Valve mechanism of pneumatic automobile engine

A pneumatic vehicle and gas distribution mechanism technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve problems such as energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

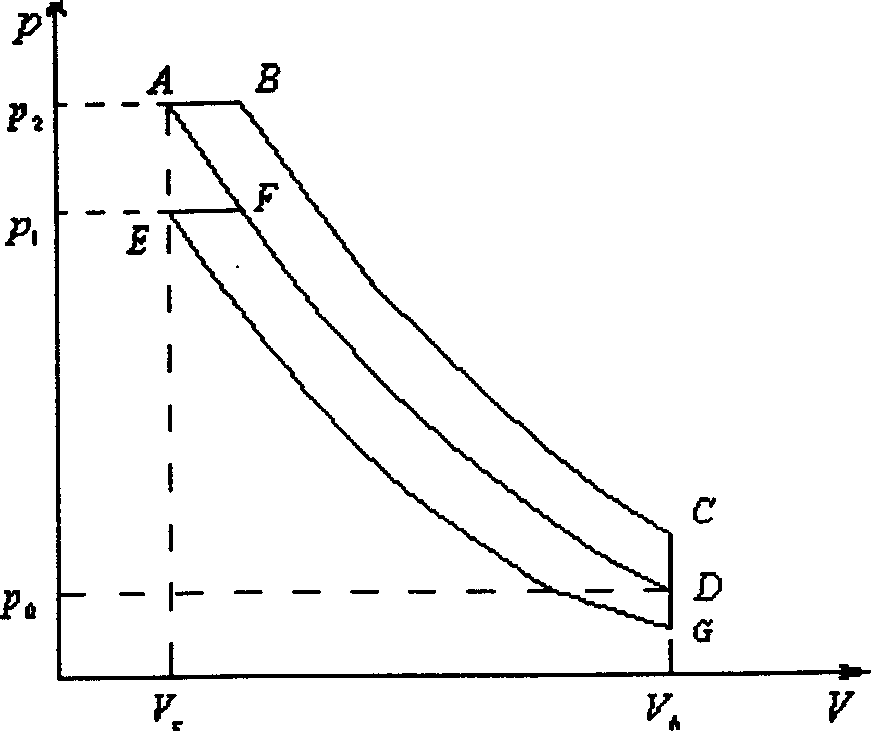

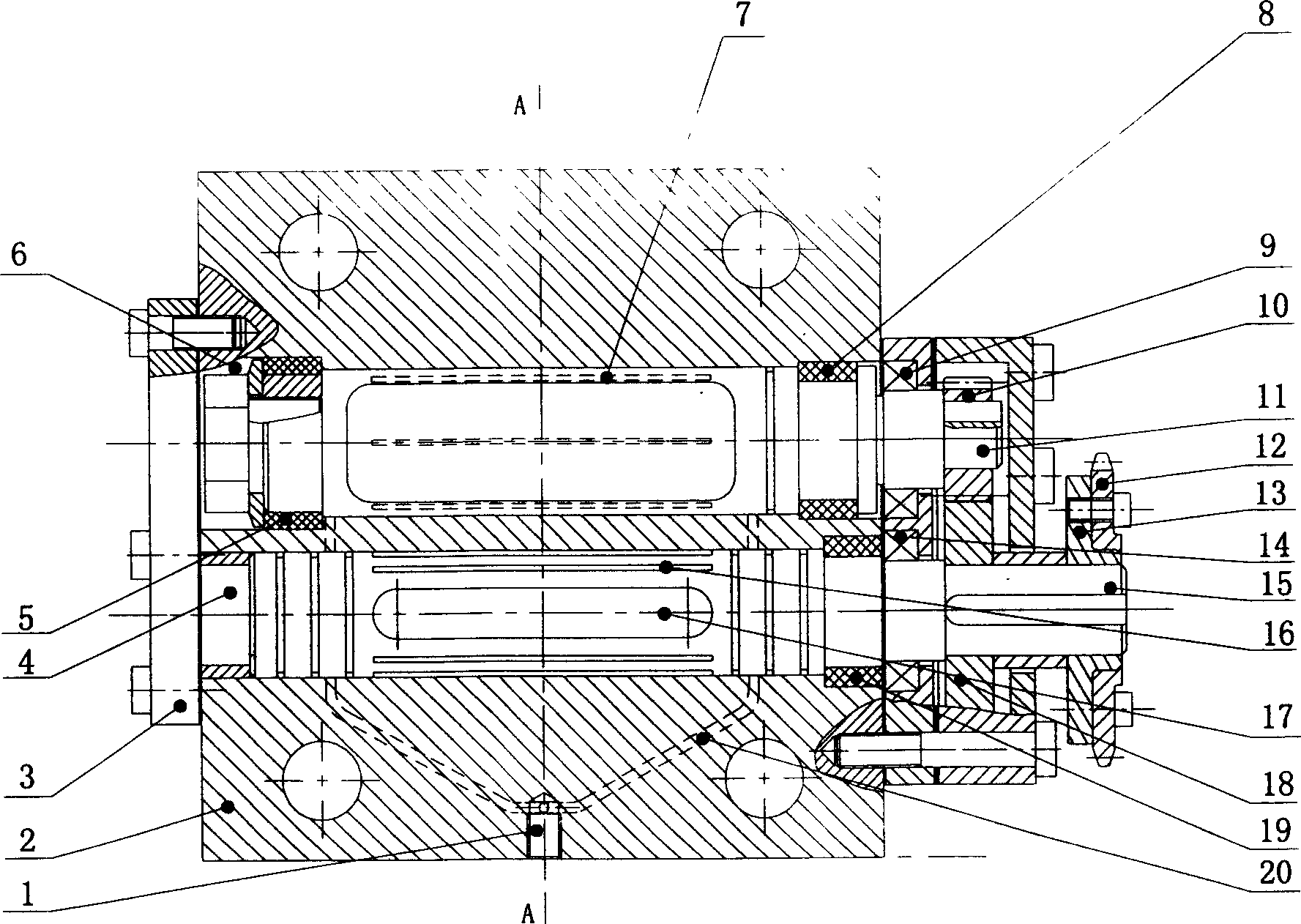

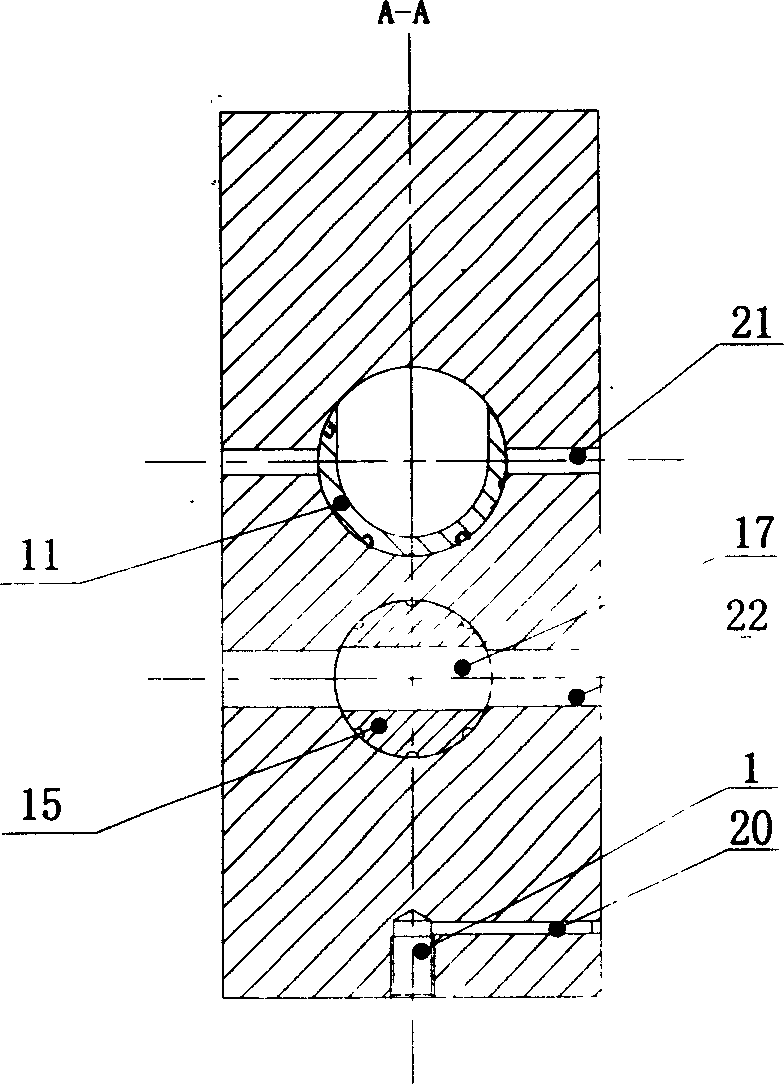

[0013] refer to figure 2 , image 3 , the gas distribution mechanism of the pneumatic automobile engine of the present invention comprises cylinder head 2, intake valve 11, exhaust valve 15, and cylinder head 2 has two cylindrical holes 4,6 parallel to each other spaced apart and two crossing cylindrical apertures respectively. The intake passage 21 and the exhaust passage 22, the intake valve 11 and the exhaust valve 15 are respectively placed in the two cylindrical holes 4, 6 of the cylinder head, and are rotationally matched with the cylindrical holes, and the two cylindrical holes One end is closed by an end cap 3 fixed to the cylinder head. The two ends of the intake valve 11 are respectively equipped with sealing rings 5 and 8 for preventing the leakage of high-pressure gas in the cavity of the intake valve. The two sealing rings can adopt standard Y x type sealing ring. There is a section of valve body with a U-shaped cross section between the two sealing rings, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com