Automatic winding machine

A technology of automatic winding machine and winding mechanism, which is applied in the direction of coil manufacturing, winding strips, and control without feedback, which can solve the problems of low degree of automation of coil winding, high product defect rate, and low work efficiency. , to achieve the effect of reducing bad items, improving product qualification rate and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

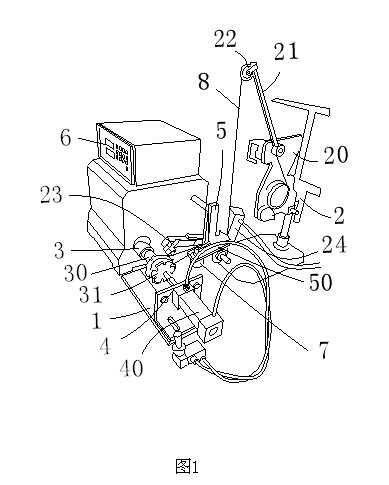

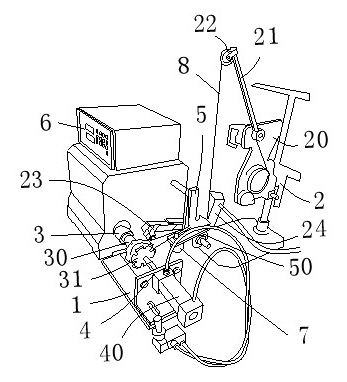

[0016] A kind of automatic winding machine of the present invention, as figure 1 As shown, it includes a base 1 and a cable arrangement 2, a fixing mechanism 3, a winding mechanism 4, a shifting mechanism 5 and a PLC automatic control system arranged on the support 1; the cable arrangement 2 includes a bracket 20, And the guide rod 21 arranged on the bracket 20, and the deviation correction sensor roller 22 arranged on the guide rod 21; the fixed mechanism 3 includes a fixed main shaft 30, and an installation fixed block 31 arranged on the fixed main shaft 30; The winding mechanism 4 includes a winding motor 40, and the winding motor 40 is connected to the mounting block 31; The deviation correction sensor roller shaft displacement part 50 of the line; the PLC automatic control system includes two parts: PLC automatic control and man-machine interface 6; the winding motor 40 and the displacement motor are all electrically connected to the PLC automatic control system; The dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com