Method for relief-grinding the cutting teeth of taps, thread formers, and similar tools, and grinding machine for carrying out said method

A technology for forming tools and cutting teeth, which is applied in the direction of grinding machines, manufacturing tools, and other manufacturing equipment/tools, etc., which can solve the problems of time-consuming reassembly and replacement process, and the unresolved problem of replacement parts inventory.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

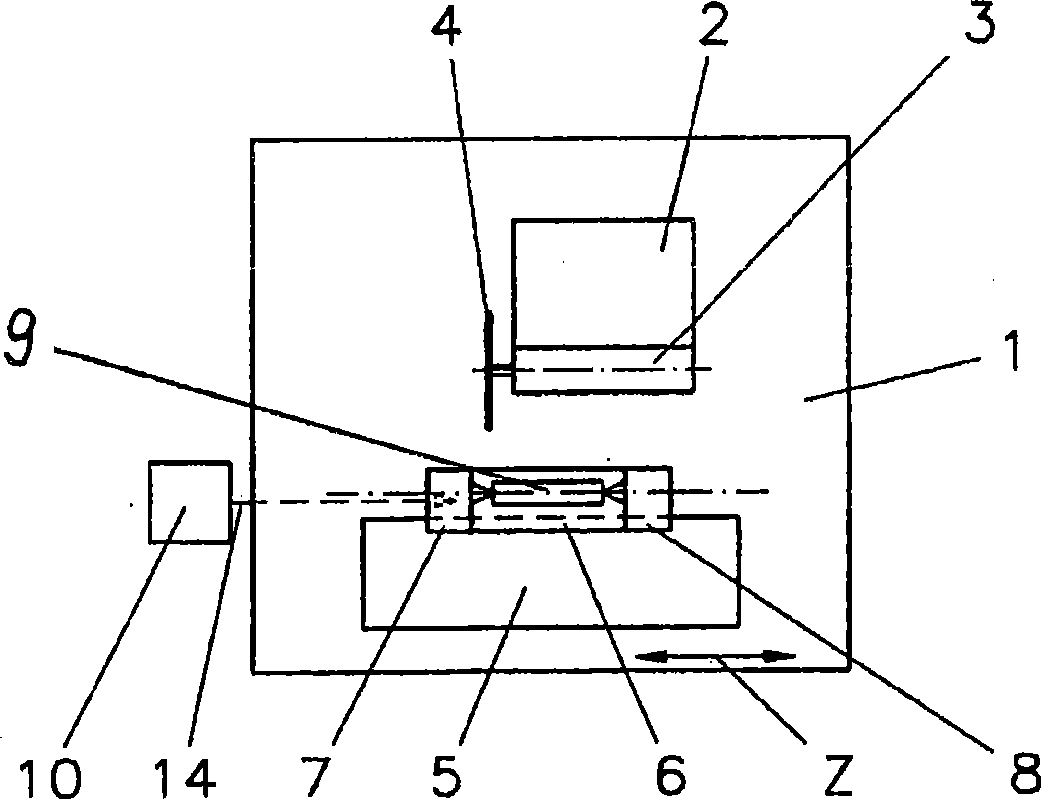

[0023] in accordance with figure 1 In the shown machine, a grinding wheel head 2 is provided on a bed 1, on which a grinding wheel spindle 3 with a rotating grinding wheel 4 is mounted, and the grinding wheel head 2 can also be pivoted about a vertical axis.

[0024] The bed 1 also carries a grinding table 5 which, as is usual, can be adjusted along its longitudinal direction (Z-axis). On the grinding table 5 there is a movable support part 6 which can be additionally adjusted on the grinding table 5 perpendicular to the Z-axis, ie in the usual direction of the X-axis. The supporting part 6 carries a headstock 7 and a tailstock 8 between which, for example, a tap or similar tool 9 can be clamped. The tool 9 that is present here is also the workpiece. The tool is thus likewise extendable along the Z-axis and at the same time controllably rotatable about its longitudinal axis, ie generally the C-axis.

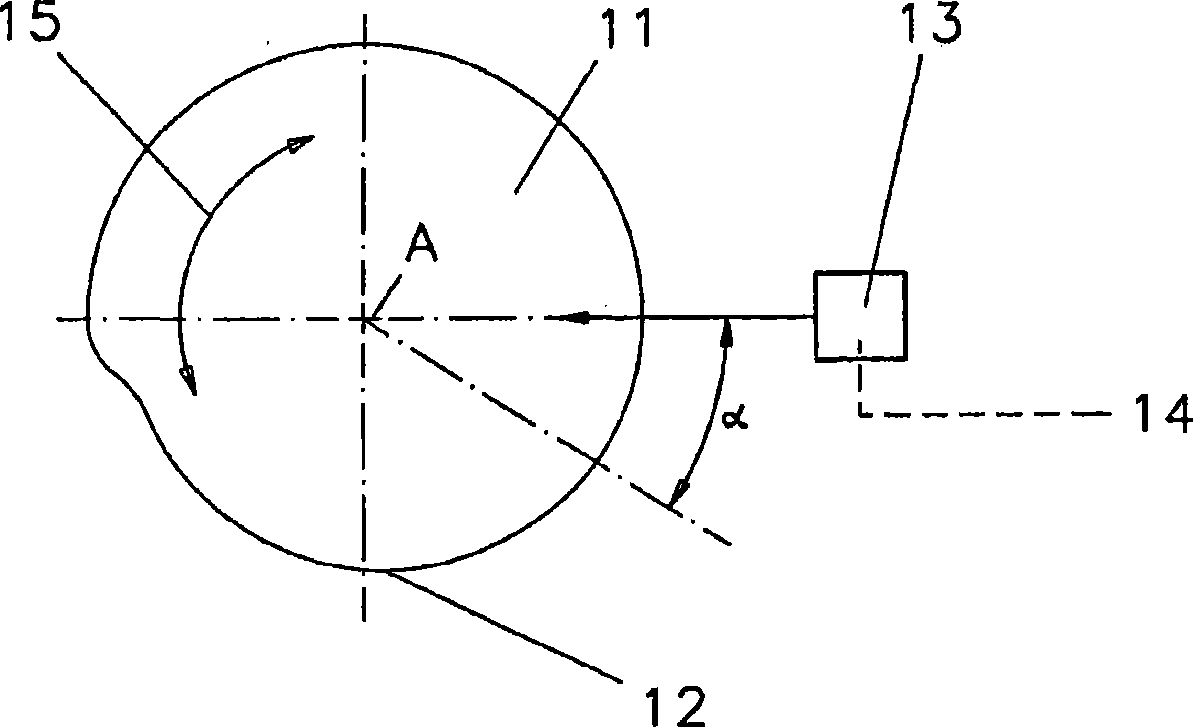

[0025] In the exemplary embodiment shown, the plane of rotation of the gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com