A no-load durability test system for electric tools and garden tools

A technology for garden tools and power tools, applied in the field of no-load durability test systems, can solve the problems of inability to meet test requirements, test time and cycle mode cannot be adjusted, power shock safety, etc., to achieve long-distance testing, improve test efficiency and The effect of system adaptability and safety improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

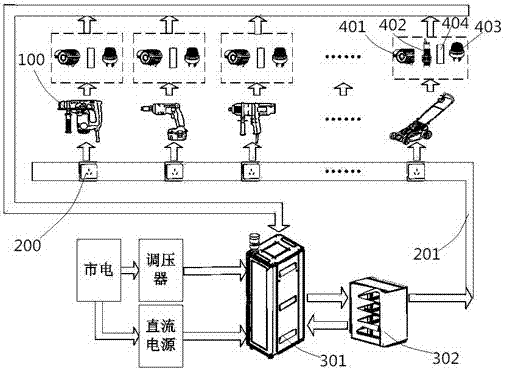

[0028] A no-load durability test system for electric tools and garden tools, including an AC test platform and a DC test platform for testing the tool 100 under test, each test platform is equipped with a number of test stations, and each station can be independently controlled , Test and save data independently without interfering with each other.

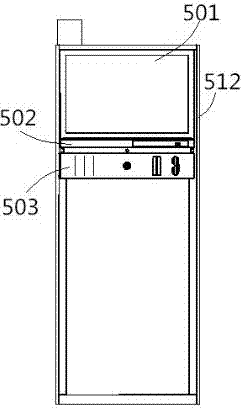

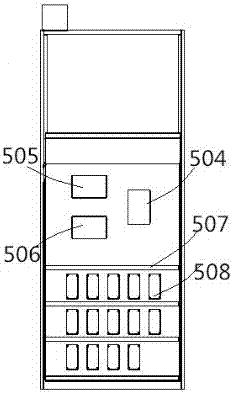

[0029] Such as figure 1 As shown, the no-load durability test system for electric tools and garden tools includes an industrial computer cabinet 301, an electrical parameter instrument cabinet 302, a wiring slot 201, a sensor and a camera 401, wherein one end of the industrial computer cabinet 301 is connected to the electrical parameter instrument cabinet 302 The electrical parameter instrument cabinet 302 is connected to the wiring groove 201; the other end of the industrial computer cabinet 301...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com