Piston type gas combustion turbine engine

A gas turbine and engine technology, applied in gas turbine installations, machines/engines, mechanical equipment, etc., can solve the problems of mass (large weight, high manufacturing difficulty, slow response speed, etc.) fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

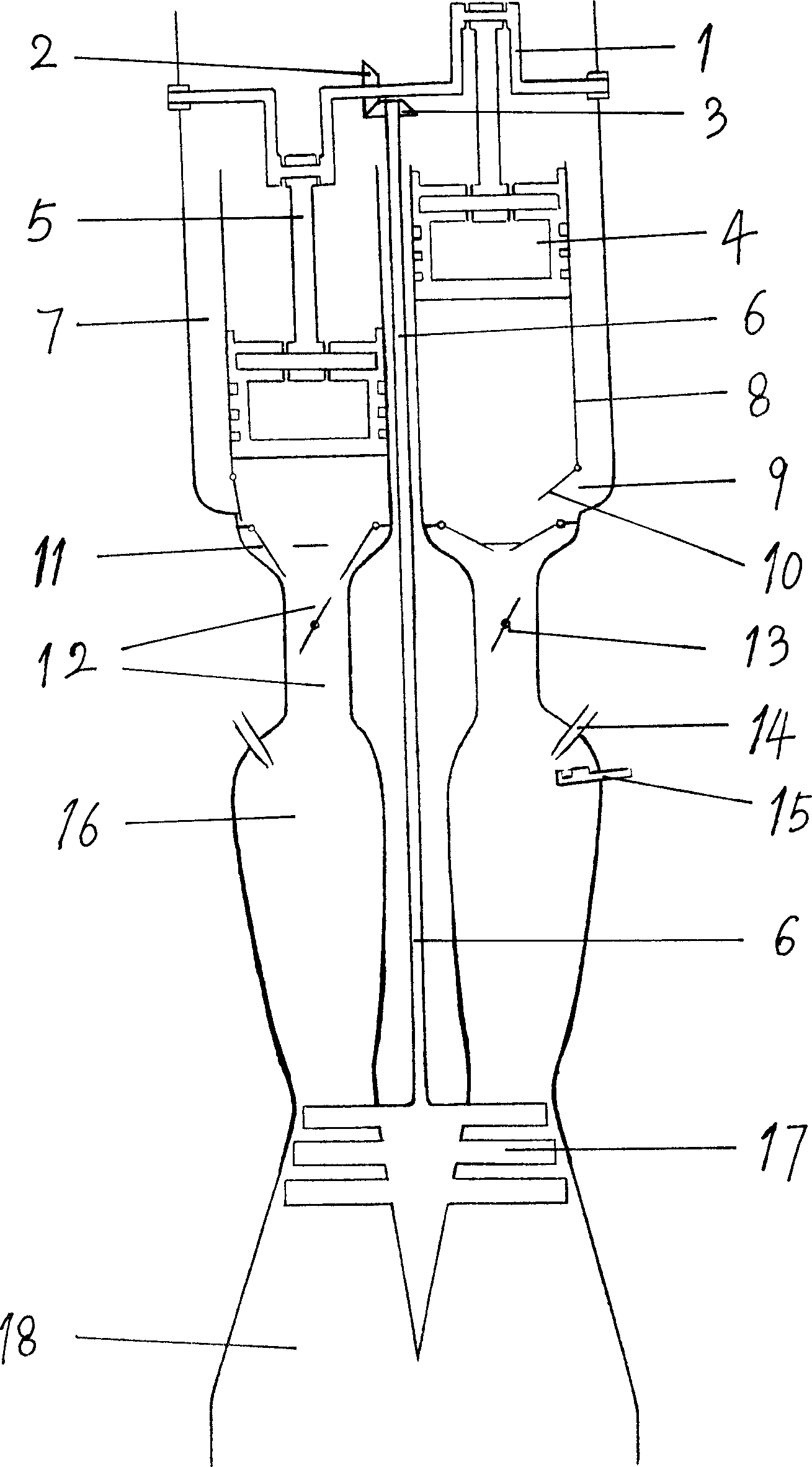

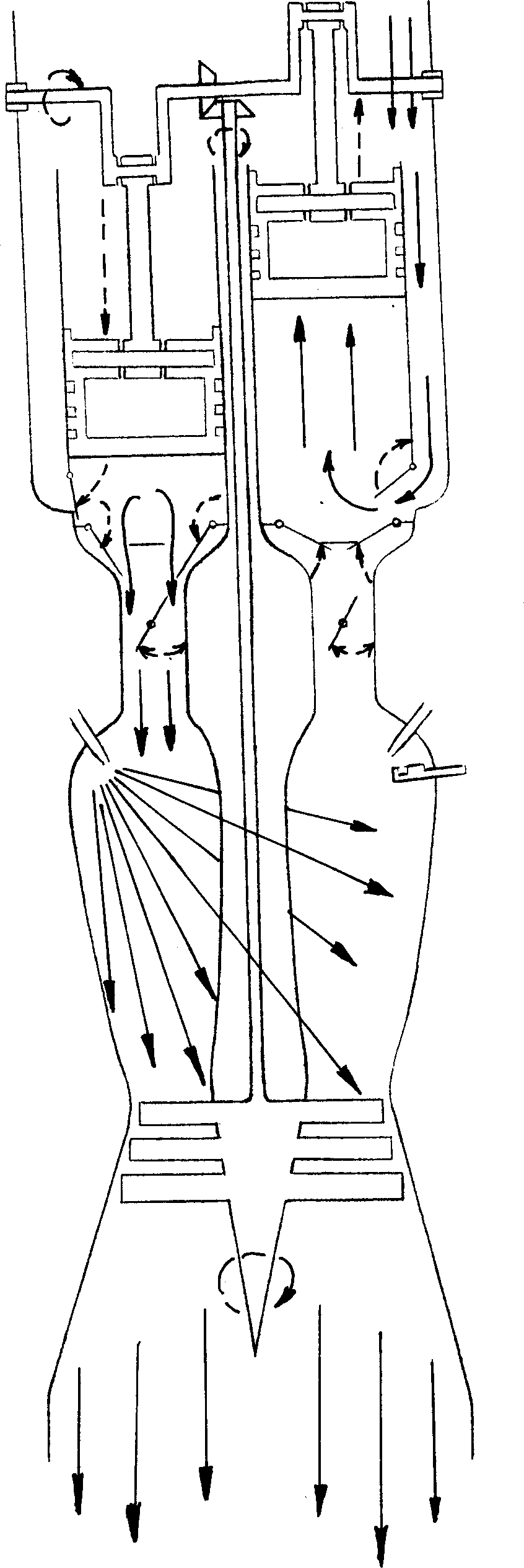

[0026] Two pistons are used as compressors, the structure can refer to figure 1 , The bevel gear (2) on the crankshaft (1) meshes with the bevel gear (3) fixed on the upper end of the turbine shaft (6), the lower end of the turbine shaft (6) is connected with the turbine (17), and the crankshaft (1) is connected with The piston connecting rod (5) is connected, and the piston connecting rod (5) is connected with the piston (4). The piston (4) can reciprocate freely in the cylinder (cylinder) (8), and the outer wall of the lower end of the cylinder (8) There is an intake port (9), an intake valve (10) is provided on the intake port (9), an air supply valve (11) is provided at the lower end of the cylinder block (8), and the end of the cylinder block (8) is connected with the compressed air (high pressure air) ) The upper end of the passage (12) is connected, the lower end of the compressed air passage (12) is connected with the combustion chamber (16), the compressed air passage (1...

Embodiment 2

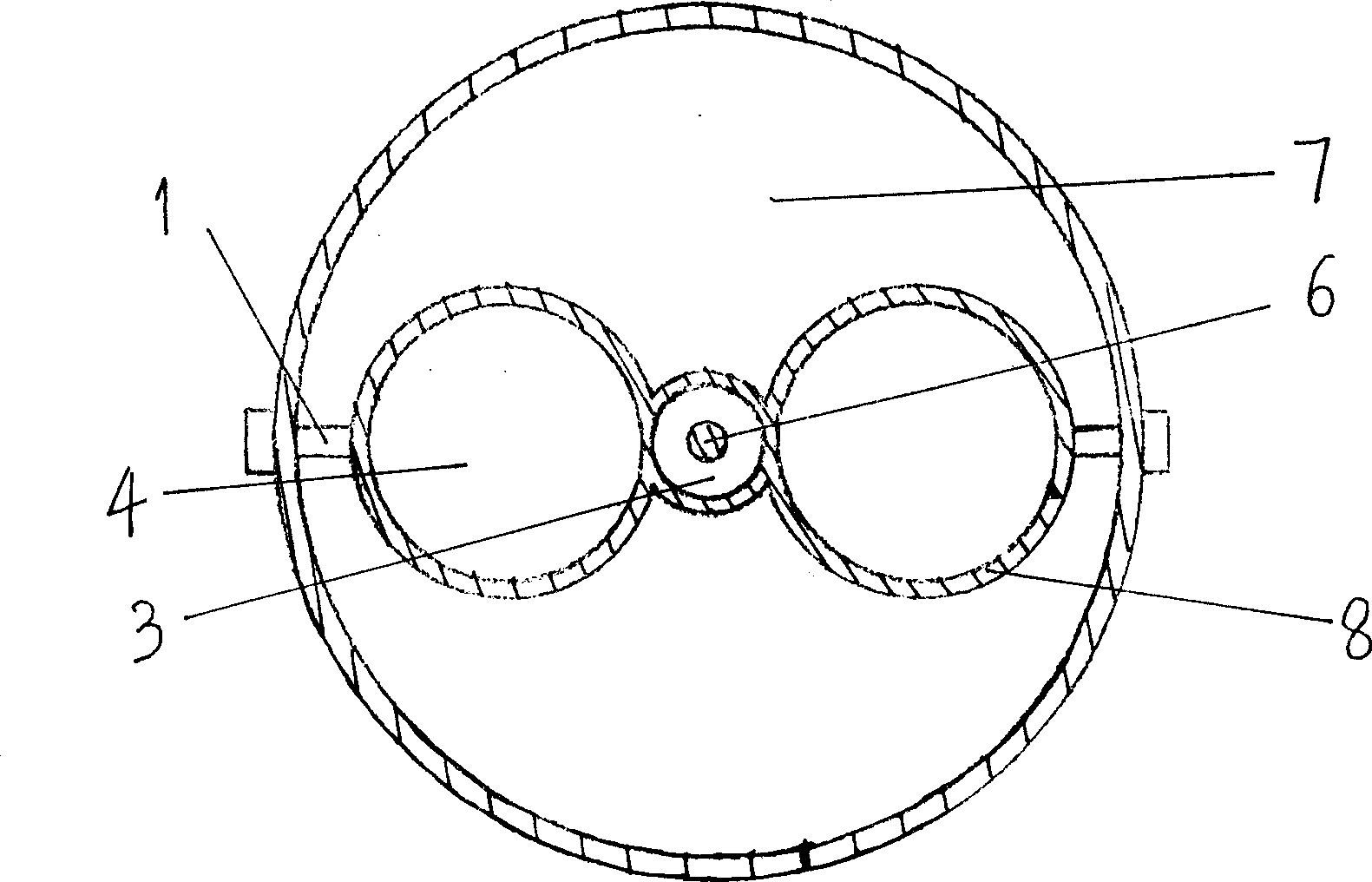

[0029] The structure of this embodiment is basically the same as that of Embodiment 1. The main difference is that this embodiment uses four pistons as a compressor, and two more pistons are added than Embodiment 1, and a crankshaft and two pistons are added correspondingly. Connecting rods, two cylinders, three gears, a gear shaft (19), two compressed air channels, two throttles and two fuel nozzles, four cylinders are joined together, and each crankshaft is connected with two pistons Rod connection, four piston connecting rods are connected to the four pistons respectively, that is, a crankshaft controls the reciprocating motion of the two pistons, please refer to Figure 6 , Figure 7 with Figure 8 . When the engine is started, the two crankshafts are driven by the turbine shaft (6) through the gear shaft (19), and the bevel gear (3) on the upper end of the turbine shaft (6) meshes with the bevel gear (2) on the gear shaft (19) , The gear (20) on the gear shaft (19) meshes wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com