Polyaryletherketone nano composite material and preparation method thereof

A nanocomposite material, polyaryletherketone technology, applied in the field of new polyaryletherketone nanocomposite materials and its preparation, can solve the problems affecting the application of materials, the reduction of polymer mechanical strength, etc., to solve the problem of poor interfacial compatibility and avoid The effect of two-phase separation and enhanced interaction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

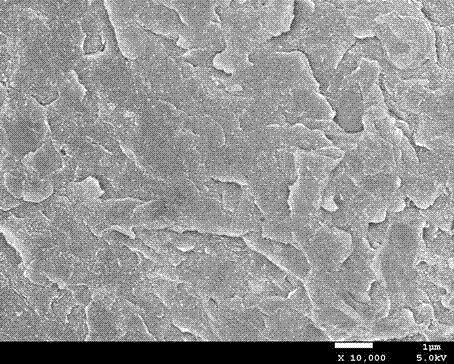

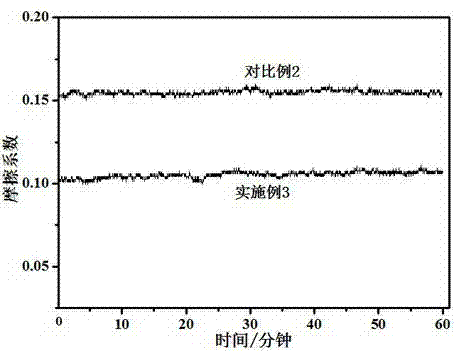

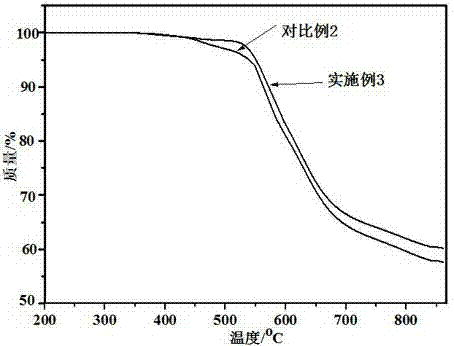

Image

Examples

preparation example Construction

[0025] 1. Preparation of polyaryletherketone nanocomposites

[0026] Unless otherwise specified, the following raw material parts are parts by weight.

Embodiment 1

[0028]Ultrasonic dispersion of 20 parts of fluorinated graphite, 100 parts of 4,4-difluorobenzophenone, and o-methylhydroquinone in an equimolar amount to 4,4-difluorobenzophenone in 80 parts of acetone, The ultrasonic frequency is 10Hz, and the ultrasonic time is 2 hours; after the solvent is removed by rotary evaporation, it is transferred to a reaction kettle with mechanical stirring, condensation device, nitrogen device and feeding device, and 100 parts of toluene and phenolic monomers are added. The molar amount of potassium carbonate and 300 parts of sulfolane, wherein toluene is a water-carrying agent; the temperature in the reactor is raised to the reflux temperature of toluene, and after the heat preservation reaction for 2 hours, the temperature is gradually raised to 240°C, and the heat preservation reaction is carried out for 6 hours. The whole reaction process is protected by nitrogen. . The product in the reaction kettle is washed with acetone and deionized water...

Embodiment 2

[0030] 0.75 parts of graphene, 100 parts of 4,4-difluorobenzophenone, and hydroquinone in an equimolar amount to 4,4-difluorobenzophenone were ultrasonically dispersed in 120 parts of ethanol, wherein the ultrasonic frequency was 40Hz, ultrasonic time is 2 hours; after the solvent is removed by rotary evaporation, it is transferred to the reaction kettle with mechanical stirring, condensation device, nitrogen device and feeding device, and 100 parts of toluene and the equivalent molar amount of hydroquinone are added. Acid agent (potassium carbonate: sodium carbonate = 19:1, molar ratio) and 630 parts of sulfolane, of which toluene is the water-carrying agent; the temperature in the reactor is raised to the reflux temperature of toluene, and after the heat preservation reaction for 4 hours, the temperature is gradually raised to 220°C , heat preservation reaction for 4 hours, nitrogen protection during the whole reaction process. The product in the reaction kettle is washed wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com