High temperature-resistant, radiation-crosslinked, low-smoke, halogen-free and flame-retardant cable material for charging pile cables, and preparation method thereof

A flame-retardant cable material and high-temperature-resistant technology, applied in rubber insulators, organic insulators, etc., can solve problems such as limited application, tear resistance, poor heat resistance and scratch resistance, and potential safety hazards of new energy vehicles, and achieve excellent performance Enhancement of physical properties and processability, resistance to environmental cracking, and improvement of severely deteriorated mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

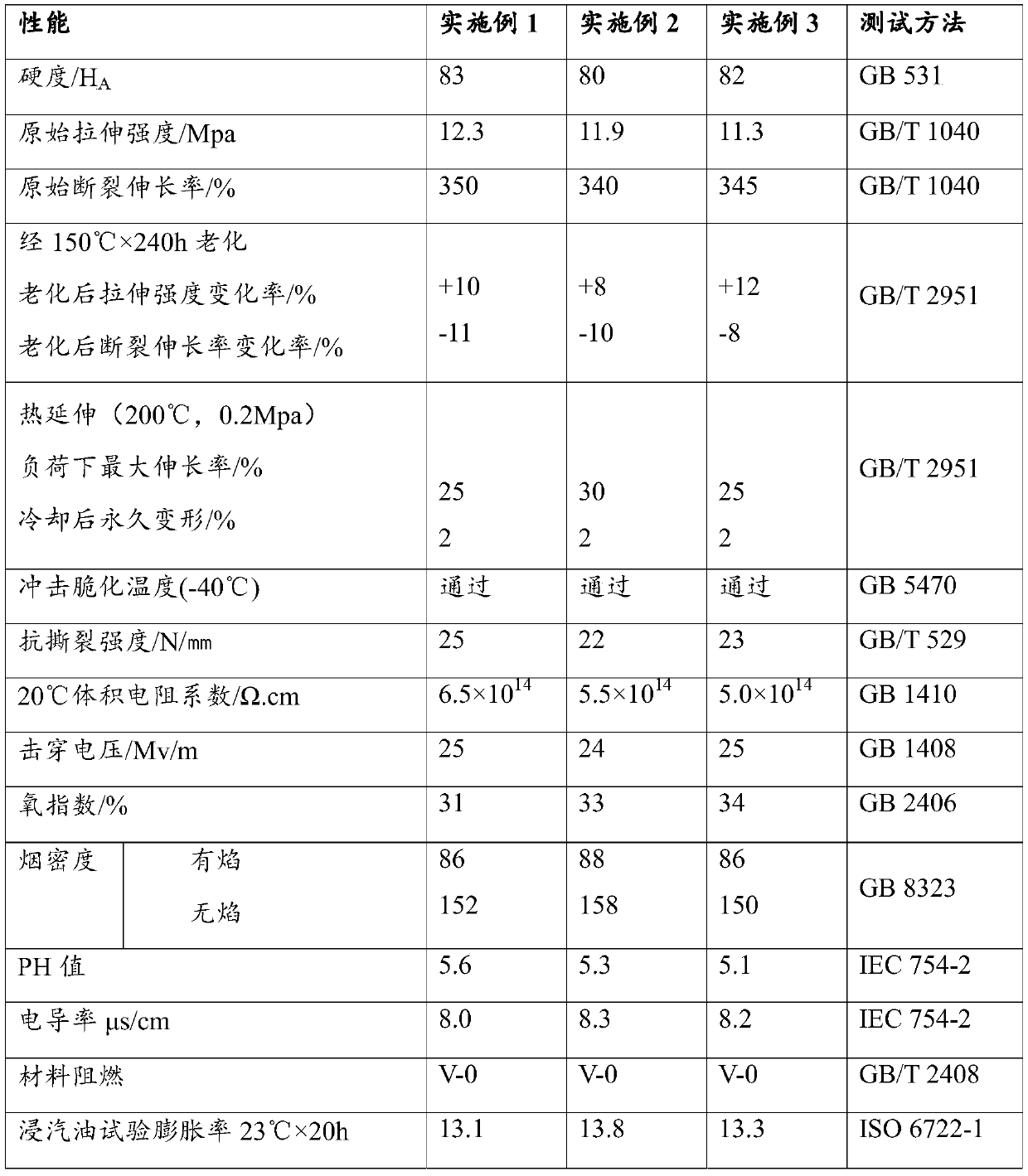

Examples

Embodiment 1

[0024] High-temperature radiation-resistant cross-linked low-smoke halogen-free flame-retardant cable material for charging pile cables. In parts by weight, the cable material includes: 56 parts of EPDM rubber, 18 parts of ethylene octene copolymer resin, maleic anhydride 10 parts of branched modified resin, 10 parts of cross-linked modified resin, 6 parts of polyethylene-acrylate rubber, 3 parts of polyphenylene ether, 60 parts of flame retardant, 30 parts of flame retardant synergist, 0.5 part of polyethylene wax, 1.2 parts of antioxidant, 0.9 parts of cross-linking agent, and 0.2 parts of anti-degradation agent.

[0025] The maleic anhydride graft modified resin is a maleic anhydride monomer graft of ethylene octene copolymer resin.

[0026] The content of ethylene in the EPDM rubber is 55wt%, and the content of 5-ethylene-2-norbornene is 3wt%.

[0027] The content of methyl acrylate in the polyethylene-acrylate rubber is 35wt%.

[0028] The melt index of the ethylene oct...

Embodiment 2

[0038]High-temperature radiation-resistant cross-linked low-smoke halogen-free flame-retardant cable material for charging pile cables. In parts by weight, the cable material includes: 70 parts of EPDM rubber, 10 parts of ethylene octene copolymer resin, maleic anhydride 8 parts of branched modified resin, 8 parts of crosslinked modified resin, 5 parts of polyethylene-acrylate rubber, 4 parts of polyphenylene ether, 75 parts of flame retardant, 25 parts of flame retardant synergist, 0.6 part of polyethylene wax, 1.5 parts of antioxidant, 1.2 parts of crosslinking agent, 0.2 parts of anti-degradation agent.

[0039] The maleic anhydride graft modified resin is a maleic anhydride monomer graft of ethylene octene copolymer resin.

[0040] The content of ethylene in the EPDM rubber is 60wt%, and the content of 5-ethylene-2-norbornene is 5wt%.

[0041] The content of methyl acrylate in the polyethylene-acrylate rubber is 38wt%.

[0042] The melt index of the ethylene octene copol...

Embodiment 3

[0052] High-temperature radiation-resistant cross-linked low-smoke halogen-free flame-retardant cable material for charging pile cables. In parts by weight, the cable material includes: 63 parts of EPDM rubber, 10 parts of ethylene octene copolymer resin, maleic anhydride 8 parts of branched modified resin, 10 parts of cross-linked modified resin, 9 parts of polyethylene-acrylate rubber, 5 parts of polyphenylene ether, 90 parts of flame retardant, 20 parts of flame retardant synergist, 0.6 part of polyethylene wax, 1.5 parts of antioxidant, 1.2 parts of crosslinking agent, 0.2 parts of anti-degradation agent.

[0053] The maleic anhydride graft modified resin is a maleic anhydride monomer graft of ethylene octene copolymer resin.

[0054] The content of ethylene in the EPDM rubber is 70wt%, and the content of 5-ethylene-2-norbornene is 8wt%.

[0055] The content of methyl acrylate in the polyethylene-acrylate rubber is 40wt%.

[0056] The melt index of the ethylene octene co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com