Device of separating upper covers of dies continuously for automatic initiating explosive device assembling production line

An automatic assembly and separation device technology, applied in the direction of transportation, packaging, conveyors, etc., can solve the problems of low degree of automation, aging equipment, increased production costs, etc., and achieve the effect of simple structure and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

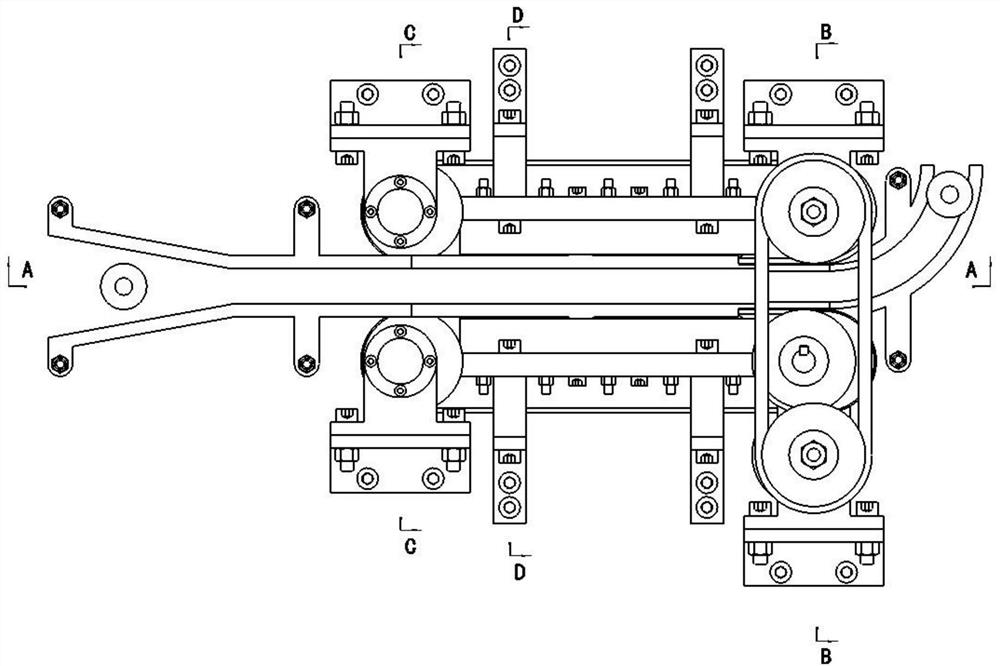

[0013] The mold cover separating device is composed of four parts: guide rail device, front conveying device, belt adjusting device and rear conveying device.

[0014] Rail device:

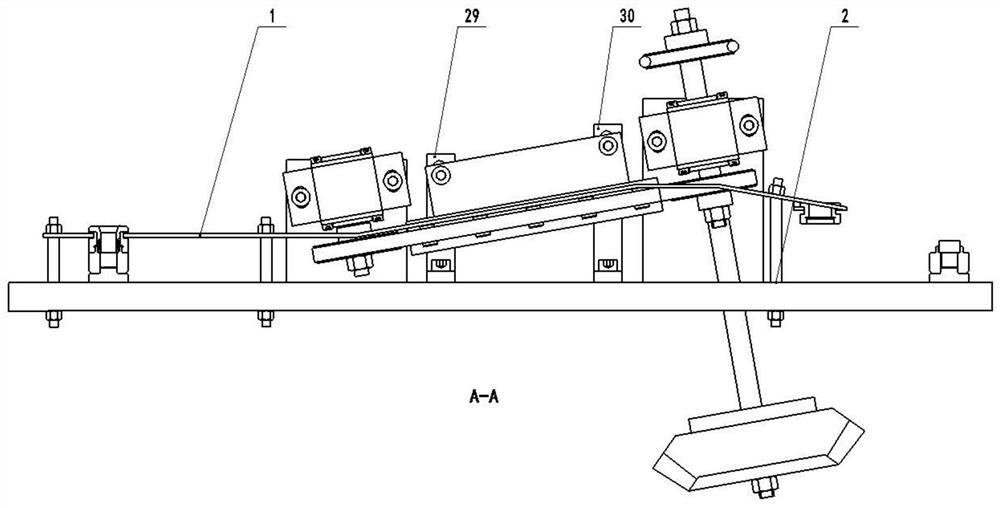

[0015] see figure 2 , the guide rail (1) on the guide rail device is fixed on the conveying platform through two guide rail pillars (2) and six screws, and the six screw rods are adjusted to ensure that the guide rail is parallel to the conveying platform, and the two guide rail pillars are adjusted to make the separated mold The upper cover smoothly enters the return conveying line, and the inclined part of the guide rail maintains an inclination angle of 10 degrees with the platform, so that the mold upper cover and the mold can be conveyed layer by layer.

[0016] Front conveyor:

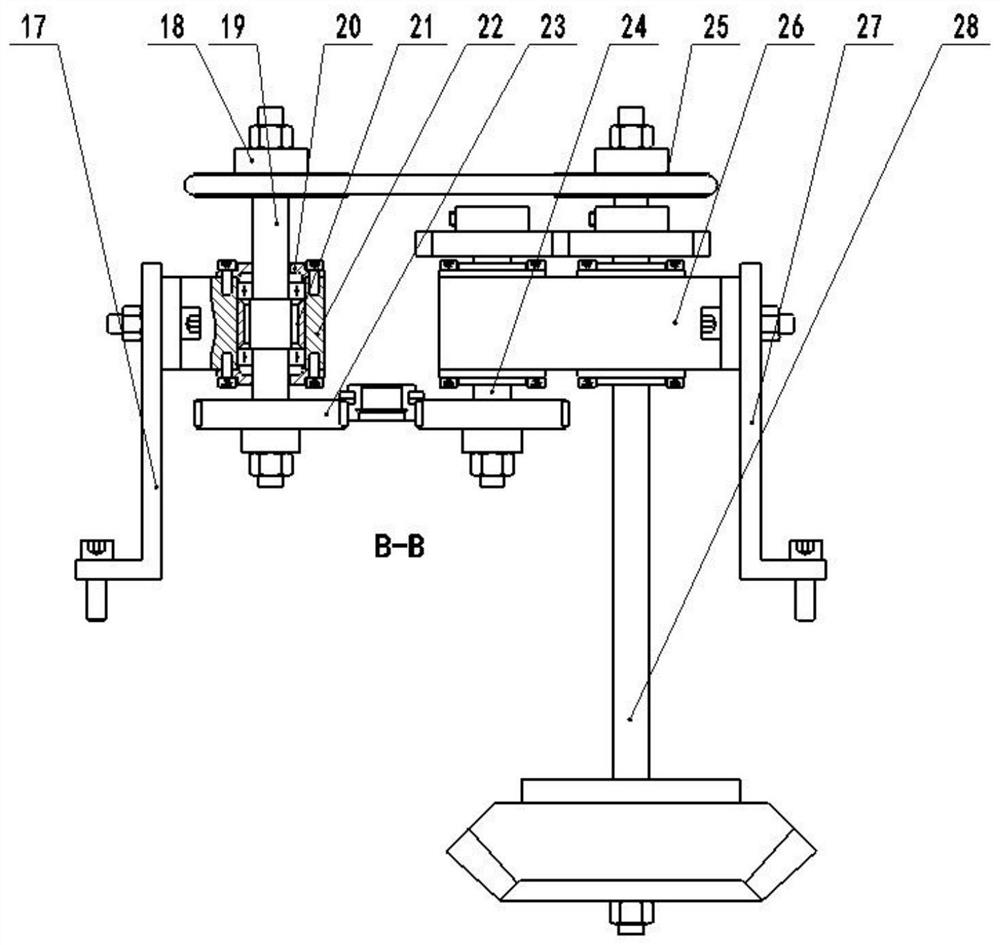

[0017] see image 3 and Figure 4 , the front transmission device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com