Centralized-packaging and flower bundling technology

A kind of craft and flower-tied technology, which is applied in the direction of packaging, transportation packaging, transportation and packaging, etc., can solve the problems of reducing the occupied area and large occupied area, and achieve the effect of high transportation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

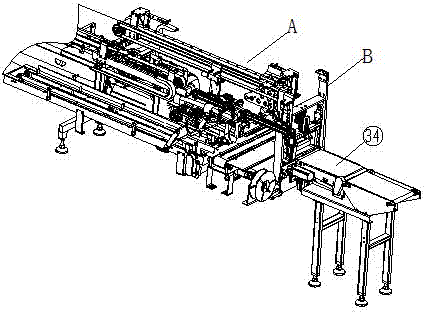

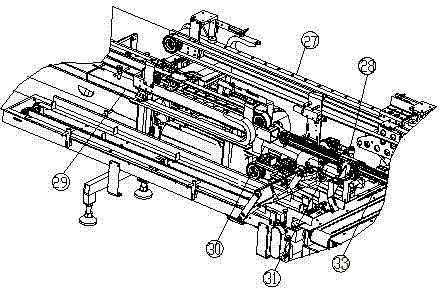

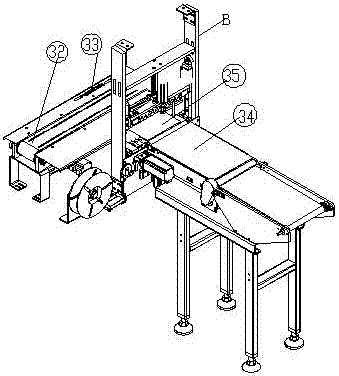

[0041] Figure 1, figure 2 , image 3 As shown, the process of wrapping flowers in the middle pack includes the material packaging step and the flower binding step;

[0042] The material packaging includes the feeding device 29 of the middle bag mechanism A, the bag feeding device 32 feeds the bag, the bag opening device 28 opens the bag, the bag opening device 31 bags and the pushing device 27 push the material to the prefabricated bag opening device 31. In the bag; the material packaging process is: the feeding device 29 of the middle bag mechanism A conveys the material to the station 30 to be pushed; while the feeding device 29 is in motion, the bag feeding device 32 of the middle bag mechanism A conveys the prefabricated bag to the opening At the bag station 33, the bag opening device 28 of the middle bag mechanism A opens the sack of the prefabricated bag. At this time, the bag opening device 31 of the middle bag mechanism stretches into the prefabricated bag opened by ...

Embodiment 2

[0047] In order to implement the present invention better, this embodiment provides a kind of flower-tie mechanism on the basis of Embodiment 1:

[0048] Such as Figure 4 , 5 , 6, 7 and 8, the described tie flower mechanism includes a support 26, a wire feeding device for wire feeding, a mouth tie device 3, a push plate 9, an upper device for folding flowers, a lower device for folding flowers, a The thread cutting device 5, the folding driving device for driving the folding upper device and the folding lower device for folding flowers, the upper driving device 1 for driving the folding upper device to move up and down, and the lower driving device 101 for driving the folding lower device to move up and down; The two vertical side plates of the support 26 are provided with guide rails 4 for the upper device for folding flowers and the lower device for folding flowers to move up and down along the support, the upper device for folding flowers includes an upper folding flower ...

Embodiment 3

[0052] In this embodiment, on the basis of Embodiment 1 or 2, the transmission device is a guide rod 14, and the guide rod 14 can move up and down relative to the upper flower folding component. In addition, the folded flower driving device in this embodiment includes a synchronous wheel driving device 19, a synchronous wheel 17 and a synchronous belt 15. The flower component is connected or connected with the lower folded flower component.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com