Patents

Literature

43results about How to "Meet the requirements of outdoor use" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-corrosion-resistance, high-weather-resistance and excellent-hydrophobicity chromium-free fingerprint-resistant coating used for galvanized steel sheet

InactiveCN104403538AImprove corrosion resistanceGood weather resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsChromium freeWater based

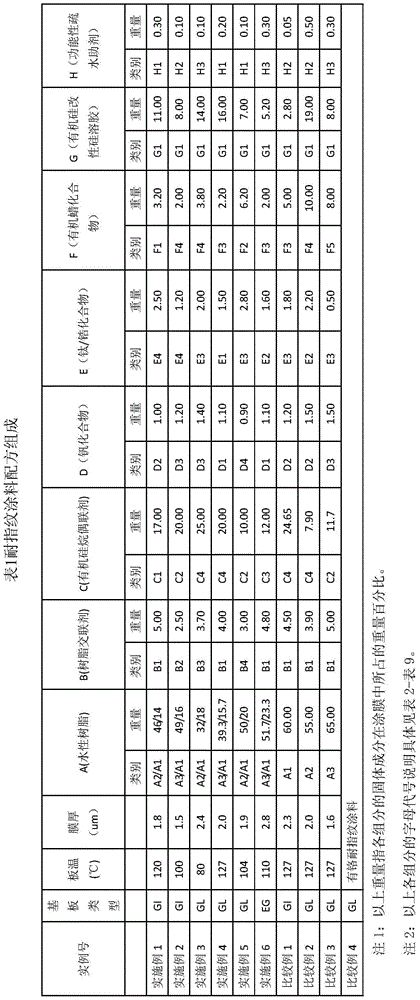

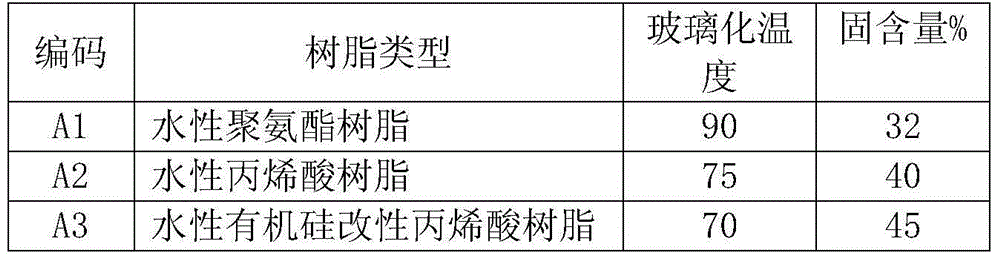

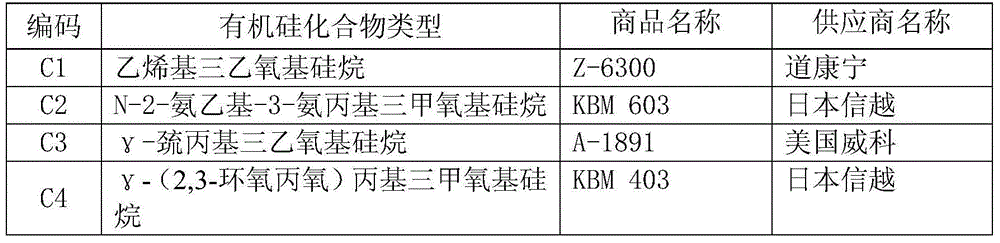

The invention relates to a high-corrosion-resistance, high-weather-resistance and excellent-hydrophobicity chromium-free fingerprint resistant coating used for a galvanized steel sheet. The water solution of the chromium-free fingerprint resistant coating consists of the following components: (A) at least two or more than two water-based resins accounting for 30-80wt% of the total solid content; (B) at least one water-based cross-linking agent accounting for 1-10wt% of the total solid content; (C) at least one organic silane coupling agent accounting for 5-40wt% of the total solid content; (D) at least one vanadium-containing compound accounting for 0.1-2wt% of the total solid content; (E) a compound of at least one element in titanium and zirconium accounting for 0.1-5wt% of the total solid content; (F) at least one organic wax compound accounting for 0.5-10wt% of the total solid content; (G) at least one organic silicon modified collosol accounting for 1-30wt% of the total solid content; (H) at least one functional hydrophobic agent accounting for 0.05-0.5wt% of the total solid content. The galvanized steel sheet on which the chromium-free fingerprint resistant coating is coated can completely meet the requirement of outdoor use.

Owner:上海华谊精细化工有限公司技术中心

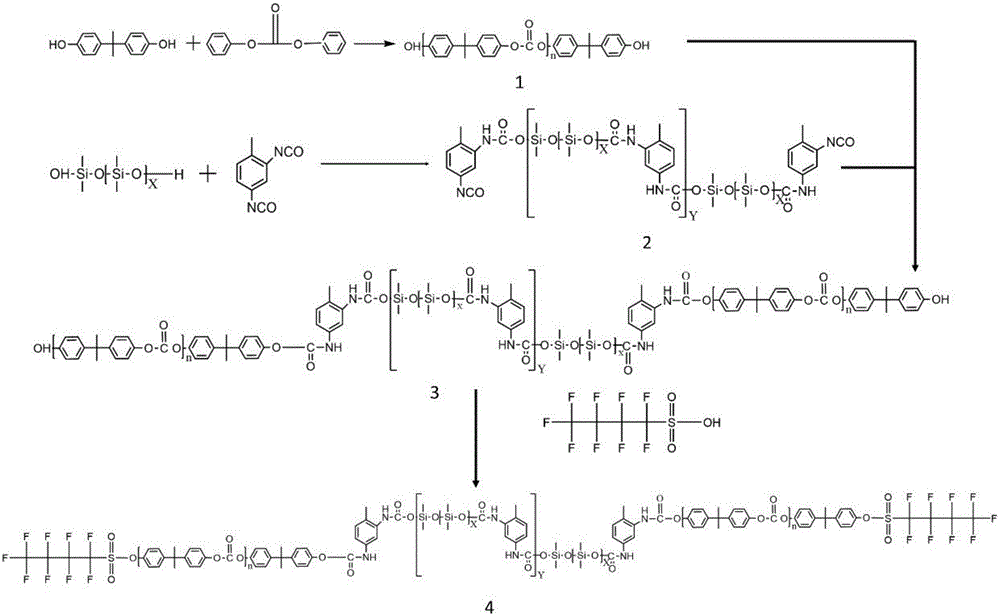

Fluorocarbon coating and method for preparing colored aluminum profiles from fluorocarbon coating

InactiveCN104449334AIncrease productivityColorfulPretreated surfacesPolyurea/polyurethane coatingsChemistryWeather resistance

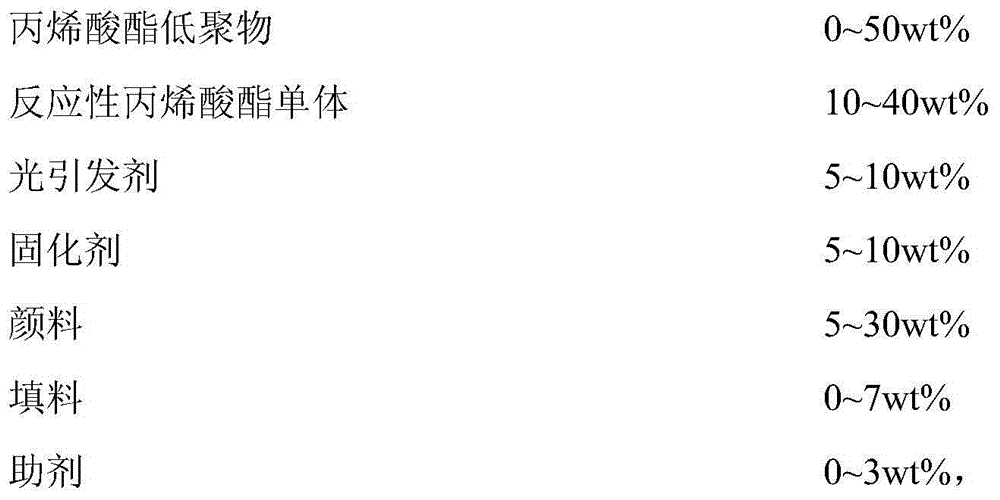

The invention discloses a fluorocarbon coating and a method for preparing colored aluminum profiles from the fluorocarbon coating, belonging to the field of chemical engineering coatings. The fluorocarbon coating comprises the following components in percentage by weight: 30wt%-70wt% of fluorinated acrylate oligomers, 0-50wt% of acrylate oligomers, 10wt%-40wt% of reactive acrylate monomers, 5wt%-10wt% of a photoinitiator, 5wt%-10wt% of a curing agent, 5wt%-30wt% of pigments, 0-7wt% of fillers and 0-3wt% of an aid. According to the fluorocarbon coating, dual curing including ultraviolet light curing and spontaneous curing can be realized; the inner wall or dead corners, which cannot be irradiated by ultraviolet light, of the profiles can be spontaneously cured within 24 hours, so that the problem that the surface of the UV ultraviolet light fluorocarbon coating cannot be irradiated by the ultraviolet light is solved; after the coating is cured, a paint film has rich colors and excellent weather resistance and can meet outdoor use requirements.

Owner:ZHUHAI DONGCHENG UV MATERIALS

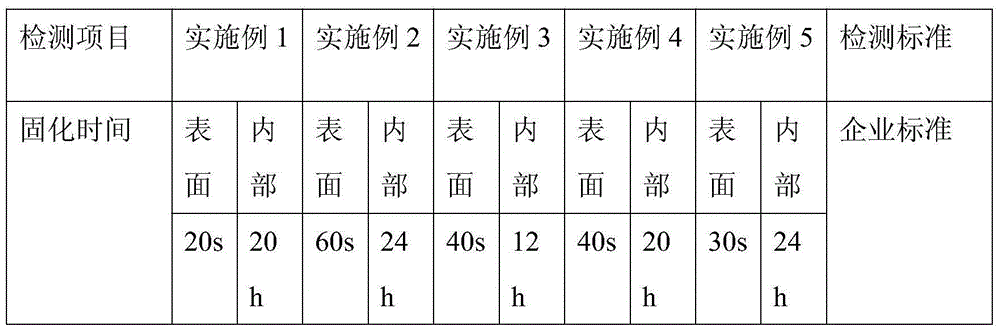

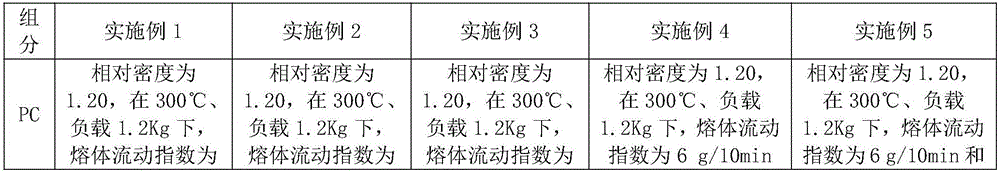

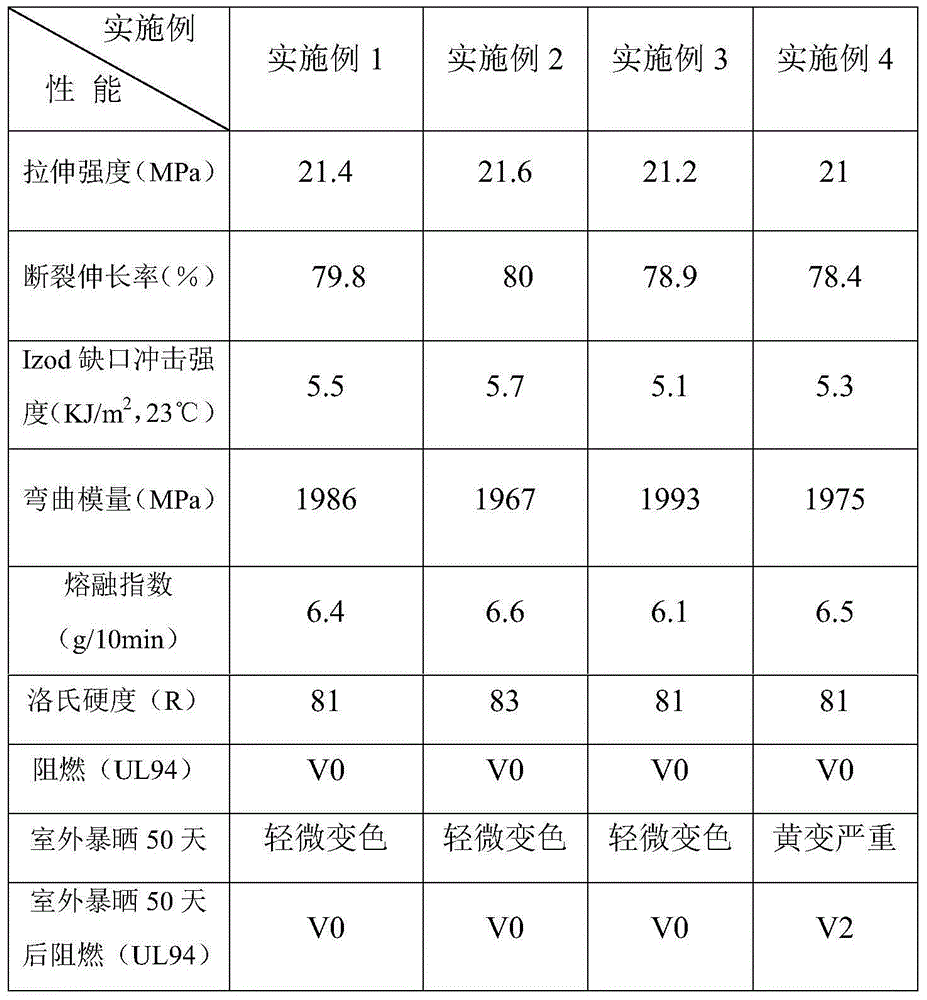

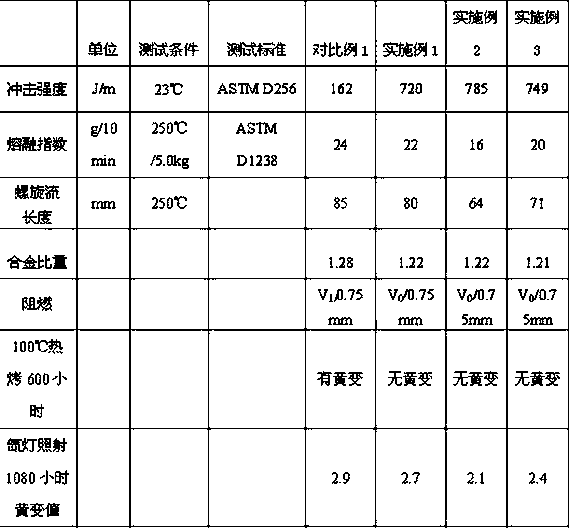

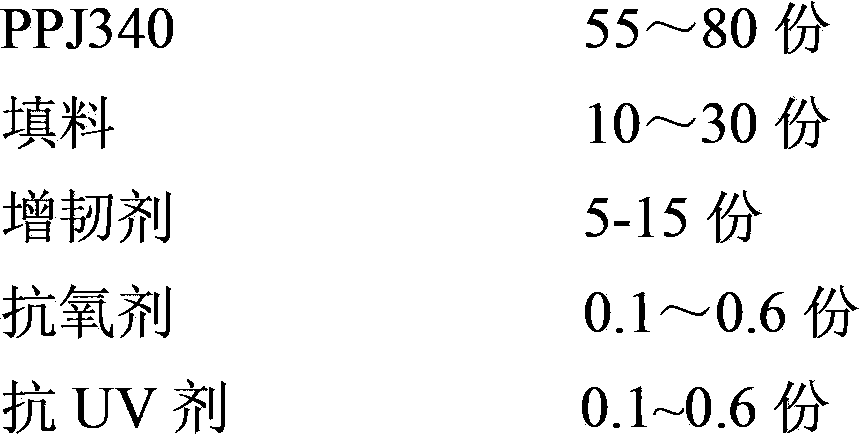

Weather-resistant and flame-resistant light-diffusion PC applicable to outdoor lampshades and preparation method of weather-resistant and flame-resistant light-diffusion PC

ActiveCN106810842AGuaranteed light transmittanceHigh flame retardant efficiencyWeather resistanceFire retardant

The invention discloses weather-resistant and flame-resistant light-diffusion PC applicable to outdoor lampshades and a preparation method of the weather-resistant and flame-resistant light-diffusion PC. The weather-resistant and flame-resistant light-diffusion PC is prepared by, by weight percentage, 81.25-90.17% of PC, 5-15% of toughening agent, 0.8% of light diffusion agent, 1.5-2.5% of flame retardant, 0.4-0.6% of synergic-effect flame retardant, 0.1-0.5% of hydrolysis-resistant agent, 0.1-0.5% of anti-UV agent, 0.03-0.05% of pigment, 0.3% of antioxidant and 0.3% of dispersing agent. The light-diffusion PC has the advantages that the light-diffusion PC is good in flame-retardant effect and weather resistance, indoor and outdoor use requirements can be satisfied, the light-diffusion PC is high in light permeability, good in toughness and ideal in appearance color, and consumers' requirements on lamps can be satisfied.

Owner:厦门天宇新材料科技有限公司

Anti-aging polypropylene plastic

The invention relates to an anti-aging polypropylene plastic comprising the following raw materials in parts by weight: 100 parts of polypropylene, 0.4-0.6 part of an antioxidant 1010, 0.1-0.3 part of a light stabilizer, 0.2-0.3 part of an ultraviolet light absorber, 36-40 parts of carbon black, 2-4 parts of nano titanium dioxide, 12-16 parts of epoxy resin, 15-20 parts of melamine, 0.2-0.6 part of a dispersant and 0.5-0.8 part of a coupling agent. According to the anti-aging polypropylene plastic disclosed by the invention, nano titanium dioxide with good dispersibility in the polypropylene plastic and melamine are added to ensure that the prepared polypropylene plastic has flame-retardant properties, meets requirements for outdoor use, and has good impact resistance, anti-aging performance and improved toughness.

Owner:ANHUI JIAMU RUBBLE & PLASTIC IND

Environment-friendly weather-resistant flame-retardant PP material and preparation method thereof

InactiveCN104448574AMeet environmental protection requirementsDoes not produce corrosive gasesEnvironmental resistanceUltraviolet lights

The invention relates to an environment-friendly weather-resistant flame-retardant PP material and a preparation method thereof. The PP material is prepared from the following components in percentage by weight: 20-30% of homo-polypropylene, 35-45% of polypropylene copolymer, 25-30% of a compound expansive type halogen-free flame-retardant, 5-10% of talcum powder, 0.2-0.4% of an ultraviolet light absorber, 0.2-0.4% of an antioxidant and 0.2-0.5% of a lubricant. The process comprises the following steps: firstly adding the materials in proportion into a mixing barrel to be uniformly mixed; then adding the mixture into a twin-screw extruder to be mixed, wherein the extruding temperatures of the first and second sections of the twin-screw extruder are 160-170 DEG C while the extruding temperatures of other sections are 170-190 DEG C and the total standing time of reactants in the twin-screw extruder is 3-5 minutes; and finally, cooling and slicing the extruded material obtained to obtain the environment-friendly weather-resistant flame-retardant PP material. By modifying PP, the material is environmentally friendly and flame-retardant, and also can satisfy the long-term anti-aging using requirement outdoors.

Owner:SUZHOU HECHANG POLYMERIC MATERIALS

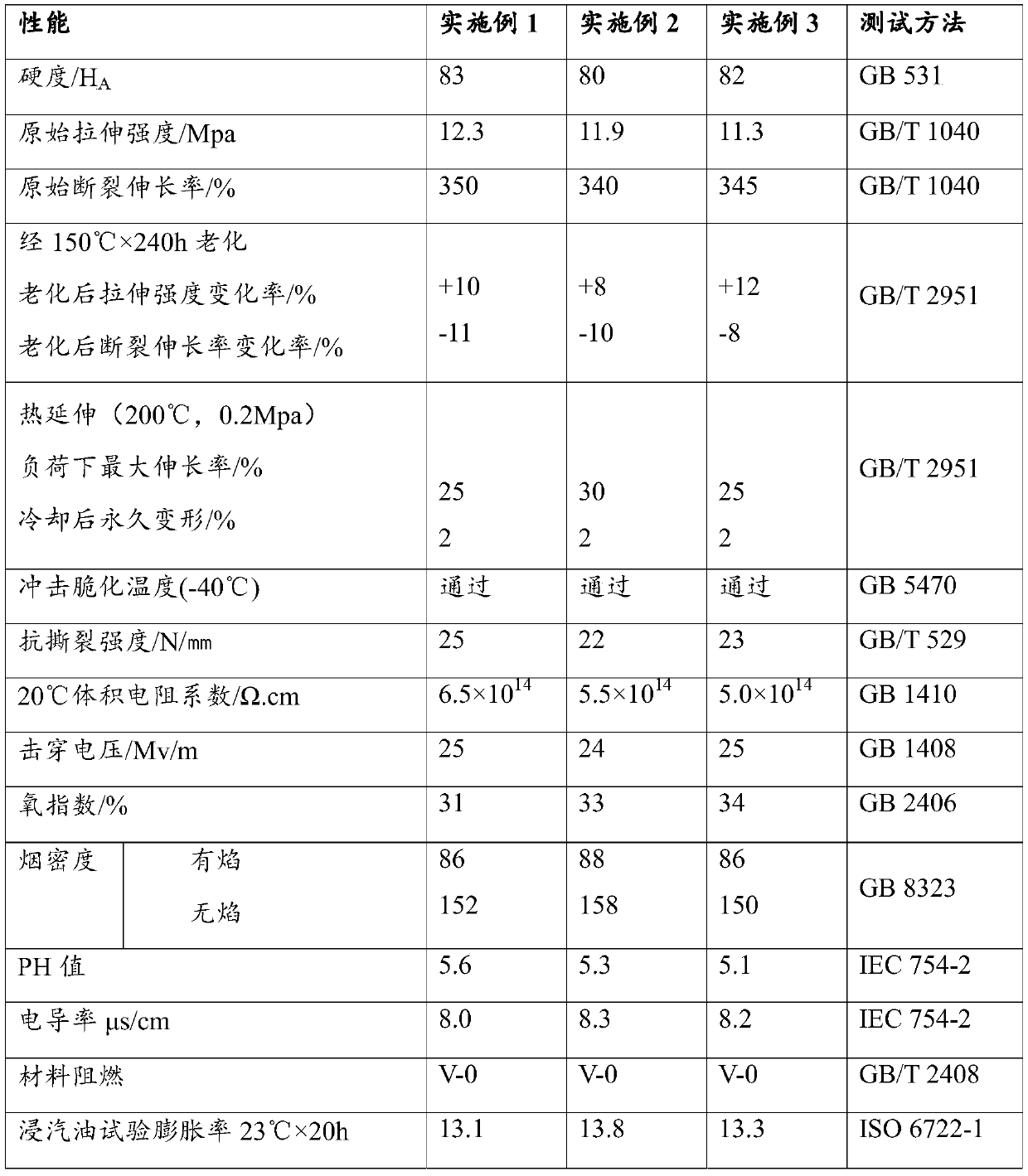

High temperature-resistant, radiation-crosslinked, low-smoke, halogen-free and flame-retardant cable material for charging pile cables, and preparation method thereof

InactiveCN110229431AGuaranteed high temperature performanceStay softRubber insulatorsPolymer scienceCrack resistance

The invention discloses a high temperature-resistant, radiation-crosslinked, low-smoke, halogen-free and flame-retardant cable material for charging pile cables, and a preparation method thereof. Thecable material comprises, by weight, 55-70 parts of ethylene-propylene-diene monomer rubber, 10-20 parts of ethylene-octene copolymer resin, 8-12 parts of maleic anhydride grafted modified resin, 8-10parts of crosslinked modified resin, 5-10 parts of polyethylene-acrylate rubber, 2-5 parts of polyphenylene ether, 60-90 parts of a flame retardant, 20-30 parts of a flame retardant synergist, 0.5-1part of polyethylene wax, 1.2-2 parts of an antioxidant, 0.9-1.2 parts of a crosslinking agent, and 0.1-0.3 part of a degradation inhibitor. The cable material of the invention can simultaneously meetthe requirements of softness, high flame retardancy, high and low temperature resistance, aging resistance, environmental crack resistance, high insulation, oil resistance, ozone resistance and ultraviolet light resistance.

Owner:WUXI JAKE PLASTIC

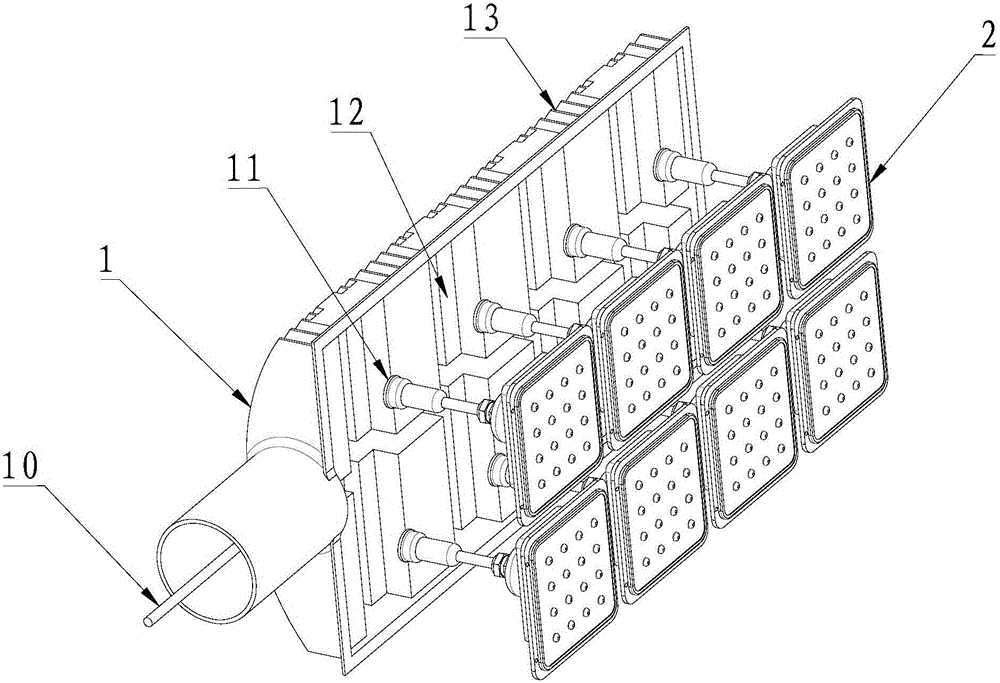

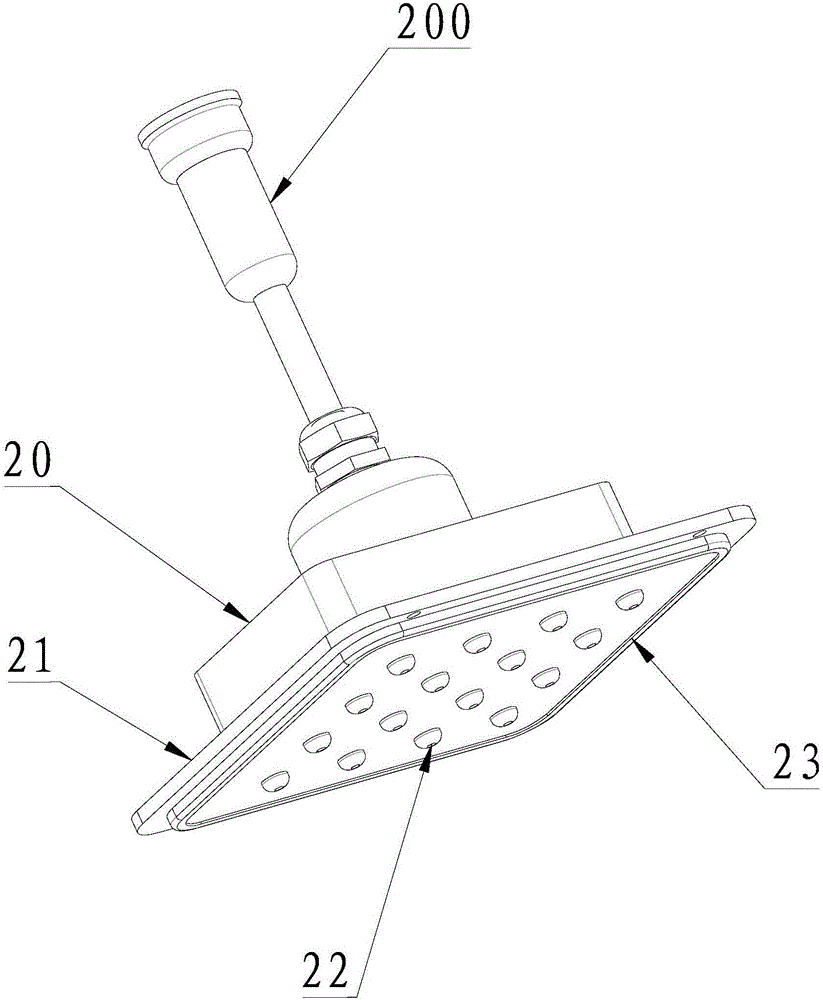

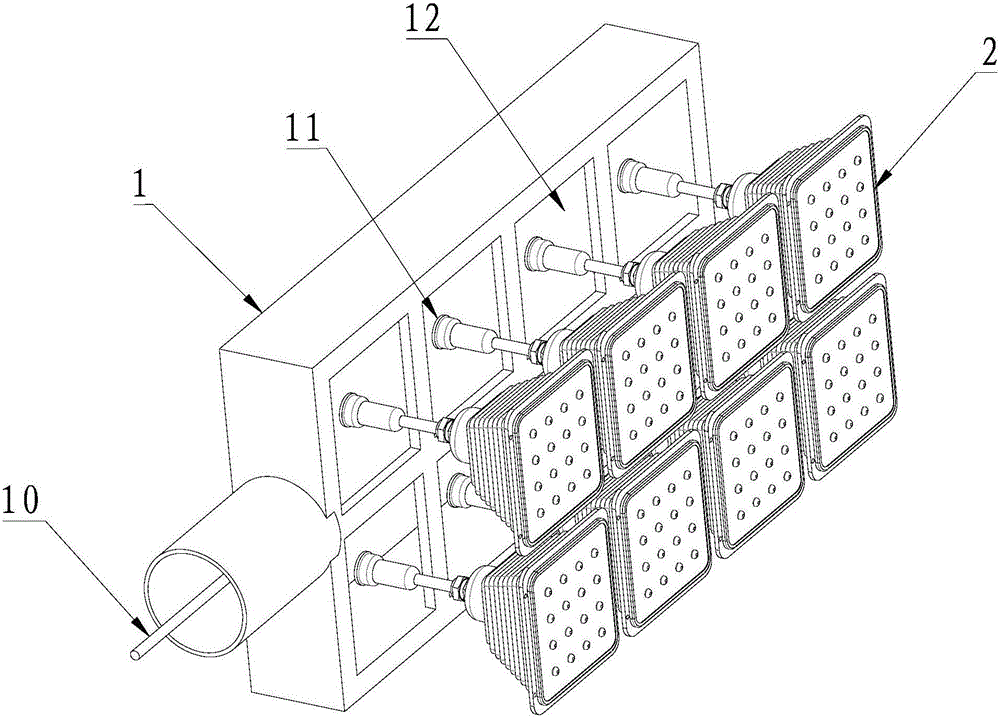

LED street lamp

InactiveCN105090845AChange powerMeet the requirements of outdoor useMechanical apparatusPoint-like light sourceEffect lightEngineering

The invention relates to an LED street lamp. An LED light source module with a ballast is adopted, and a lamp base is only used for providing a power input interface and fixing the LED light source module. In use, one or more LED light source modules can be mounted on the lamp base according to actual lighting requirements, and the lamp base is used in cooperation with the self-ballast LED light source modules of various specifications, so that the total power of the LED street lamp is changed, different use requirements are met, the use range of the LED street lamp is expanded, and upgrading of the self-ballast LED light source modules is facilitated; in addition, water resistance and anti-creeping treatment and the like are carried out on connections of all components of the LED street lamp, so that the LED street lamp is good in overall waterproof effect, high in protection performance, long in service life, compact in structure, easy to produce and assemble and capable of completely meeting outdoor use requirements of the LED street lamp.

Owner:FUJIAN HONGBO OPTO ELECTRONICS TECH CO LTD

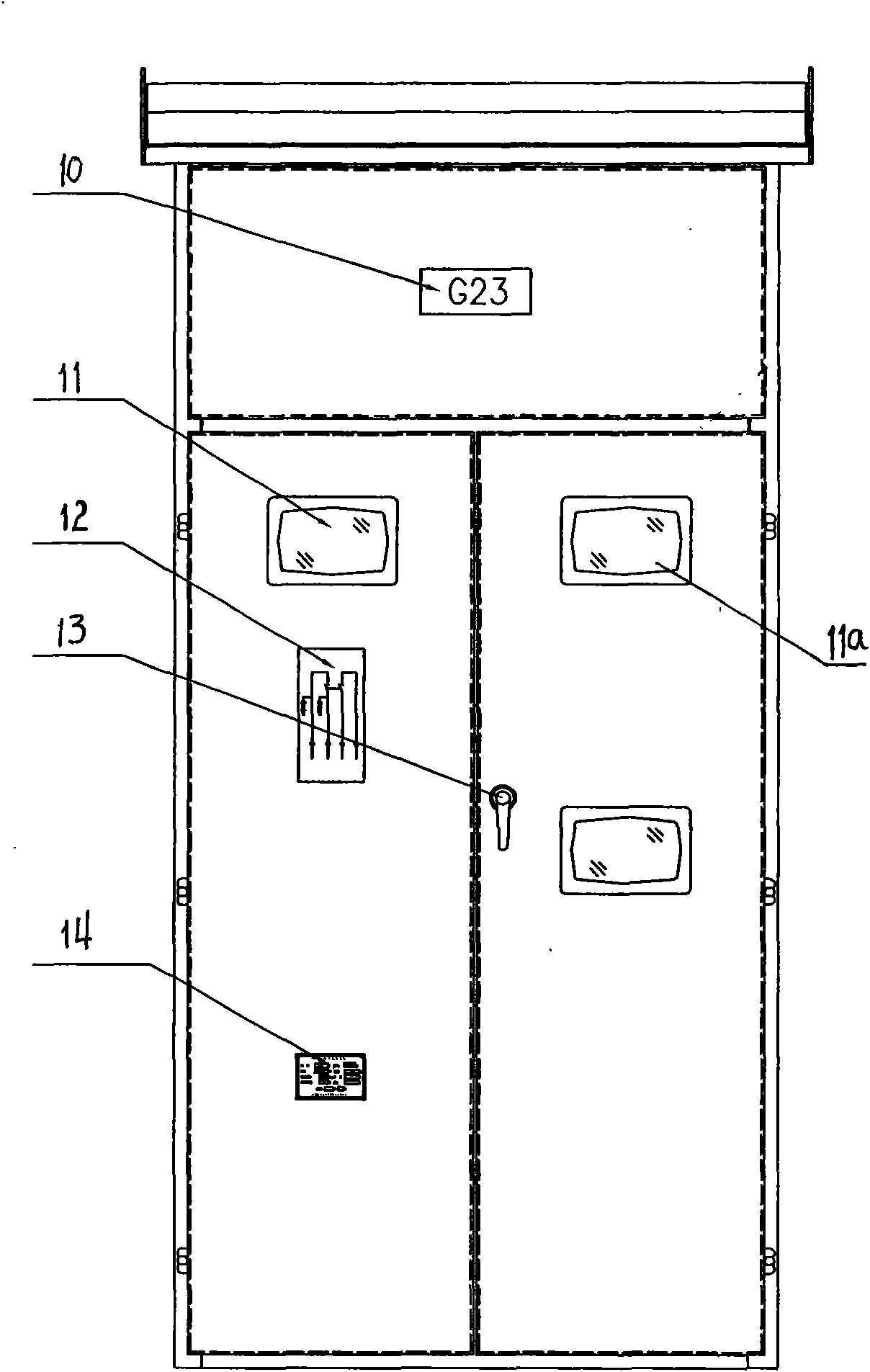

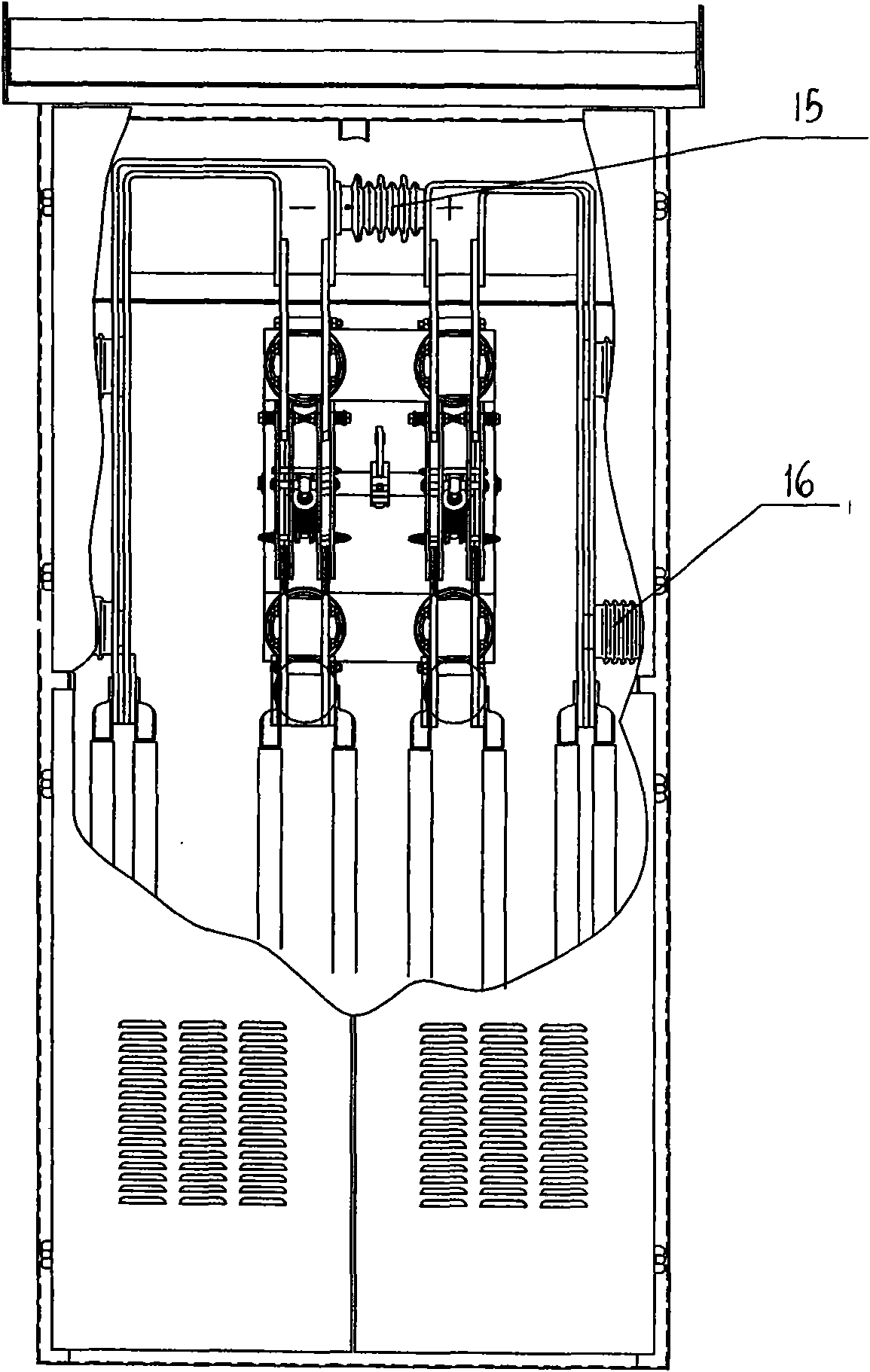

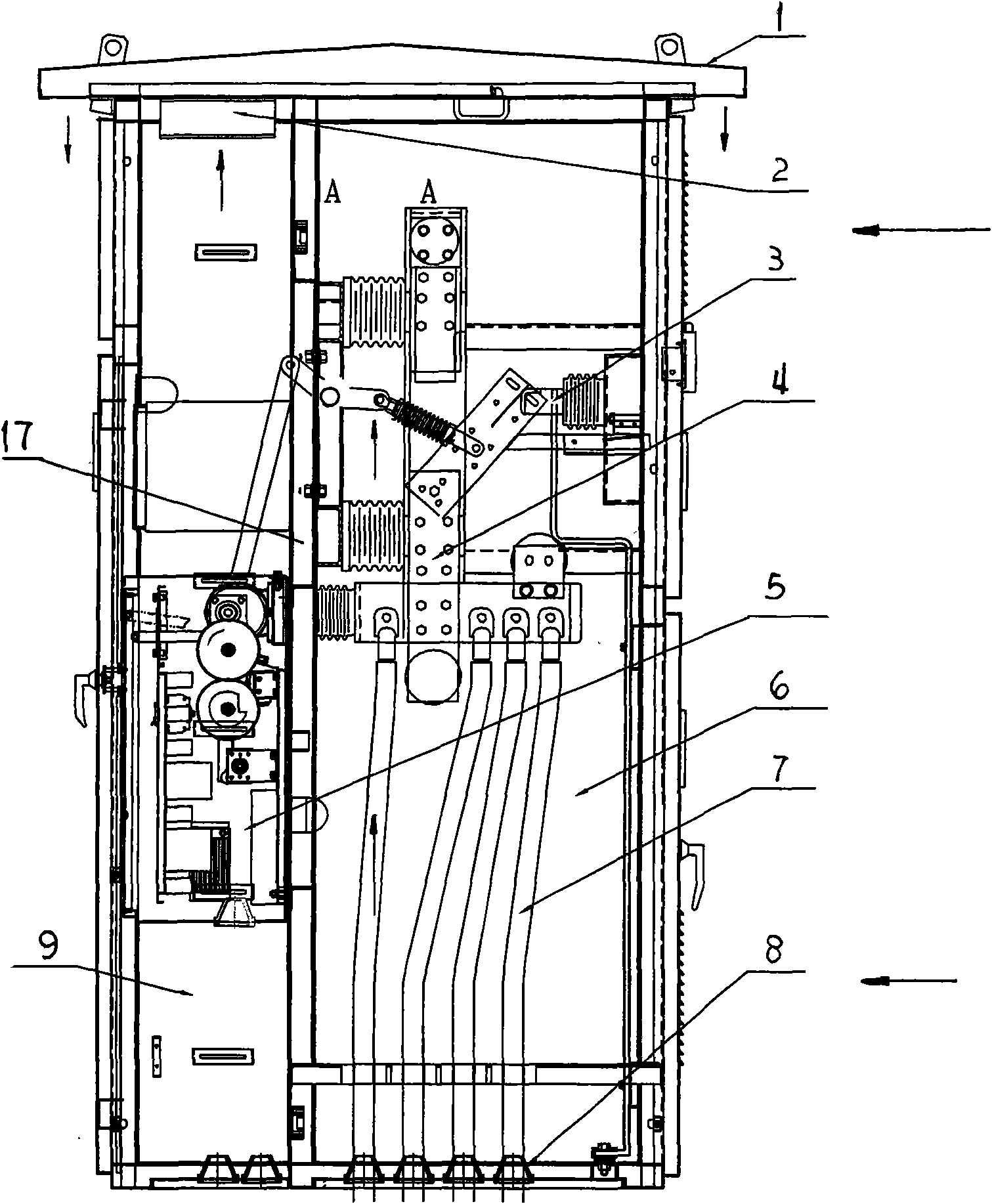

Double-pole isolating switch cabinet for outdoor direct current 1500 V contact net system

InactiveCN101794968AUnique top cover designMeet the requirements of protection level (IP44D)Substation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsElectromagnetic lockWindow shutter

The invention relates to a double-pole isolating switch cabinet for an outdoor direct-current 1500 V contact net system, which belongs to a high-power direct-current double-pole isolating switch cabinet used for subways or urban light rail systems. The cavity of the cabinet body is separated into a front chamber, an upper back chamber and a lower back chamber through a longitudinal baffle and a horizontal baffle; an electric operating mechanism is arranged in the front chamber; the direct-current double-pole isolating switch is installed in the upper back chamber; a primary cable is arranged in the lower back chamber; a shell-type rain-proof ceiling is installed on the cabinet, a heat radiating blower is installed on the rain-proof ceiling, an air outlet of the heat radiating blower is connected with an air inlet of the rain-proof ceiling, periphery eaves of the rain-proof ceiling is provided with a plurality of air outlets, doors of the upper back chamber and the lower back chamber are both provided with air inlet shutters, and the upper part of the vertical baffle and the horizontal baffle are both provided with air vents; and the lower back chamber is also provided with an electric heater. A back door is provided with an electromagnetic lock provided with electric interlocking control. The invention not only can radiate heat, ventilate the cabinet and exhaust air, but also can prevent condensation and satisfy the usage requirement of outdoor environment.

Owner:成都通力集团股份有限公司

Weather-resistant and flame-retardant PC/PBT alloy and preparation method thereof

The invention discloses a weather-resistant and flame-retardant PC / PBT alloy. The weather-resistant and flame-retardant PC / PBT alloy comprises raw materials of organosilicon modified polycarbonate, polybutylene terephthalate, compatibilizer, flame retardant, flame retardant auxiliary, anti-dripping agent, transesterification inhibitor, antioxidant, liquid lubricant, and UV absorber. According to the weather-resistant and flame-retardant PC / PBT alloy, an organic transesterification inhibitor having a good compatibility with a matrix is added to the alloy, so that the alloy material surface is smooth and free of pocking marks, and at the same time, the transesterification inhibitor used is organophosphorus which can play a synergistic effect with a brominated flame retardant, thereby reducing the using amount of the flame retardant.

Owner:DONGGUAN HONOUR E P

PVC environment-friendly calcium-zinc stabilizer

The invention relates to the technical field of materials, and discloses a PVC environment-friendly calcium-zinc stabilizer. The PVC environment-friendly calcium-zinc stabilizer comprises the following components in parts by weight: 10-30 parts of a calcium salt main stabilizer, 10-30 parts of a zinc salt main stabilizer, 15-25 parts of modified hydrotalcite, 10-20 parts of a lubricant, 5-10 partsof modified halloysite nanotubes, 1-5 parts of an antioxidant, 1-5 parts of an auxiliary stabilizer and 1-5 parts of an ultraviolet absorber. The PVC environment-friendly calcium-zinc stabilizer provided by the invention has the advantages of high stability, strong initial coloring power and good precipitation resistance, and overcomes the defect of easiness in precipitation in a traditional calcium-zinc processing process. According to the PVC environment-friendly calcium-zinc stabilizer, aiming at different products, a plasticization degree adjustment range is wide, and the defect that thetraditional calcium-zinc stabilizer is earlier and faster in plasticization is overcome. The PVC environment-friendly calcium-zinc stabilizer provided by the invention has high weather resistance, theweather resistance of the PVC environment-friendly calcium-zinc stabilizer is equivalent to the weather resistance of a traditional lead salt system, and the requirements for outdoor use of PVC products are met.

Owner:杭州凌洲塑胶科技有限公司

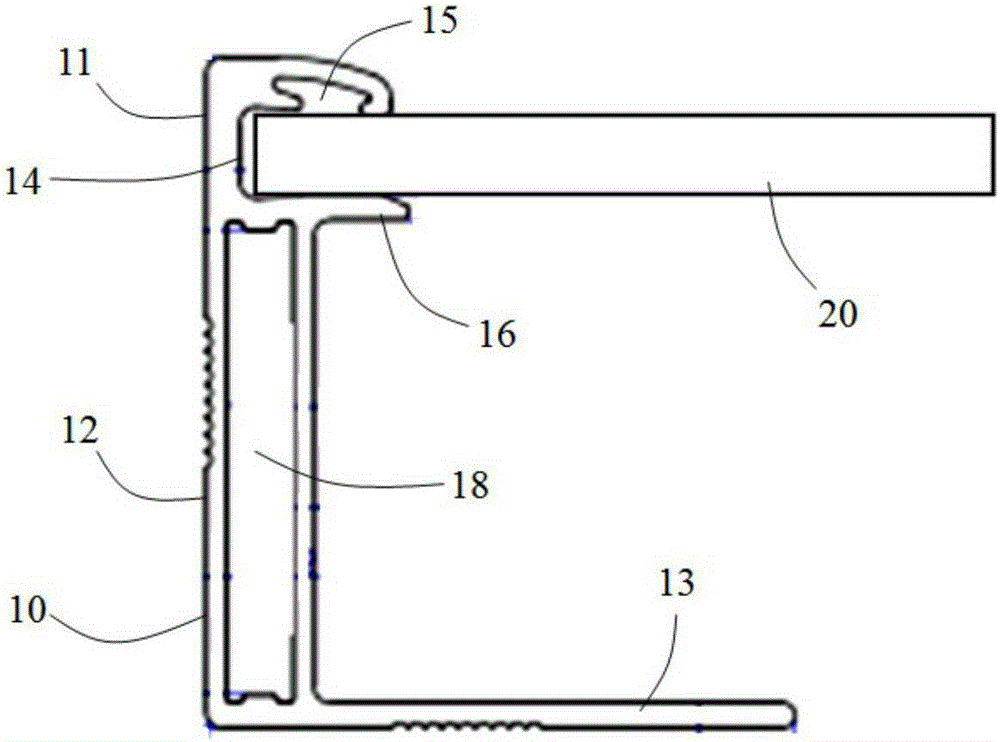

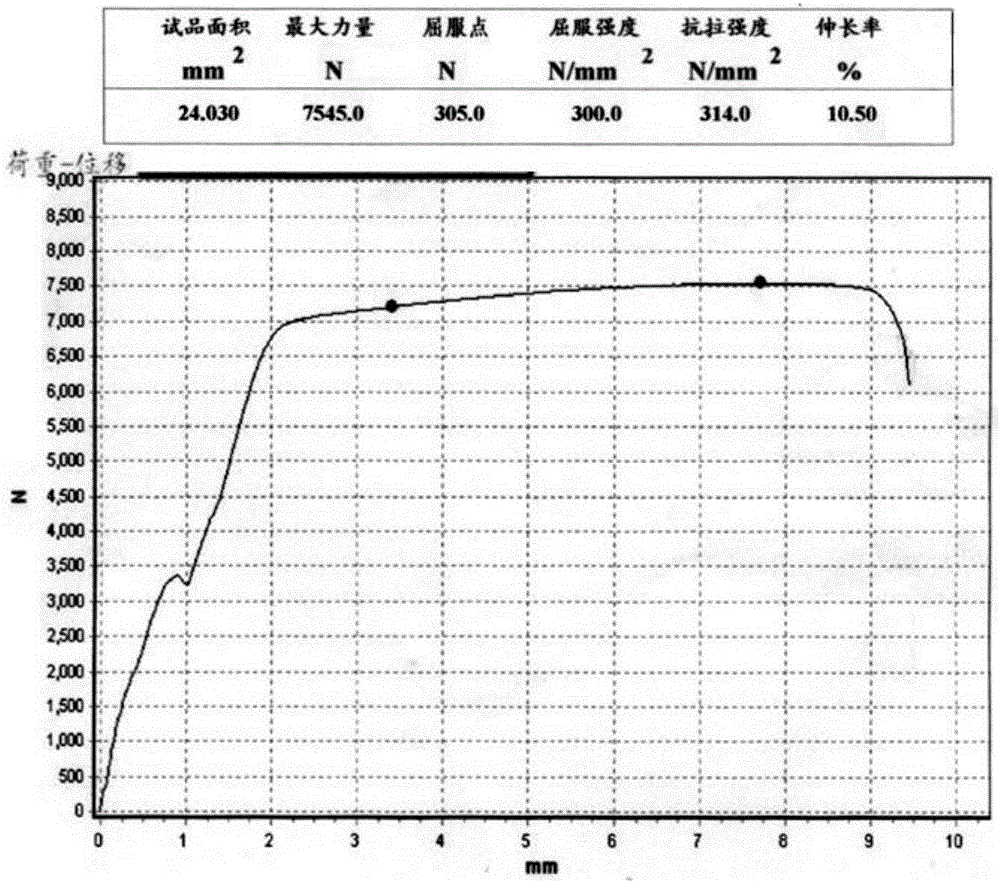

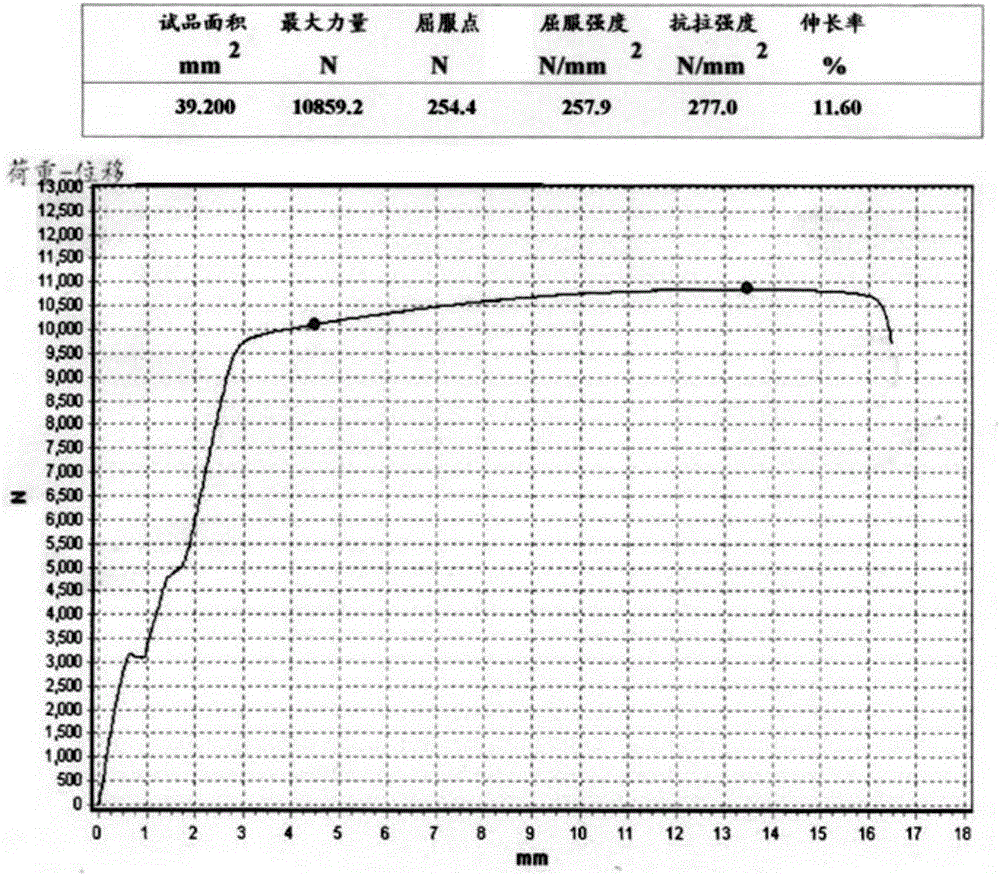

Novel photovoltaic module

ActiveCN105207596AImprove mechanical propertiesHigh yield strengthPhotovoltaicsPhotovoltaic energy generationChromiumMagnesium

The invention relates to a novel photovoltaic module which comprises a laminating piece and an alloy frame surrounding the peripheral edges of the laminating piece, wherein the alloy frame is an aluminum alloy frame and comprises the following trace elements in percentage by weight: 0.4-0.7% of silicon, less than or equal to 0.25% of iron, 0.05-0.4% of copper, 0.7-1.0% of magnesium, less than 0.2% of chromium, less than 0.1% of lead and less than 0.1% of tin. According to the invention, the novel aluminum alloy frame is adopted, so that the mechanical property of the photovoltaic module can be improved greatly, more strict outdoor use requirements are met, through testing, the photovoltaic module has higher yield strength, tensile strength and hardness, the mechanical property of the novel photovoltaic module provided by the invention is obviously superior to that of the photovoltaic module adopting a common No. 6063 aluminum alloy frame in the prior art and in addition, the weight and the production cost of the frame can be reduced.

Owner:CSI SOLAR POWER GROUP CO LTD +1

Flame-retardant PP plate and preparation method thereof

InactiveCN110791014AImprove flame retardant performanceGood weather resistancePolymer sciencePolymer chemistry

The invention belongs to the technical field of PP plates, and particularly relates to a flame-retardant PP plate and a preparation method thereof. The flame-retardant PP plate comprises the followingraw materials by mass: 83-85% of a PP material; 9-11% of a flame retardant; 1.5-4% of a toughening agent; 0.1-0.3% of a main antioxidant; 0.1-0.3% of a secondary antioxidant; 0.1-0.3% of an ultraviolet absorber; 0.05-0.15% of diffusion oil; and 1-3% of color masterbatch. The preparation method of the flame-retardant PP plate comprises the following steps: 1) stirring the raw materials, and 2) carrying out high-temperature extrusion molding. The flame-retardant PP plate has the advantages of good flame retardancy, good weather resistance, good toughness, good mechanical properties, long service lifetime and good ultraviolet resistance, and can meet the requirements of outdoor use.

Owner:DONGGUAN ZHISEN HARDWARE PLASTIC PROD CO LTD

Preparation method of high-strength PP material containing coffee grounds

The invention provides a high-strength PP material containing coffee grounds. The high-strength PP material comprises the following components: 35-45% of copolymerized PP, 30-45% of the coffee grounds, 5-10% of talcum powder, 0.2-0.4% of an ultraviolet light absorber, 0.2-0.4% of an antioxidant and 0.2-0.5% of a lubricant. The method comprises the following steps: adding the components into a mixing cylinder according to the ratio, and uniformly mixing; adding the mixture into a double-screw extruder for mixing; wherein the extrusion temperature of the first section and the second section of the double-screw extruder is 160-170 DEG C, the extrusion temperature of other sections is 170-190 DEG C, and the total residence time of reactants in the double-screw extruder is 3-5 minutes; and finally, extruding the obtained material, cooling and dicing to obtain the high-strength PP material containing the coffee grounds. By modifying PP, environmental protection and flame retardance are achieved, and the outdoor long-term anti-aging use requirement can be met.

Owner:咖法科技(上海)有限公司

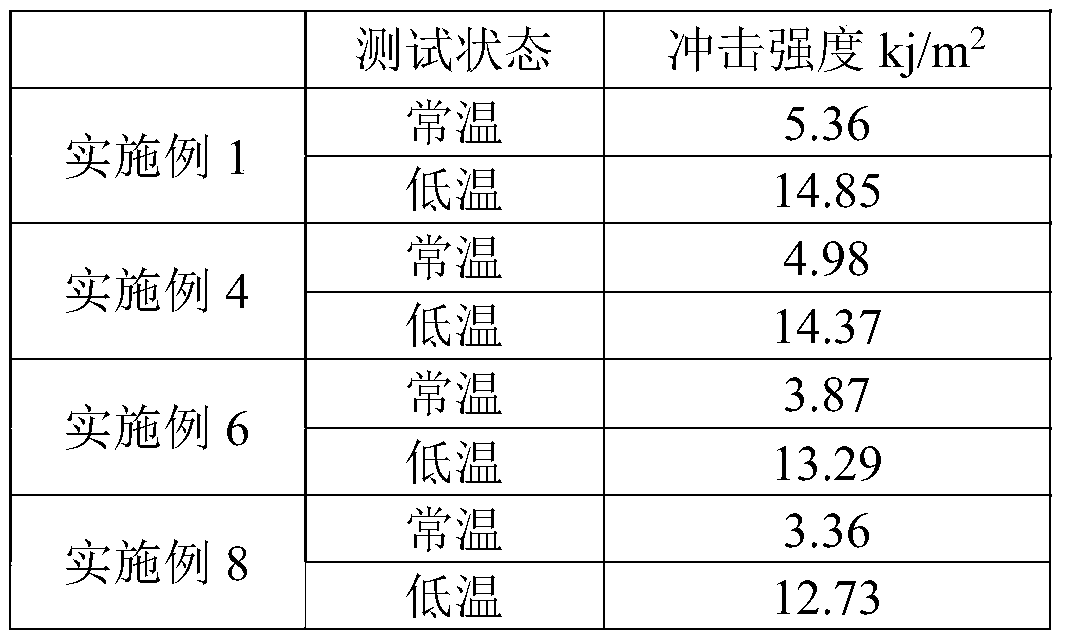

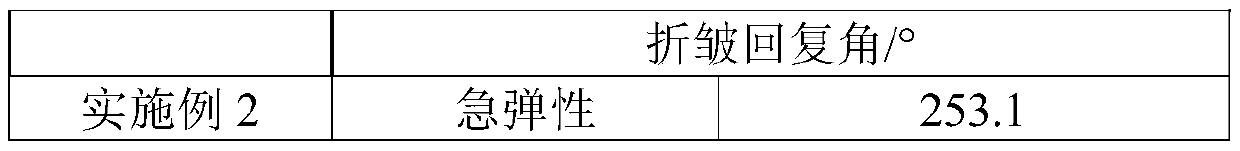

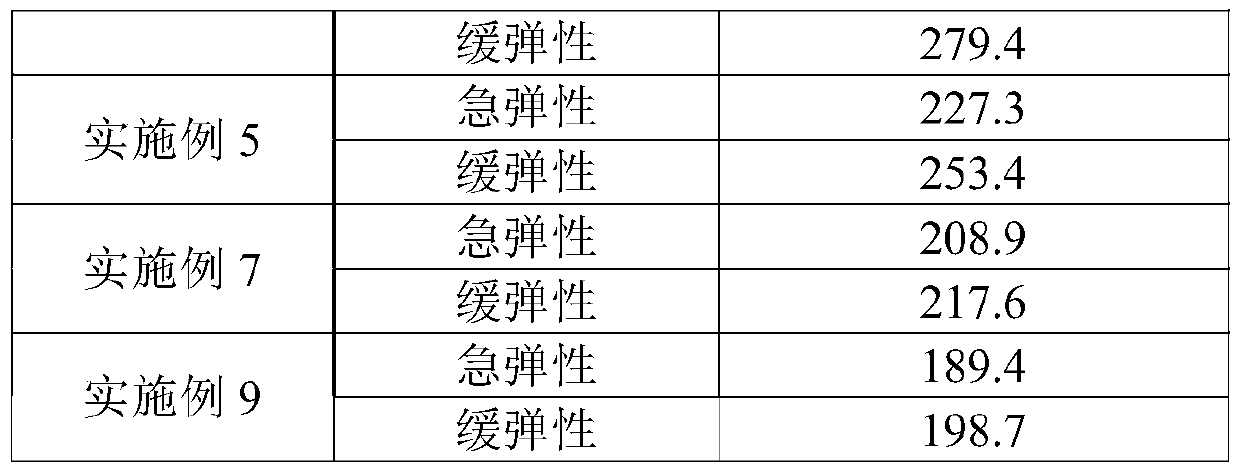

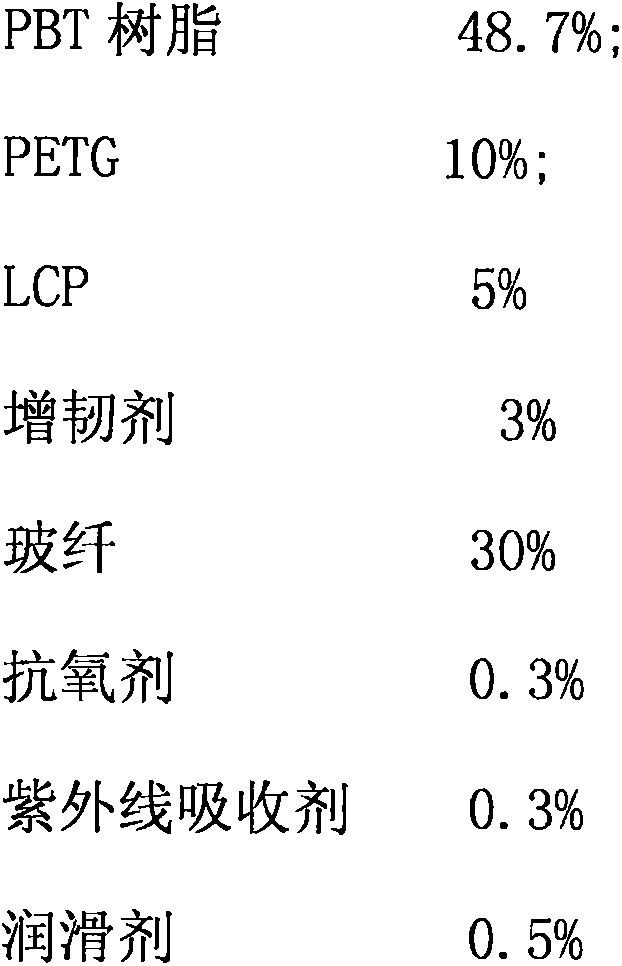

Engineering plastic with high surface and high performance and preparing method thereof

InactiveCN106519592AHigh surface glossImprove processing fluidityCarbon blackPolyethylene terephthalate glycol

The invention relates to an engineering plastic with high surface and high performance and preparing method thereof. The composite material comprises 30%-70% of PBT (polybutylece terephthalate) resin, 5%-15% of PETG (polyethylene terephthalate glycol), 5%-10% of LCP (liquid crystal polymer), 20%-50% of alkali-free glass fiber, 1%-5% of flexibilizer, 0.1%-1% of antioxidant, 0.1%-1% of UV (ultraviolet), 0.1%-1% of lubricant, 0.1%-1% of a coupling reagent, and 1%-3% of carbon black master batches. By adding PETG (polybutylece terephthalate), the surface of the prepared material is enabled to be smooth and free of floating fibers. By adding a liquid crystal polymer, the degree of crystallinity and the heat distortion temperature of the material are increased. The preparing method comprises the steps of after putting PBT (polybutylece terephthalate), PETG (polyethylene terephthalate glycol), LCP (liquid crystal polymer) and auxiliaries according to a certain proportion into a high mixing machine to mix for 2-5 min, firstly pouring the mixture into a main feeding opening of a twin-screw extruder, then making a glass fiber enter the twin-screw extruder from a glass fiber opening or a side feeding opening, extruding the glass fiber by the twin-screw for bar stretching, and finally carrying out water cooling, air drying and grain-sized dicing, wherein the temperature in the granulation process should be controlled at 180-240 DEG C, and the screw rotation speed should be controlled at 300-400 RPM. The engineering plastic with high surface and high performance has the advantages of being good in mechanical properties, smooth in surface, free of floating fiber, resistant to heat and weather and the like, and is applicable to the fields of automobile parts and, mechanical parts and the like.

Owner:温州科力塑业有限公司

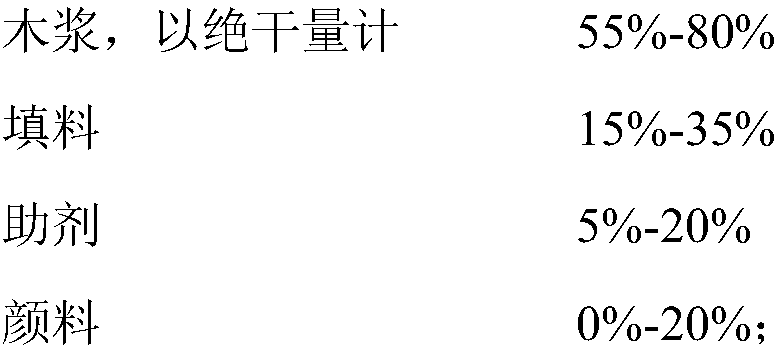

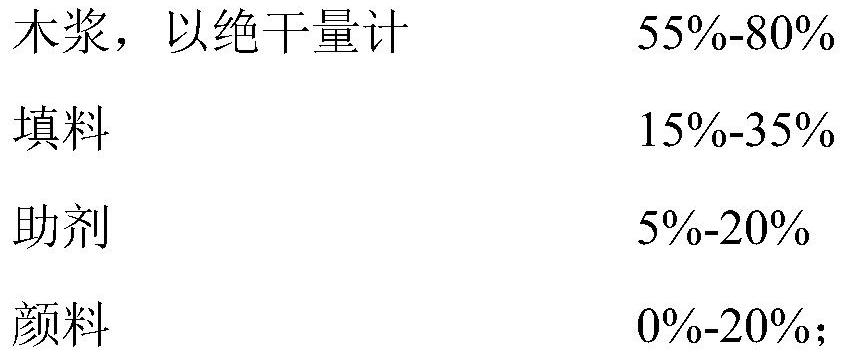

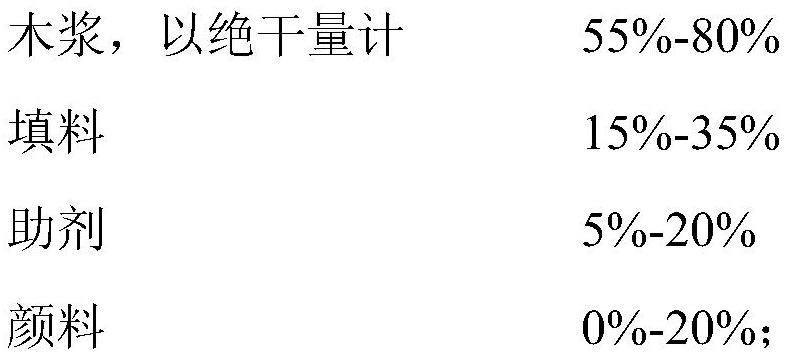

Overcoating base paper used for outdoor highly-strengthened plate and preparation method of overcoating base paper

ActiveCN108130815AIncrease coverageImprove breathabilitySpecial paperReinforcing agents additionFiberPapermaking

The invention belongs to the technical field of papermaking, and in particular relates to overcoating base paper used for an outdoor highly-strengthened plate and a preparation method of the overcoating base paper. The base paper is prepared from the following raw materials: wood pulp, a filler, an auxiliary agent and a pigment, wherein the auxiliary agent is composed of sodium hydroxide, sulphuric acid, aluminium sulphate and a wet strength agent; and the filler is composed of titanium dioxide, magnesium silicate and kaolin. The prepared overcoating base paper used for the outdoor highly-strengthened plate provided by the invention has a good covering property, fiber distribution uniformity, fine paper surfaces, strong corrosion resistance, a high sun-proof grade, and high water washing color fastness; and after the base paper is impregnated with melamine for veneering, the base paper is impregnated into a solution with the pH of 3.5-10, and no phenomena such as blistering and deformation of the paper happen; and the sun-proof grade is 6 grade or more, and the water washing color fastness is high. The invention also provides a preparation method of the overcoating base paper usedfor the outdoor highly-strengthened plate, and the base paper has high practicability and scientific and reasonable operation, and is simple and practicable.

Owner:ZIBO OU MU SPECIAL PAPER

Method for enhancement treatment through anaerobic heat treatment of poplar and impregnation with melamine urea formaldehyde resin

ActiveCN108058254AReduce moisture contentMeet the requirements of outdoor useWood treatment detailsThermal wood treatmentWater vaporNitrogen

The invention discloses a method for enhancement treatment through anaerobic heat treatment of poplar and impregnation with melamine urea formaldehyde resin. The method comprises the steps of preparing poplar wood, carrying out anaerobic heat treatment on the poplar wood, carrying out impregnation with the low-viscosity melamine urea formaldehyde resin, and carrying out drying and curing treatmentor pressurization drying and curing treatment. The method is characterized by comprising the steps that drying treatment is carried out on the poplar wood, dressing treatment is carried out on the dried poplar wood, the dressed poplar wood is subjected to anaerobic heat treatment under the protection of water vapor or nitrogen, the poplar wood subjected to anaerobic heat treatment is placed intothe normal-temperature and low-viscosity melamine urea formaldehyde resin for impregnation treatment at a certain temperature, after a certain time, the poplar wood is taken out and is placed on a support, residual resin on the surface of the poplar wood is scraped so as to enable the surface of the poplar wood to be subjected to air drying and then be subjected to drying and resin curing treatment, and therefore the poplar wood subjected to enhancement treatment through anaerobic heat treatment of the poplar and impregnation with the melamine urea formaldehyde resin is prepared.

Owner:BEIHUA UNIV

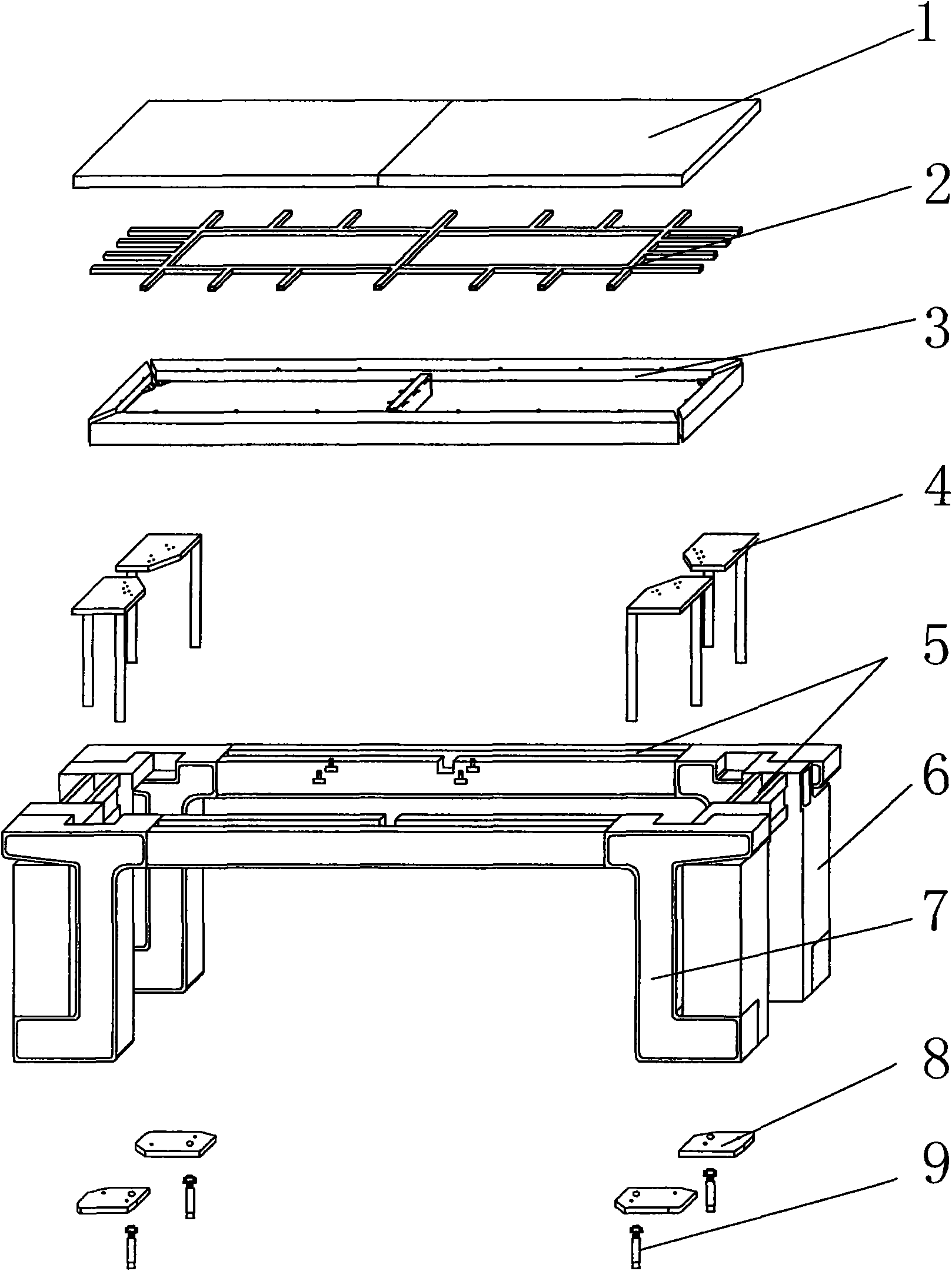

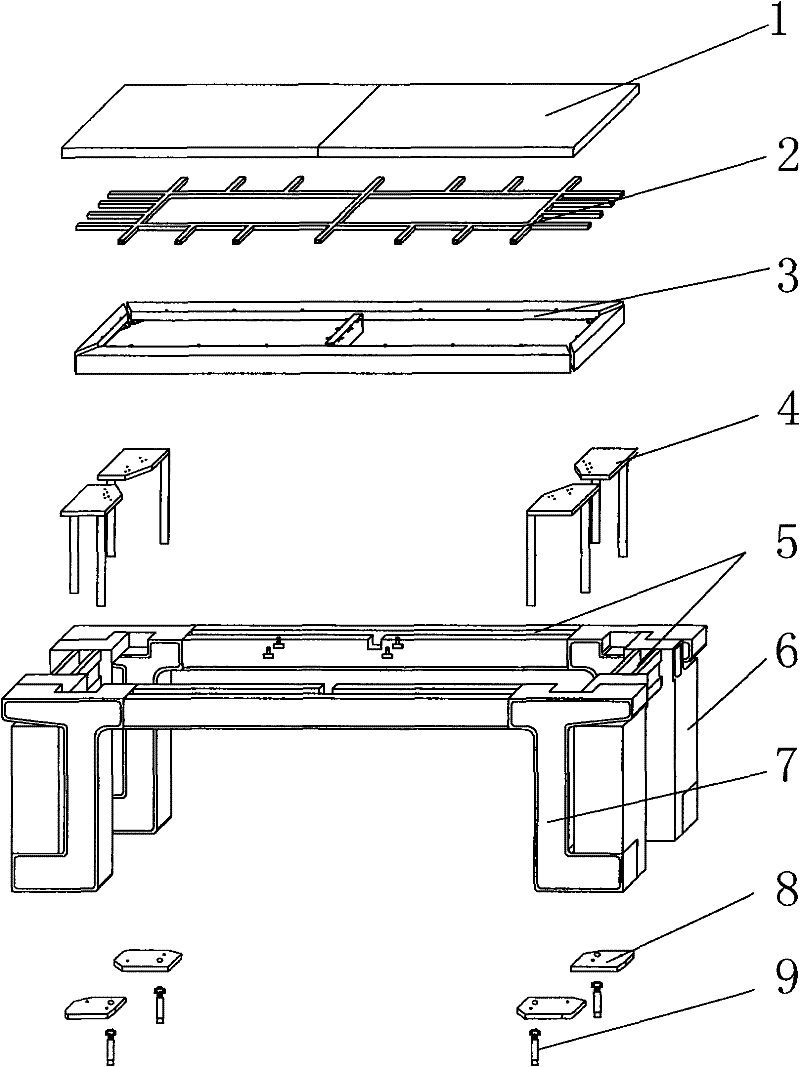

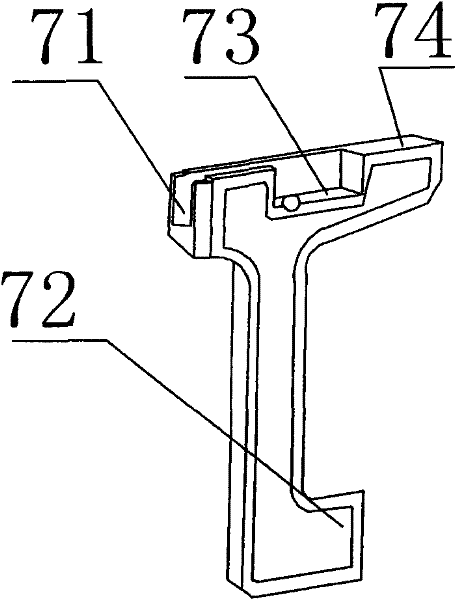

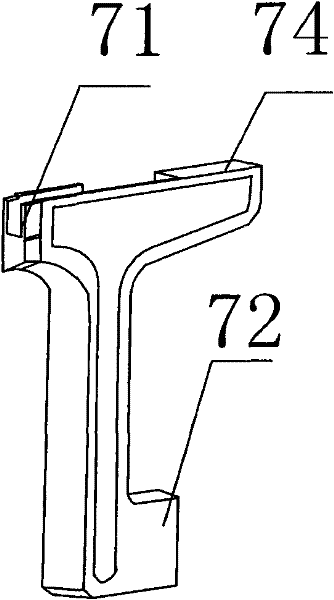

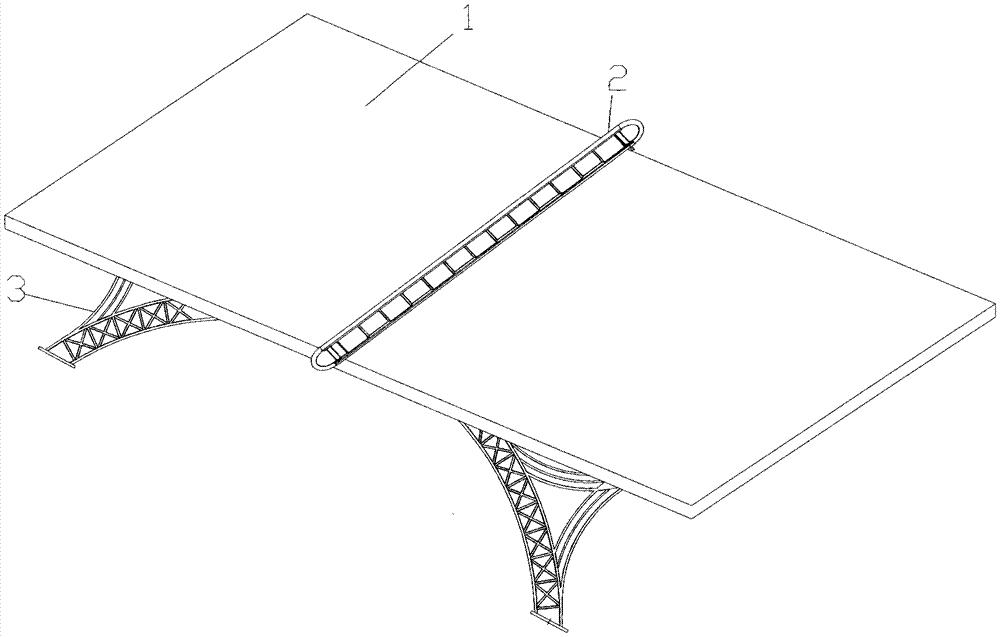

Outdoor table-tennis table

InactiveCN101927081ANot easy to shakeReduce manufacturing costSport apparatusFoot supportsMetallic materials

The invention provides a table-tennis table suitable for outdoor use. The table-tennis table is firm and durable, is convenient to transport and has a low production cost. The outdoor table-tennis table comprises a ball table top and a leg supporting structure, wherein the leg supporting structure comprises a table top supporting frame, a cross beam, a cross beam shell, a foot supporting frame, a foot bottom plate, a cross beam foot shell and a connecting piece. A metal material is adopted to manufacture the framework of the outdoor table-tennis table, and an engineering plastic is adopted as a coating layer, so the production cost is reduced, the whole weight is lightened, and simultaneously the outdoor table-tennis table meets the requirements on the outdoor use, has high comprehensive performance, and is firm and durable.

Owner:张耀辉

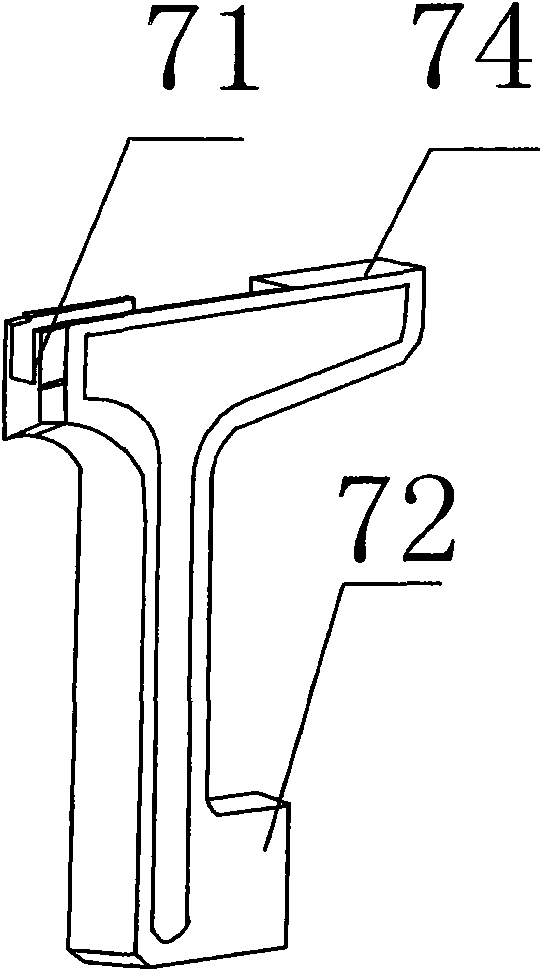

Electrical cable higher in safety

InactiveCN104766667AImprove waterproof performanceImprove fire performanceClimate change adaptationPower cables with screens/conductive layersFiberYarn

The invention discloses an electrical cable higher in safety. The electrical cable comprises an outer protection sleeve and inner protection sleeves. The outer protection sleeve is composed of a flame retardant protective layer, a polyvinylidene chloride protection film layer, a shielding layer and an aluminum foil layer from outside to inside. The outer protection sleeve is internally provided with an inverted-Y-shaped framework. The tail end of the inverted-Y-shaped framework is fixedly connected with the aluminum foil layer. The inverted-Y-shaped framework is internally provided with an aluminum framework in an embedded mode. Each inner protection sleeve is sequentially divided into a high-intensity fiber yarn layer and a waterproof layer from outside to inside. According to the electrical cable higher in safety, the shielding layer is additionally arranged in the outer protection sleeve, most electromagnetic radiation can be shielded, the body health of a user in the using process is guaranteed, and the additionally-arranged aluminum cross-shaped framework makes electric contact with the aluminum foil layer in the outer protection sleeve, so that transmission consumption is lowered to the minimum; the high-intensity fiber yarn layer, the waterproof layer and a flame retardant protection layer are additionally arranged, so that the tensile, waterproof and fireproof performance of the electrical cable can be further enhanced.

Owner:杜志刚

A kind of pvc environment-friendly calcium zinc stabilizer

The invention relates to the technical field of materials, and discloses a PVC environment-friendly calcium-zinc stabilizer. The PVC environmentally friendly calcium-zinc stabilizer comprises the following parts by weight: 10-30 parts of calcium salt main stabilizer, 10-30 parts of zinc salt main stabilizer, 15-25 parts of modified hydrotalcite, 10-20 parts of lubricant, 5-10 parts of modified halloysite nanotubes, 1-5 parts of antioxidant, 1-5 parts of auxiliary stabilizer and 1-5 parts of ultraviolet absorber. The PVC environment-friendly calcium-zinc stabilizer of the invention has high stability, strong initial tinting strength and good precipitation resistance, and overcomes the defect of easy precipitation in the traditional calcium-zinc processing process. The PVC environment-friendly calcium-zinc stabilizer of the present invention has a wide adjustment range of the degree of plasticization for different products, and overcomes the disadvantage that the plasticization of the traditional calcium-zinc stabilizer is early and fast. The PVC environment-friendly calcium-zinc stabilizer of the invention has high weather resistance, which is comparable to the weather resistance of the traditional lead salt system, and meets the requirements for outdoor use of PVC products.

Owner:杭州凌洲塑胶科技有限公司

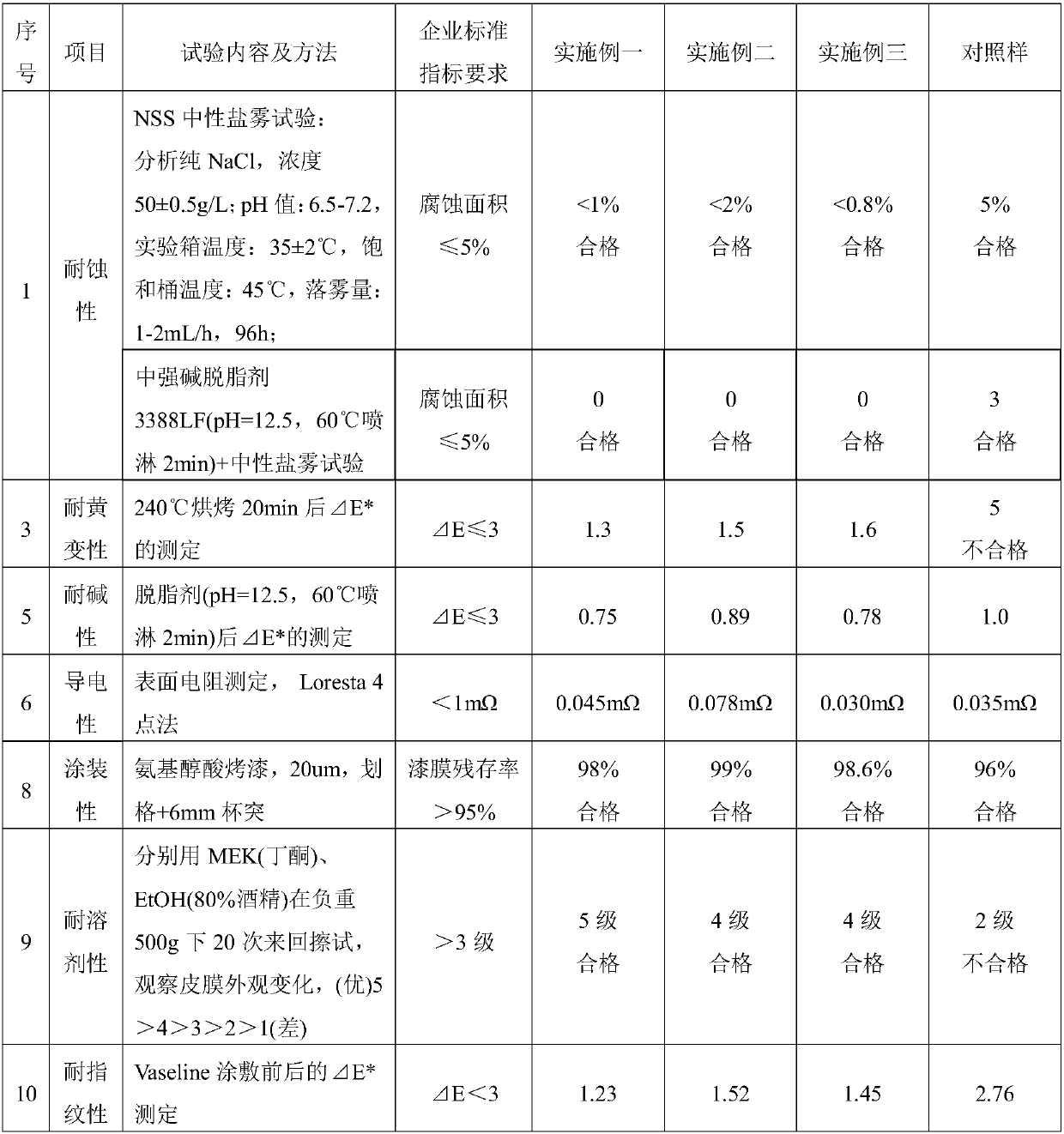

Highly-anticorrosive and chromium-free anti-fingerprint coating and preparation method thereof

InactiveCN109535942AGood yellowing resistanceAccelerated corrosionAnti-corrosive paintsEpoxy resin coatingsChromium freeAcrylic resin

The invention discloses a highly-anticorrosive and chromium-free anti-fingerprint coating and a preparation method thereof, and belongs to the technical field of coatings. The anti-fingerprint coatingcomprises 10-50 wt% of epoxy acrylic resin, 8-20 wt% of silica sol, 1-10 wt% of alkoxysilane, 1-5 wt% of ethylene glycol, 3-10 wt% of polytetrafluoroethylene wax, 0.5-3 wt% of a corrosion inhibitor,0.1-1 wt% of a wetting agent, 0.1-1 wt% of a defoamer, and the balance of deionized water; and the corrosion inhibitor is any one or two of sodium molybdate and ammonium molybdate. The invention alsoprovides a preparation method of the anti-fingerprint coating. The addition of the epoxy acrylic resin and anticorrosive assistants improves the yellowing resistance, the corrosion resistance and thesolvent resistance of the anti-fingerprint coating; the action of the alkoxysilane improves the adhesion and the paint spreading property of the coating, and makes the coating contain no toxic heavy metals and have good fingerprint resistance; and the preparation method is simple, and is suitable for industrial production.

Owner:青岛海创化学品有限责任公司

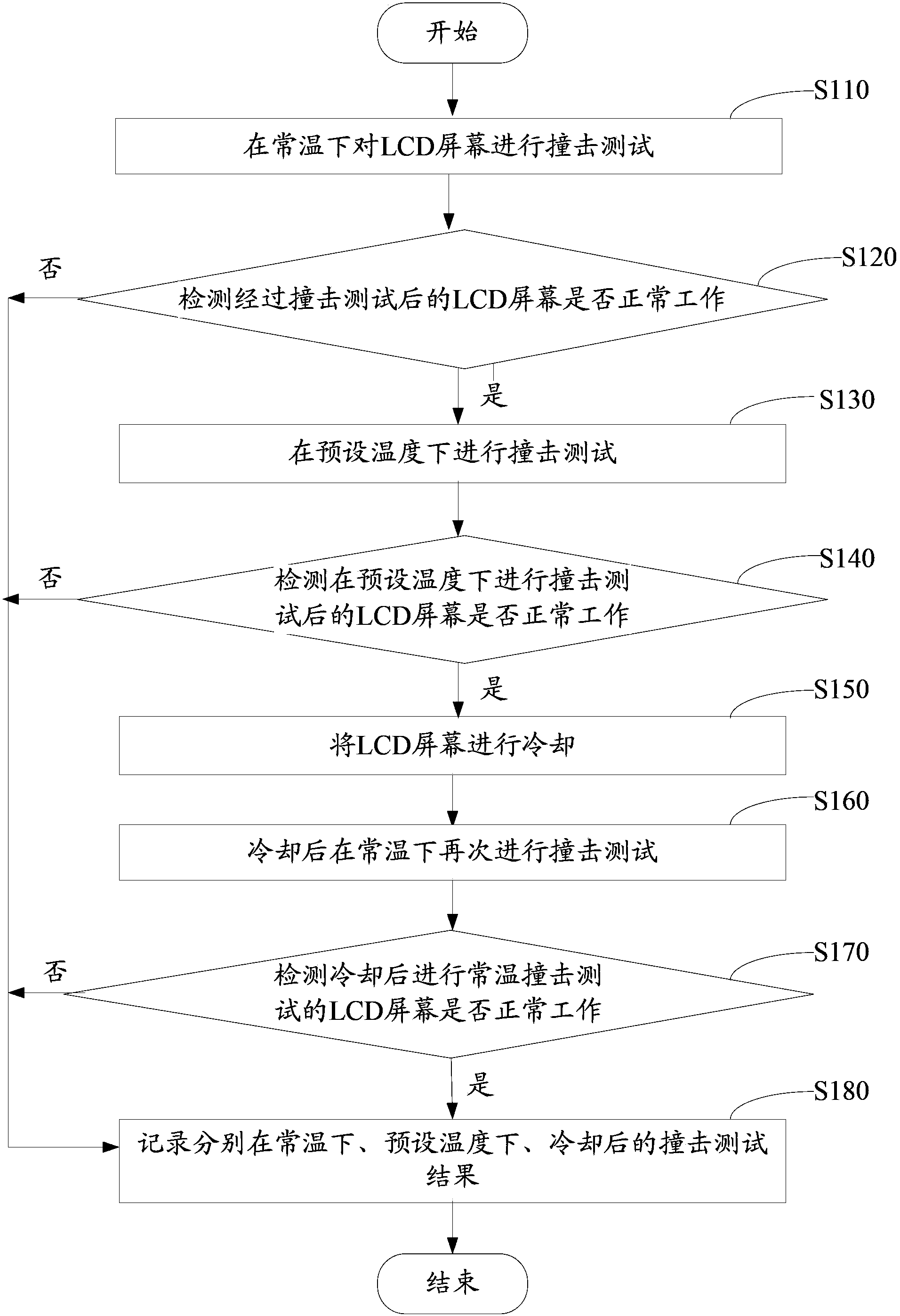

LCD screen hardness test method

InactiveCN103838012AMeet the requirements of outdoor useInvestigating material hardnessNon-linear opticsCrash testEngineering

The invention provides an LCD screen hardness test method. The LCD screen hardness test method comprises the following steps: an impact test is conducted on an LCD screen at normal temperature; whether the LCD screen works normally or not after the impact test is detected, and if yes, an impact test is conducted at preset temperature; whether the LCD screen works normally after the impact test at preset temperature or not is detected, and if yes, the LCD screen is cooled; the impact test is conducted on the LCD screen at normal temperature again after the LCD screen is cooled; whether the LCD screen which is subjected to the impact test at normal temperature after being cooled works normally or not is detected. According to the LCD screen hardness test method, the LED screen is directly subjected to the impact test, subjected to the impact test again at high temperature (55DEG C-65DEG C) and subjected to the impact test after being cooled from the high temperature, as a result, the situation that the LCD screen is subjected to impact or collision outdoors can be simulated, and whether the hardness of the LCD screen meets the requirement of outdoor use or not can be detected.

Owner:OCEANKING DONGGUAN LIGHTING TECH +2

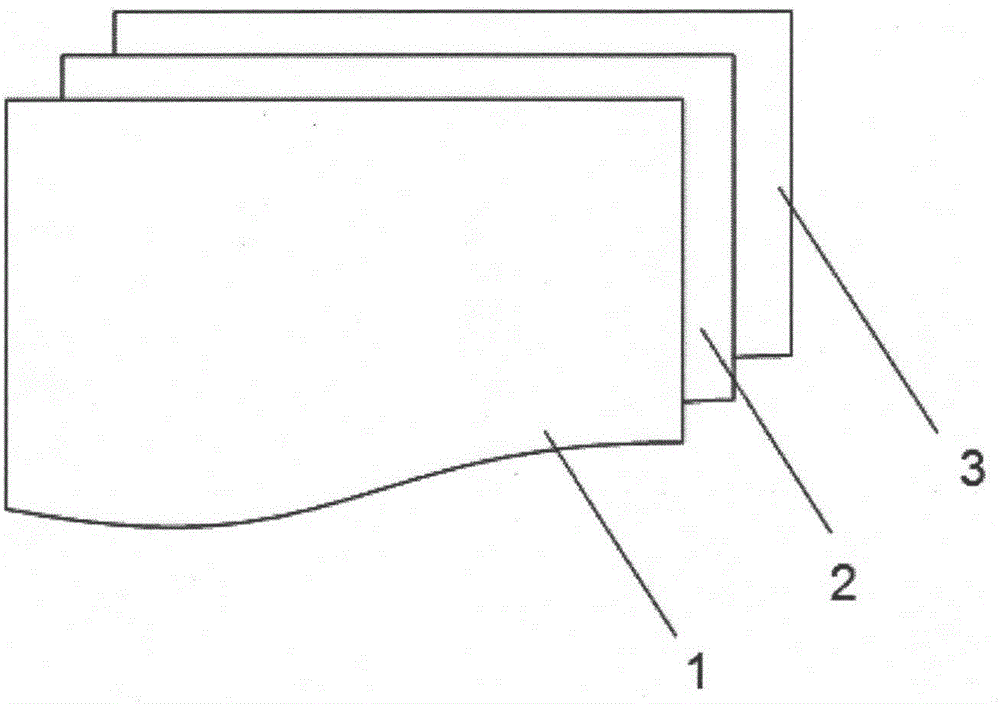

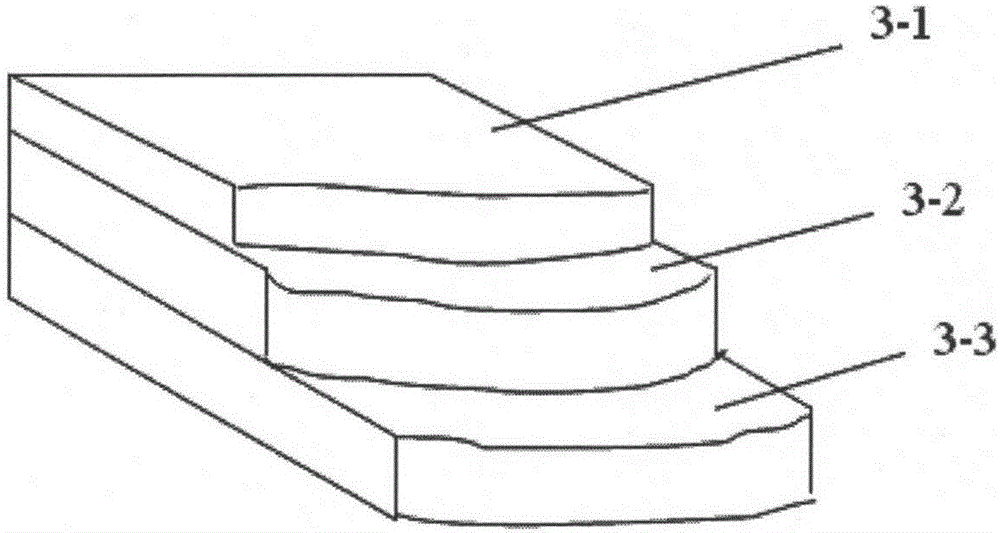

Solar cell backboard membrane

InactiveCN106206806AComposite goodAvoid damagePhotovoltaic energy generationSemiconductor devicesUltravioletDaylight

The invention provides a solar cell backboard membrane. The solar cell backboard membrane is combined to the outmost layer of a solar cell backboard and is of a multi-layer coextrusion structure. The solar cell backboard membrane comprises an ultraviolet absorption layer used for absorbing most ultraviolet in sunlight, a reflecting layer used for reflecting and removing residual ultraviolet which penetrates through the ultraviolet absorbing layer, and a composite layer which is combined to an inside membrane on the solar cell backboard in advance which are sequentially arranged from outside to inside. By means of free radicals produced when the ultraviolet absorbing layer absorbs solar radiation, the ageing resistance is improved; due to the fact that the residual ultraviolet penetrating through the ultraviolet absorbing layer is reflected and removed through the reflecting layer, damage to a polyethylene film is relieved, the luminous reflectance is increased, and the power generation efficiency is improved; by means of the composite layer, it is guaranteed that the membrane has good composite performance. The solar cell backboard membrane has ultrahigh reflectivity, good anti-ultraviolet performance and excellent composite strength. The solar cell backboard membrane can meet the requirement of long-time outdoor using of the solar cell backboard, in the production process, the solar cell backboard membrane is easy to rework, waste is reduced, and the cost is low.

Owner:上海紫江彩印包装有限公司

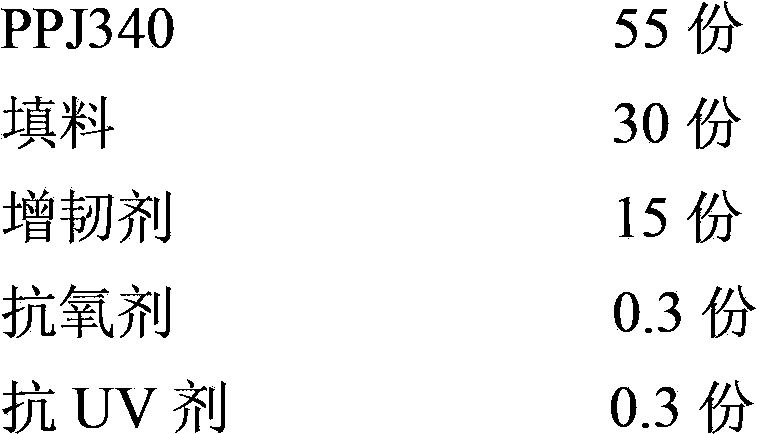

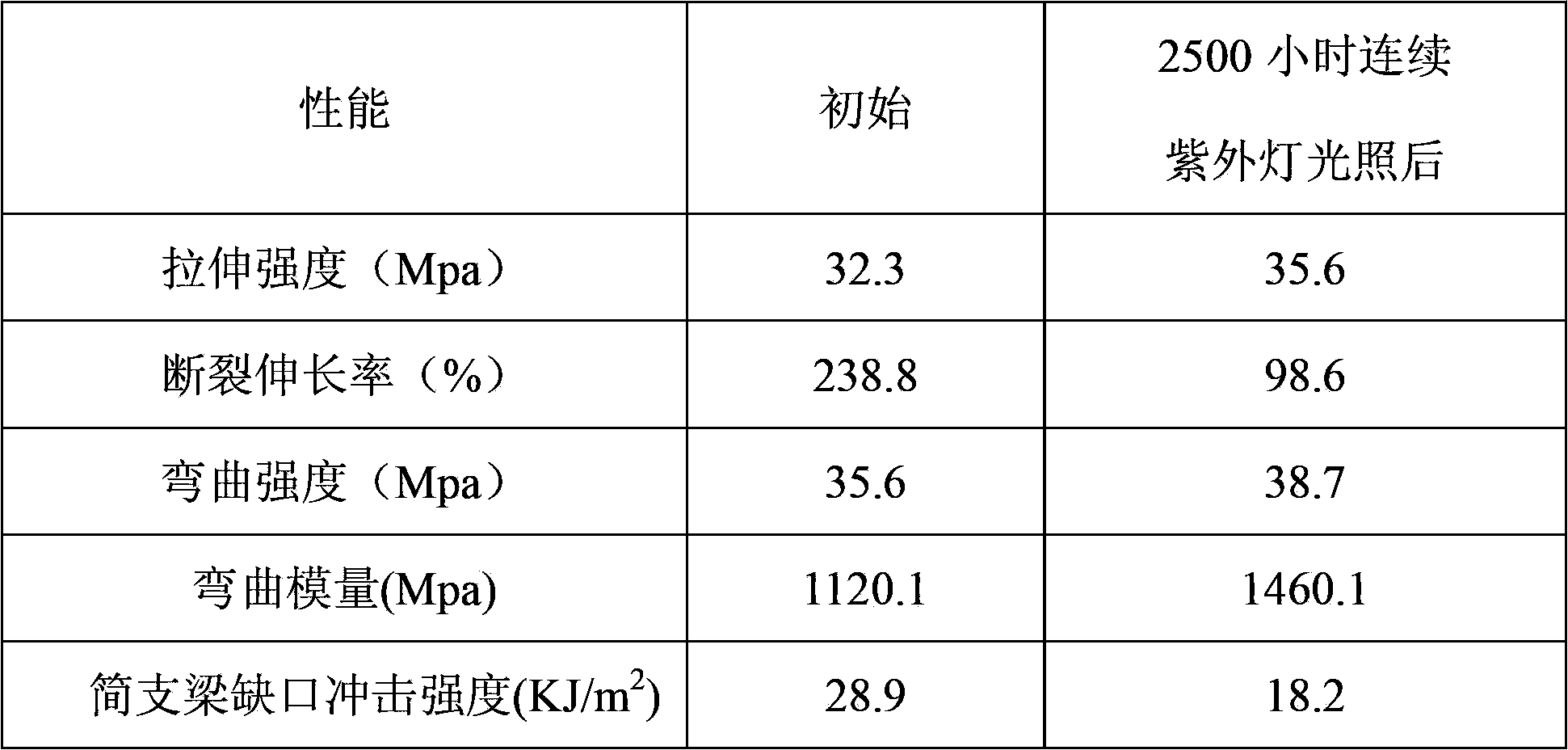

Modified polypropylene material and preparation method thereof

The invention belongs to the technical field of plastic products. An unmodified polypropylene material has the disadvantages of bad toughness, bad environment stress cracking resistance, easy brittle creaking, easy environmental light and heat ageing and the like, so the service life of products is influenced. The invention discloses a modified polypropylene material and a preparation method thereof. An antioxidant and an anti-UV agent are added according to the characteristics of the polypropylene material to improve the weather ability of polypropylene in order to improve the natural light ageing and thermo-oxidative aging performances of the polypropylene material, so a problem of the performance reduction caused by ageing when partial plastic pallets are used outdoor for a long term is solved, and relevant fields having high use requirements, such as the outdoor material circulation industry in the especially-long illumination time south, are satisfied.

Owner:SHANGHAI PALLET PLASTIC

Outdoor table-tennis table

InactiveCN101927081BNot easy to shakeReduce manufacturing costSport apparatusFoot supportsMetallic materials

Owner:张耀辉

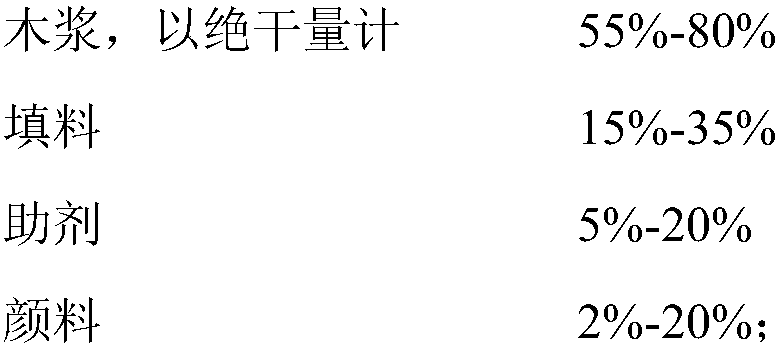

Finishing base paper for outdoor high-strength board and preparation method thereof

ActiveCN108130815BIncrease coverageImprove breathabilitySpecial paperReinforcing agents additionFiberSilicic acid

The invention belongs to the technical field of papermaking, and in particular relates to overcoating base paper used for an outdoor highly-strengthened plate and a preparation method of the overcoating base paper. The base paper is prepared from the following raw materials: wood pulp, a filler, an auxiliary agent and a pigment, wherein the auxiliary agent is composed of sodium hydroxide, sulphuric acid, aluminium sulphate and a wet strength agent; and the filler is composed of titanium dioxide, magnesium silicate and kaolin. The prepared overcoating base paper used for the outdoor highly-strengthened plate provided by the invention has a good covering property, fiber distribution uniformity, fine paper surfaces, strong corrosion resistance, a high sun-proof grade, and high water washing color fastness; and after the base paper is impregnated with melamine for veneering, the base paper is impregnated into a solution with the pH of 3.5-10, and no phenomena such as blistering and deformation of the paper happen; and the sun-proof grade is 6 grade or more, and the water washing color fastness is high. The invention also provides a preparation method of the overcoating base paper usedfor the outdoor highly-strengthened plate, and the base paper has high practicability and scientific and reasonable operation, and is simple and practicable.

Owner:ZIBO OU MU SPECIAL PAPER

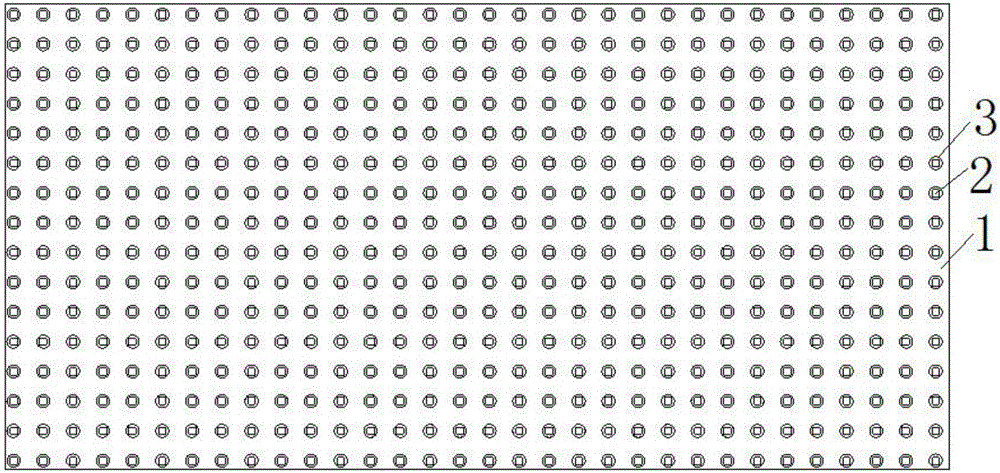

Outdoor display screen unit board and manufacturing method thereof

PendingCN106023828AImprove qualityConsistent colorElectric circuit arrangementsGas-tight/water-tight arrangementsSurface mountingDevice material

The invention discloses an outdoor display screen unit board and a manufacturing method thereof, belonging to the technical field of semiconductor devices. The outdoor display screen unit board comprises a PCB (printed circuit board), a plurality of SMD (surface mount device) lamps and waterproof parts, wherein the SMD lamps are fixed to the PCB; each waterproof part is arranged on the external surface of each SMD lamp; each SMD lamp comprises one or a plurality of LED (light-emitting diode) chips, a sealing part and a pin; the sealing part is arranged around the LED chip; and the end of the pin extends to the outside of the sealing part, and is connected with the circuit on the PCB. The manufacturing method comprises the following steps: fixing, and adding the waterproof layer. The outdoor display screen unit board has the advantages of high quality, uniform color, simpler manufacturing requirements for outdoor SMD lamps, and much lower price and cost.

Owner:深圳市九晟光电通讯科技有限公司

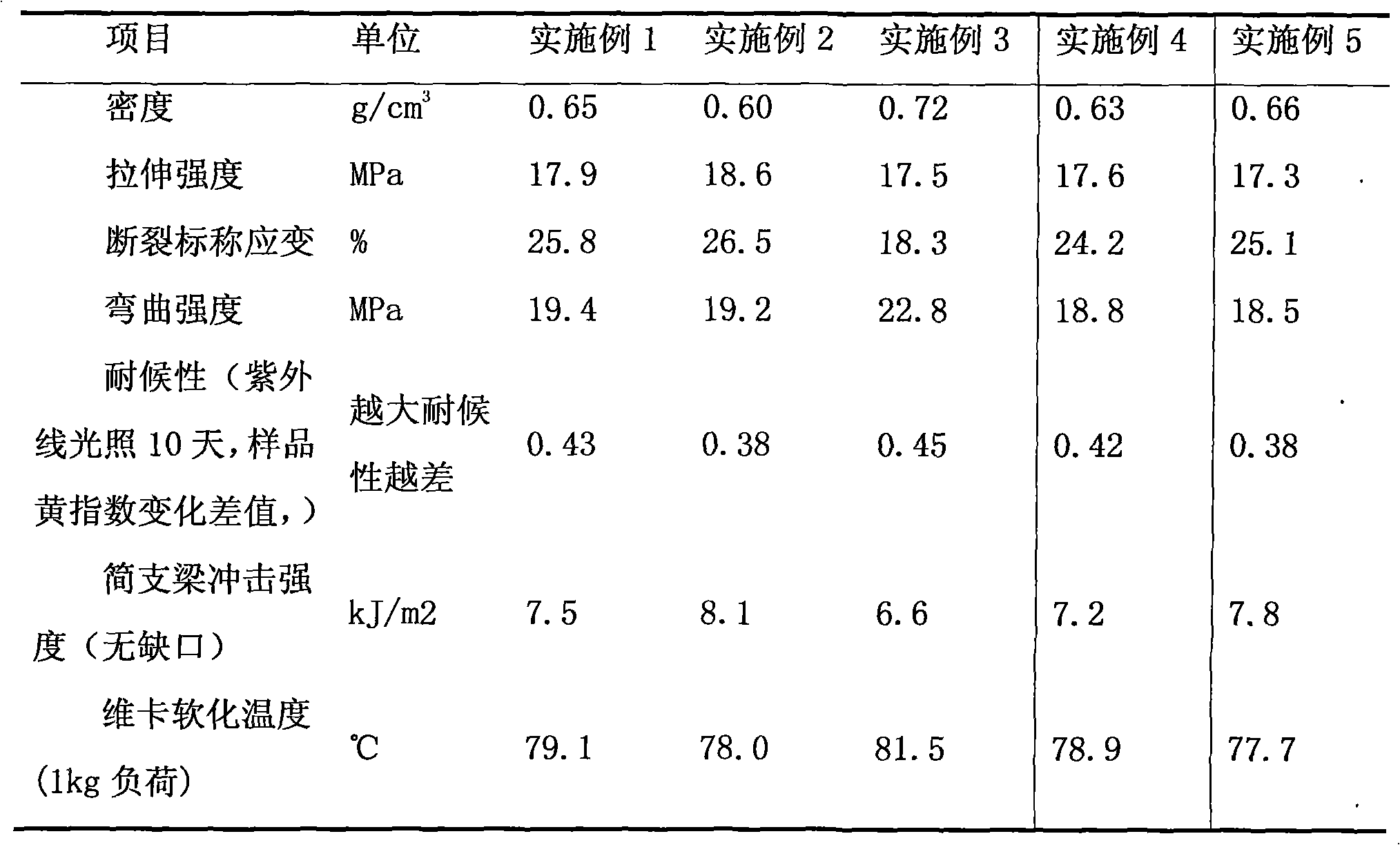

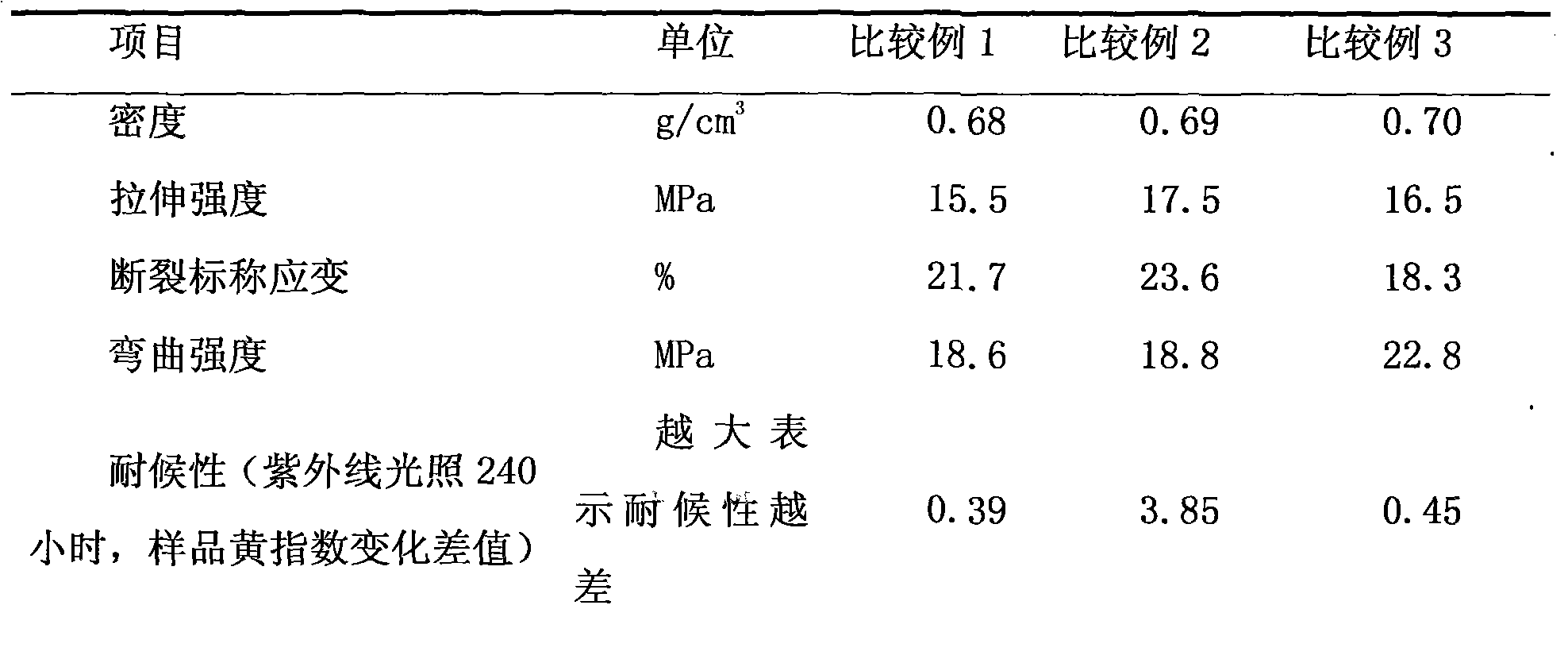

Light ageing resistant low-cost renewable polyvinyl chloride (PVC) foamed composite material and preparation method thereof

The invention discloses a light ageing resistant low-cost renewable polyvinyl chloride (PVC) foamed composite material and a preparation method thereof. The light ageing resistant low-cost renewable PVC foamed composite material is a foamed material prepared by compositely processing a macromolecular substance and other materials. The light ageing resistant low-cost renewable PVC foamed composite material is characterized by being prepared from the following raw materials in part by mass: 100 parts of PVC, 4 to 10 parts of foaming stabilizer, 0.5 to 2 parts of foaming agent, 0.4 to 1.0 part of auxiliary foaming agent, 0.05 to 0.2 part of foaming agent aid, 5 to 10 parts of processing aid, 0.5 to 2.5 parts of lubricant, 0.5 to 1.0 part of light stabilizer, 0.5 to 1.0 part of auxiliary light stabilizer and 30 to 50 parts of activated wood meal, bamboo flour or rice husk. The light ageing resistant low-cost renewable PVC foamed composite material is suitable for outdoors, has excellent mechanical properties, is added with a great amount of wood meal and the like, and can be recycled; and the preparation method for the recyclable light ageing resistant low-cost renewable PVC foamed composite material has the advantages of small equipment investment, simple manufacturing process, and low production cost.

Owner:CHINA PETROLEUM & CHEM CORP

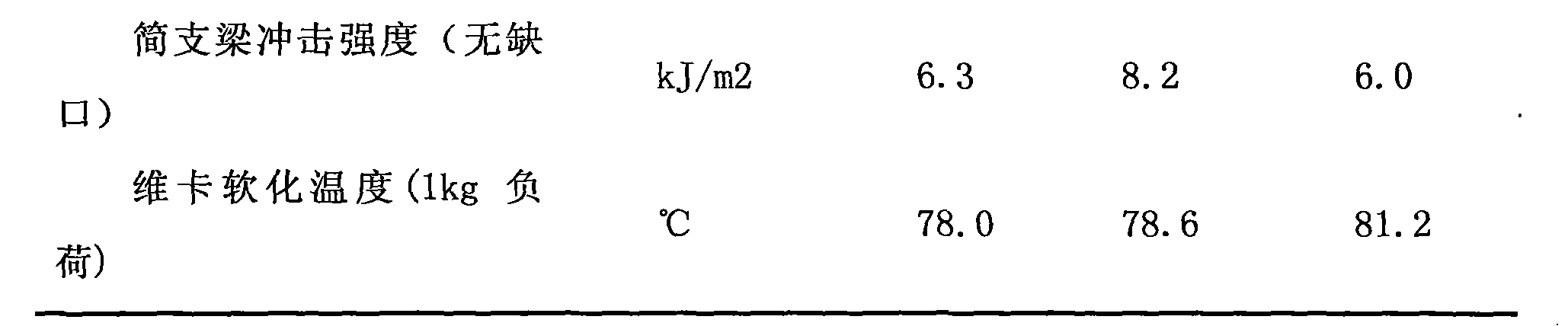

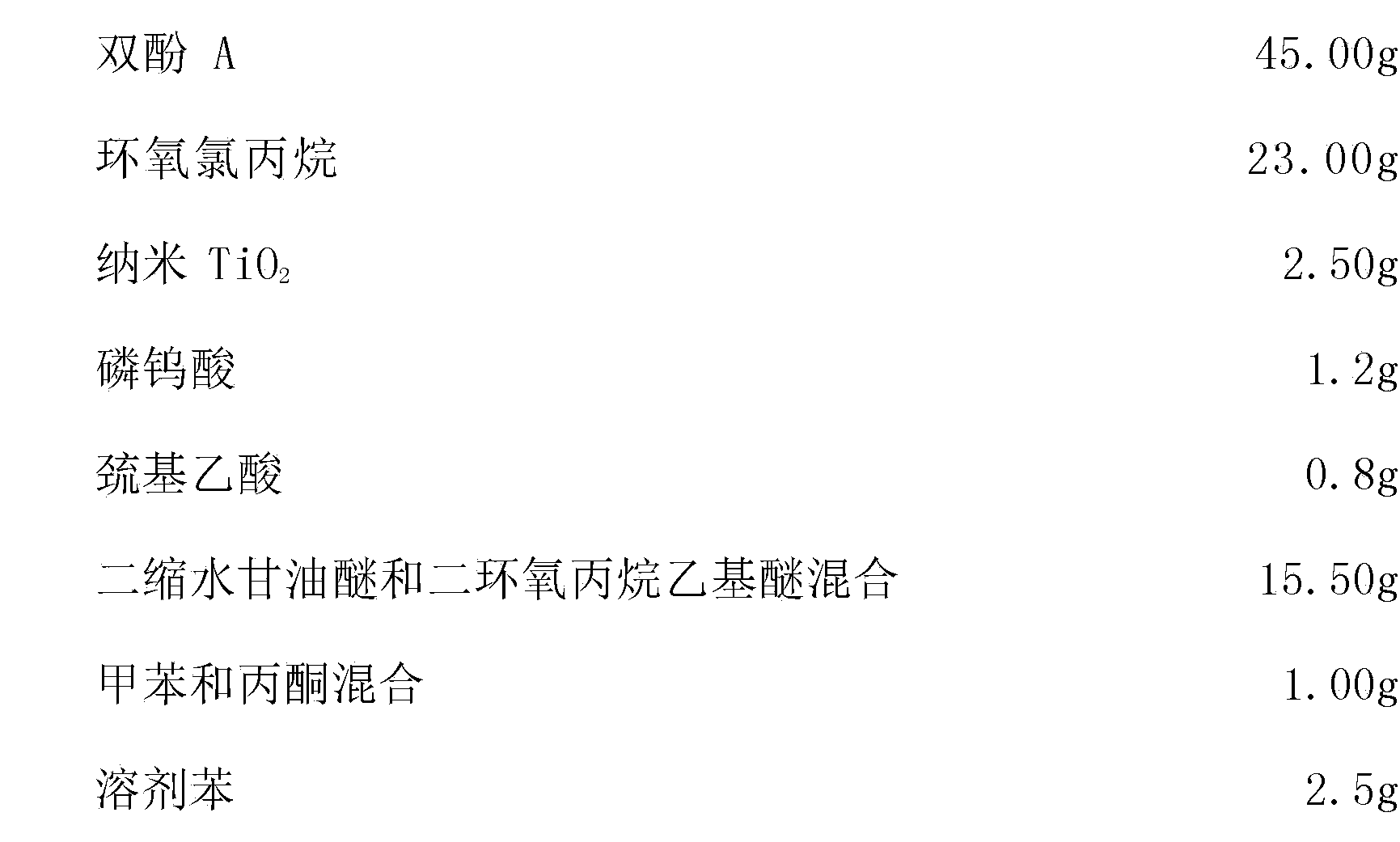

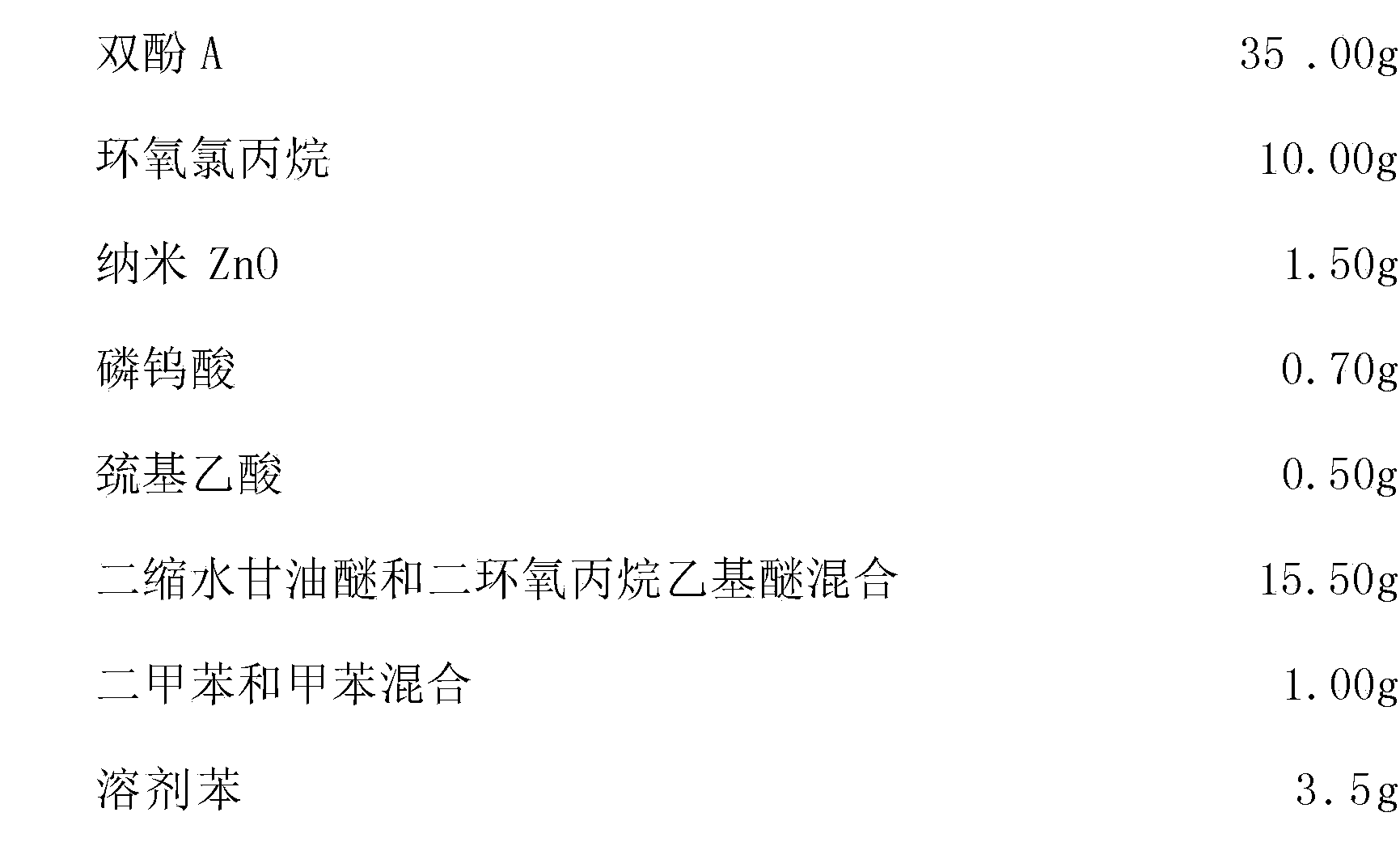

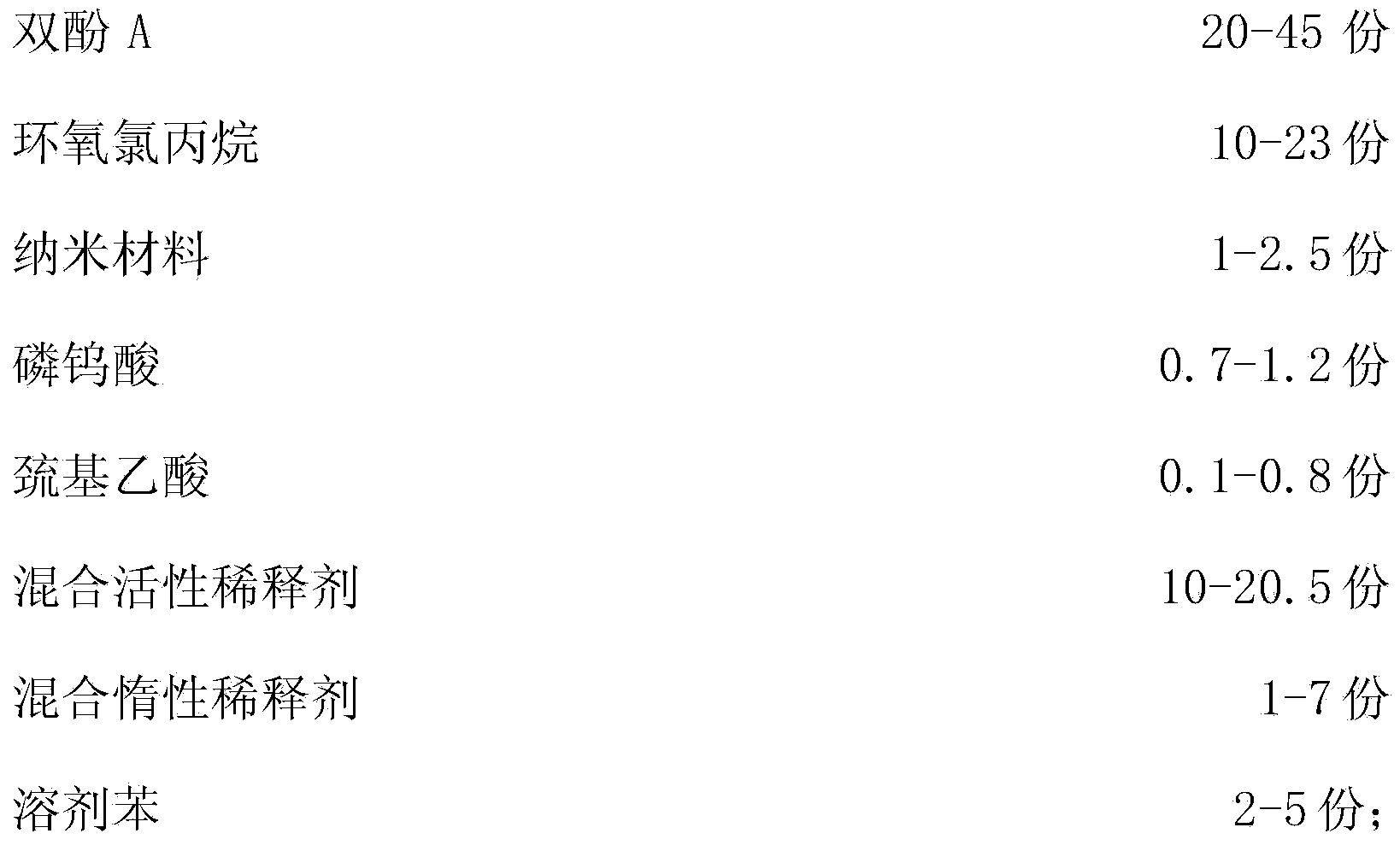

Nano-modified epoxy resin and preparation method thereof

InactiveCN103044657BImprove performanceGood weather resistanceEpoxy resin coatingsMercaptoacetic acidBisphenol A

The present invention discloses a nano-modified epoxy resin, comprising by weight: 20-45 parts of bisphenol-A, 10-23 parts of epoxy chloropropane, 1-2.5 parts of a nano-material, 0.7-1.2 parts of phosphotungstic acid, 0.1-0.8 parts of mercaptoacetic acid, 10-20.5 parts of a mixed active diluent, 1-7 parts of a mixed inert diluent, and 2-5 parts of benzene; and also discloses a preparation method of the nano-modified epoxy resin, which uses a two-step method and is added with the nano-material to prepare the nano-modified epoxy resin. The problem of difficult polymerization between nanomaterial and epoxy resin is overcome by using the method to prepare the nano-modified epoxy resin. The product is superior in performance, especially the weather resistance is increased by 40% than traditional products, artificial aging resistance is up to 1000 hours, and the product fully meets the requirements for outdoor use.

Owner:徐世前

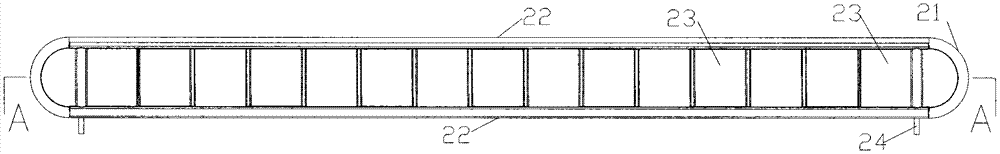

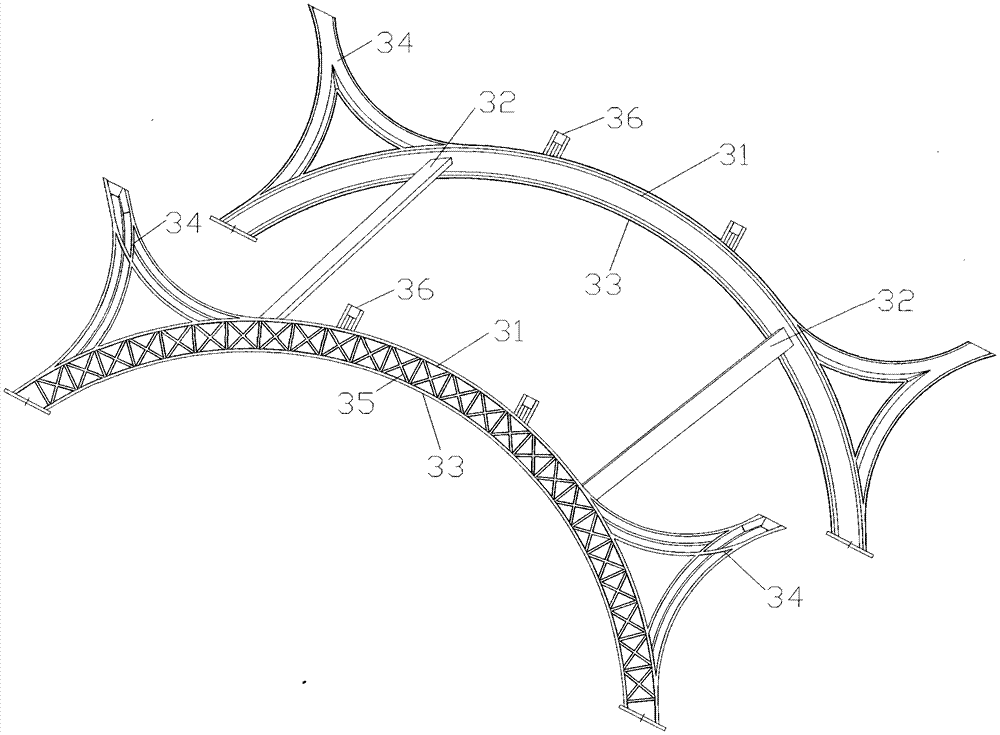

SMC table tennis table

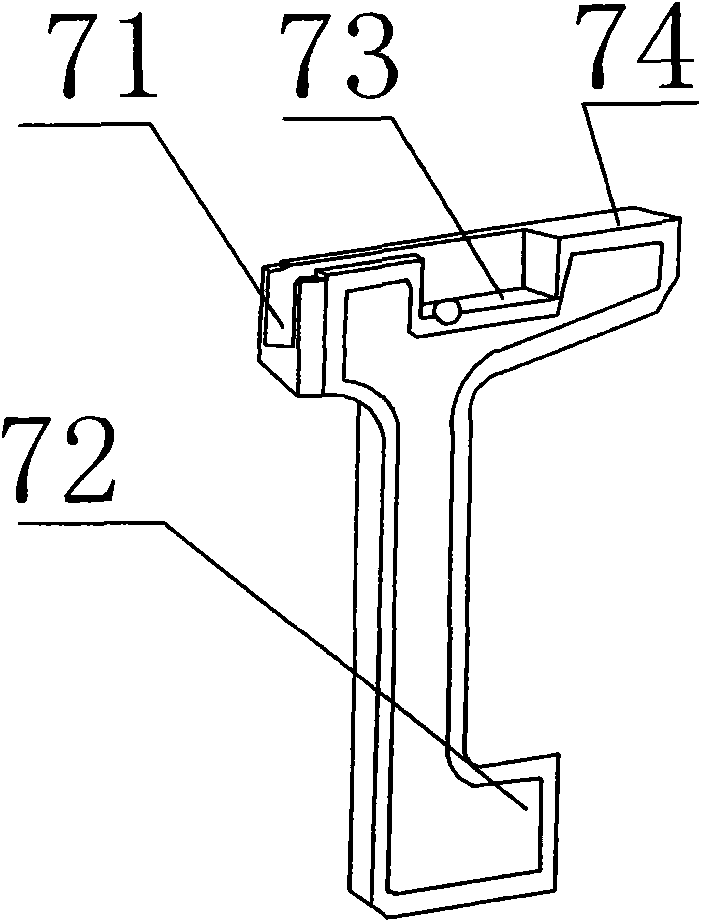

InactiveCN103933712AReduce manufacturing costReduce weightCard tablesSport apparatusShaped beamEngineering

The invention provides an SMC table tennis table. The SMC table tennis table comprises an SMC table top, an SMC tennis net and an SMC bracket. The SMC tennis net comprises a left arc-shaped side frame, a right arc-shaped side frame, an upper cross beam and a lower cross beam. A plurality of mutually-connected baffles are arranged between the upper cross beam and the lower cross beam. The two ends of the lower cross beam are respectively and downwards provided with a fixing column. The SMC tennis net is fixed to the SMC table top through iron connecting pieces. The SMC bracket is mainly composed of bracket side beams and bracket cross beams, wherein the two sides of the upper portion of an arch-shaped beam body of each bracket side beam are respectively provided with a herringbone support which is fixedly connected with the SMC table top, the arch-shaped beam bodies are provided with fixed bosses which are fixedly connected with the SMC table top, and the bottoms of the arch-shaped beam bodies are provided with disk-type bases which are fixed to the ground through expansion bolts. The table tennis table top, the tennis net and the bases are all made of SMC materials; by the adoption of the SMC materials, the production cost is lowered, the whole weight of the SMC table tennis table is reduced, the requirement of users for outdoor use is met, and the SMC table tennis table is good in the comprehensive performance, firm and durable; meanwhile, the SMC table tennis table is integrally of an assembly structure, thereby being convenient to disassemble, assemble and transport.

Owner:DEZHOU SONBO COMPOUND MATERIALS

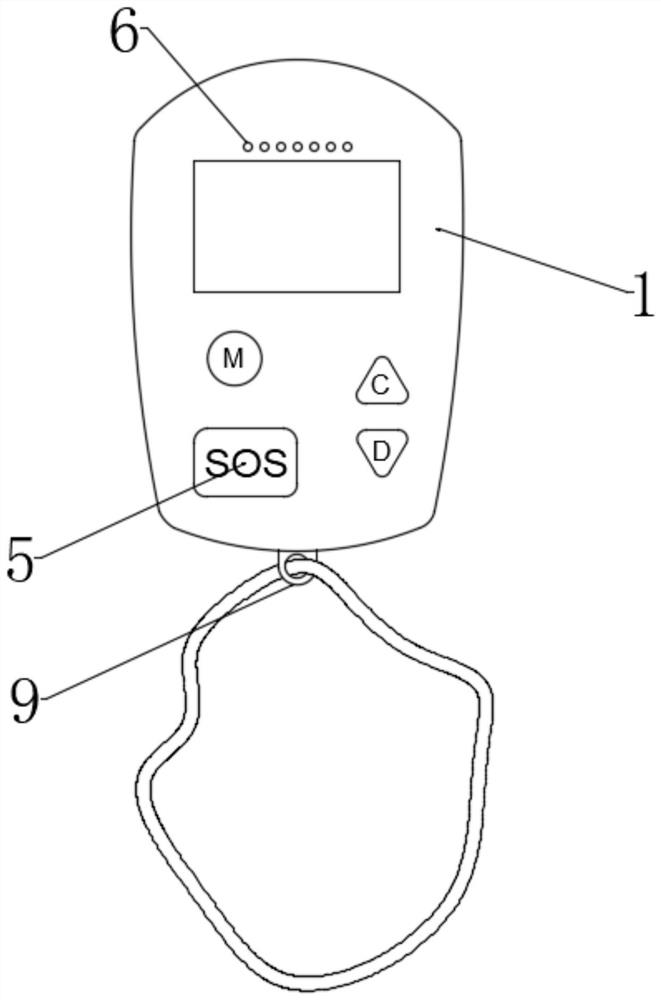

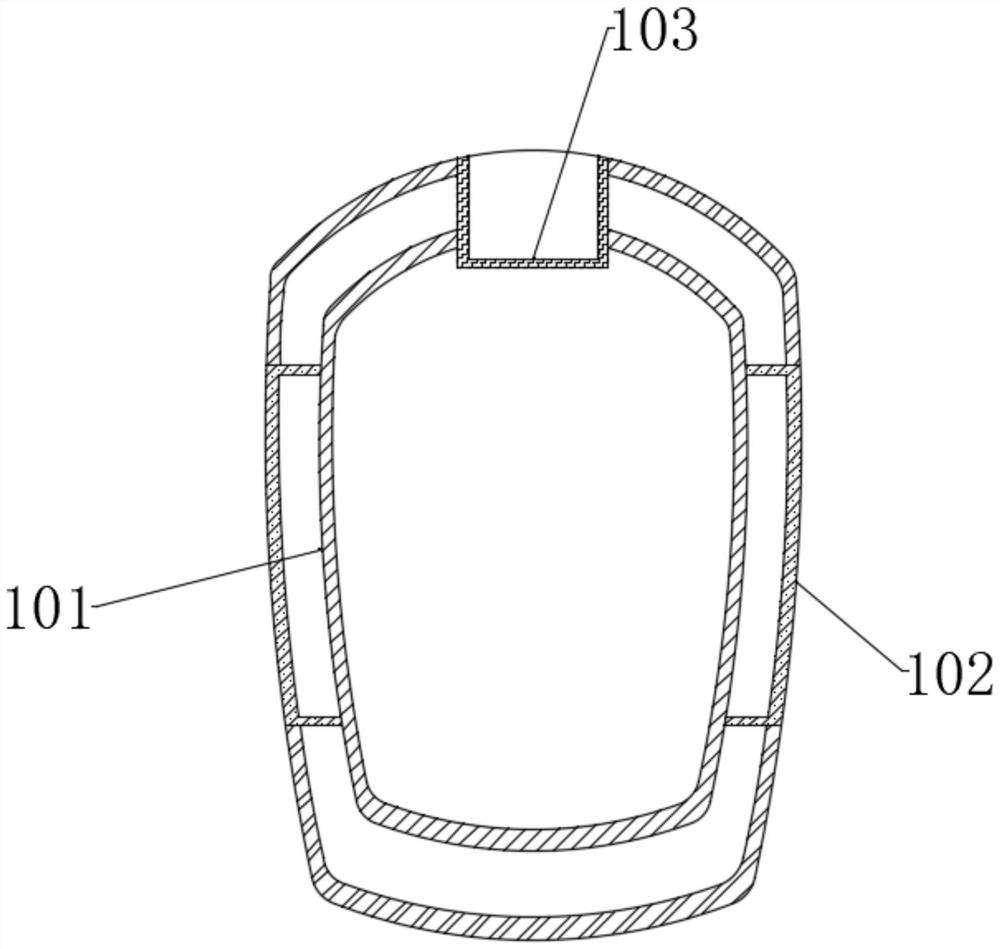

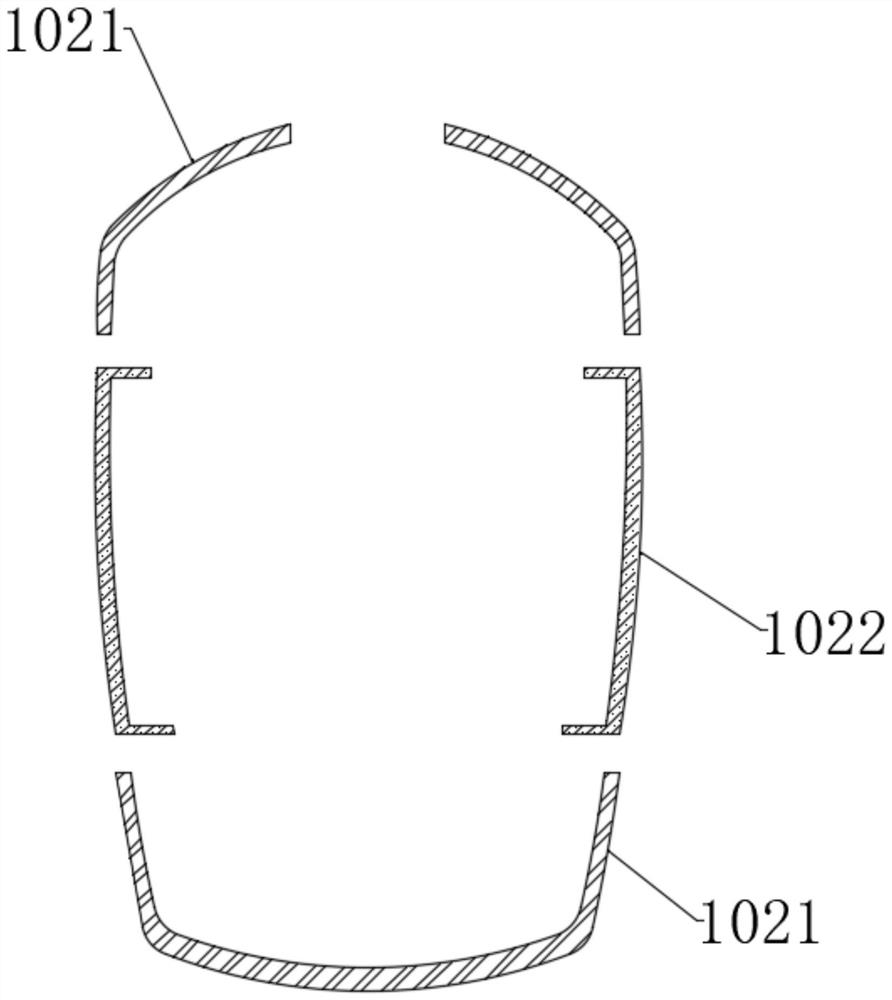

New portable instrument for monitoring diabetic nephropathy

ActiveCN113687080BImprove shock resistance and drop resistanceMeet the requirements of outdoor useCasings/cabinets/drawers detailsSubstation equipmentNephrosisDisease

The invention discloses a new type of portable instrument for diabetic nephropathy monitoring. A double-layer shell is provided on the basis of the existing portable detection instrument to protect the internal components of the instrument, and honeycomb shock absorption is filled between the double-layer shells. body, so as to effectively improve the performance of the portable detection instrument against shock and drop. By setting a pneumatic protective bag at the test paper socket, the pneumatic protective bag will remain closed before the test paper is inserted, and play an effective role in dustproof and waterproof. On the one hand, the pneumatic protective bag can fix the inserted test paper to prevent the test paper from falling off during the test and cause the test to fail. The emergency help function is added on the basis of the existing portable instrument body. For the elderly, there is a high probability that they will be accompanied by In this way, effective life support can be obtained in the event of other diseases, and a displacement sensor is also installed in the test paper socket to monitor whether the test paper is inserted in place to ensure the effectiveness of the test.

Owner:XUZHOU MEDICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com