Hose wear resistance testing machine

A wear-resistant testing and hose technology, which is applied in testing wear resistance, measuring devices, instruments, etc., can solve the problems of inability to clean dust, testing, and time-consuming, so as to solve the problem of inaccurate test data and improve testing accuracy. , the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

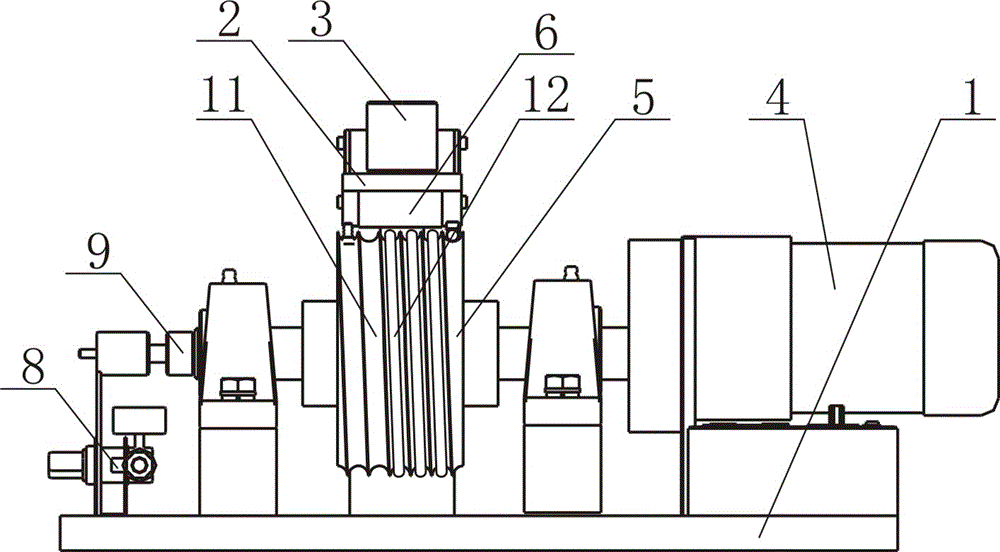

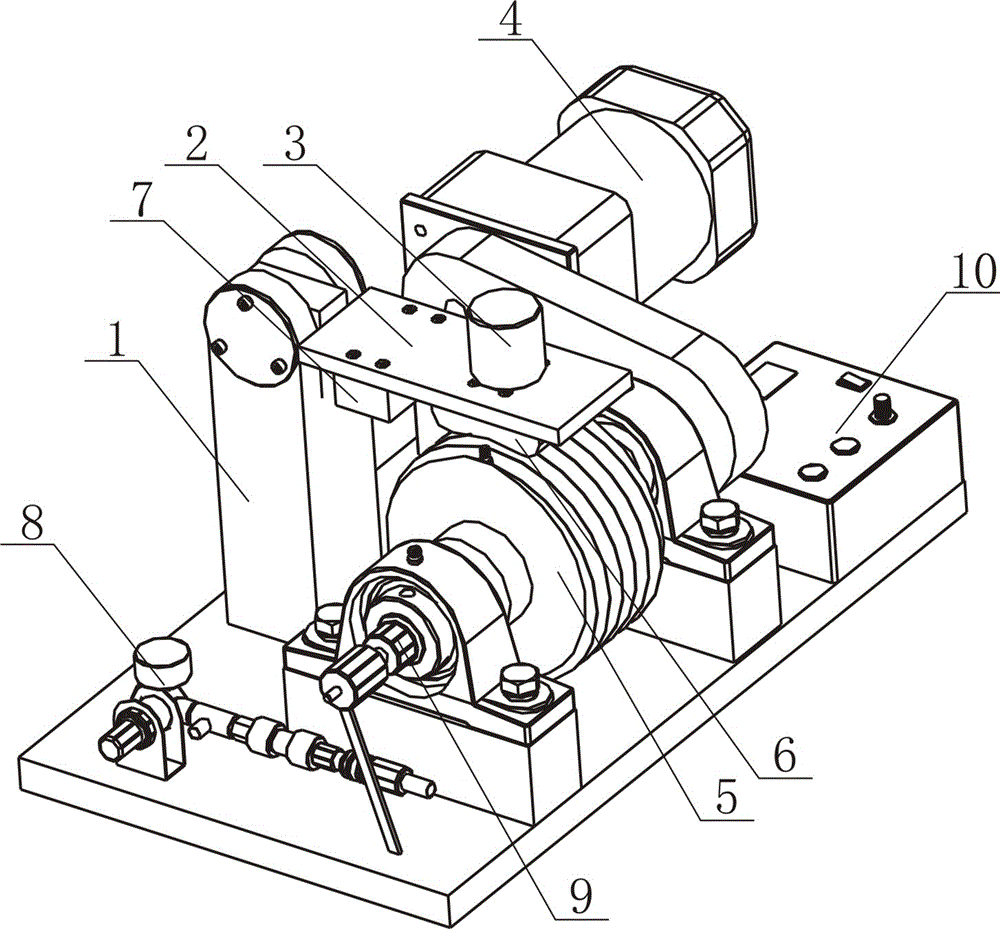

[0024] Such as figure 1 , 2 As shown, the hose abrasion testing machine includes machine base 1, movable arm 2, French code 3, motor 4, hose positioning roller 5, sandpaper 6, high-pressure air nozzle 7, high-pressure air control device 8, and high-speed rotary joint 9 And the control box 10, one end of the movable arm 2 is hinged on the machine base 1 through a hinge shaft, the other end is a free end, the sandpaper is fixed on the movable arm 2, and the surface of the hose positioning roller 5 is provided with a spiral groove 11, which is The measuring hose 12 is placed in the spiral groove 11. During work, the movable arm 2 that can rotate vertically presses the sandpaper 6 on the tested hose 12, and the French code 3 is pressed on the movable arm 2. To adjust the pressure of the movable arm on the hose under test. The motor 4 drives the hose positioning roller 5 to rotate through the transmission mechanism, the tested hose 12 rotates together with the hose positioning ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com