Solar cell backboard membrane

A technology for solar cells and backplane films, which is applied in circuits, photovoltaic power generation, electrical components, etc., and can solve problems such as the impact of backplane film anti-ultraviolet ability on the service life of solar cells, affecting the output power of solar cells, and the decrease in reflectivity of backplanes. , to achieve the effect of meeting the requirements of outdoor use, improving anti-aging ability and excellent composite strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment provides a composite film for solar battery backplane with ultra-high reflectivity and high anti-ultraviolet performance, which is a polyethylene film.

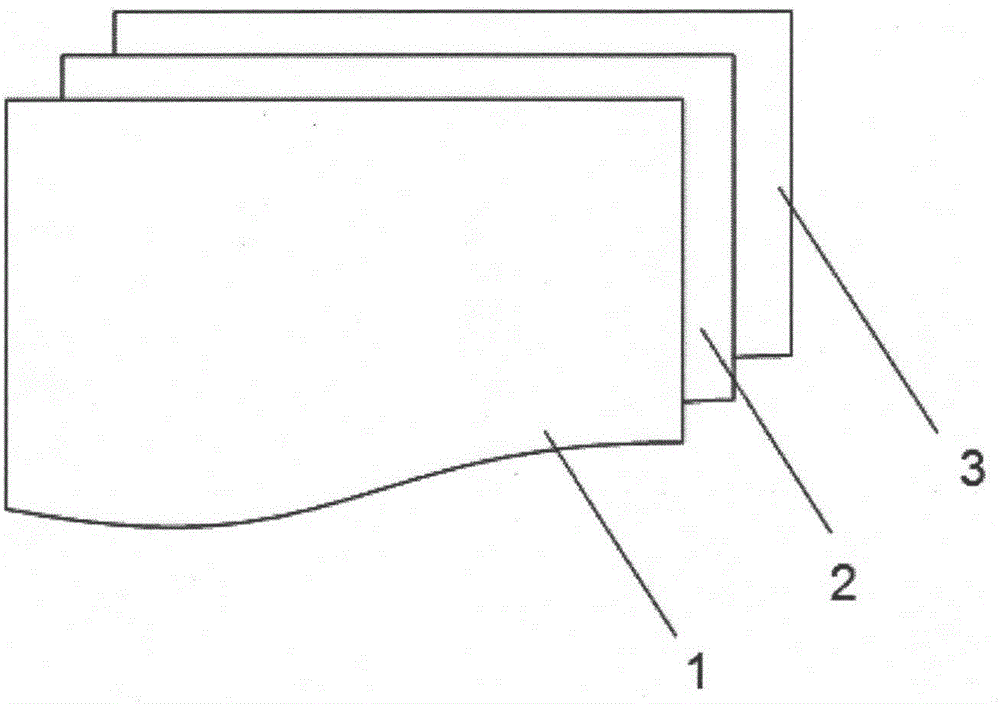

[0028] Such as figure 1 As shown, three layers of films are usually compounded on the back plate of the solar cell, which are fluorine film 1, polyester film 2, and polyethylene film 3 provided in this embodiment in sequence from the inside to the outside.

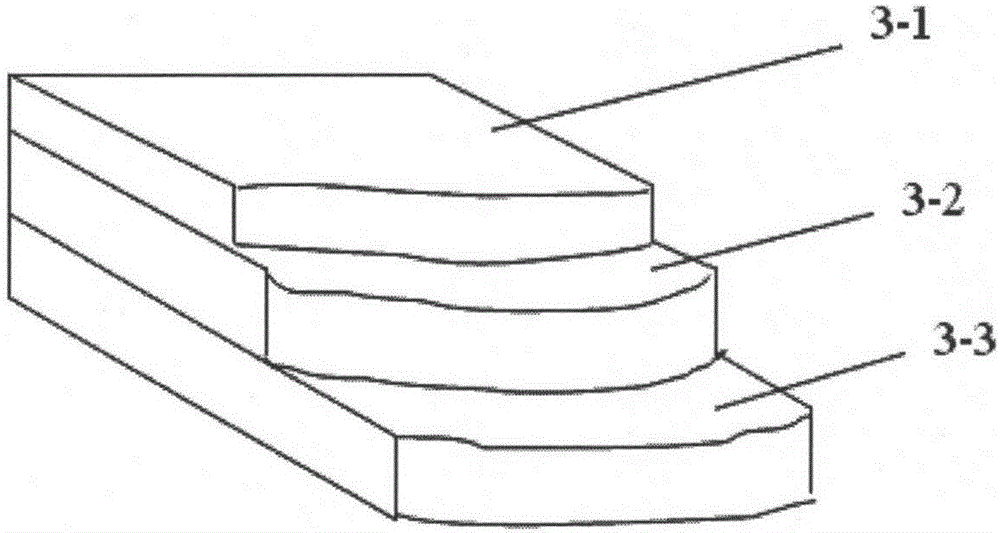

[0029] figure 2 It is a schematic structural diagram of the polyethylene film provided in this embodiment, and the polyethylene film is sequentially composed of a composite layer 3-1, a reflective layer 3-2, and an ultraviolet absorbing layer 3-3 from the inside to the outside. The polyethylene film is a multi-layer co-extrusion structure, which is formed by co-extrusion blow molding.

[0030] The thickness of the polyethylene film was 50 μm. Wherein, the composite layer 3-1 has a thickness of 10 μm, the reflective layer 3-2 has a thickness of 3...

Embodiment 2

[0037] This embodiment provides a composite film for solar battery backplane with ultra-high reflectivity and high anti-ultraviolet performance, which is a polyethylene film.

[0038] Such as figure 1 As shown, three layers of films are usually compounded on the back plate of the solar cell, which are fluorine film 1, polyester film 2, and polyethylene film 3 provided in this embodiment in sequence from the inside to the outside.

[0039] figure 2 It is a schematic structural diagram of the polyethylene film provided in this embodiment, and the polyethylene film is sequentially composed of a composite layer 3-1, a reflective layer 3-2, and an ultraviolet absorbing layer 3-3 from the inside to the outside. The polyethylene film is a multi-layer co-extrusion structure, which is formed by co-extrusion blow molding.

[0040] The thickness of the polyethylene film was 100 μm. Wherein, the composite layer 3-1 has a thickness of 20 μm, the reflective layer 3-2 has a thickness of ...

Embodiment 3

[0047] This embodiment provides a composite film for solar battery backplane with ultra-high reflectivity and high anti-ultraviolet performance, which is a polyethylene film.

[0048] Such as figure 1 As shown, three layers of films are usually compounded on the back plate of the solar cell, which are fluorine film 1, polyester film 2, and polyethylene film 3 provided in this embodiment in sequence from the inside to the outside.

[0049] figure 2 It is a schematic structural diagram of the polyethylene film provided in this embodiment, and the polyethylene film is sequentially composed of a composite layer 3-1, a reflective layer 3-2, and an ultraviolet absorbing layer 3-3 from the inside to the outside. The polyethylene film is a multi-layer co-extrusion structure, which is formed by co-extrusion blow molding.

[0050] The polyethylene film thickness was 150 μm. Wherein, the composite layer 3-1 has a thickness of 30 μm, the reflective layer 3-2 has a thickness of 90 μm, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com