Engineering plastic with high surface and high performance and preparing method thereof

An engineering plastic, high-performance technology, applied in the field of polyester materials, can solve the problems of high surface requirements, complex structure, low toughness, etc., and achieve the effects of improving processing fluidity, high surface gloss, and reducing friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

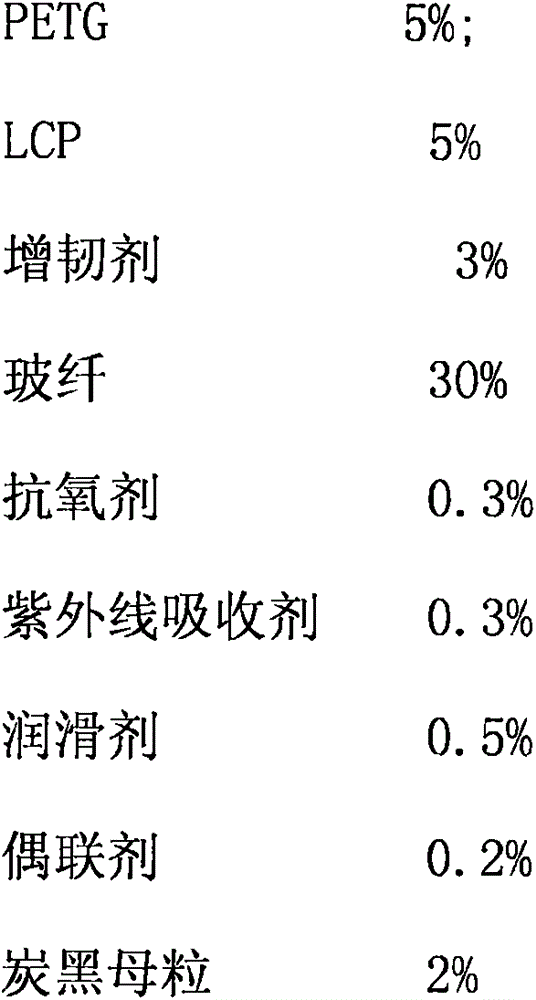

[0020] Adopt the raw material of following weight ratio:

[0021]

[0022]

[0023] Add the above-mentioned raw materials with a good weight ratio into the high mixer and mix them thoroughly for 4 minutes before discharging, then put the mixed materials into the extruder from the main feed port of the twin-screw extruder, and the glass fiber is made of Side feeder added. Finally, the composite material is obtained through water cooling, air drying and granulation. During the whole granulation process, the temperature should be controlled at 180-230° C., and the screw speed should be controlled at 360 RPM.

Embodiment 2

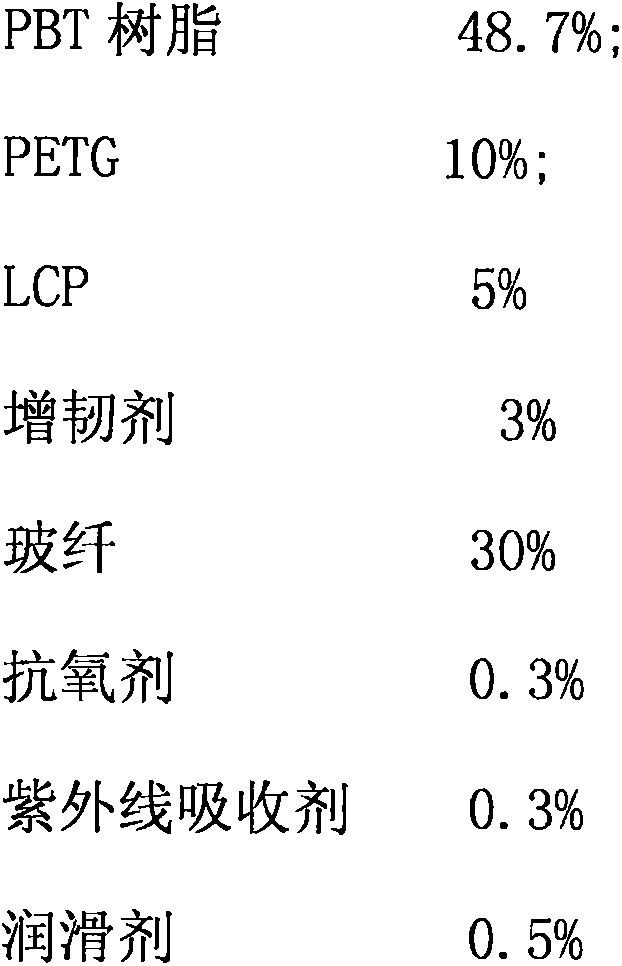

[0025] Adopt the raw material of following weight ratio:

[0026]

[0027]

[0028] Add the above-mentioned raw materials with a good weight ratio into the high mixer and mix them thoroughly for 4 minutes before discharging, then put the mixed materials into the extruder from the main feed port of the twin-screw extruder, and the glass fiber is made of Side feeder added. Finally, the composite material is obtained through water cooling, air drying and granulation. During the whole granulation process, the temperature should be controlled at 180-230° C., and the screw speed should be controlled at 360 RPM.

Embodiment 3

[0030] Adopt the raw material of following weight ratio:

[0031]

[0032] Add the above-mentioned raw materials with a good weight ratio into the high mixer and mix them thoroughly for 4 minutes before discharging, then put the mixed materials into the extruder from the main feed port of the twin-screw extruder, and the glass fiber is made of Side feeder added. Finally, the composite material is obtained through water cooling, air drying and granulation. During the whole granulation process, the temperature should be controlled at 180-230° C., and the screw speed should be controlled at 360 RPM.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com