Patents

Literature

146results about How to "Change power" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and apparatus for an ambient energy battery or capacitor recharge system

InactiveUS7088031B2Improve the environmentChange powerPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive devicesMassive gravityInfrared

The present invention relates to the field of battery and capacitor charging. In particular, the present invention provides pulsed current charging using changes, regardless of polarity, in the local energy environment to obtain power. The present invention relates, for example, to ambient energy charging thin film batteries, other batteries, or capacitors, via, for example, polyvinyladine fluoride homopolymer (PVDF), PVDF bi-axially poled, or other piezoelectric materials. Ambient energy may be defined as any change in energy within the local environment. Charging can be accomplished with, and is not limited to, positive or negative changes of the following energy types: thermal; visible light, including infrared and ultraviolet; mechanical motion or impact; triboelectric, including airflow or physical contact; movement in relation to a gravitational plane (increase or decrease in gravitational potential energy); and radio frequency (RF) electromagnetic energy, regardless of specific frequency.

Owner:SAPURAST RES

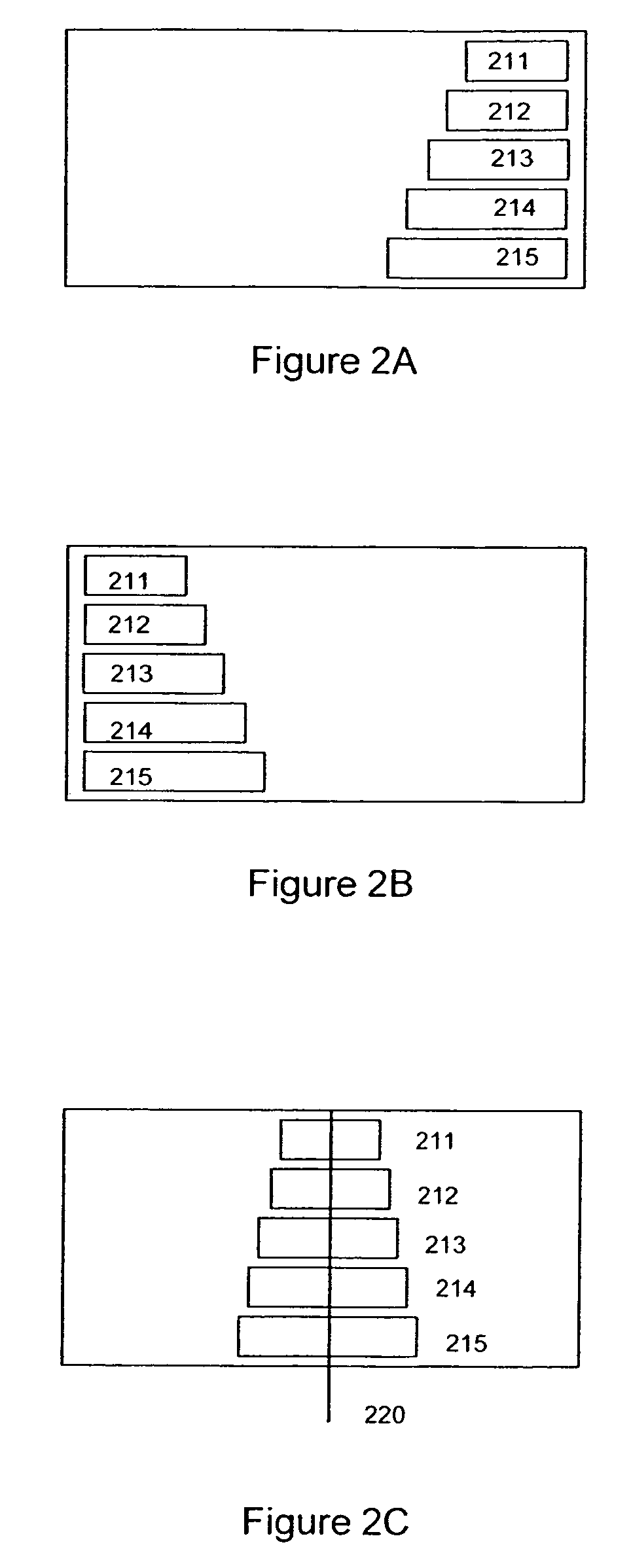

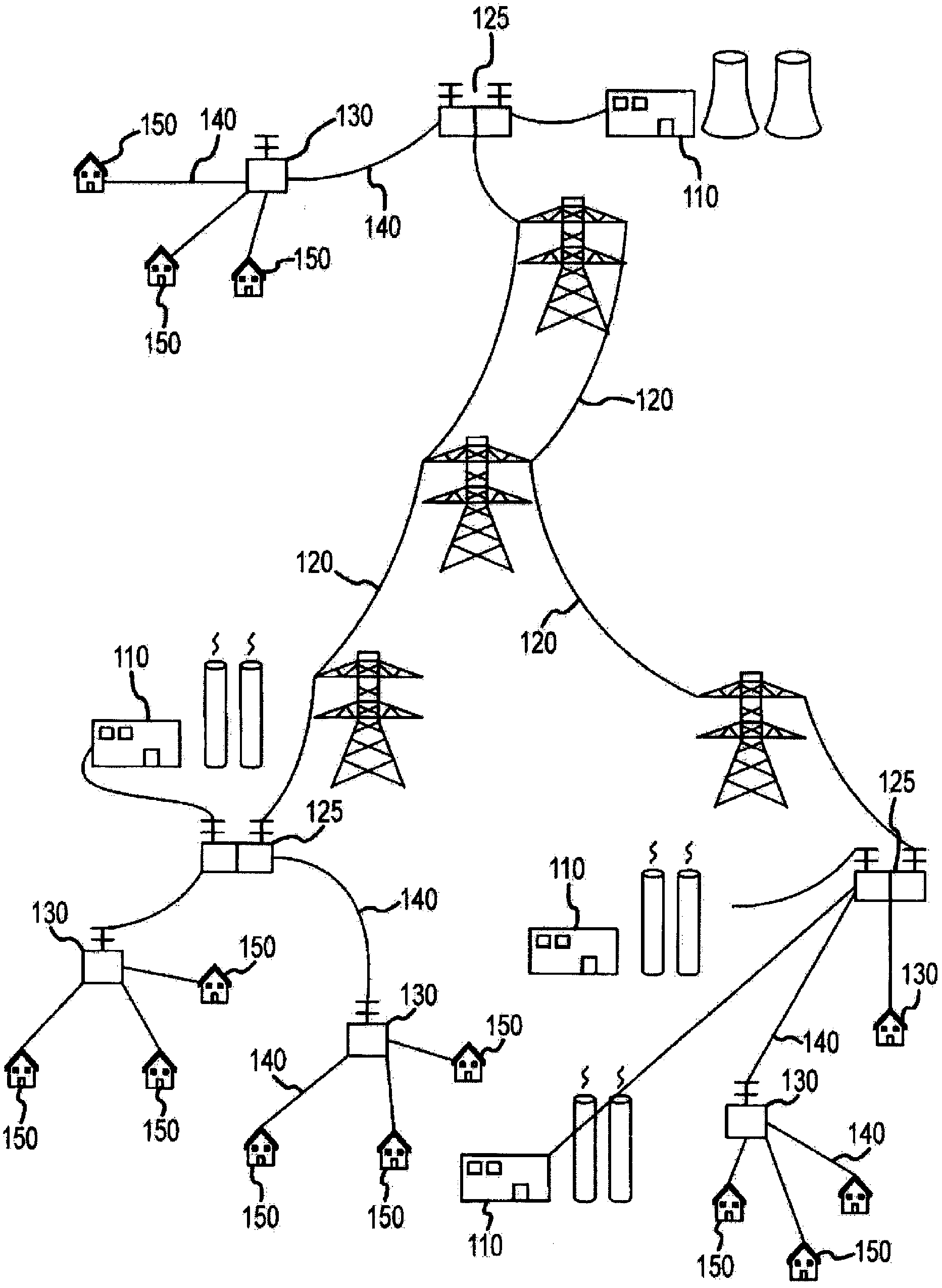

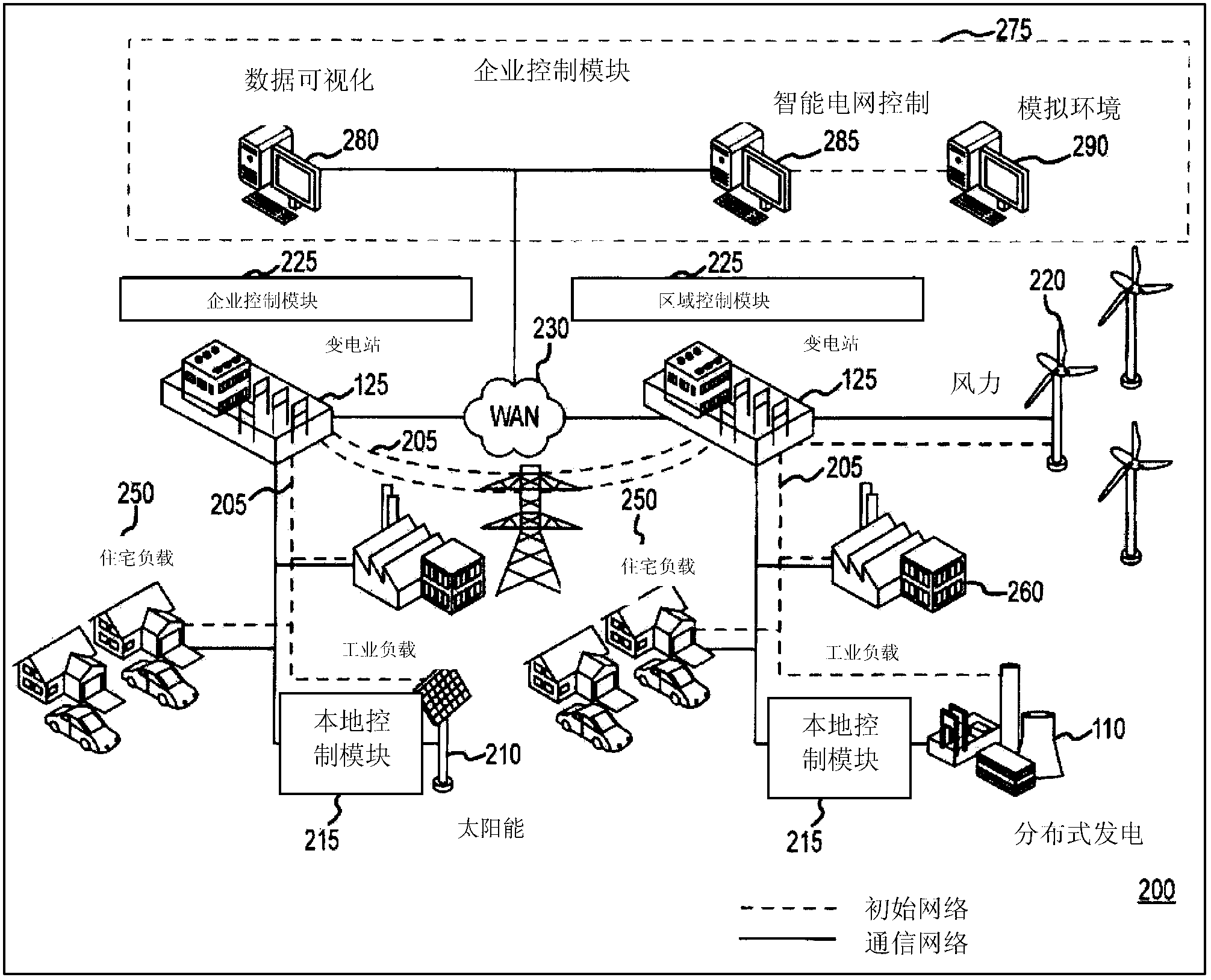

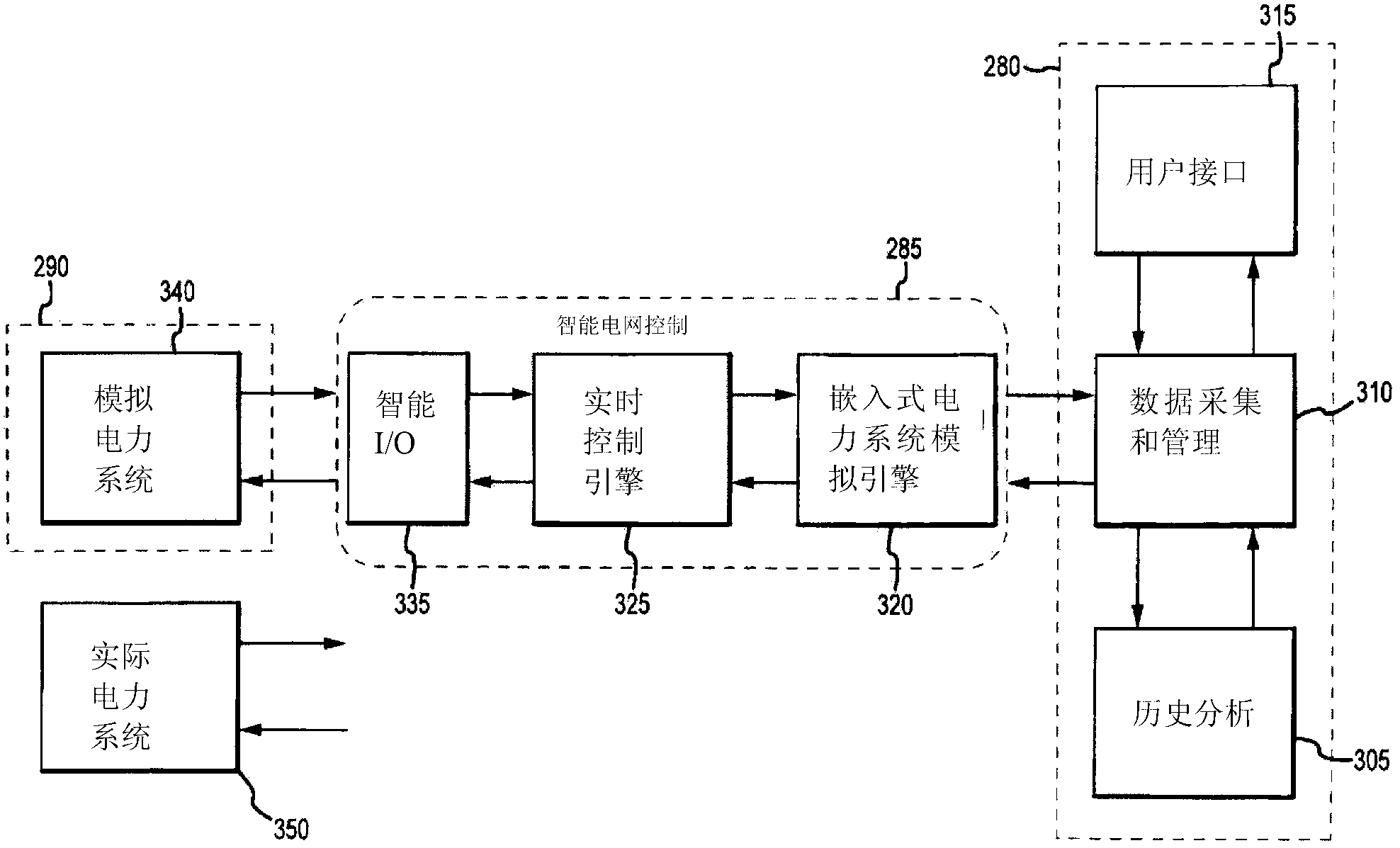

Dynamic distributed power grid control system

ActiveCN102725933ASmooth connectionMaintain stabilityProgramme controlComputer controlPower flowControl system

A system for dynamically managing and controlling distributed energy resources in a transmission / distribution power grid is disclosed. A plurality of regions within a transmission / distribution power grid is autonomously managed using regional control modules. Each regional control module oversees the management and control of the transmission / distribution power grid and is further associated with a plurality of local control modules that interface with distributed energy resources within a region. Power production and power consumption are monitored and analyzed by the enterprise control module which, upon determining that power consumption within a region does not match power producing capability, dynamically reallocates distributed energy resources throughout the grid keeping the system balance.; Power flow at key nodes within the network are monitored and analyzed by the local control modules, regional control modules, and enterprise control modules with compensating actions taken in the event that system parameter risks violating safety, stability, or operational thresholds.

Owner:SPIRAE

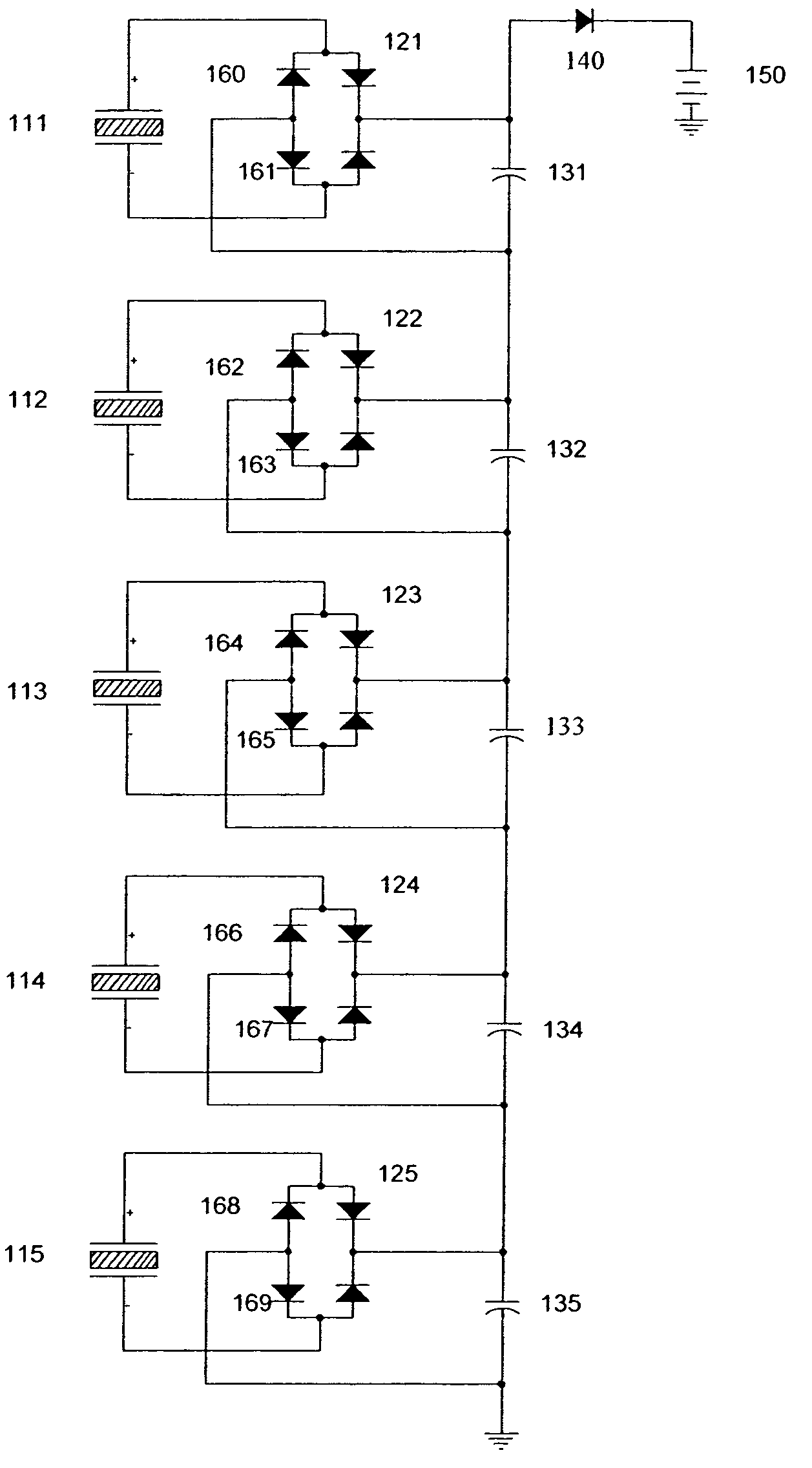

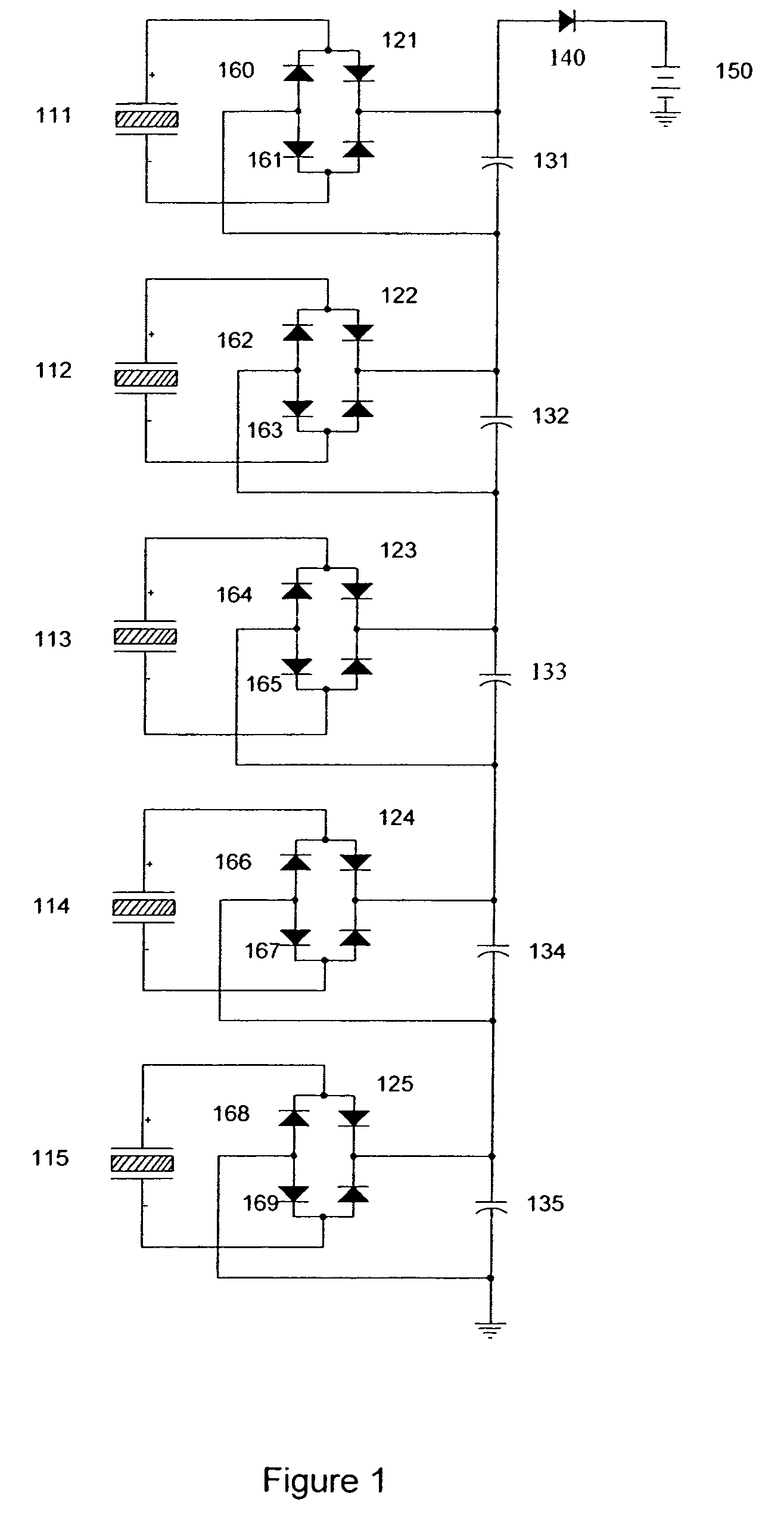

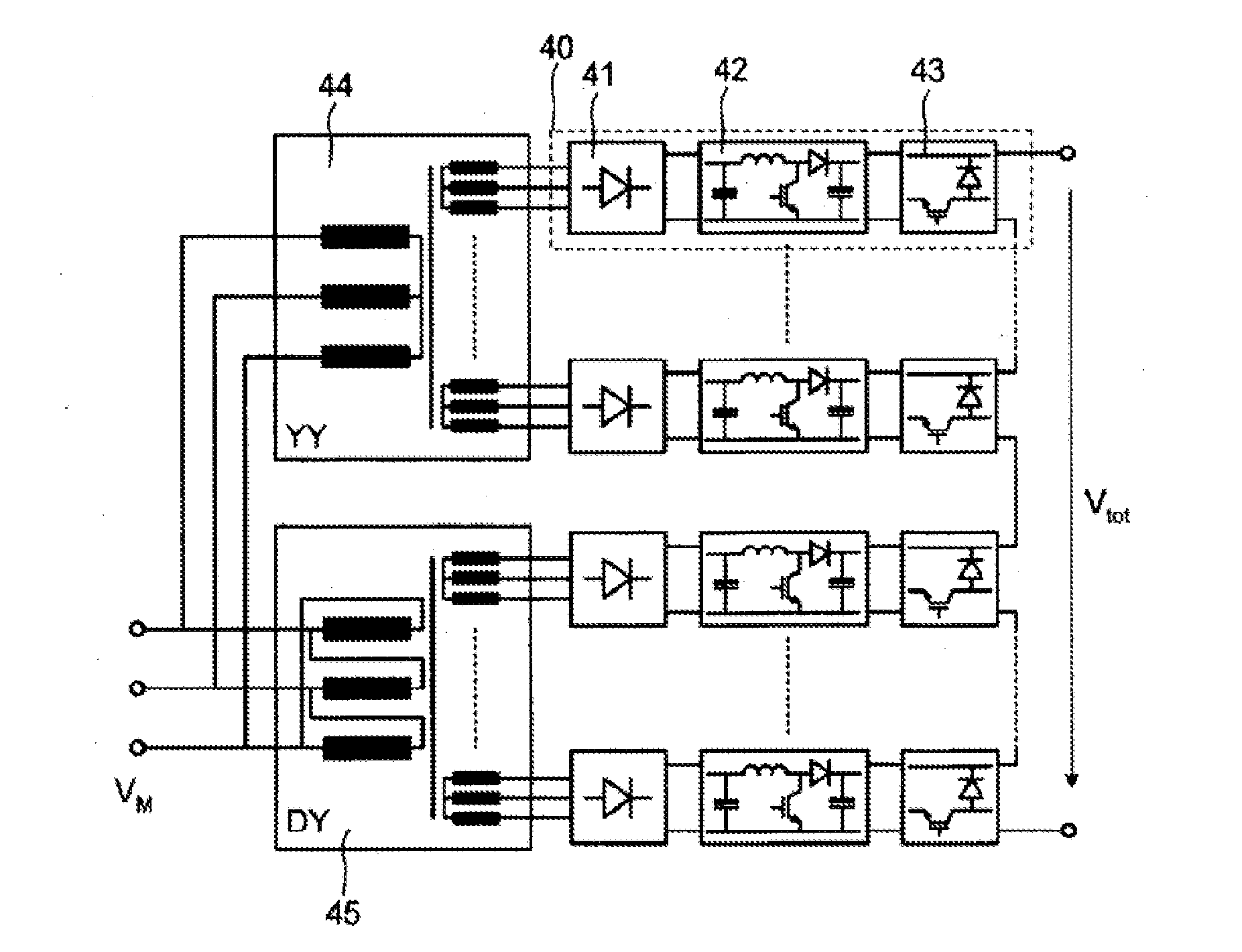

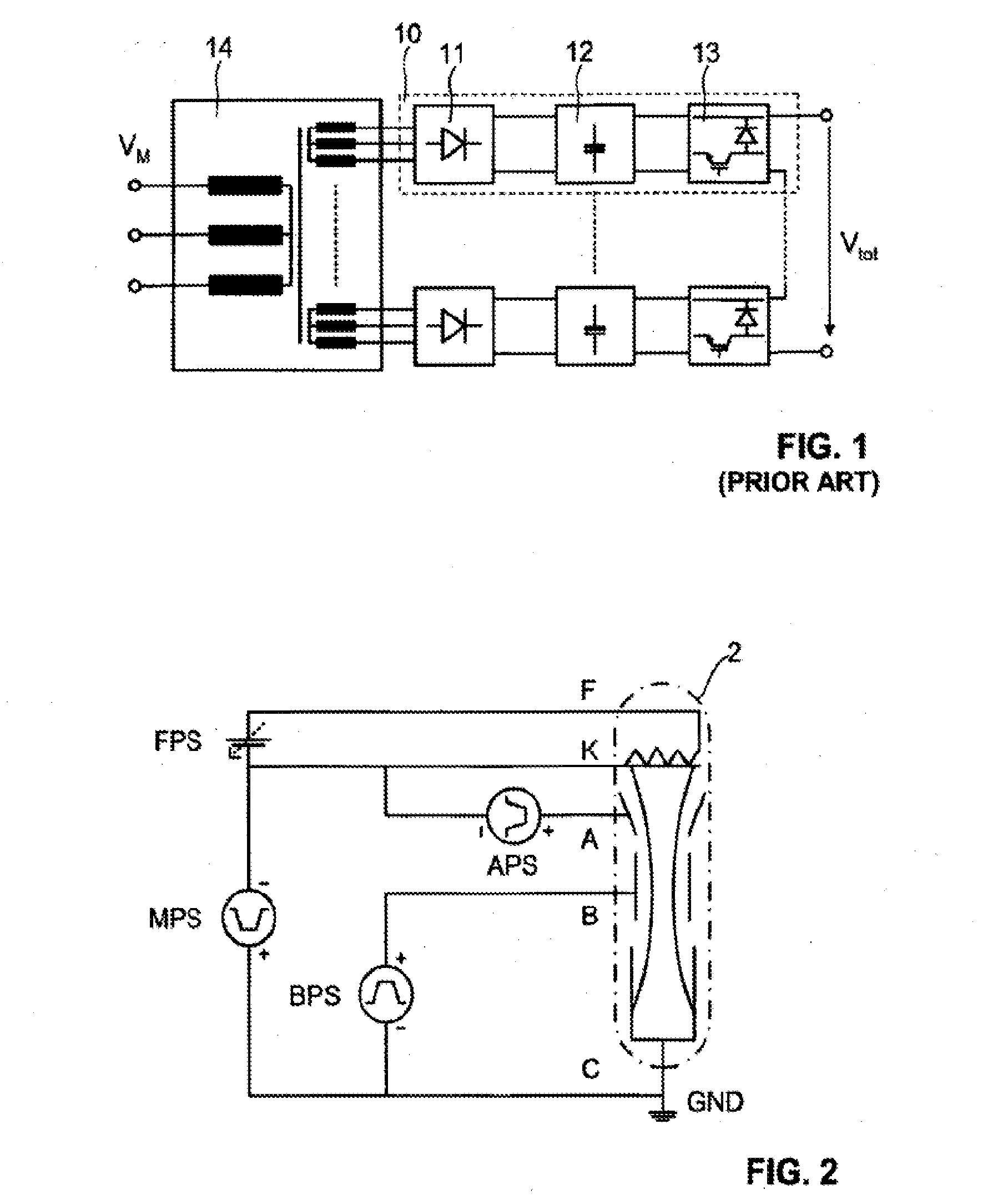

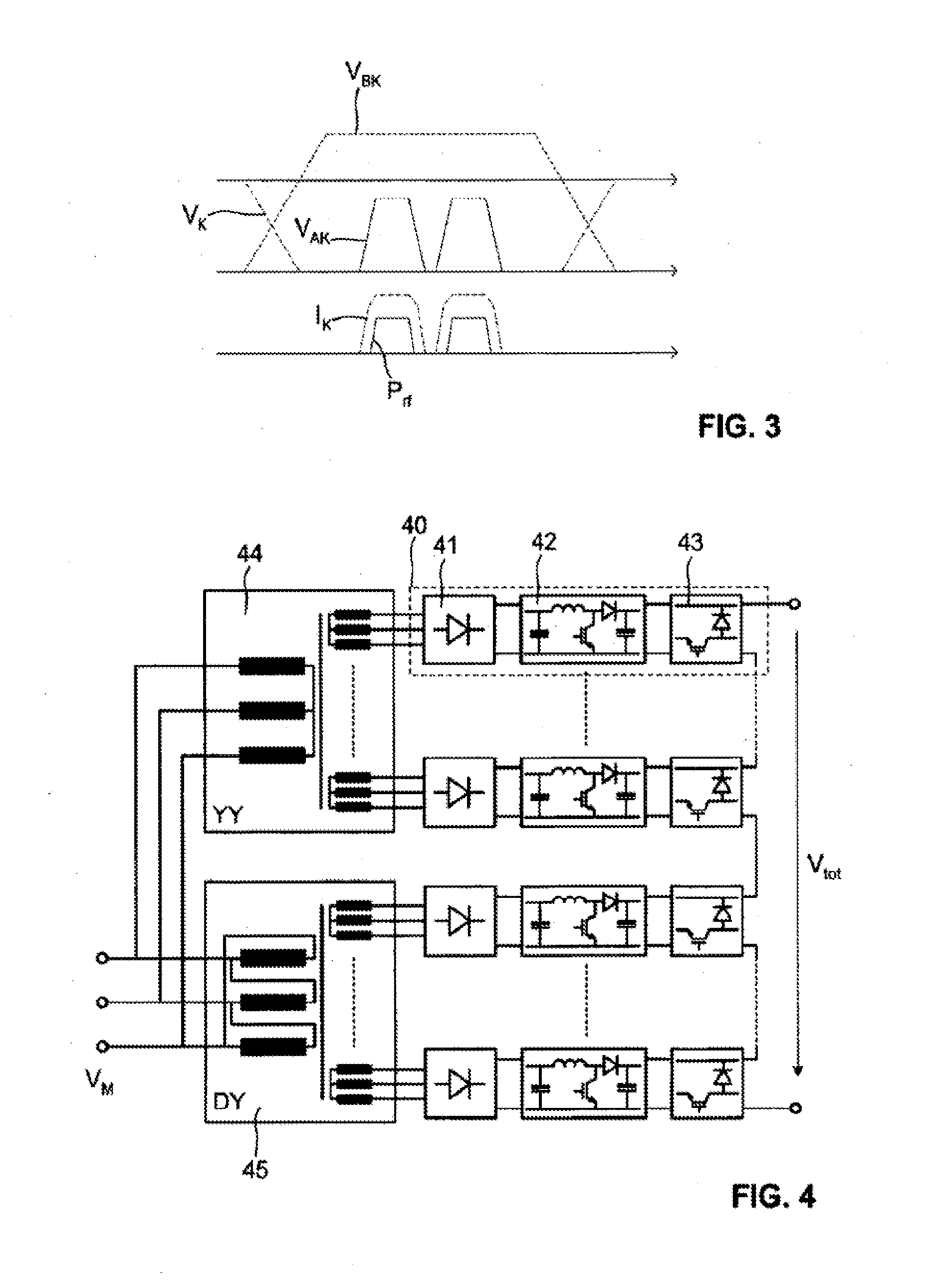

Stabilized high-voltage power supply

ActiveUS20140097747A1Stable output voltageLow voltage rippleElectric signal transmission systemsThree-or-more-wire dc circuitsDc dc converterDc link voltage

A stabilized high-voltage power supply is disclosed, having a general setup similar to a pulse-step modulator. The power supply comprises a plurality of DC power modules (40) having their outputs connected in a series configuration. Each power module comprises a DC voltage source (41), a DC-DC converter (42), and an output switching circuit (43). The total output voltage of the power supply is regulated by regulating the DC link voltage at the output of each power module. This is achieved by an appropriate feedback control circuit driving the DC-DC converter of each power module. In this manlier, low output ripple and a rapid response to changes in output current can be achieved. The power supply may be used, e.g., as the cathode power supply of a gyrotron.

Owner:AMPEGON POWER ELECTRONICS AG

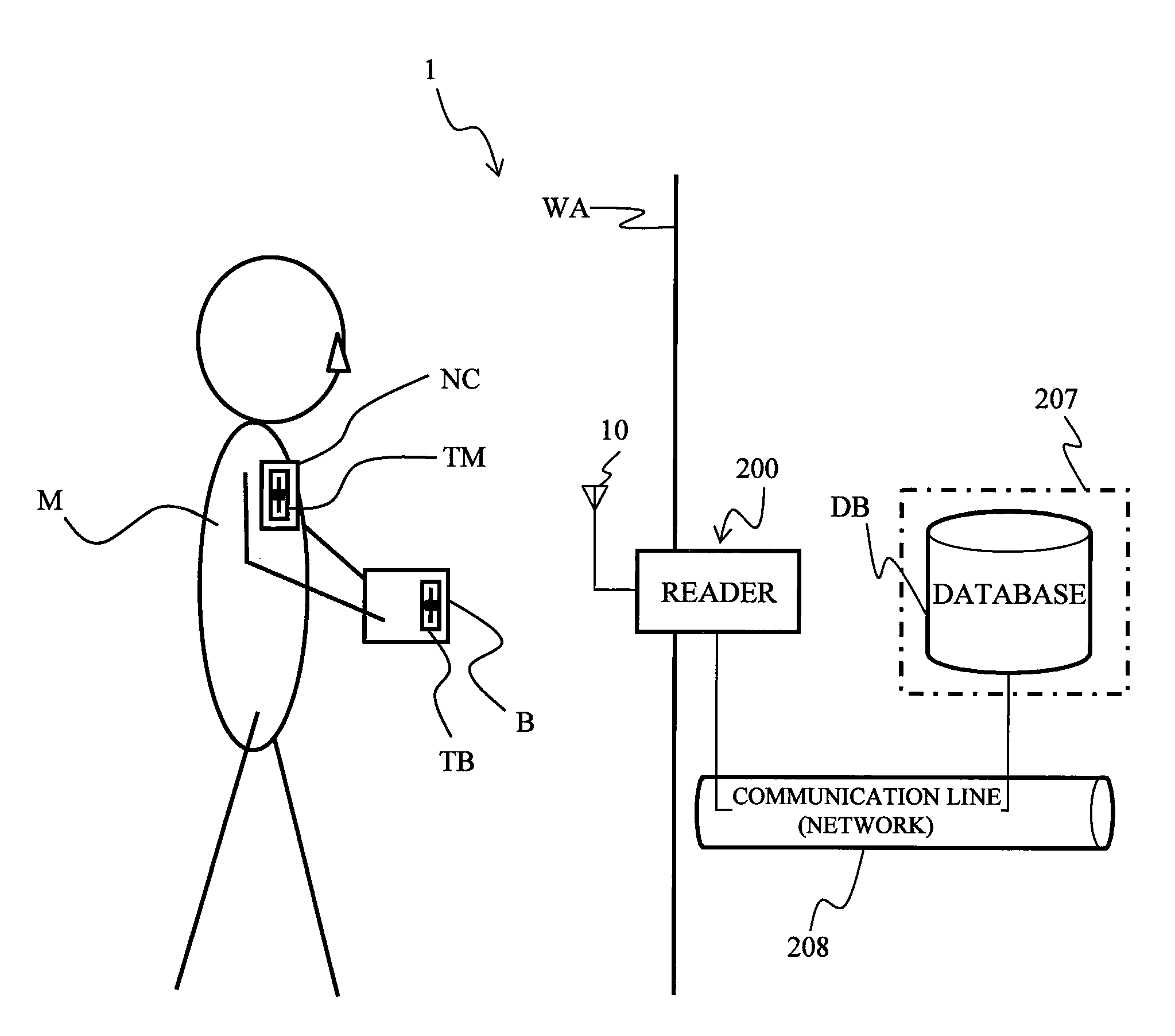

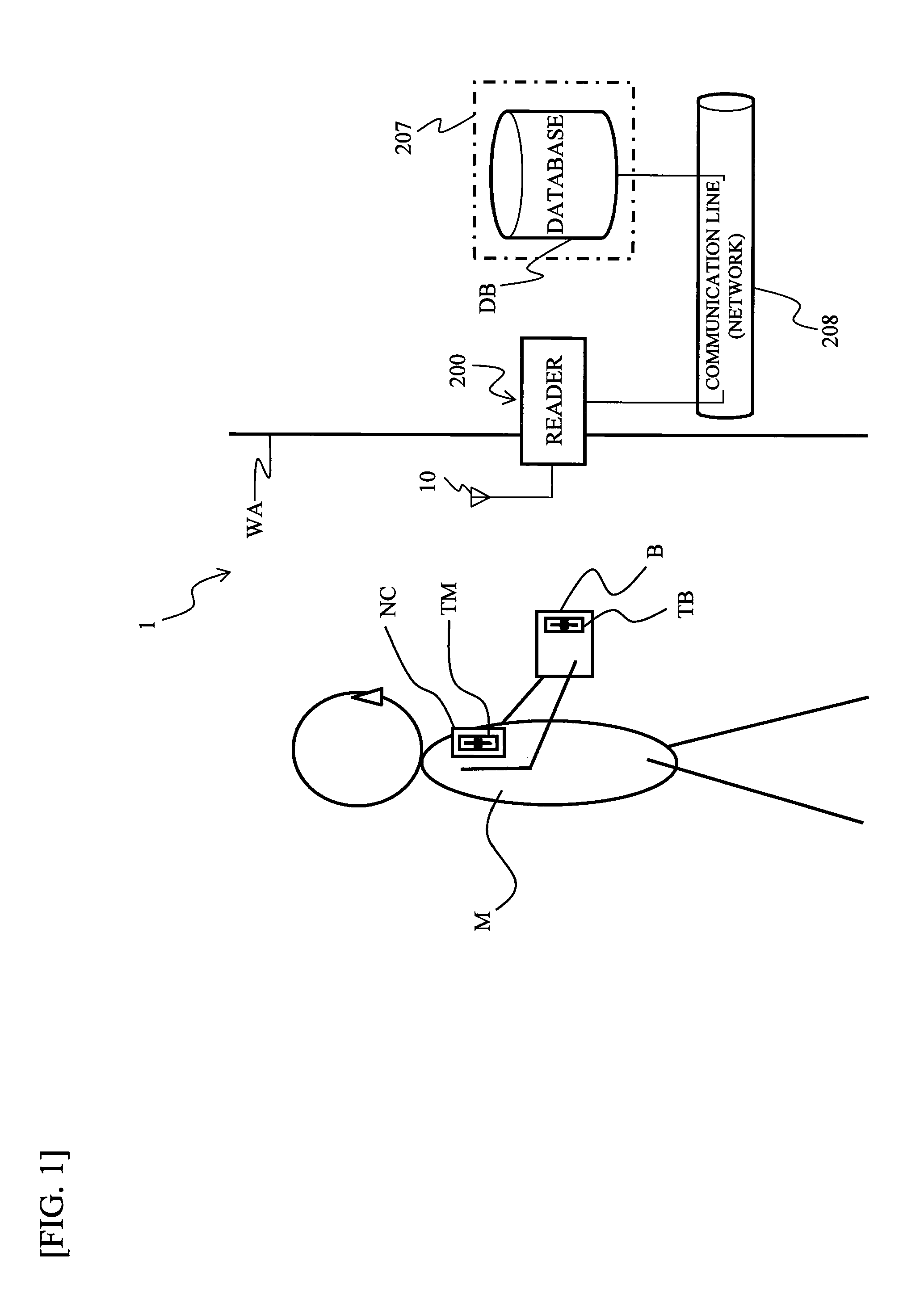

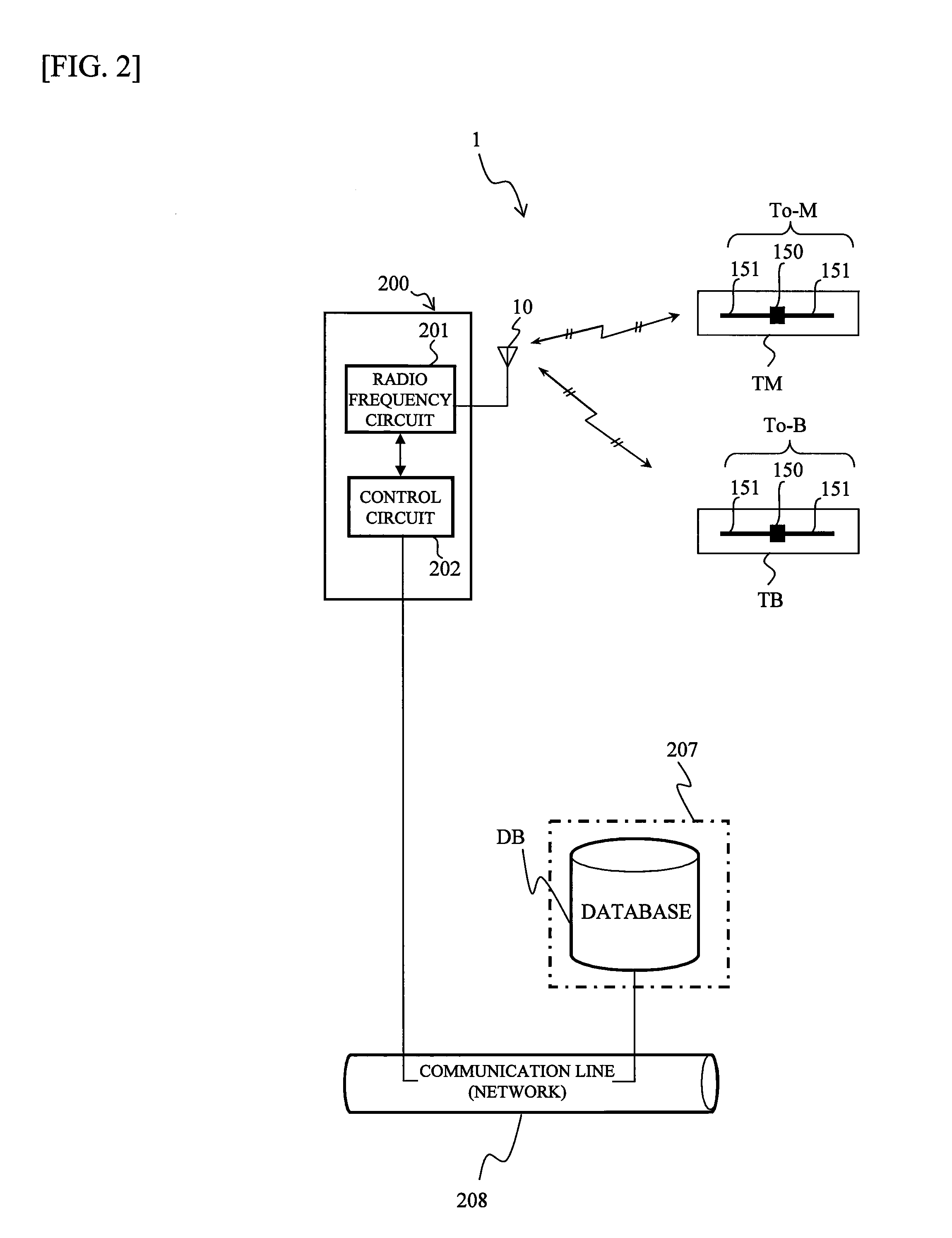

Apparatus for communicating with RFID tag and system for article management

InactiveUS20110156907A1Change powerMemory record carrier reading problemsCo-operative working arrangementsRadio frequencyComputer science

This disclosure discloses an apparatus for communicating with a radio frequency identification (RFID) tag, comprising: an apparatus antenna device configured to perform radio communication with a plurality of RFID tag circuit elements including a first RFID tag circuit element and a second RFID tag circuit element; a power control portion; an information obtaining portion configured to obtain information from the first RFID tag circuit element and the second RFID tag circuit element, based on the power controlled by the power control portion; and an association processing portion configured to perform the association processing of tag identification information of the second RFID tag circuit element with tag identification information of the first RFID tag circuit element.

Owner:BROTHER KOGYO KK

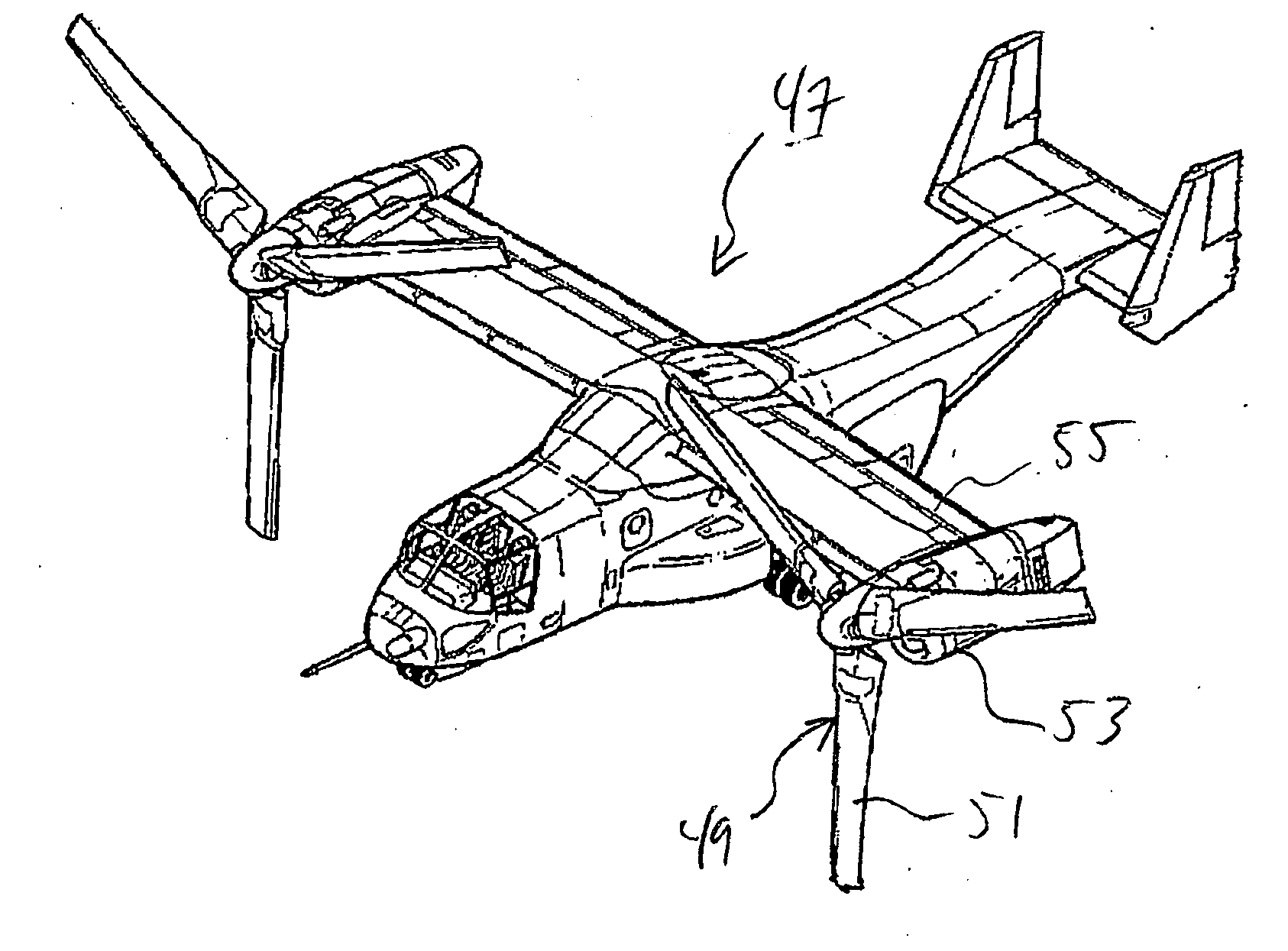

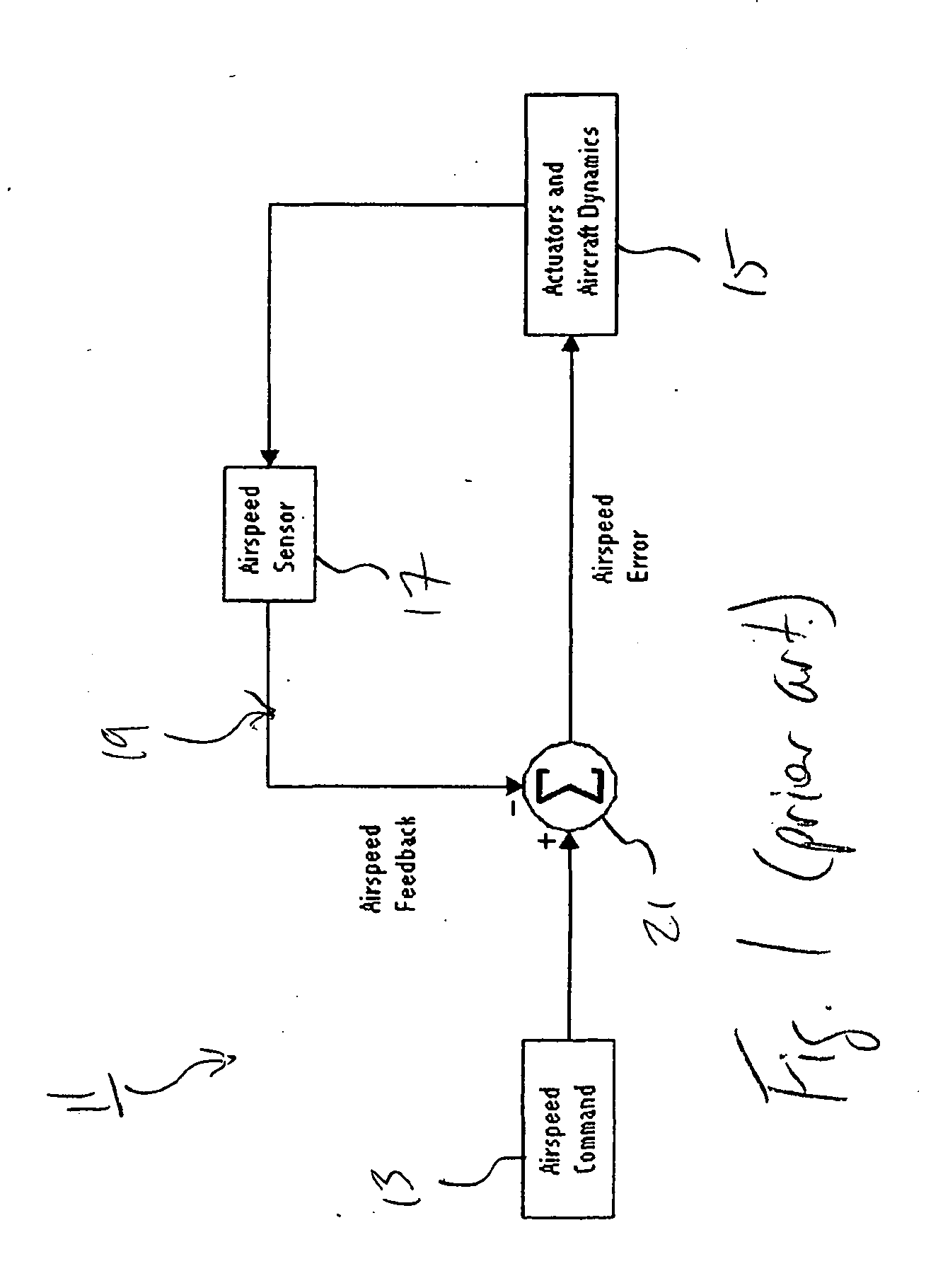

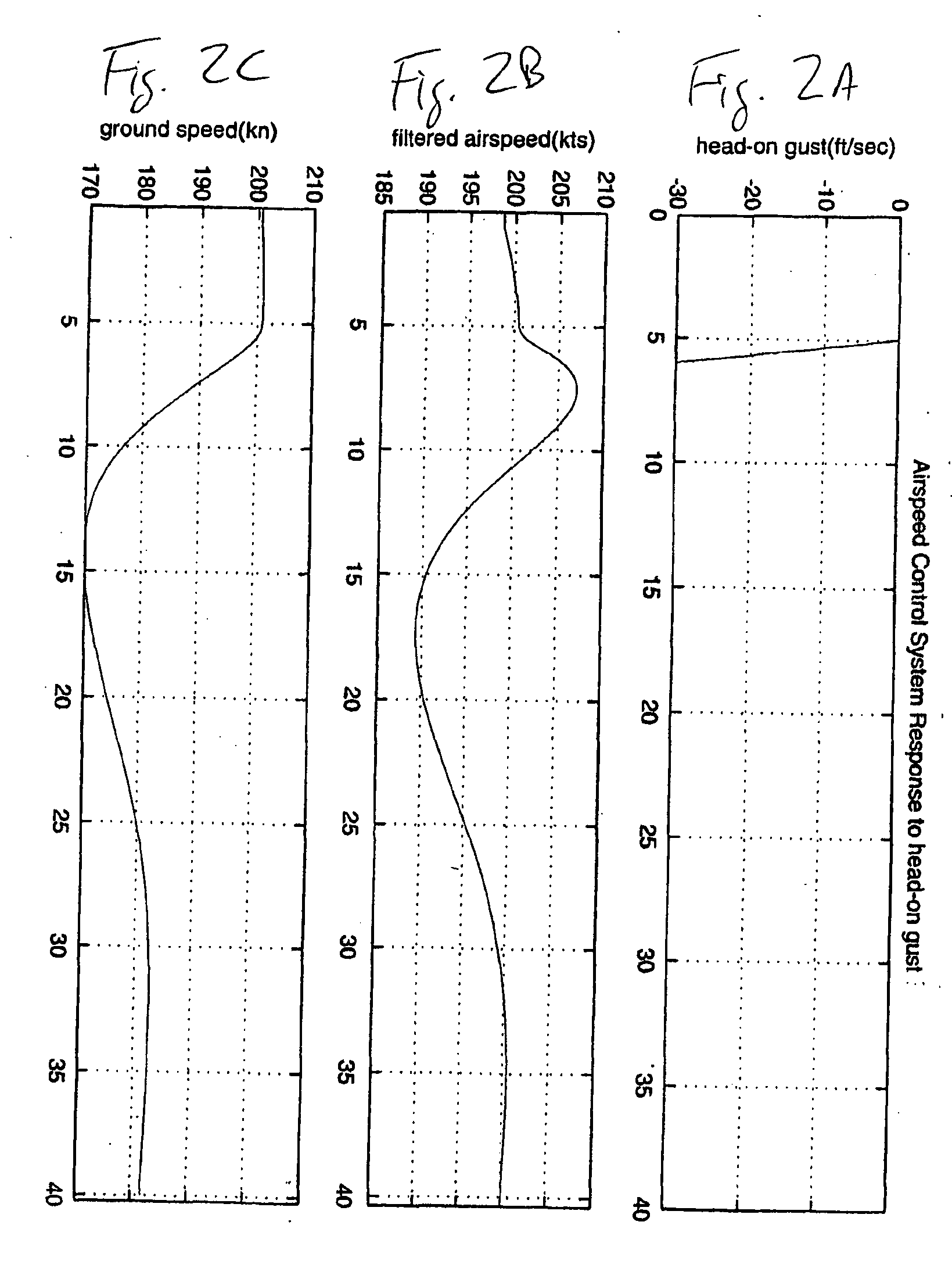

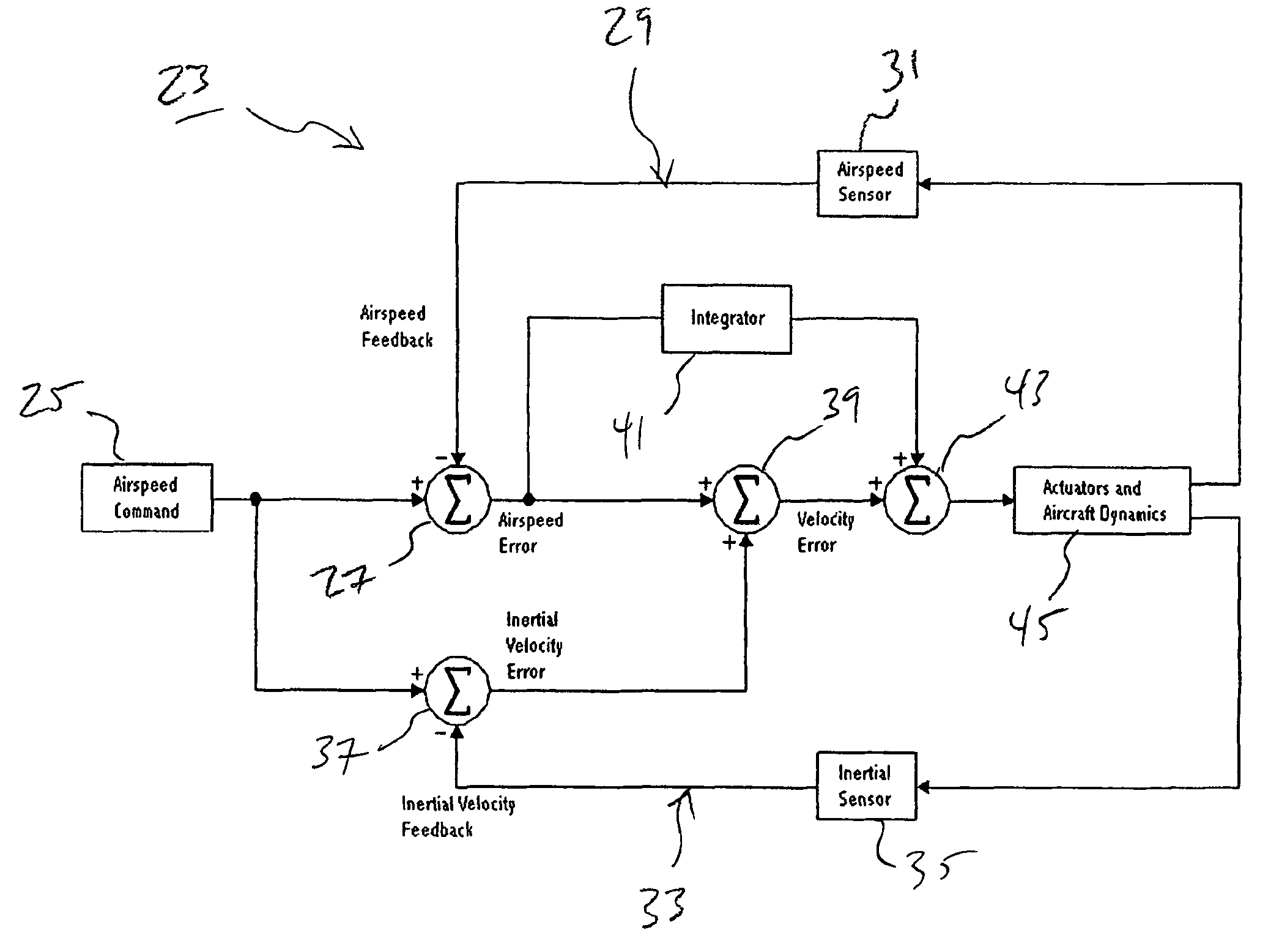

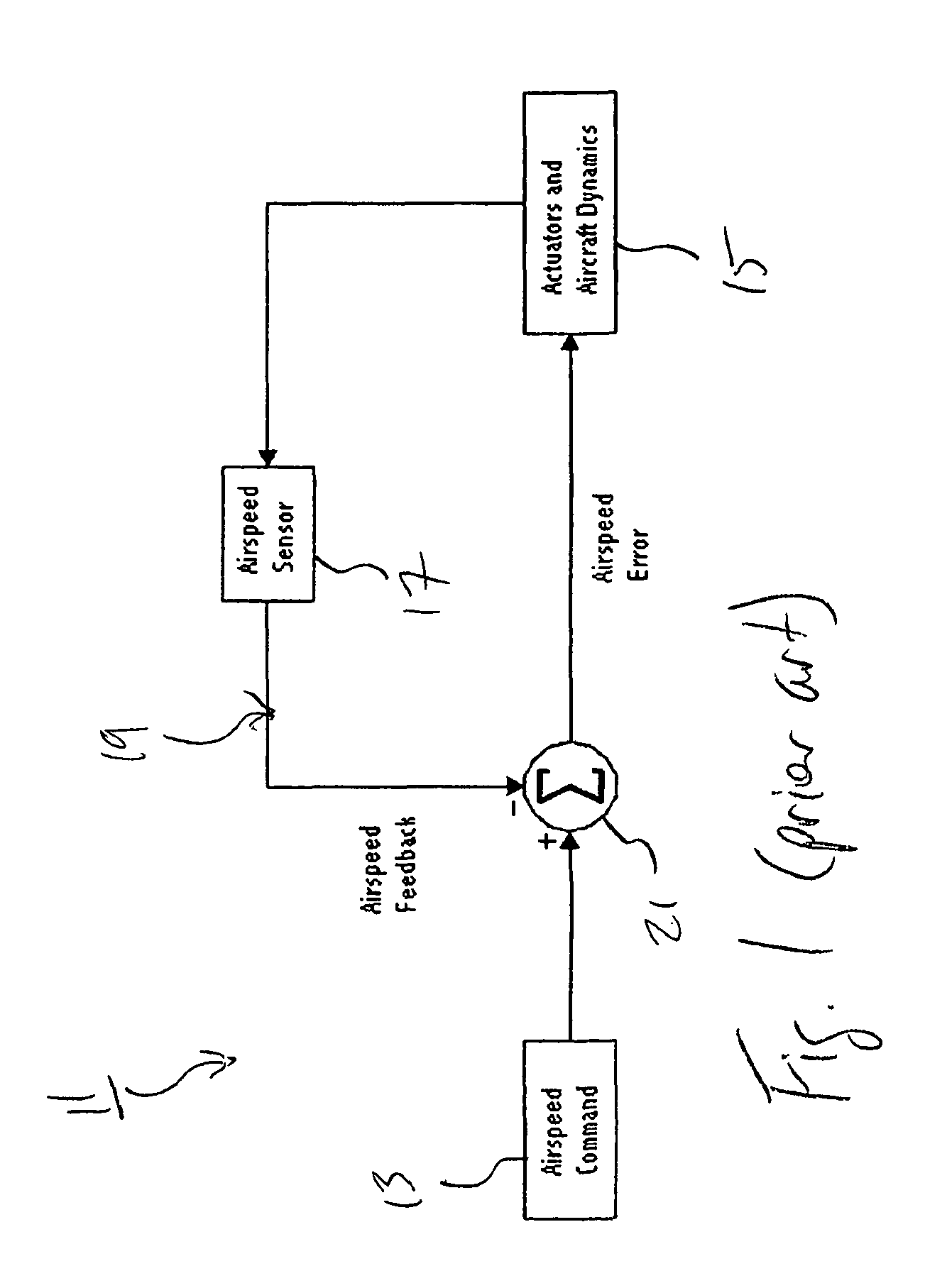

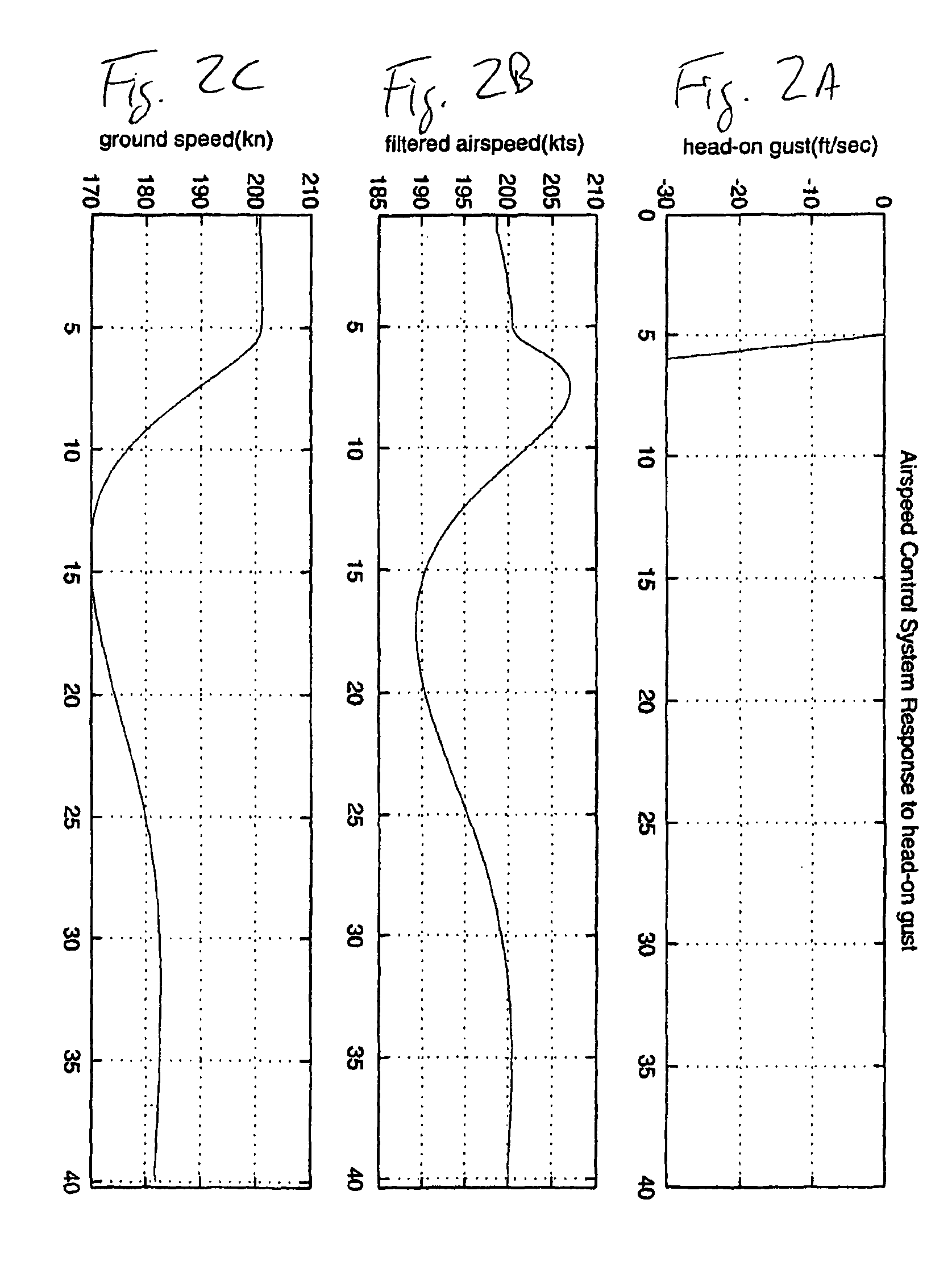

Automatic Velocity Control System For Aircraft

ActiveUS20080308682A1Minimize primary error signalImprove stabilityAircraft power plantsAircraft stabilisationSpeed control systemEngineering

A flight control system for an aircraft receives a selected value of a first parameter, which is either the airspeed or inertial velocity of the aircraft. A primary feedback loop generates a primary error signal that is proportional to the difference between the selected value and a measured value of the first parameter. A secondary feedback loop generates a secondary error signal that is proportional to the difference between the selected value of the first parameter and a measured value of a second flight parameter, which is the other of the airspeed and inertial velocity. The primary and secondary error signals are summed to produce a velocity error signal, and the velocity error signal and an integrated value of the primary error signal are summed to produce an actuator command signal. The actuator command signal is then used for operating aircraft devices to control the first parameter to minimize the primary error signal.

Owner:TEXTRON INNOVATIONS

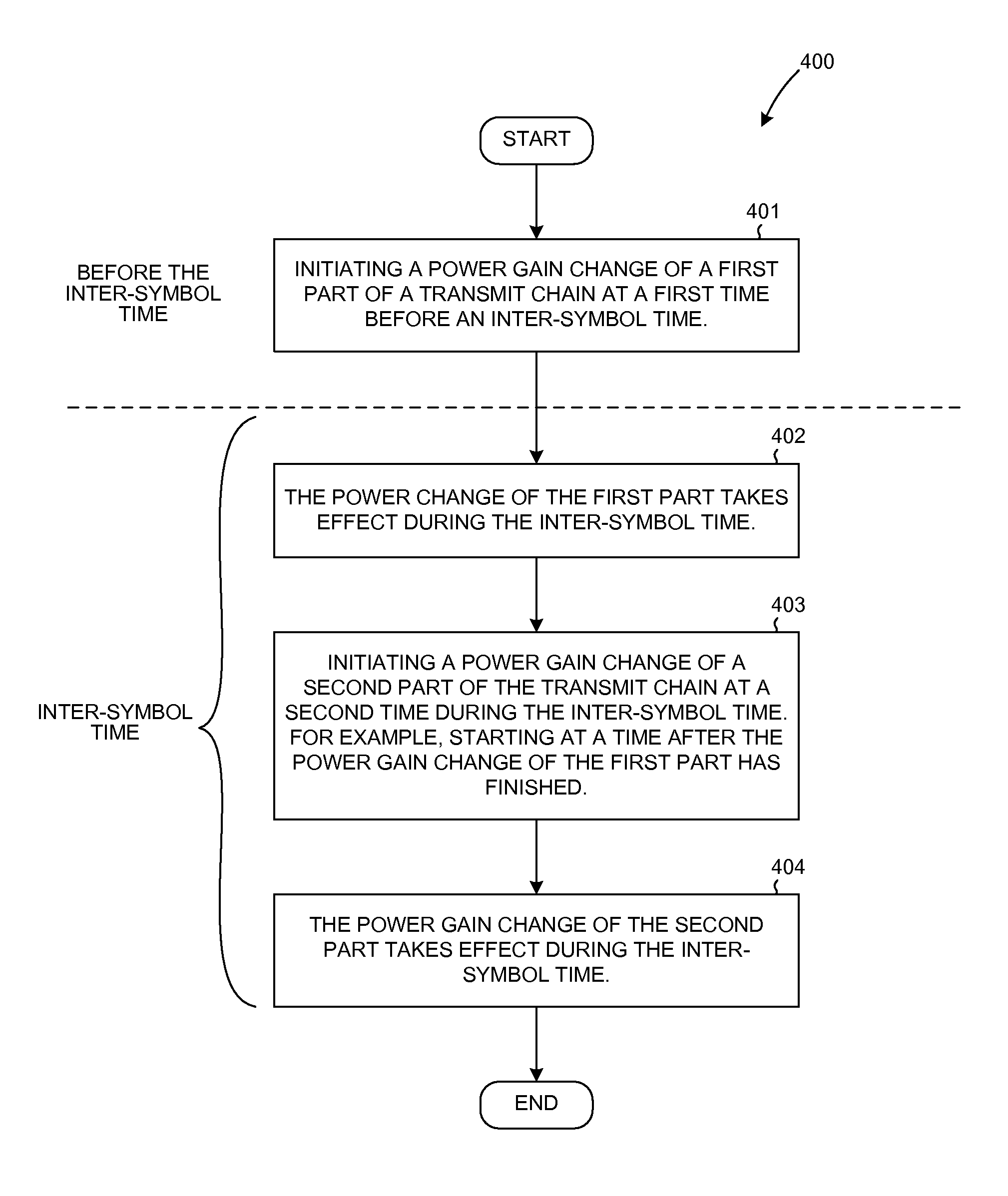

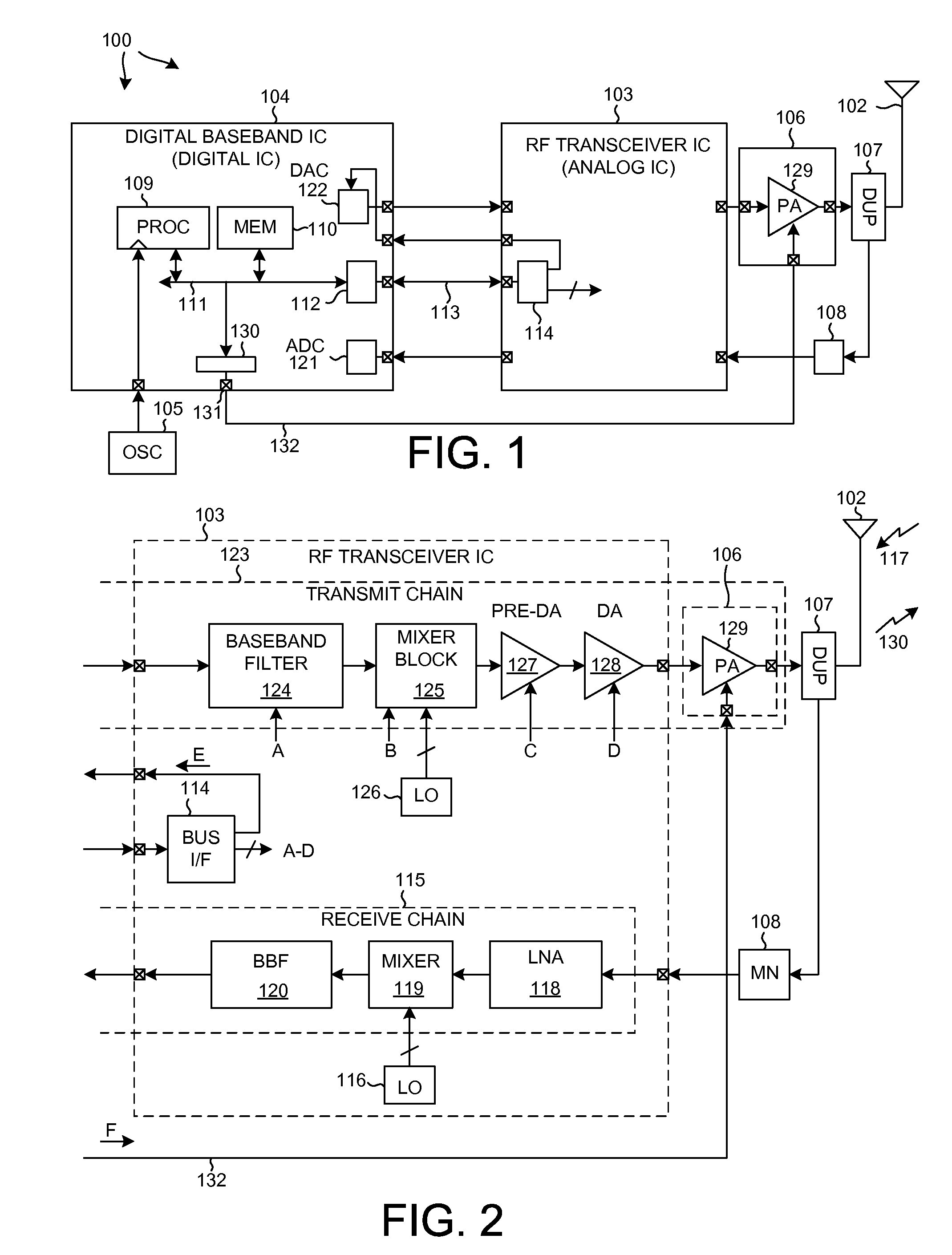

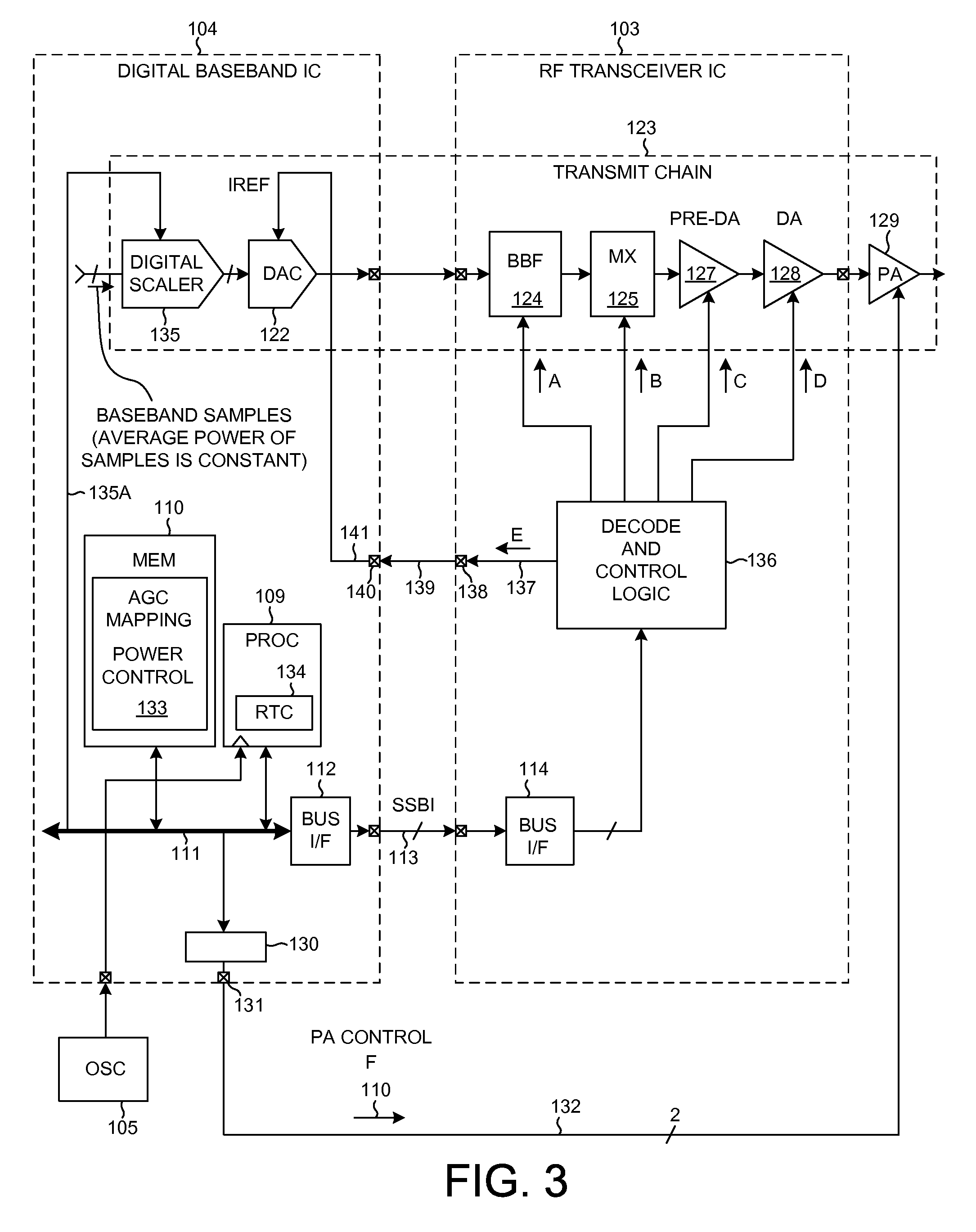

Transmitter chain timing and transmit power control

InactiveUS8385465B2Change powerGain controlAmplitude-modulated carrier systemsCommunications systemTransmitted power

Owner:QUALCOMM INC

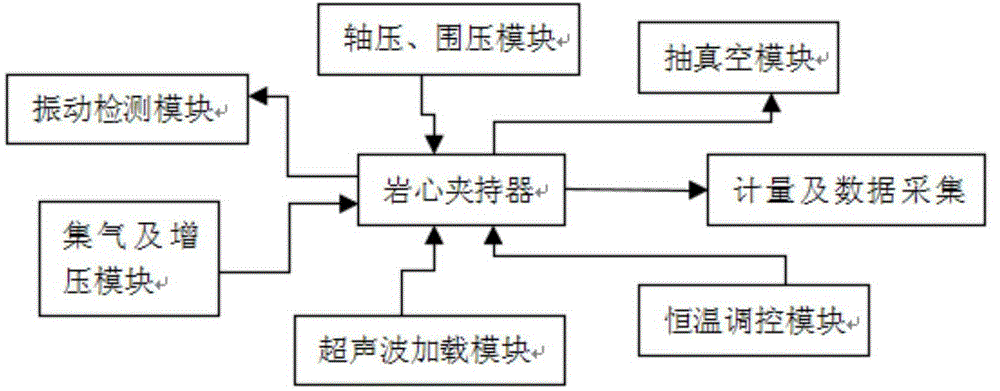

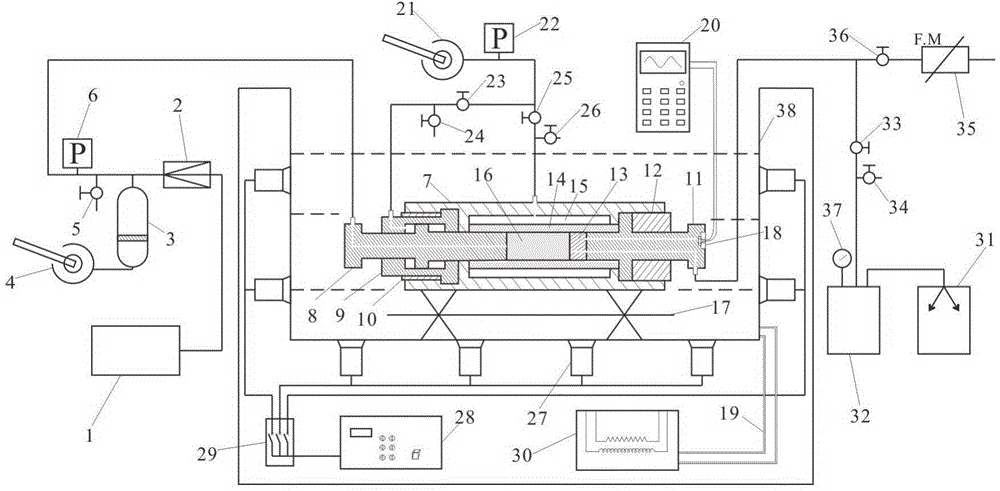

Experimental device for promoting gas flowing with ultrasonic waves

InactiveCN104819914AOptimizing development techniquesEnhanced overall recoverySurface/boundary effectPermeability/surface area analysisRock coreVibration detection

The invention discloses an experimental device for promoting gas flowing with ultrasonic waves. The experimental device comprises a rock core holding unit, a constant-temperature regulating module and an axial load and confining pressure module, wherein a rock core inside the rock core holding unit is connected with a gas gathering and pressurizing module and a vacuumizing module; an ultrasonic loading module is arranged around the rock core holding unit which is connected with a vibration detection module; the experimental device further comprises a measuring and data acquisition module which is used for acquiring the axial load and the confining pressure of the rock core and the pressure and speed at a gas inlet. The experimental device for simulating the gas flowing rules of coalbed methane in immediate vicinity of wellbore under ultrasonic loading is capable of providing different temperatures and experimental conditions under three-axis stress states; ultrasonic fields with different frequencies and different power are respectively loaded in a vertical flowing direction, a down-flowing direction and a reverse flowing direction; impacts of an ultrasonic and mechanical vibration and a thermal effect to the gas flowing can be separated through a water-bath constant-temperature module; an impact of single factors such as mechanical vibration and thermal effect to the flowing can be simulated.

Owner:CHINA UNIV OF MINING & TECH

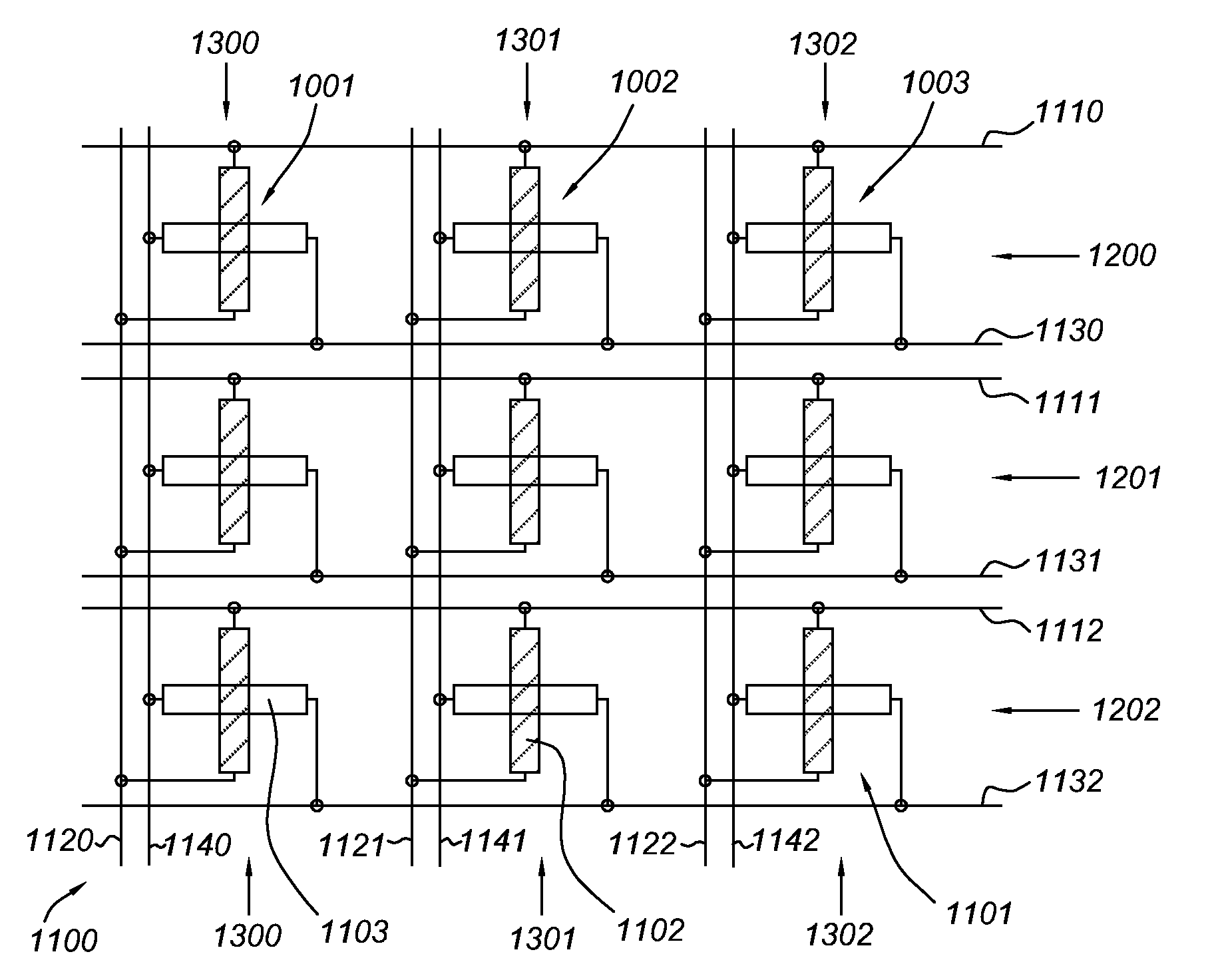

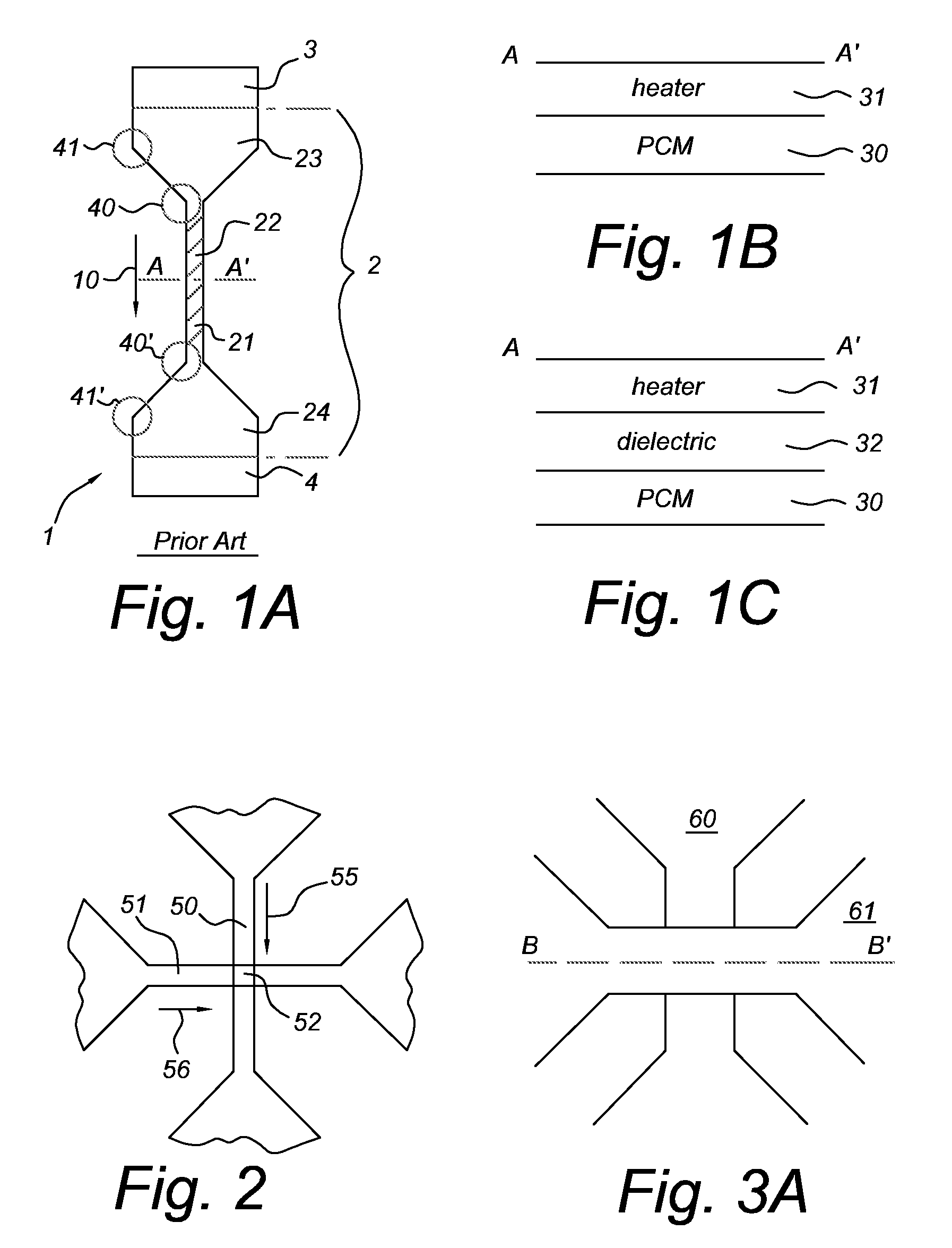

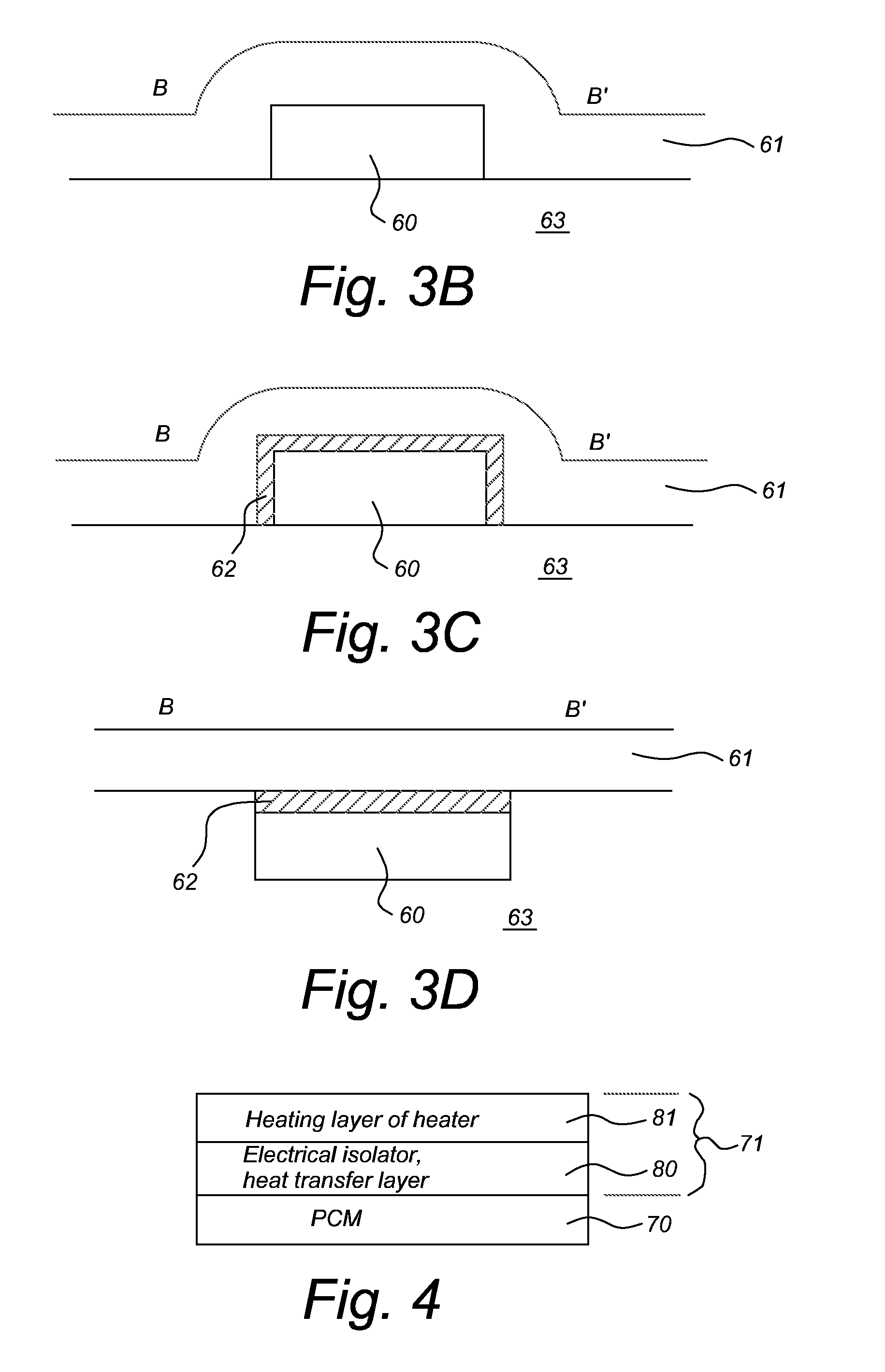

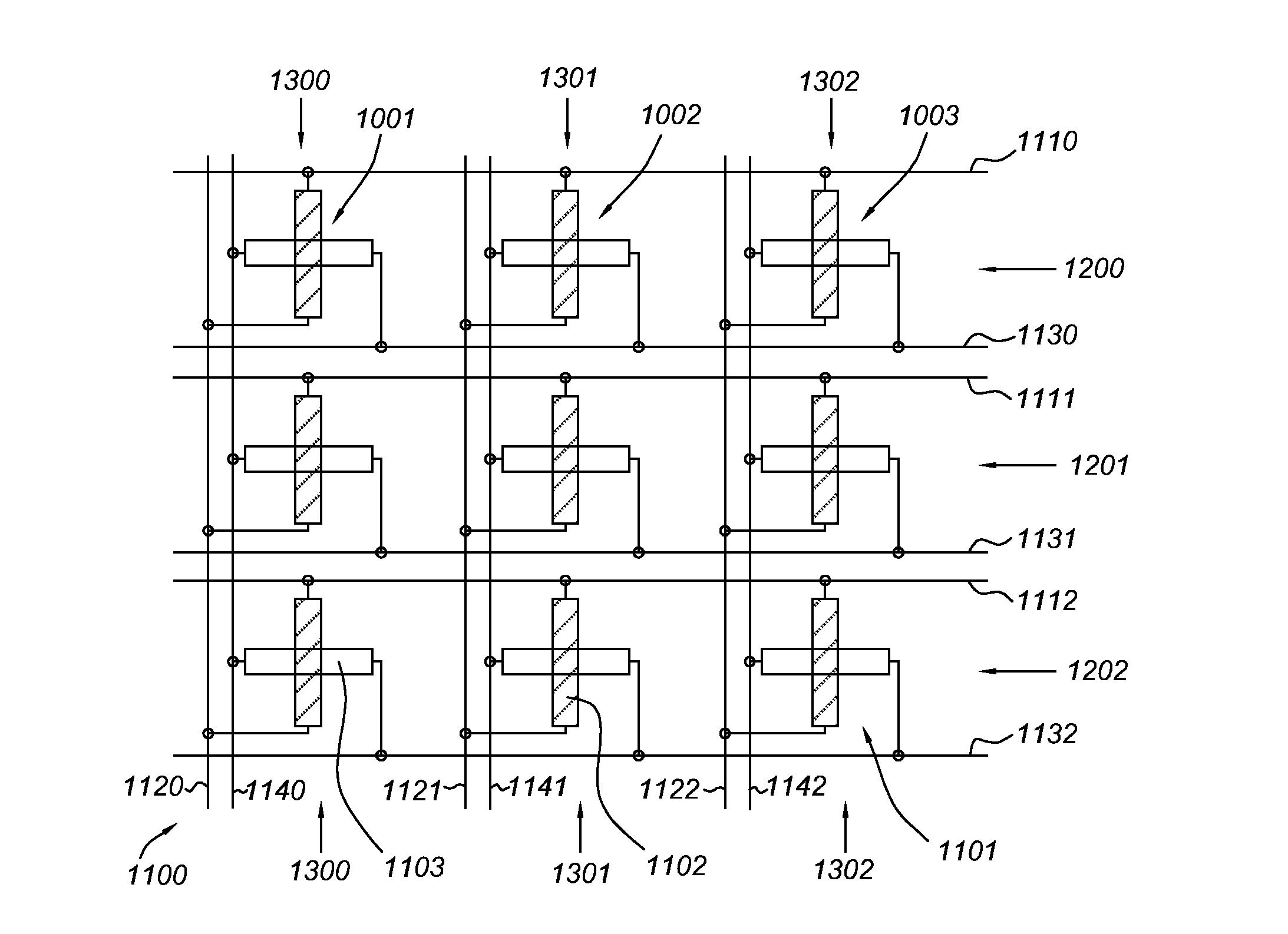

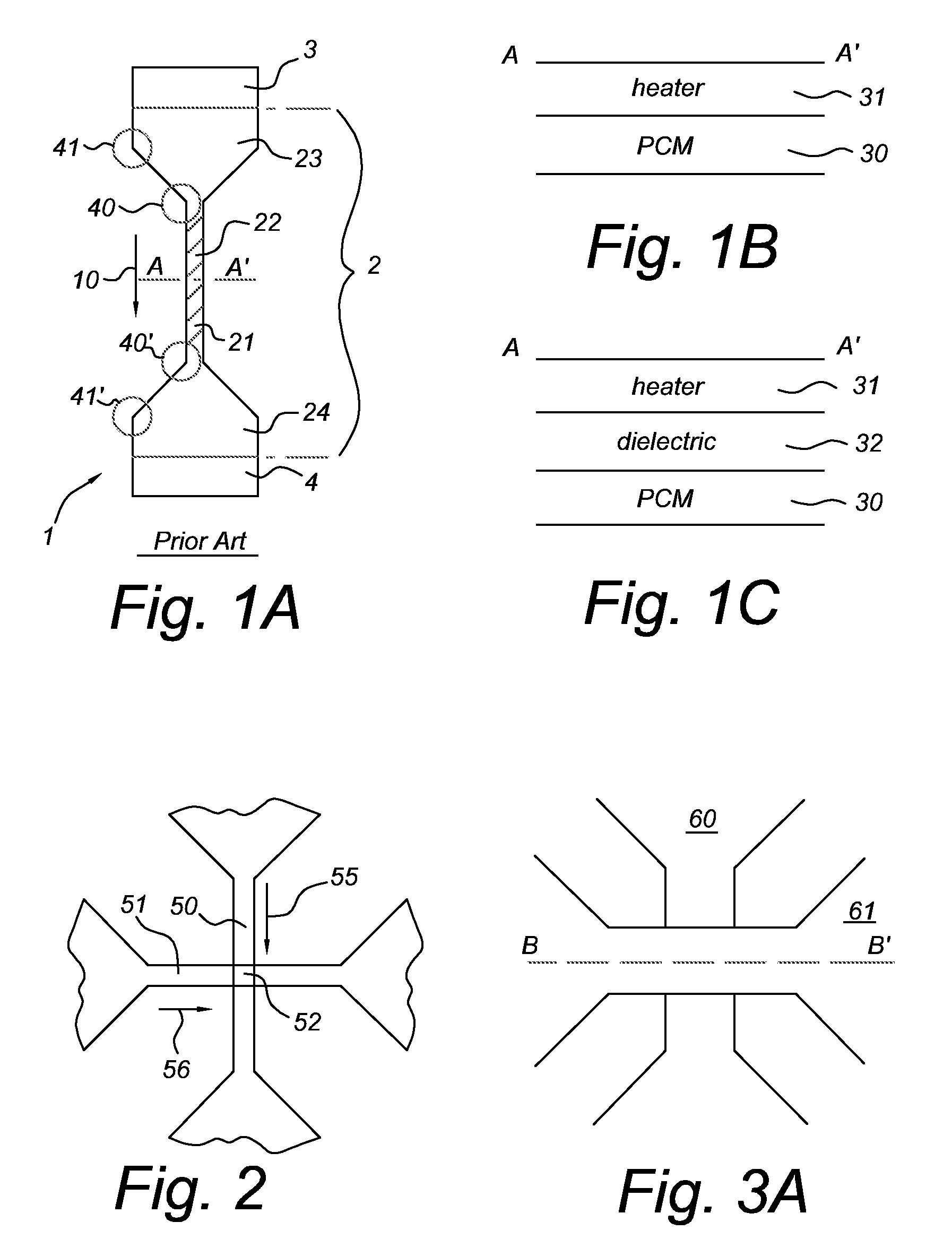

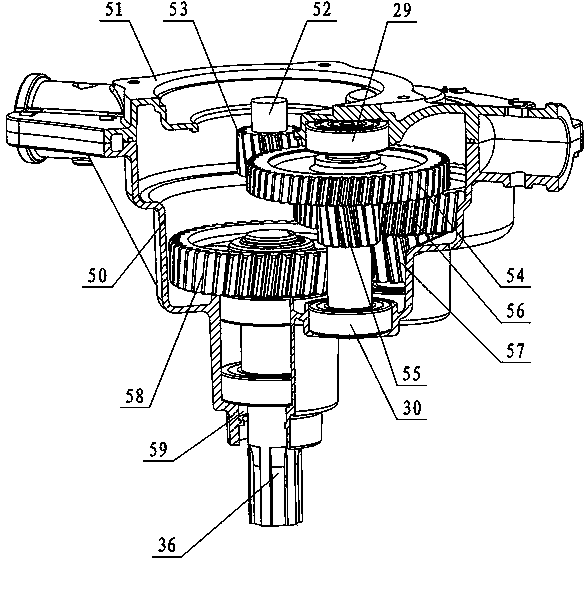

Electric device comprising phase change material and heating element

InactiveUS20100188892A1Limits delaminationLimits segregationSolid-state devicesSemiconductor/solid-state device manufacturingSecondary stagePhase-change material

An electric device has a resistor including a phase change material changeable between a first phase and a second phase within a switching zone. The resistor has a first resistance when the phase change material is in the first phase and a different second resistance, when the phase change material is in the second phase. The resistor may conduct a first current. The device has a heating element that may conduct a second current for enabling a transition of the phase change material from the first to the second phase. At the position of the switching zone, the resistor is arranged as a first line and the heating element is arranged as a second line. The first and second line may conduct the first current and the second current respectively, wherein the first line and the second line cross at the position of the switching zone.

Owner:NXP BV

Electric device comprising phase change material and heating element

InactiveUS8174877B2Limits delaminationLimits segregationSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringSecondary stage

An electric device has a resistor including a phase change material changeable between a first phase and a second phase within a switching zone. The resistor has a first resistance when the phase change material is in the first phase and a different second resistance, when the phase change material is in the second phase. The resistor may conduct a first current. The device has a heating element that may conduct a second current for enabling a transition of the phase change material from the first to the second phase. At the position of the switching zone, the resistor is arranged as a first line and the heating element is arranged as a second line. The first and second line may conduct the first current and the second current respectively, wherein the first line and the second line cross at the position of the switching zone.

Owner:NXP BV

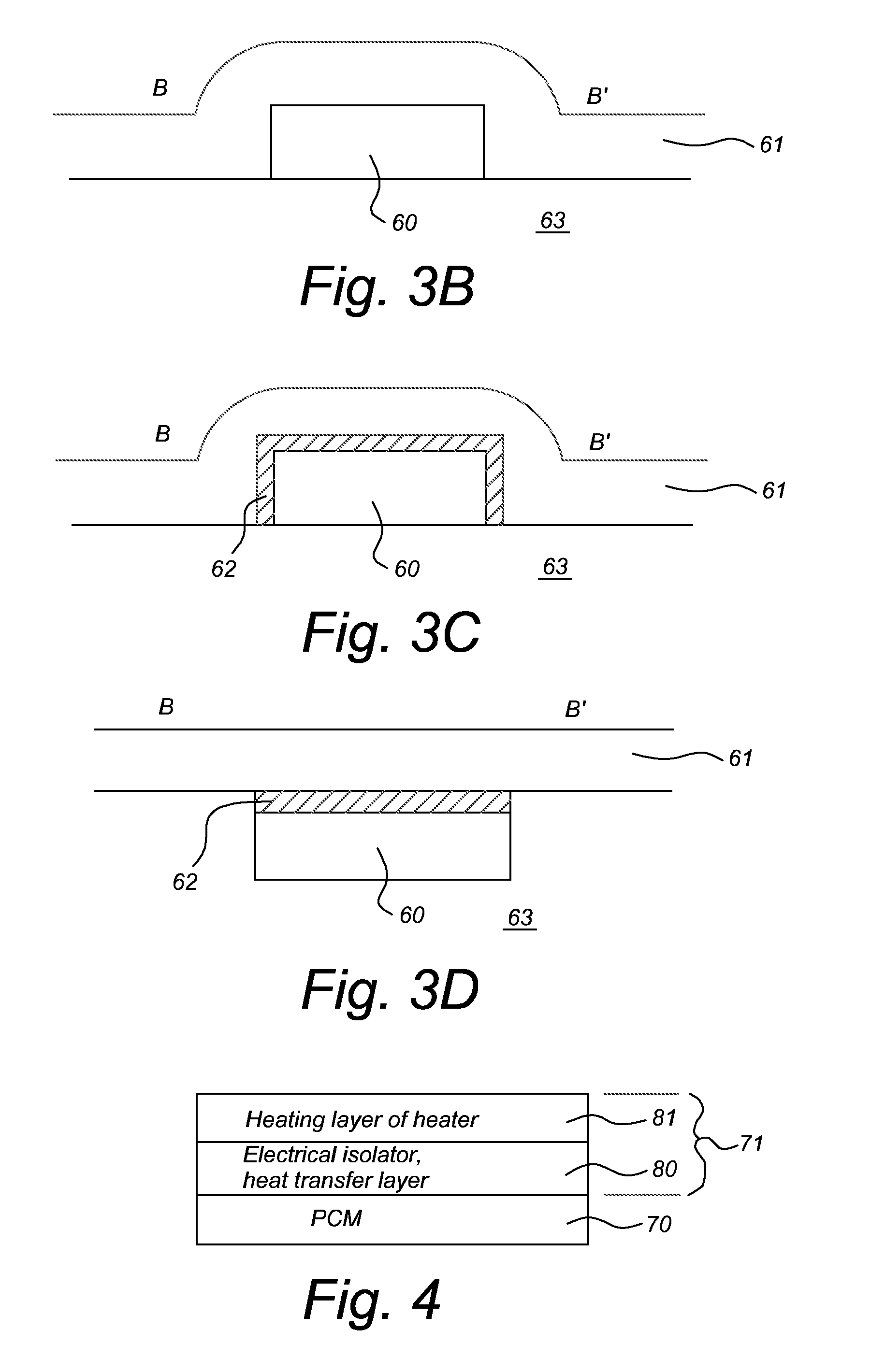

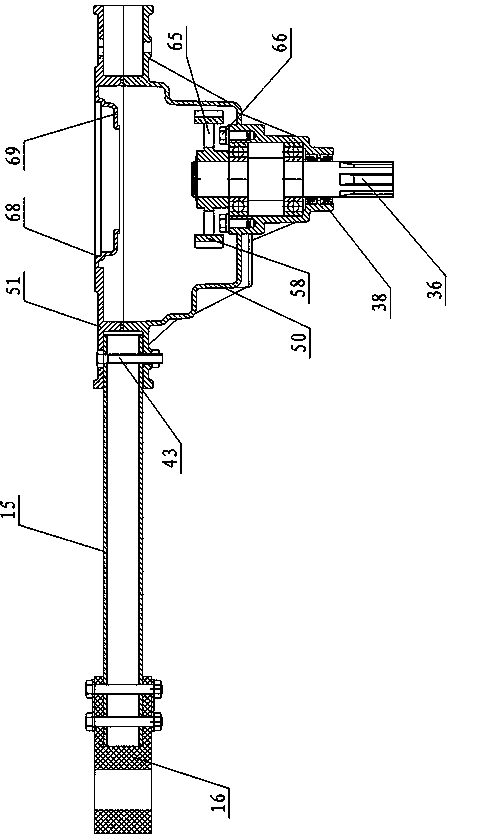

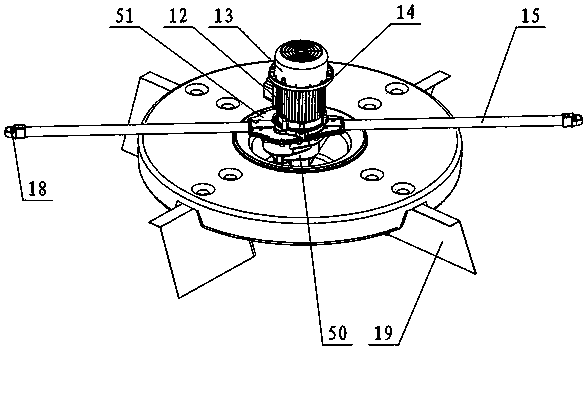

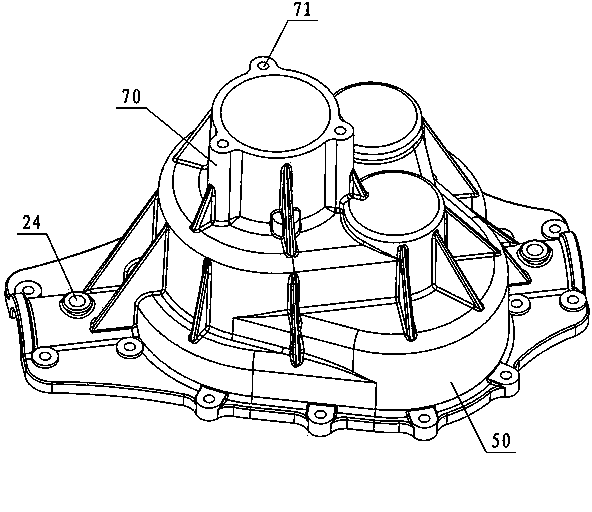

Water agitating surge machine

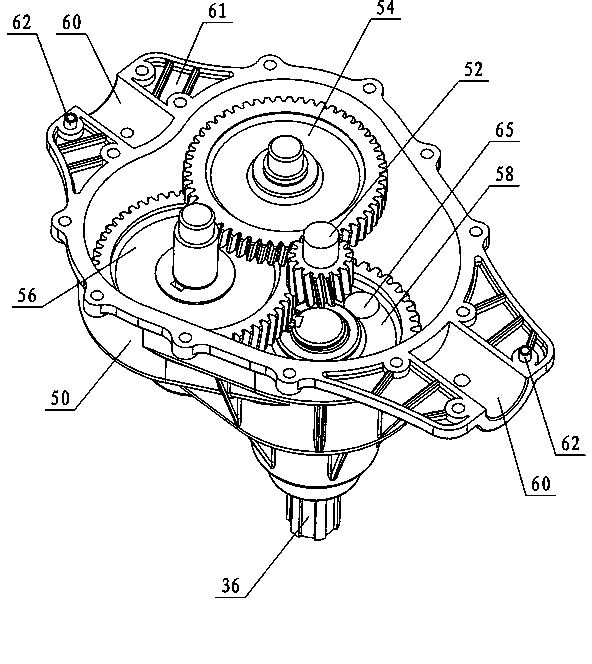

ActiveCN103907563AOutstanding FeaturesHighlight significant progressPisciculture and aquariaGearing detailsBlow moldingReducer

The invention relates to a water agitating surge machine. The water agitating surge machine mainly comprises a motor, a reducer casing, a floating body, vanes and fixing rods, wherein the motor is vertically installed on the reducer casing, the reducer casing mainly comprises a casing body, a reduction gear, a bearing and an output shaft, the output shaft downwards extends through a sealed chamber to drive the floating body to rotate with the vanes, the whole machine floats on the water by the aid of the floating body, and the motor and the reducer casing are fixed by the fixing rods to float on the water without rotation. The floating body is a hollow shell which is formed by blow molding, and the floating body is in a shape of approximate square, approximate rectangle, approximate triangle or circle and the like.

Owner:吴为国

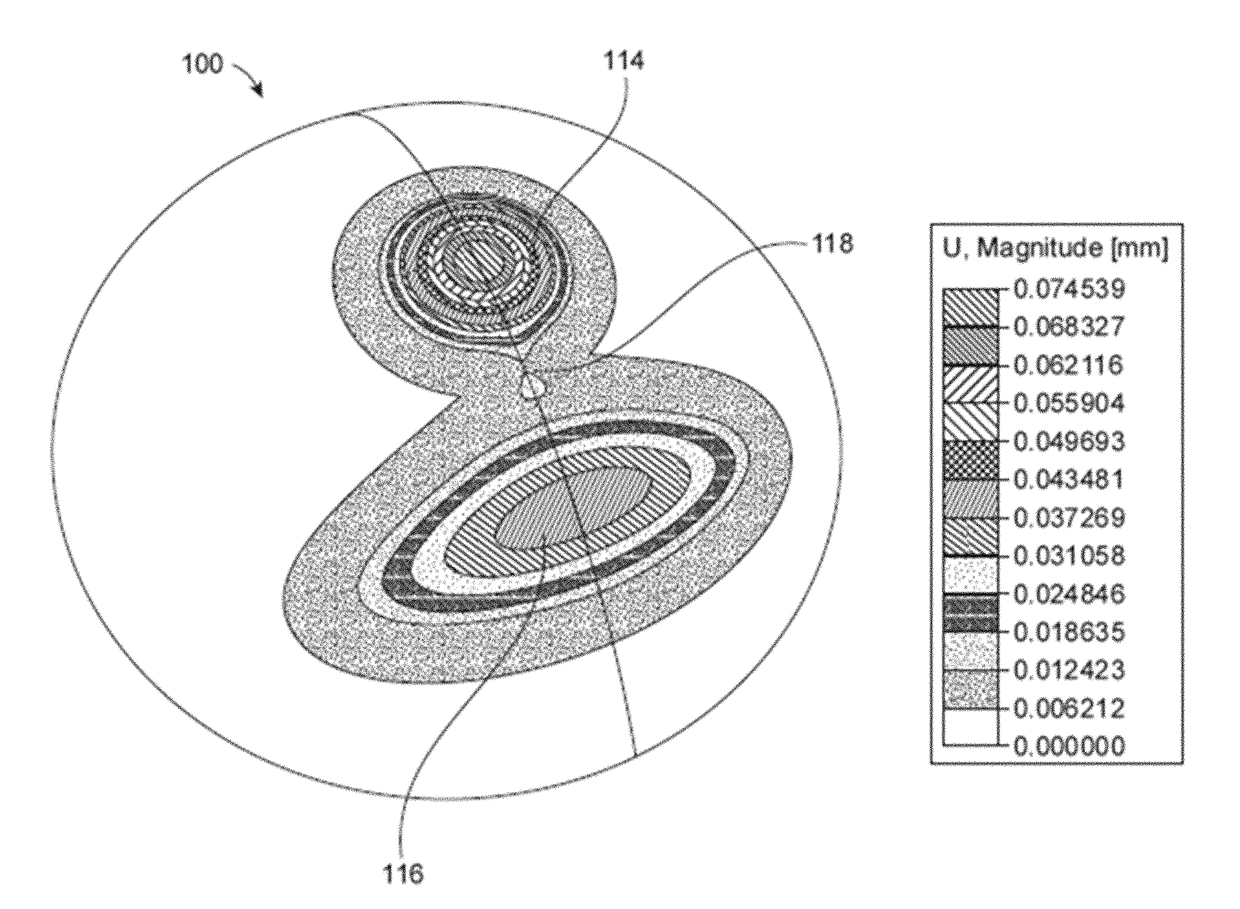

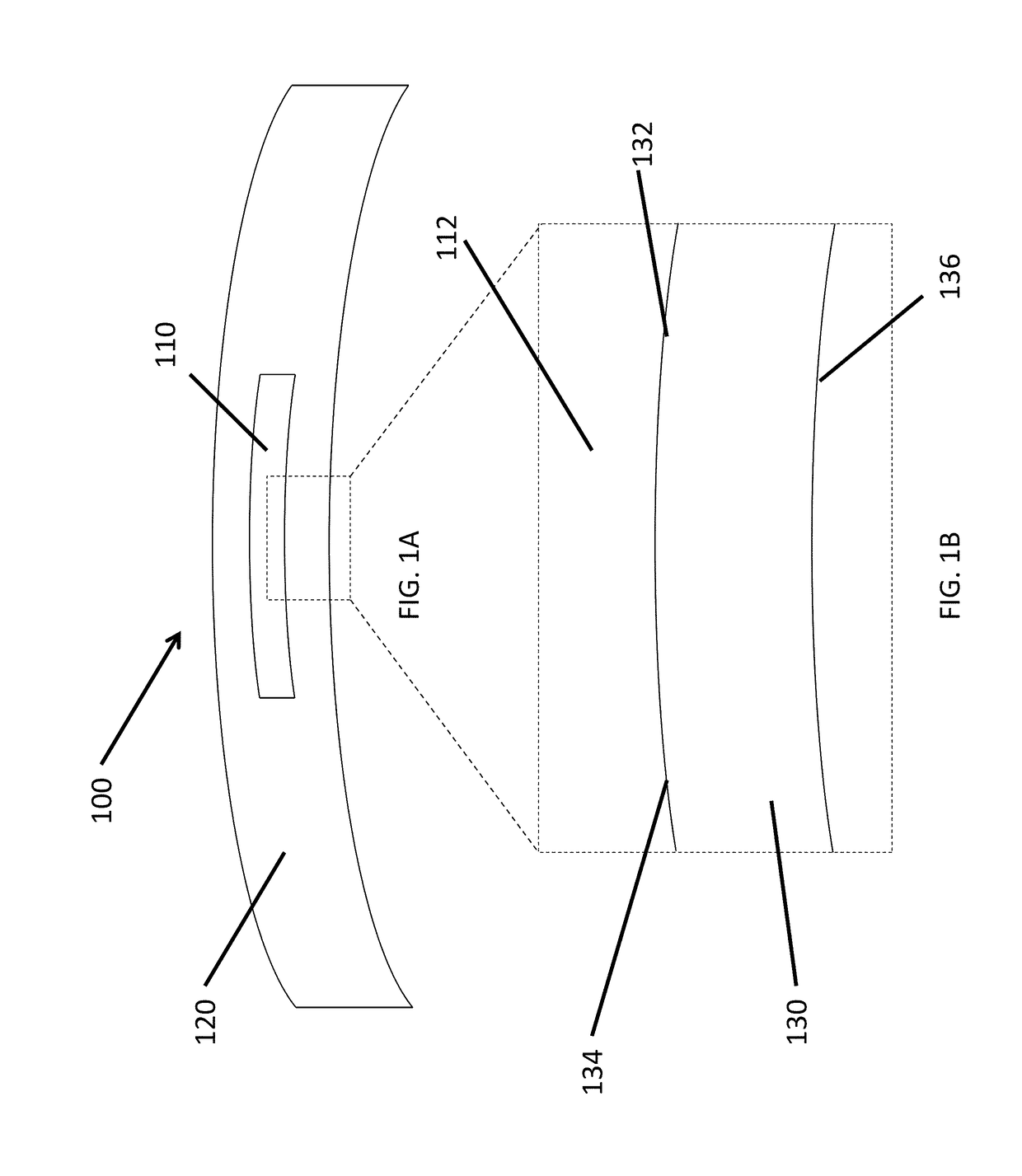

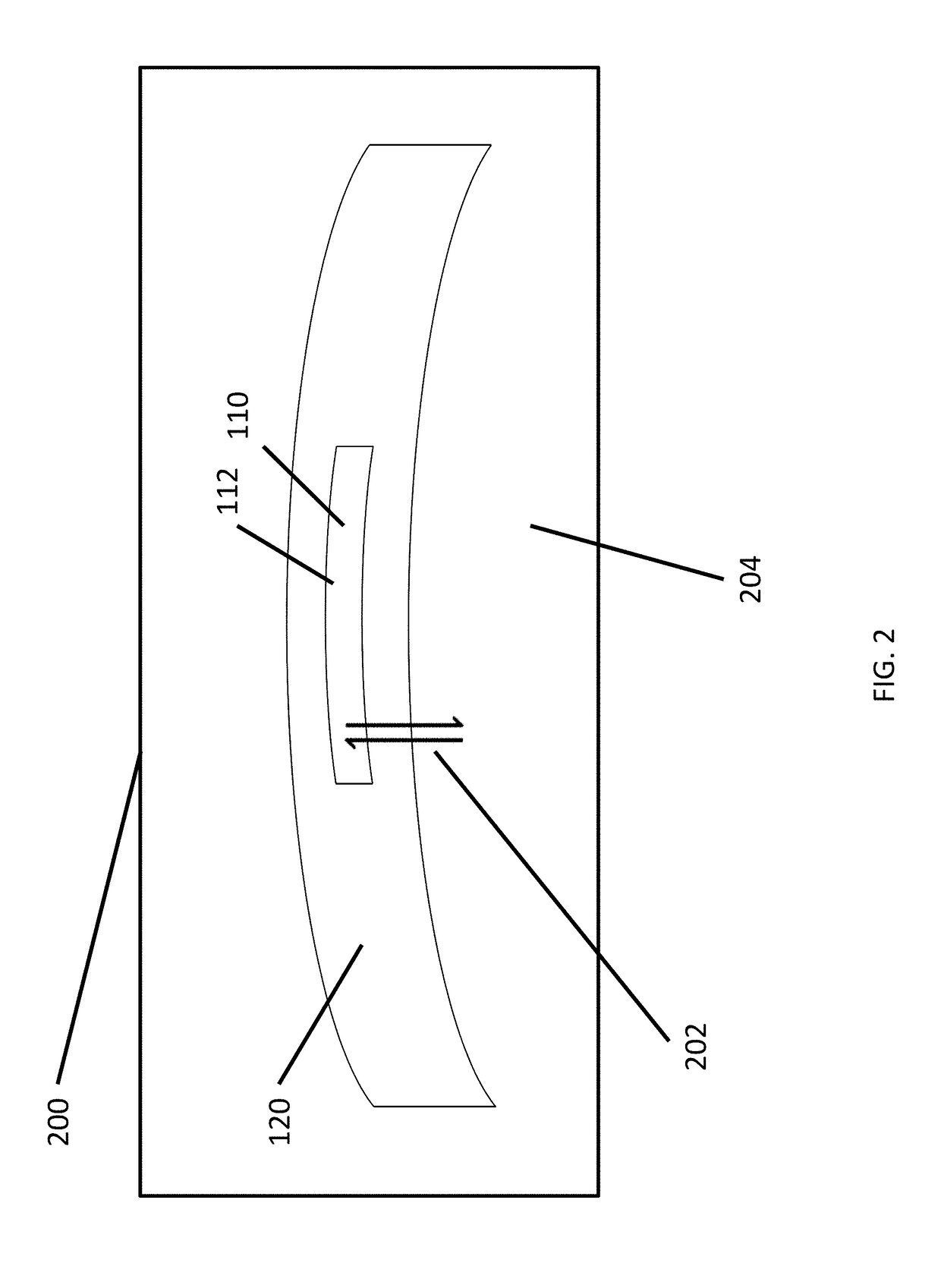

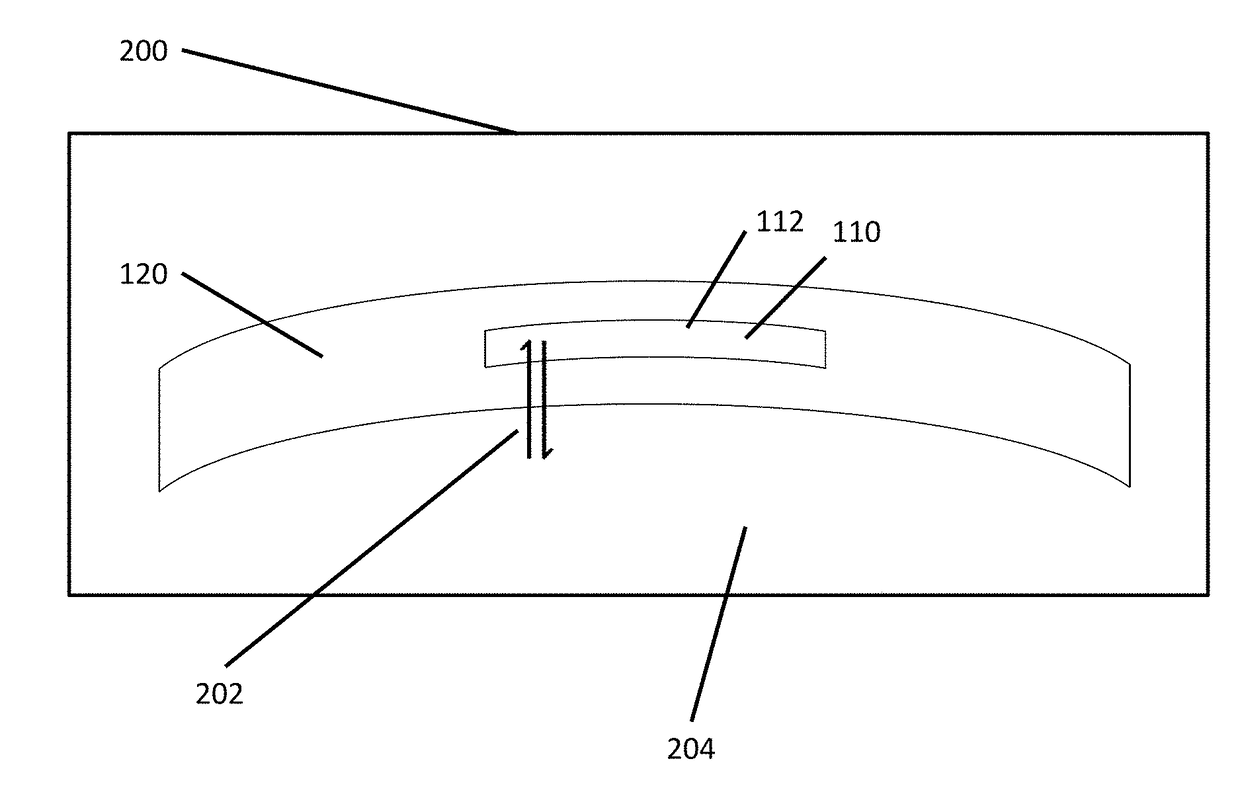

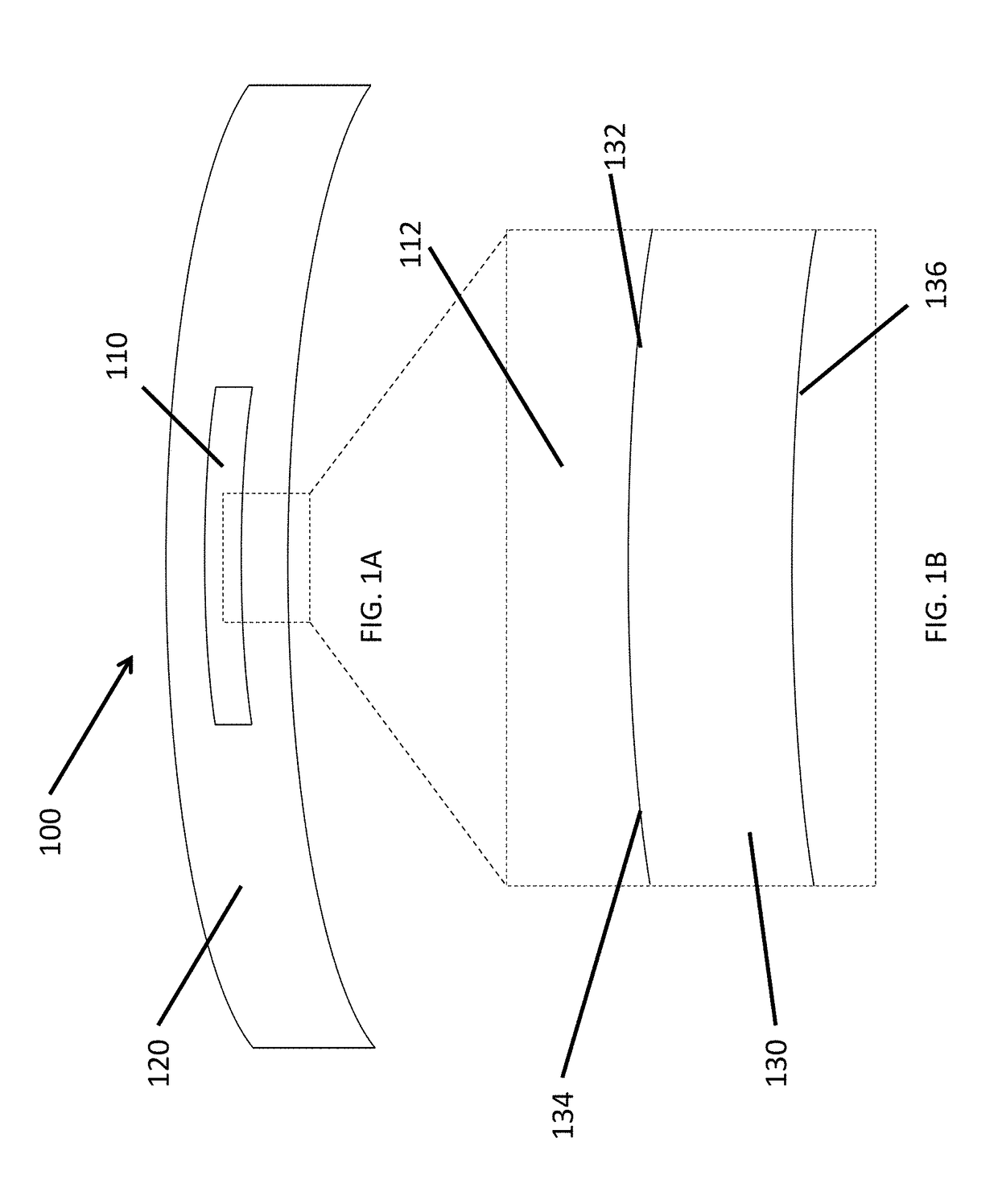

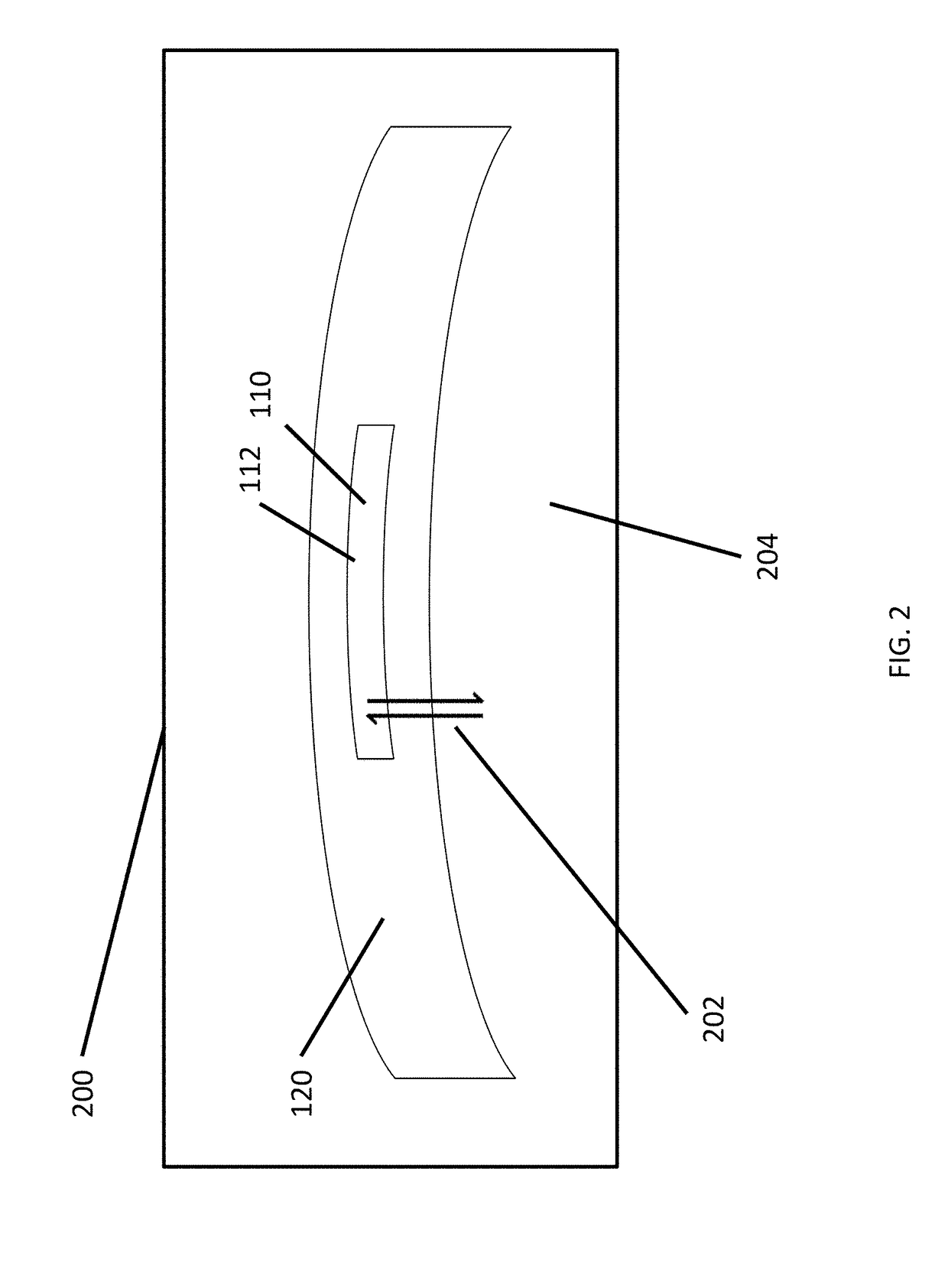

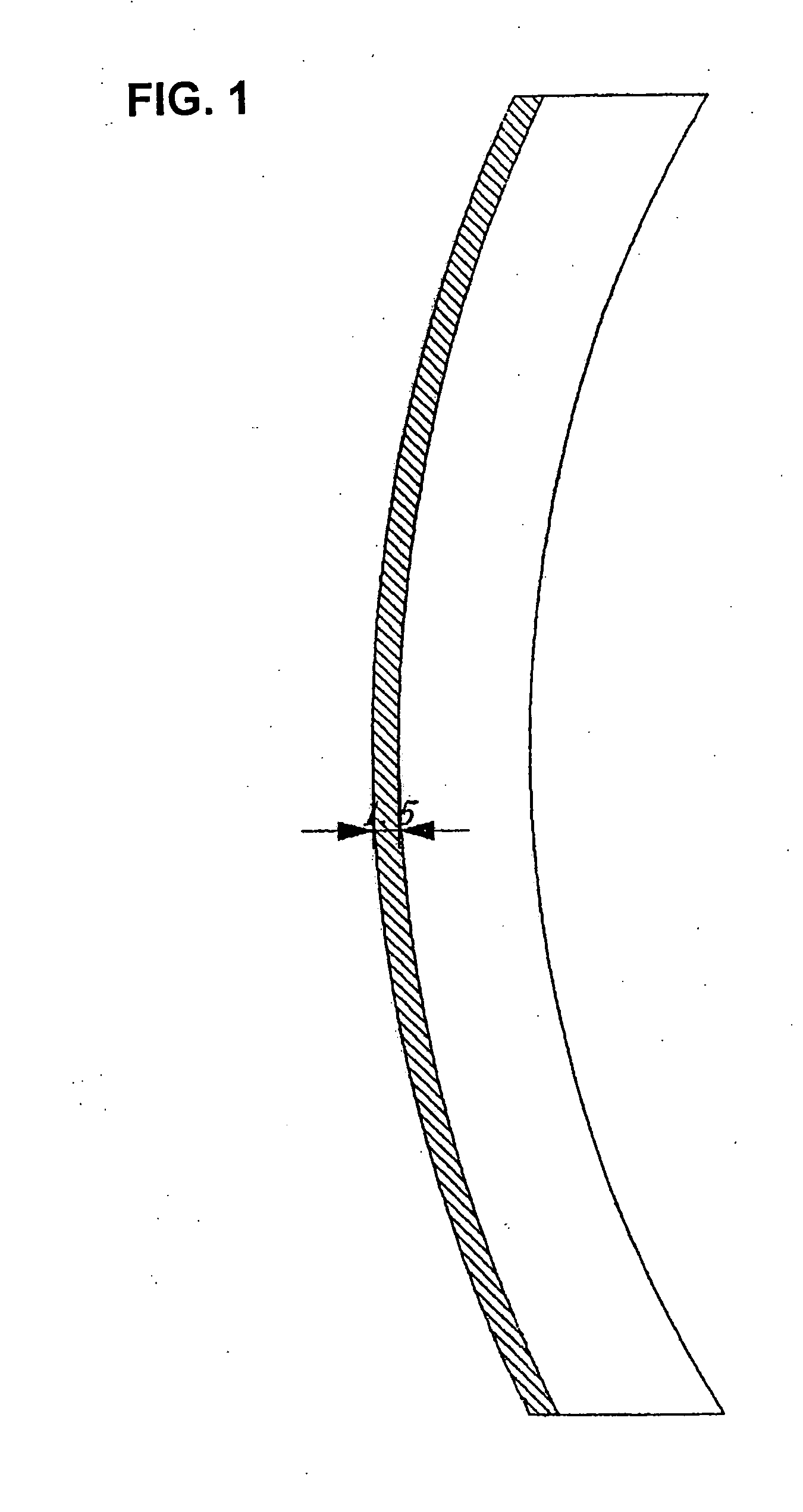

Accommodating lens with cavity

A lens comprises an internal cavity structure formed by dissolution of a soluble insert material. The internal soluble material may dissolve through a body of a lens such as a contact lens in order to form the cavity within the contact lens. The cavity within the lens can be shaped in many ways, and corresponds to the shape of the dissolved material, such that many internal cavity shapes can be readily fabricated within the contact lens. The insert can be placed in a mold with a pre-polymer material, and the pre-polymer material cured with the insert placed in the mold to form the lens body. The polymerized polymer may comprise a low expansion polymer in order to inhibit expansion of the lens when hydrated. The polymer may comprise a hydrogel when hydrated. The soft contact lens material comprises a sufficient amount of cross-linking to provide structure to the lens and shape the cavity.

Owner:ONEFOCUS VISION

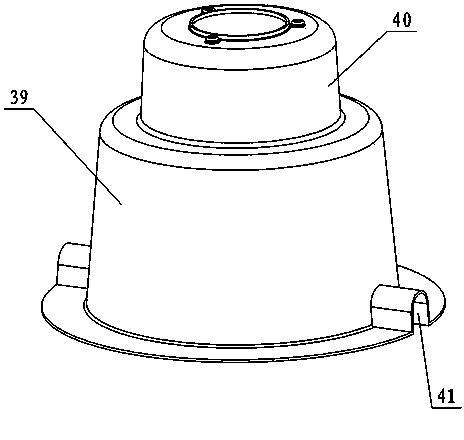

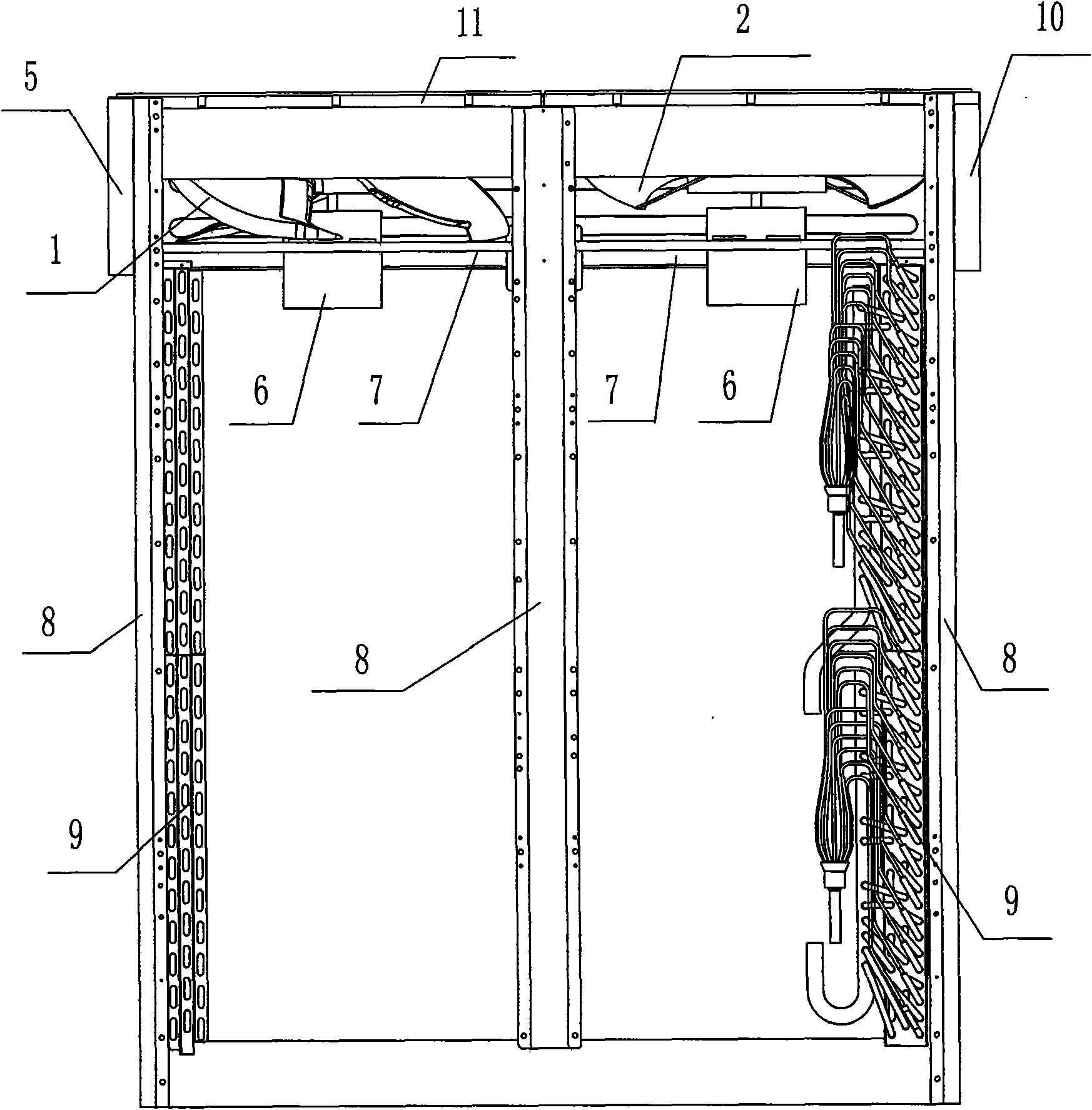

Swelling machine and manufacturing method of swelling machine floating body

ActiveCN103563829AChange powerImprove diffusion abilityPisciculture and aquariaGear wheelElectric machinery

The invention relates to a swelling machine and a manufacturing method of a swelling machine floating body. The swelling machine mainly comprises a motor, a reduction gearbox, a floating body, blades and a fixing rod, wherein the floating body is a hollow shell body, mounting spaces for mounting the blades are arranged on the circumference of the lower part of the floating body, and the blades are arranged in the mounting spaces; the middle part of the upper part of the floating body is sunken, an upper shell and a lower shell of the sunken part are integrated, and the sunken part is provided with a connection space matched with an output shaft; the reduction gearbox is mainly consists of a box body, a reduction gear, a bearing and the output shaft; the fixing rod is arranged on the reduction gearbox, a sealing chamber is arranged at the lower end of the reduction gearbox, the output shaft downwards extends out of the sealing chamber to drive the floating body to rotate together with the blades, and the motor and the reduction gearbox are fixed by the fixing rod to float on the water surface without rotation.

Owner:ZHEJIANG FORDY MACHINERY

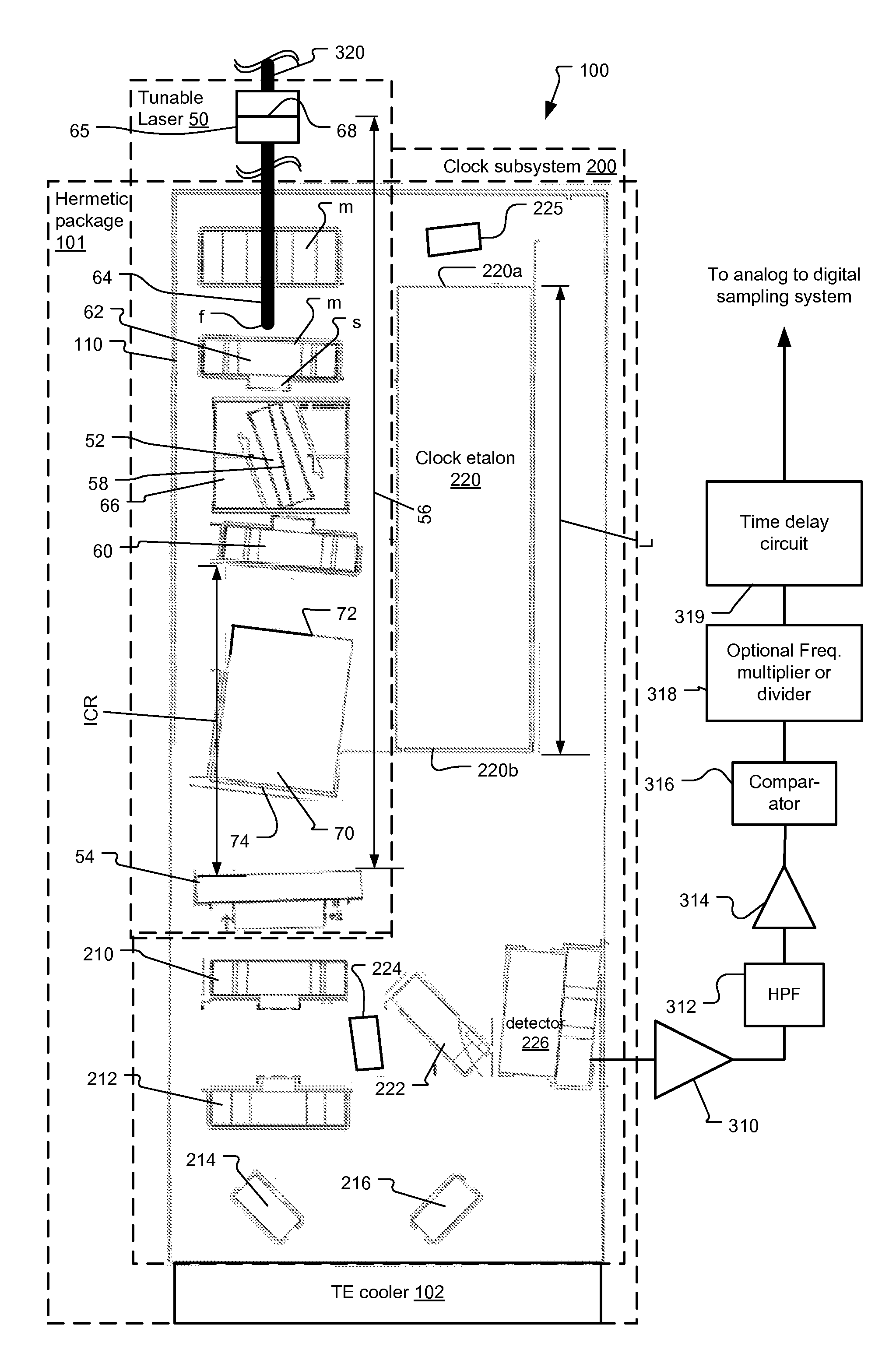

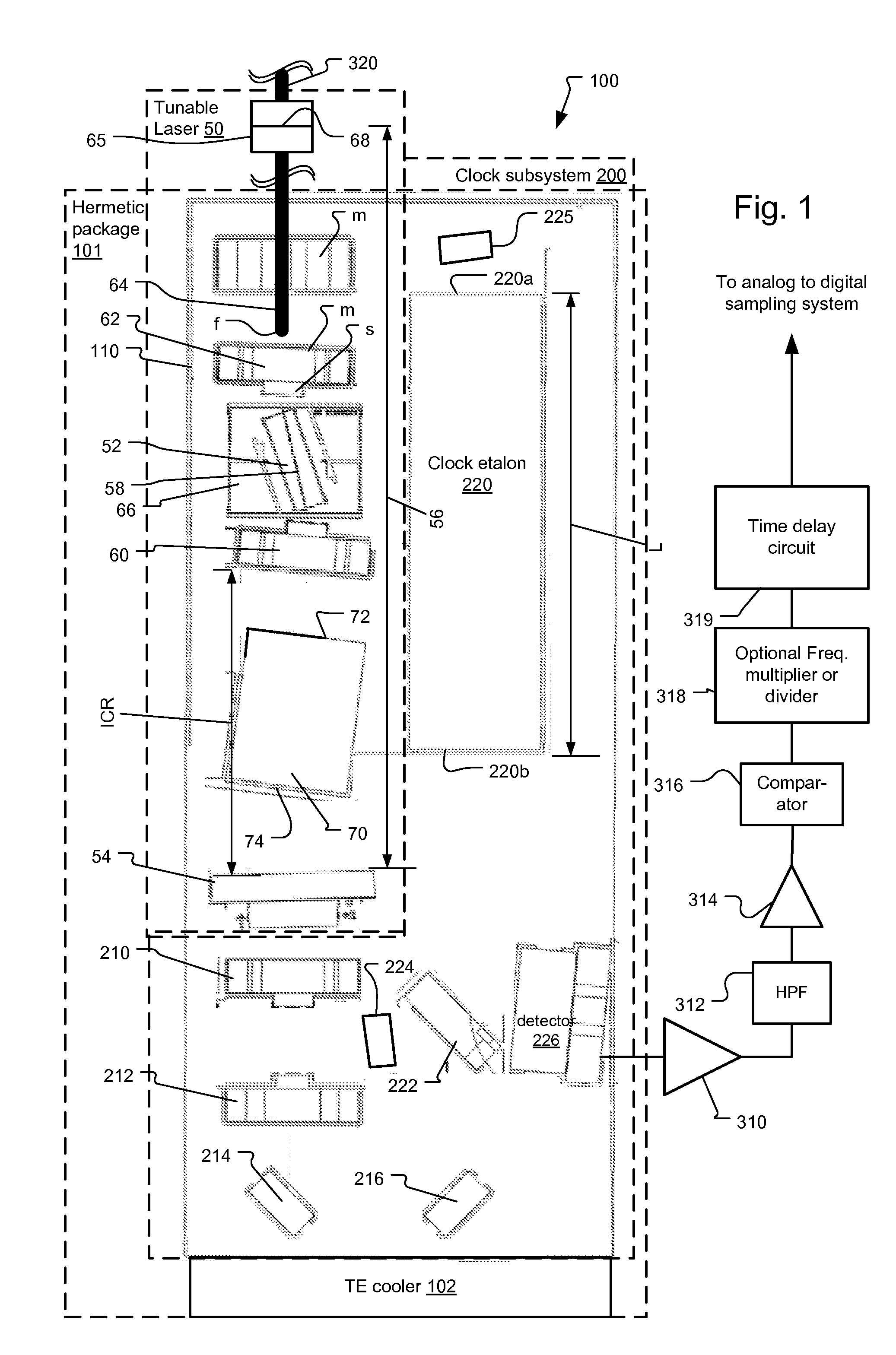

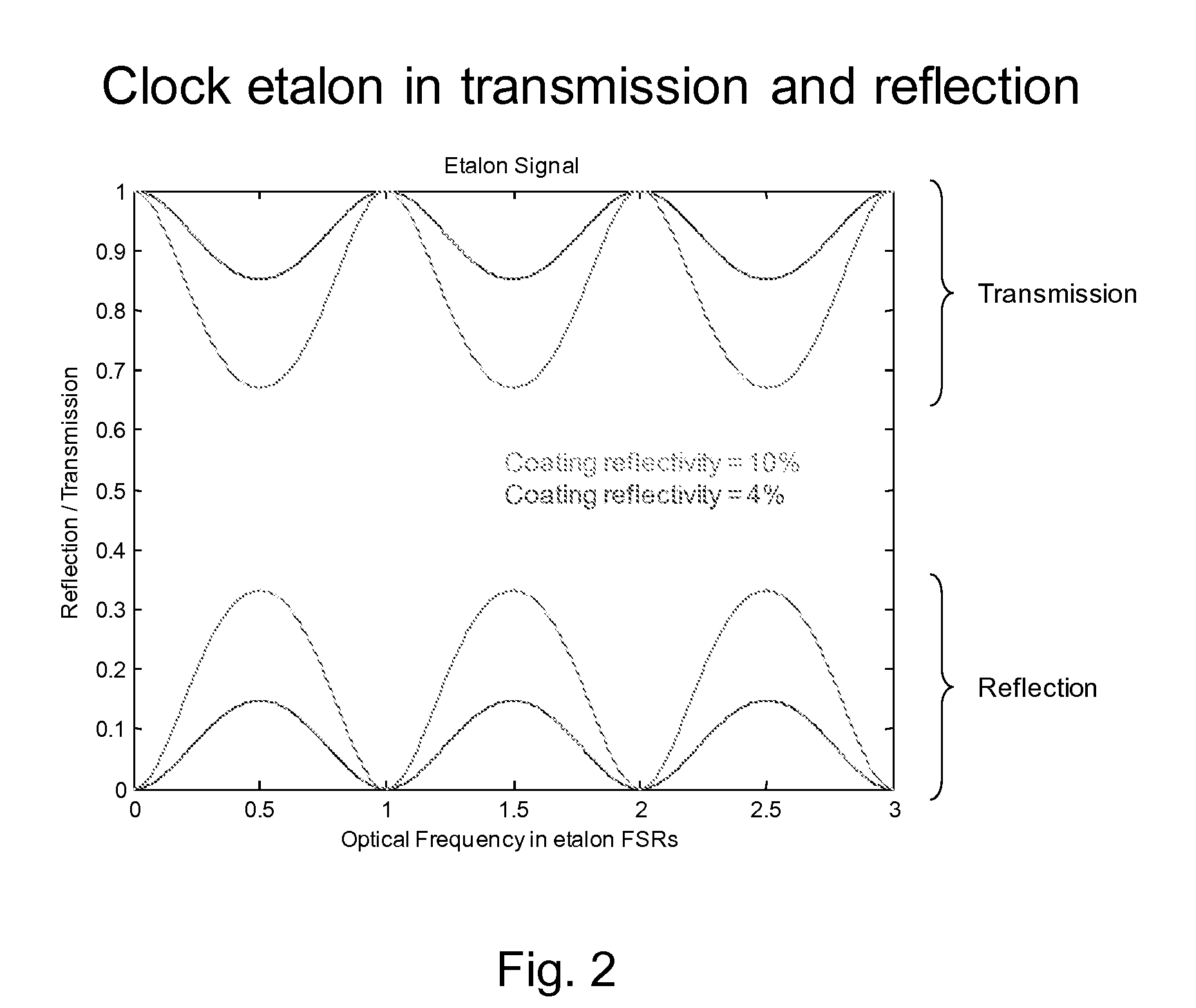

Optical coherence tomography laser with integrated clock

ActiveUS8564783B2Increase distanceReduce polarizationLaser detailsInterferometersOptical cavityOptical table

A frequency swept laser source for TEFD-OCT imaging includes an integrated clock subsystem on the optical bench with the laser source. The clock subsystem generates frequency clock signals as the optical signal is tuned over the scan band. Preferably the laser source further includes a cavity extender in its optical cavity between a tunable filter and gain medium to increase an optical distance between the tunable filter and the gain medium in order to control the location of laser intensity pattern noise. The laser also includes a fiber stub that allows for control over the cavity length while also controlling birefringence in the cavity.

Owner:EXCELITAS TECH

Automatic velocity control system for aircraft

ActiveUS7931238B2Minimizes the undesirable accelerations encounteredMinimizes the undesirable accelerations encountered by passengersAircraft power plantsAircraft controlSpeed control systemActuator

A flight control system for an aircraft receives a selected value of a first parameter, which is either the airspeed or inertial velocity of the aircraft. A primary feedback loop generates a primary error signal that is proportional to the difference between the selected value and a measured value of the first parameter. A secondary feedback loop generates a secondary error signal that is proportional to the difference between the selected value of the first parameter and a measured value of a second flight parameter, which is the other of the airspeed and inertial velocity. The primary and secondary error signals are summed to produce a velocity error signal, and the velocity error signal and an integrated value of the primary error signal are summed to produce an actuator command signal. The actuator command signal is then used for operating aircraft devices to control the first parameter to minimize the primary error signal.

Owner:TEXTRON INNOVATIONS

Accommodating lens with cavity

ActiveUS20170371180A1Increase optical powerChange in optical powerOptical articlesCoatingsCross-linkDissolution

A lens comprises an internal cavity structure formed by dissolution of a soluble insert material. The internal soluble material may dissolve through a body of a lens such as a contact lens in order to form the cavity within the contact lens. The cavity within the lens can be shaped in many ways, and corresponds to the shape of the dissolved material, such that many internal cavity shapes can be readily fabricated within the contact lens. The insert can be placed in a mold with a pre-polymer material, and the pre-polymer material cured with the insert placed in the mold to form the lens body. The polymerized polymer may comprise a low expansion polymer in order to inhibit expansion of the lens when hydrated. The polymer may comprise a hydrogel when hydrated. The soft contact lens material comprises a sufficient amount of cross-linking to provide structure to the lens and shape the cavity.

Owner:ONEFOCUS VISION

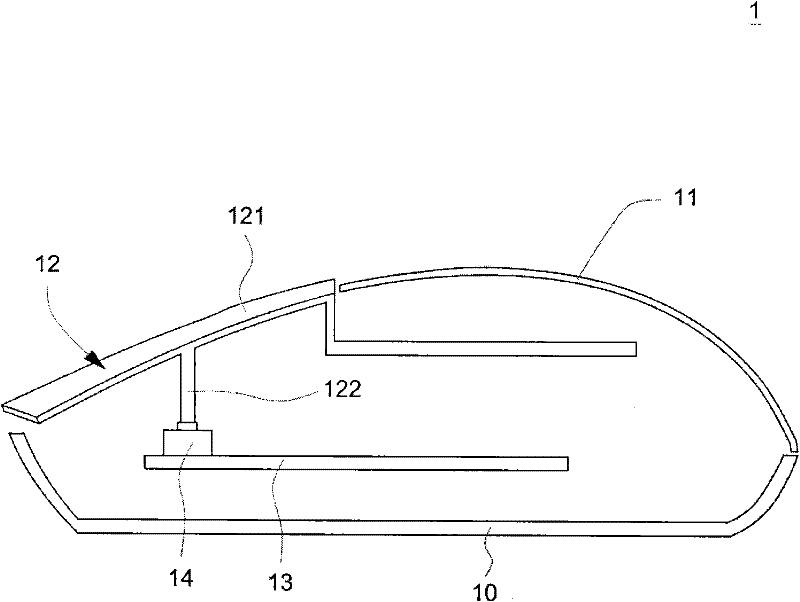

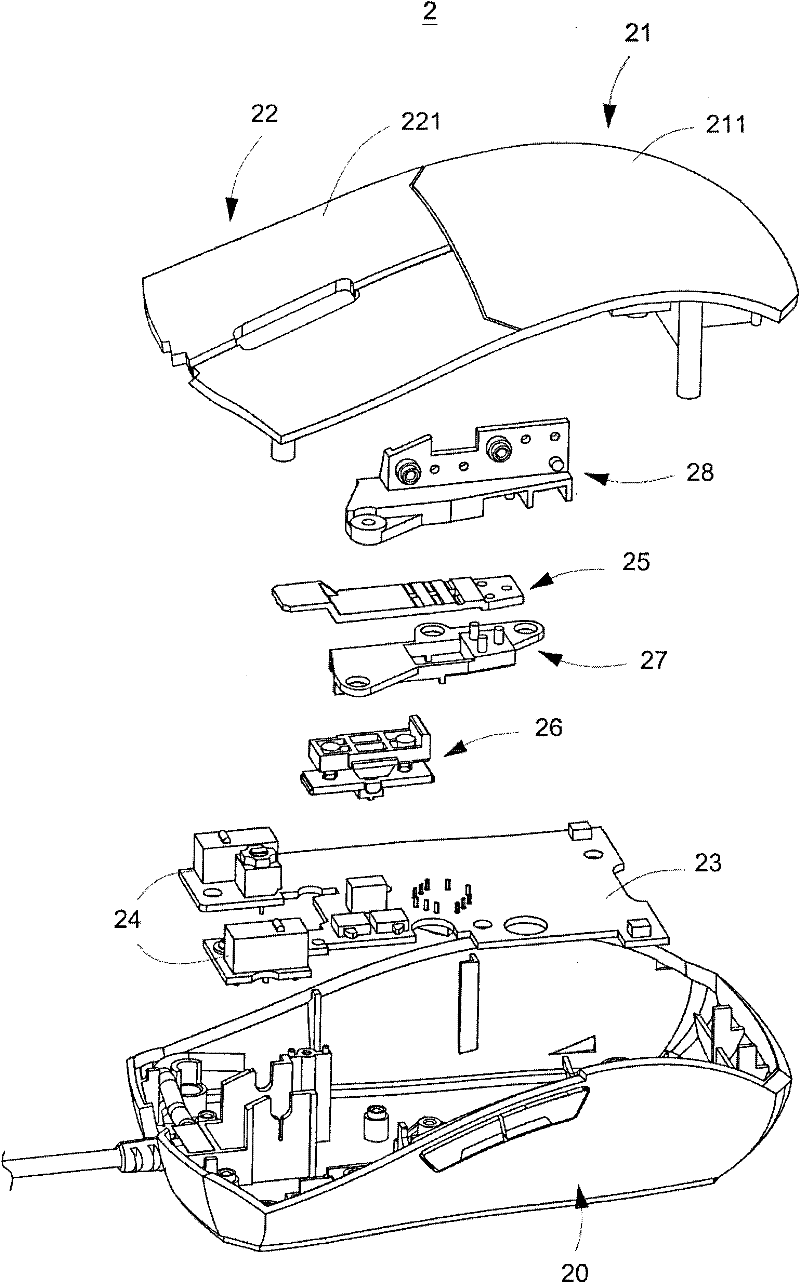

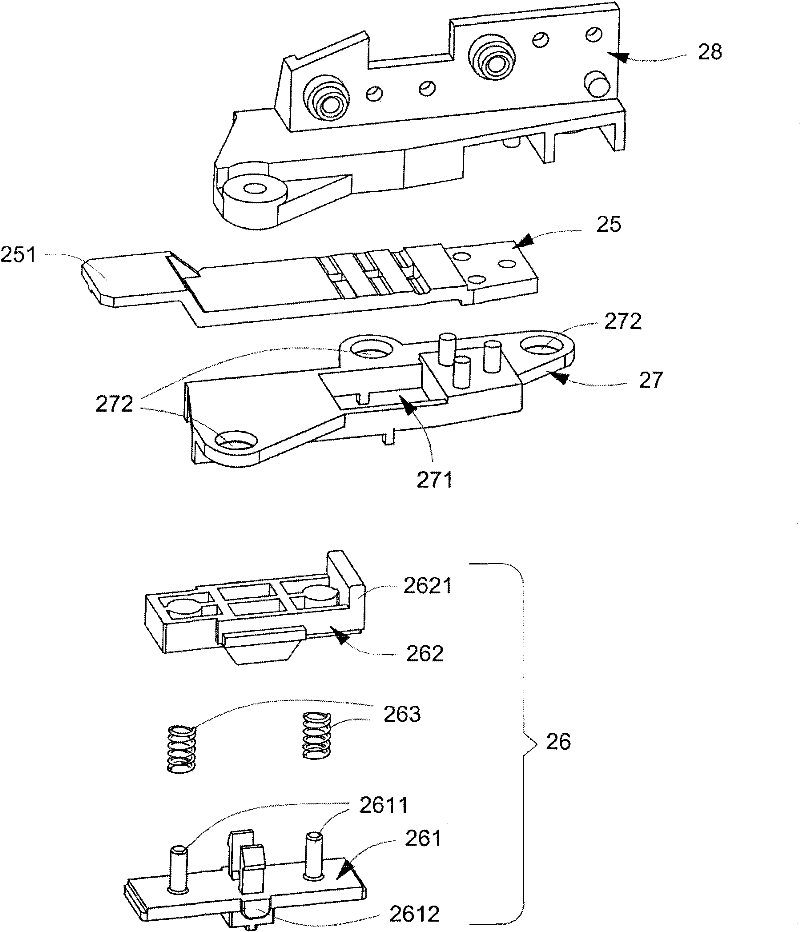

A mouse device capable of changing the pressing force of a button

InactiveCN102298451AChange powerIncreased operating comfortElectric switchesTactile feedbackContact pressureEngineering

The invention provides a mouse device with a changeable key touch pressure. The mouse device comprises a base, keys arranged on a shell, a pressure plate in contact with the keys and a shift element in contact with the pressure plate, wherein the shift element extends out of the base and can be moved. When the shift element is moved to a first position and comes into contact with a first contact part of the pressure plate, the force required for touching and pressing the key is first key touch pressure. When the shift element is moved to a second position and comes into contact with a second contact part of the pressure plate, the force required for touching and pressing the key is second key touch pressure. The mouse device provided by the invention has the advantage of improved operation comfortableness.

Owner:PRIMAX ELECTRONICS LTD

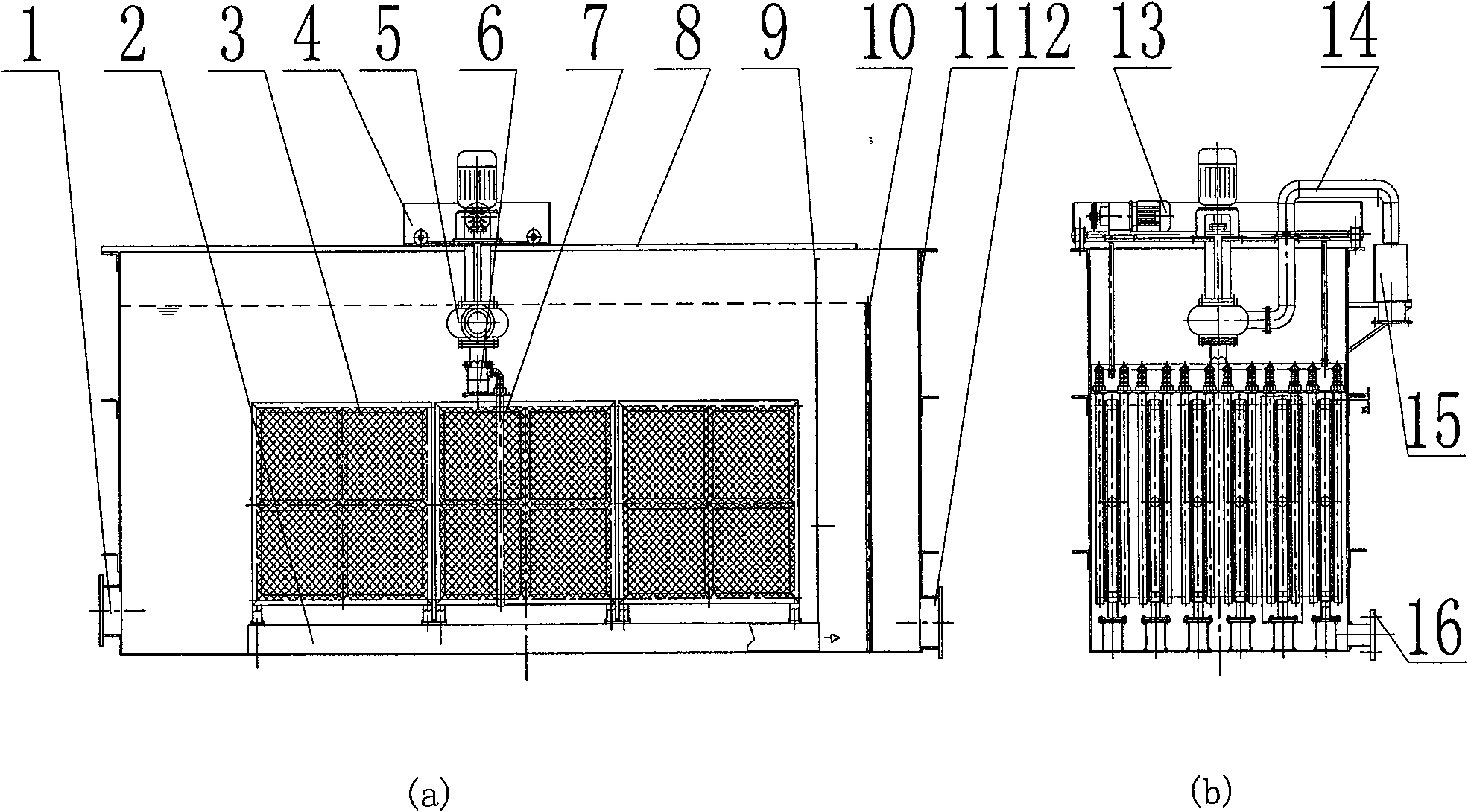

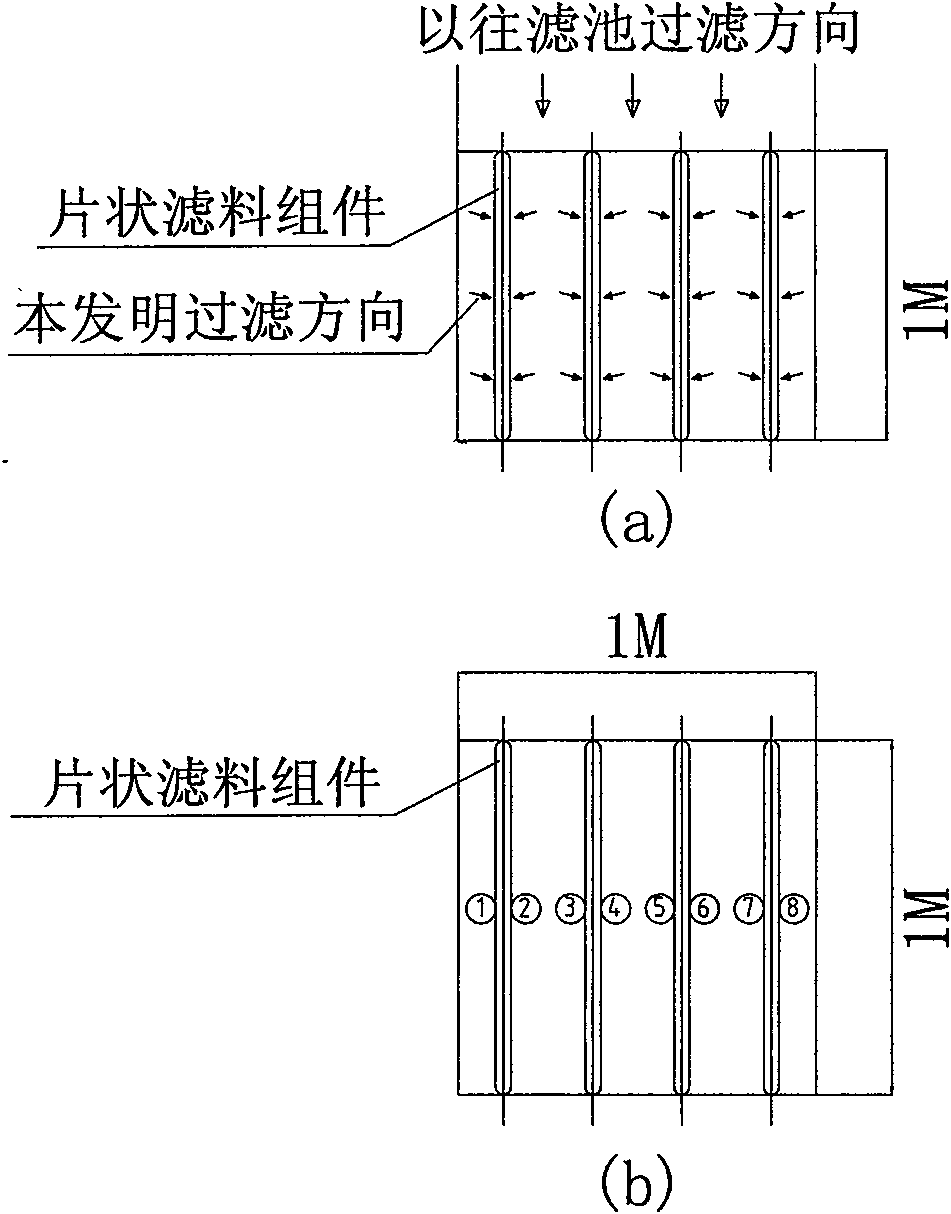

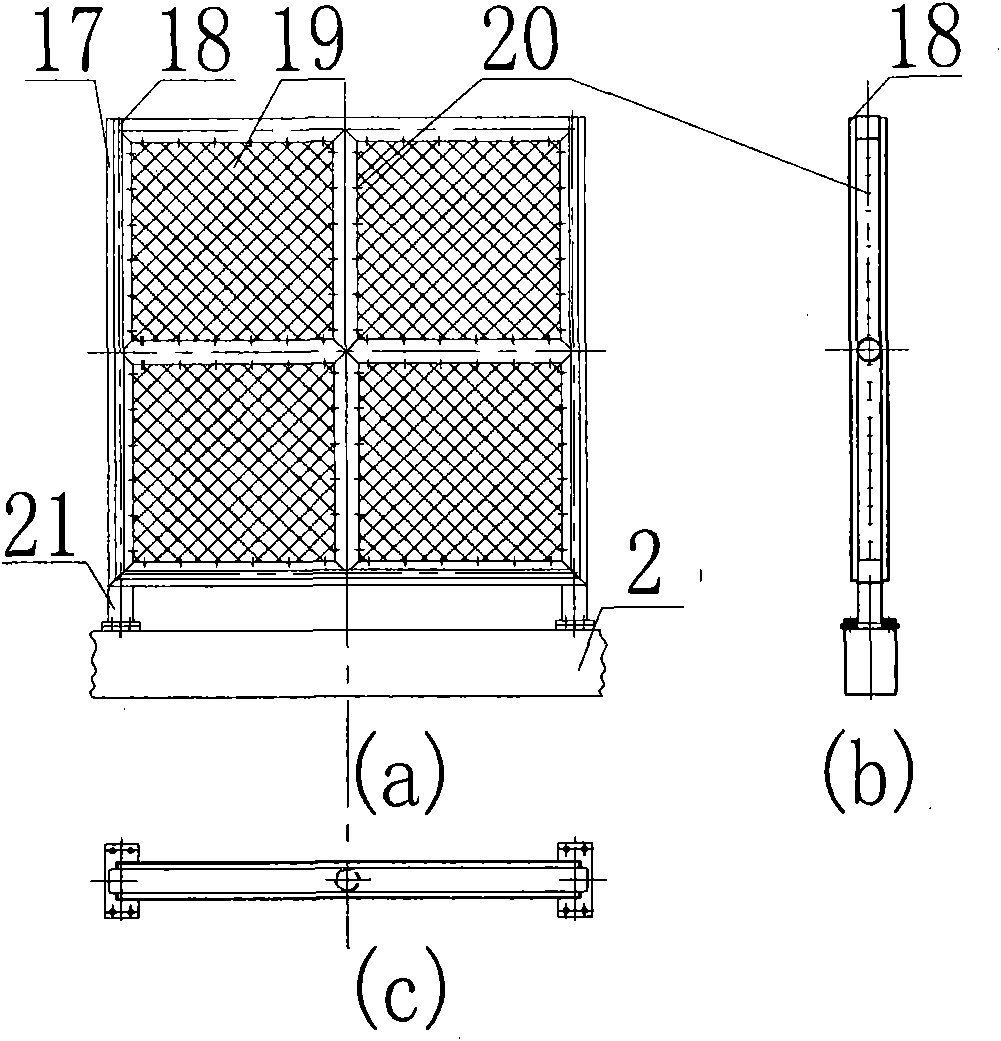

Filtering device with filter body adopting flaky filtering material

InactiveCN101658739ALess investmentSmall footprintStationary filtering element filtersLight filterSystem configuration

The invention belongs to the technical field of water treatment, in particular to a filtering device with a filter body adopting flaky filtering materials. The filtering device comprises a flaky filtering assembly, a dredging pipe, a dredging pump, a dolly, a dolly guide rail, a clapboard, an effluent weir and a shell, wherein a water inlet, a water outlet and a vent nozzle are arranged below theshell, the flaky filtering assembly is vertically arranged in the shell, a clear water outlet pipe is arranged at the bottom of the flaky filtering assembly, the effluent weir is vertically fixed at the water outlet near the shell, the clapboard is vertically fixed in the shell and positioned between the flaky filtering assembly and the effluent weir, the dolly guide rail is positioned at the topof the shell, the dolly is positioned on the dolly guide rail and can move on the dolly guide rail back and forth, the dredging pump is fixed below the dolly, one end of the dredging pipe is positioned at two sides of the flaky filtering material assembly, and the other end of the dredging pipe is connected with the dredging pump by a main dredging pipe. The invention adopts valve-free operationsand the light filtering materials, increases the filtering area, reduces the filtering load, has less backwashing water consumption and flexible system collocation and is convenient for increasing treating scale. The invention has the advantages of low energy consumption, small occupying area, simple operation and maintenance, and the like, and has higher purifying efficiency while in integrated application with the generate water treatment technology as well as wide application prospects.

Owner:TONGJI UNIV

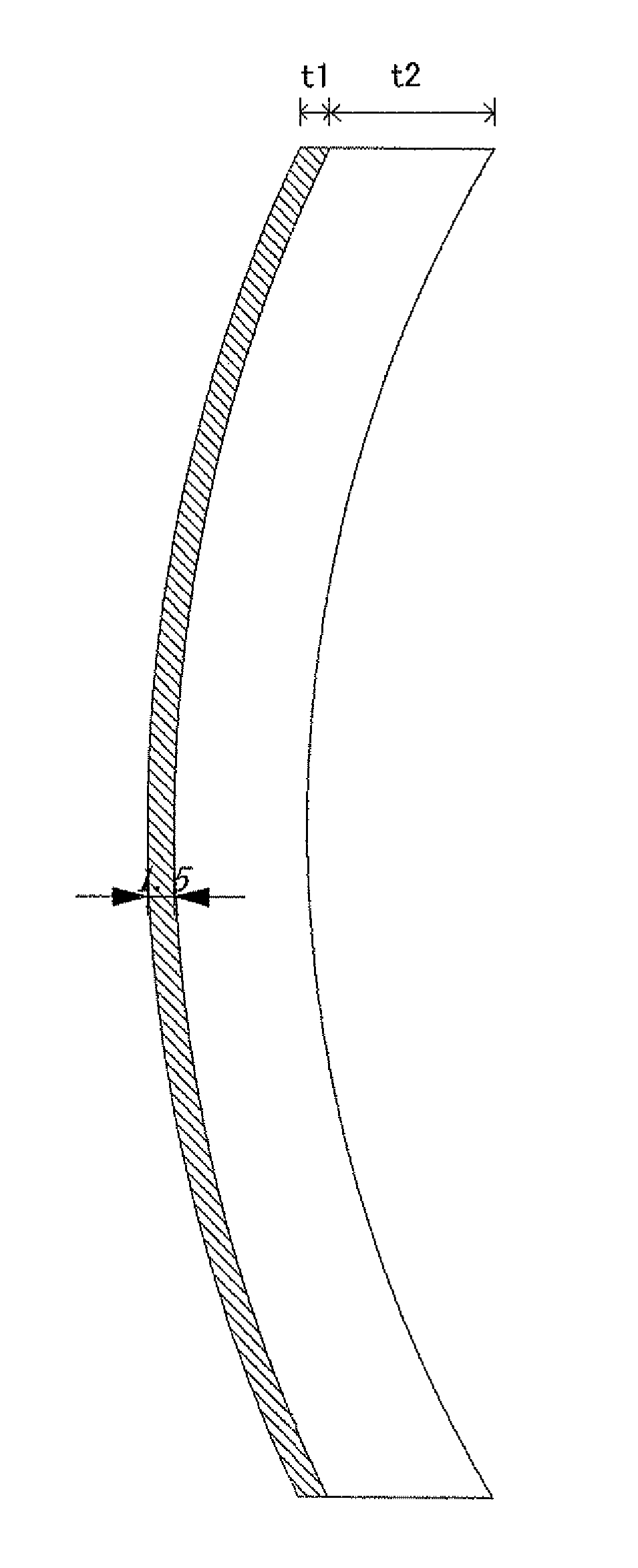

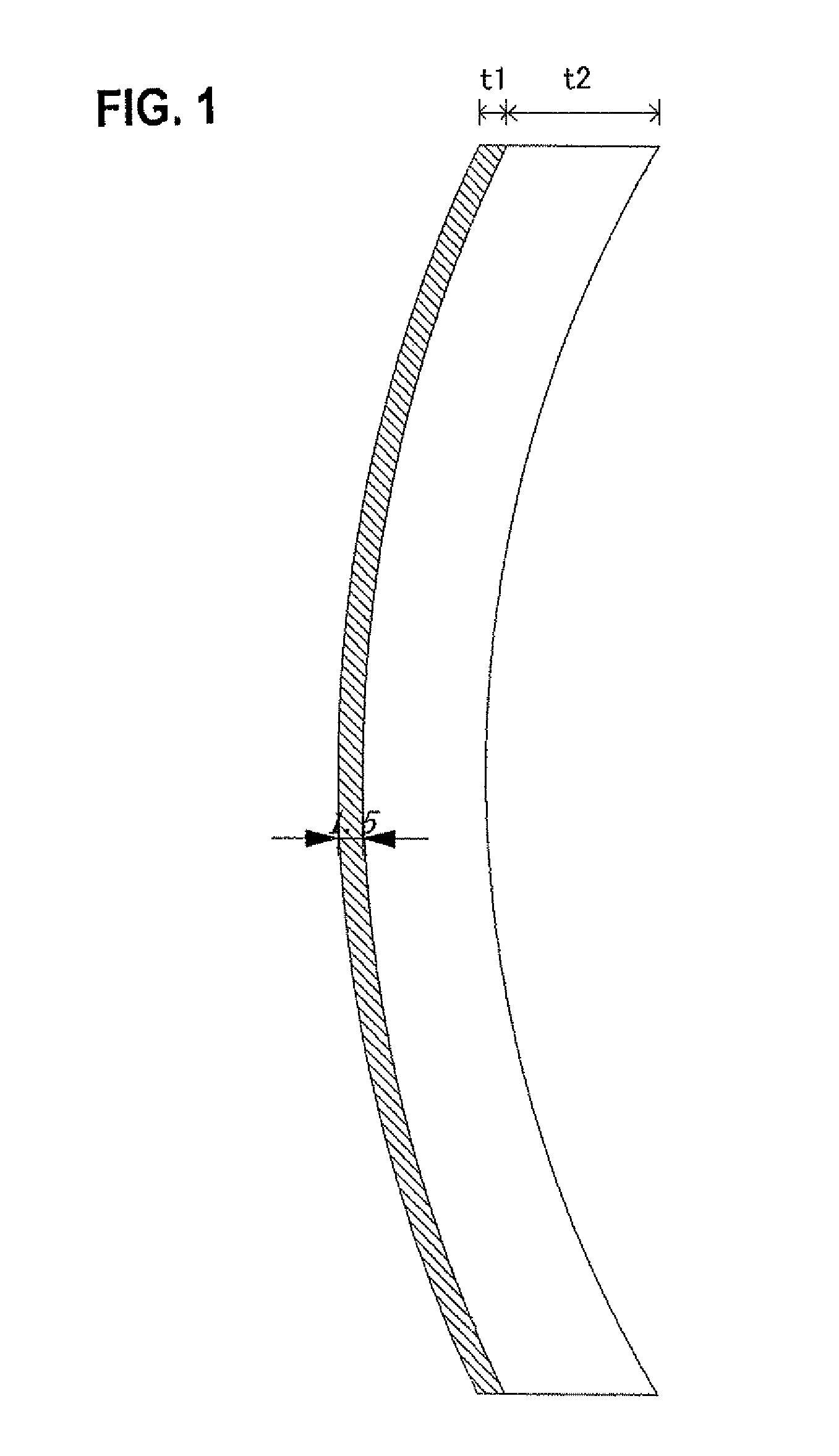

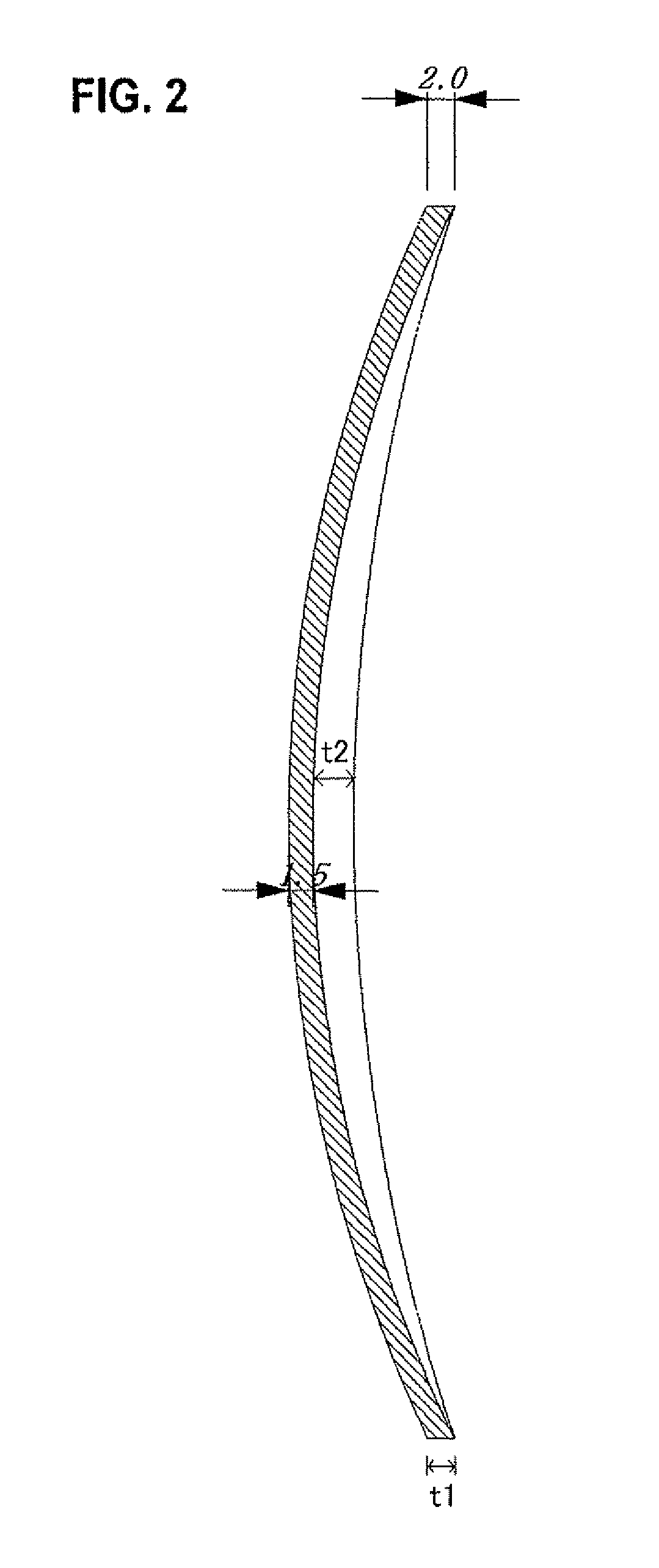

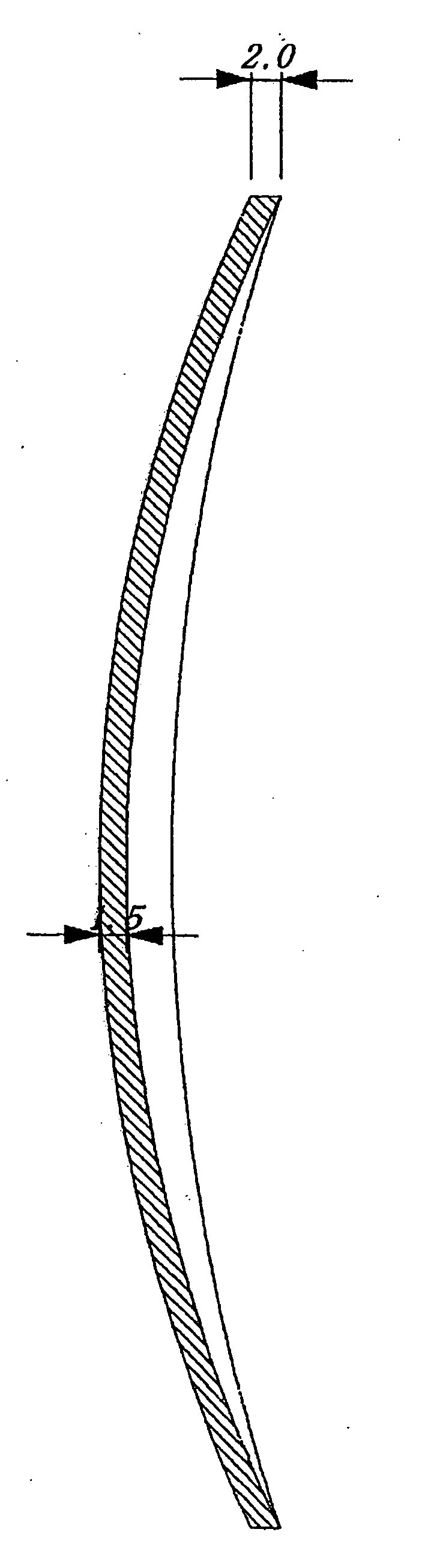

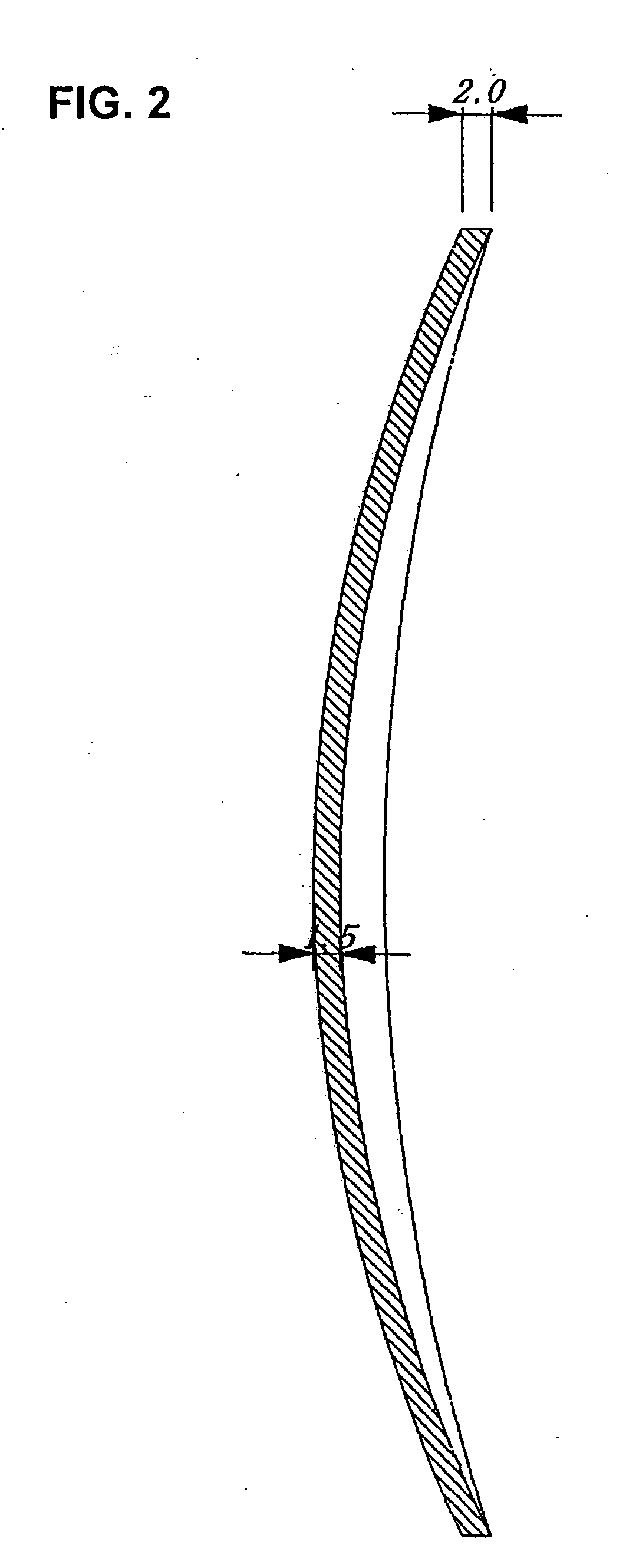

Tinted semi-finished lens having impact resistance and method for manufacturing the same

ActiveUS8292430B2Change powerUniformly formedSpectales/gogglesOptical articlesThird partyOptoelectronics

Provided is a method for manufacturing a tinted semi-finished lens that uses polycarbonate, has high light shielding effect, has impact resistance even after polishing, and can have a uniform tint. In particular, in order to provide a tinted semi-finished lens that has the same light shielding at the lens center and the lens edge when a wearer looks through the tinted lens, and furthermore, that seems to have the same light shielding when a third party looks at the wearer, a tinted layer having a uniform thickness and a transparent layer on the back side are integrally formed. Furthermore, in order to provide the impact resistance to either of the resins included in the layers, a low flow resin having a large molecular weight and a short flow length is used. In order to minimize lens distortion and to provide the impact resistance to the lens, the transparent layer employs a resin having the impact resistance, and the transparent layer is formed first and then the tinted layer is formed as an additional layer. Moreover, provided is a method for simultaneously manufacturing two sets of tinted lenses. In the method, two sets of molds are used, a first molded product is obtained in one of the two sets of the molds, and then is transferred to the other mold to form a second molded product, and simultaneously, another first molded product is molded in the first mold.

Owner:MIYOSHI INDAL ENTERPRISE

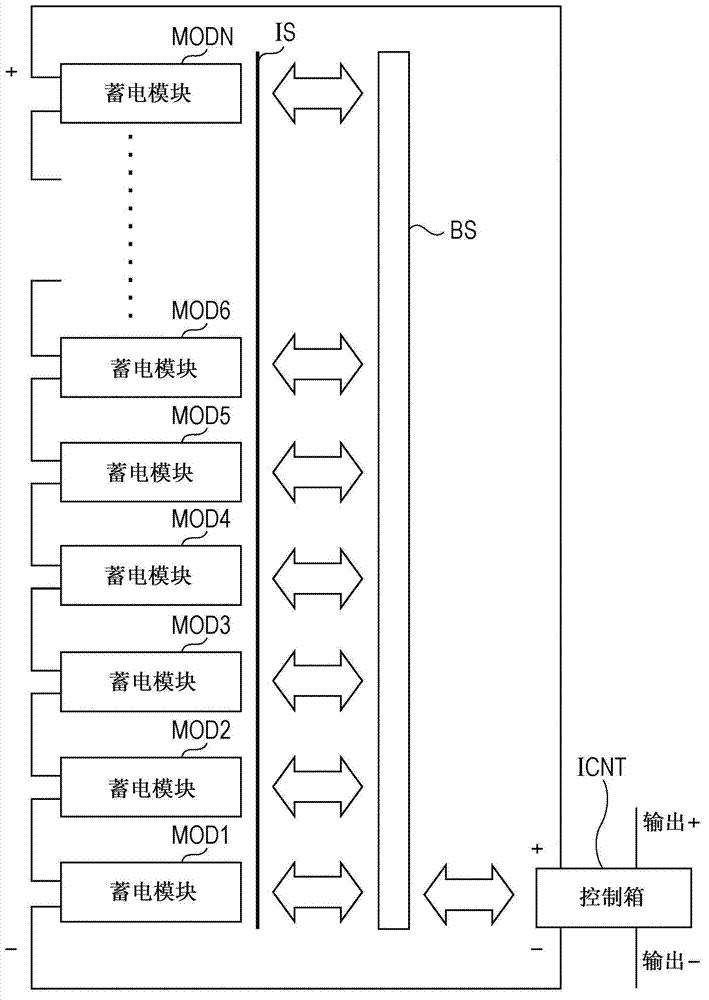

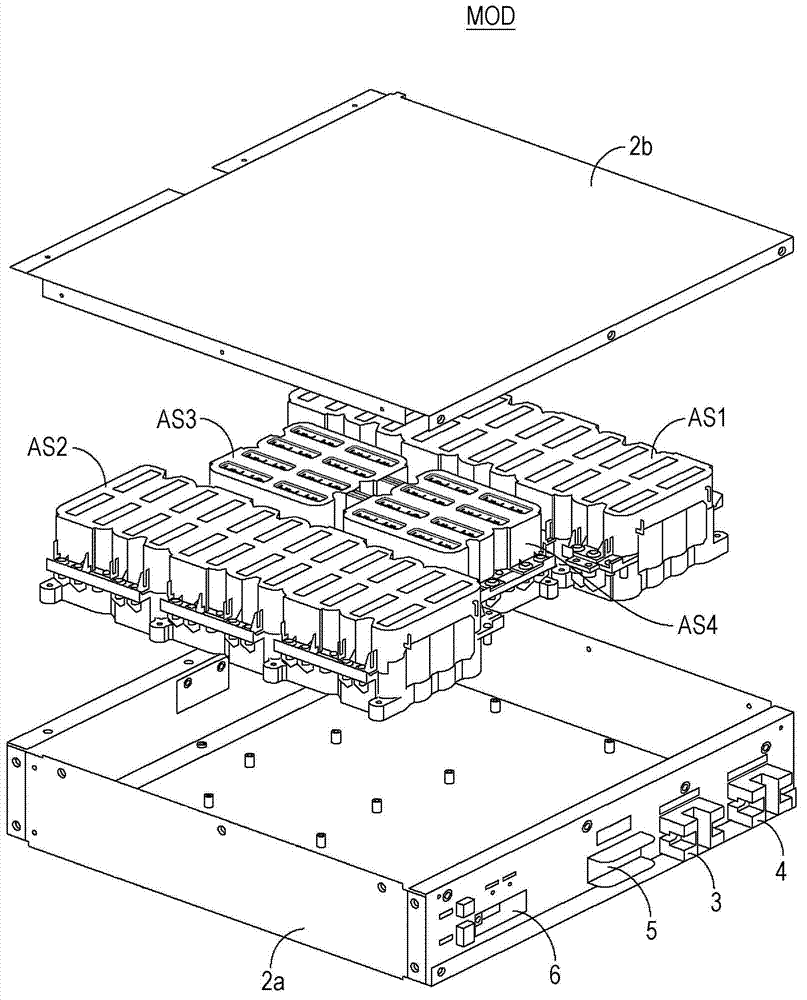

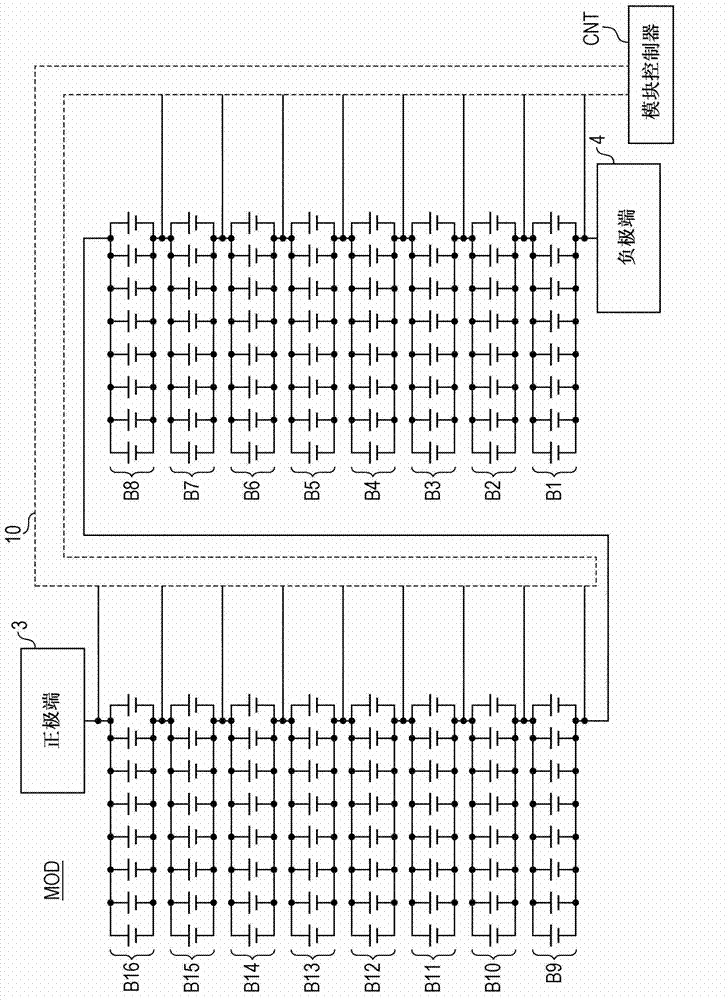

Power storage apparatus and electric vehicle

ActiveCN102969747AEasy wiringChange powerBatteries circuit arrangementsElectrical testingElectrical batteryElectric power system

A power storage apparatus, electric device, electric vehicle, and power system are disclosed. In an example embodiment, a power storage apparatus includes a battery block comprising a plurality of battery cells and an isolating unit that enables wireless information transfer regarding battery information of the battery block.

Owner:MURATA MFG CO LTD

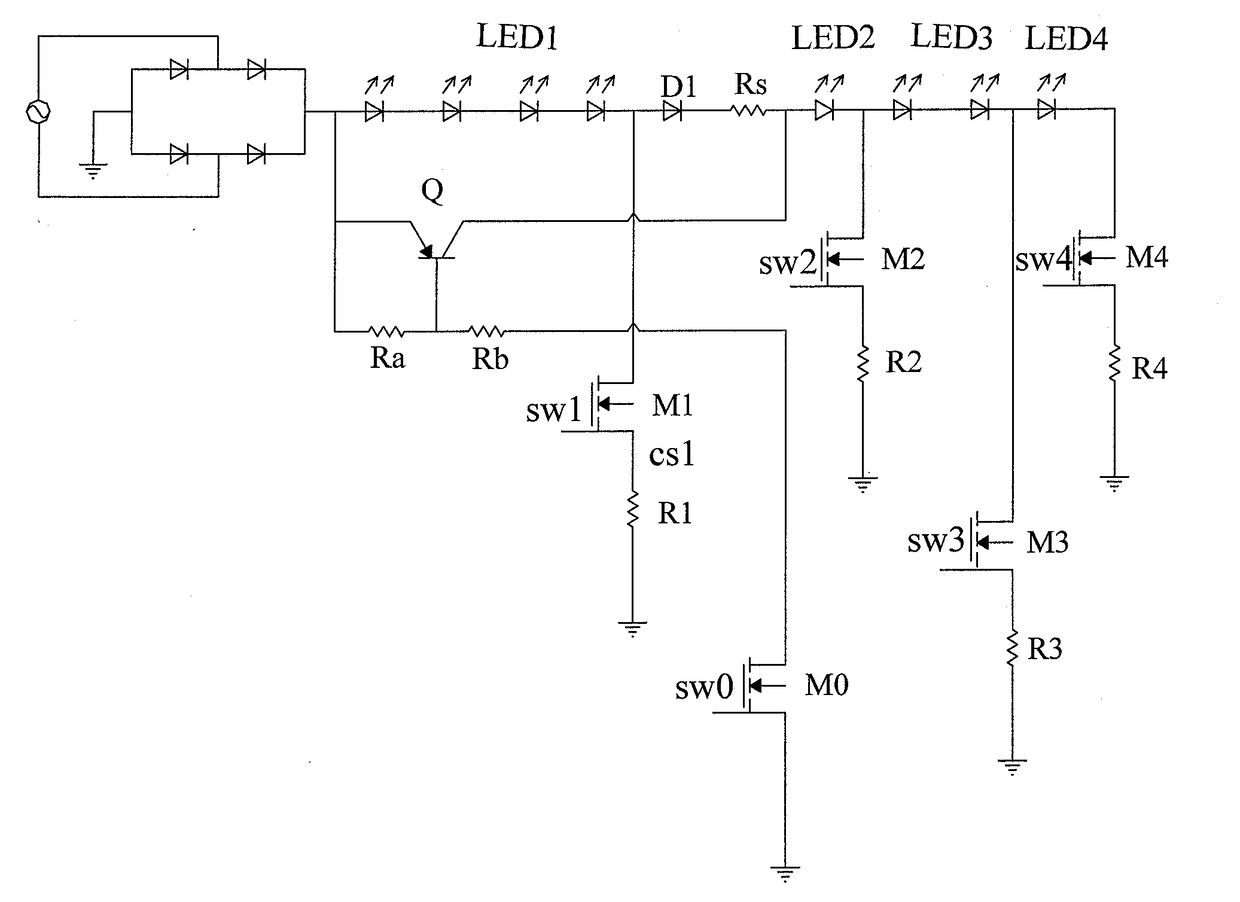

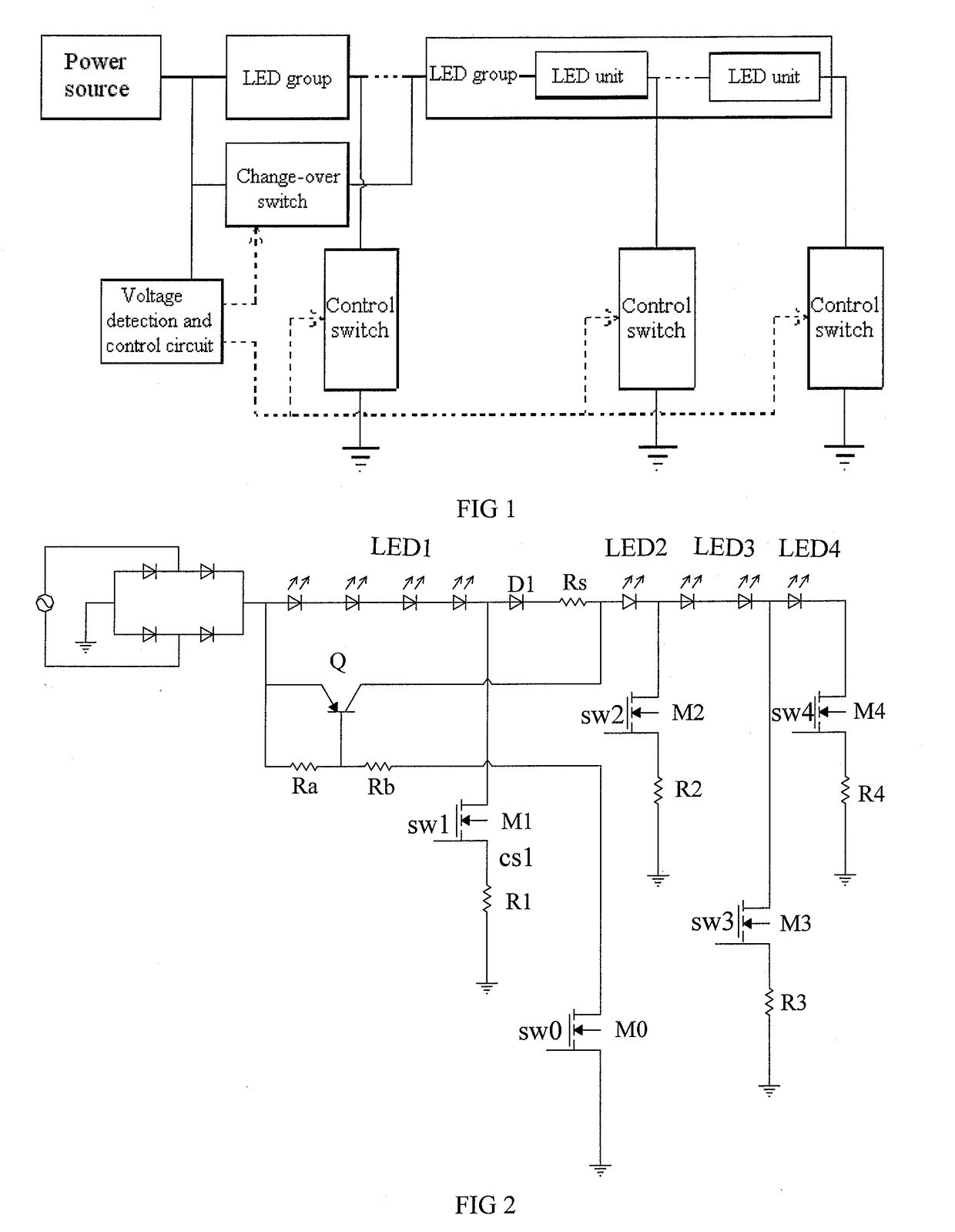

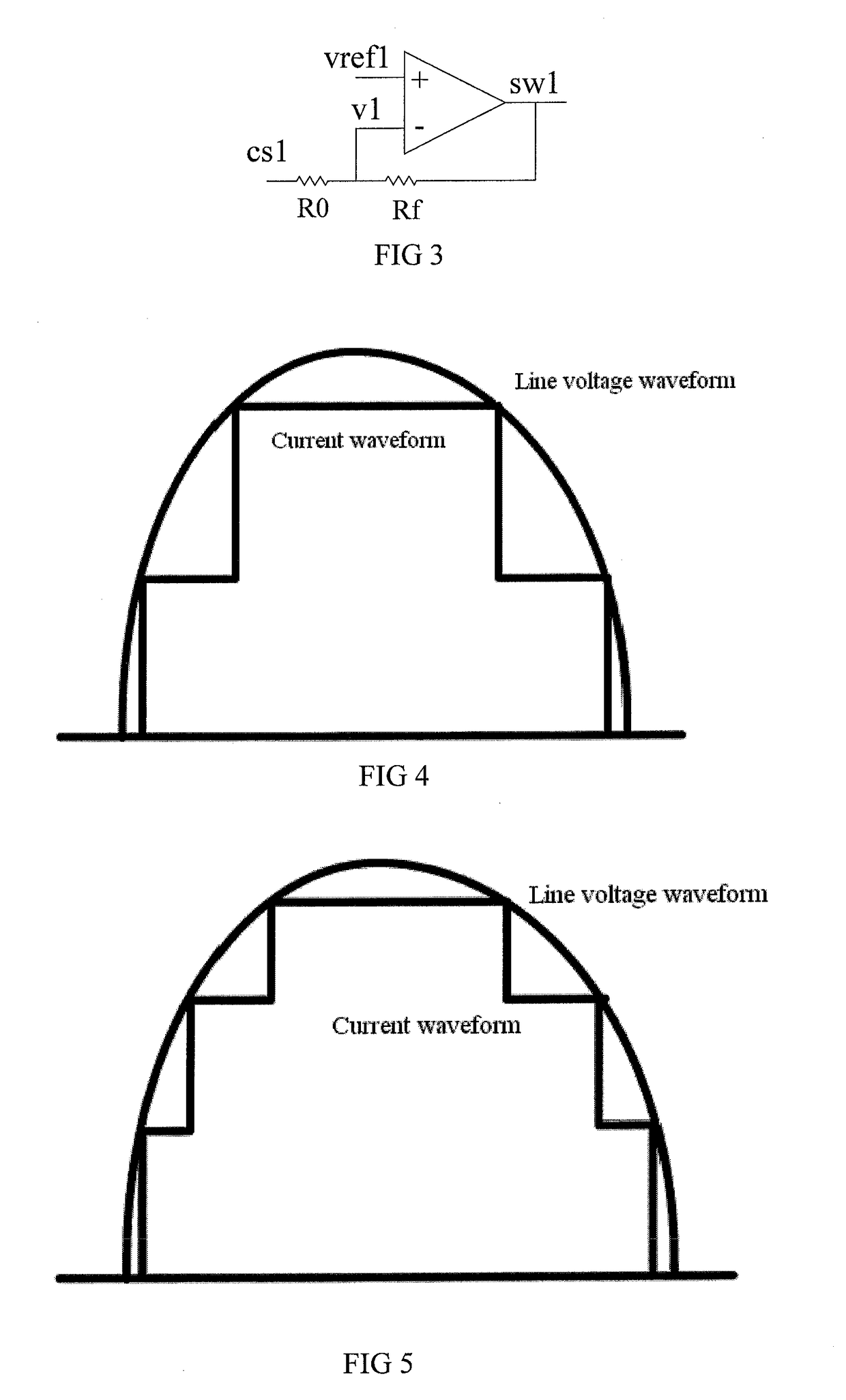

A full voltage segmented linear constant-current LED drive circuit in auto switchover mode

ActiveUS20170318631A1Reduce Harmonic DistortionChange powerElectrical apparatusElectroluminescent light sourcesDriver circuitPower factor

The present invention discloses a full voltage segmented linear constant-current LED drive circuit in an auto switchover mode, comprising a minimum two groups of LEDs in parallel connection in proper sequence and a voltage detection and control circuit used for detection of power voltage; positive terminal of each group of LEDs is directly connected or indirectly connected to the power source via the change-over switch; negative terminal of each group of LEDs is grounded via corresponding control switch; wherein, one group of LEDs comprises a minimum two groups of LED units in series connection in proper sequence; negative terminal of each LED unit is grounded via corresponding control switch; the change-over switch and control switch are connected to and controlled by the voltage detection and control circuit to change inter-group parallel connection mode and ON / OFF of different LED units. The drive circuit according to the present invention can switch over series and parallel connection mode of LED, which can also easily adjust total load current in time according to voltage fluctuation mode, and thereby reduce harmonic distortion, and cater to power factor.

Owner:CHENHUI GUANGBAO TECH CO LTD

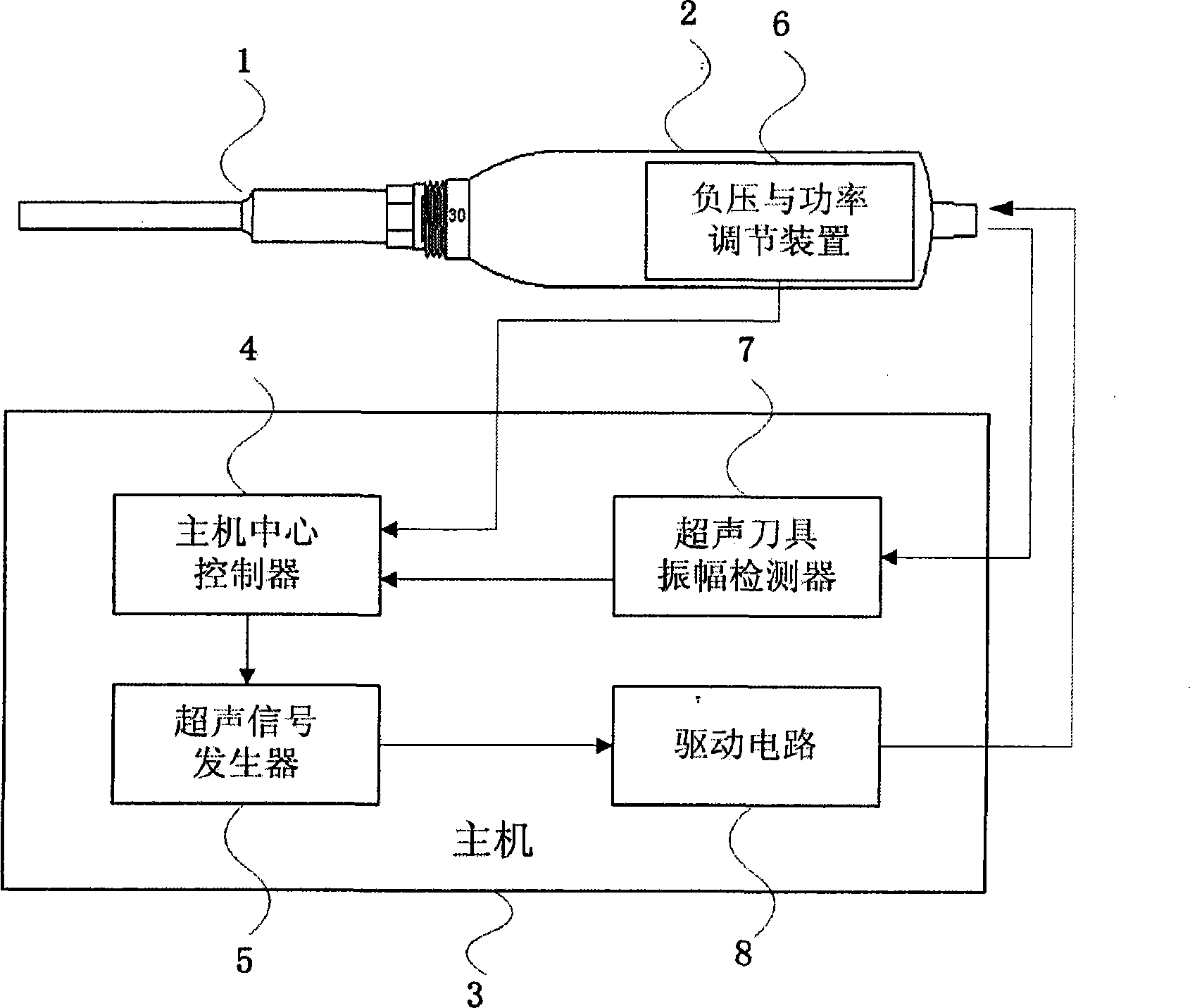

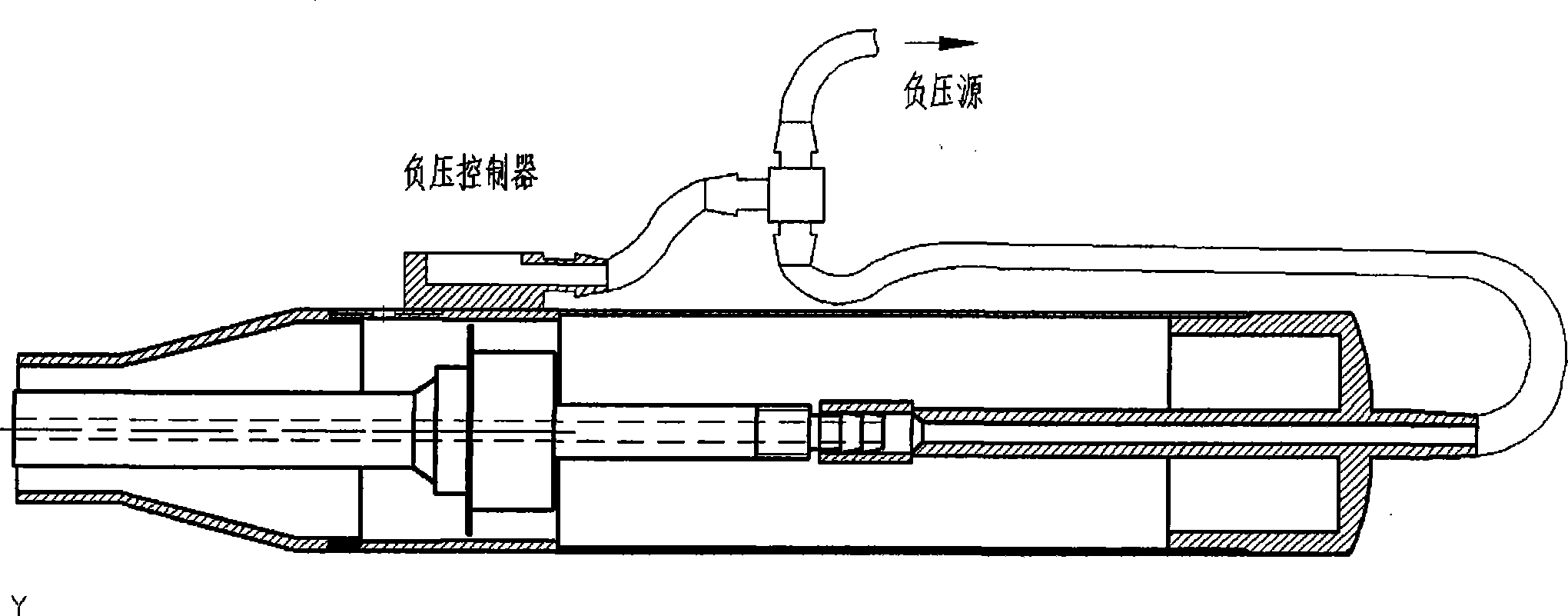

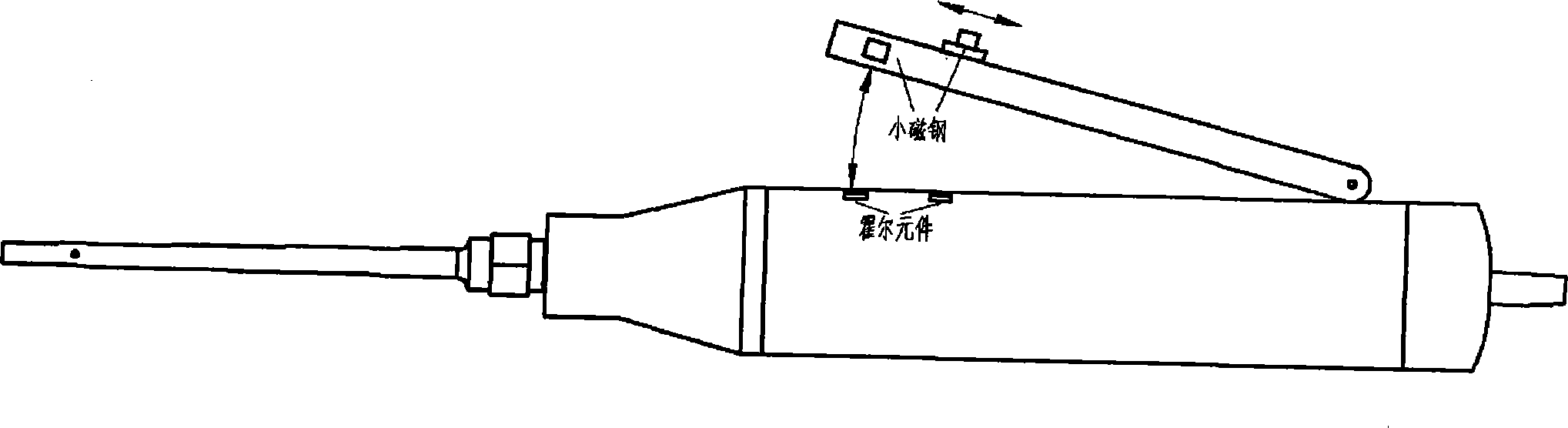

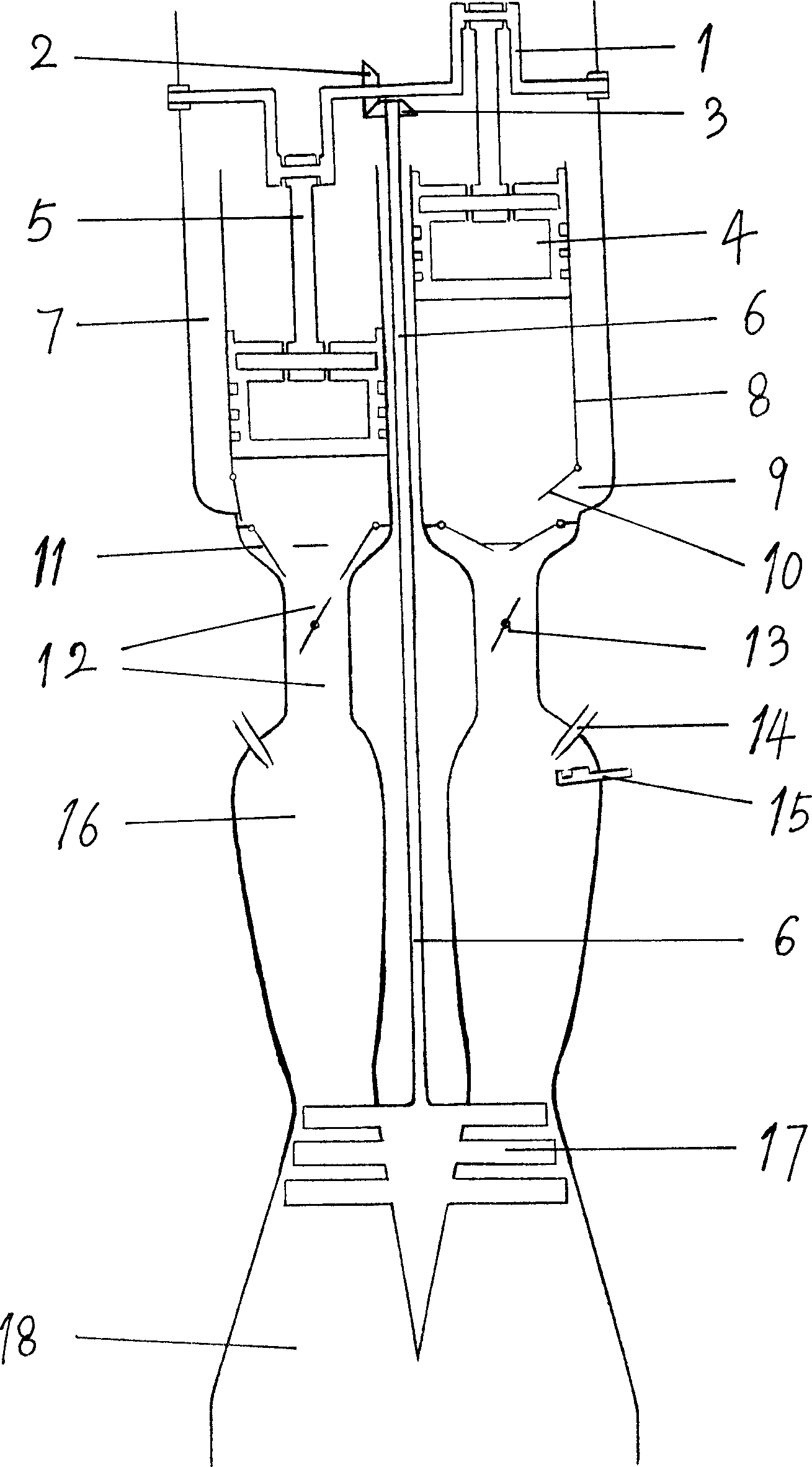

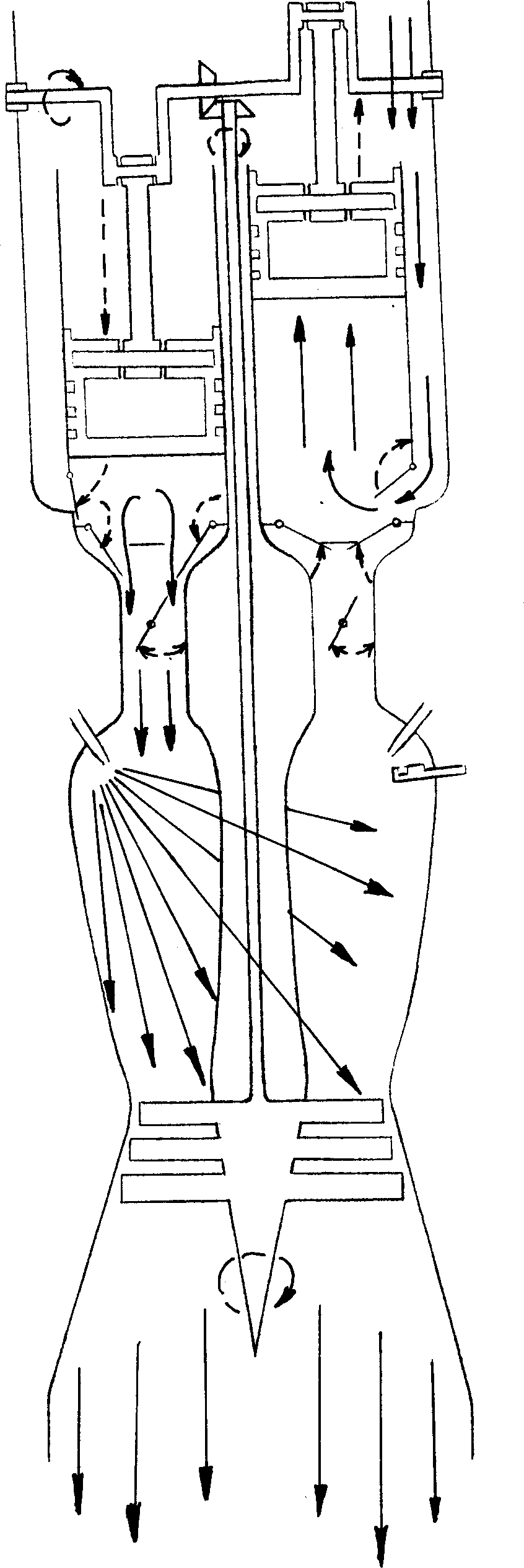

Ultrasonic aspiration operation system capable of being controlled accurately

ActiveCN103720492APrecise control of amplitudeMaintain a constant output amplitudeUltrasound therapySurgeryElectric signalUltrasonic vibration

An ultrasonic aspiration operation system capable of being controlled accurately structurally comprises an ultrasonic cutter (1), an ultrasonic handle (2) and a main machine (3). The ultrasonic cutter (1) is used for transmitting ultrasonic vibration. The ultrasonic handle (2) is connected with the ultrasonic cutter (1), converts ultrasonic frequency electrical signals into mechanical vibration, drives the ultrasonic cutter (1) to work, can detect the amplitude of the ultrasonic cutter (1) through a sensing piece, the amplitude is fed back to the main machine in an electrical signal mode, and the negative pressure and the power can be adjusted in a mechanical mode or an electrical signal mode. The main machine (3) gives ultrasonic frequency signals, drives the ultrasonic handle (2) to work, and can receive the amplitude, detected through the sensing piece, of the ultrasonic cutter (1) and adjust the output power according to the signals so as to control the output amplitude accurately.

Owner:北京速迈医疗科技有限公司

Piston type gas combustion turbine engine

The present invention relates to a piston type gas turbine engine. It is characterized by that it adopts piston instead of air compressor of traditional gas turbine engine, the crankshaft is connected with piston connecting rod, the piston connecting rod is connected with piston, said piston can be reciprocally moved in the cylinder body, on lower end wall of said cylinder body an air inlet valve is set, the tail end of said cylinder body is equipped with an air supply valve, in the compressed air channel a throttle valve is set, the conical gear on the crankshaft is meshed with the conical gear in the upper end of turbine rotating shaft, and the lower end of said turbine, rotating shaft is connected with turbine.

Owner:李志文

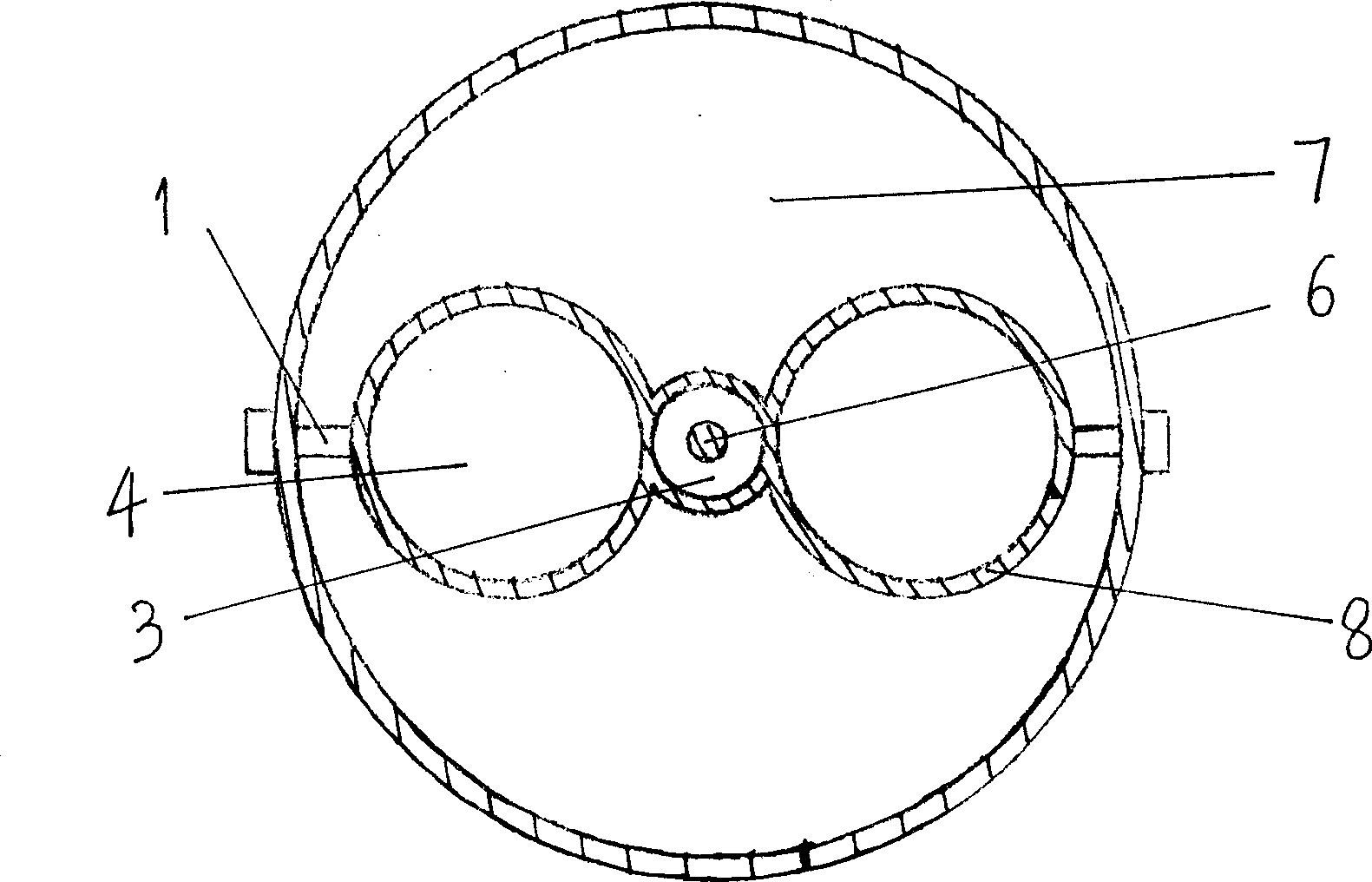

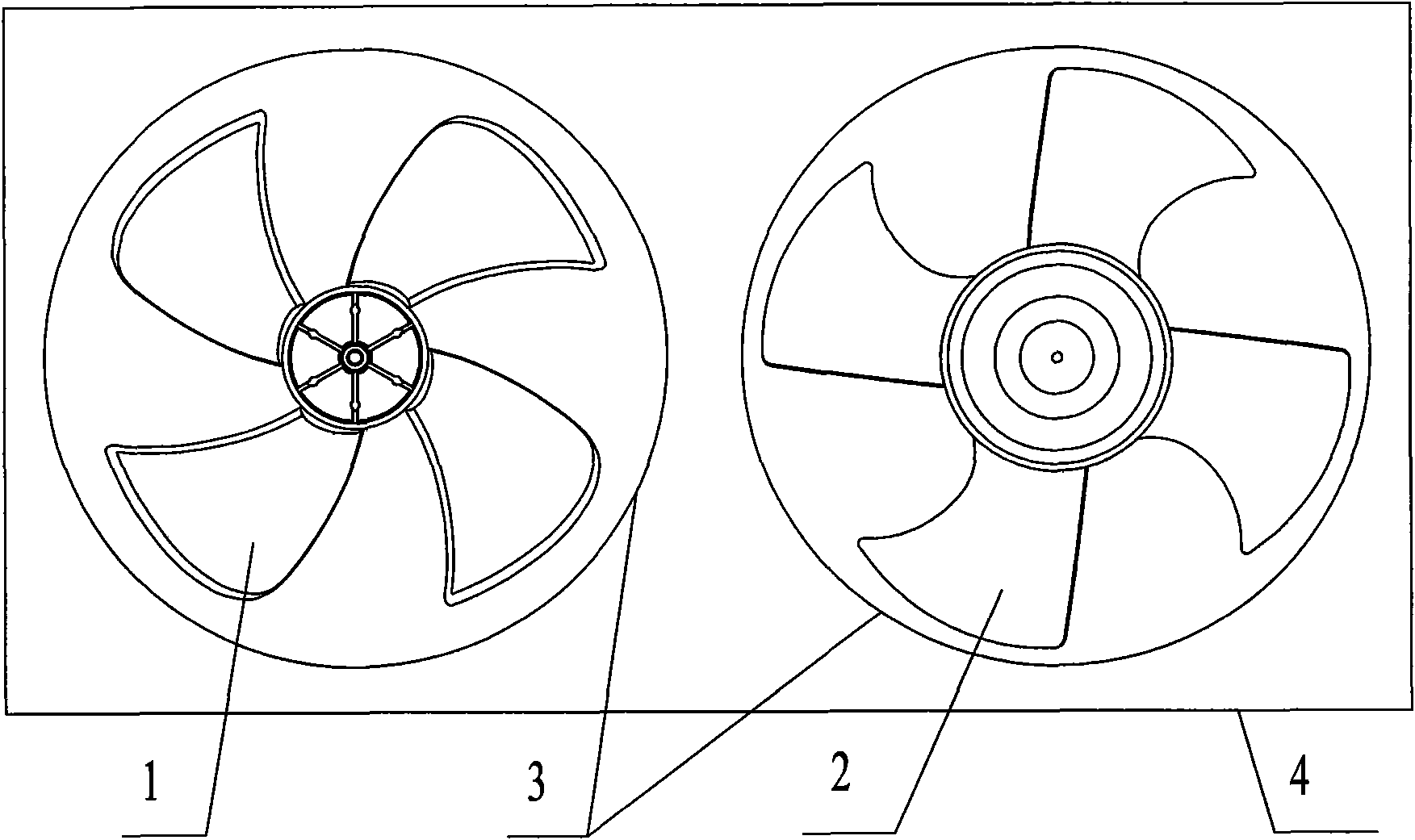

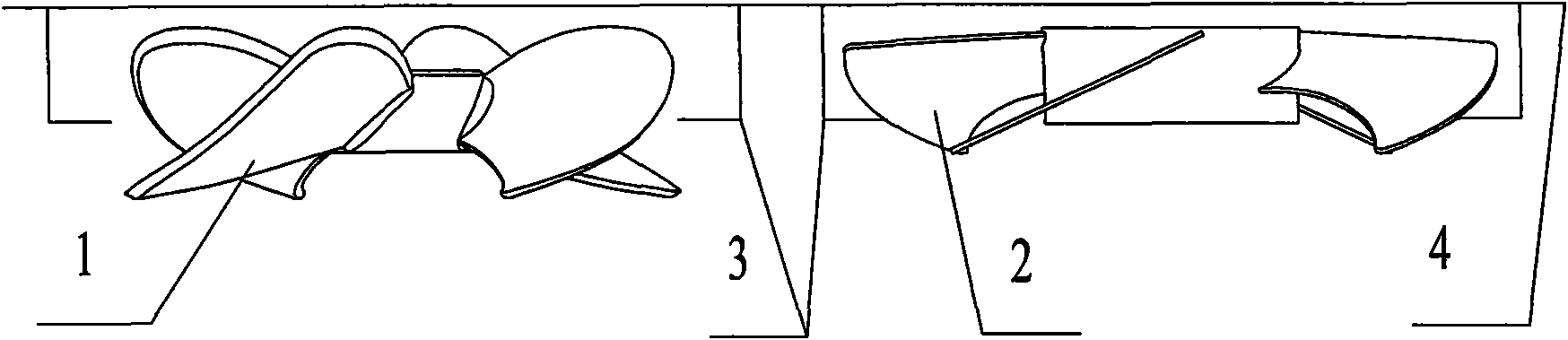

Double axial-flow wind wheel system

ActiveCN101644274AImprove sound qualityIngenious designPump componentsPump installationsEngineeringMachining system

The invention provides a double axial-flow wind wheel system, comprising a first axial-flow wind wheel (1) and a second axial-flow wind wheel (2); wherein the rotate speed of the first axial-flow windwheel (1) is N1 circle / minute, the number of blade is Z1, and rotating basic frequency F1=Z1XN1 / 60 Hz; and the rotate speed of the second axial-flow wind wheel (w) is N2 circle / minute, the number ofblade is Z2, and rotating basic frequency F2=Z2XN2 / 60 Hz. The system is characterized in that the rotating basic frequency between the first axial-flow wind wheel (1) and the second axial-flow wind wheel (2) is in the range of 4-20 Hz. When being used in an outer machine of an air conditioning room with top wind out structure, side wind out structure or oblique upper wind out structure, because the rotating basic frequency between the first axial-flow wind wheel (1) and the second axial-flow wind wheel (2) is from 4 to 20 Hz, the system can change the rotating noise voice pressure and the voice powder of the double axial-flow wind wheel, thereby greatly weakening or completely removing the beat vibration formed by overlapping the rotating noise of the two wind wheels, obviously improving the tone quality of the outer machine system of the double axial-flow wind wheel, effectively preventing the metal plate structure from resonating, and reaching the aim of reducing the vibration and improving the reliability of the whole machine.

Owner:MIDEA GRP CO LTD

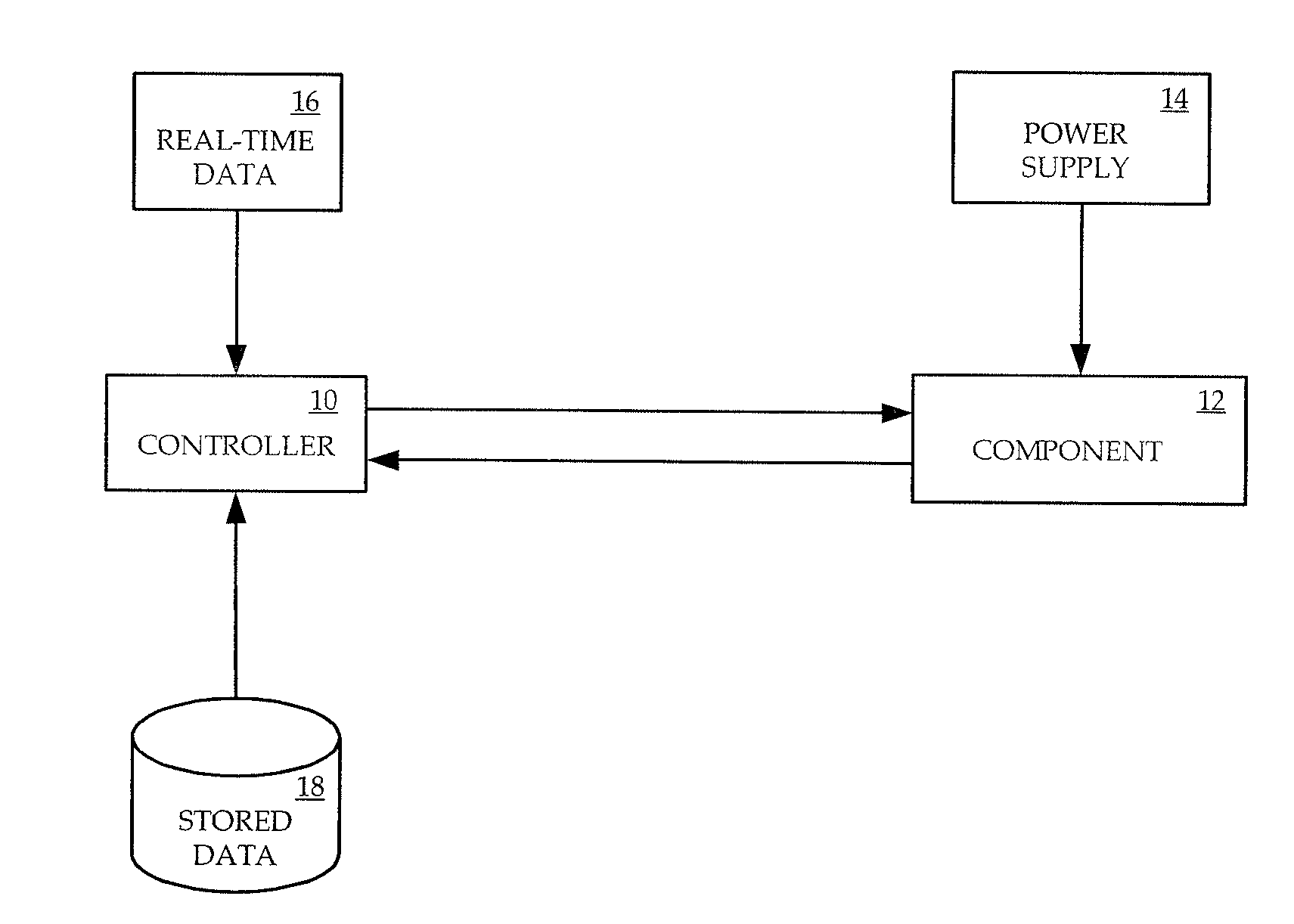

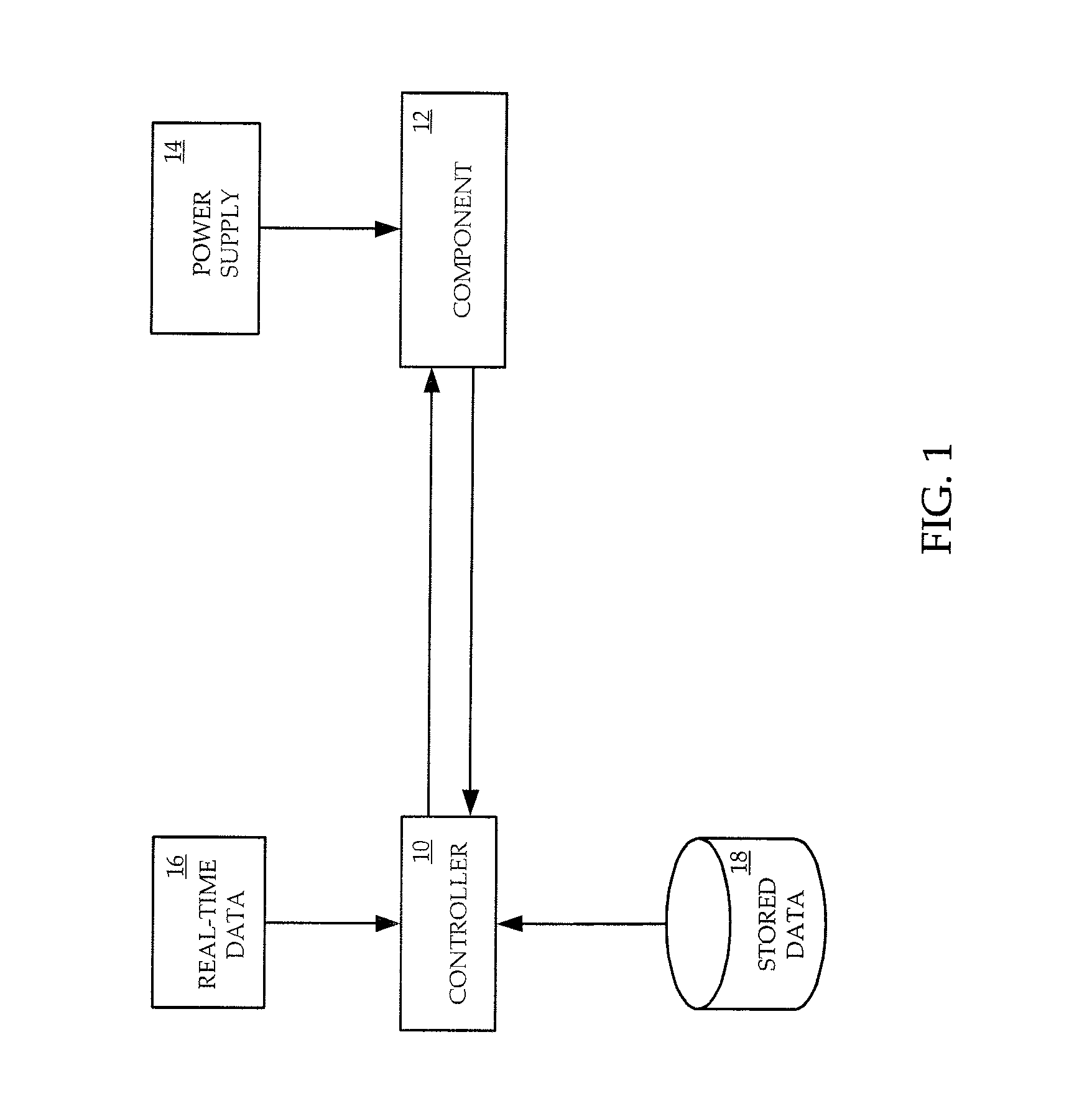

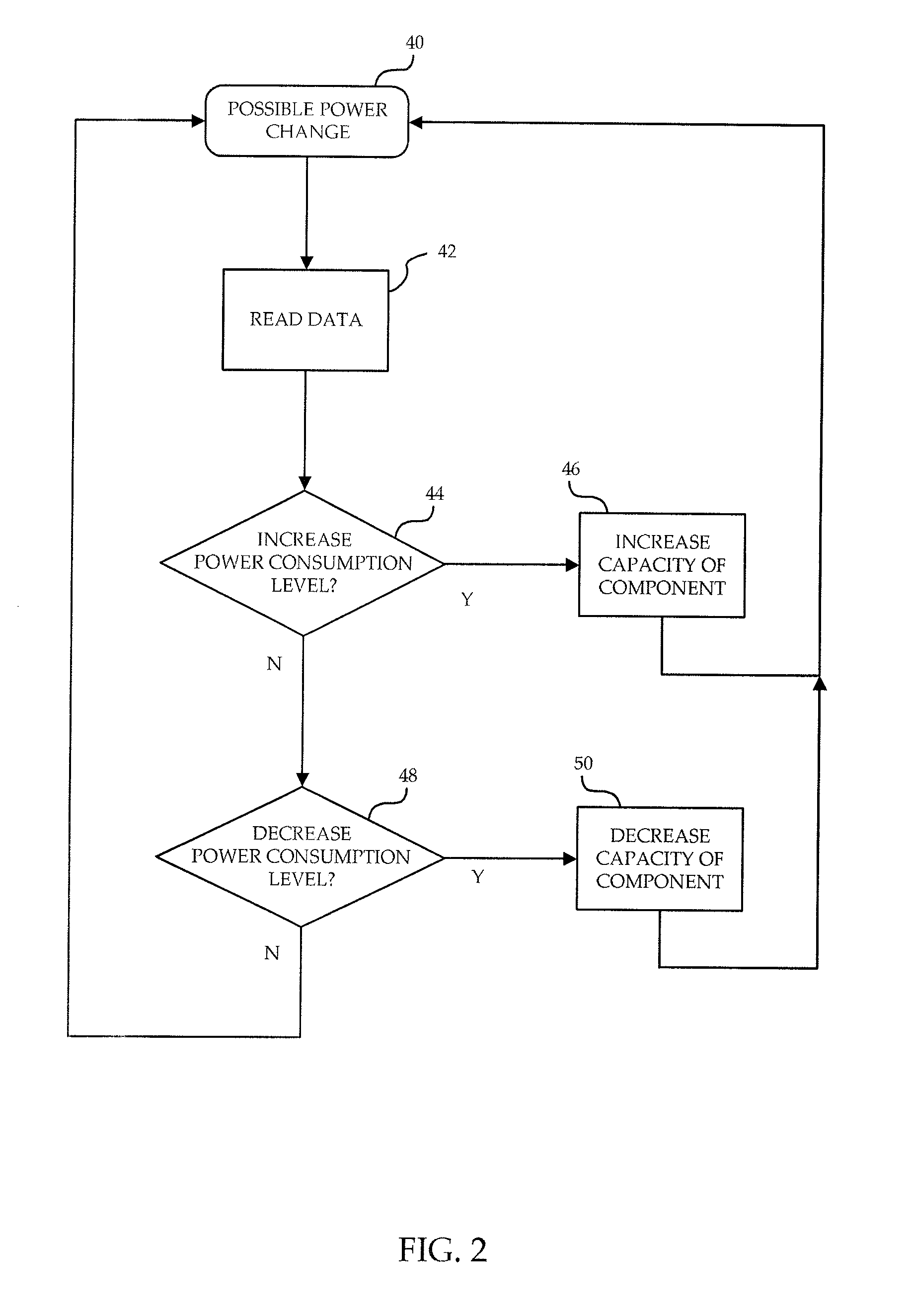

Power saving node controller

InactiveUS20130061072A1Reduce power consumptionReduce operating costsEnergy efficient ICTVolume/mass flow measurementReal-time dataTelecommunications equipment

A method and apparatus are provided which allow telecommunication equipment to adjust its power consumption. A controller within a telecommunication node uses data to determine whether to reduce the power consumption of components within the node. The data can be real-time data fed to the node or controller, or data read from storage, or both, depending on the particular implementation. Various examples of data and decision-making are given.

Owner:ALCATEL LUCENT SAS

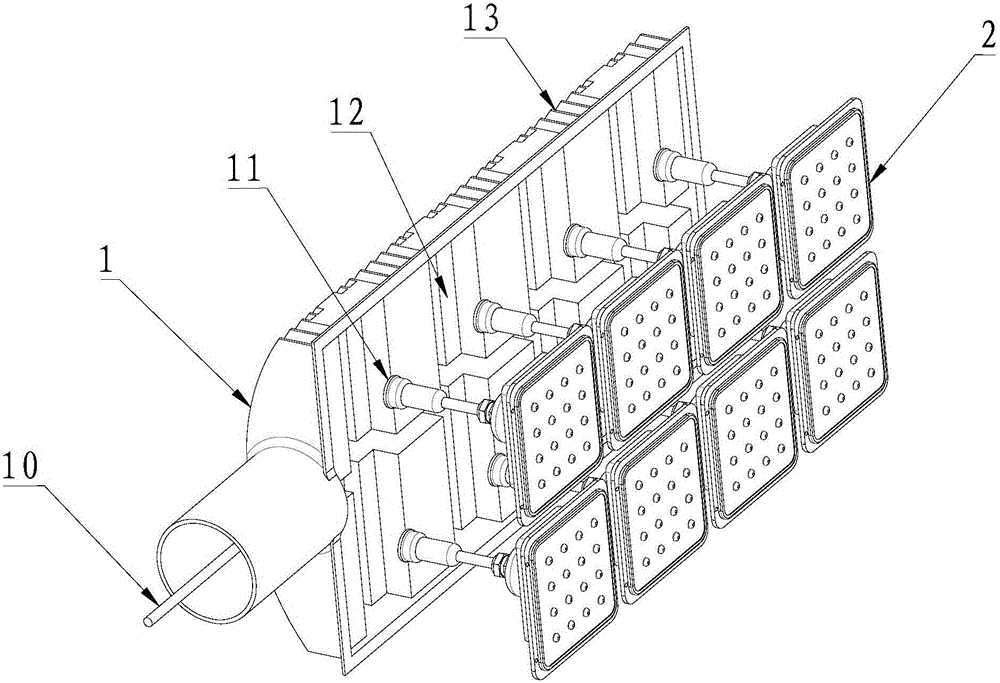

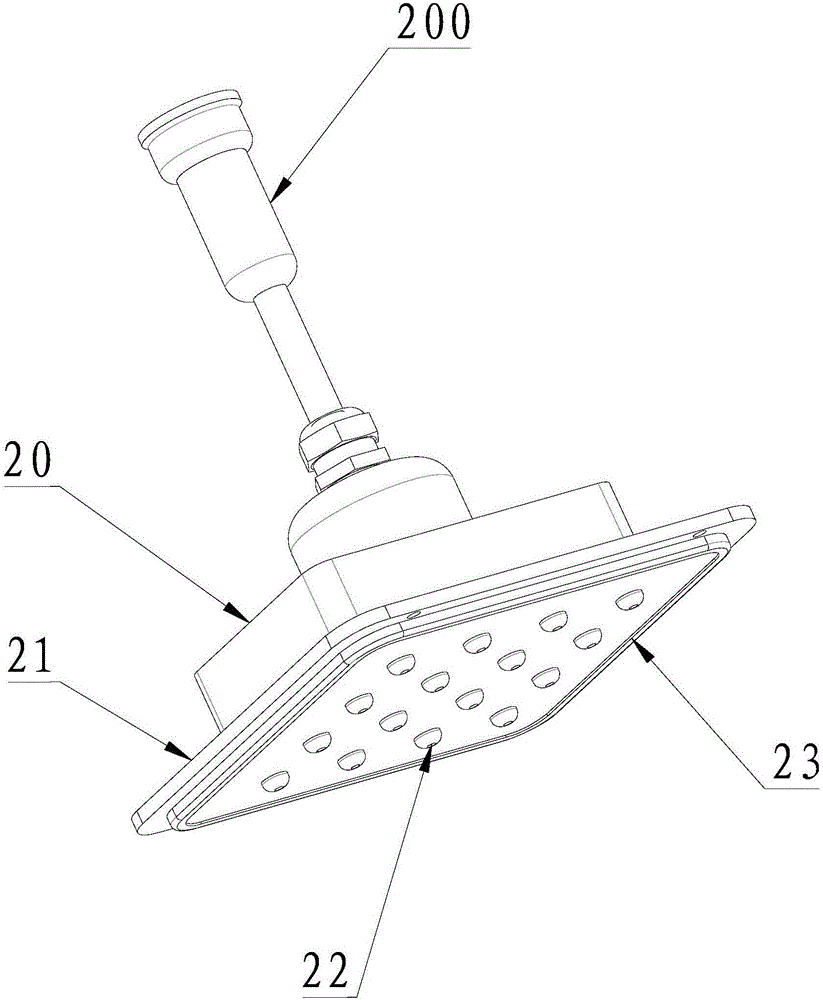

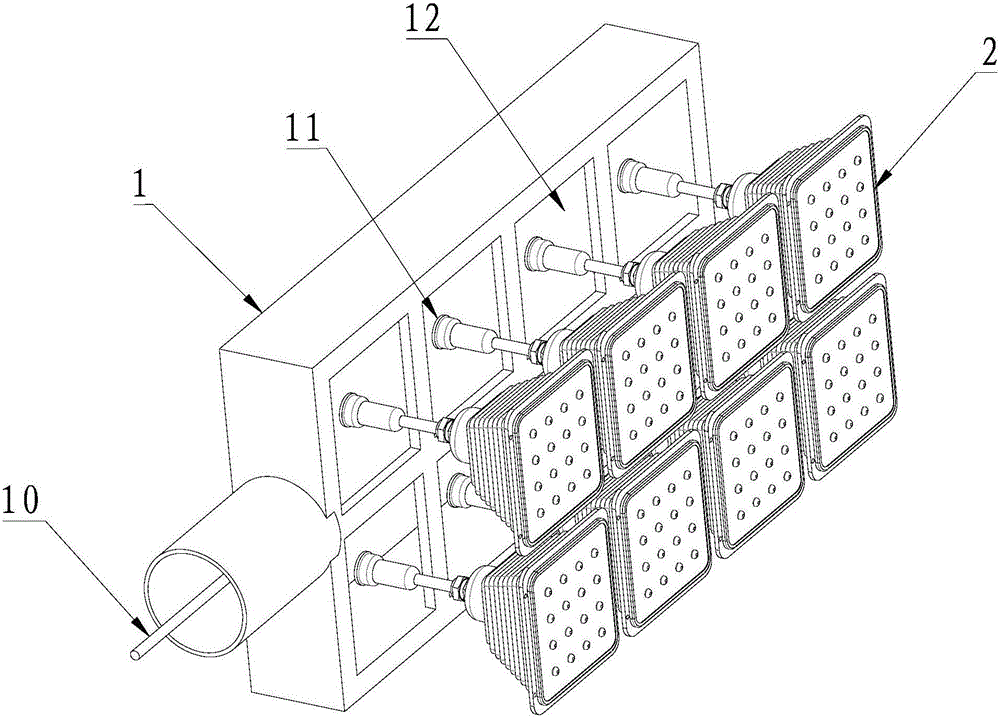

LED street lamp

InactiveCN105090845AChange powerMeet the requirements of outdoor useMechanical apparatusPoint-like light sourceEffect lightEngineering

The invention relates to an LED street lamp. An LED light source module with a ballast is adopted, and a lamp base is only used for providing a power input interface and fixing the LED light source module. In use, one or more LED light source modules can be mounted on the lamp base according to actual lighting requirements, and the lamp base is used in cooperation with the self-ballast LED light source modules of various specifications, so that the total power of the LED street lamp is changed, different use requirements are met, the use range of the LED street lamp is expanded, and upgrading of the self-ballast LED light source modules is facilitated; in addition, water resistance and anti-creeping treatment and the like are carried out on connections of all components of the LED street lamp, so that the LED street lamp is good in overall waterproof effect, high in protection performance, long in service life, compact in structure, easy to produce and assemble and capable of completely meeting outdoor use requirements of the LED street lamp.

Owner:FUJIAN HONGBO OPTO ELECTRONICS TECH CO LTD

Tinted semi-finished lens having impact resistance and method for manufacturing the same

ActiveUS20110063569A1Change powerUniformly formedSpectales/gogglesOptical articlesThird partyOptoelectronics

Provided is a method for manufacturing a tinted semi-finished lens that uses polycarbonate, has high light shielding effect, has impact resistance even after polishing, and can have a uniform tint. In particular, in order to provide a tinted semi-finished lens that has the same light shielding at the lens center and the lens edge when a wearer looks through the tinted lens, and furthermore, that seems to have the same light shielding when a third party looks at the wearer, a tinted layer having a uniform thickness and a transparent layer on the back side are integrally formed. Furthermore, in order to provide the impact resistance to either of the resins included in the layers, a low flow resin having a large molecular weight and a short flow length is used. In order to minimize lens distortion and to provide the impact resistance to the lens, the transparent layer employs a resin having the impact resistance, and the transparent layer is formed first and then the tinted layer is formed as an additional layer. Moreover, provided is a method for simultaneously manufacturing two sets of tinted lenses. In the method, two sets of molds are used, a first molded product is obtained in one of the two sets of the molds, and then is transferred to the other mold to form a second molded product, and simultaneously, another first molded product is molded in the first mold.

Owner:MIYOSHI INDAL ENTERPRISE

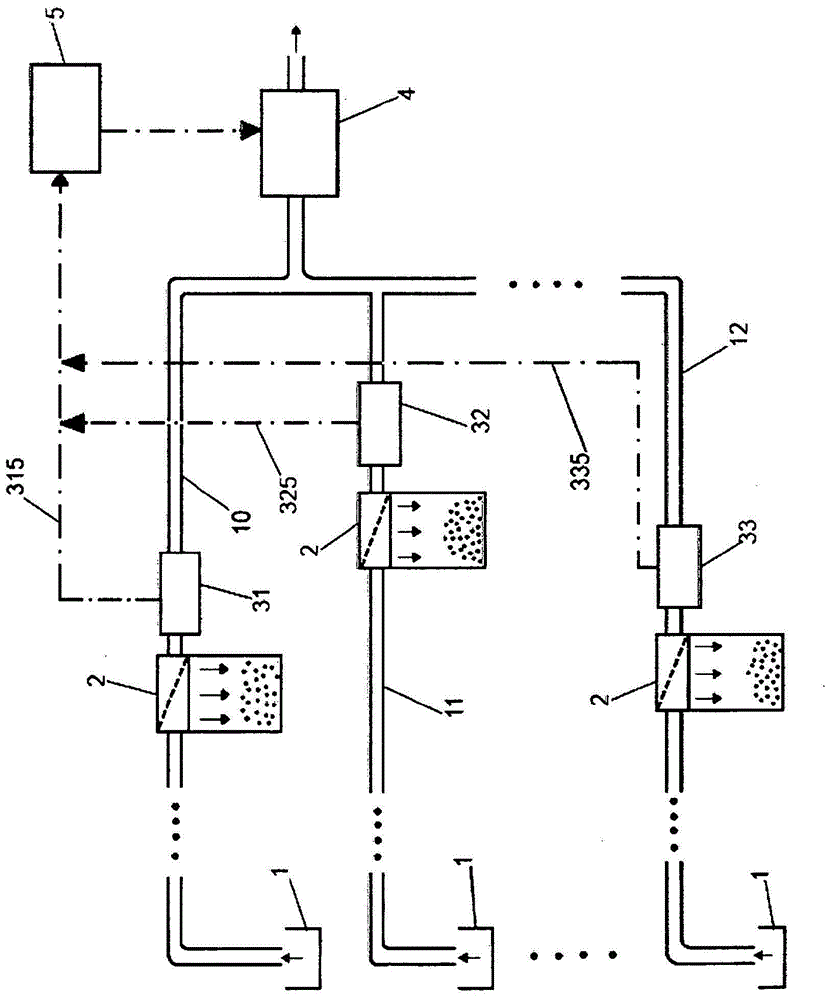

Pneumatic conveying installation

Disclosed is a pneumatic conveying installation, in particular a cut tobacco conveying installation, for conveying a material to be conveyed, in particular cut tobacco, in a gas stream, comprising a plurality of conveying lines (10, 11, 12) that are filled with material to be conveyed in the gas stream, in particular the air steam, and comprising at least one separating device (2) for each of the conveying lines (10, 11, 12). The separating device (2) is integrated into each of the conveying lines (10, 11, 12) and is designed so as to separate the material to be conveyed and to further conduct the remaining gas stream that has been substantially separated from the material to be conveyed in the conveying line. A regulation unit (31, 32, 33) is arranged downstream of each separating device (2) in the conveying line, which regulation unit comprises and regulates a throttle device so as to set a predefined conveying speed in the respective conveying line (10, 11, 12) by setting a throttle level above or equal to a predefined minimum value (Rmin), wherein the conveying installation has a common conveying device for conveying the material to be conveyed through the conveying lines (10, 11, 12). The conveying installation comprises a control and regulation device (5), which communicates with the conveying device (4) and which is designed to record the momentary throttle levels of the throttle devices and to vary the conveying power of the conveying device (4). The control and regulation device (5) is further designed to vary the conveying power of the conveying device (4) such that the throttle level of at least one throttle device lies, in each case, in the range of the minimum throttle level (Rmin).

Owner:RIEDEL FILTERTECHNIK GMBH

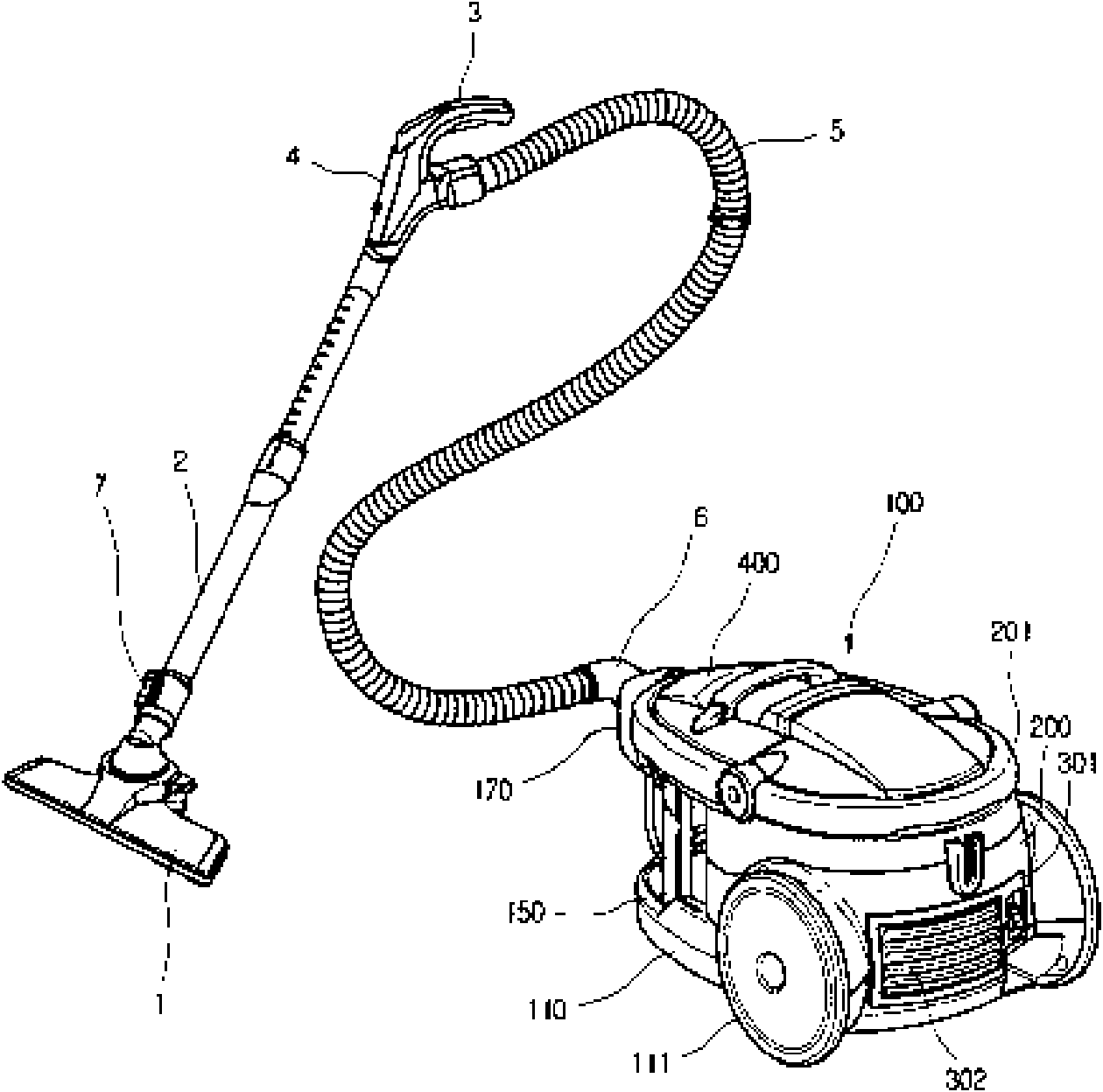

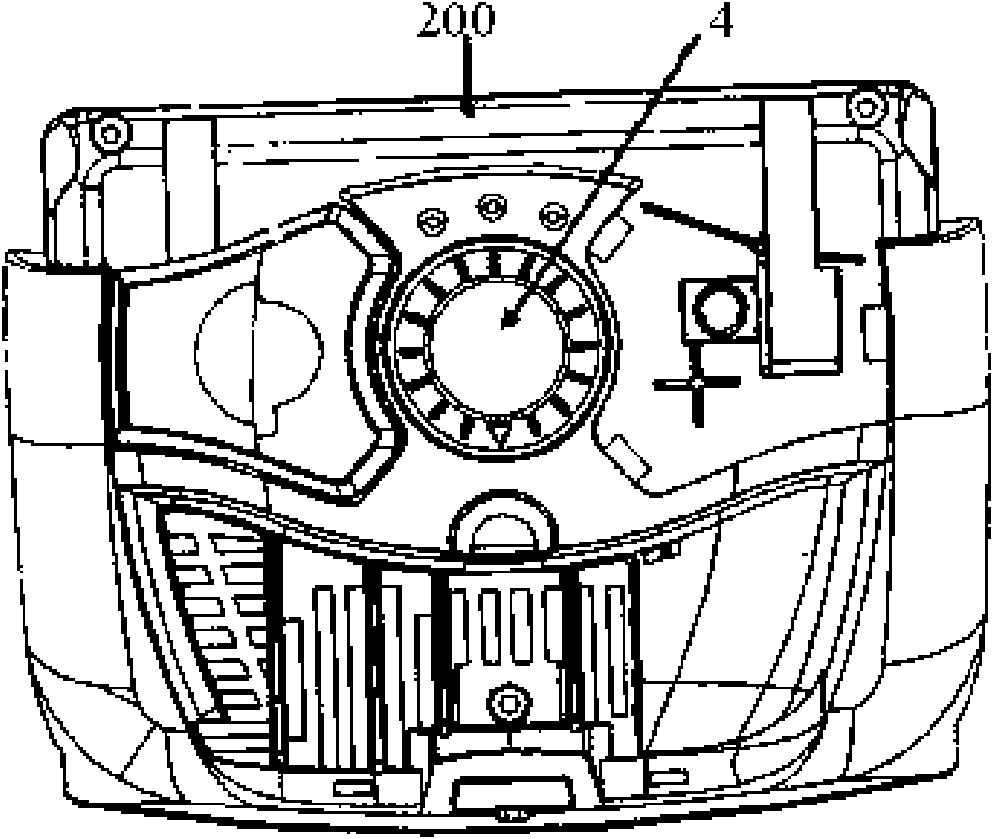

Power adjusting device for dust collector

InactiveCN101884513AIncrease the radius of rotationChange powerElectric equipment installationSuction forceEngineering

The invention discloses a power adjusting device for a dust collector, which is used for adjusting the power of the dust collector to meet the requirements of different occasions on suction. The power adjusting device consists of a knob, a knob bracket and a rheostat connected with the knob, wherein the power adjusting device is arranged on the side part of a dust collector body; and only a part of the knob is exposed outside the dust collector body. The power adjusting device can allow a user to optionally, conveniently and continuously change the power of the dust collector so as to meet the requirements of different places on the suction of the dust collector, and reduces a needed space, enhances touch effect, improves use convenience, simultaneously increases the rotation radius of the knob and enhances use safety.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

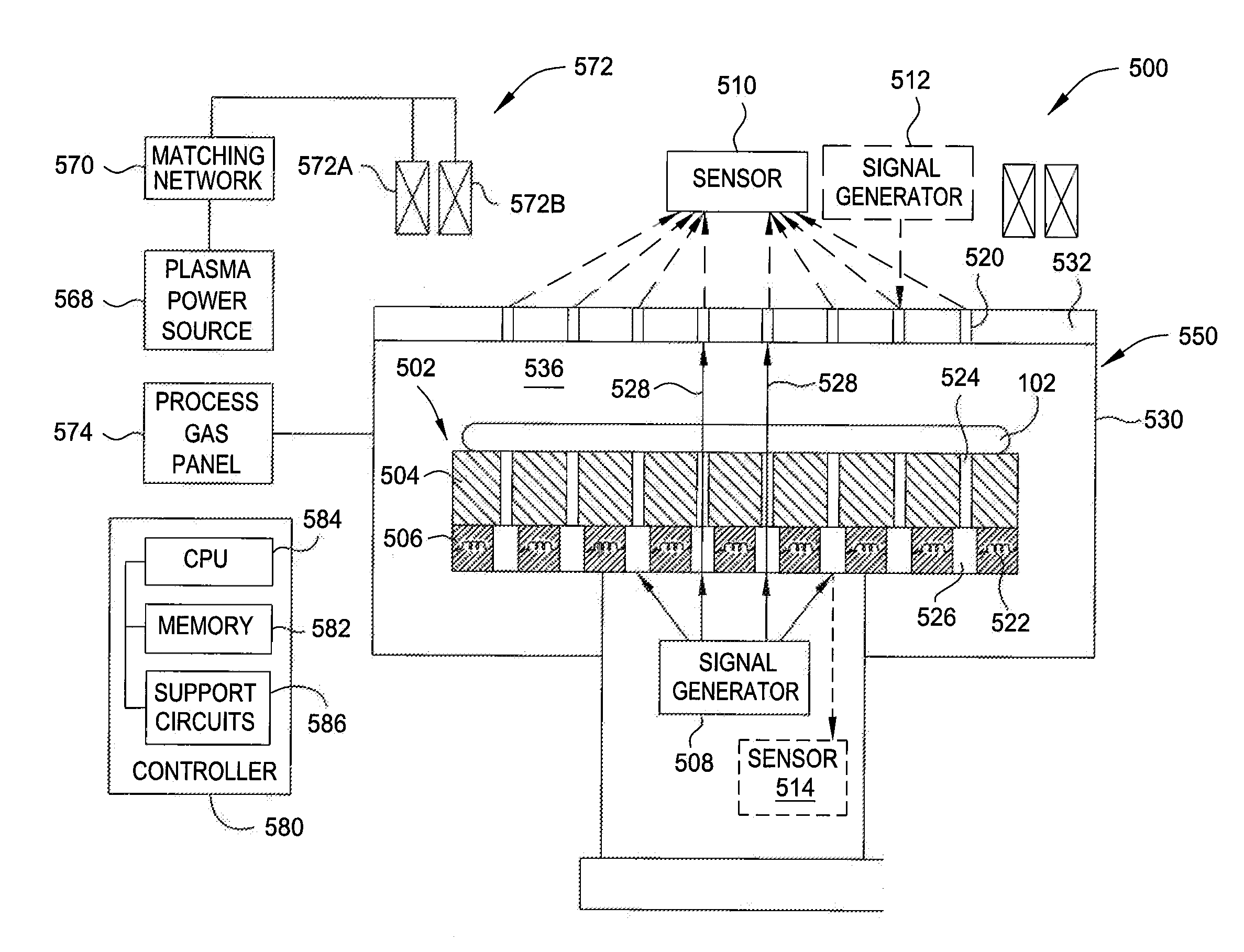

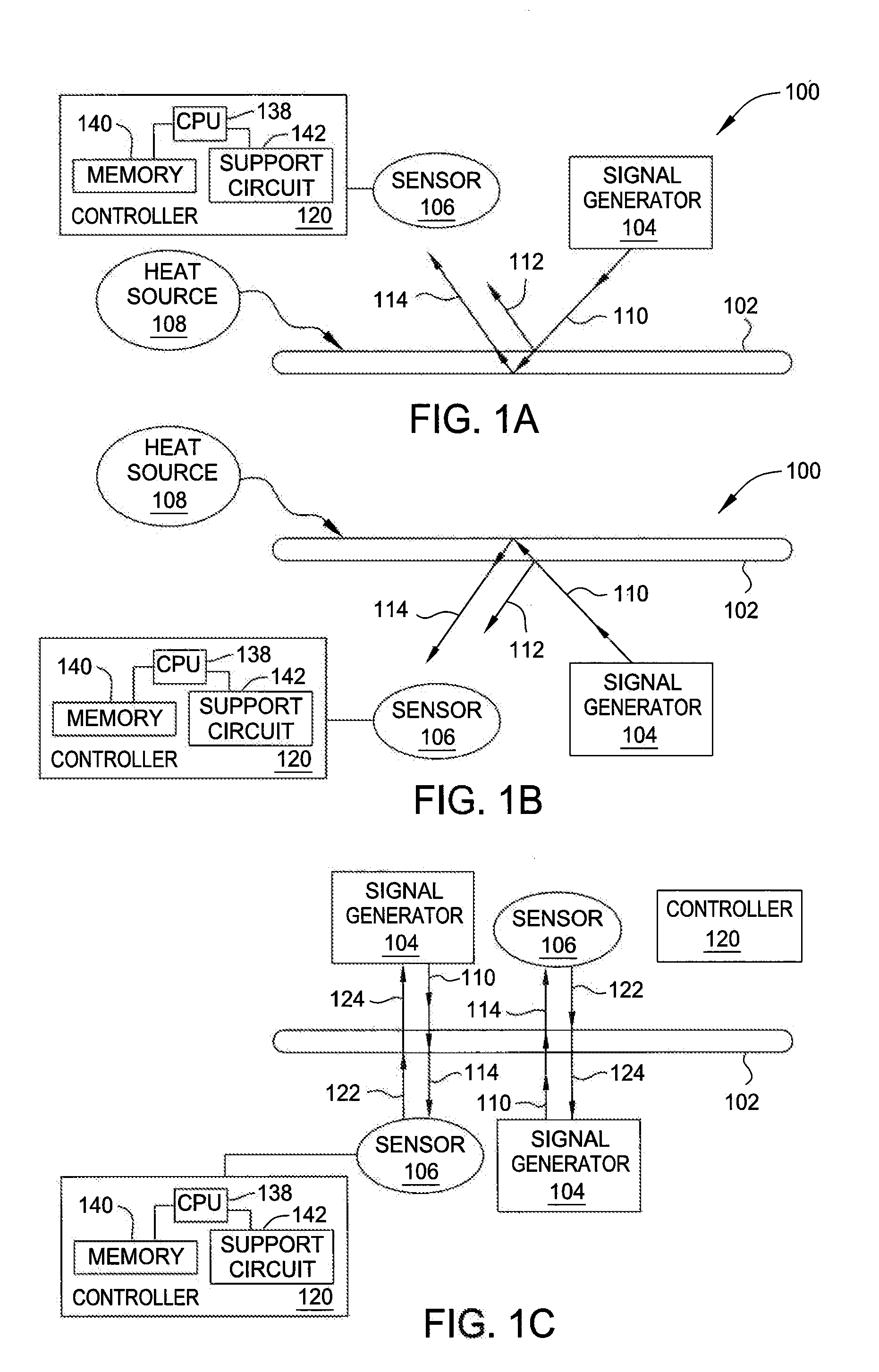

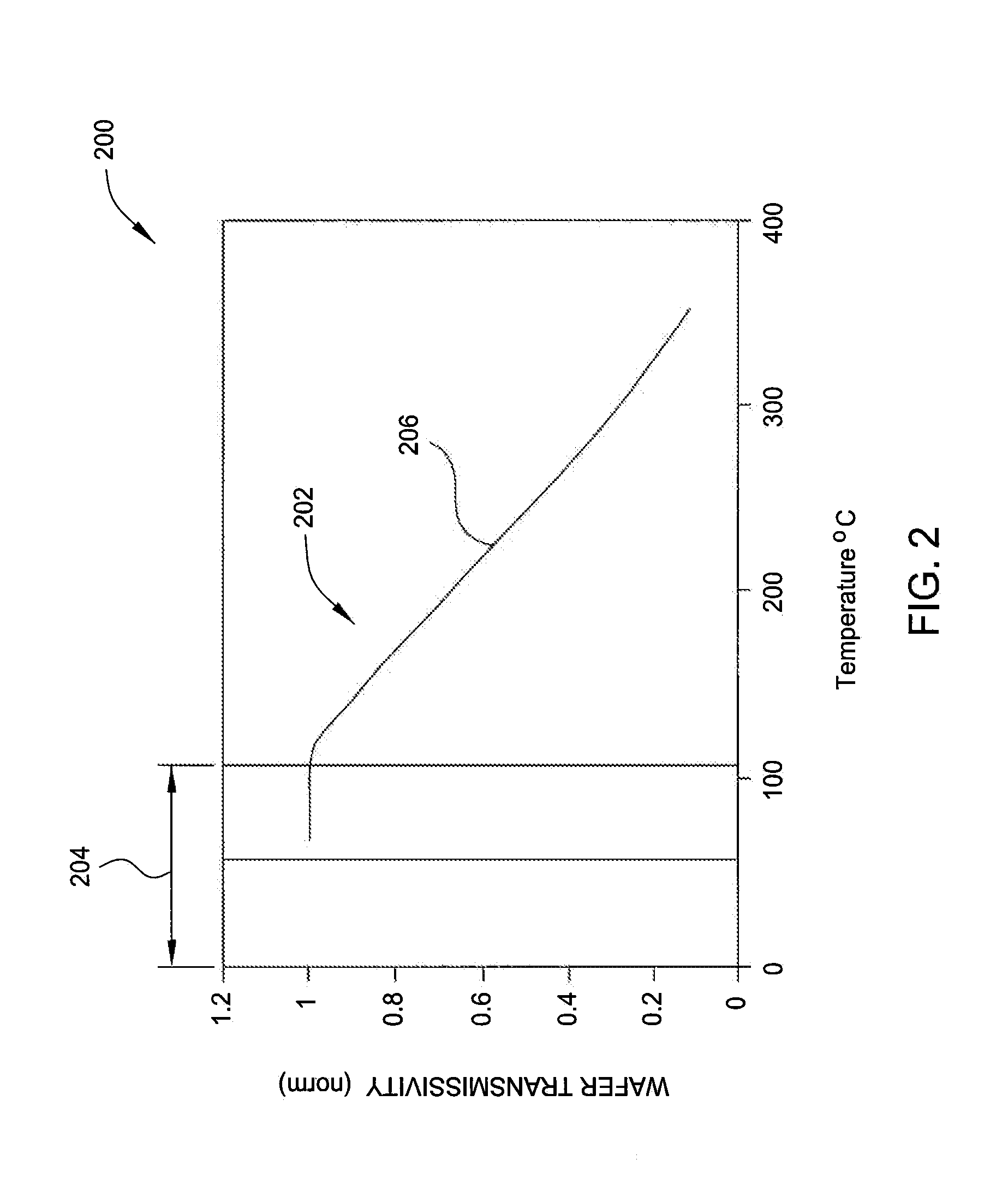

Method and apparatus for wafer temperature measurement using an independent light source

InactiveUS20130059403A1Change powerRadiation pyrometrySemiconductor/solid-state device testing/measurementTransmittanceSignal generator

An apparatus is provided for measuring a substrate temperature during an etching process, comprising: one or more windows formed in a substrate supporting surface; a first signal generator configured to pulse a first signal; and a first sensor positioned to receive energy transmitted from the first signal generator through the one or more windows. A method is provided for measuring a substrate temperature during an etching process comprising: heating a substrate using radiant energy; pulsing a first light; determining a metric indicative of total transmittance through the substrate when the first light is pulsed on; determining a metric indicative of background transmittance through the substrate when the first light is pulsed off; and determining a process temperature.

Owner:APPLIED MATERIALS INC

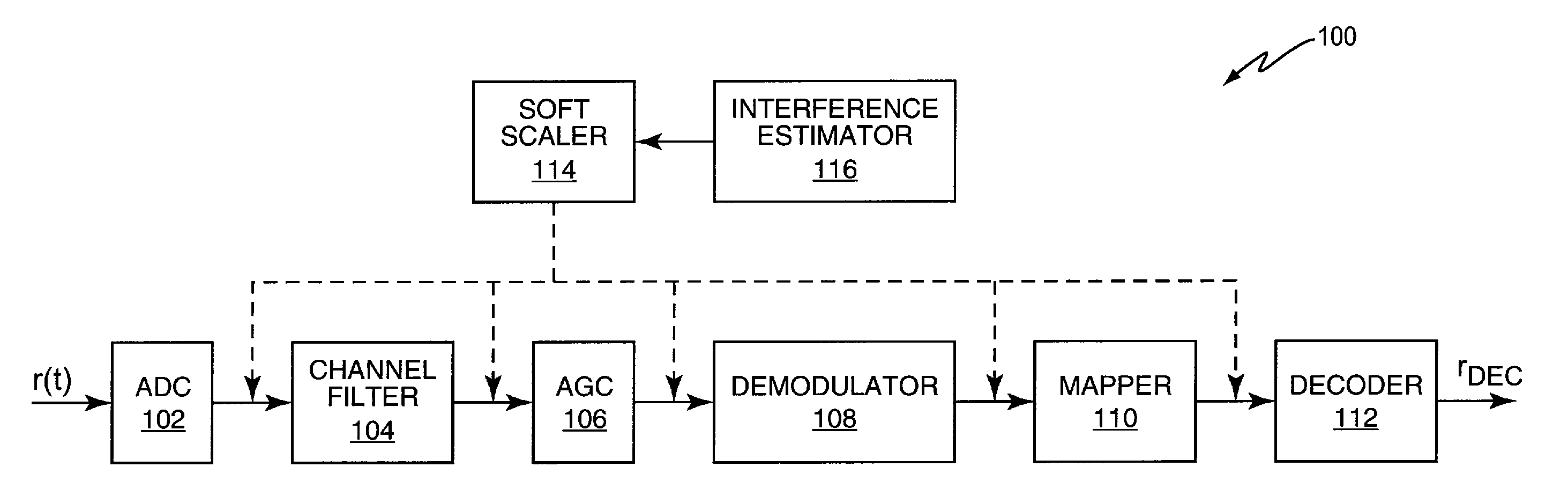

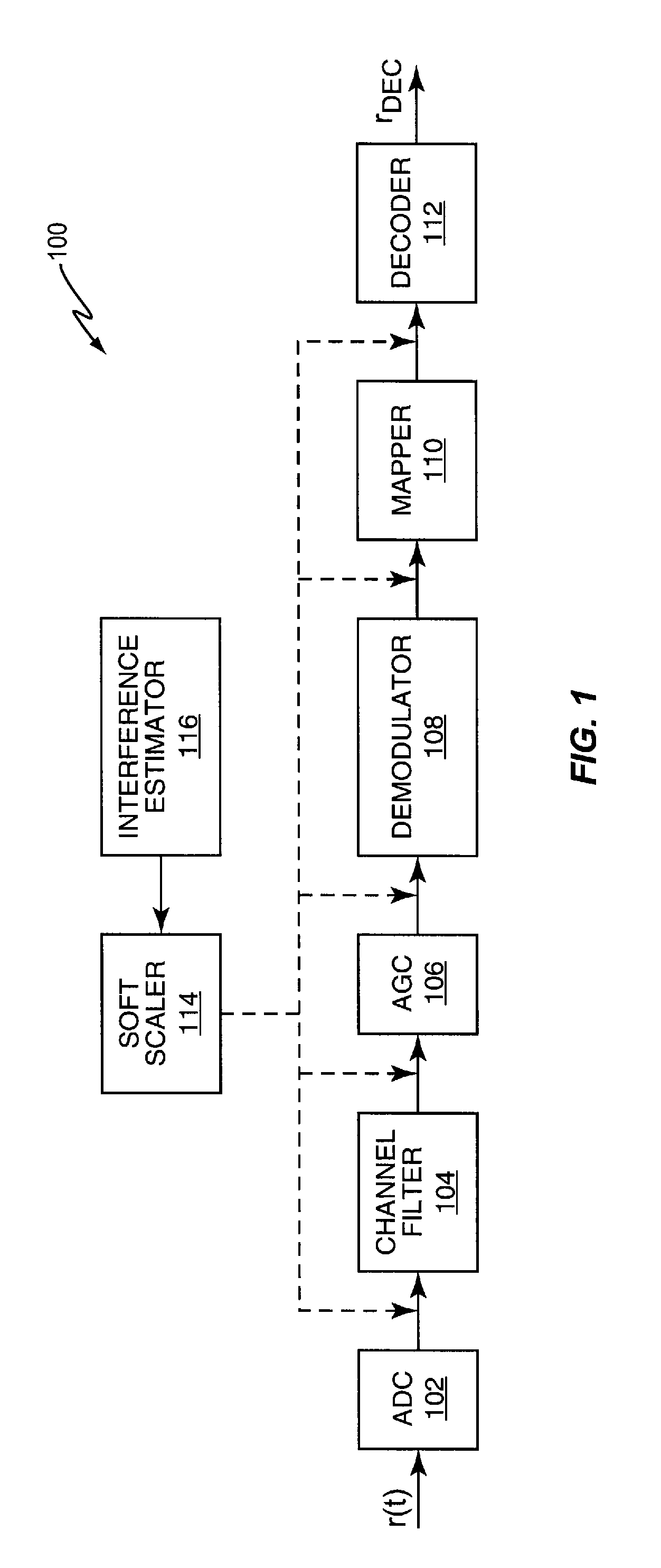

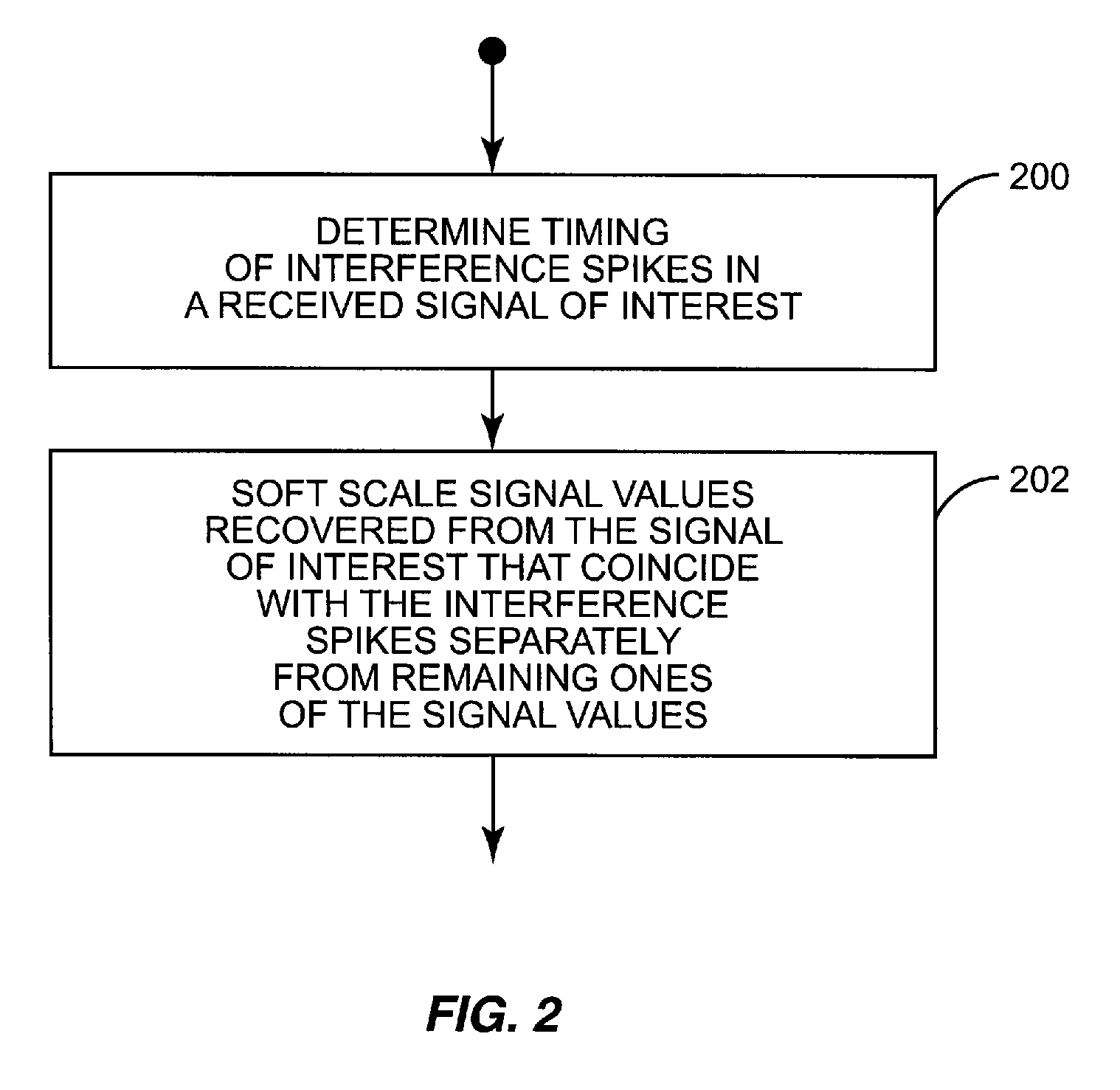

Soft Scaling Method and Apparatus

ActiveUS20100002813A1Accurate trackingChange powerError preventionLine-faulsts/interference reductionSignal of interestEngineering

A received signal of interest is processed by determining timing of interference spikes in the received signal of interest. Receivers can determine when certain types of interference spikes are expected to occur, e.g., based on when different users are scheduled to transmit data during an overlapping portion of the same transmission time interval. The interference timing information is used by the receiver to soft scale signal values recovered from the received signal of interest that coincide with the interference spikes separately from remaining ones of the signal values. This way, fast changing interference power can be accurately tracked during periods of known interference spikes while also accurately tracking slower changing interference power during other periods.

Owner:TELEFON AB LM ERICSSON (PUBL)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com