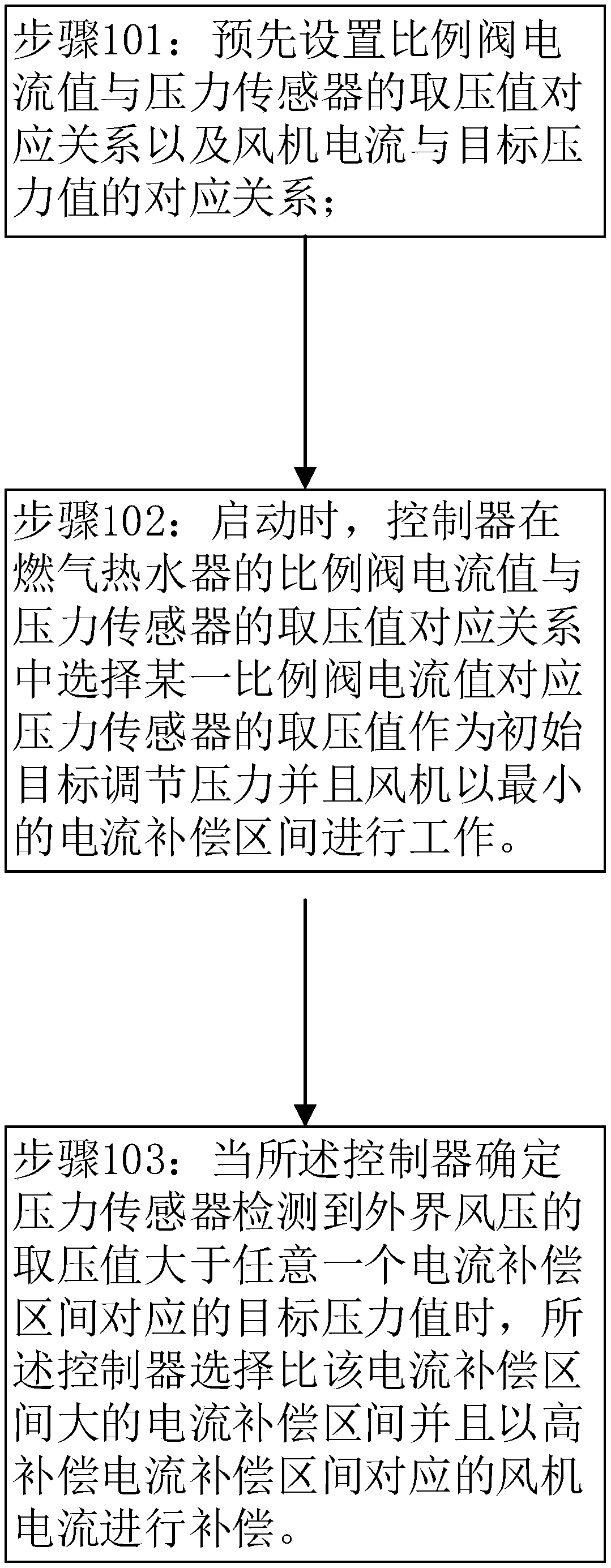

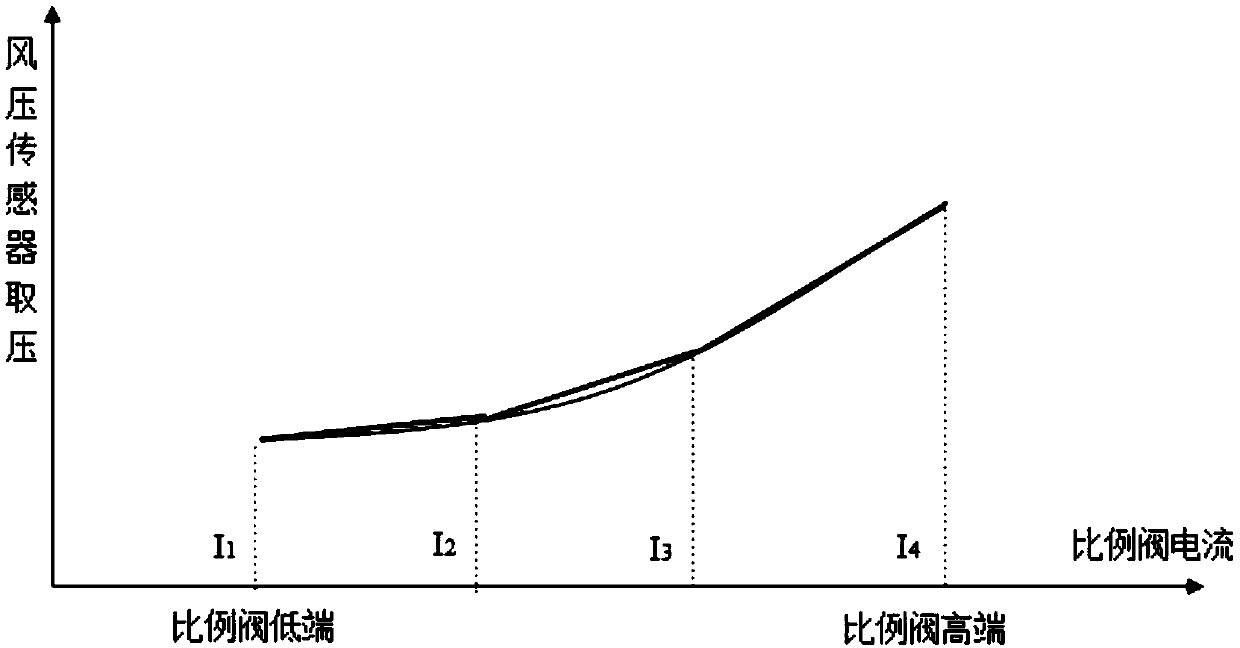

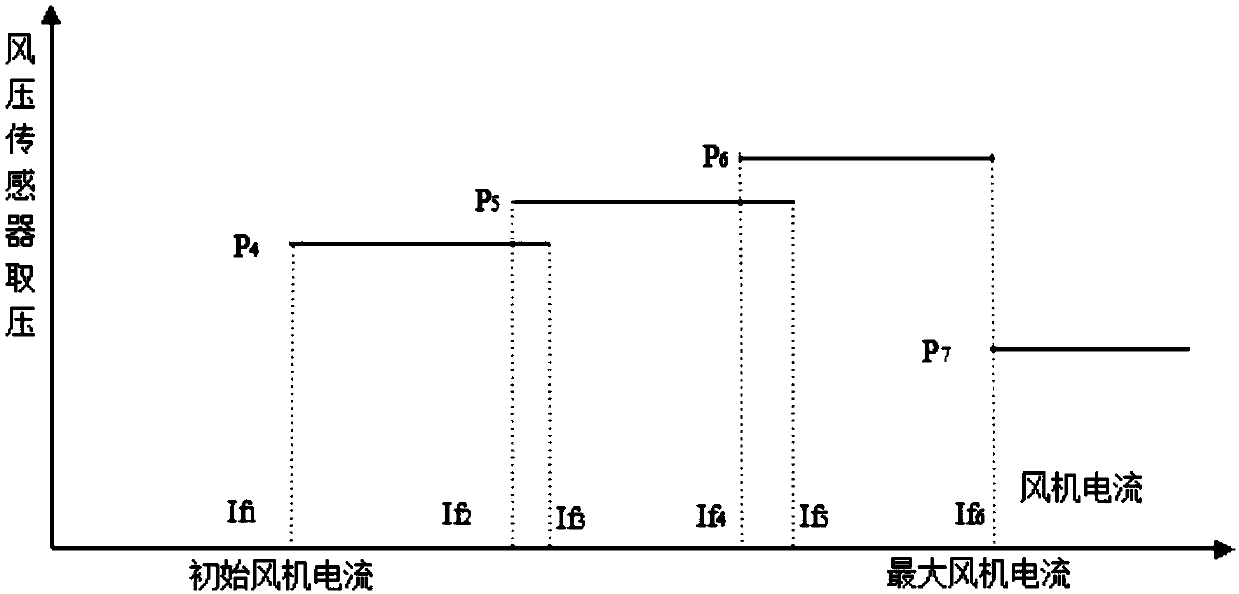

Control method for self-adaptive air pressure of gas water heater

The invention discloses a control method for self-adaptive air pressure of a gas water heater. The control method for the self-adaptive air pressure of the gas water heater comprises the steps of presetting a corresponding relation between proportioning valve current values and air pressure sensor pressure-tapping values, and dividing a fan current into at least one current compensation interval from small to large, wherein each current compensation interval corresponds to a target pressure value; during starting, using a controller for selecting the air pressure sensor pressure-tapping valuecorresponding to one proportioning valve current value from the corresponding relation between the proportioning valve current values and the air pressure sensor pressure-tapping values, using as initial target adjusting pressure, and operating the fan at the initial current; and then, when the controller determines that an air pressure sensor detects a change occurred between an outside air pressure tapping value and a preset baseline, using the controller for compensating the fan current. According to the control method for the self-adaptive air pressure of the gas water heater provided by the invention, the fan rotating speed can be adjusted in real time according to the air pressure change, and air required for the normal operation of the gas water heater is always guaranteed.

Owner:VATTI CORP LTD

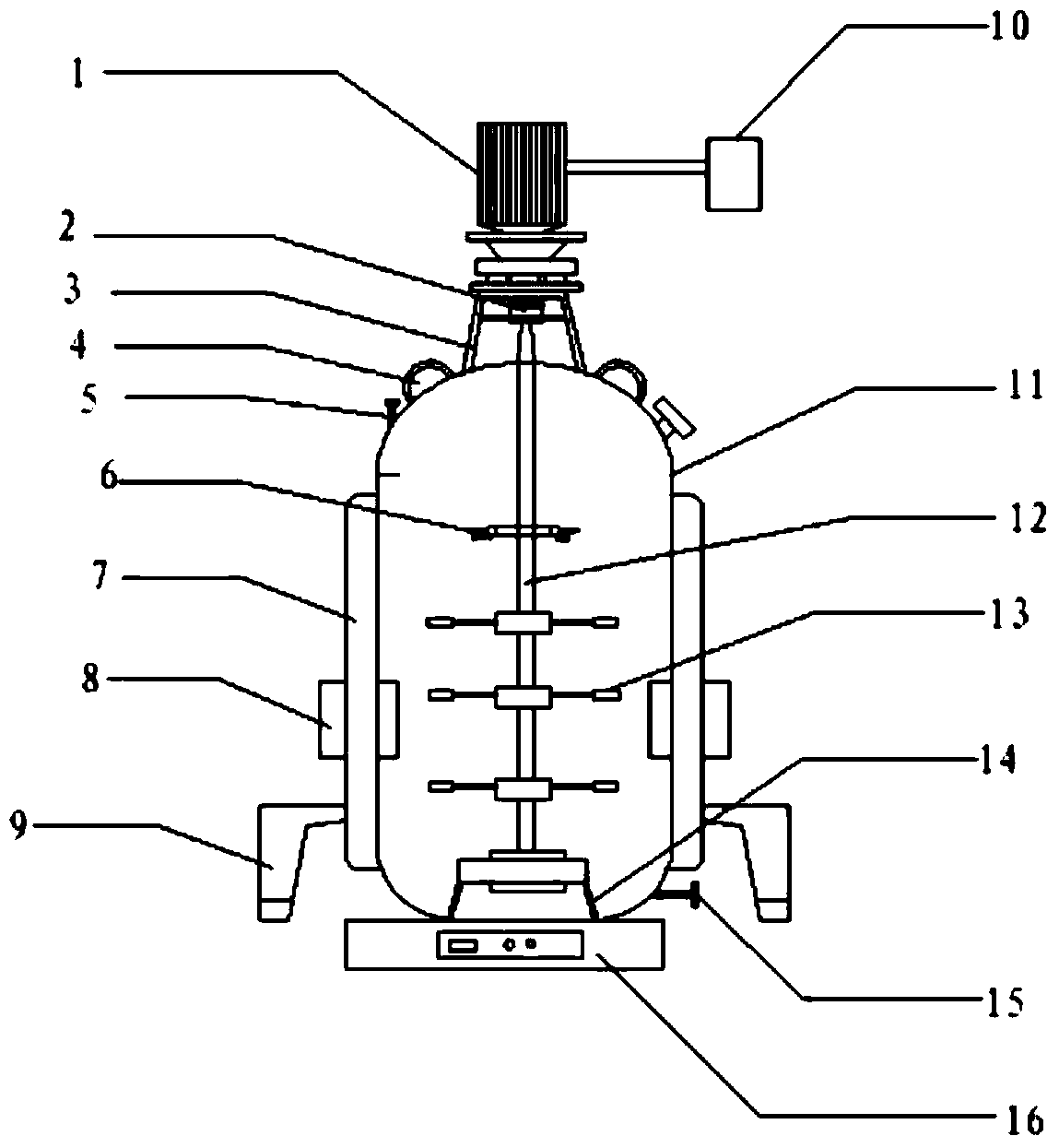

Material mixing and fermenting device

InactiveCN103468562AAdjust the speedIncrease speedBioreactor/fermenter combinationsBiological substance pretreatmentsFrequency changerElectric machine

The invention relates to a material mixing and fermenting device. The material mixing and fermenting device comprises a tank body, a temperature measuring device, a rotating shaft, blades, a defoaming device, three tank body supports, an electric stove plate, a motor, a shaft coupling, a frequency converter and a motor support. The top of the tank body is provided with a feed port, a lifting lug and a manhole, the tank bottom is in a flat bottom structure, a discharge port is formed in the tank bottom, the temperature measuring device is positioned on the side wall of the tank body, and the temperature measuring device can directly observe a temperature value in the tank from the outside of the tank; the top of the rotating shaft is connected with the shaft coupling, and the bottom of the rotating shaft is articulated with a support seat on the bottom surface in the tank body; the blades are crisscross arranged on the rotating shaft; the defoaming device is positioned on the rotating shaft and can timely eliminate liquid bubbles produced by stirring; the three tank body supports are uniformly distributed on the side wall of the tank body; one end of the shaft coupling is connected with the rotating shaft, and one end of the shaft coupling is connected with the motor; the frequency converter is connected with the motor and can adjust the rotational speed of the motor; the material mixing and fermenting device has the advantages of simple heating structure, low cost, convenience in maintenance, uniformity in material mixing, safety and reliability.

Owner:TIANJIN CITY BINHAI NEW AREA JURONG TECH

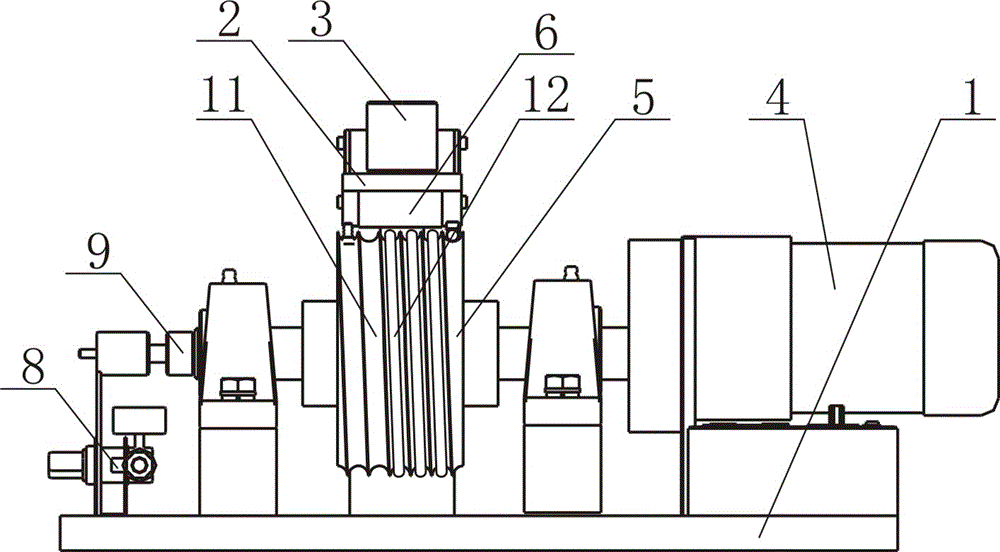

Hose wear resistance testing machine

PendingCN106483034AAddressing inaccurate flawsImprove test accuracyInvestigating abrasion/wear resistanceMotor driveEngineering

The invention discloses a hose wear resistance testing machine which comprises a machine seat, a movable arm, a motor, abrasive paper and a hose positioning roller. One end of the movable arm is hinged on the machine seat through a hinging shaft while the other end of the same is a free end, the abrasive paper is fixed on the movable arm, a spiral groove is formed in the surface of the hose positioning roller, a tested hose is put in the spiral groove, the movable arm presses the abrasive paper onto the tested hose which is filled with gas, the motor drives the hose positioning roller to rotate through a transmission mechanism, the tested hose rotates along with the hose positioning roller, and the abrasive paper abrades the tested hose. The hose wear resistance testing machine further comprises a high-pressure gas nozzle and a weight, the high-pressure gas nozzle is used for blowing away dust generated by friction between the abrasive paper and the tested hose, and the weight is used for adjusting pressure applied on the tested hose by the movable arm. The hose wear resistance testing machine is closer to actual using scene of the hose, the defect that testing data are not accurate enough is overcome, experiment period is shortened, testing accuracy is improved, and diverse testing modes are realized.

Owner:GUANGDONG HELI PLASTIC CO LTD

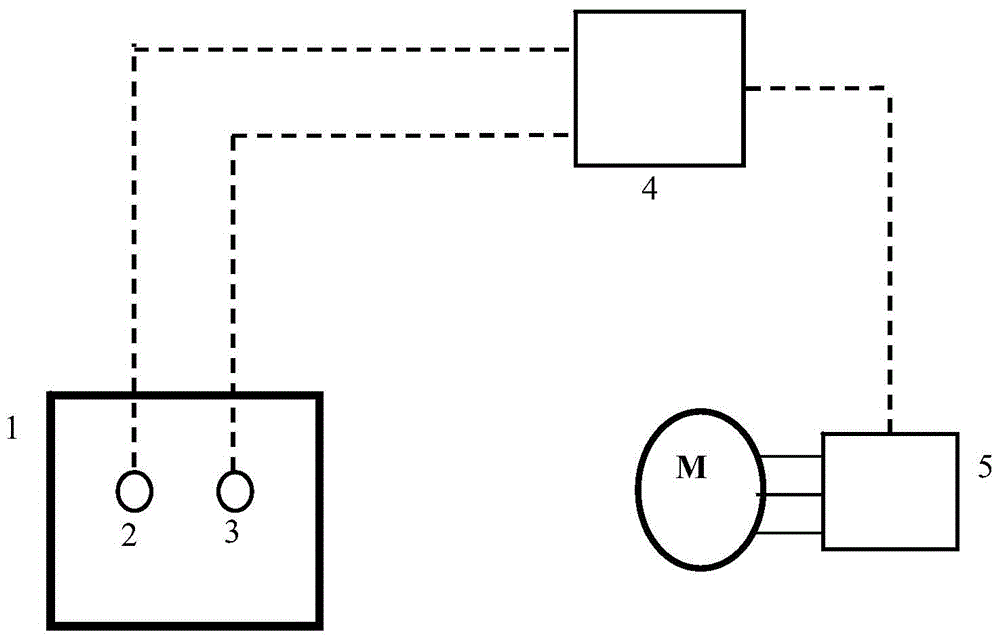

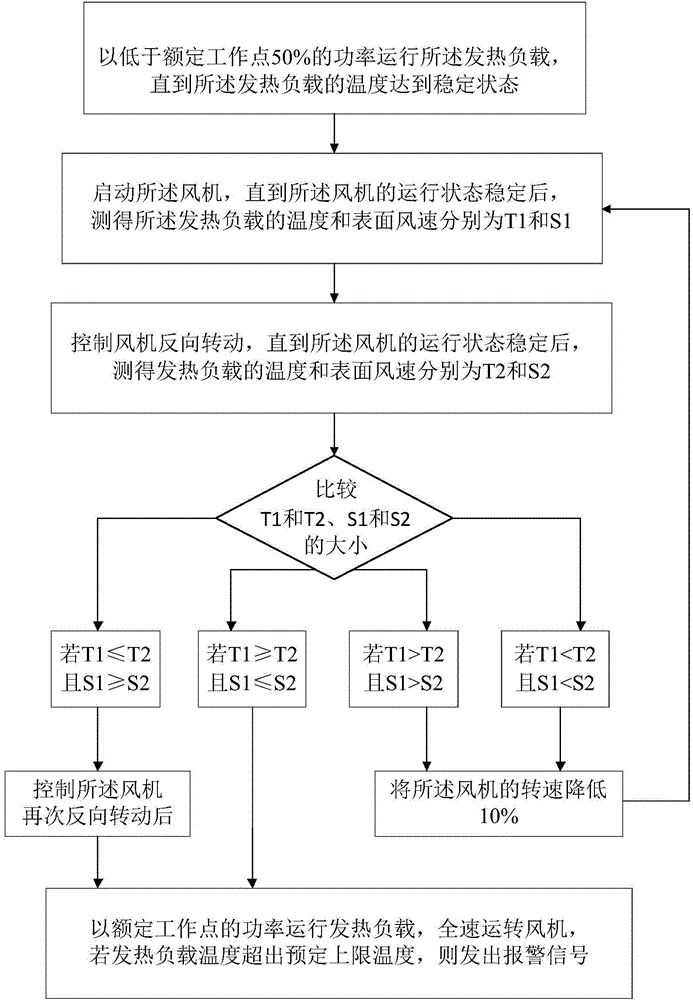

Draught fan control device and control method in power electronic power cabinet

ActiveCN104791281AGuaranteed uptimeExtended service lifePump controlNon-positive displacement fluid enginesElectric power transmissionElectric machinery

The invention provides a draught fan control device and control method in a power electronic power cabinet. The draught fan control device comprises a sensor unit, a draught fan controller and a master controller. The control method is to determine the optimal operation mode through the measurement and the comparison of temperature and wind speed of a heat load case when the draught fan operates in the forward direction and the reverse direction. Compared with the prior art, the control device is simple and efficient in structure, interior structures of the draught fan and the power cabinet are not changed, meanwhile, the heat dissipation efficiency of the draught fan in the flexible power transmission and distribution converter valve power cabinet is improved, and the reliable operation of the power cabinet is guaranteed. The control method is simple and practicable, the rotation speed and the rotation direction of the draught fan are determined according to the heat dissipation condition of the load in the power cabinet, different heat dissipation schemes are provided for different power cabinets, the wide application of the power cabinet is achieved, meanwhile, the effective heat dissipation mode improves the service life and the operation efficiency of the power cabinet, the overheat phenomenon caused by the inverse connection of the circuit of the draught fan is prevented, and the operation reliability of the power cabinet is guaranteed.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +1

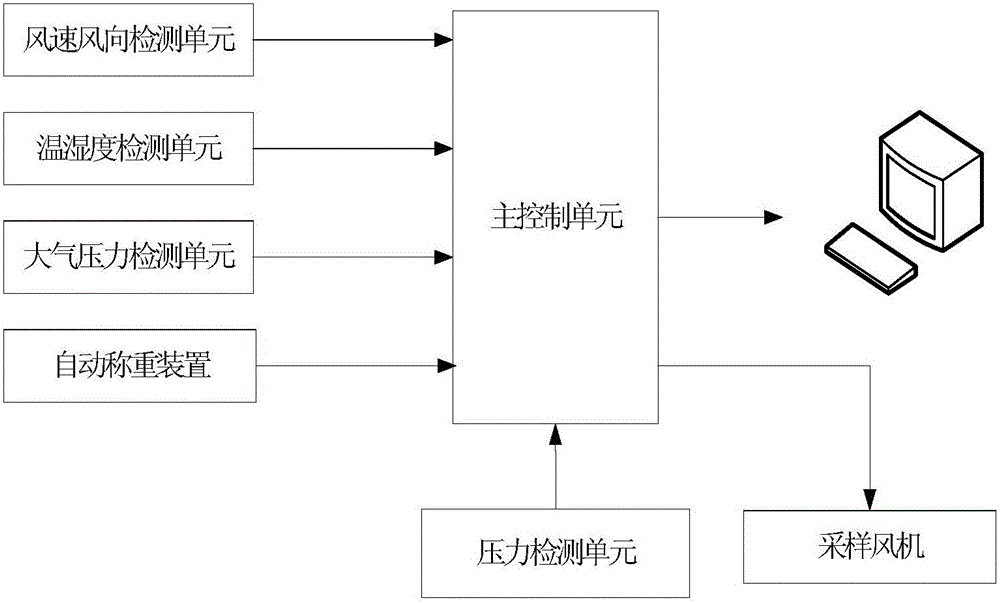

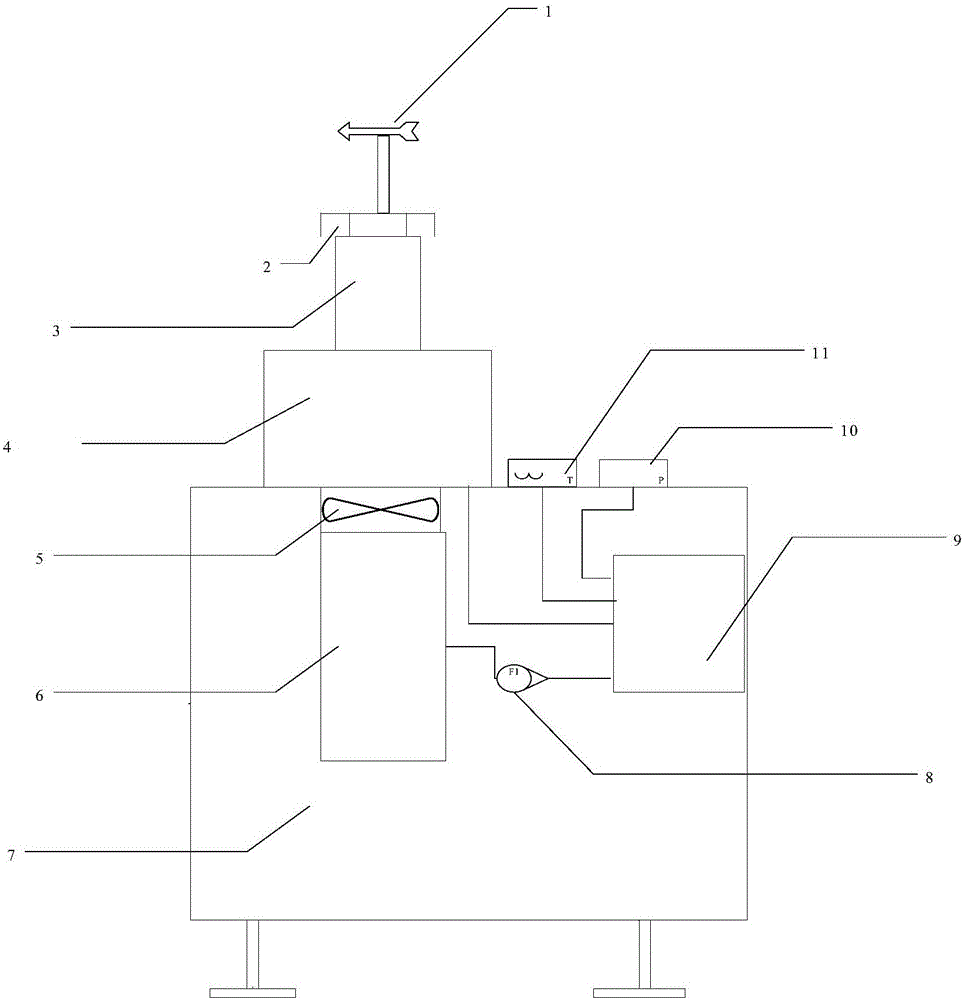

Environment sampling and monitoring system and method based on fine particles

InactiveCN106323828AAdjust the speedRealize traceabilityParticle suspension analysisMonitoring siteControl signal

The invention relates to an environment sampling and monitoring system and method based on fine particles. The system comprises an environment detection device, a fine particle sampling device, and a main control unit. The environment detection device sends detected environment parameters to the main control unit. The sampling device comprises a fine particle cutter, an automatic weighing device, a sampling fan, and a static pressure cabin pressure detecting unit. The fine particle cutter grades the sampled fine particles and delivers the graded fine particles to the automatic weighing device. The automatic weighing device weighs the fine particles. The static pressure cabin pressure detecting unit and the automatic weighing device send signals to the main control unit. The main control unit outputs a control signal to the sampling fan. The main control unit determines the actual sampling flow of fine particles according to the static pressure and controls the rotation speed of the sampling fan according to the actual sampling flow. The provided method comprehensively takes the environment parameters of a monitoring site and the formation and flowing situation of fine particles into account, the source of discharged fine particles is traced, and the problem that the source of discharged fine particles is not easy to find by the conventional monitoring method is solved.

Owner:SHANGHAI INSTR RES INST

Turbine machine with long service life

ActiveCN110778391AWarm up fastNot easy to damageInternal combustion piston enginesExhaust apparatusElectric machineMachine

The invention discloses a turbine machine with the long service life. The turbine motor comprises a machine body, an air inlet is formed in the right side of the machine body, an exhaust port is formed in the left side of the machine body, thus, a regulating motor is started, a motor shaft and a moving block are driven to rotate, then driven blocks, extending sliding blocks and adjusting blocks are driven to move to the left side and the right side, then the diameter of a pressure pipeline can be controlled, and the rotating speeds of turbines are increased. According to the turbine machine with the long service life, the effect that a turbine machine body can generate large power when the exhaust amount of an automobile is small can be achieved, compared with a traditional turbine motor,preheating of the turbine machine body can be accelerated through the turbine machine with the long service life, so that when the turbine machine is used in winter, the turbine machine body is not prone to damage, and then the service life of the turbine machine body is prolonged.

Owner:创客帮(山东)科技服务有限公司

Control method of soybean milk machine

The invention discloses a control method of a soybean milk machine. The soybean milk machine comprises a heating module used for heating materials, a motor module for stirring and smashing the materials and a control device for controlling the heating module and the motor module to work; the soybean milk machine is further provided with a sound detection module, and when the control device controls the motor module to work, the sound pressure value detected by the sound detection module is obtained, and displayed through a display device. The sound pressure value of a sound pressure signal detected in the working period of the soybean milk machine is obtained and displayed, a user effectively acquires the range of noise in time, the acceptance degree of the user to the noise is improved, and the user experience is improved. Since detection display is conducted when the motor module of the soybean milk machine works, the energy is saved, and the consumption is reduced.

Owner:JOYOUNG CO LTD

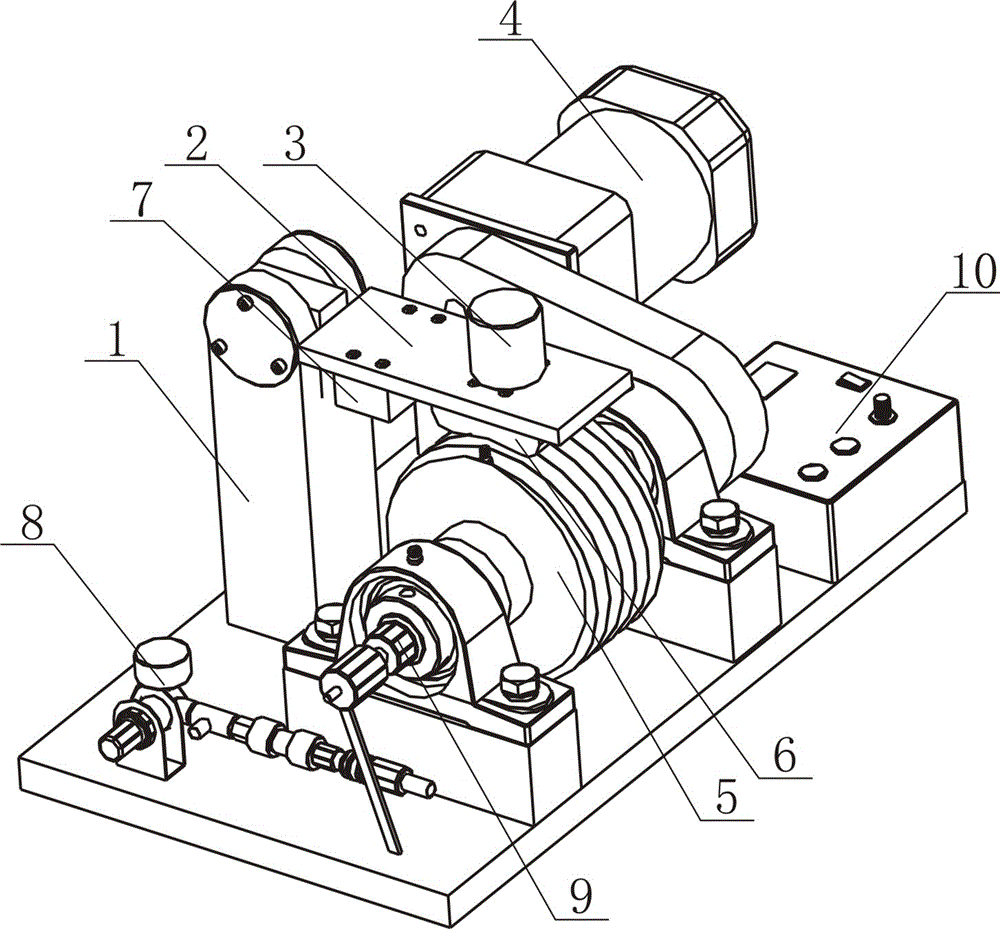

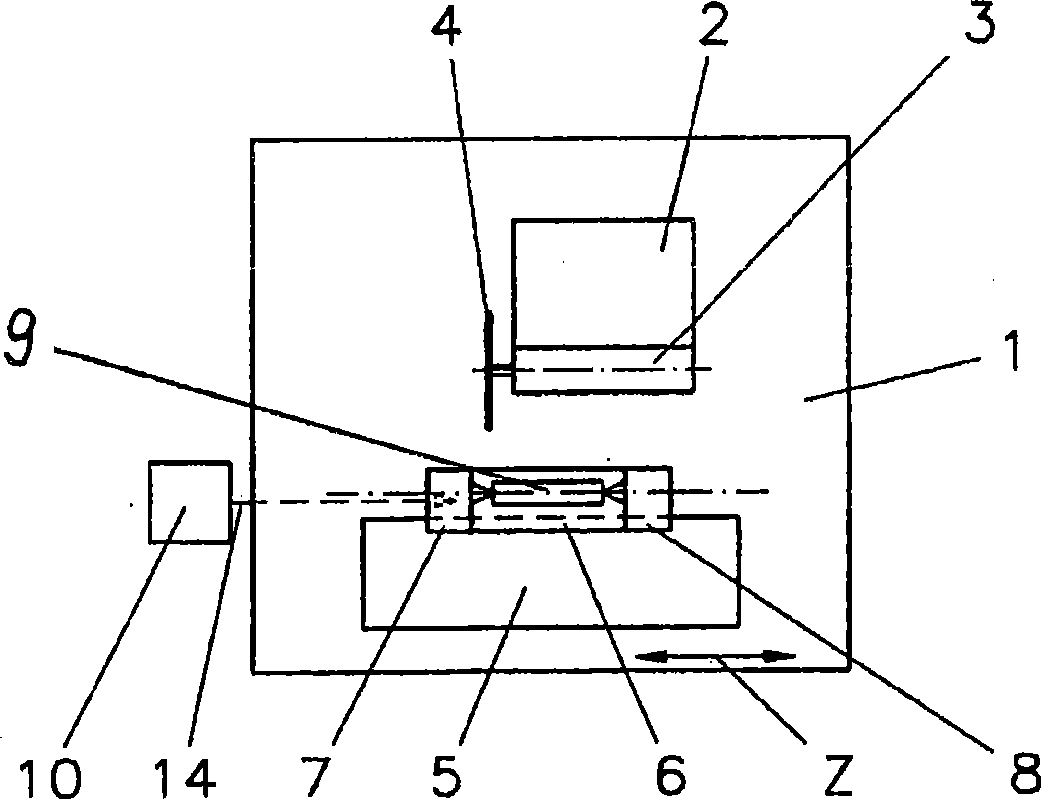

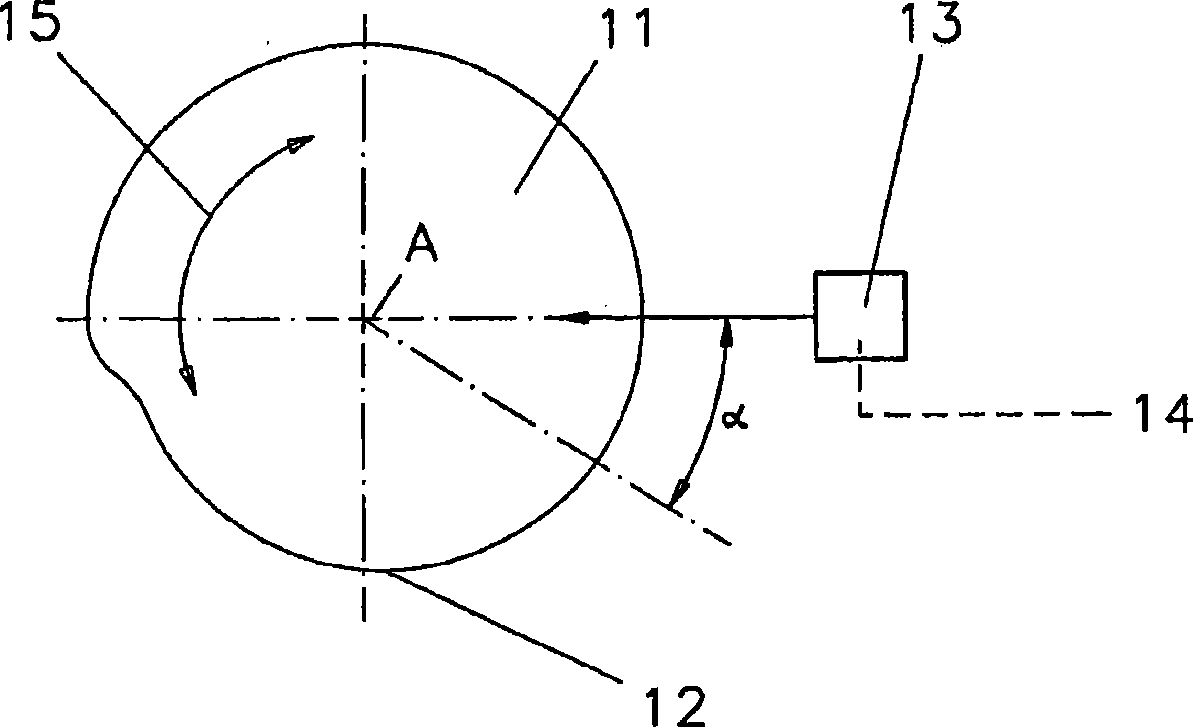

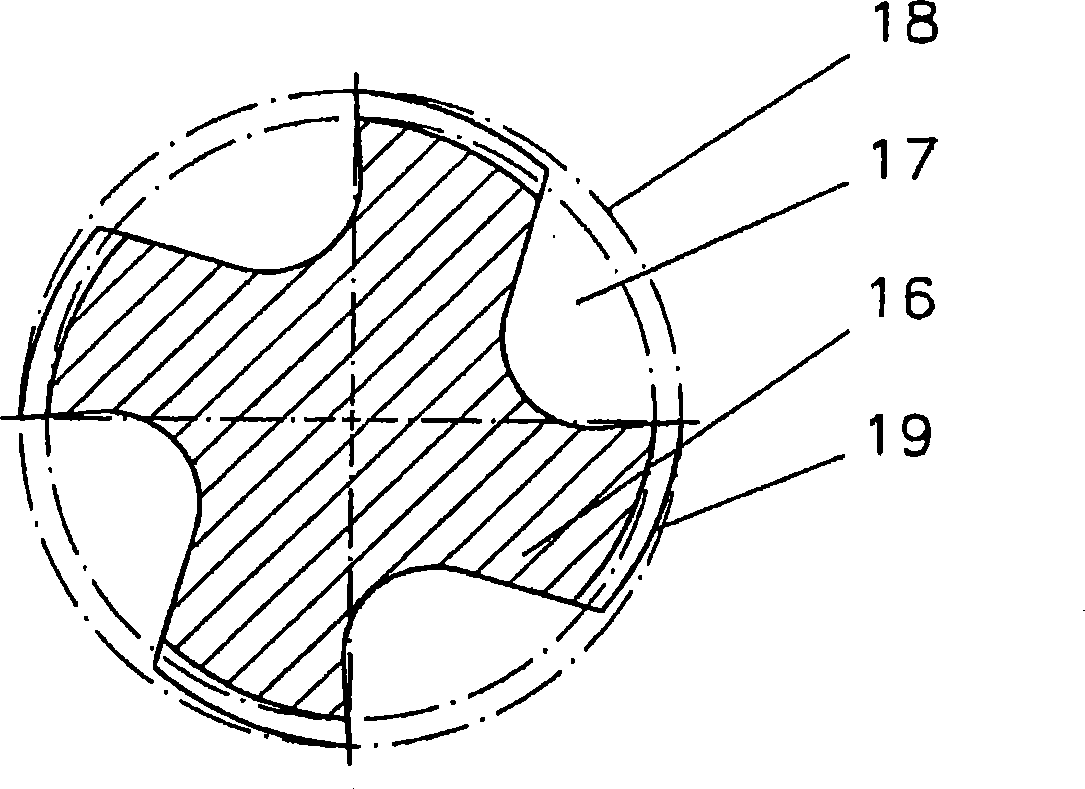

Method for relief-grinding the cutting teeth of taps, thread formers, and similar tools, and grinding machine for carrying out said method

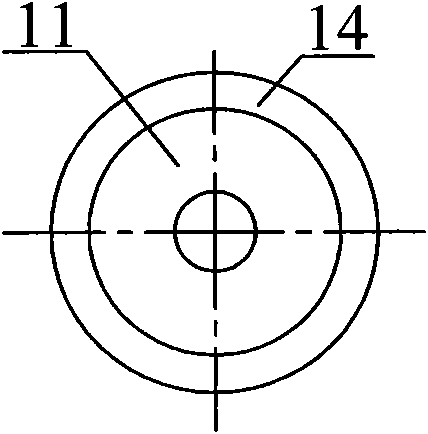

ActiveCN101500748AAvoid tremor hazardSolve inventory problemsMilling cuttersCopying process control systemsCamElectric control

In prior art, an additional radial inward movement that is performed in accordance with a rotating cam disk is imparted on the grinding disk in order to relief-grind the cutting teeth and the chamfer of taps and the cutting teeth of thread formers. The invention relates to a cam disk (11) which can be rotated about an axis A and is provided with a control cam (12). Said control cam (12) forms a group of curves according to a large number of possible undercut contours on the grinding teeth of the tap or thread former, which are to be relief-ground. In order to obtain a specific undercut contour on a cutting tooth, a limited angle of rotation alpha is selected from the control cam (12). Said area is mechanically, optically, or electronically scanned by means of a scanning device (13). To this avail, the cam disk (11) performs an oscillating rotary movement only above the selected section of the control cam (12) (arrow indicating the direction of rotation 15). Relief-grinding of the cutting tooth is completed once a fore-and-aft movement has been performed, and the grinding disk returns to the starting position thereof. The result of the scan is transmitted to an electronic control device via a signal line (14).

Owner:ERWIN JUNKER MASCHNINENFAB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com