Work head, and power tool and adaptors for installing work head

A power tool and working head technology, applied in the field of power tools, can solve the problems of easy wear and vibration of the installation hole and the driving part, and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

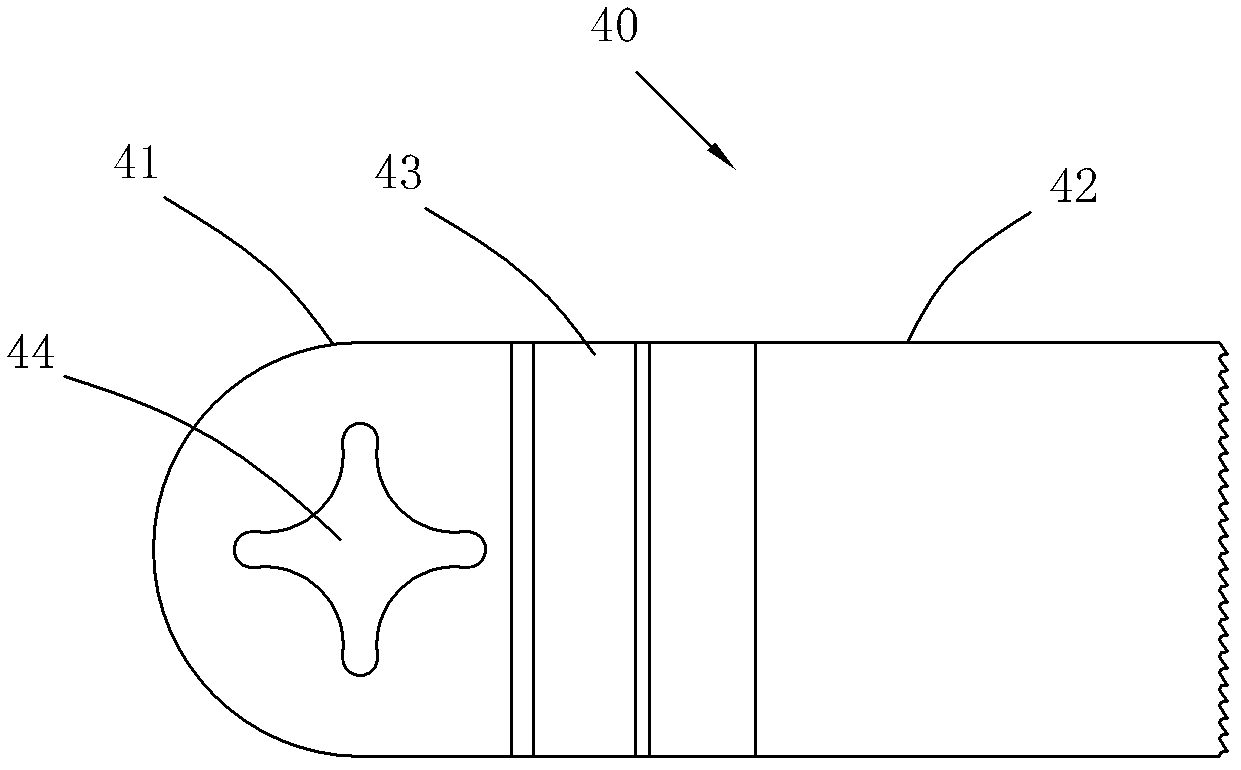

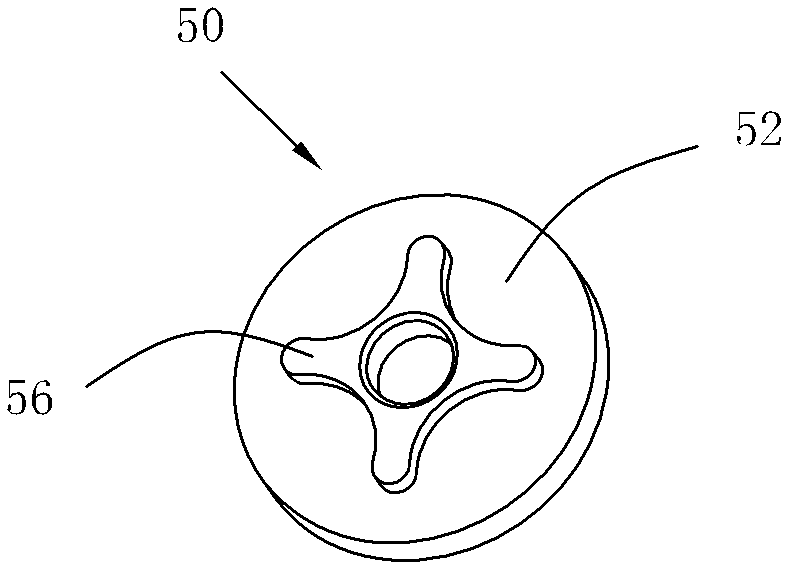

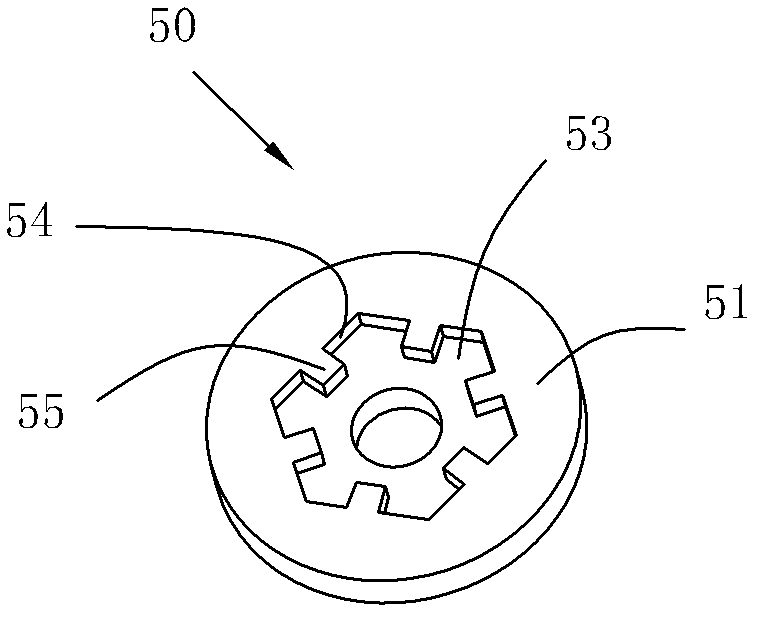

[0063] The purpose of the present invention is to provide an interface solution that can be applied to oscillating power tools (such as a multi-function machine) or rotary grinding power tools (such as a sander) and prevent the fit from vibrating due to wear. The installation hole of the working head of the present invention is provided with at least one straight edge, and a protrusion extending toward the center of the installation hole is arranged on the straight edge; the output shaft or the adapter of the power tool is arranged to cooperate with the straight edge of the working head The wall, and the recessed part for accommodating the above-mentioned protruding part is correspondingly provided on the matching wall. When the working head is installed on the output shaft or the adapter, the protrusion on the straight edge of the wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com