Patents

Literature

32results about How to "Full automation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

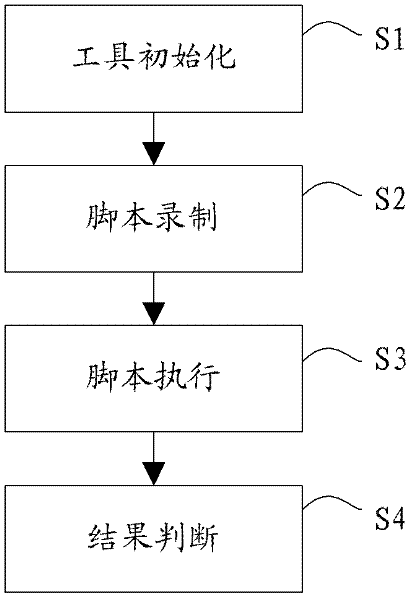

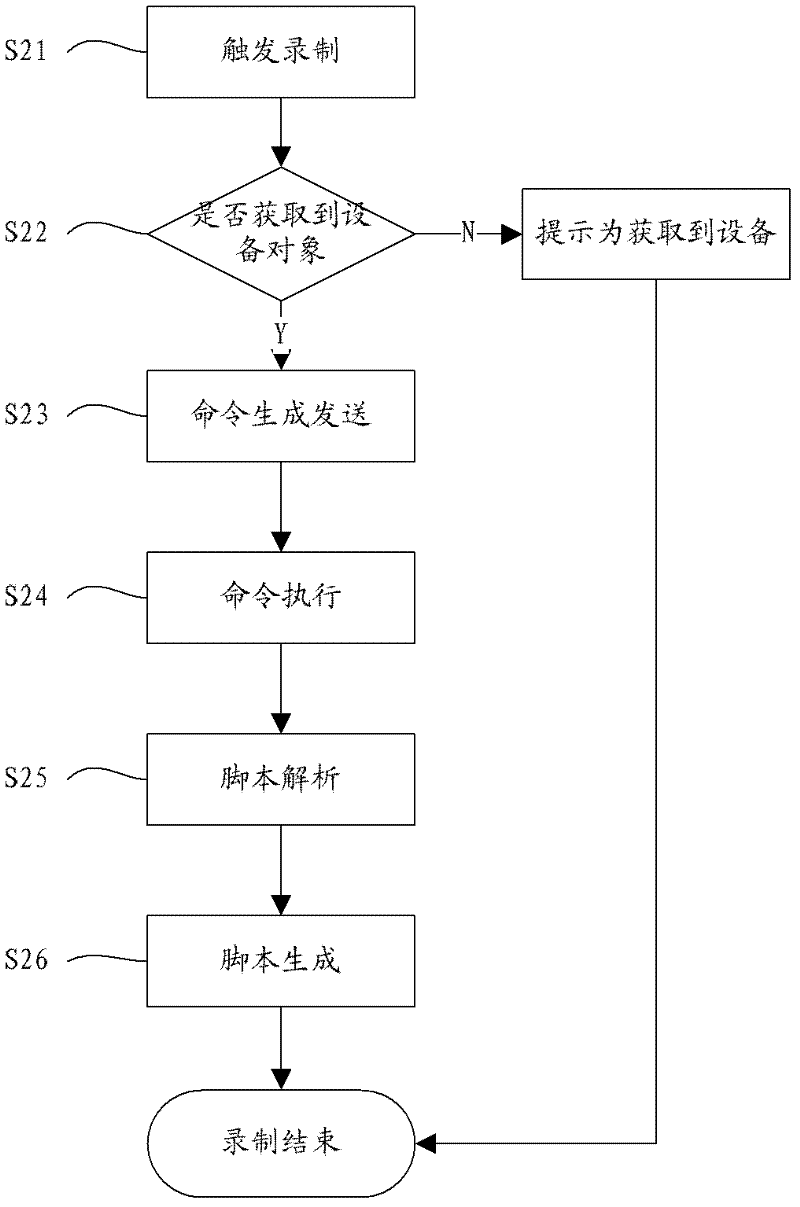

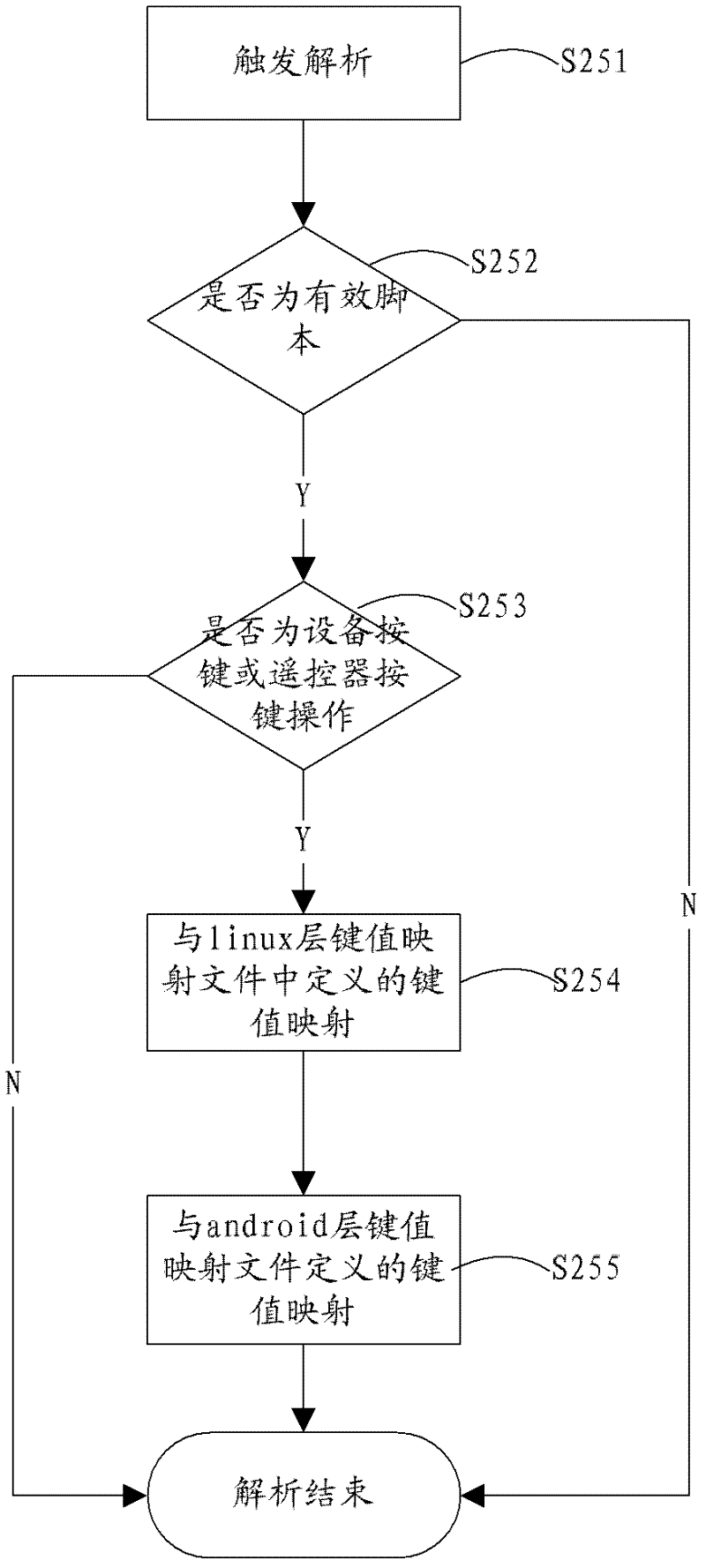

Android-platform-based automated testing method and testing tool

ActiveCN102419732ASave human and material resourcesFull automationSoftware testing/debuggingMaterial resourcesComputer hardware

The invention provides an android-platform-based automated testing method and an android-platform-based testing tool. The testing method comprises the following steps of: script recording: recording operation events and generating an executable script of an android platform; script execution: executing the executable script after an equipment object receives a command for executing the script; and result judgment: judging whether an automated example is adopted according to a script execution result. By adoption of the testing method, the event script is recorded and played back and interface elements are automatically compared to obtain a test result and realize automated testing, and the whole testing process only needs a tester to read the test result, so the method is accurate and fast to implement, and a lot of manpower and material resources are saved. The android-platform-based automated testing method and the android-platform-based testing tool can be used as fast automated testing method and tool which are widely used in the android program test industry.

Owner:SHENZHEN FALCON NETWORK MEDIA CO LTD

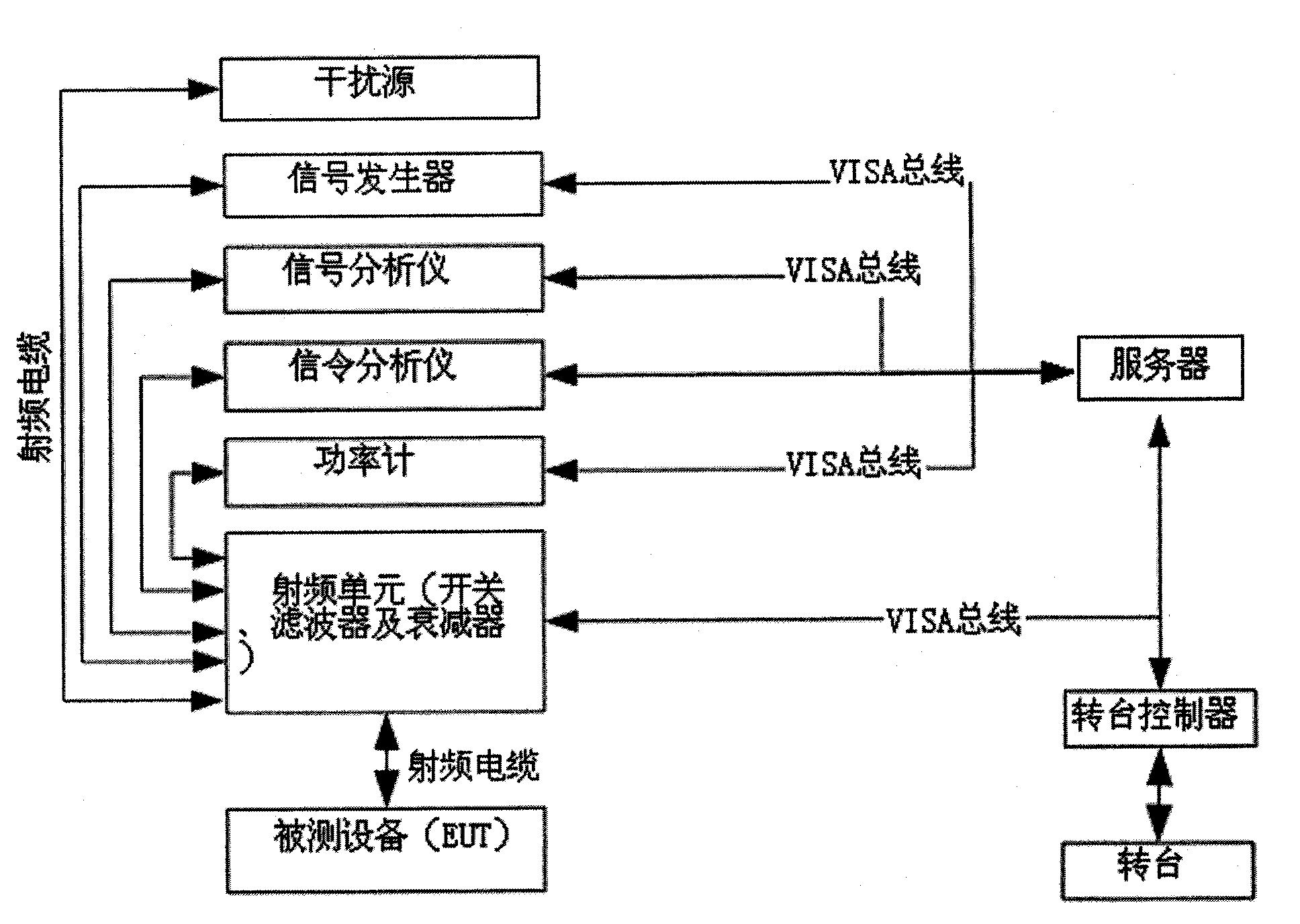

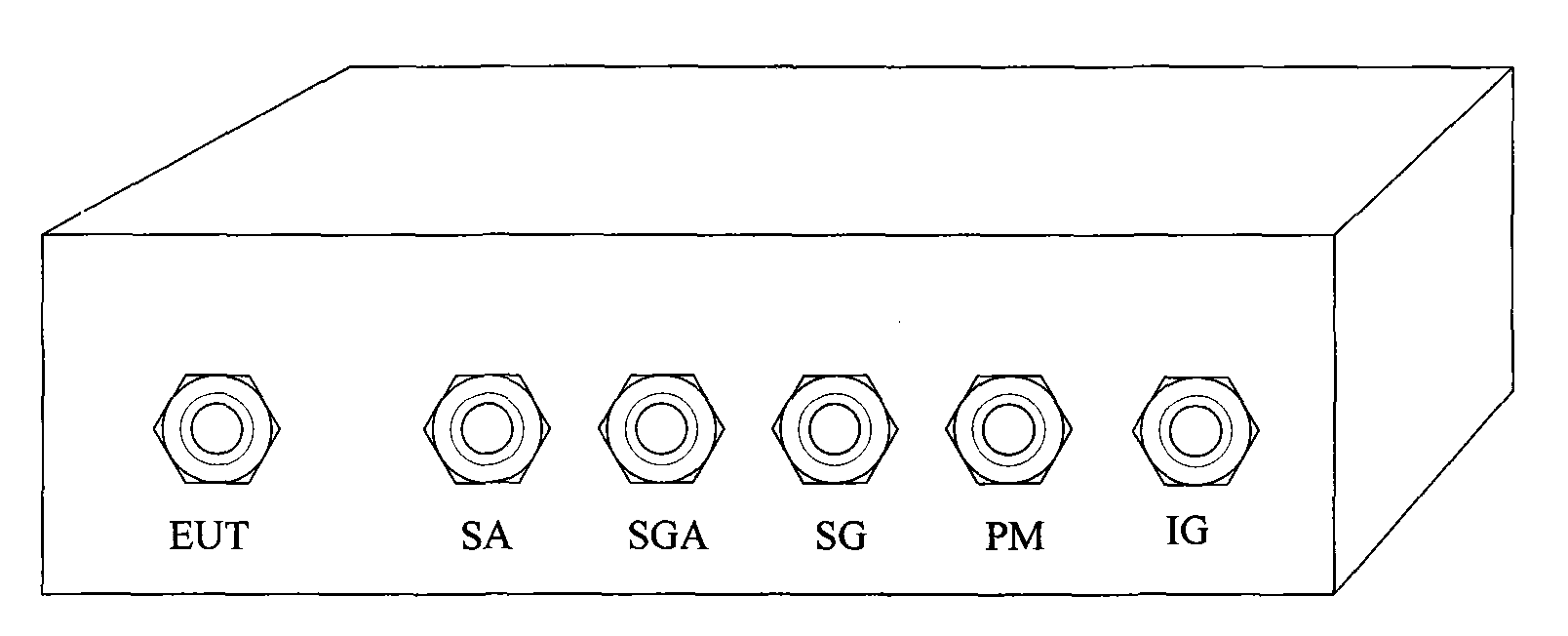

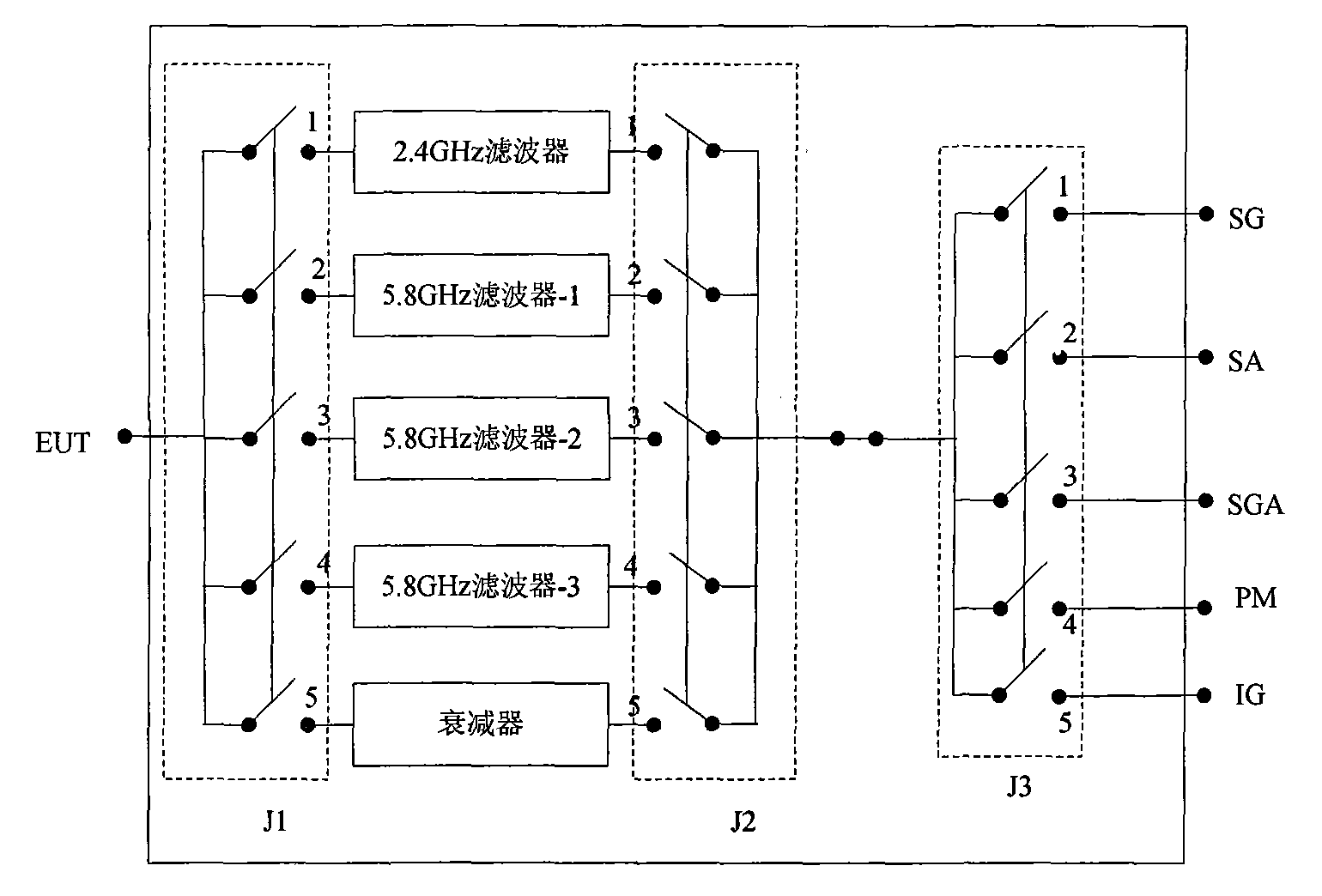

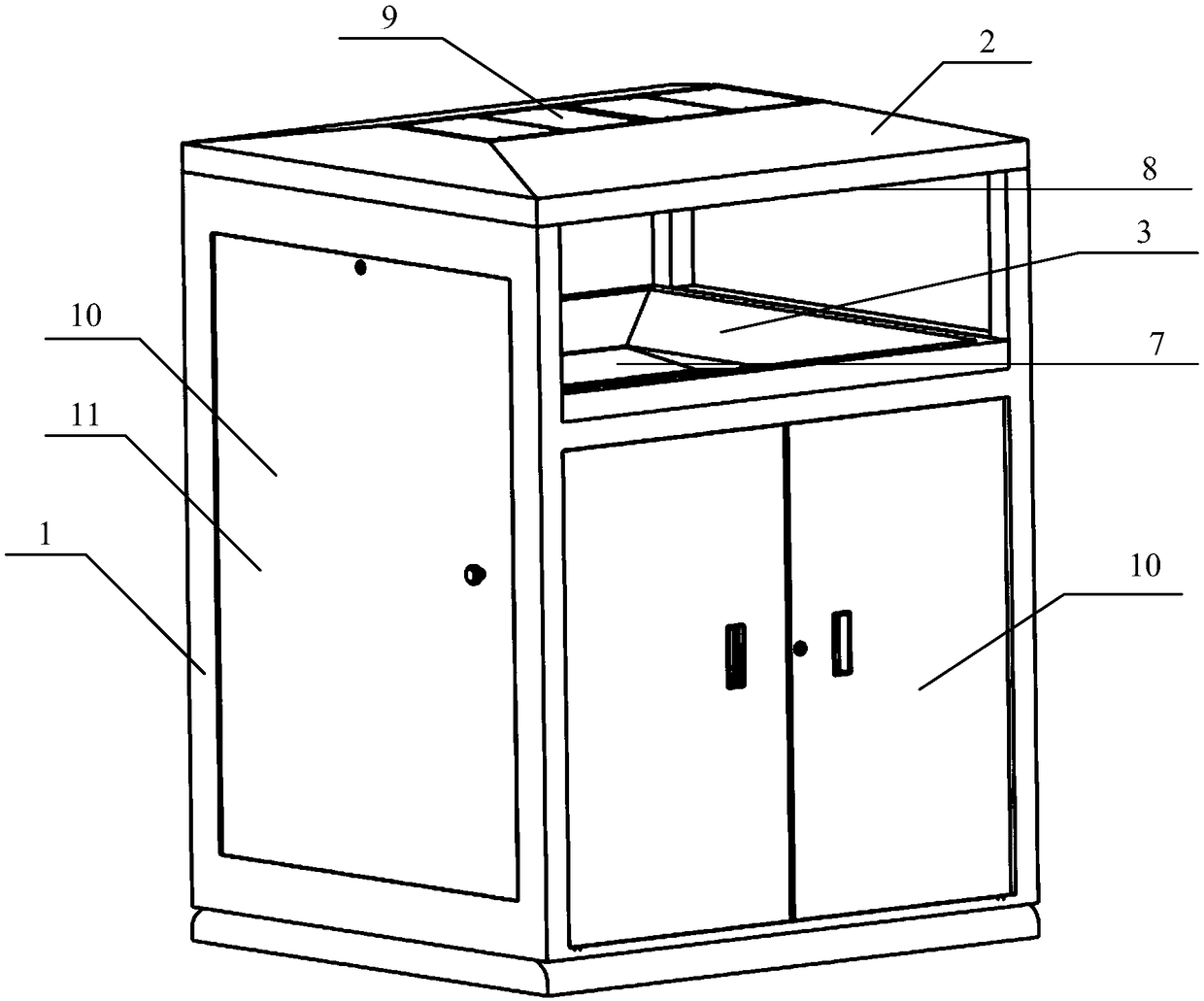

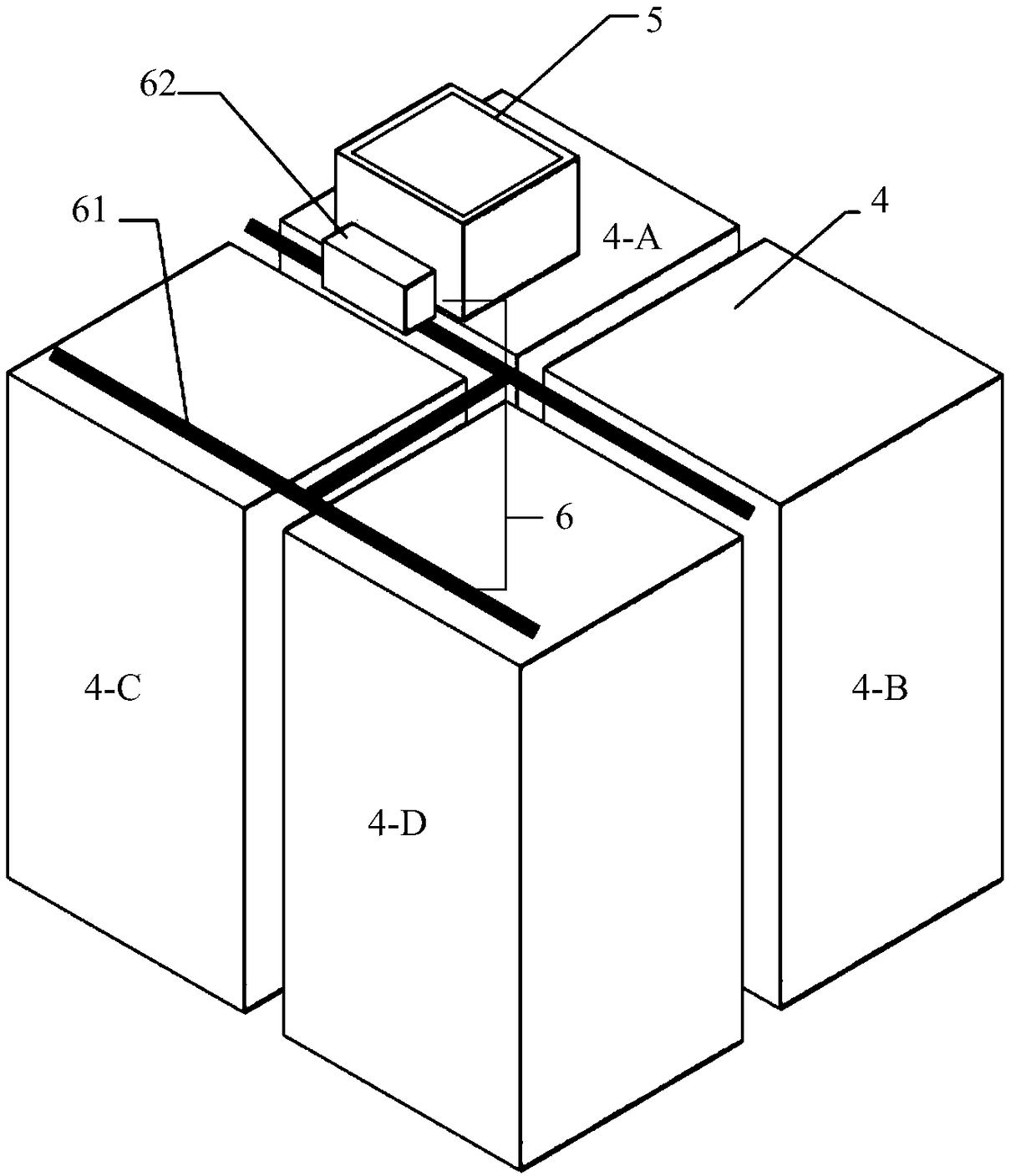

WLAN/WAPI wireless device radio frequency/over-the-air performance testing system

A WLAN / WAPI wireless device radio frequency / over-the-air performance testing system, used for radio frequency performance test of a WLAN / WAPI wireless device, comprises a signal generator, a signal analyzer, a signaling analyzer, a power meter, a radio frequency switch, a filter and an attenuator unit, a turntable / turntable controller and a server provided with automatic testing software. The radio frequency performance testing system is arranged in a large-sized testing cabinet, the operation of the system is centralizedly controlled by a high-performance server, the testing software can test the radio frequency performance and over-the-air performance according to user's requirement and related standard / technologies(CE,FCC standard and WAPI technology) and over-the-air performance requirement. The WLAN / WAPI wireless device radio frequency / over-the-air performance testing system can fully cover various tests and OTA tests of WLAN / WAPI wireless device of 802.11a / 802.11b / 802.11g standard under CE / FCC / WAPI standard, and can realize automation of tests utmostly.

Owner:TELECOMM METROLOGY CENT OF MINIST OF IND & INFORMATION TECH

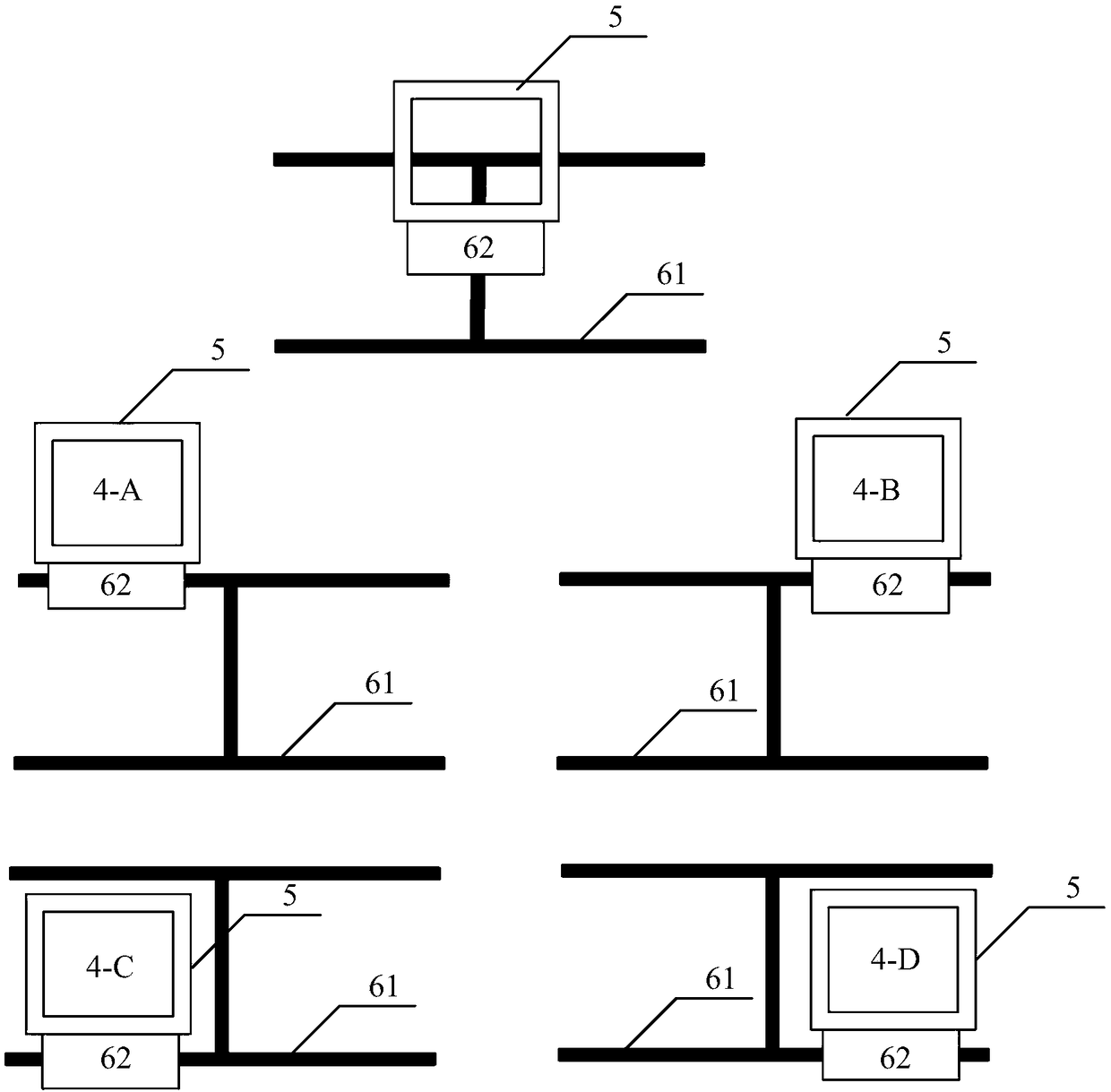

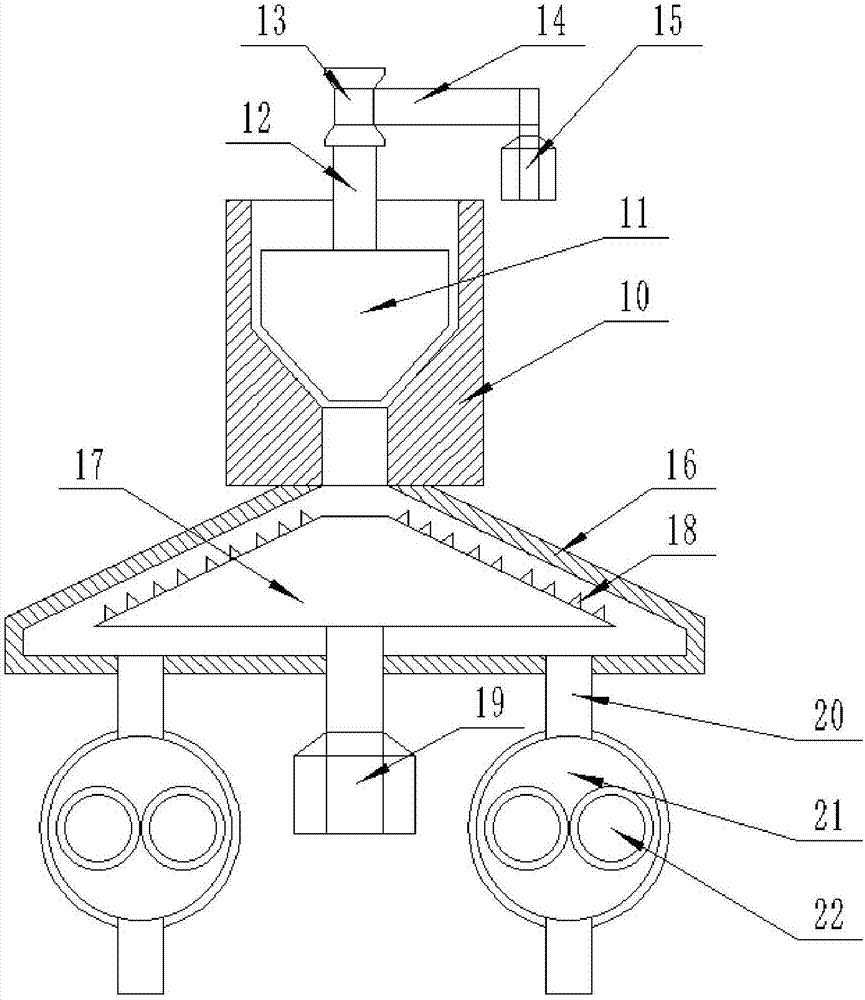

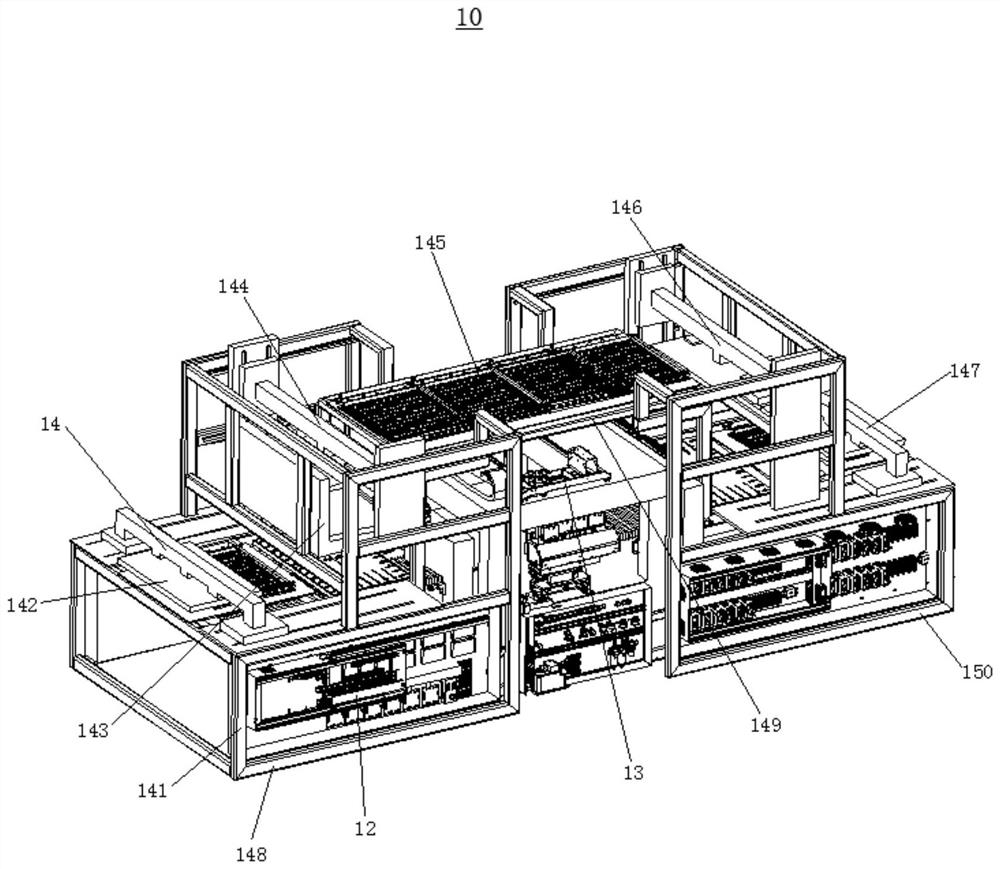

Intelligent dustbin with classification function

PendingCN109335371AImprove experienceNo human intervention requiredWaste collection and transferRefuse receptaclesWaste collectionEngineering

The invention discloses an intelligent dustbin with a classification function. The intelligent dustbin with the classification function comprises a unified feed inlet. Waste thrown into the intelligent dustbin through the feed inlet is received, recognized and classified in a waste storage area and then enters a waste collection area (classification sub-dustbin) of a corresponding type through a feed guide channel and a guide mechanism, the waste storage area is opened, and then the waste automatically falls into a sub-dustbin of a corresponding type. The whole process of throwing the waste into the intelligent dustbin, recognizing the waste and automatically guiding the waste into the corresponding classification sub-dustbin is automatic, and manual intervention is not needed. The waste does not need to be recognized before being thrown into the intelligent dustbin, so that users does not need to wait for a classification and recognition result by holding the waste by hand, and user experience is good and is similar to that of common dustbins. The guide mechanism comprises an I-shaped guide rail. The I-shaped guide rail is arranged so that the guide mechanism can move more flexibly within a wider range and can adapt to dustbins arranged in a plurality of rows and columns, such as dustbins arranged in two rows and two columns or dustbins arranged in two rows and three columns.

Owner:上海檀楠信息科技有限公司

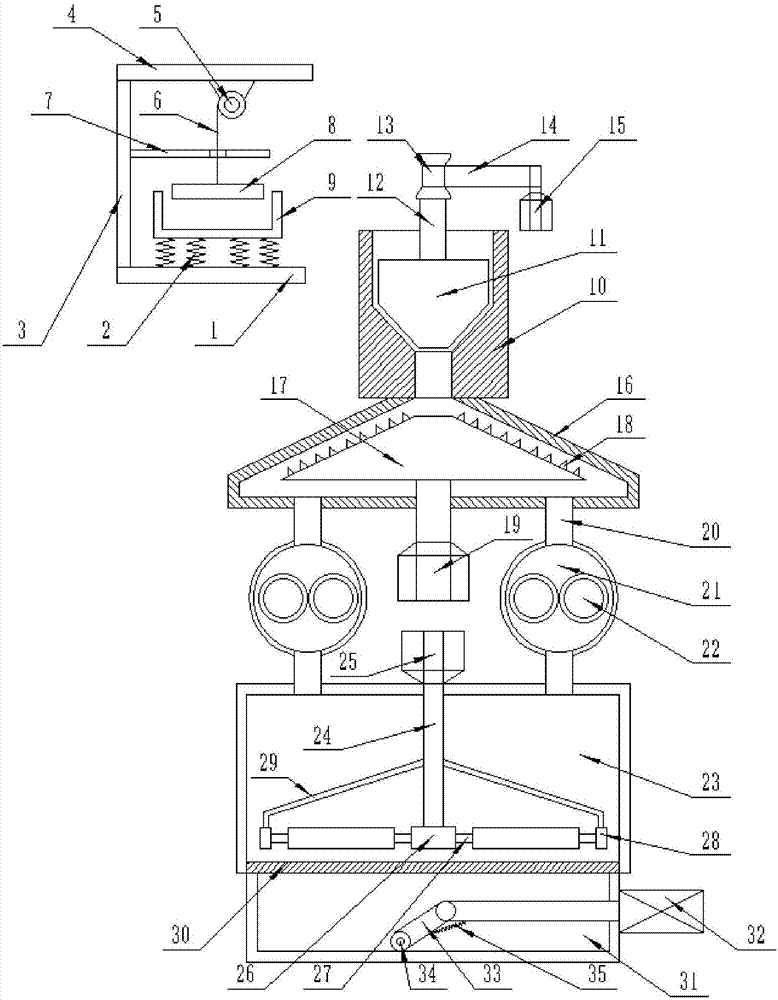

Solid waste crushing treatment device for machining

The invention discloses a solid waste crushing treatment device for machining. The solid waste crushing treatment device for machining disclosed by the invention is reasonable and simple in structure,low in production cost and convenient to mount. The solid waste crushing treatment device for machining disclosed by the invention is convenient to operate, quick to treat and time- and labor-saving.Solid wastes are placed in a concave chamber, a rolling motor drives a crushing hammer to crush the solid wastes, then the solid wastes are placed in a grinding chamber, a first motor drives a grinding roller to grind the solid wastes, the solid wastes enter a crushing chamber, a crushing shaft crushes the solid wastes which then enter a grinding chamber and are ground by means of the grinding roller, then the solid wastes enter an upper refining particle chamber, a grinding rotating rod grinds and refines the solid wastes, and the solid wastes are filtered by means of a filter screen, the solid wastes which are big in particle are continuously ground and refined by the grinding rotating rod, and finally, a pinch roller further refines the solid wastes. By means of the technical points, the solid wastes are crushed, and the solid waste crushing treatment device for machining is automatic in full course and high in efficiency.

Owner:NANTONG INST OF TECH

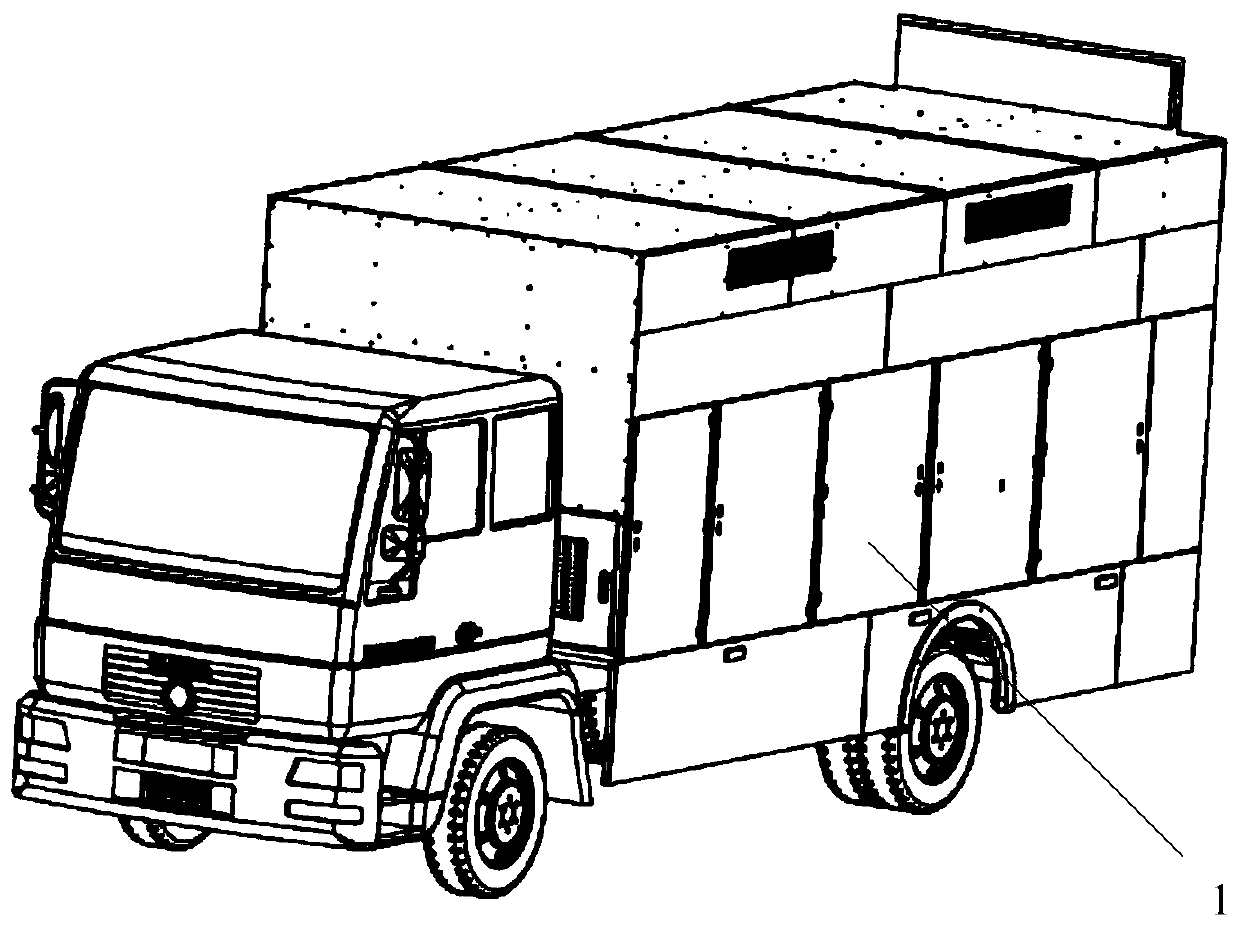

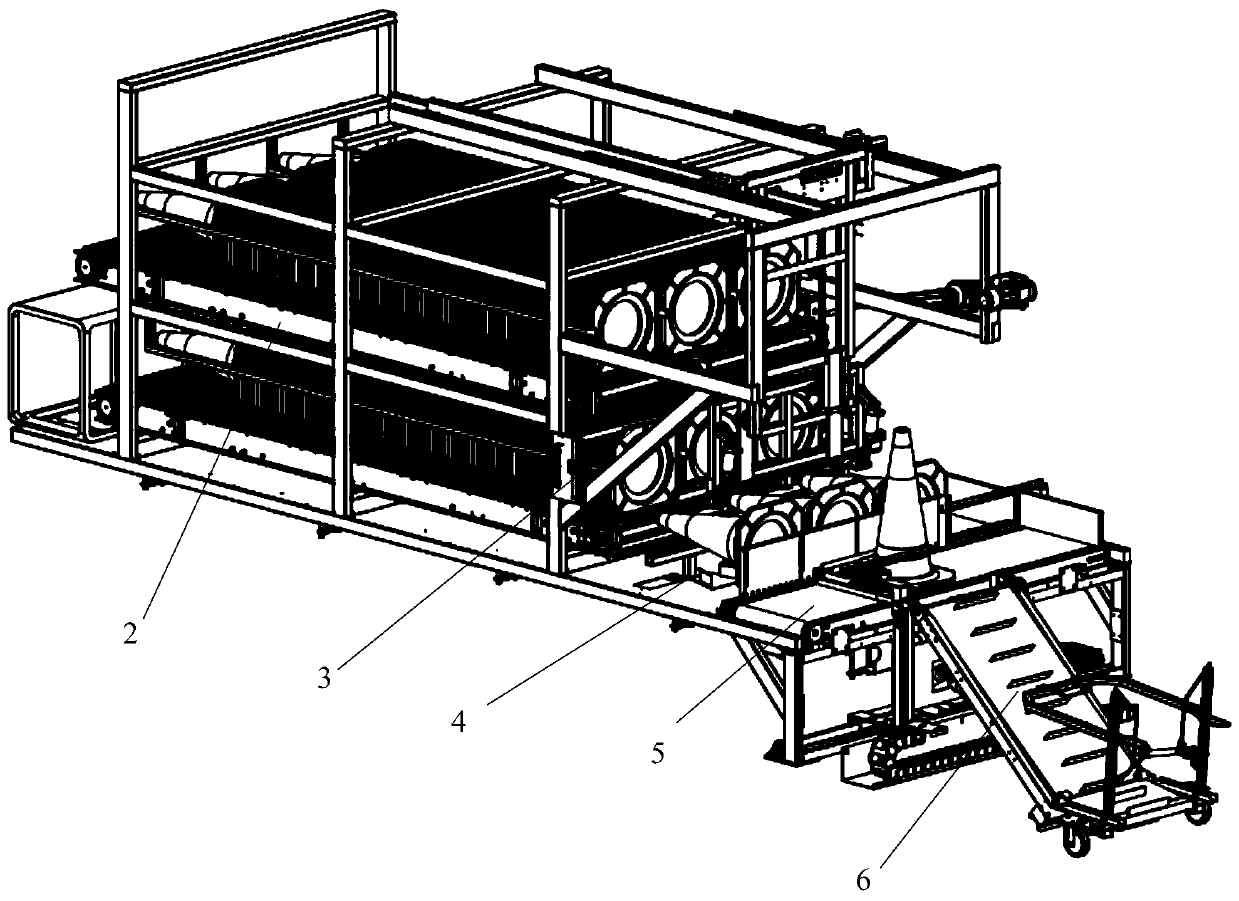

Safety cone automatic collection and placement vehicle

Owner:深圳市海威立德科技有限公司

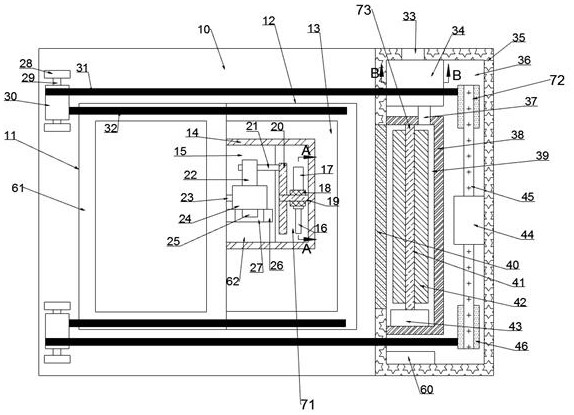

Control device for realizing photovoltaic and alternating current parallelized self-adaptive compensation

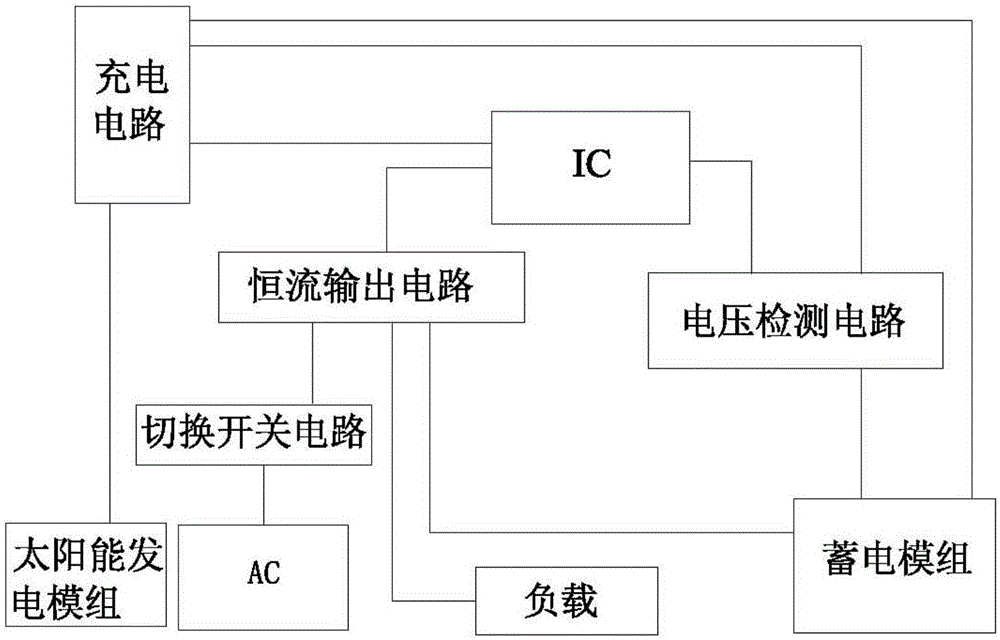

PendingCN106160200AImprove environmental adaptabilityImprove the stability of useBatteries circuit arrangementsElectric powerEngineeringSolar power

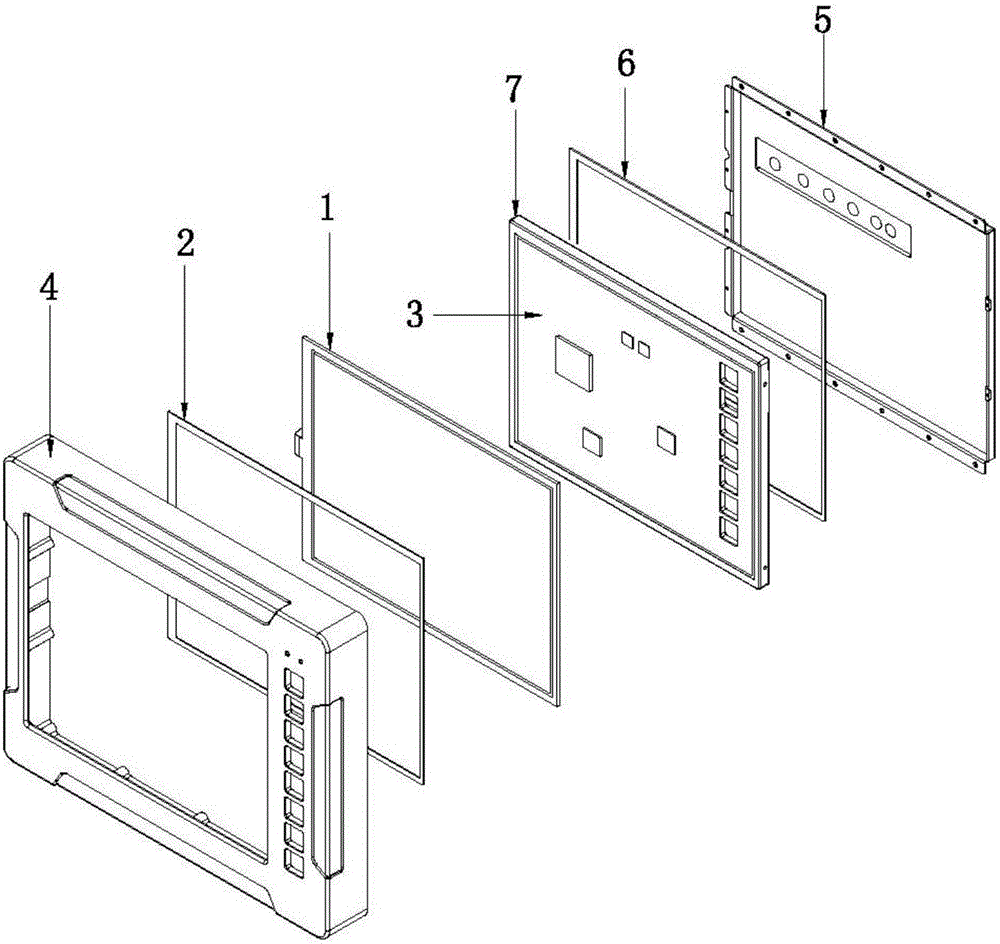

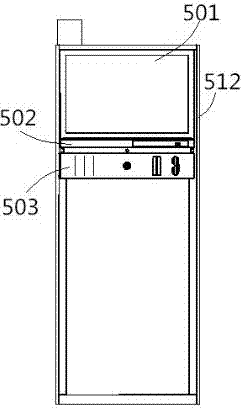

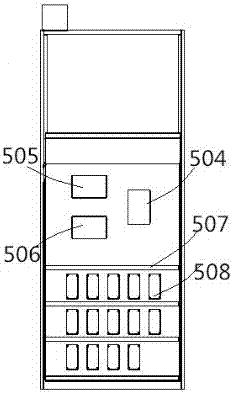

The invention discloses a control device for realizing photovoltaic and alternating current parallelized self-adaptive compensation. The control device comprises a touch display screen, a seal gasket, a self-adaptive compensation PCB (printed circuit board) control panel, an insulation shell and a rear cover. The control device is ingenious and reasonable in structural design, an effective seal structure is formed on a contact surface of the insulation shell and the touch display screen through the seal gasket to obtain excellent waterproof and dustproof effects, and accordingly the control device has a function of corrosion resistance in long-time operation in a high-humidity environment, and environment adaptability and stability in use are greatly improved while service life is prolonged greatly. When quantity of solar electricity stored in an electricity storage module is consumed to a preset value, the mains supply is converted into direct-current through the self-adaptive compensation PCB control panel to realize automatic seamless cut-in, and switching after sudden power failure caused by electricity shortage is avoided. By adoption of a solar power generation module for charging the electricity storage module, seamless connection between solar energy and the mains supply is realized while photovoltaic and alternating current parallelized self-adaptive compensation is realized, and solar utilization efficiency is improved effectively.

Owner:SICHUAN SHUWANG TECH

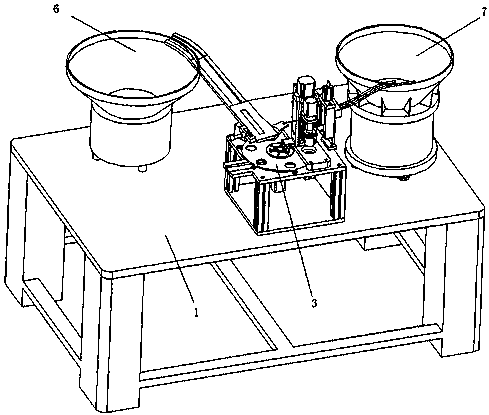

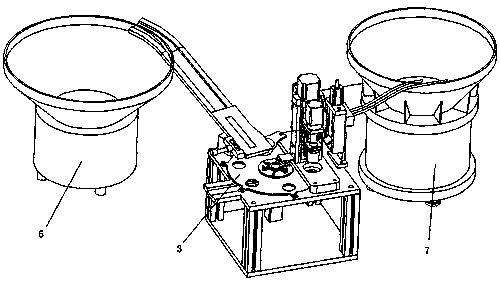

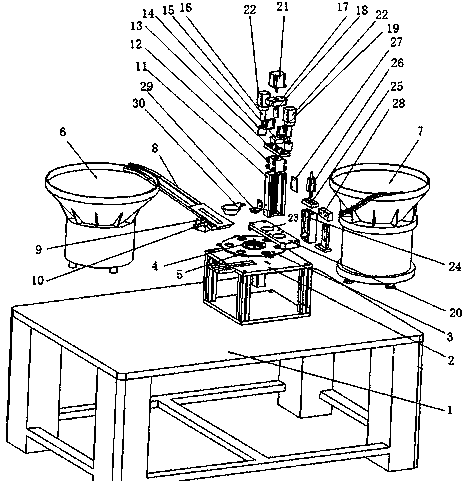

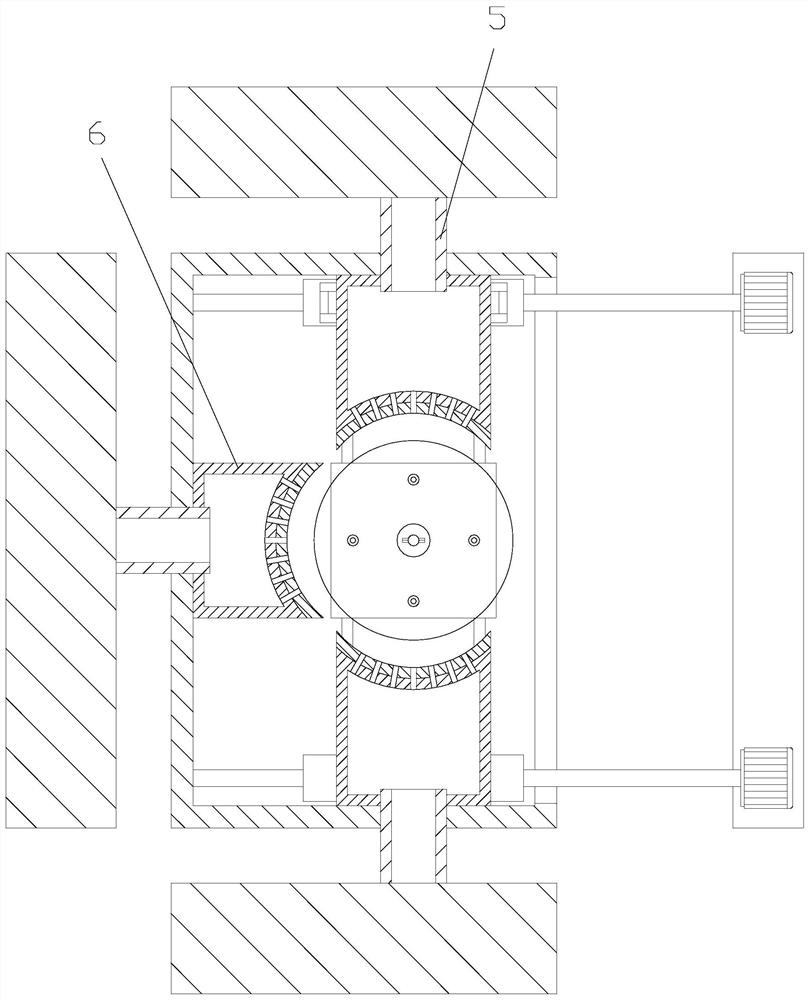

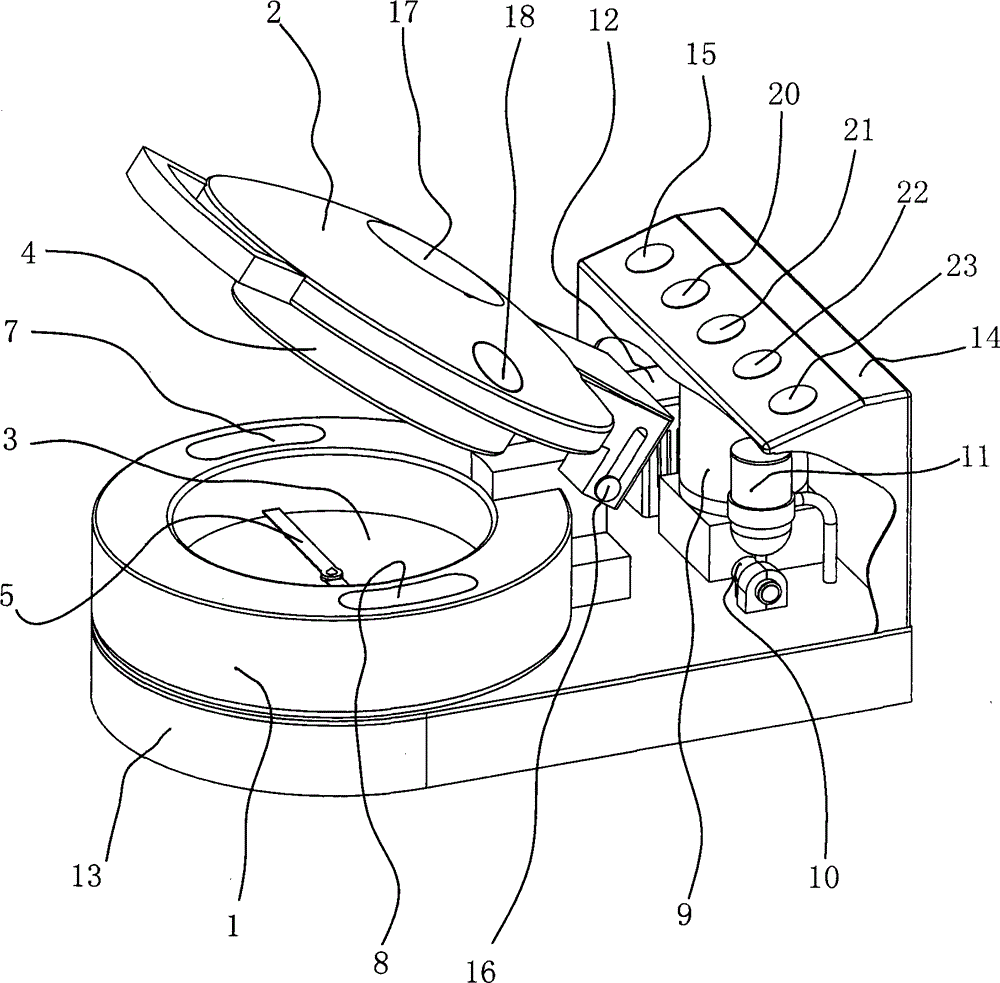

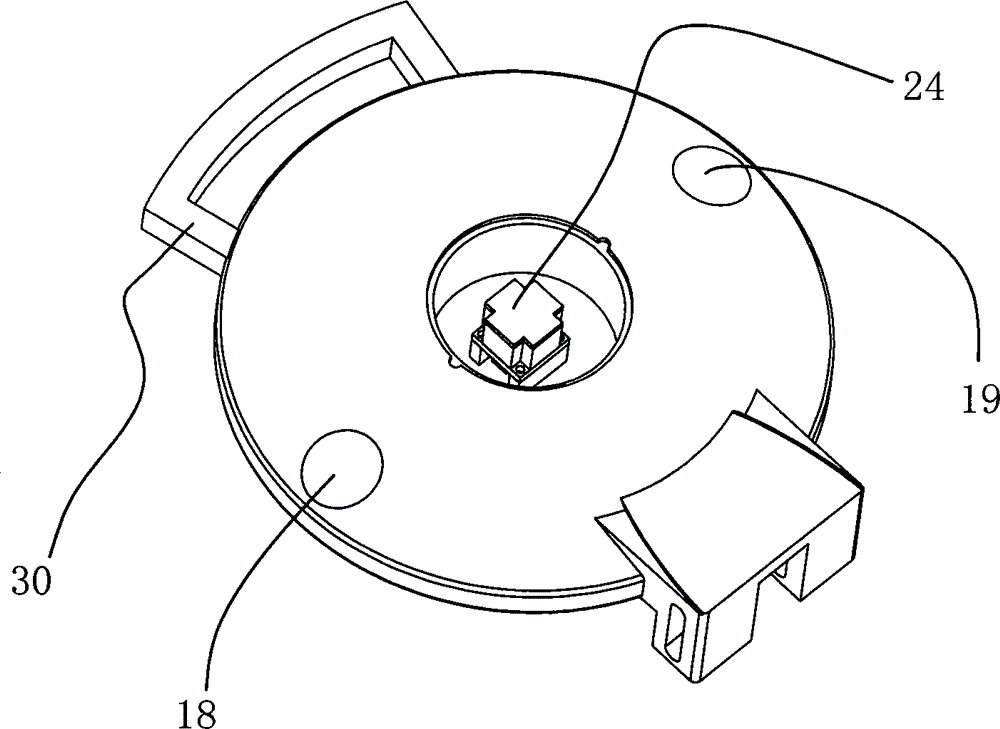

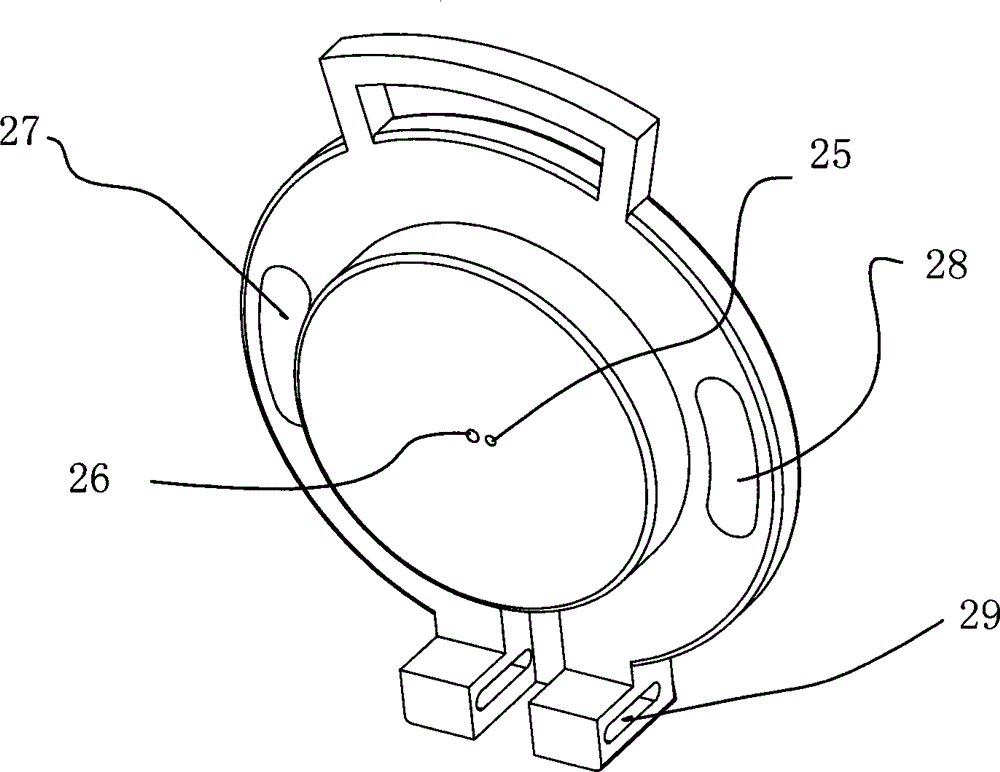

Automatic assembling device for steering column bearings

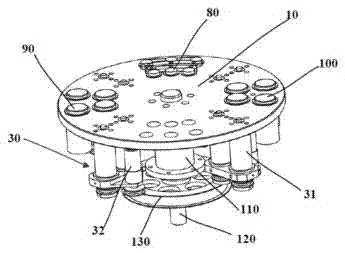

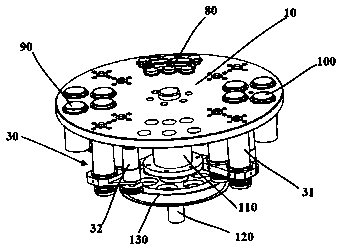

ActiveCN110116304AImprove the efficiency of automatic assemblyImprove stabilityMetal working apparatusSteering columnArchitectural engineering

The invention discloses an automatic assembling device for steering column bearings. The device includes a workbench; the middle part of the workbench is provided with a frame; the frame is provided with a six-station turntable used for placing a bearing support; the middle part of the six-station turntable is provided with a bearing support locating block, and the circumference of the six-stationturntable is provided with steel ball location holes; the two sides of the frame are respectively provided with a bearing support vibration plate and a steel ball vibration plate; the bearing supportvibration plate moves the bearing support to the bearing support locating block to fix through a transport channel; the steel ball vibration plate moves steel balls to the bearing support fixed on the six-station turntable to fix through the transport channel; and the upper part of the six-station turntable is provided with a press fitting device used for pressing the steel balls on the bearing support. Directional column bearing automatic assembling effects can be achieved by arranging the six-station turntable, the bearing support vibration plate and the steel ball vibration plate to cooperate with the press fitting device.

Owner:广州市安永实业有限公司

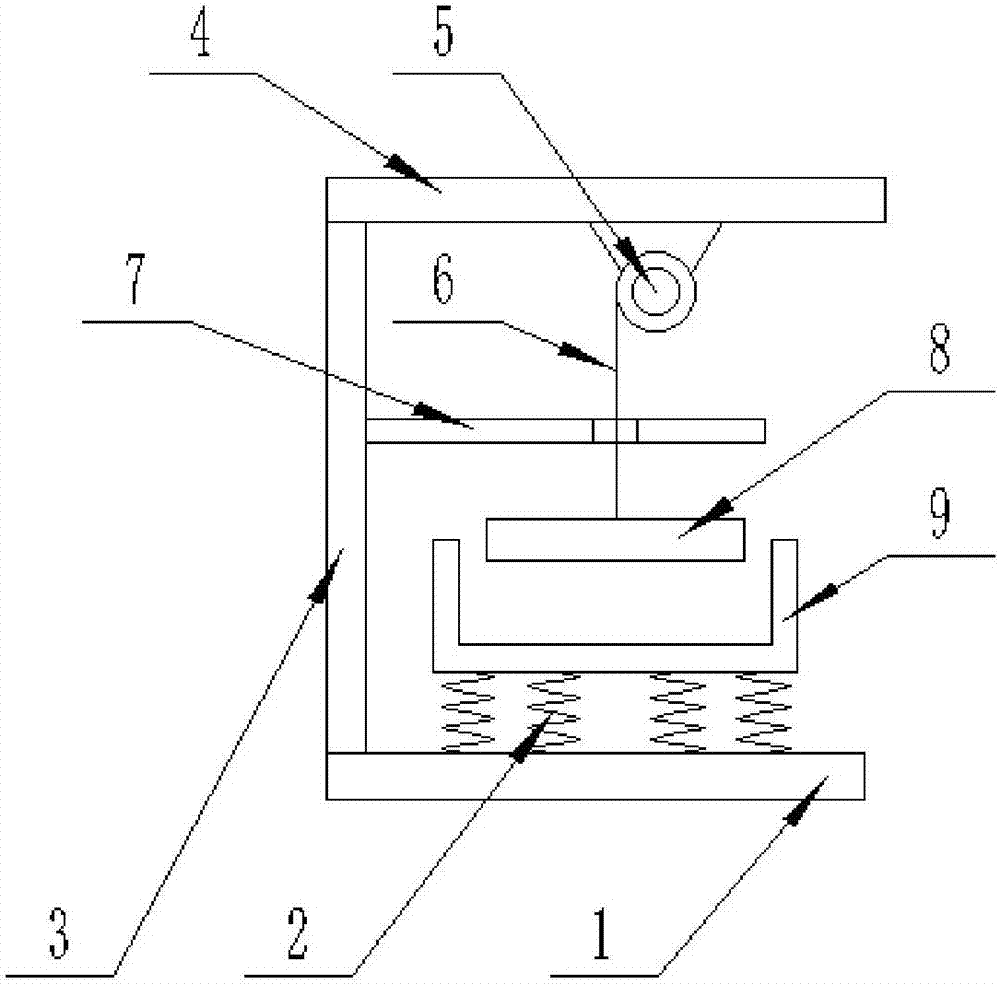

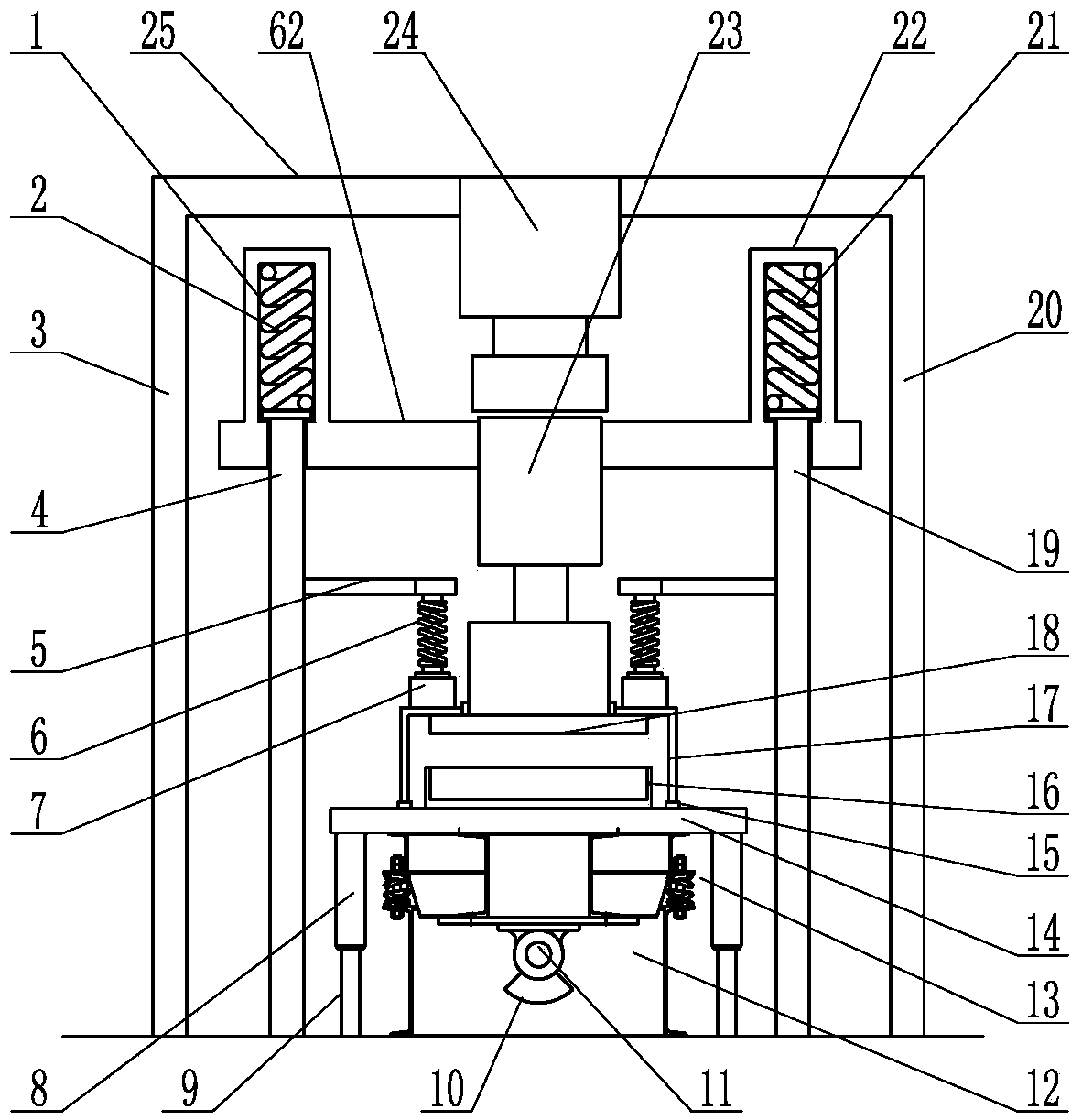

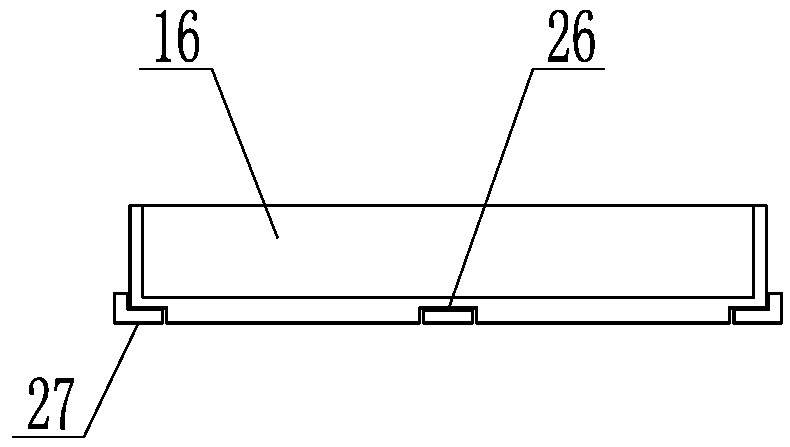

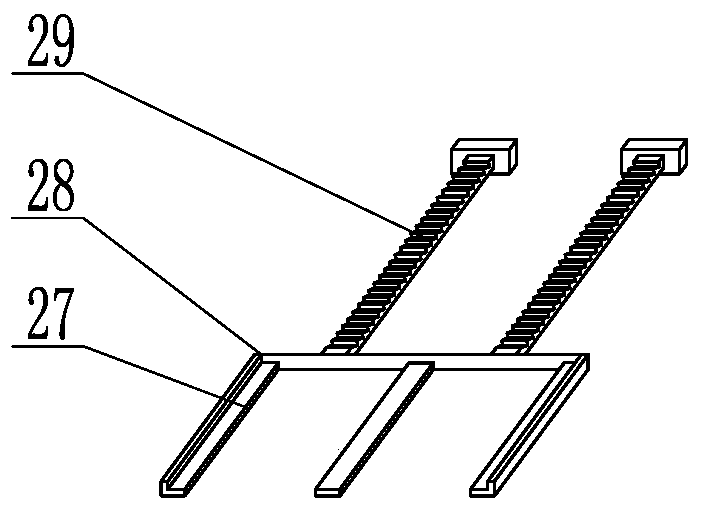

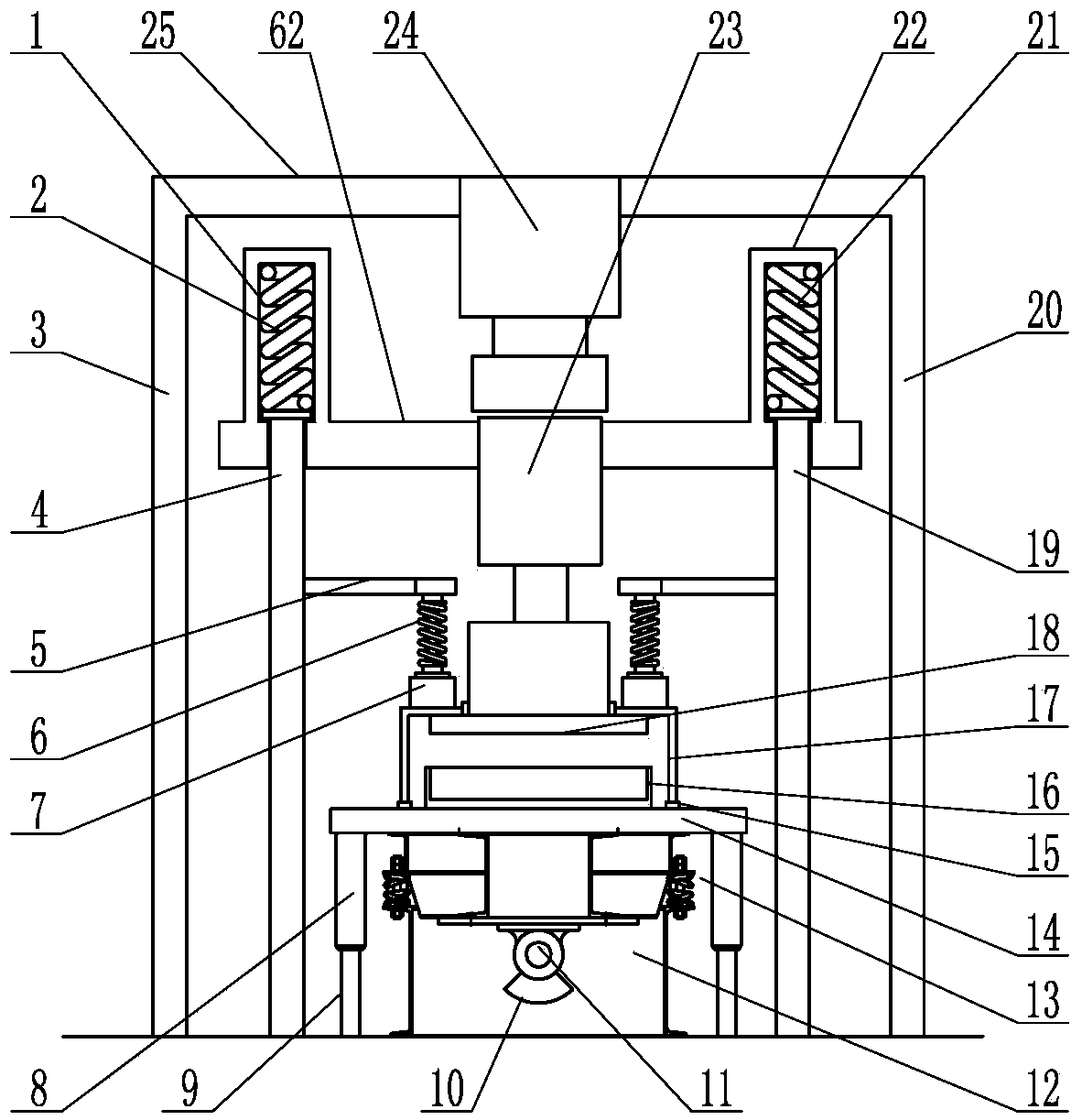

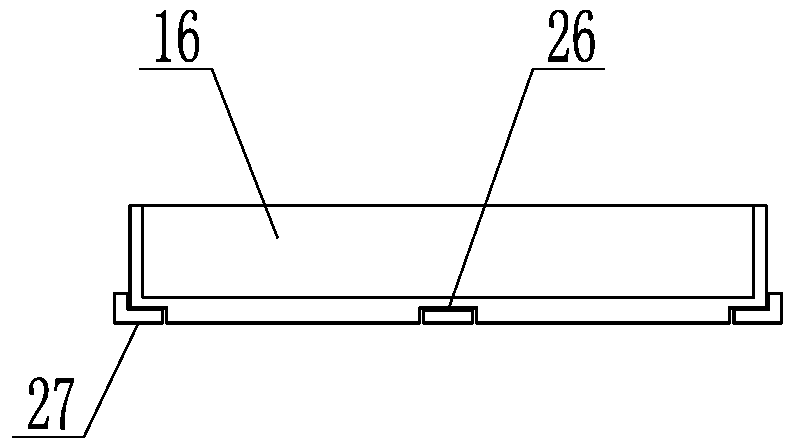

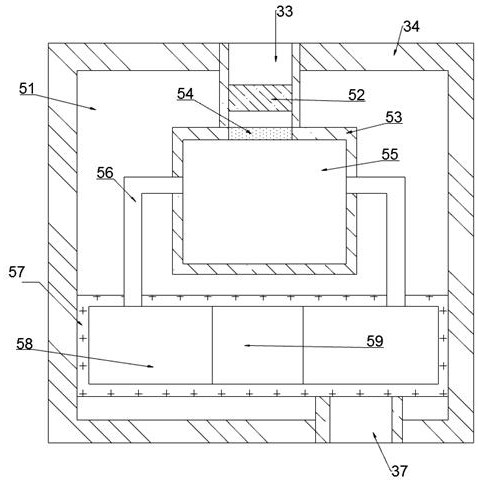

High-pressure vacuum vibration shaping machine

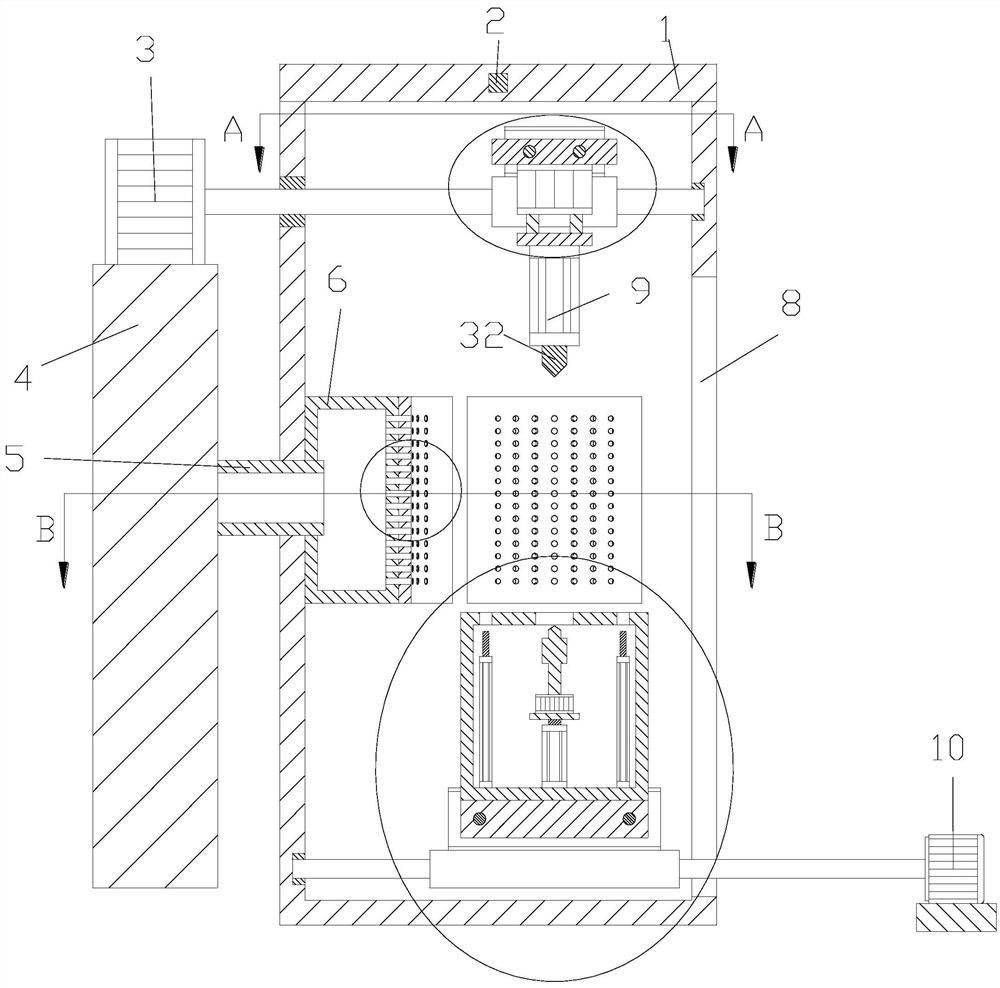

The invention discloses a high-pressure vacuum vibration shaping machine, and belongs to the field of building material high-density forming equipment. The high-pressure vacuum vibration shaping machine is characterized by comprising an outer rack, an inner rack, a base, a vibrator, a vibration table, a pressing mould, a pressing block, a first press machine, a second press machine and a vacuum chamber; the base, the vibrator, the vibration table, the pressing mould, the pressing block and the vacuum chamber are all arranged in the inner rack; the vibrator is connected to the vibration table;the vibration table is arranged on the base through spring devices; the pressing mould is arranged on the vibration table; a mould cavity is formed in the pressing mould; the pressing block is locatedabove the pressing mould and is connected to a telescopic arm of the first press machine; the first press machine is arranged on the top of the inner rack; the second press machine is arranged on theouter rack and is located above the first press machine; the vibrator comprises a vibration motor which is arranged on the bottom of the vibration table; and an eccentric rotation wheel is arranged on a motor shaft of the vibration motor. By adopting the high-pressure vacuum vibration shaping machine, the problem that pressure is insufficient in a pressing production process of quartz plates canbe solved, and product quality is effectively improved.

Owner:ZIBO XIANG PENG MACHINERY

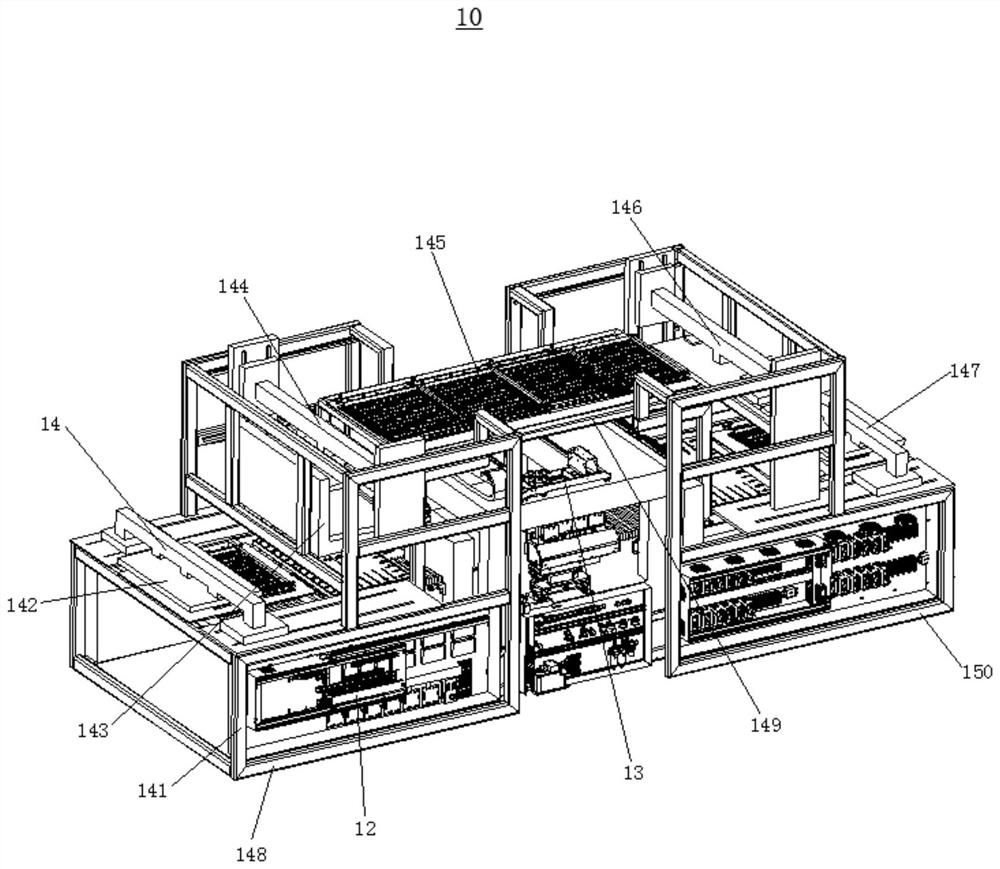

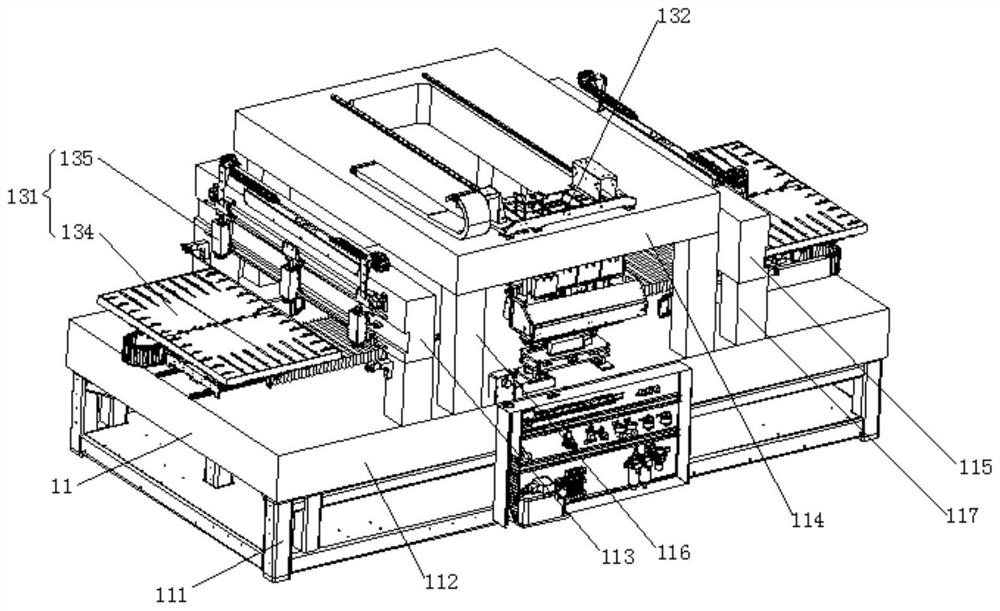

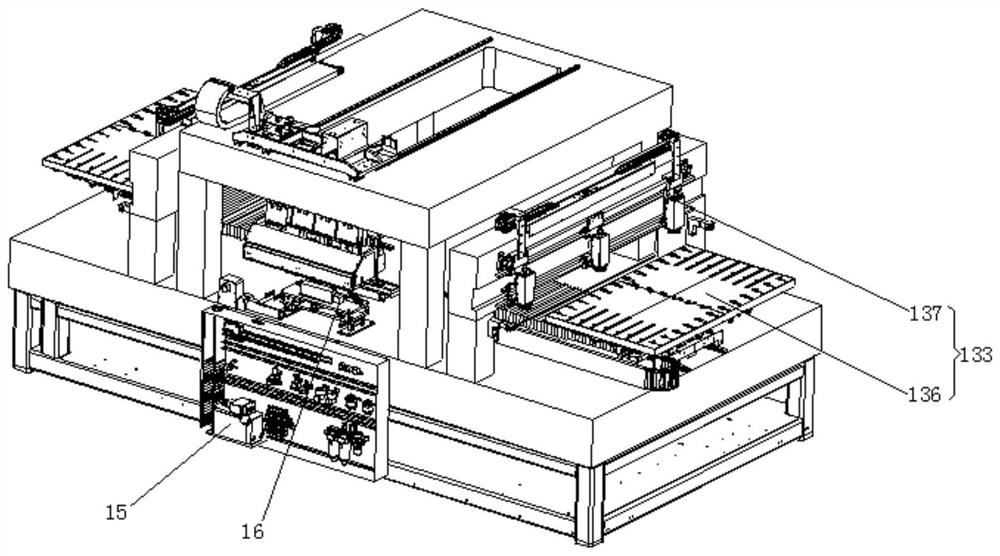

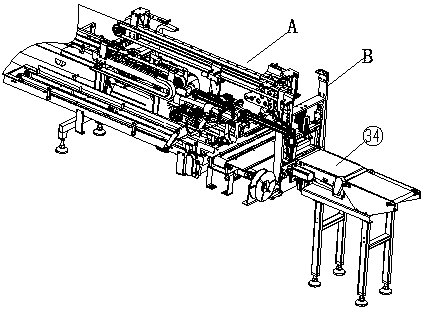

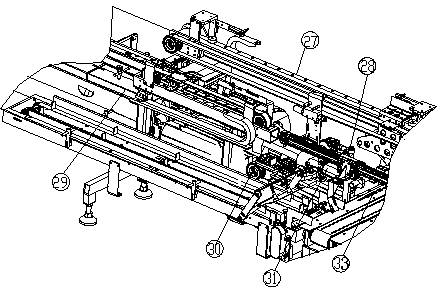

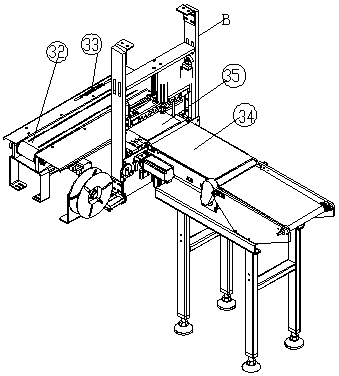

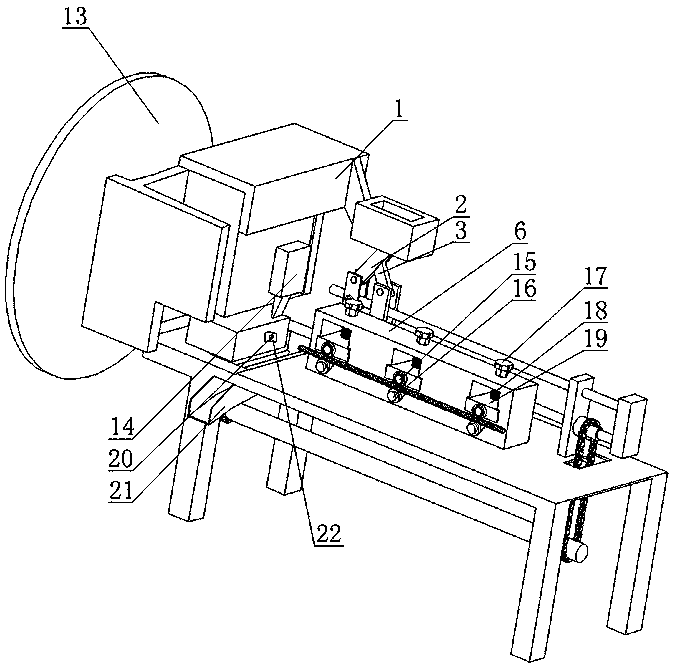

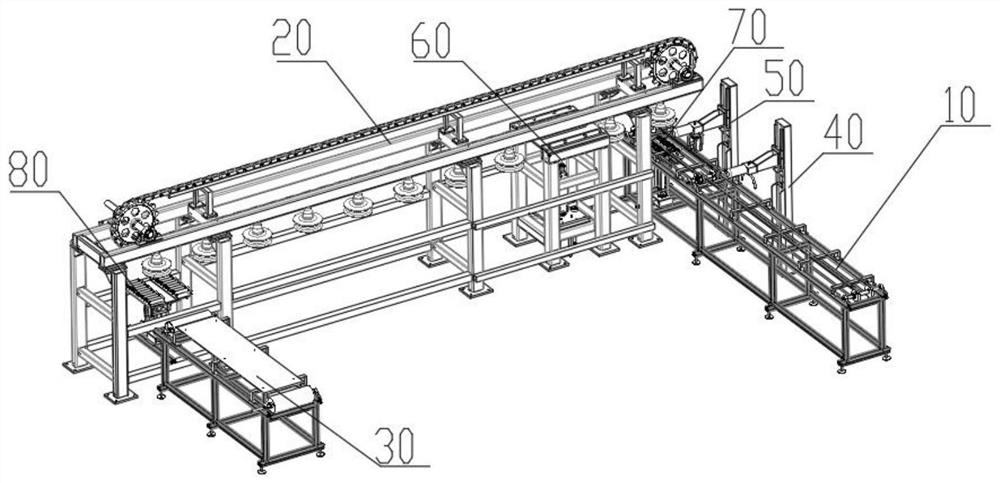

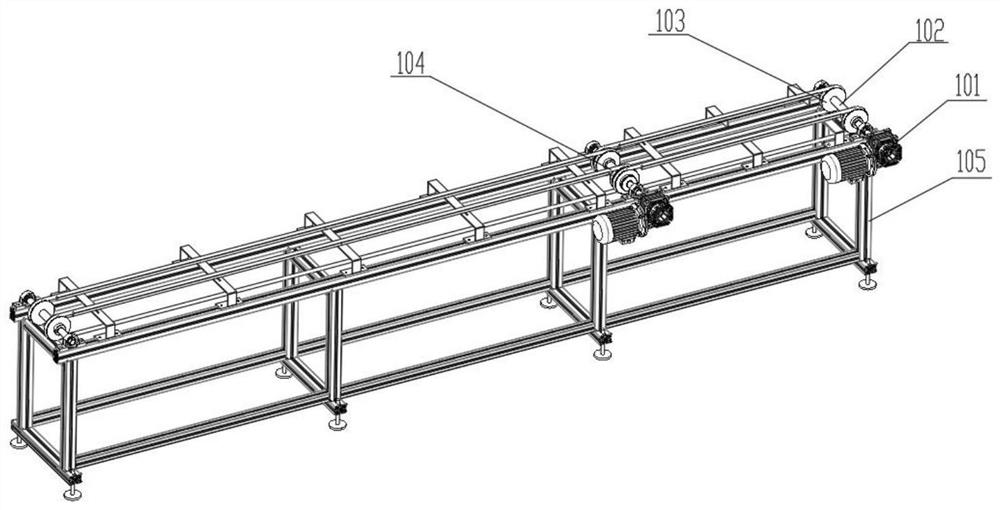

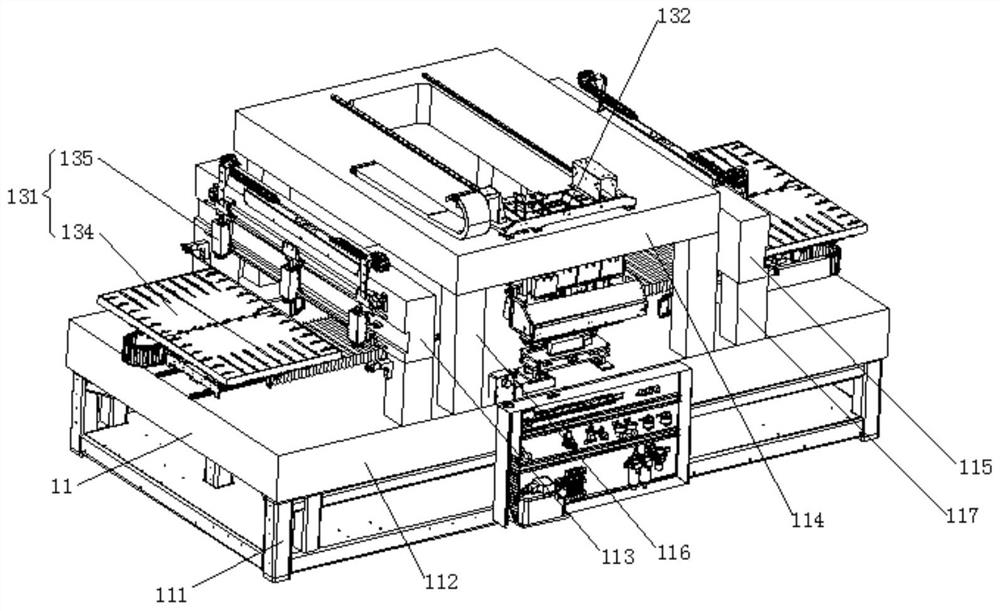

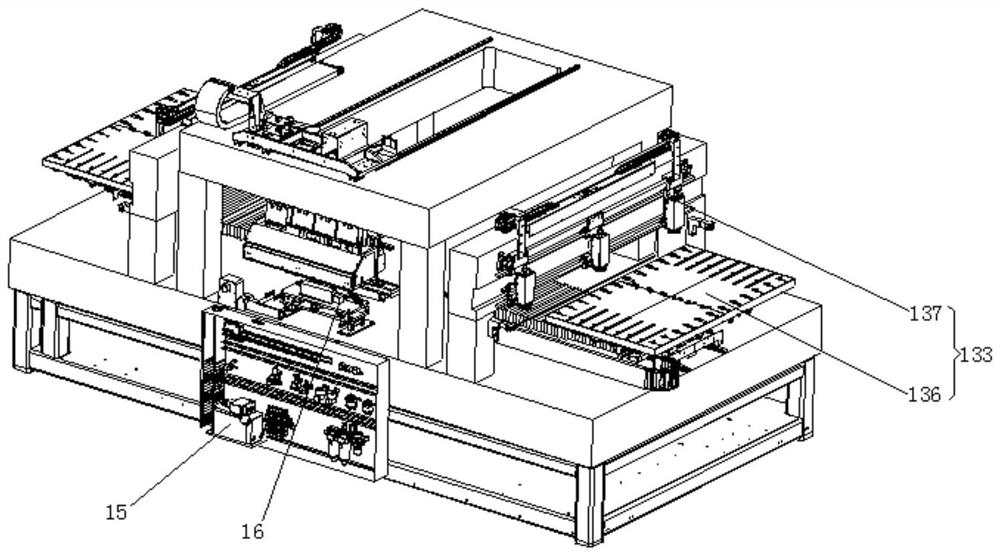

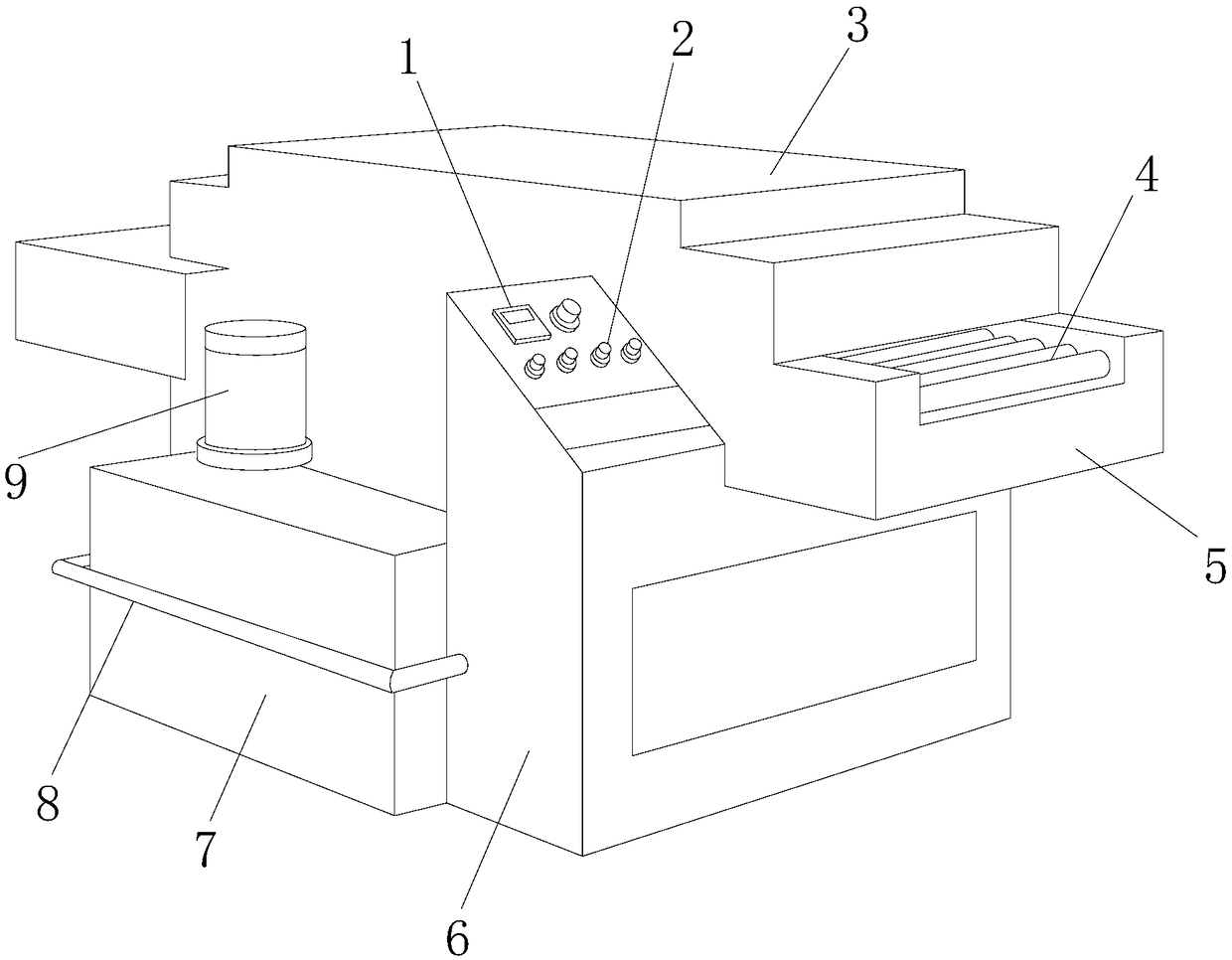

Circuit board double-sided jet printing all-in-one machine and method

ActiveCN112918129AExpand production scaleFull automationDuplicating/marking methodsTypewritersMechanical engineeringIndustrial engineering

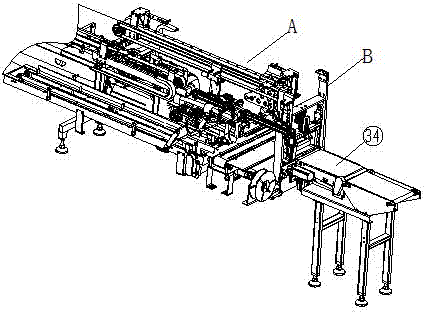

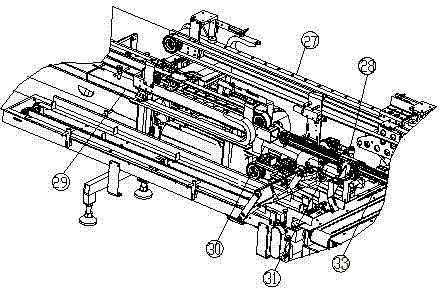

The invention relates to the technical field of circuit board ink-jet printing, in particular to a circuit board double-sided jet printing all-in-one machine which comprises a jet printing body and a board conveying mechanism assembly. The jet printing body comprises a first jet printing part, a jet printing trolley and a second jet printing part, and the jet printing trolley is located between the first jet printing part and the second jet printing part. The first jet printing part conveys the circuit board to the jet printing trolley, after the jet printing trolley performs ink-jet printing on the first surface of the circuit board, The board conveying mechanism assembly moves the circuit board located at the first jet printing part to the second jet printing part and turns over the circuit board in the transferring process so that the first face of the circuit board can be located on the second jet printing part, the second jet printing part conveys the circuit board to the jet printing trolley, and ink-jet printing is conducted on the second face of the circuit board through the jet printing trolley. The invention further relates to a circuit board double-sided jet printing method which adopts the circuit board double-sided jet printing all-in-one machine.

Owner:선전진신테크놀로지컴퍼니리미티드

High-pressure vacuum vibratory forming machine

The invention provides a high-pressure vacuum vibratory forming machine and belongs to the field of building material high-density forming equipment. The high-pressure vacuum vibratory forming machineis characterized by comprising an outer rack, an inner rack, a base, a vibrator, a vibrating table, a pressing die, a pressing die, a pressing block, a first pressure machine, a second pressure machine and a vacuum chamber. The base, the vibrator, the vibrating table, the pressing die, the pressing block and the vacuum chamber are arranged in the inner rack. The vibrator is connected with the vibrating table which is installed on the base through a spring device. The pressing die is installed on the vibrating table. The pressing die is provided with a die cavity. The pressing block is locatedabove the pressing die. The pressing block is connected with a telescoping arm of a first pressure machine. The first pressure machine is installed on the top of the inner frame. A second pressure machine is installed on the outer rack and located above the first pressure machine. The vibrator comprises a vibrating motor. The vibrating motor is installed on the bottom of the vibrating table. An eccentric rotating wheel is installed on a motor shaft of the vibrating motor. The high-pressure vacuum vibratory forming machine can solve the problem that in the quartz plate pressing production process, pressure is insufficient, and the product quality can be effectively improved.

Owner:ZIBO XIANG PENG MACHINERY

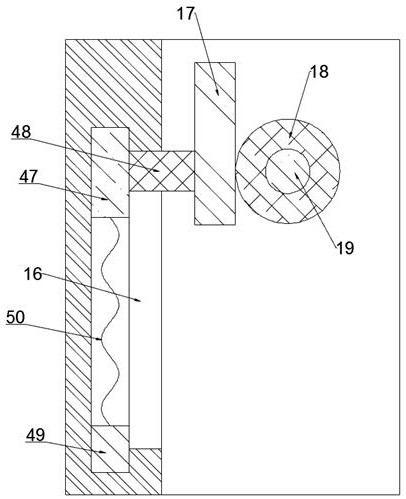

High-speed blanking machine for blanking spring pads

The invention discloses a high-speed blanking machine for blanking spring pads. The high-speed blanking machine comprises a machine frame. A tool apron and a transmission device are mounted on the machine frame. The tool apron moves up and down on the machine frame through the transmission device. A cutter is arranged on the tool apron. The high-speed blanking machine is characterized in that a stop block is arranged below the cutter, and the tool apron is hinged to a first connecting rod which is hinged to a second connecting rod; a fixing seat is arranged on the machine frame and provided with a movable guiding rod and a movable worm, and the guiding rod and the worm are connected through a connecting block and then move together; the other end of the first connecting rod is hinged to the guiding rod, and the other end of the second connecting rod is hinged to the fixing seat; and a conveying frame is arranged on the machine frame and provided with a plurality of feeding wheel sets, each feeding wheel set comprises a driven wheel and a pressing wheel, a worm gear is arranged on a wheel shaft of each driven wheel and engaged with the worm, and the worm is in transmission connection with the transmission device. By adoption of the technical scheme, metal wires can be blanked at a high speed, the whole course is automatic, and the structure is simple.

Owner:瑞安市旭东冲压机械厂

Windowing ventilation system capable of automatically detecting indoor air

InactiveCN111928370AFlexible switchingFull automationMechanical apparatusLighting and heating apparatusSlide windowWindow opening

The invention discloses a windowing ventilation system capable of automatically detecting indoor air. The windowing ventilation system capable of automatically detecting indoor air comprises a wall body; a window is arranged in the wall body, a first sliding window is arranged in the window in a sliding mode, first glass is arranged in the first sliding window, a clamping block is fixedly arrangedat the front end of the first glass, a clamp cavity is arranged in the clamping block, the clamp cavity penetrates through the upper end face and the lower end face of the clamping block, a second sliding window is arranged on the left side of the first sliding window and arranged in the window in a sliding mode, an unlocking device is fixedly arranged at the right end of the second sliding window, the unlocking device comprises an unlocking bin, and the unlocking bin is fixedly arranged at the right end of the second sliding window. The windowing ventilation system is internally provided with the unlocking device, unlocking is conducted by rotating and twisting a lock handle, in addition, the window is flexibly opened and closed by pulling up, active air blowing is conducted after the window is opened, the windowing ventilation system can adapt to environment to adjust humidity, the whole process is automatic, and efficiency and convenience are achieved.

Owner:温州雪尚电子科技有限公司

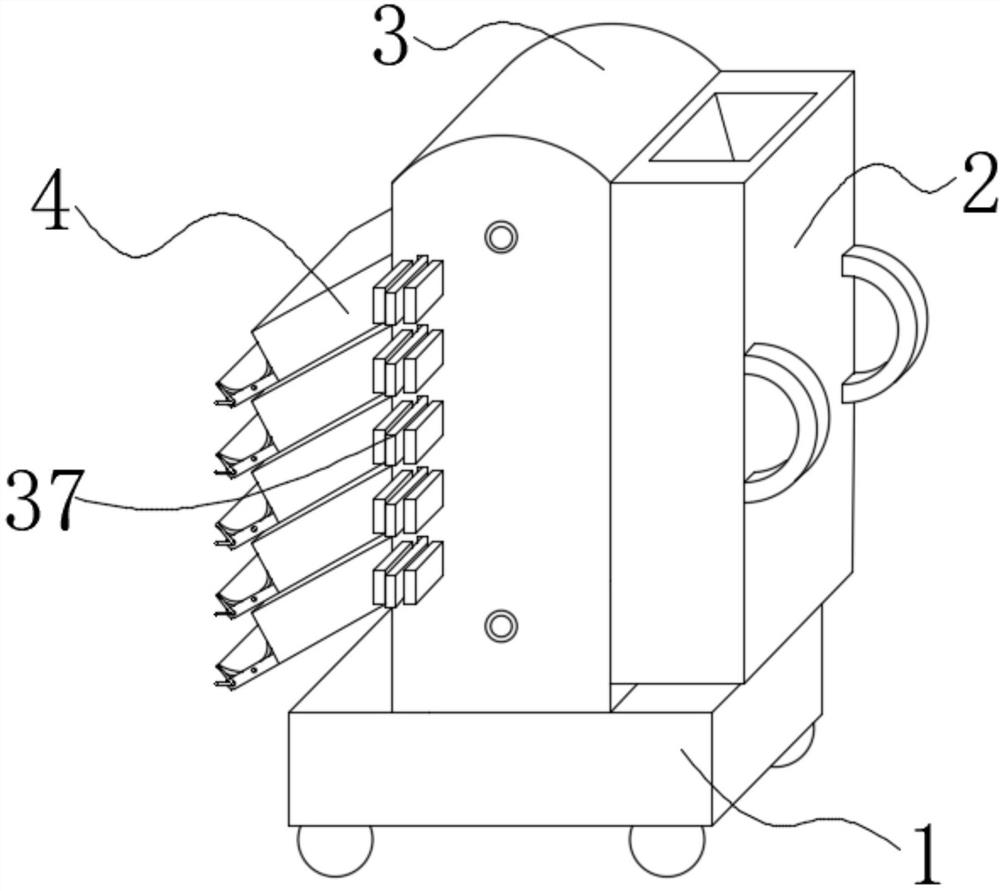

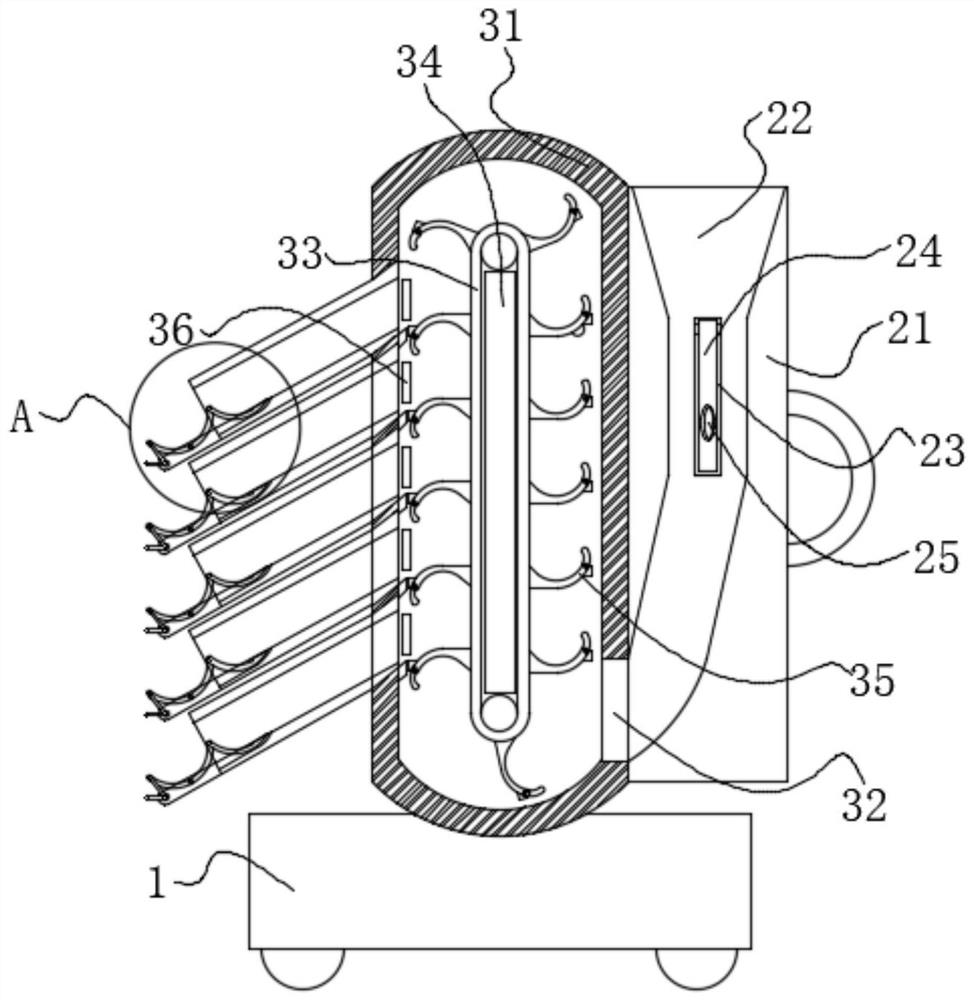

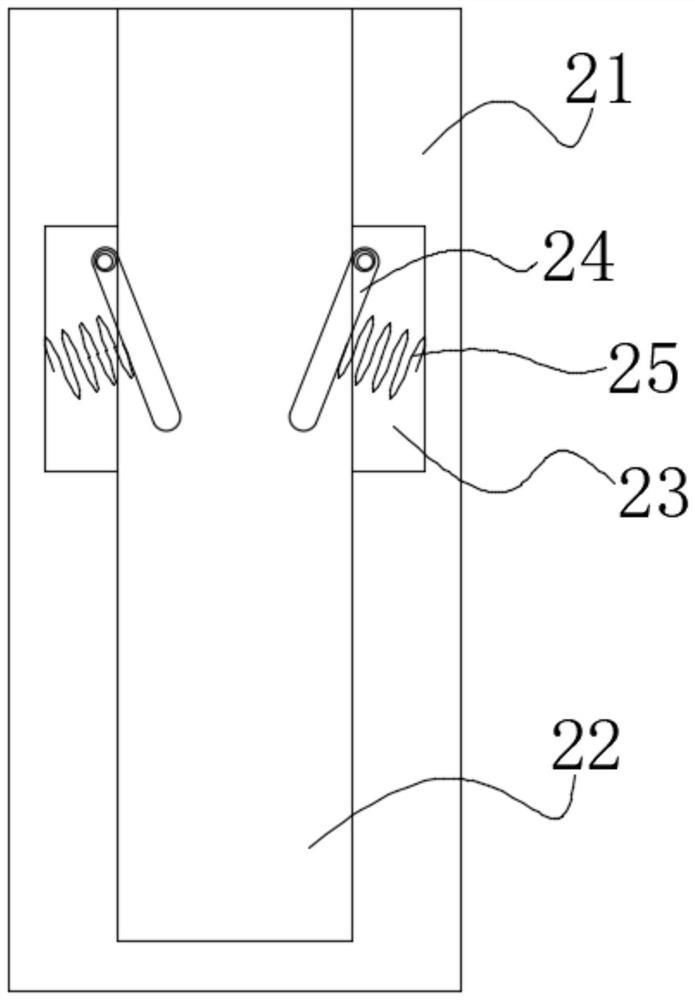

Flavor and fragrance injector

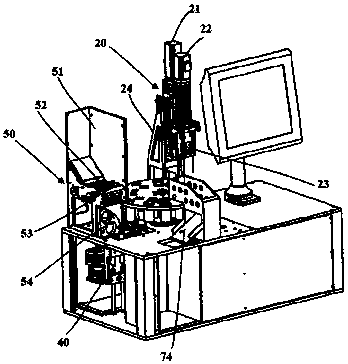

InactiveCN107156898AImprove injection efficiencyFull automationCigarette manufactureFlavorEngineering

The invention provides a flavor and fragrance injector, comprising at least one cigarette container each defining one or more cigarette receiving cavities; a station device configured to at least drive each cigarette container from an injection station to a cigarette discharge station; an injection device configured to charge a flavor and / or fragrance into cigarettes in each cigarette receiving cavity of the corresponding cigarette container when the cigarette container is positioned at the injection station; and a cigarette discharge device configured to drive the cigarettes in each cigarette receiving cavity of the corresponding cigarette container to leave the cigarette container when the cigarette container is at the cigarette charge station. The flavor and fragrance injector is capable of discharging cigarettes injected with the flavor and fragrance out of the cigarette receiving cavities by the aid of the cigarette discharge device, and driving the cigarettes into a cigarette collection box through a cigarette guide device, full automation is achieved, and flavor and fragrance injection efficiency is improved.

Owner:BEIJING HUIRONGHE TECH

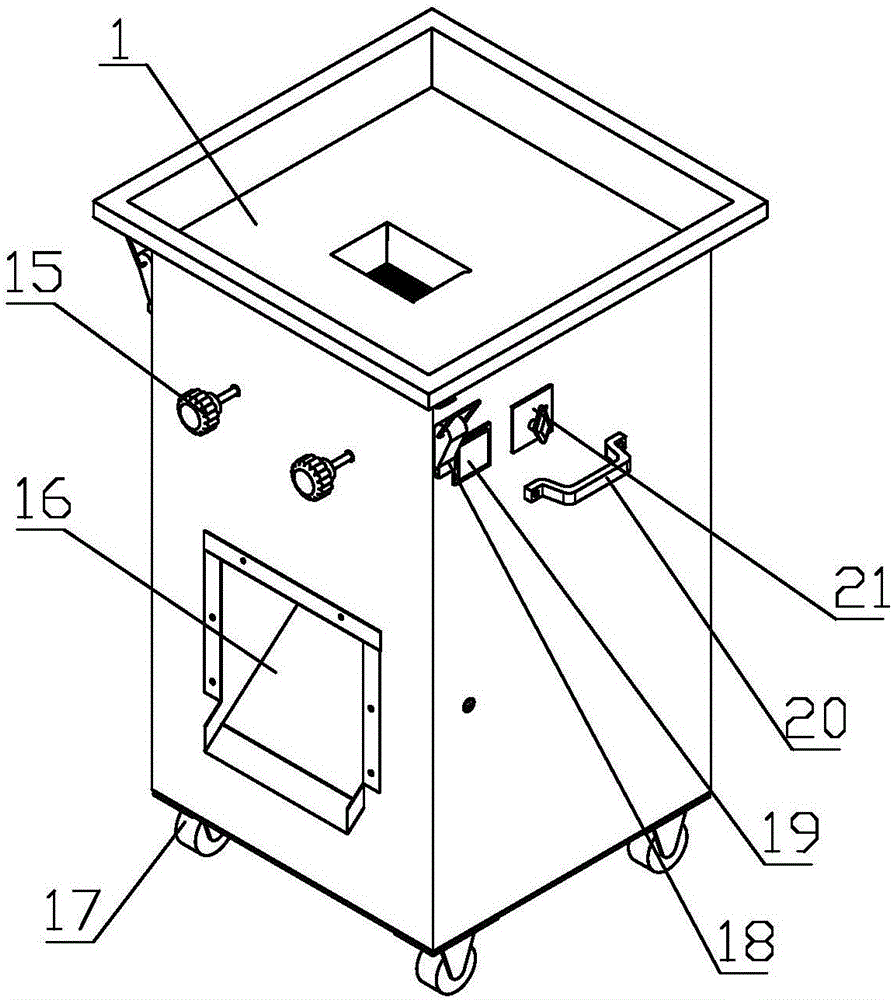

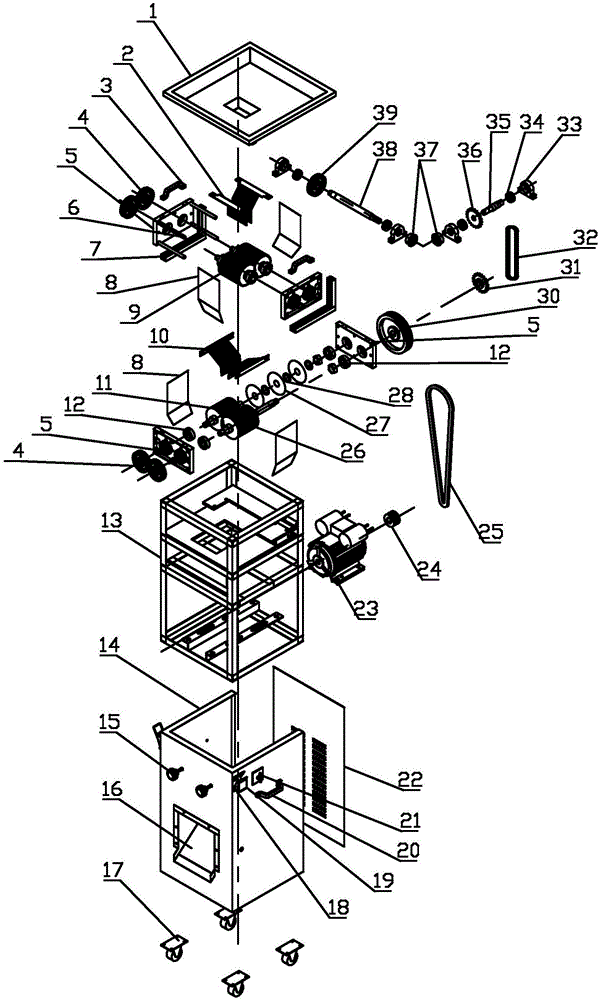

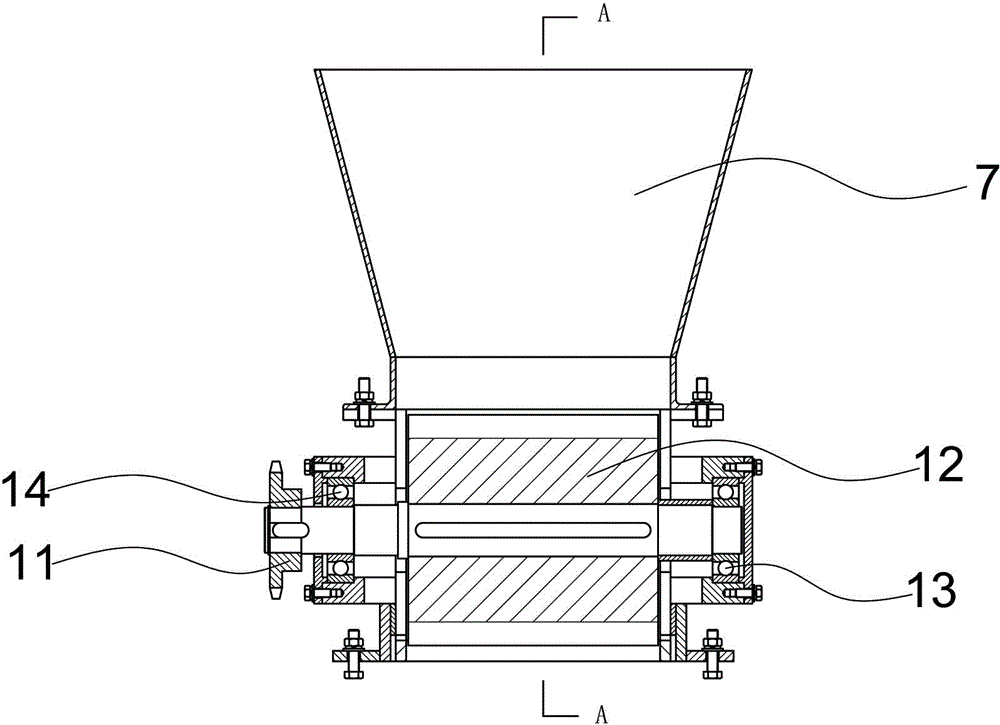

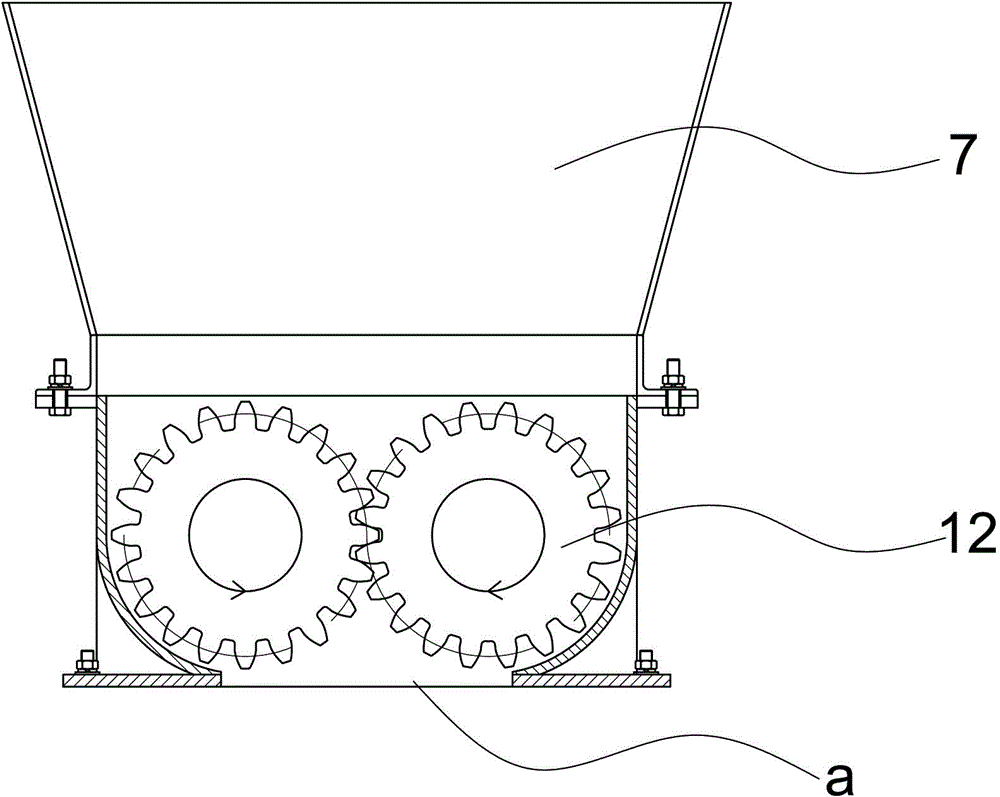

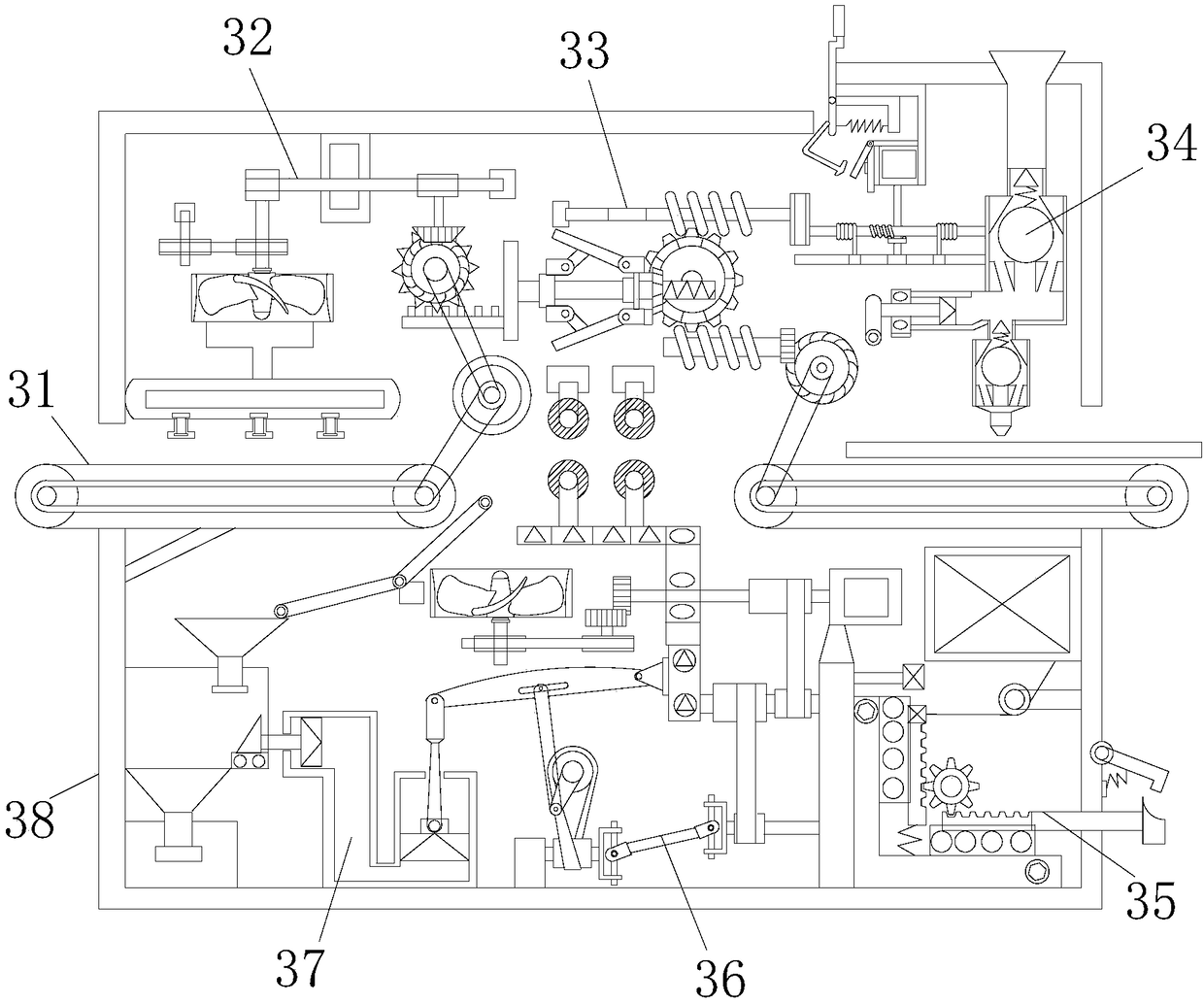

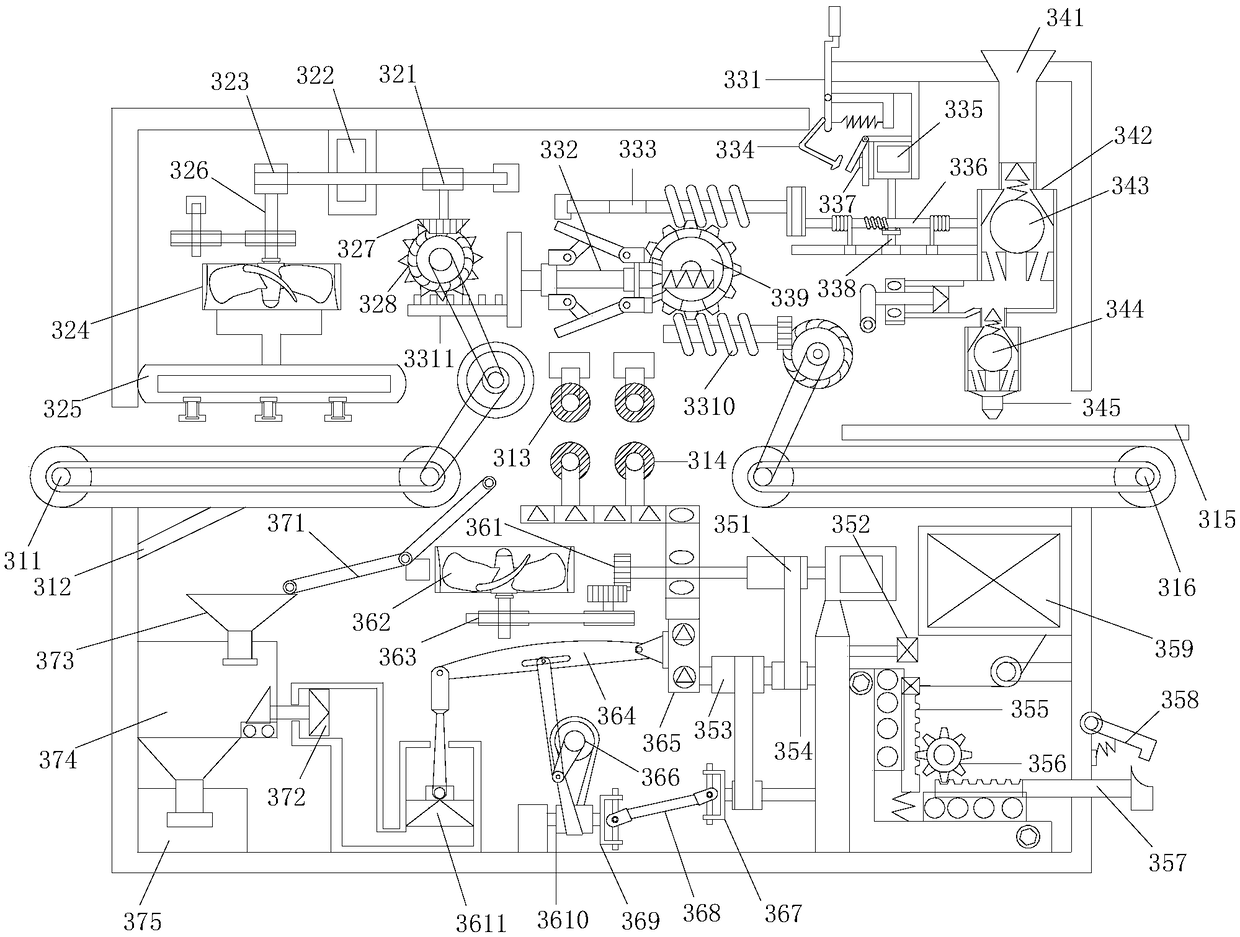

Shredded meat machine

The invention discloses a shredded meat machine comprising a rack; a front box is installed at the outer peripheral surface of the rack; a rear box is installed at the rear side of the rack; the rear box is connected with the front box; the front box is provided with a discharge port; the rack is provided with a baffle plate which is installed above the discharge port; the lateral wall of the front box is provided with a power switch and a reversible switch; the rack is provided with a motor; an end part of the rack is provided with a meat basin; the front part of the motor is provided with a first belt pulley; the rack is provided with a second slicing knife set, a third slicing knife set and a first slicing knife set; the second slicing knife set and the third slicing knife set are arranged in parallel arrangement; the first slicing knife set is installed above the second slicing knife set and the third slicing knife set; the rack is provided with two sets of side plates; the second slicing knife set, the third slicing knife set and the first slicing knife set are installed among the side plates; the rack is provided with a first knife comb and a second knife comb. The shredded meat machine facilitates sliced meat to be cut into shredded meat and then shredded meat is discharged from the discharge port; the whole process is automatic, simple and convenient.

Owner:ZHENGJIANG SHARK FOOD MASCH CO LTD

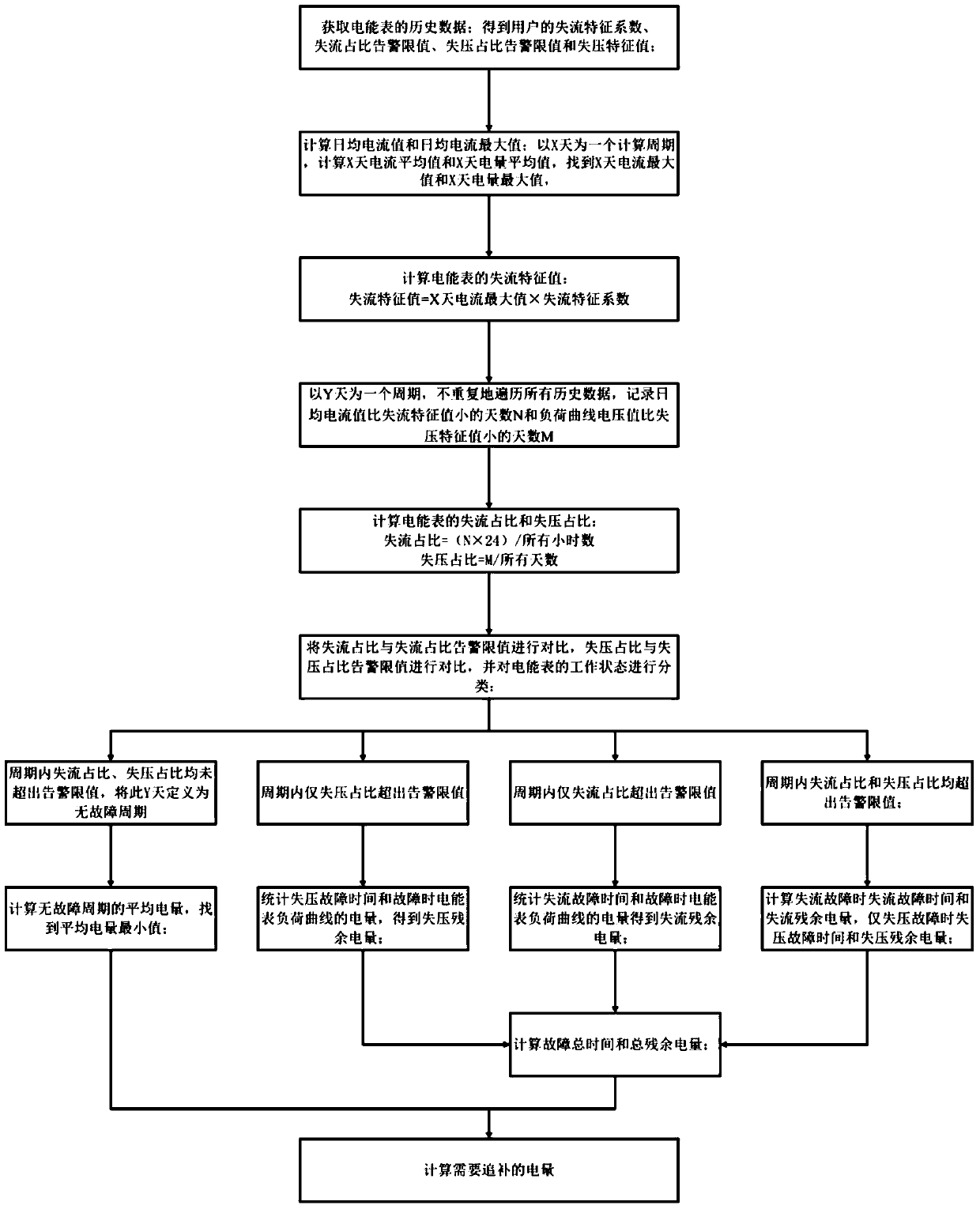

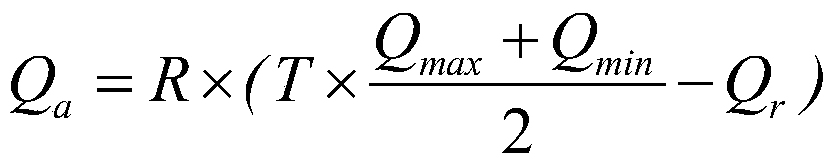

Electricity replenishment method based on load curve

ActiveCN105631762BFollow up accuratelyCalculation speedData processing applicationsElectrical measurementsAverage currentEngineering

The invention discloses an electric power retrieving method based on a load curve. The electric power retrieving method based on the load curve comprises the steps that historical data of an electric energy meter are obtained, and a current loss characteristic coefficient, a current loss ratio alarm limit value, a voltage loss ratio alarm limit value and a voltage loss characteristic value are obtained; the maximum value of current of seven days and the maximum value of electric power of seven days are calculated; a current loss characteristic value is calculated; the number of days in which a daily average current value is less than the current loss characteristic value and the number of hours in which a load curve voltage value is less than the voltage loss characteristic value are calculated; the current loss ratio and the voltage loss ratio of the electric energy meter are calculated; the minimum value of average electric power of a fault free period is calculated; total fault time and total residual electric power are calculated; and electric power required to be retrieved is calculated. Electric power retrieving can be automatically performed under the condition of voltage loss and current loss of the electric energy meter without influence of the present power consumption state of the electric energy meter so that the electric power retrieving method based on the load curve is suitable for the electric energy meters of various types of electric energy loads and various types of metering modes, wide in range of application, automatic in the whole course, accurate in calculation and high in calculation speed and is realized by using computers completely.

Owner:WILLFAR INFORMATION TECH CO LTD

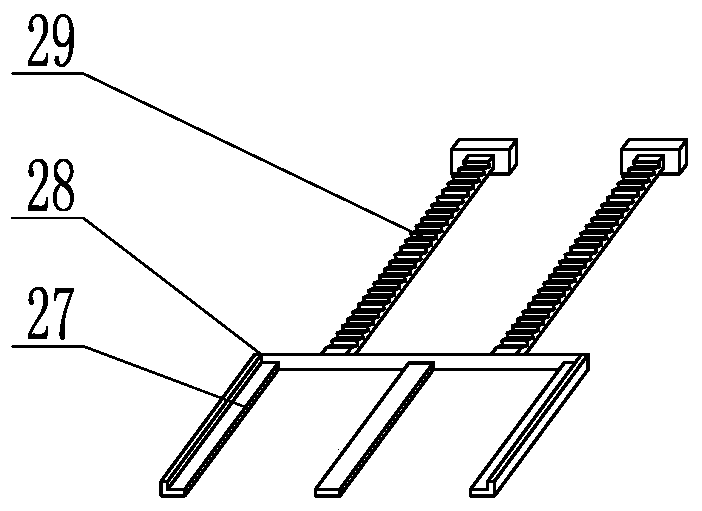

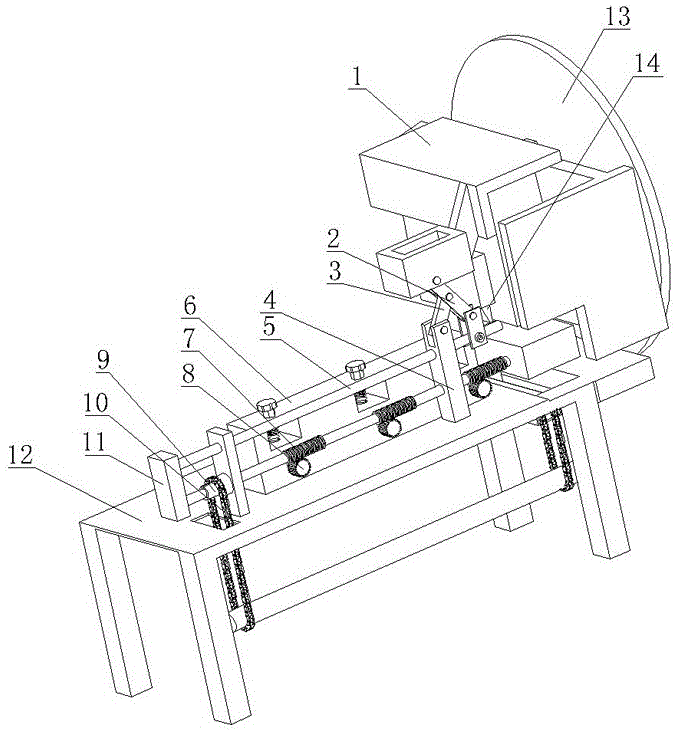

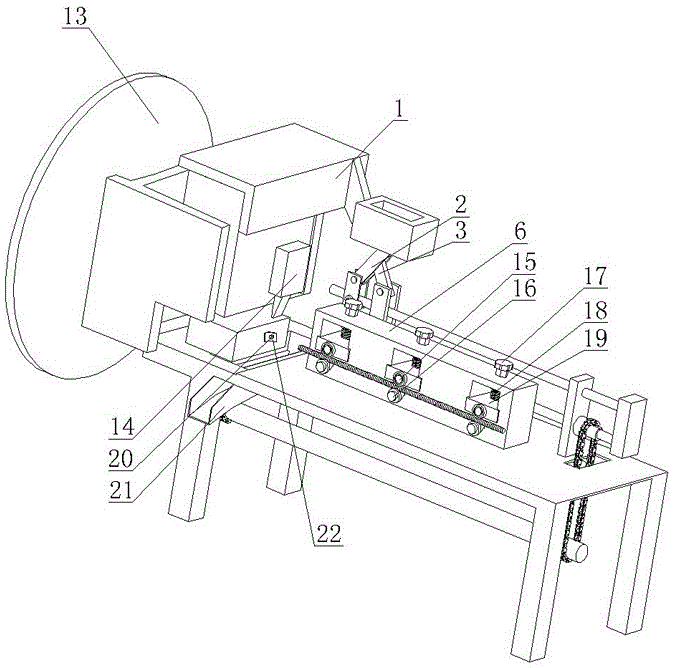

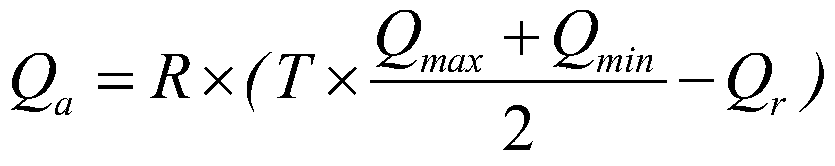

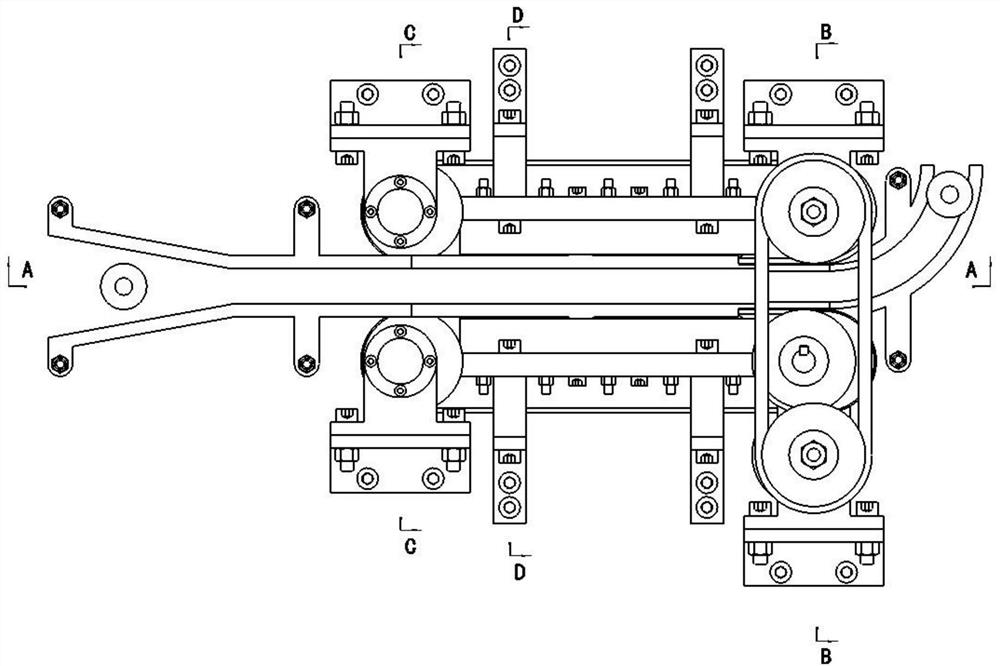

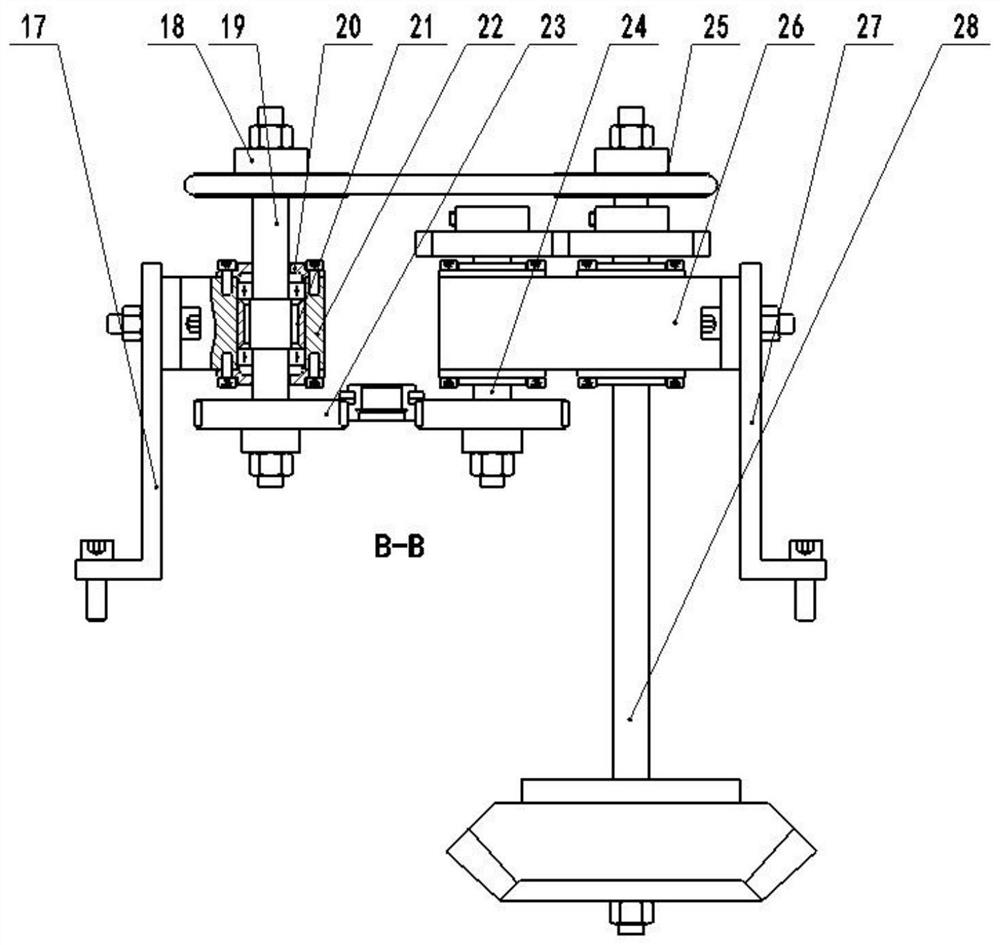

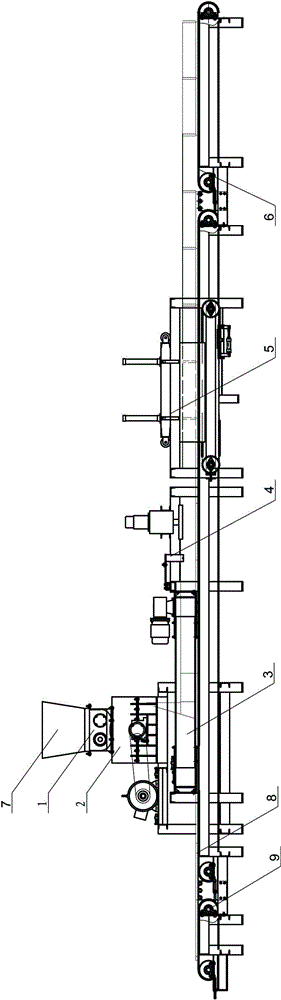

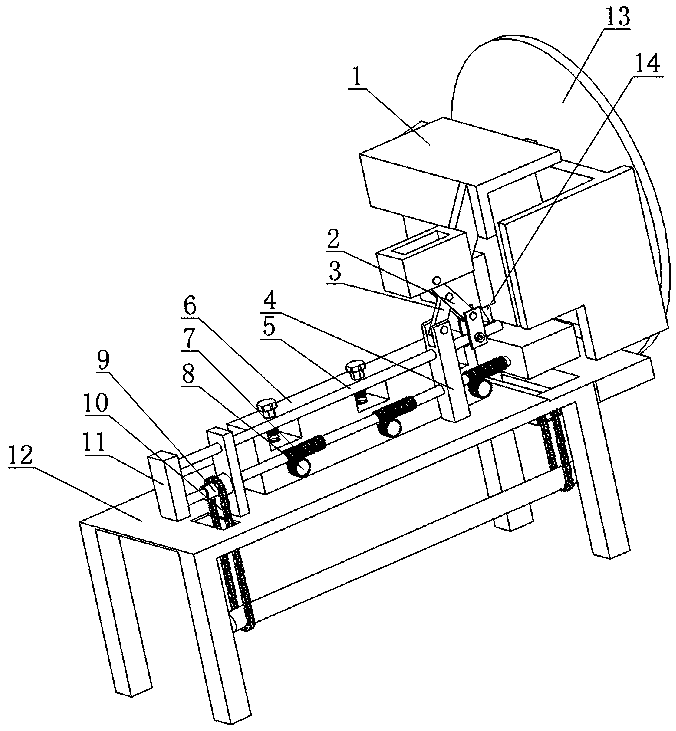

Device of separating upper covers of dies continuously for automatic initiating explosive device assembling production line

The invention relates to a device of separating upper covers of dies. The device is composed of four parts: a guide rail device, a front conveying device, a belt adjusting device and a back conveyingdevice. The guide rail device is used for separating and transferring the upper covers of the dies; the front conveying device is used for driving the upper covers of the dies to enter the guide raildevice smoothly; the belt adjusting device is used for adjusting a tensile force of a belt and enabling ten bearings to be in contact with the belt tightly through a spring to ensure that the upper covers of the dies are obliquely and continuously conveyed along the guide rail device; and the back conveying device is used for driving the upper covers and the dies to move forward on a guide rail and conveying the separated upper covers of the dies back to a conveyor line. The dies with to-be-separated upper covers of the dies move at a speed of 20 m / min on the conveyor belt, rectangular slot bodies are formed in the outer diameters of the upper covers of the dies, and the upper covers enter the rectangular slot bodies by a shifting fork in the oblique guide rail device. The dies are conveyed on the conveyor belt at an original speed, and the upper covers of the dies are driven by the shifting fork to move upward along the inclined guide rail, so that the upper covers of the dies are separated from the dies to achieve a demand of separating the upper covers of the dies automatically. The separated upper covers of the dies are conveyed back to original stations through the conveyor belt and the rest of dies are further conveyed to follow-up stations to be assembled.

Owner:CHANGCHUN EQUIP TECH RES INST

Middle bandage flower craft

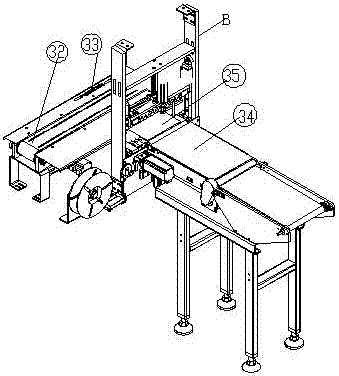

ActiveCN107054772BRealize seamless dockingFull automationWrapper twisting/gatheringEngineeringPackaging machine

The invention provides a centralized-packaging and flower bundling technology. The centralized-packaging and bundling technology comprises the steps of material packaging and flower bundling. The material packaging step comprises the sub-steps of feeding of a centralized-packaging mechanism material feeding device, bag sending of a bag sending device, bag opening of a bag-opening device, bag expanding of a bag expanding device and pushing of materials into an expanded prefabricated bag by a material pushing device. The flower bundling step includes the sub-steps that after the materials are pushed into the prefabricated bag, the material pushing device continues forwards pushing so that the prefabricated bag which contains the materials can penetrate through a flower bundling opening of a flower bundling mechanism and then can be pushed to a to-be-flower-bundled station in front of the flower bundling mechanism, in this moment, the flower bundling mechanism located between a bag-opening station and a flower-bundling station conducts flower bundling on the prefabricated bag containing the materials, and after flower bundling is completed, the prefabricated bag is output from the to-be-flower-bundled station of a centralized-packaging and flower bundling all-in-one machine. According to the centralized-packaging flower bundling technology, a specific design structure is adopted, a flower bundling machine is integrated onto an centralized-packaging machine to form the centralized-packaging flower bundling all-in-one machine and the centralized-packaging flower bundling technology thereof, so that full-automatic packaging of the materials is achieved.

Owner:FOSHAN SOONTRUE MACHINERY EQUIP

Casting forming method and forming system for refractory green brick

InactiveCN103009467BReduce moisture contentSmall amount of deformationCeramic shaping apparatusBrickBand shape

The invention discloses a casting forming method and a forming system for a refractory green brick. The casting forming method comprises the following steps of: casting refractory green brick pug into a continuous forming cavity at a high speed by a casting device to form a band-shaped green body; forming the side face of the band-shaped green body by using a green brick side face forming device; cutting the rough top surface of the band-shaped green body off by shaping; and cutting the band-shaped green body according to the size of a brick support plate to obtain a finished refractory green brick. According to the casting forming method, the water content of a raw material is lower than that of the raw material used in extrusion forming and pouring forming, and is higher than that of the raw material used in die forming, and the method belongs to non-pressure forming. The green body is regular in shape after forming, is free from residual inner stress, and has relatively low water content; in a green body sintering process, the deflection is small, and allowance is reduced during forming of the green body; and after sintering, the cold processing allowance is reduced, the mechanical abrasion and the energy consumption of cold cutting processing are reduced, and full automation of the green body can be realized among procedures of subsequent drying, kiln stacking before sintering, transportation after sintering and cold-cutting processing.

Owner:ANHUI SYNCHRONOUS AUTOMATION TECH

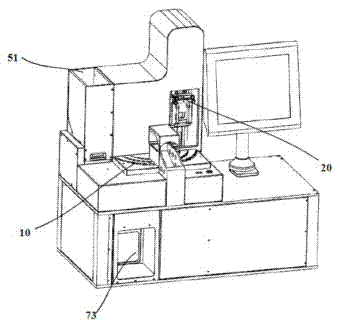

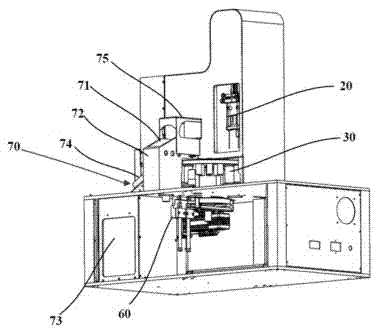

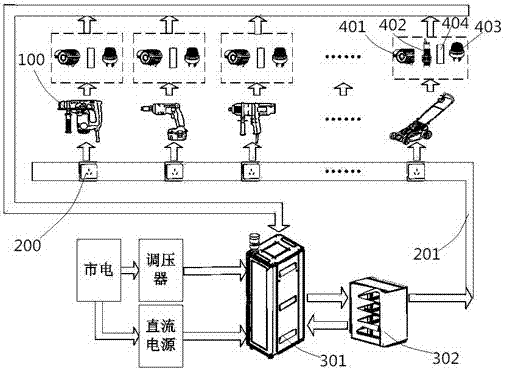

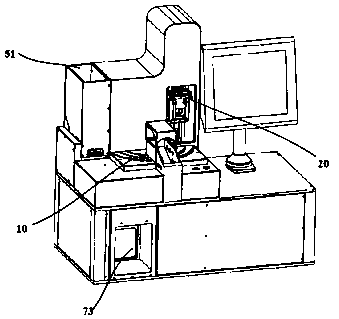

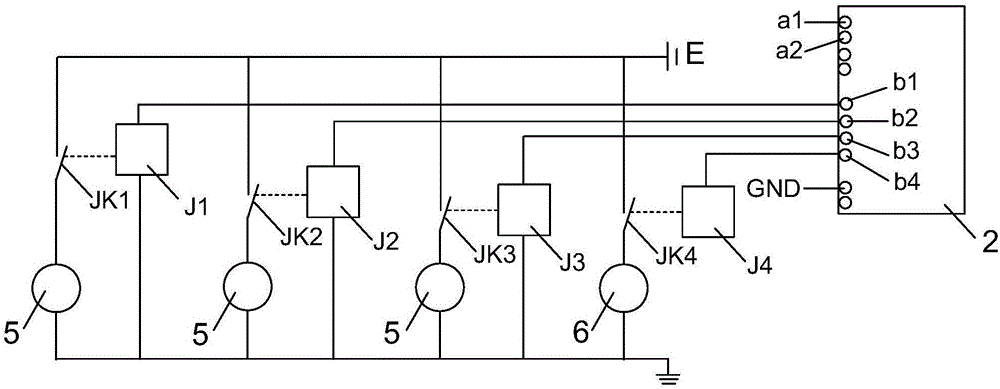

A no-load durability test system for electric tools and garden tools

ActiveCN104569679BNo-load durability test Intelligent safetyRealize remote testingElectrical testingStructural/machines measurementTest efficiencyElectricity

The invention discloses a no-load durability testing system for an electric tool and a gardening tool and belongs to the technical field of automatic monitoring. The no-load durability testing system comprises an industrial personnel computer cabinet, an electrical parameter instrument cabinet, a wiring groove, a sensor and a camera. One end of the industrial personnel computer cabinet is connected with the electrical parameter instrument cabinet, the electrical parameter instrument cabinet is connected with the wiring groove, the other end of the industrial personel computer cabinet is connected with the sensor and the camera, a power source of electric supply is connected with the industrial personnel computer cabinet through a voltage regulator and a direct-current power source. According to the no-load durability testing system, a test can be started by plugging power plugs of the tested tools into a socket of the wiring groove, long-distance testing can be achieved, manual intervention is not needed, and safety is improved; a direct-current testing platform and an alternating-current testing platform are available, each platform can be provided with a plurality of stations, each station corresponds to one tested tool, all the stations are independent from one another, non-interference parallel operation is achieved, and the testing efficiency and the system adaptability are improved. An industrial personnel computer is used for completing control of tests, monitoring of data and safety protection, the whole process is automatic, and the no-load durability testing system for the electric tool and the gardening tool is intelligent and safe.

Owner:JIANGSU UNIV

Centralized-packaging and flower bundling technology

ActiveCN107054772ARealize seamless dockingFull automationWrapper twisting/gatheringEngineeringPackaging machine

The invention provides a centralized-packaging and flower bundling technology. The centralized-packaging and bundling technology comprises the steps of material packaging and flower bundling. The material packaging step comprises the sub-steps of feeding of a centralized-packaging mechanism material feeding device, bag sending of a bag sending device, bag opening of a bag-opening device, bag expanding of a bag expanding device and pushing of materials into an expanded prefabricated bag by a material pushing device. The flower bundling step includes the sub-steps that after the materials are pushed into the prefabricated bag, the material pushing device continues forwards pushing so that the prefabricated bag which contains the materials can penetrate through a flower bundling opening of a flower bundling mechanism and then can be pushed to a to-be-flower-bundled station in front of the flower bundling mechanism, in this moment, the flower bundling mechanism located between a bag-opening station and a flower-bundling station conducts flower bundling on the prefabricated bag containing the materials, and after flower bundling is completed, the prefabricated bag is output from the to-be-flower-bundled station of a centralized-packaging and flower bundling all-in-one machine. According to the centralized-packaging flower bundling technology, a specific design structure is adopted, a flower bundling machine is integrated onto an centralized-packaging machine to form the centralized-packaging flower bundling all-in-one machine and the centralized-packaging flower bundling technology thereof, so that full-automatic packaging of the materials is achieved.

Owner:FOSHAN SOONTRUE MACHINERY EQUIP

High-speed punching machine for punching spring pads

The invention discloses a high-speed blanking machine for blanking spring pads. The high-speed blanking machine comprises a machine frame. A tool apron and a transmission device are mounted on the machine frame. The tool apron moves up and down on the machine frame through the transmission device. A cutter is arranged on the tool apron. The high-speed blanking machine is characterized in that a stop block is arranged below the cutter, and the tool apron is hinged to a first connecting rod which is hinged to a second connecting rod; a fixing seat is arranged on the machine frame and provided with a movable guiding rod and a movable worm, and the guiding rod and the worm are connected through a connecting block and then move together; the other end of the first connecting rod is hinged to the guiding rod, and the other end of the second connecting rod is hinged to the fixing seat; and a conveying frame is arranged on the machine frame and provided with a plurality of feeding wheel sets, each feeding wheel set comprises a driven wheel and a pressing wheel, a worm gear is arranged on a wheel shaft of each driven wheel and engaged with the worm, and the worm is in transmission connection with the transmission device. By adoption of the technical scheme, metal wires can be blanked at a high speed, the whole course is automatic, and the structure is simple.

Owner:瑞安市旭东冲压机械厂

Flavor and fragrance injector

ActiveCN107149162BImprove injection efficiencyFull automationCigarette manufactureEngineeringFood flavor

The invention provides an essence and perfume injector. The essence and perfume injector comprises: at least one cigarette accommodating device, wherein every cigarette accommodating device limits one or more cigarette accommodating cavities; a station device provided with the at least one cigarette accommodating device to carry the at least one accommodating device to an injection station from a cigarette inserting station; a cigarette feeding device used for making cigarettes enter all the cigarette accommodating cavities of every cigarette accommodating device when every cigarette accommodating device is positioned in the cigarette inserting device; and an injection device used for making an essence and / or a perfume enter the cigarettes in every cigarette accommodating cavities of the cigarette accommodating device when every cigarette accommodating device is positioned in the injection station. The essence and perfume injector allows the cigarettes to be automatically inserted to the cigarette accommodating cavities of the cigarette accommodating device through the cigarette feeding device and then essence and perfume injection to be carried out, so full automation is realized, and the essence and perfume injection efficiency is increased.

Owner:BEIJING HUIRONGHE TECH

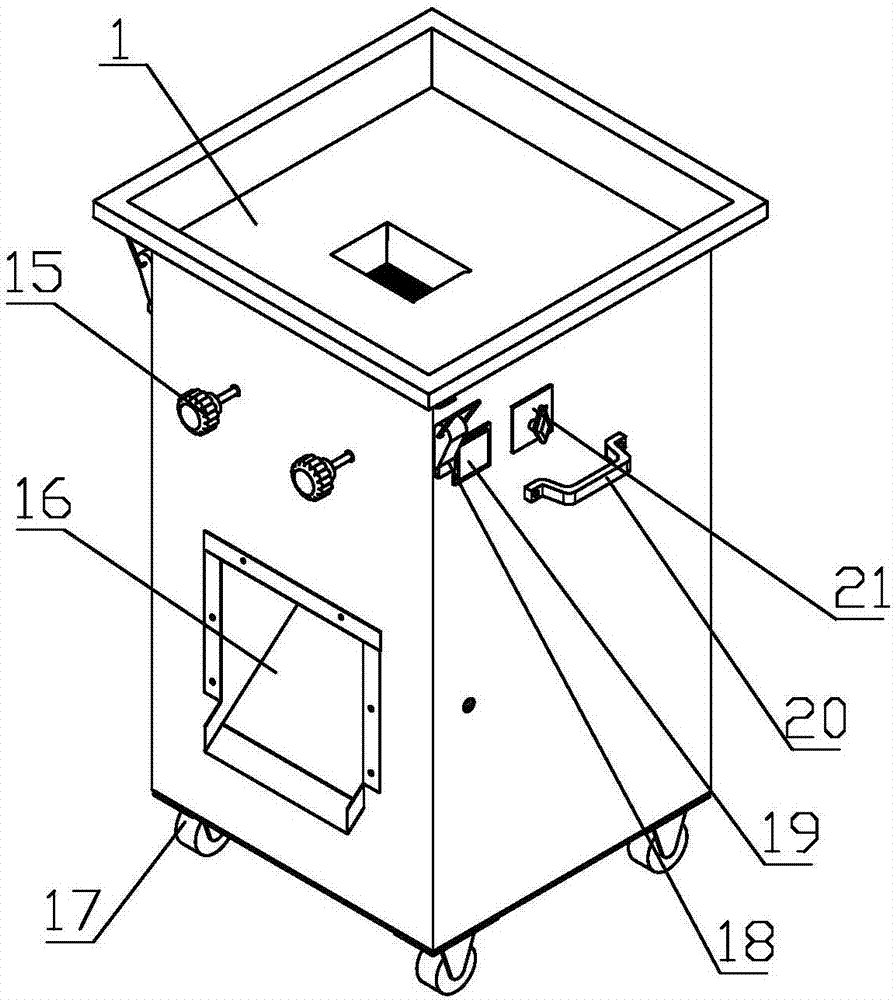

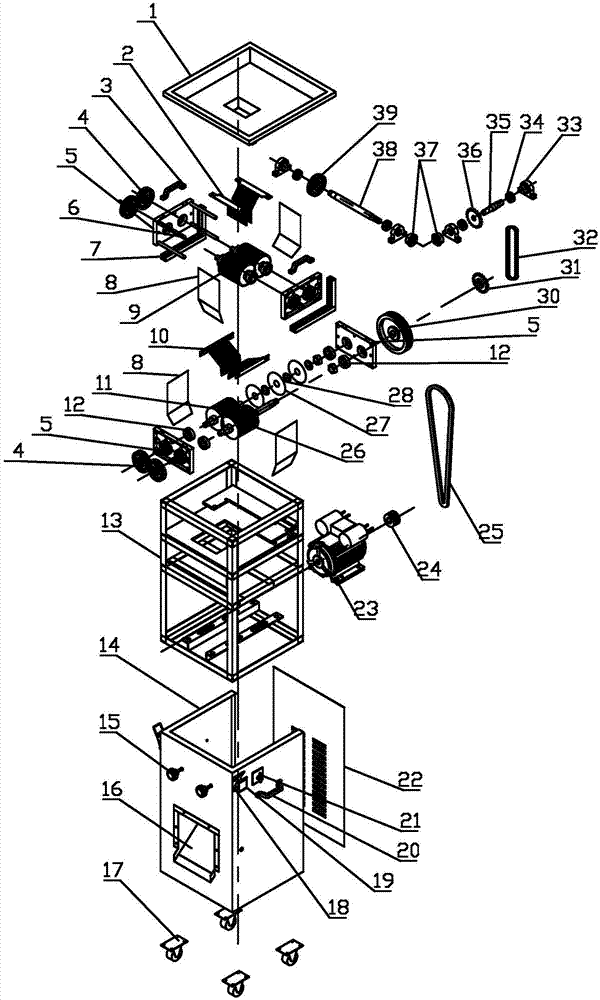

An automatic sub-mesh grinding and collecting device for raw ore and its application method

ActiveCN110124821BAutomatic collectionSolve the situation that only a single specified mesh can be ground at a timeDirt cleaningGrain treatmentsMining engineeringElectric machinery

The invention discloses an automatic mesh grinding and collecting device of raw ore. The device comprises a box body, dust collectors fixedly connected with the ground are arranged at the front side,the rear side and the rear side of the box body, motors I which are fixedly connected with the ground are arranged at the front end and the rear end of the right side of the box body. The device andthe method have the beneficial effects that the structure is simple, the operation is simple and convenient, a crushing step is directly skipped for grinding, the cost is saved, can be used for carrying out multi-mesh grinding on the raw ore at one step, raw ore powder can be automatically collected in the grinding process, so that the condition that the raw ore can only grind a single specified mesh in the prior art is solved, the conditions of repeated feeding and discharging and changing grinding tools with different meshes are avoided, the whole process is automatic, simple, efficient, convenient and fast are achieved.

Owner:池州灵芝化建材料科技有限公司

a shredded meat machine

The invention discloses a shredded meat machine comprising a rack; a front box is installed at the outer peripheral surface of the rack; a rear box is installed at the rear side of the rack; the rear box is connected with the front box; the front box is provided with a discharge port; the rack is provided with a baffle plate which is installed above the discharge port; the lateral wall of the front box is provided with a power switch and a reversible switch; the rack is provided with a motor; an end part of the rack is provided with a meat basin; the front part of the motor is provided with a first belt pulley; the rack is provided with a second slicing knife set, a third slicing knife set and a first slicing knife set; the second slicing knife set and the third slicing knife set are arranged in parallel arrangement; the first slicing knife set is installed above the second slicing knife set and the third slicing knife set; the rack is provided with two sets of side plates; the second slicing knife set, the third slicing knife set and the first slicing knife set are installed among the side plates; the rack is provided with a first knife comb and a second knife comb. The shredded meat machine facilitates sliced meat to be cut into shredded meat and then shredded meat is discharged from the discharge port; the whole process is automatic, simple and convenient.

Owner:ZHENGJIANG SHARK FOOD MASCH CO LTD

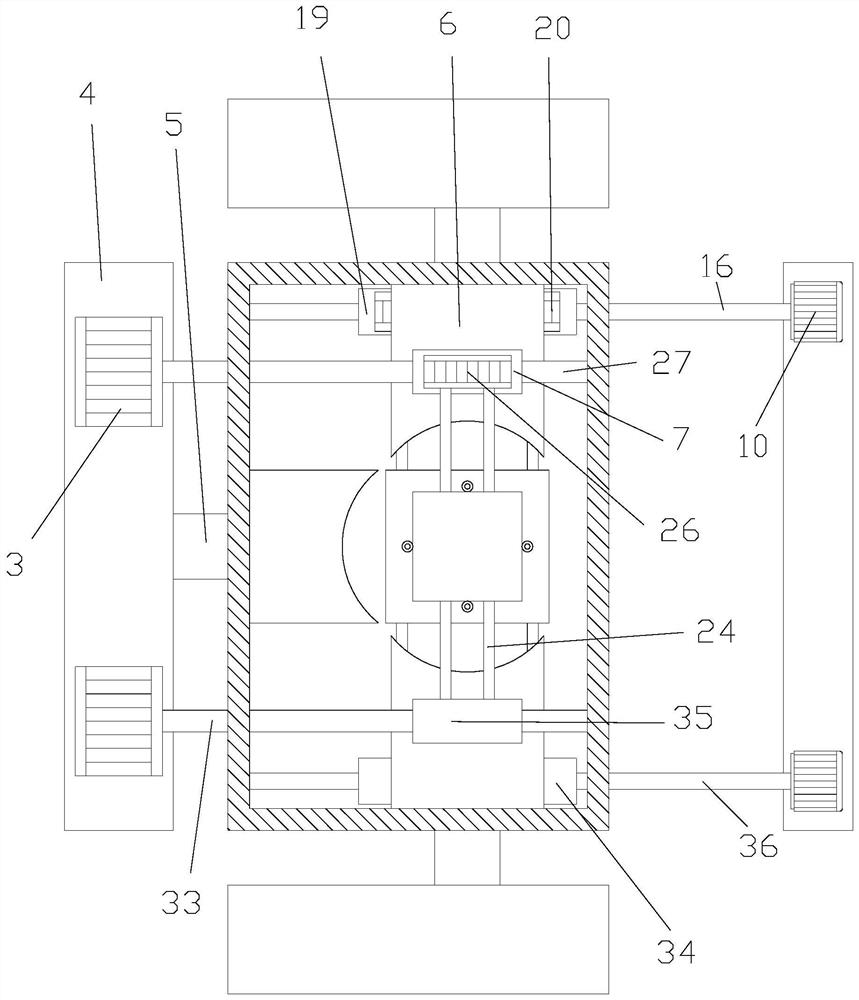

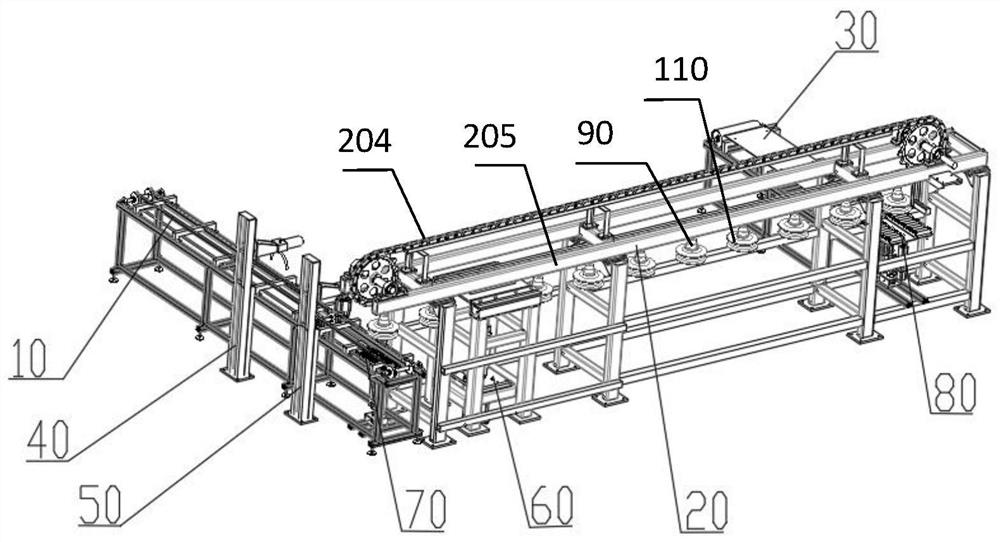

Tension test equipment for disc-shaped suspension type porcelain insulator

PendingCN112098218AImprove test accuracyReduced pull requirementsMaterial strength using tensile/compressive forcesPull forceEngineering

The invention relates to tension test equipment for a disc-shaped suspension type porcelain insulator. The equipment comprises a left rack, a middle rack and a right rack, the middle rack comprises achain which is arranged on the middle rack and moves in the circumferential direction, a pull rod for the chain to penetrate through, a plurality of hooks which are evenly arranged on the chain deviceat intervals, a hydraulic stretching device which is close to the left rack and used for stretching an insulator, and a jacking inclination device which is adjacent to the right rack and located on the same horizontal line with the right rack. The left rack comprises a first conveying device arranged on the left rack and used for conveying an insulator, a high-pressure water spraying device usedfor cleaning the insulator, a positioning device located on one side of the high-pressure water spraying device and used for rotationally positioning the insulator, and a jacking and throwing-in device arranged on the left rack and located below the end of the pull rod. The tension test equipment can test the tension of the insulators one by one, has low requirements on the tension of the equipment, is high in test precision, is automatic in the whole process, saves manpower and improves the test efficiency.

Owner:SINOMA JIANGXI ELECTRICAL PORCELAIN ELECTRIC CO LTD

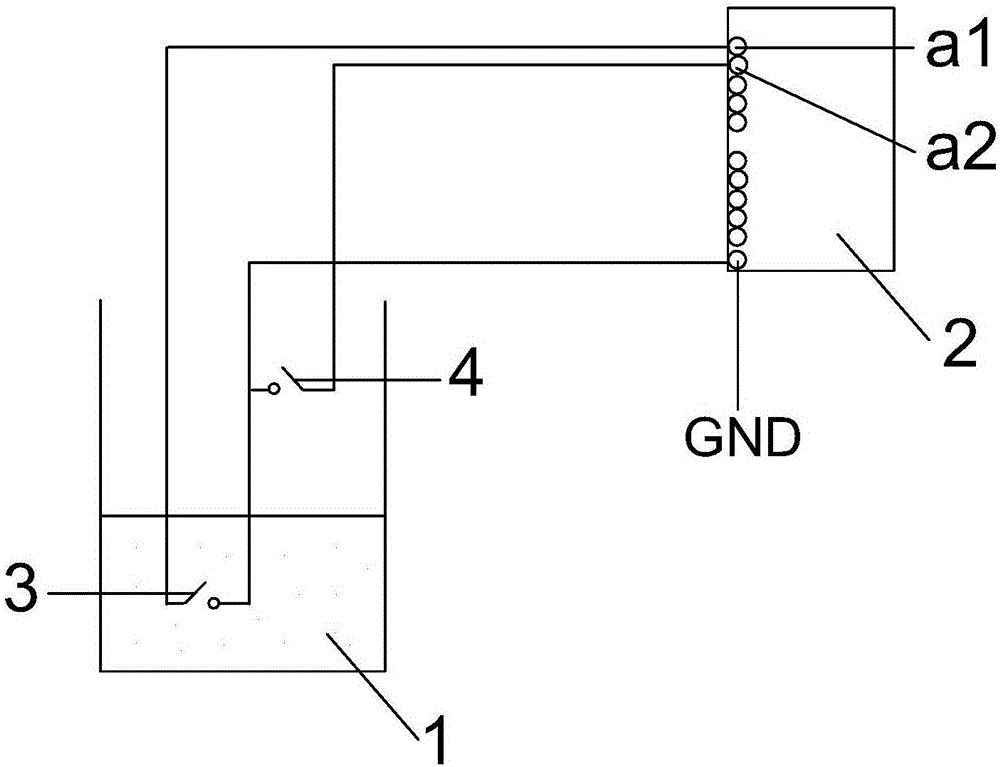

Intelligent water suction control device for water towers

InactiveCN106193196AConvenient lifeRealize pumping automationWater supply tanksPumping plantsLower limitElectricity

The invention relates to an intelligent water suction control device for a plurality of water towers. The intelligent water suction control device comprises a processor, a plurality of water level sensing electrodes and a water suction control circuit, wherein the water level sensing circuits are respectively used for sensing the water levels of the water towers; each water level sensing circuit comprises a low water level switch and a high water level switch; the water suction control circuit comprises a plurality of first relays, second relays, electromagnetic valves and a water suction machine, and the number of electromagnetic valves is the same with the number of first relays; each first relay is provided with a first normally-open contact, and each second relay is provided with a second normally-open contact. When the water level in each water tower is lower than the setting lower limit threshold value, each water suction machine is energized to work; when the water level in each water tower is higher than the setting lower limit threshold value, each water suction machine is deenergized. The intelligent water suction control device for the water towers has the advantages that the processor is used for detecting the high and low water level switches of the water towers, and controlling the connection and disconnection of electromagnetic valves and the opening and closing of water suction machines; the automatic water suction of multiple water towers is realized, and the convenience is brought for the life of people.

Owner:玉林市民族中学

Spinning roller cart for spinning workshop

InactiveCN113911192AReduce the need for manual operationAvoid damageHand carts with multiple axesHand cart accessoriesPhysicsCart

The invention discloses a spinning roller cart for a spinning workshop, and relates to the technical field of spinning equipment. The spinning roller cart for a spinning workshop comprises a base, a roller installing device, a roller arranging device and a roller receiving device, the roller arranging device is fixedly installed on the upper surface of the base, and the roller installing device is fixedly connected to the right side of the roller arranging device. According to the spinning roller cart for a spinning workshop, the roller installing device is arranged, due to the fact that an opening of a flaring channel is large, an operator does not need to adjust the direction of a spinning roller manually and only needs to throw away the spinning roller with hands, many manual operation requirements are reduced, due to the effect of a pressure reduction plate in a flaring channel, the middle of the flaring channel can be narrowed, when the two ends of the spinning roller make contact with the two pressure reduction plates, the two sides of the spinning roller should be too narrow, and the drooping speed of the spinning roller is temporarily reduced, so that the situation that the rollers collide with one another due to too high downward pressing speed and are damaged is prevented, and the rollers can be sequentially arranged in the flaring channel.

Owner:尹希阳

Circuit board double-sided inkjet printing all-in-one machine and method

ActiveCN112918129BExpand production scaleFull automationDuplicating/marking methodsTypewritersMechanical engineeringIndustrial engineering

The present invention relates to the technical field of inkjet printing of circuit boards, in particular to a double-sided inkjet printing machine for circuit boards, which includes a printing body and a sheet material conveying mechanism assembly. The printing body includes a first printing part, a printing dolly and the second printing section, the printing dolly is located between the first printing section and the second printing section, the first printing section transports the circuit board to the printing trolley, and the printing trolley After inkjet printing is performed on the first side of the circuit board, the sheet material conveying mechanism assembly moves the circuit board at the first printing section to the second printing section and turns the circuit board over during the transfer process. The first surface of the circuit board is located on the second printing section, and the second printing section transports the circuit board to the printing trolley, and the inkjet printing is performed on the second surface of the circuit board by the printing trolley. The present invention also relates to a method for double-sided jet printing of a circuit board, which adopts the above-mentioned integrated machine for double-sided jet printing of a circuit board.

Owner:선전진신테크놀로지컴퍼니리미티드

Designing method of full-automatic electric baking pan

The invention discloses a designing method of a full-automatic electric baking pan. The designing method aims to settle a problem of incapability of directly making a pancake from raw material for making the pancake in an existing electric baking pan. The designing method comprises the following steps of forming an accommodating chamber by an upper pan and a lower pan, wherein the accommodating chamber is cake-shaped, and finishing dough kneading, dough forming and dough poking in the accommodating chamber; providing a mixing part which is rotatably arranged in the accommodating chamber that is formed by the upper pan and the lower pan, wherein the mixing part is used for finishing dough kneading together with the accommodating chamber; and providing a motor which is transmissibly connected with the mixing part. According to the electric baking pan which is designed according to the designing method can obtain the pan cake just through directly placing the raw materials such as powder and water for forming the dough into the accommodating chamber and performing energization for starting.

Owner:杨建甫

Wood floor coloring device

The invention discloses a wood floor coloring device. The wood floor coloring device structurally comprises a controller,mode adjusting buttons,a transporting and coloring device,a roller,an operatingplatform,a control box,a dyestuff chamber,a water drawing pipe and a water drawing motor. The transporting and coloring device is provided with a uniform speed transporting mechanism,a hot air dryingdevice,a fixed driving device,a dyestuff coloring device,a push triggering device,a mechanical transmission device,a dyestuff recovery device and a metal frame. The wood floor coloring device has theadvantages that by means of the added transporting and coloring device,wood floors pass the coloring device through a transporting conveying belt,a material drawing pump in a paint tank draws paint,the paint enters a coloring roller through a paint conveying pipe,the paint dyes the wood floors through material through holes in the surface of the coloring roller,the paint on the wood floors is uniformly brushed,the excessive paint permeates into the paint tank,resources are saved,the dyed wood floors are conveyed into the drying box to be surface-dried,the whole process is automatic,and the working efficiency is high.

Owner:湖州友星木业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com